TOYOTA CAMRY 1999 Service Repair Manual

CAMRY 1999

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57448/w960_57448-0.png

TOYOTA CAMRY 1999 Service Repair Manual

Trending: ground clearance, index, horn, headrest, low beam, headlights, oil filter

Page 481 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±32

(d) Remove the bearing cage from drive pinion.

(e) Using SST, press out the bearing.

SST 09950±00020

Page 482 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±33

GENERAL NOTES

The instructions here are organized so that you work on only one component group at a time.

This will help avoid confusion from similar±looking parts of different subassemblies being on your work-

bench at the same time.

The component groups are inspected and repaired from the converter housing side.

As much as possible, complete the inspection, repair and assembly before proceeding to the next compo-

nent group. If a component group cannot be assembled because parts are being ordered, be sure to keep

all parts of that group in a separate container while proceeding with disassembly, inspection, repair and

assembly of other component groups.

Recommended fluid for the automatic transaxle: ATF D±@@@@@: [g 2] or DEXRON®@@@@@: [g

3](DEXRON®@@@@@: [g 2])

1. GENERAL CLEANING NOTES:

(a) All disassembled parts should be washed clean and any fluid passages and holes blown through with

compressed air.

(b) When using compressed air to dry parts, always aim away from yourself to prevent accidentally spray-

ing automatic transaxle fluid or kerosene in your face.

(c) The recommended automatic transaxle fluid or kerosene should be used for cleaning.

2. PARTS ARRANGEMENT:

(a) After cleaning, the parts should be arranged in the correct order to allow efficient inspection, repairs,

and reassembly.

(b) When disassembling a valve body, be sure to keep each valve together with the corresponding spring.

(c) New brakes and clutches that are to be used for replacement must be soaked in transaxle fluid for at

least fifteen minutes before assembly.

3. GENERAL ASSEMBLY:

(a) All oil seal rings, clutch discs, clutch plates, rotating parts, and sliding surfaces should be coated with

transmission fluid prior to reassembly.

(b) All gaskets and rubber O±rings should be replaced.

(c) Make sure that the ends of a snap ring are not aligned with one of the cutouts and are installed in the

groove correctly.

(d) If a worn bushing is to be replaced, the subassembly containing that bushing must be replaced.

(e) Check thrust bearings and races for wear or damage. Replace if necessary.

(f) Use petroleum jelly to keep parts in place.

AX02T±07

Page 483 of 4592

AUTOMATIC TRANSAXLESECOND COAST BRAKE ±

AX±34

SECOND COAST BRAKE

COMPONENTS

SECOND COAST BRAKE PISTON

DISASSEMBLY

1. REMOVE OIL SEAL RING

Remove the oil seal ring from the piston.

2. REMOVE PISTON ROD

(a) Remove the E±ring while pushing the piston with needle±

nose pliers.

