TOYOTA CAMRY 1999 Service Repair Manual

CAMRY 1999

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57448/w960_57448-0.png

TOYOTA CAMRY 1999 Service Repair Manual

Trending: roof rack, fuse box diagram, MPG, wiper, towing capacity, clock, transmission line

Page 471 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±22

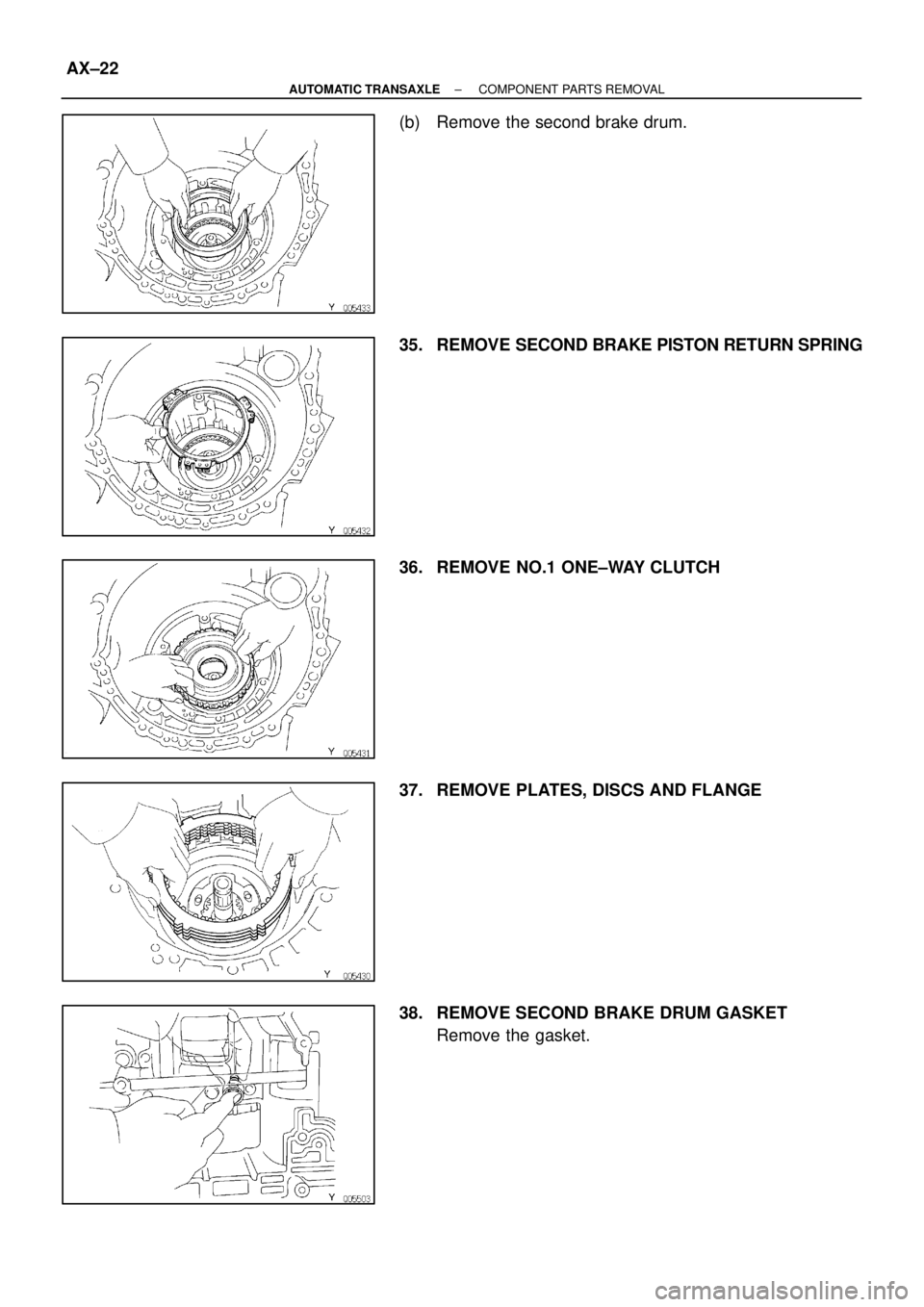

(b) Remove the second brake drum.

35. REMOVE SECOND BRAKE PISTON RETURN SPRING

36. REMOVE NO.1 ONE±WAY CLUTCH

37. REMOVE PLATES, DISCS AND FLANGE

38. REMOVE SECOND BRAKE DRUM GASKET

Remove the gasket.

