clutch TOYOTA CAMRY 1999 Service Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1999, Model line: CAMRY, Model: TOYOTA CAMRY 1999Pages: 4592, PDF Size: 55.16 MB

Page 176 of 4592

AUTOMATIC TRANSAXLEOPERATION ±

AX±6

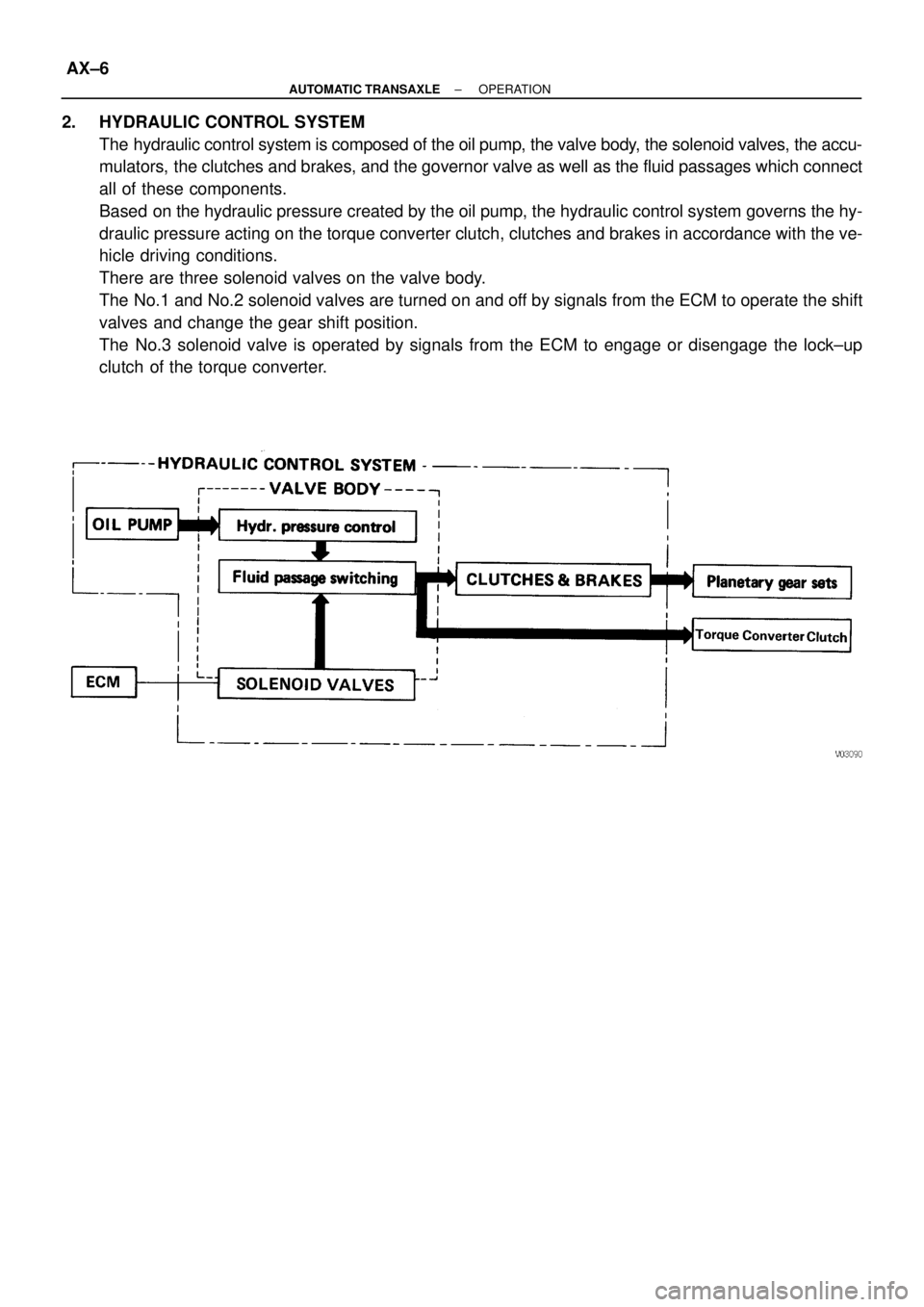

2. HYDRAULIC CONTROL SYSTEM

The hydraulic control system is composed of the oil pump, the valve body, the solenoid valves, the accu-

mulators, the clutches and brakes, and the governor valve as well as the fluid passages which connect

all of these components.

Based on the hydraulic pressure created by the oil pump, the hydraulic control system governs the hy-

draulic pressure acting on the torque converter clutch, clutches and brakes in accordance with the ve-

hicle driving conditions.

There are three solenoid valves on the valve body.

The No.1 and No.2 solenoid valves are turned on and off by signals from the ECM to operate the shift

valves and change the gear shift position.

The No.3 solenoid valve is operated by signals from the ECM to engage or disengage the lock±up

clutch of the torque converter.