AX02U±02

AX02V±02

Page 484 of 4592

AUTOMATIC TRANSAXLESECOND COAST BRAKE ±

AX±35

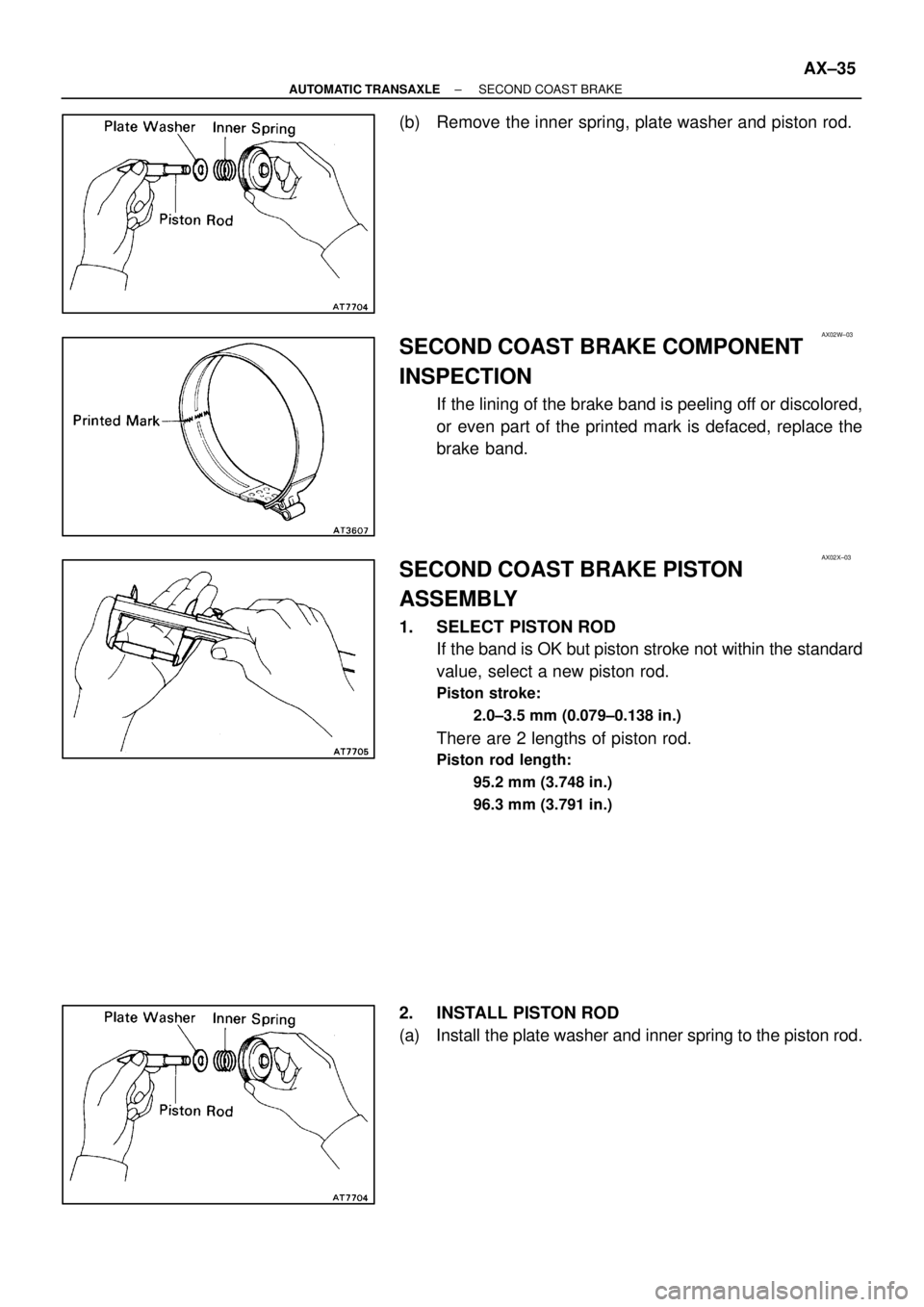

(b) Remove the inner spring, plate washer and piston rod.

SECOND COAST BRAKE COMPONENT

INSPECTION

If the lining of the brake band is peeling off or discolored,

or even part of the printed mark is defaced, replace the

brake band.

SECOND COAST BRAKE PISTON

ASSEMBLY

1. SELECT PISTON ROD

If the band is OK but piston stroke not within the standard

value, select a new piston rod.

Piston stroke:

2.0±3.5 mm (0.079±0.138 in.)

There are 2 lengths of piston rod.

Piston rod length:

95.2 mm (3.748 in.)

96.3 mm (3.791 in.)

2. INSTALL PISTON ROD

(a) Install the plate washer and inner spring to the piston rod.