Page 472 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±23

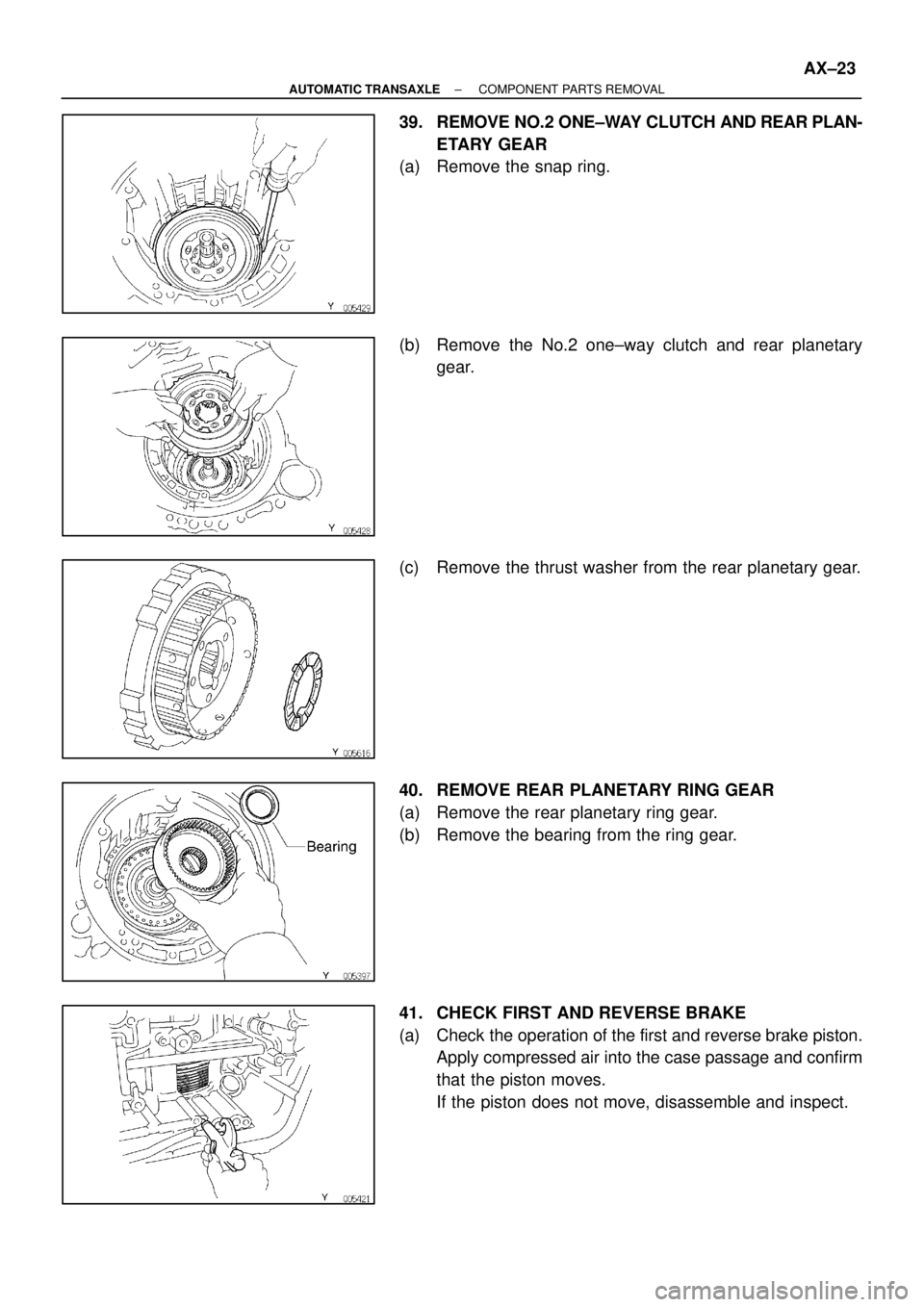

39. REMOVE NO.2 ONE±WAY CLUTCH AND REAR PLAN-

ETARY GEAR

(a) Remove the snap ring.

(b) Remove the No.2 one±way clutch and rear planetary

gear.

(c) Remove the thrust washer from the rear planetary gear.

40. REMOVE REAR PLANETARY RING GEAR

(a) Remove the rear planetary ring gear.

(b) Remove the bearing from the ring gear.

41. CHECK FIRST AND REVERSE BRAKE

(a) Check the operation of the first and reverse brake piston.

Apply compressed air into the case passage and confirm

that the piston moves.

If the piston does not move, disassemble and inspect.