Page 177 of 4592

AUTOMATIC TRANSAXLEOPERATION ±

AX±7

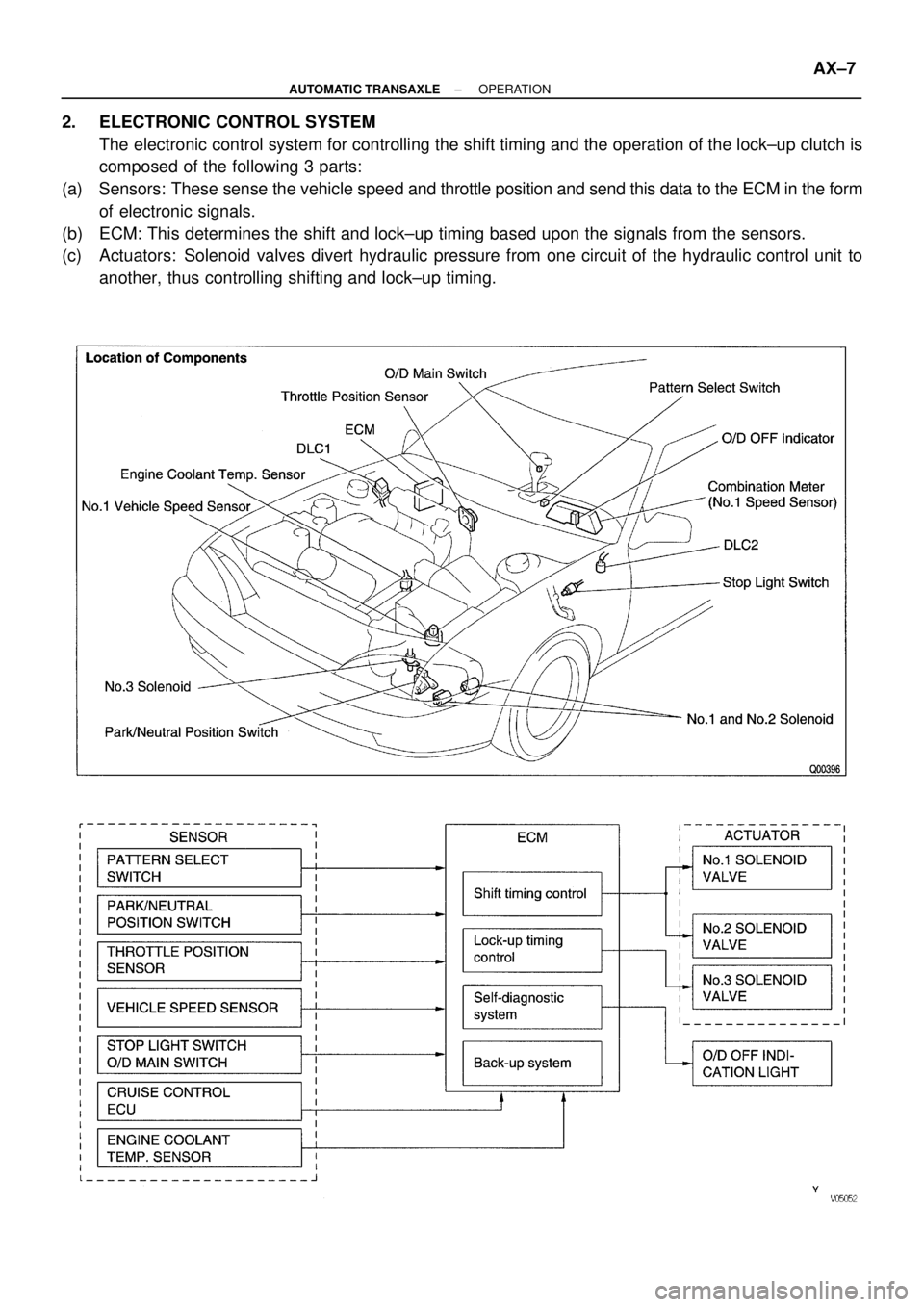

2. ELECTRONIC CONTROL SYSTEM

The electronic control system for controlling the shift timing and the operation of the lock±up clutch is

composed of the following 3 parts:

(a) Sensors: These sense the vehicle speed and throttle position and send this data to the ECM in the form

of electronic signals.

(b) ECM: This determines the shift and lock±up timing based upon the signals from the sensors.

(c) Actuators: Solenoid valves divert hydraulic pressure from one circuit of the hydraulic control unit to

another, thus controlling shifting and lock±up timing.