AX02W±03

AX02X±03

Page 485 of 4592

AUTOMATIC TRANSAXLESECOND COAST BRAKE ±

AX±36

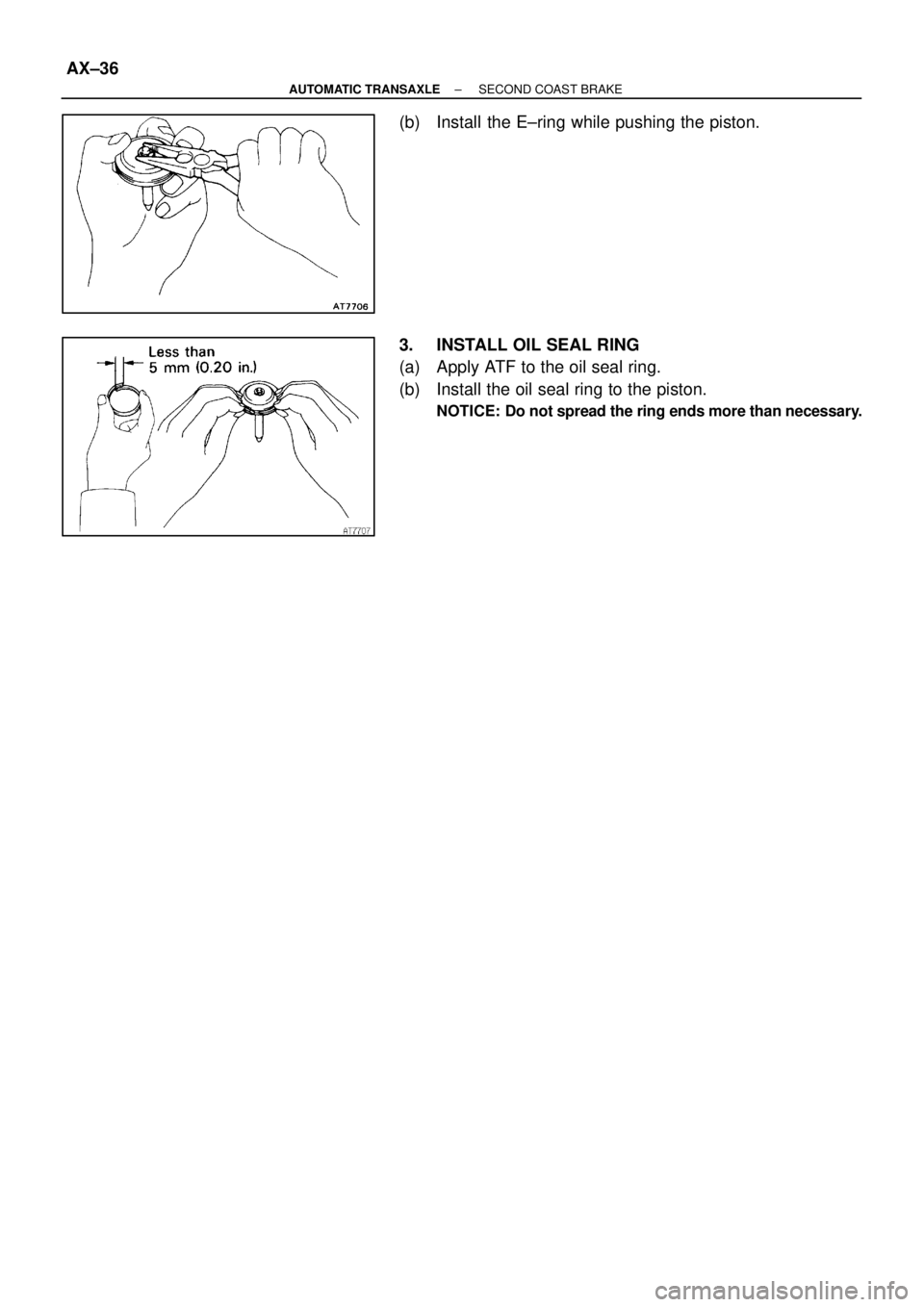

(b) Install the E±ring while pushing the piston.

3. INSTALL OIL SEAL RING

(a) Apply ATF to the oil seal ring.

(b) Install the oil seal ring to the piston.

NOTICE: Do not spread the ring ends more than necessary.