Page 473 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±24

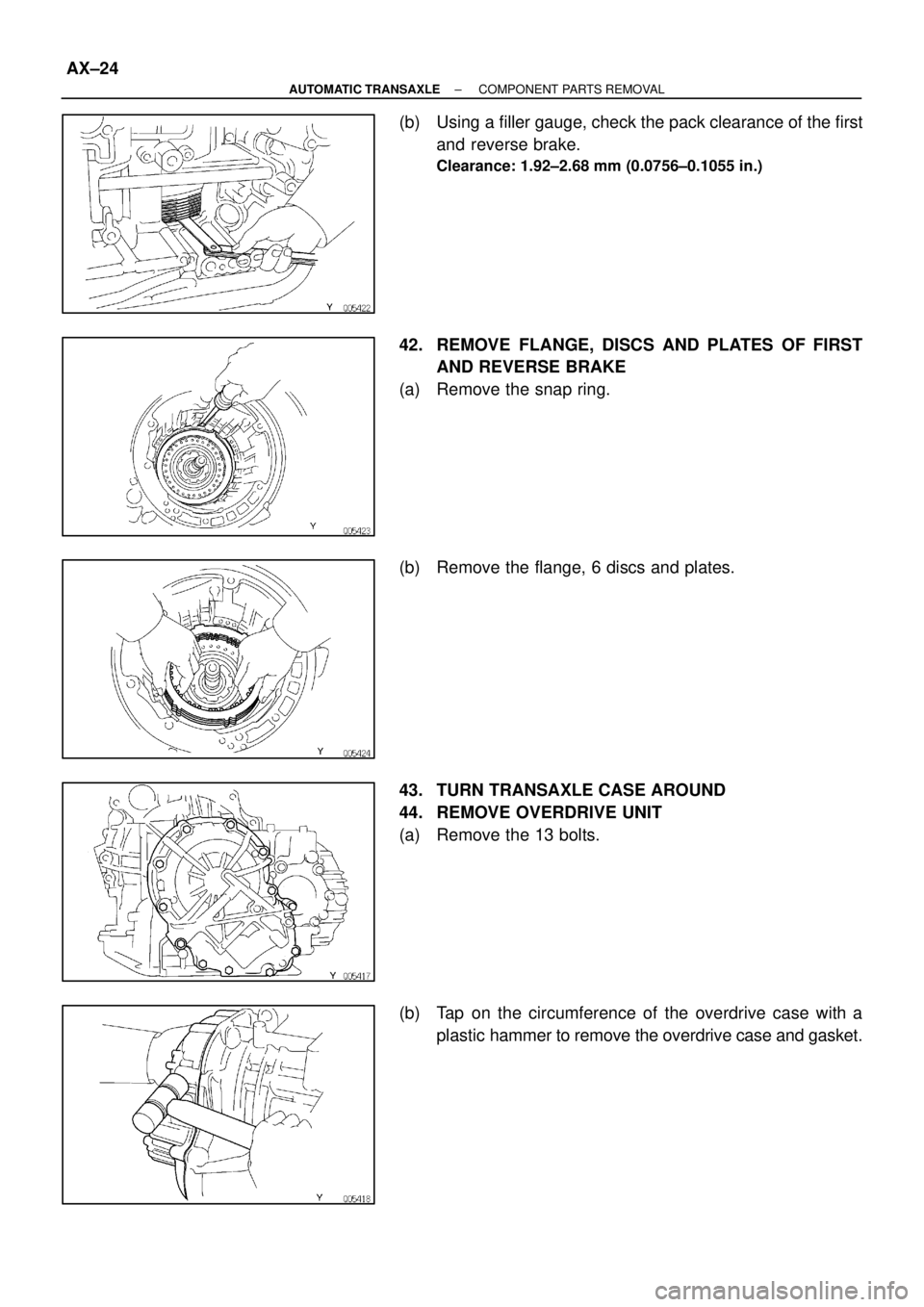

(b) Using a filler gauge, check the pack clearance of the first

and reverse brake.

Clearance: 1.92±2.68 mm (0.0756±0.1055 in.)

42. REMOVE FLANGE, DISCS AND PLATES OF FIRST

AND REVERSE BRAKE

(a) Remove the snap ring.

(b) Remove the flange, 6 discs and plates.

43. TURN TRANSAXLE CASE AROUND

44. REMOVE OVERDRIVE UNIT

(a) Remove the 13 bolts.

(b) Tap on the circumference of the overdrive case with a

plastic hammer to remove the overdrive case and gasket.

Page 474 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±25

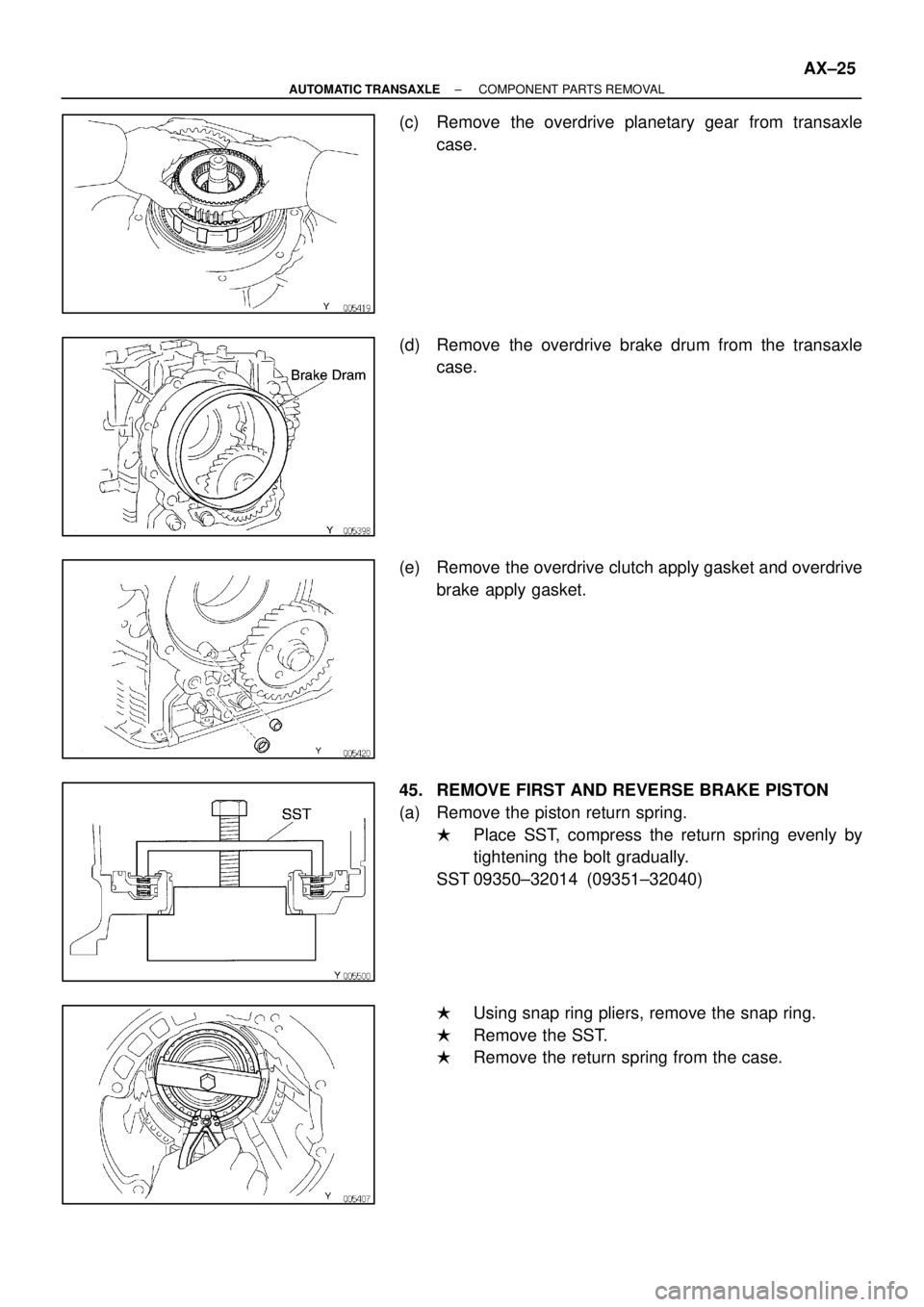

(c) Remove the overdrive planetary gear from transaxle

case.