Page 189 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±19

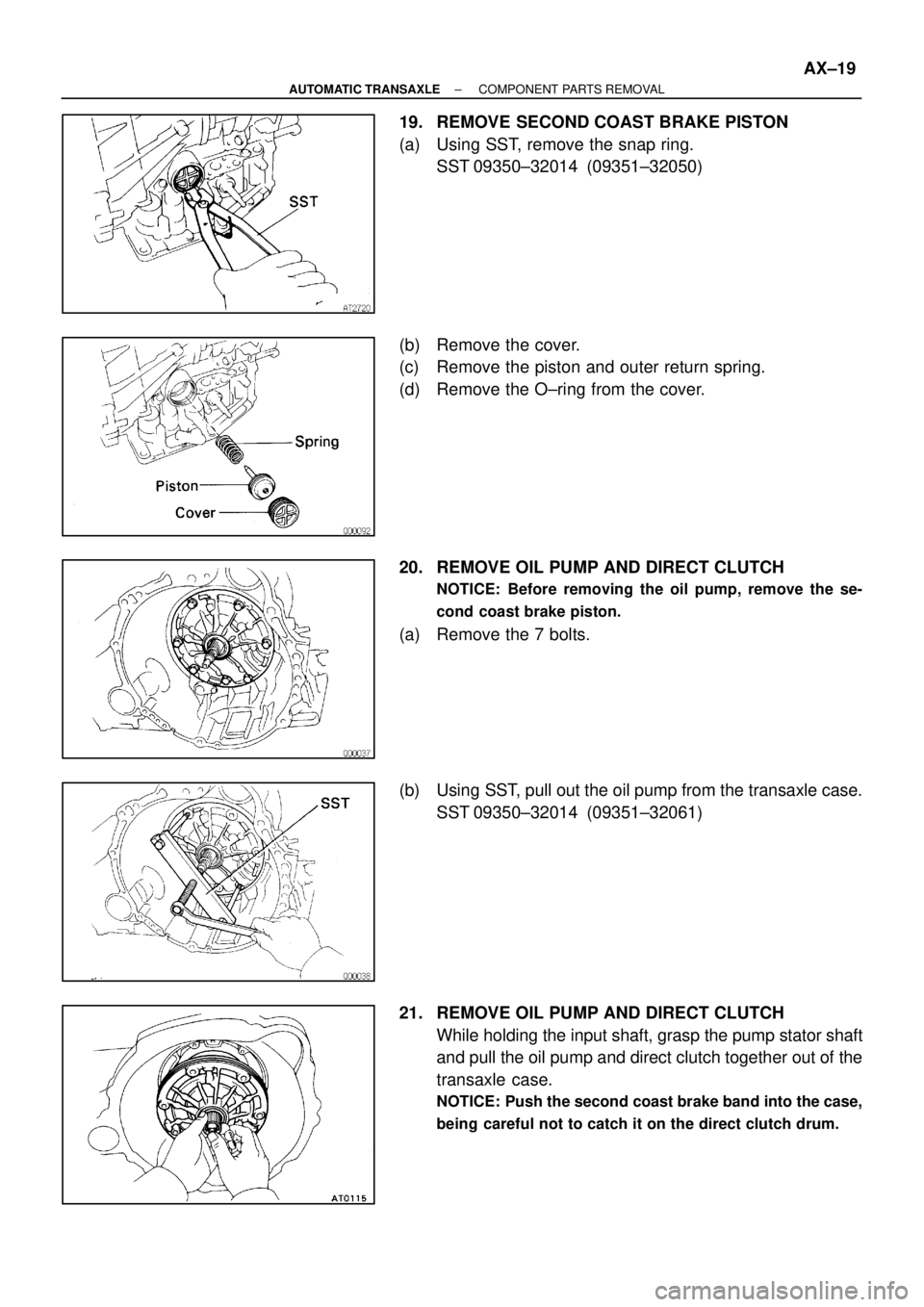

19. REMOVE SECOND COAST BRAKE PISTON

(a) Using SST, remove the snap ring.

SST 09350±32014 (09351±32050)

(b) Remove the cover.

(c) Remove the piston and outer return spring.

(d) Remove the O±ring from the cover.

20. REMOVE OIL PUMP AND DIRECT CLUTCH

NOTICE: Before removing the oil pump, remove the se-

cond coast brake piston.

(a) Remove the 7 bolts.

(b) Using SST, pull out the oil pump from the transaxle case.

SST 09350±32014 (09351±32061)

21. REMOVE OIL PUMP AND DIRECT CLUTCH

While holding the input shaft, grasp the pump stator shaft

and pull the oil pump and direct clutch together out of the

transaxle case.

NOTICE: Push the second coast brake band into the case,

being careful not to catch it on the direct clutch drum.