Page 486 of 4592

AUTOMATIC TRANSAXLEOIL PUMP ±

AX±37

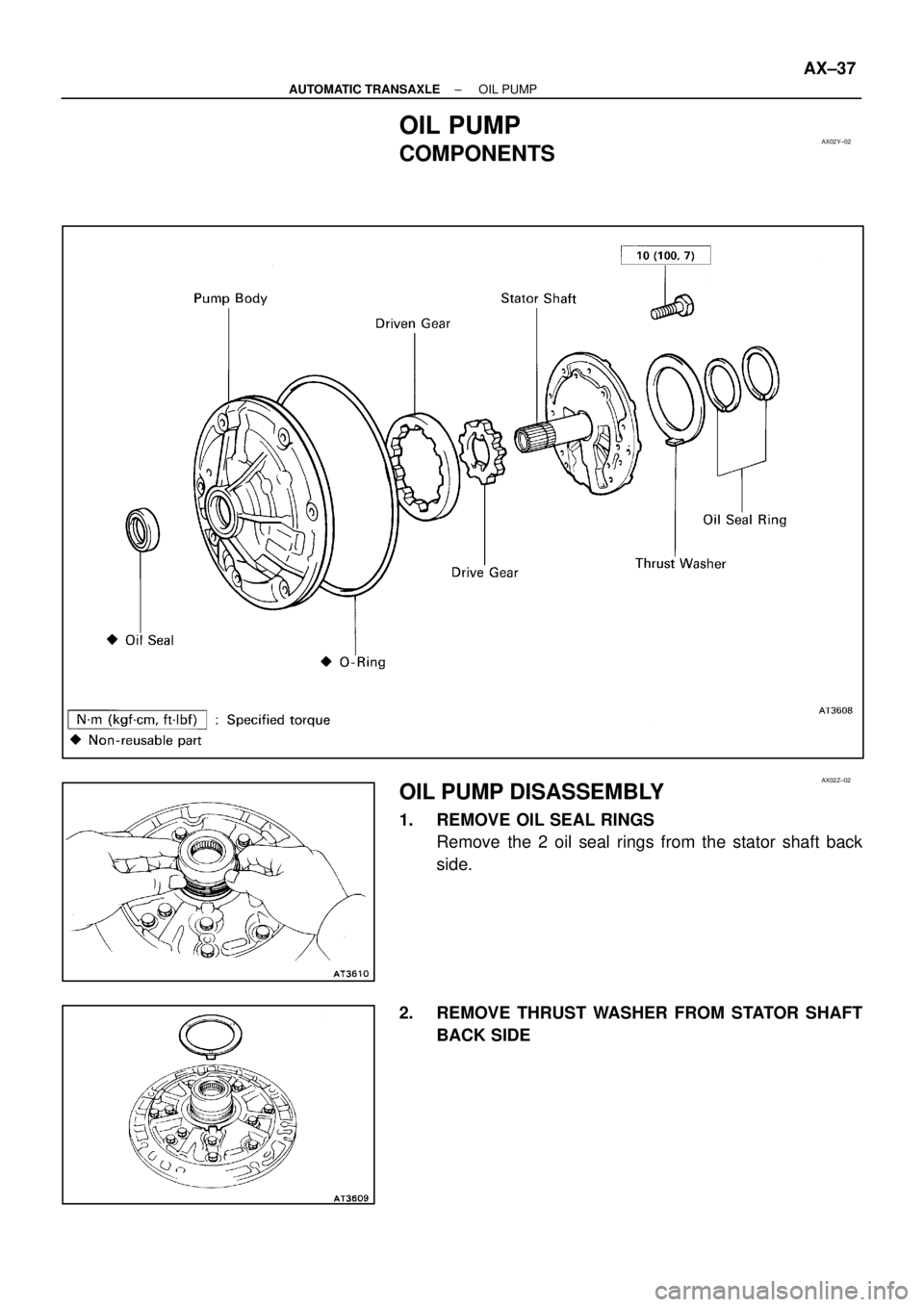

OIL PUMP

COMPONENTS

OIL PUMP DISASSEMBLY

1. REMOVE OIL SEAL RINGS

Remove the 2 oil seal rings from the stator shaft back

side.