(d) Remove the overdrive brake drum from the transaxle

case.

(e) Remove the overdrive clutch apply gasket and overdrive

brake apply gasket.

45. REMOVE FIRST AND REVERSE BRAKE PISTON

(a) Remove the piston return spring.

�Place SST, compress the return spring evenly by

tightening the bolt gradually.

SST 09350±32014 (09351±32040)

�Using snap ring pliers, remove the snap ring.

�Remove the SST.

�Remove the return spring from the case.

Page 475 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±26

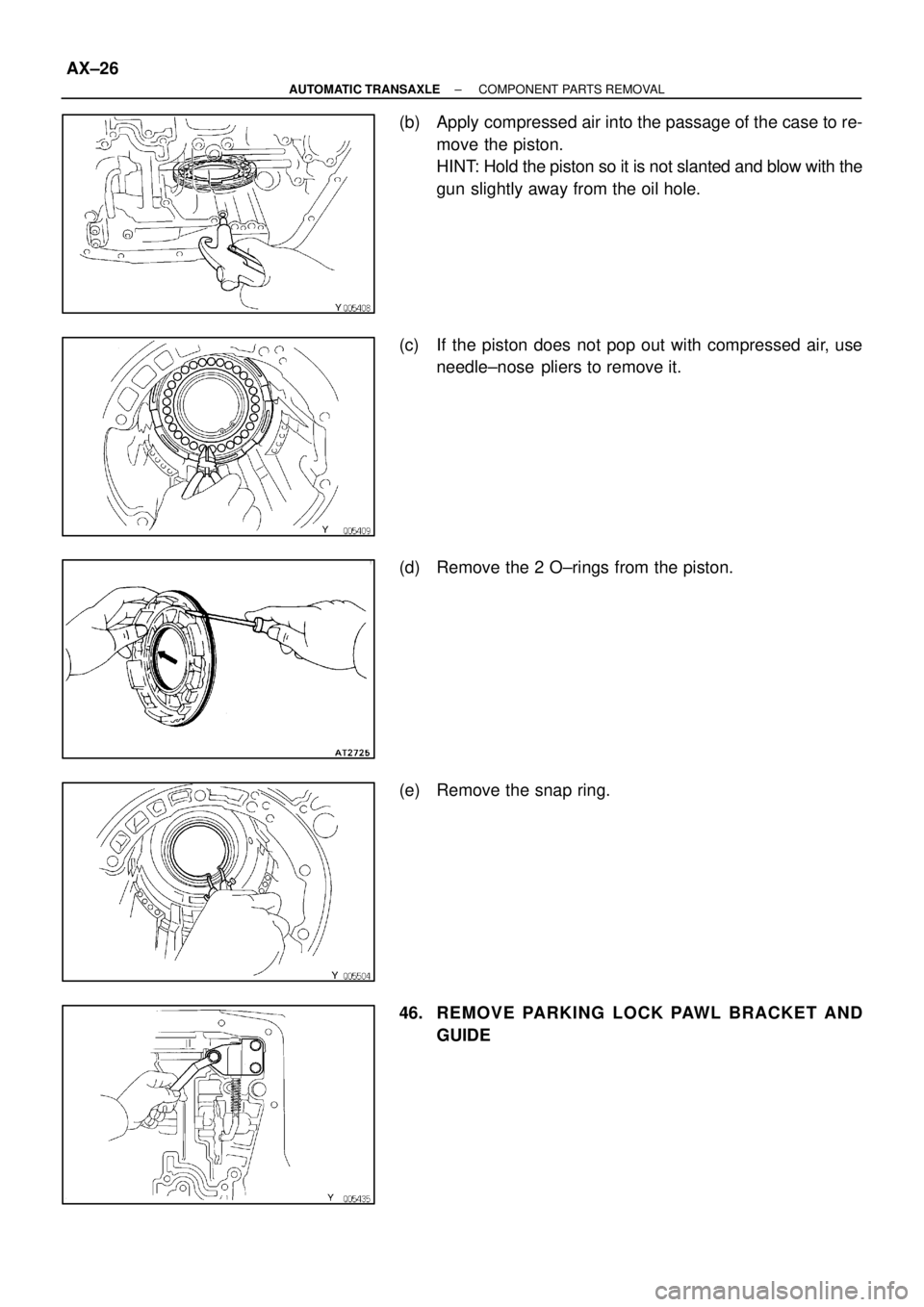

(b) Apply compressed air into the passage of the case to re-

move the piston.

HINT: Hold the piston so it is not slanted and blow with the

gun slightly away from the oil hole.

(c) If the piston does not pop out with compressed air, use

needle±nose pliers to remove it.

(d) Remove the 2 O±rings from the piston.

(e) Remove the snap ring.