Page 190 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±20

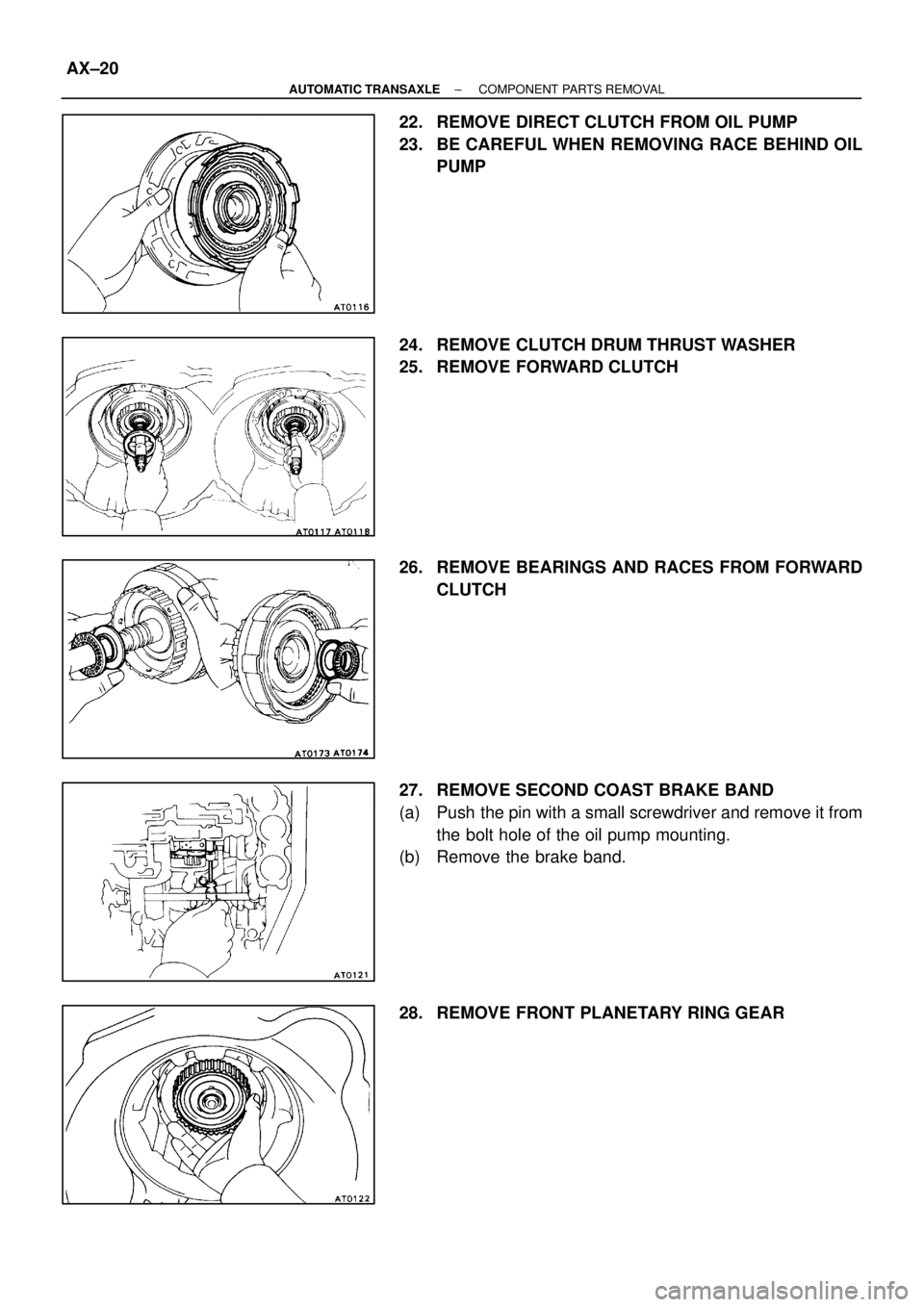

22. REMOVE DIRECT CLUTCH FROM OIL PUMP

23. BE CAREFUL WHEN REMOVING RACE BEHIND OIL

PUMP

24. REMOVE CLUTCH DRUM THRUST WASHER

25. REMOVE FORWARD CLUTCH

26. REMOVE BEARINGS AND RACES FROM FORWARD

CLUTCH

27. REMOVE SECOND COAST BRAKE BAND

(a) Push the pin with a small screwdriver and remove it from

the bolt hole of the oil pump mounting.

(b) Remove the brake band.