2. REMOVE THRUST WASHER FROM STATOR SHAFT

BACK SIDE

AX02Y±02

AX02Z±02

Page 487 of 4592

AUTOMATIC TRANSAXLEOIL PUMP ±

AX±38

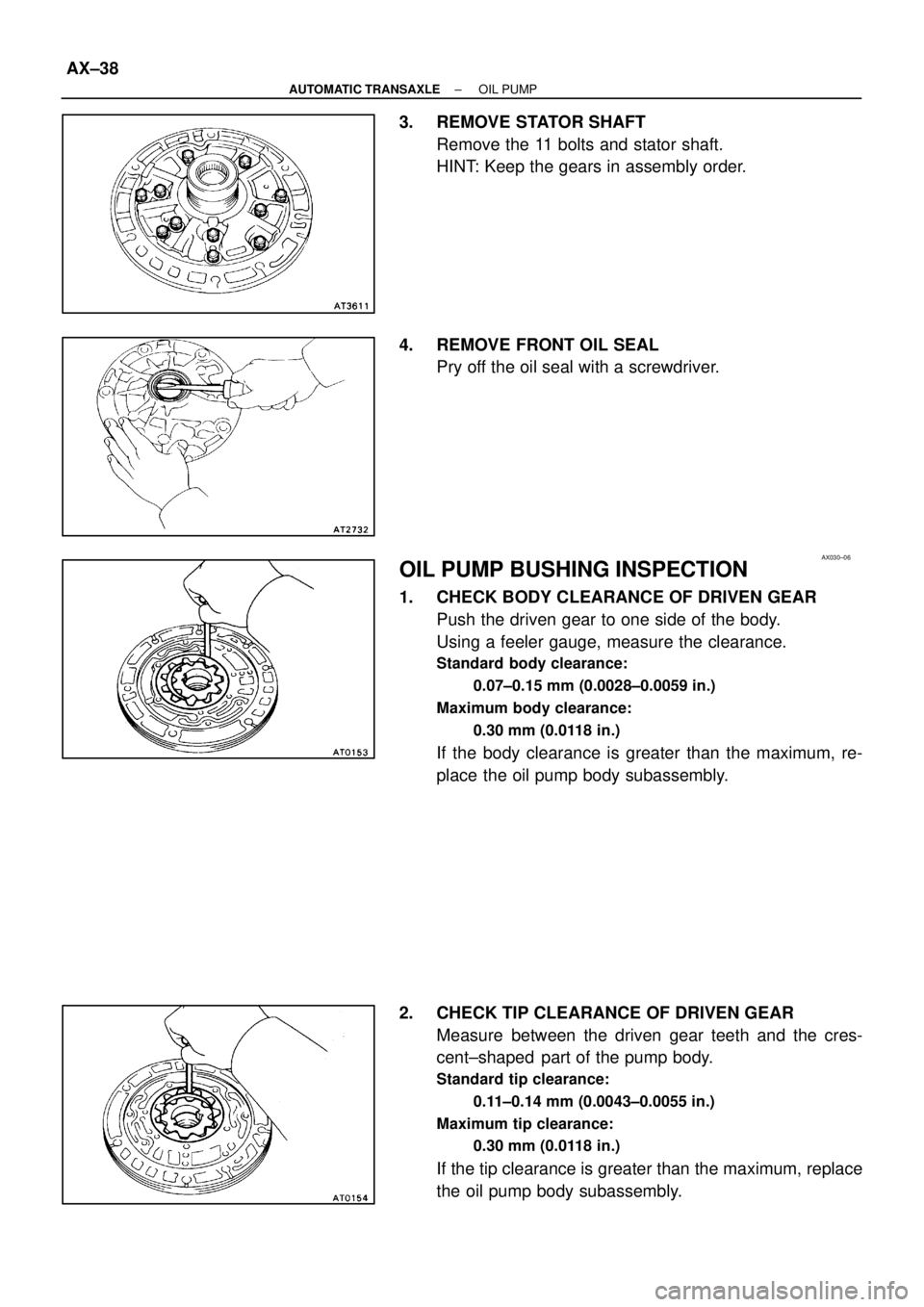

3. REMOVE STATOR SHAFT

Remove the 11 bolts and stator shaft.

HINT: Keep the gears in assembly order.

4. REMOVE FRONT OIL SEAL

Pry off the oil seal with a screwdriver.

OIL PUMP BUSHING INSPECTION

1. CHECK BODY CLEARANCE OF DRIVEN GEAR

Push the driven gear to one side of the body.

Using a feeler gauge, measure the clearance.

Standard body clearance:

0.07±0.15 mm (0.0028±0.0059 in.)

Maximum body clearance:

0.30 mm (0.0118 in.)

If the body clearance is greater than the maximum, re-

place the oil pump body subassembly.

2. CHECK TIP CLEARANCE OF DRIVEN GEAR

Measure between the driven gear teeth and the cres-

cent±shaped part of the pump body.

Standard tip clearance:

0.11±0.14 mm (0.0043±0.0055 in.)

Maximum tip clearance:

0.30 mm (0.0118 in.)

If the tip clearance is greater than the maximum, replace

the oil pump body subassembly.