46. REMOVE PARKING LOCK PAWL BRACKET AND

GUIDE

Page 476 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±27

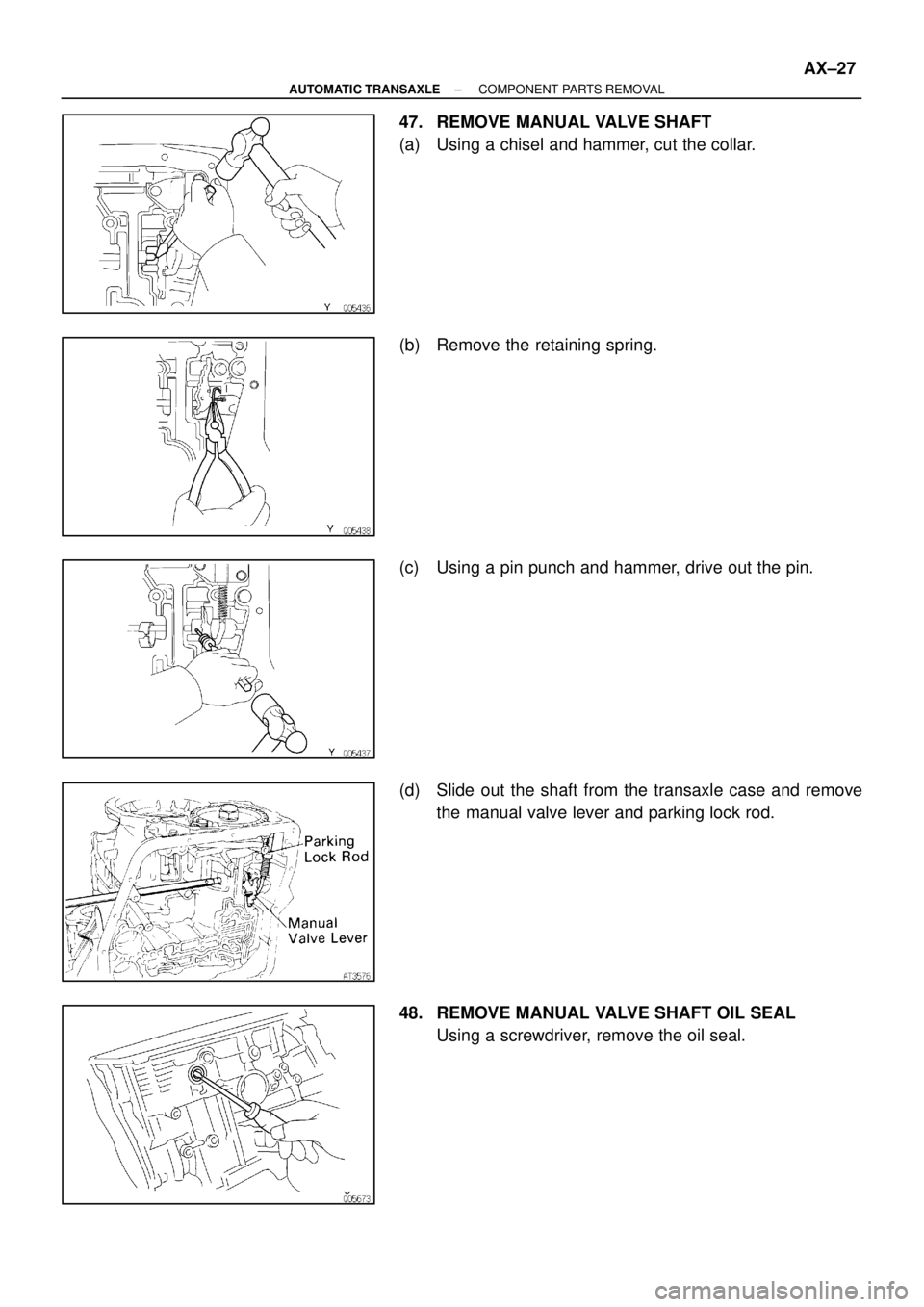

47. REMOVE MANUAL VALVE SHAFT

(a) Using a chisel and hammer, cut the collar.

(b) Remove the retaining spring.

(c) Using a pin punch and hammer, drive out the pin.

(d) Slide out the shaft from the transaxle case and remove

the manual valve lever and parking lock rod.

48. REMOVE MANUAL VALVE SHAFT OIL SEAL

Using a screwdriver, remove the oil seal.