28. REMOVE FRONT PLANETARY RING GEAR

Page 191 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±21

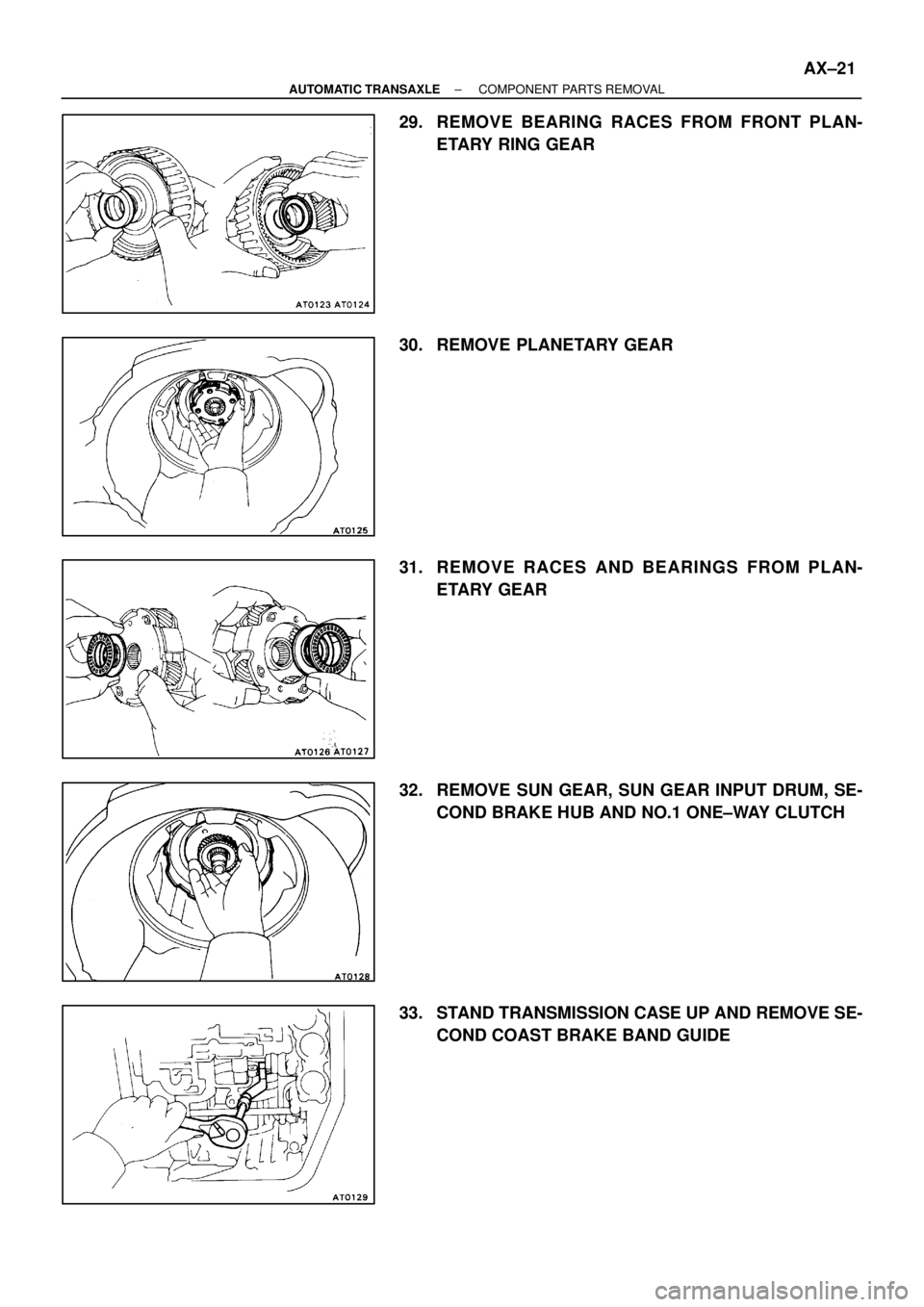

29. REMOVE BEARING RACES FROM FRONT PLAN-

ETARY RING GEAR

30. REMOVE PLANETARY GEAR

31. REMOVE RACES AND BEARINGS FROM PLAN-

ETARY GEAR

32. REMOVE SUN GEAR, SUN GEAR INPUT DRUM, SE-

COND BRAKE HUB AND NO.1 ONE±WAY CLUTCH

33. STAND TRANSMISSION CASE UP AND REMOVE SE-

COND COAST BRAKE BAND GUIDE

Page 193 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±23

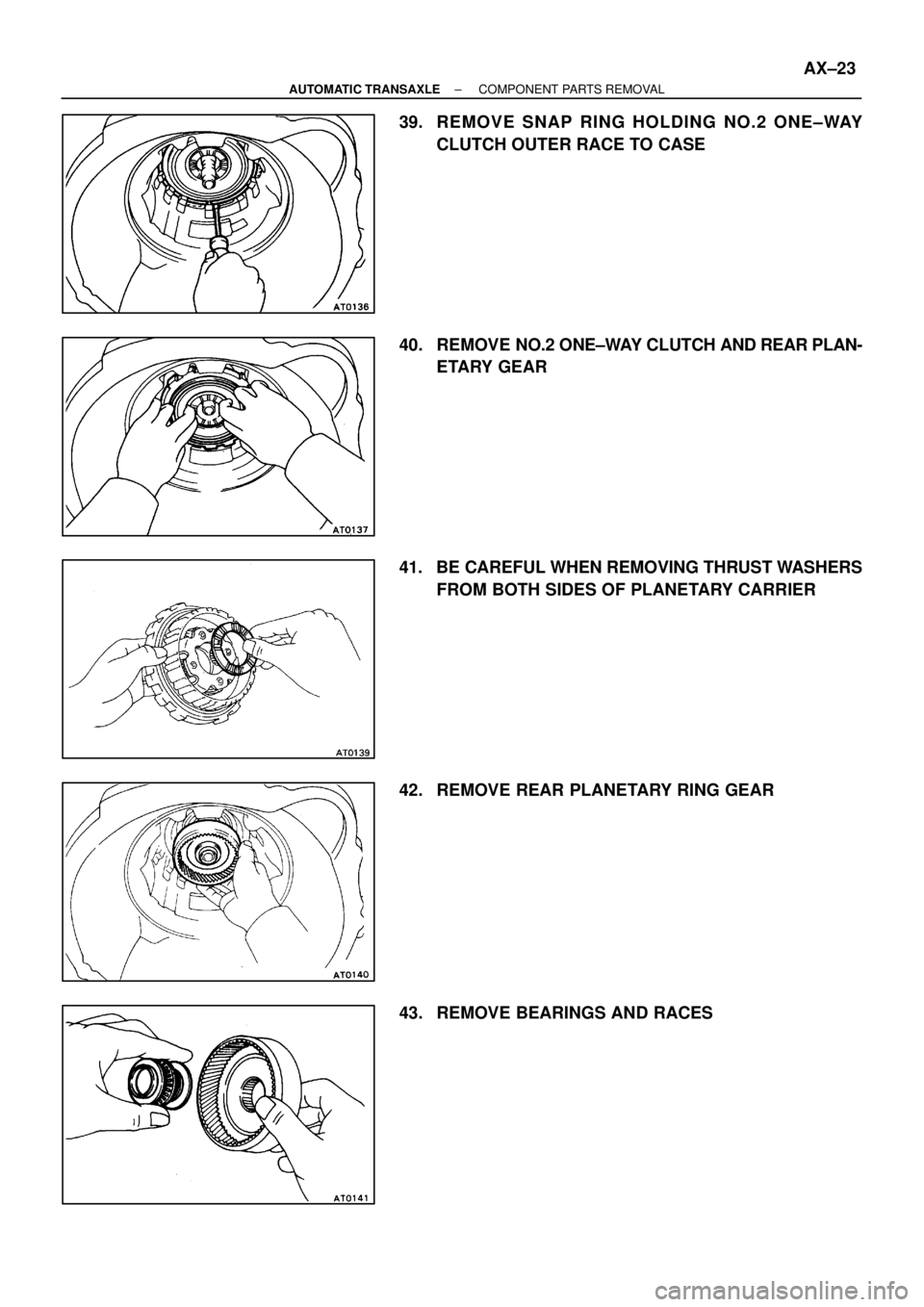

39. REMOVE SNAP RING HOLDING NO.2 ONE±WAY

CLUTCH OUTER RACE TO CASE

40. REMOVE NO.2 ONE±WAY CLUTCH AND REAR PLAN-

ETARY GEAR

41. BE CAREFUL WHEN REMOVING THRUST WASHERS

FROM BOTH SIDES OF PLANETARY CARRIER

42. REMOVE REAR PLANETARY RING GEAR

43. REMOVE BEARINGS AND RACES

Page 195 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS REMOVAL ±

AX±25

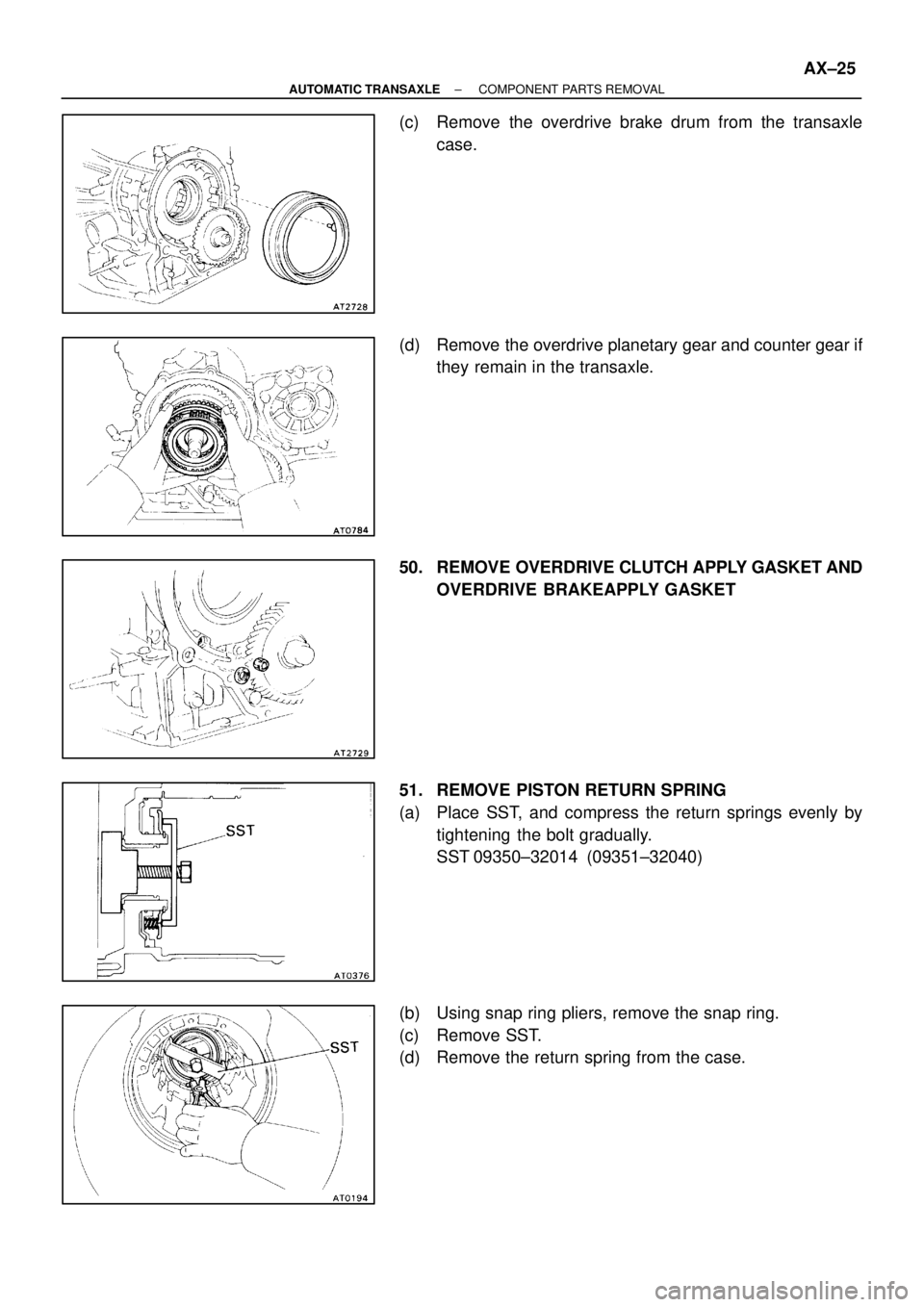

(c) Remove the overdrive brake drum from the transaxle

case.

(d) Remove the overdrive planetary gear and counter gear if

they remain in the transaxle.

50. REMOVE OVERDRIVE CLUTCH APPLY GASKET AND