AX030±06

Page 488 of 4592

AUTOMATIC TRANSAXLEOIL PUMP ±

AX±39

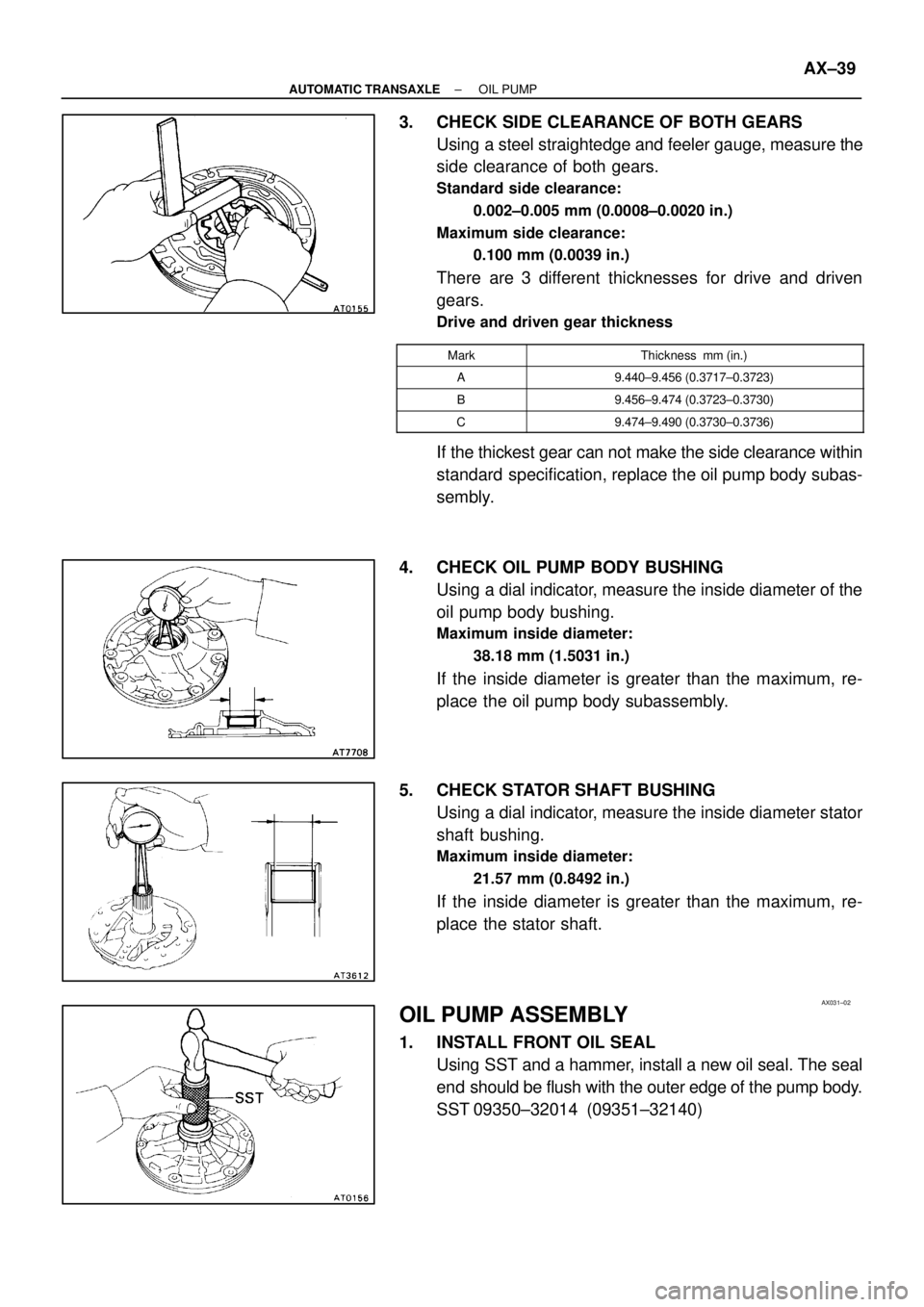

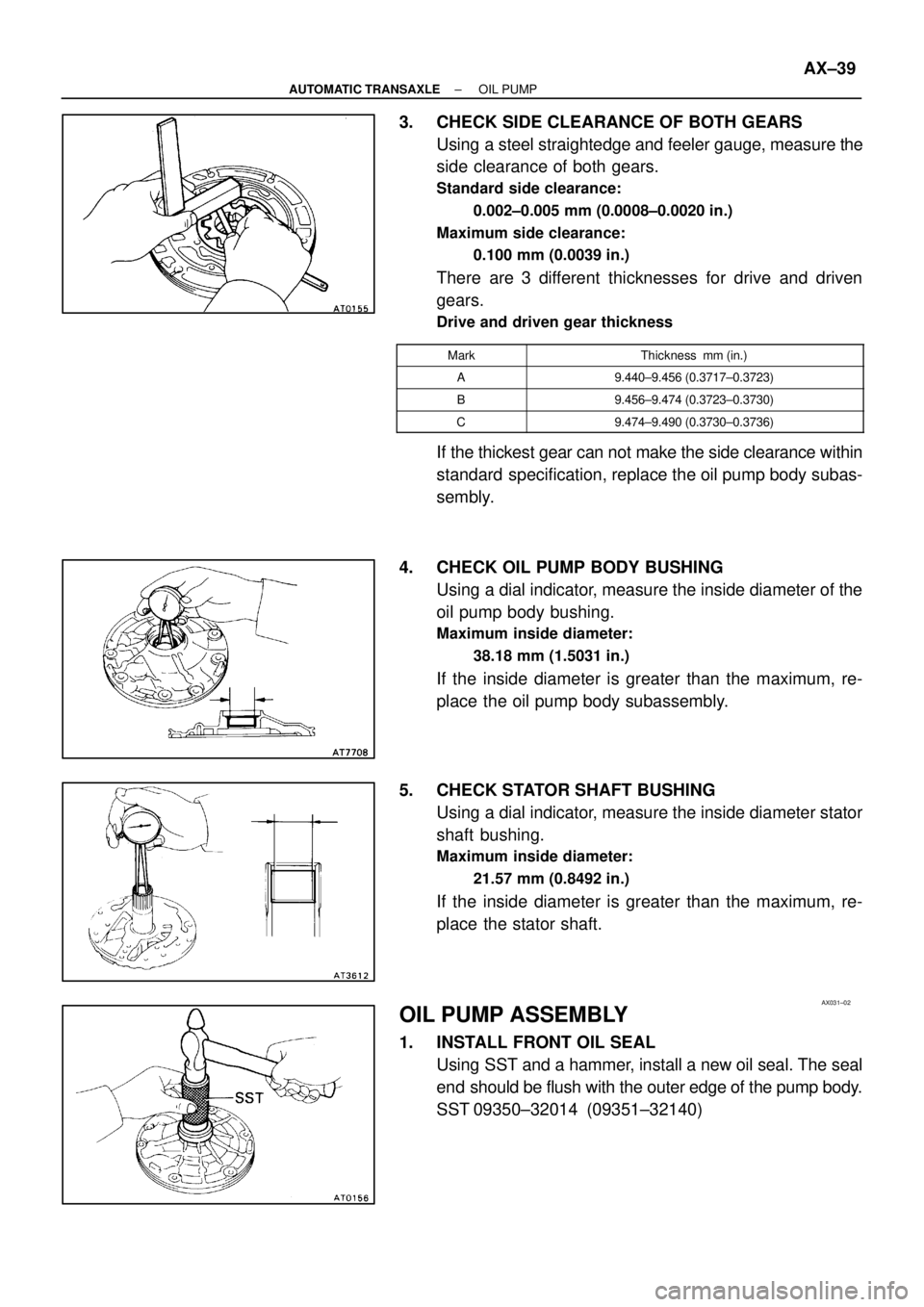

3. CHECK SIDE CLEARANCE OF BOTH GEARS

Using a steel straightedge and feeler gauge, measure the

side clearance of both gears.

Standard side clearance:

0.002±0.005 mm (0.0008±0.0020 in.)

Maximum side clearance:

0.100 mm (0.0039 in.)

There are 3 different thicknesses for drive and driven

gears.

Drive and driven gear thickness

MarkThickness mm (in.)

A9.440±9.456 (0.3717±0.3723)

B9.456±9.474 (0.3723±0.3730)

C9.474±9.490 (0.3730±0.3736)

If the thickest gear can not make the side clearance within

standard specification, replace the oil pump body subas-

sembly.

4. CHECK OIL PUMP BODY BUSHING

Using a dial indicator, measure the inside diameter of the

oil pump body bushing.

Maximum inside diameter:

38.18 mm (1.5031 in.)

If the inside diameter is greater than the maximum, re-

place the oil pump body subassembly.

5. CHECK STATOR SHAFT BUSHING

Using a dial indicator, measure the inside diameter stator

shaft bushing.

Maximum inside diameter:

21.57 mm (0.8492 in.)

If the inside diameter is greater than the maximum, re-

place the stator shaft.

OIL PUMP ASSEMBLY

1. INSTALL FRONT OIL SEAL

Using SST and a hammer, install a new oil seal. The seal

end should be flush with the outer edge of the pump body.

SST 09350±32014 (09351±32140)

AX031±02

Page 489 of 4592

AUTOMATIC TRANSAXLEOIL PUMP ±

AX±40

2. INSTALL DRIVEN GEAR AND DRIVE GEAR

Make sure the top of the gears are facing upward.

3. INSTALL STATOR SHAFT TO PUMP BODY

(a) Align the stator shaft with each bolt hole.

(b) Torque the 11 bolts.

Torque: 10 N´m (100 kgf´cm, 7 ft´lbf)

4. INSTALL THRUST WASHER

(a) Coat the thrust washer with petroleum jelly.

(b) Align the tab of the washer with the hollow of the pump

body.

5. INSTALL OIL SEAL RINGS

Install the 2 oil seal rings to the stator shaft back side.

NOTICE: Do not spread the ring ends more than necessary.

HINT: After installing the oil seal rings, check that they

move smoothly.

6. CHECK PUMP DRIVE GEAR ROTATION

Turn the drive gear with 2 screwdrivers and make sure it

rotates smoothly.

NOTICE: Be careful not to damage the oil seal lip.