Page 477 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±28

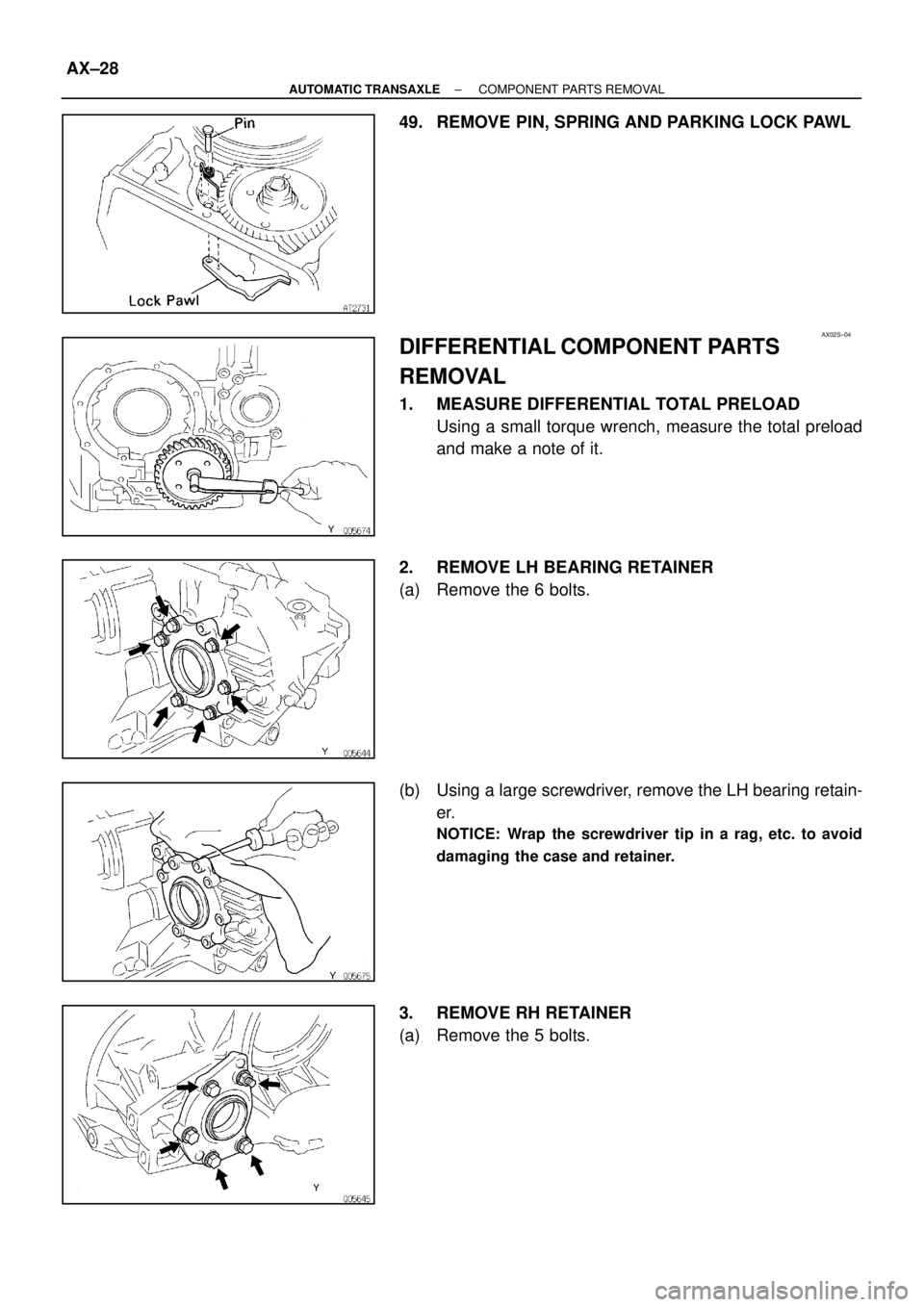

49. REMOVE PIN, SPRING AND PARKING LOCK PAWL

DIFFERENTIAL COMPONENT PARTS

REMOVAL

1. MEASURE DIFFERENTIAL TOTAL PRELOAD

Using a small torque wrench, measure the total preload

and make a note of it.

2. REMOVE LH BEARING RETAINER

(a) Remove the 6 bolts.

(b) Using a large screwdriver, remove the LH bearing retain-

er.

NOTICE: Wrap the screwdriver tip in a rag, etc. to avoid

damaging the case and retainer.

3. REMOVE RH RETAINER

(a) Remove the 5 bolts.