OVERDRIVE BRAKEAPPLY GASKET

51. REMOVE PISTON RETURN SPRING

(a) Place SST, and compress the return springs evenly by

tightening the bolt gradually.

SST 09350±32014 (09351±32040)

(b) Using snap ring pliers, remove the snap ring.

(c) Remove SST.

(d) Remove the return spring from the case.

Page 202 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS ±

AX±32

COMPONENT PARTS

GENERAL NOTES

The instructions here are organized so that you work on only one component group at a time.

This will help avoid confusion from similar±looking parts of different subassemblies being on your work-

bench at the same time.

The component groups are inspected and repaired from the converter housing side.

As much as possible, complete the inspection, repair and assembly before proceeding to the next com-

ponent group. If a component group cannot be assembled because parts are being ordered, be sure

to keep all parts of that group in a separate container while proceeding with disassembly, inspection,

repair and assembly of other component groups.

Recommended fluid for the automatic transaxle:

DEXRON ® @@@@@: [g 2]

GENERAL CLEANING NOTES:

1. All disassembled parts should be washed clean and any fluid passages and holes blown through with

compressed air.

2. When using compressed air to dry parts, always aim away from yourself to prevent accidentally spray-

ing automatic transmission fluid or kerosene in your face.

3. The recommended automatic transaxle fluid or kerosene should be used for cleaning.

PARTS ARRANGEMENT:

1. After cleaning, the parts should be arranged in the correct order to allow efficient inspection, repairs,

and reassembly.

2. When disassembling a valve body, be sure to keep each valve together with the corresponding spring.

3. New brakes and clutches that are to be used for replacement must be soaked in transaxle fluid for at

least 15 minutes before assembly.

GENERAL ASSEMBLY:

1. All oil seal rings, clutch discs, clutch plates, rotating parts, and sliding surfaces should be coated with

transmission fluid prior to reassembly.

2. All gaskets and rubber O±rings should be replaced.

3. Make sure that the ends of a snap ring are not aligned with one of the cutouts and are installed in the

groove correctly.