Page 490 of 4592

AUTOMATIC TRANSAXLEDIRECT CLUTCH ±

AX±41

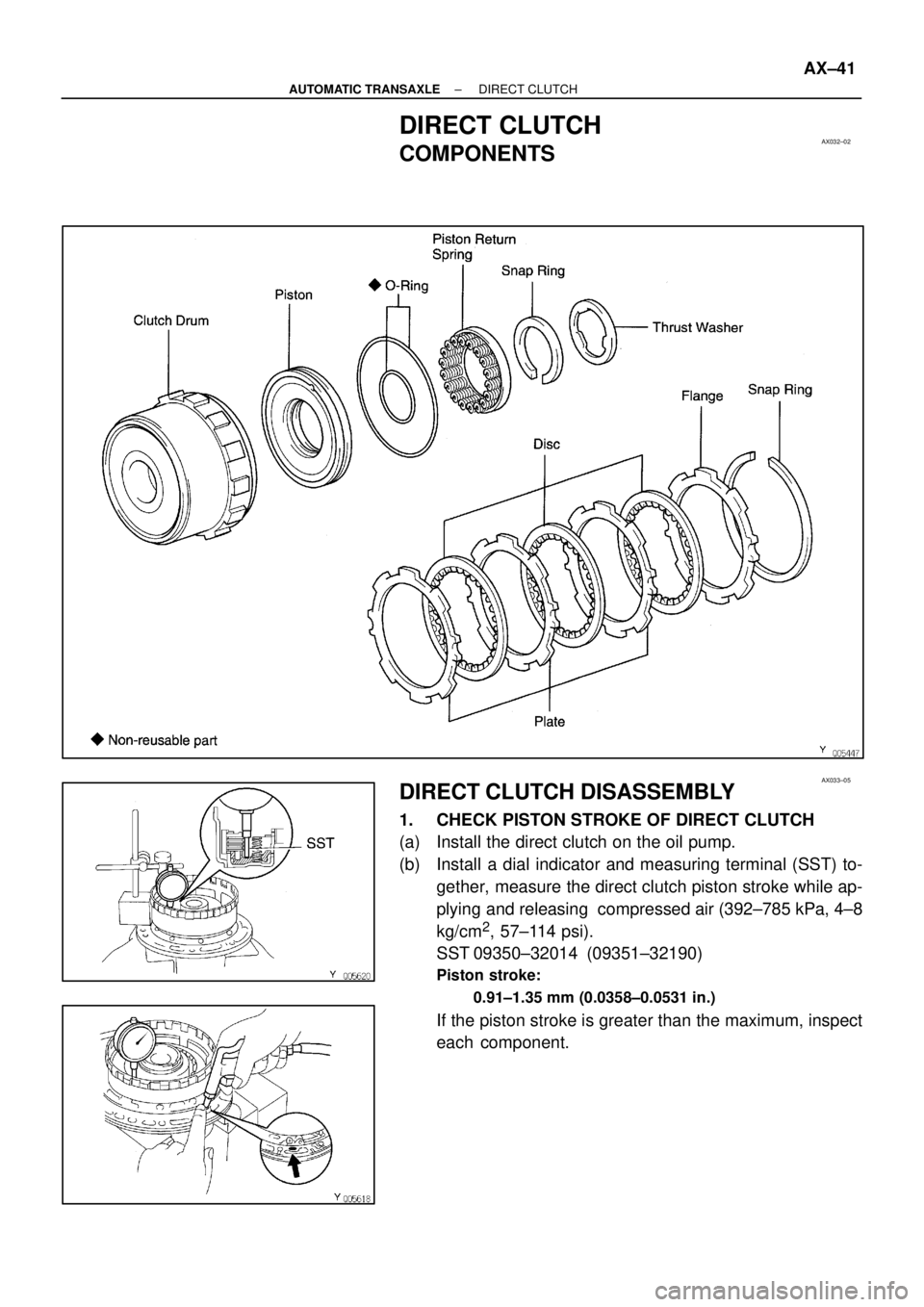

DIRECT CLUTCH

COMPONENTS

DIRECT CLUTCH DISASSEMBLY

1. CHECK PISTON STROKE OF DIRECT CLUTCH

(a) Install the direct clutch on the oil pump.

(b) Install a dial indicator and measuring terminal (SST) to-

gether, measure the direct clutch piston stroke while ap-

plying and releasing compressed air (392±785 kPa, 4±8

kg/cm

2, 57±114 psi).

SST 09350±32014 (09351±32190)

Piston stroke:

0.91±1.35 mm (0.0358±0.0531 in.)

If the piston stroke is greater than the maximum, inspect

each component.

AX032±02

AX033±05

Trending: headrest, transmission line, water pump, light, overhead cam, transmission oil, mirror