AX02S±04

Page 478 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±29

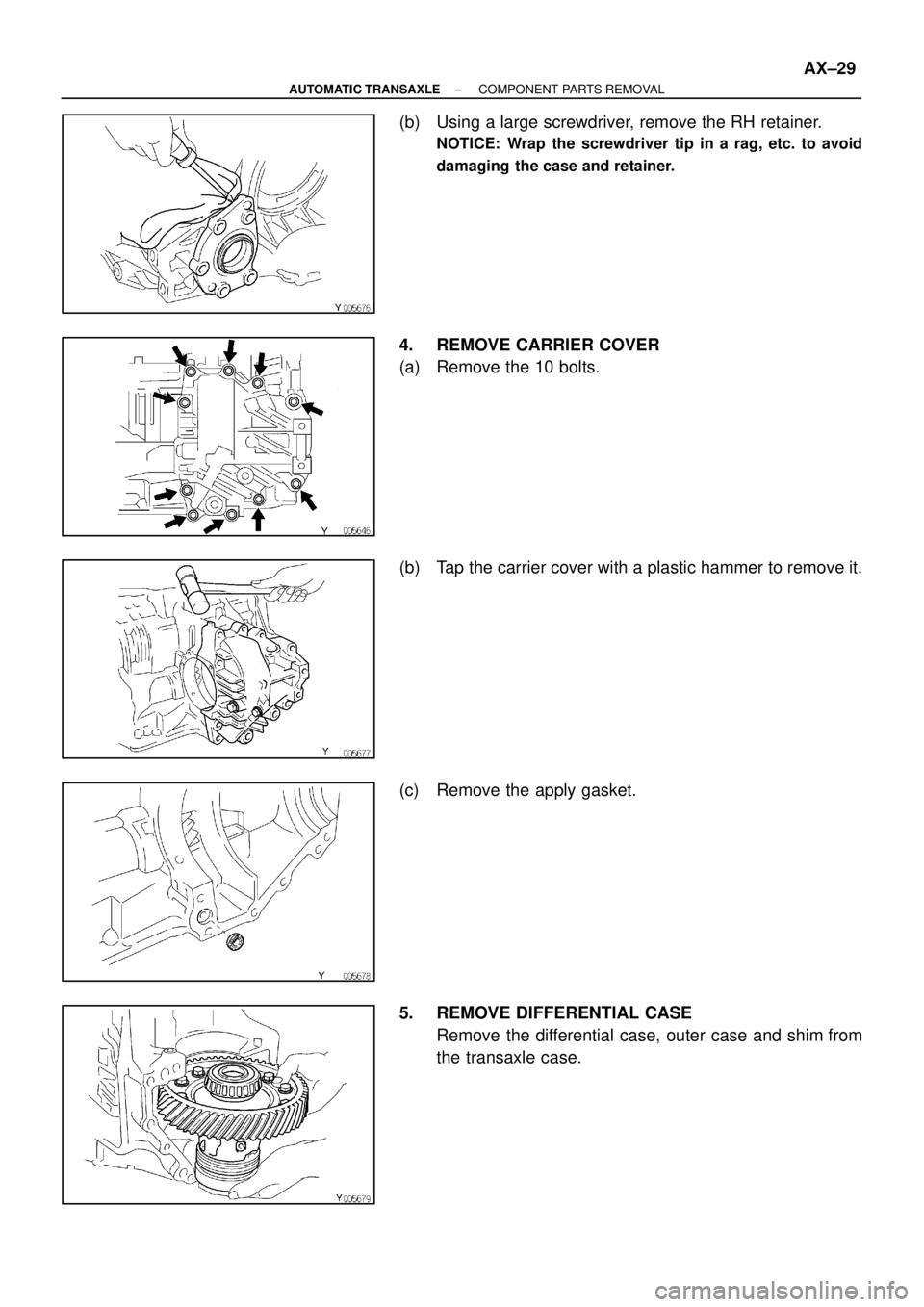

(b) Using a large screwdriver, remove the RH retainer.

NOTICE: Wrap the screwdriver tip in a rag, etc. to avoid

damaging the case and retainer.

4. REMOVE CARRIER COVER

(a) Remove the 10 bolts.

(b) Tap the carrier cover with a plastic hammer to remove it.

(c) Remove the apply gasket.

5. REMOVE DIFFERENTIAL CASE

Remove the differential case, outer case and shim from

the transaxle case.

Page 479 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±30

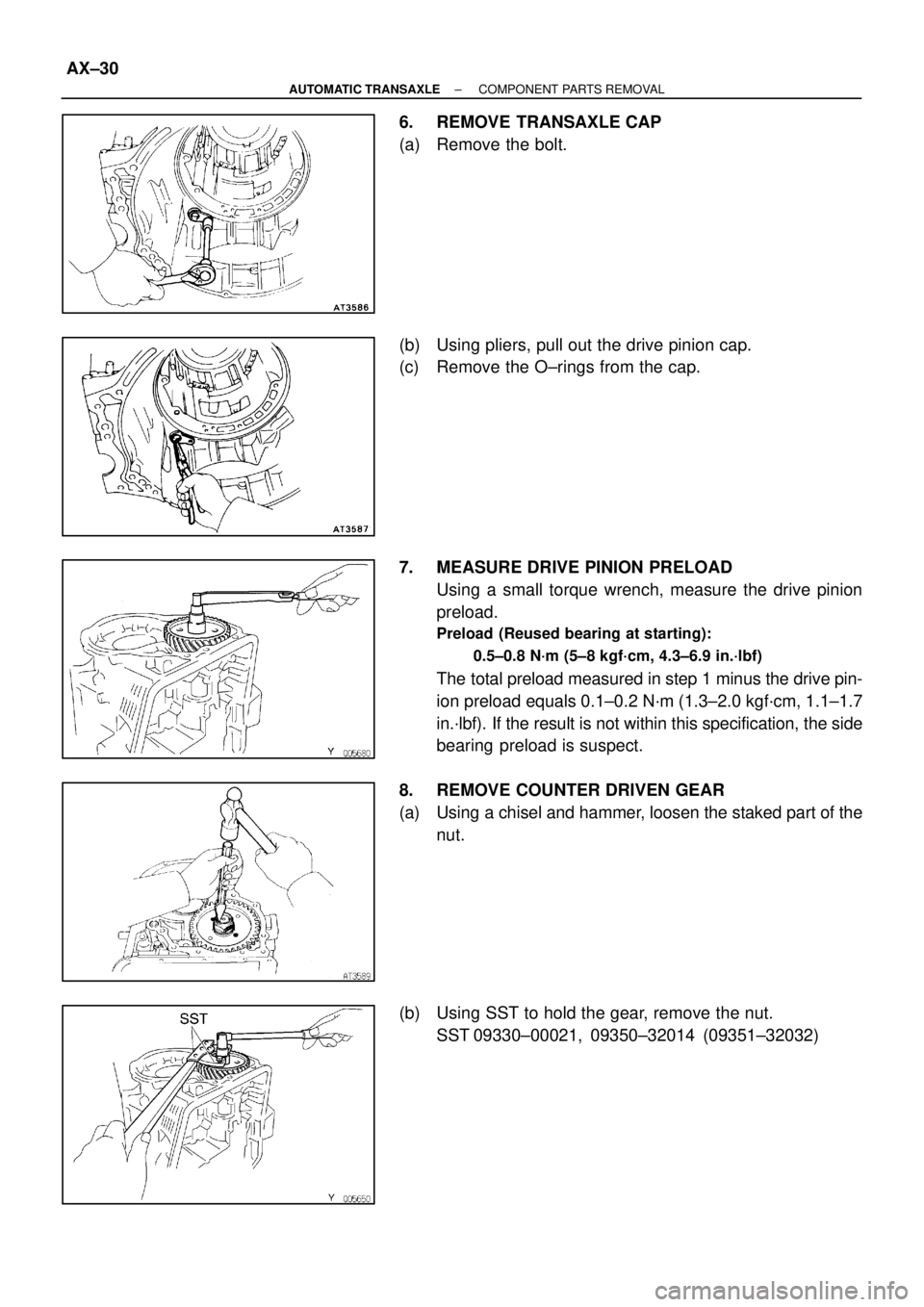

6. REMOVE TRANSAXLE CAP

(a) Remove the bolt.

(b) Using pliers, pull out the drive pinion cap.

(c) Remove the O±rings from the cap.

7. MEASURE DRIVE PINION PRELOAD

Using a small torque wrench, measure the drive pinion

preload.

Preload (Reused bearing at starting):

0.5±0.8 N´m (5±8 kgf´cm, 4.3±6.9 in.´lbf)

The total preload measured in step 1 minus the drive pin-

ion preload equals 0.1±0.2 N´m (1.3±2.0 kgf´cm, 1.1±1.7

in.´lbf). If the result is not within this specification, the side

bearing preload is suspect.

8. REMOVE COUNTER DRIVEN GEAR

(a) Using a chisel and hammer, loosen the staked part of the

nut.

(b) Using SST to hold the gear, remove the nut.

SST 09330±00021, 09350±32014 (09351±32032)

Page 480 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±31

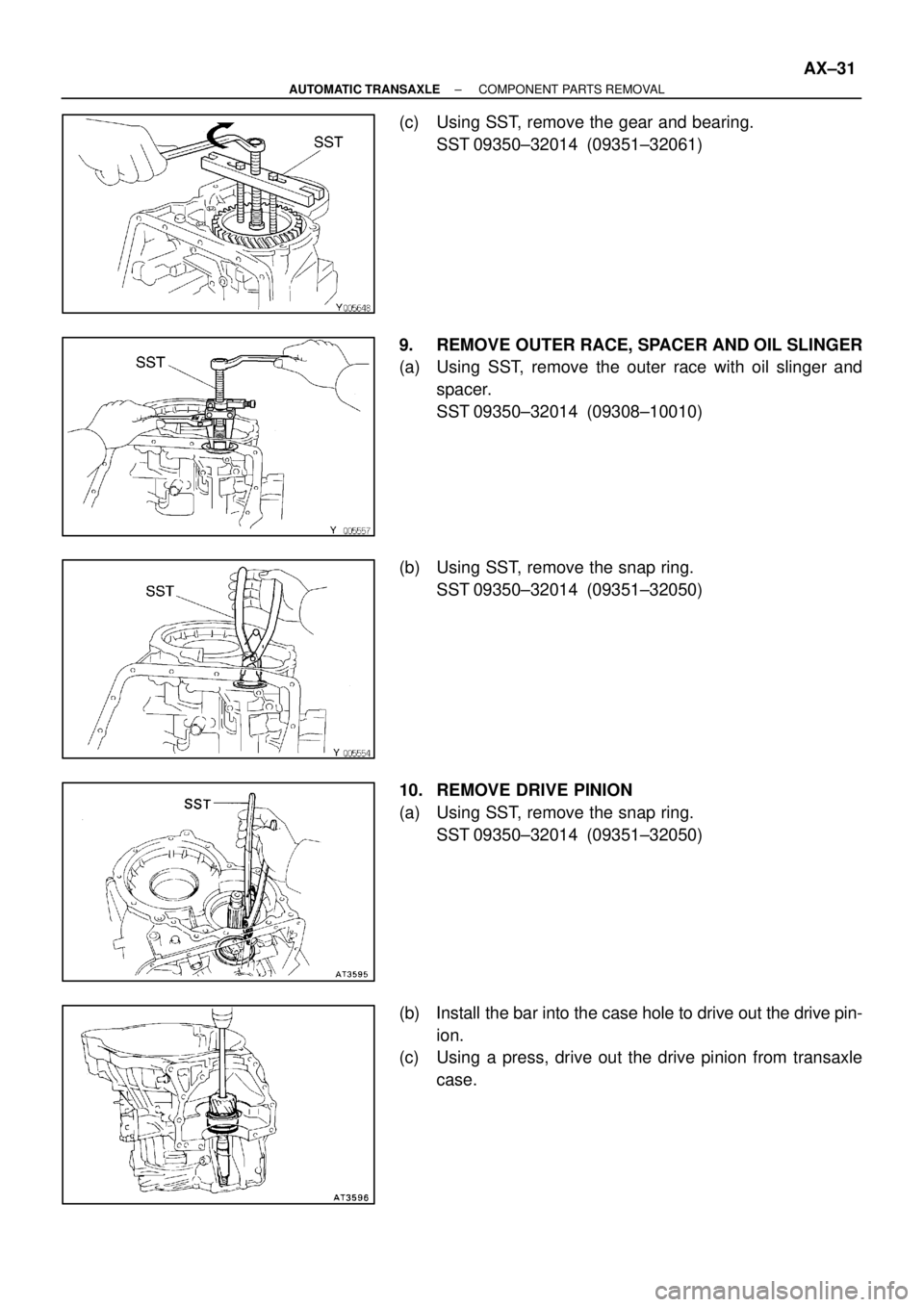

(c) Using SST, remove the gear and bearing.

SST 09350±32014 (09351±32061)

9. REMOVE OUTER RACE, SPACER AND OIL SLINGER

(a) Using SST, remove the outer race with oil slinger and

spacer.

SST 09350±32014 (09308±10010)

(b) Using SST, remove the snap ring.

SST 09350±32014 (09351±32050)

10. REMOVE DRIVE PINION

(a) Using SST, remove the snap ring.

SST 09350±32014 (09351±32050)

(b) Install the bar into the case hole to drive out the drive pin-

ion.

(c) Using a press, drive out the drive pinion from transaxle

case.

Trending: tire pressure, AUX, phone, brake pads, hood latch, bulb, headlamp