4. If a worn bushing is to be replaced, the subassembly containing that bushing must be replaced.

5. Check thrust bearings and races for wear or damage. Replace if necessary.

6. Use petroleum jelly to keep parts in place.

AX0EY±02

Page 210 of 4592

AUTOMATIC TRANSAXLEDIRECT CLUTCH ±

AX±40

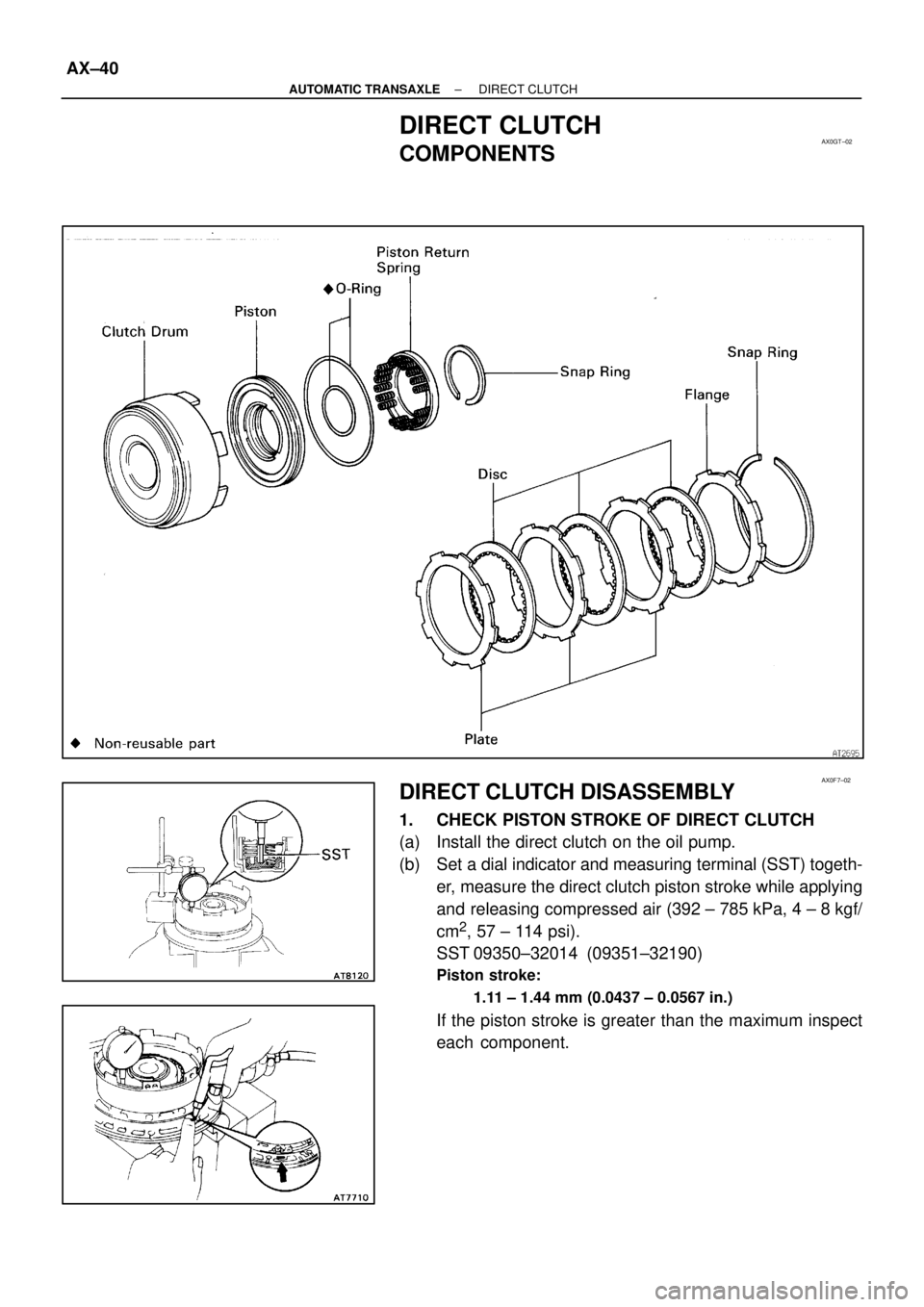

DIRECT CLUTCH

COMPONENTS

DIRECT CLUTCH DISASSEMBLY

1. CHECK PISTON STROKE OF DIRECT CLUTCH

(a) Install the direct clutch on the oil pump.

(b) Set a dial indicator and measuring terminal (SST) togeth-

er, measure the direct clutch piston stroke while applying

and releasing compressed air (392 ± 785 kPa, 4 ± 8 kgf/

cm

2, 57 ± 114 psi).

SST 09350±32014 (09351±32190)

Piston stroke:

1.11 ± 1.44 mm (0.0437 ± 0.0567 in.)

If the piston stroke is greater than the maximum inspect

each component.

AX0GT±02

AX0F7±02

Page 211 of 4592

AUTOMATIC TRANSAXLEDIRECT CLUTCH ±

AX±41

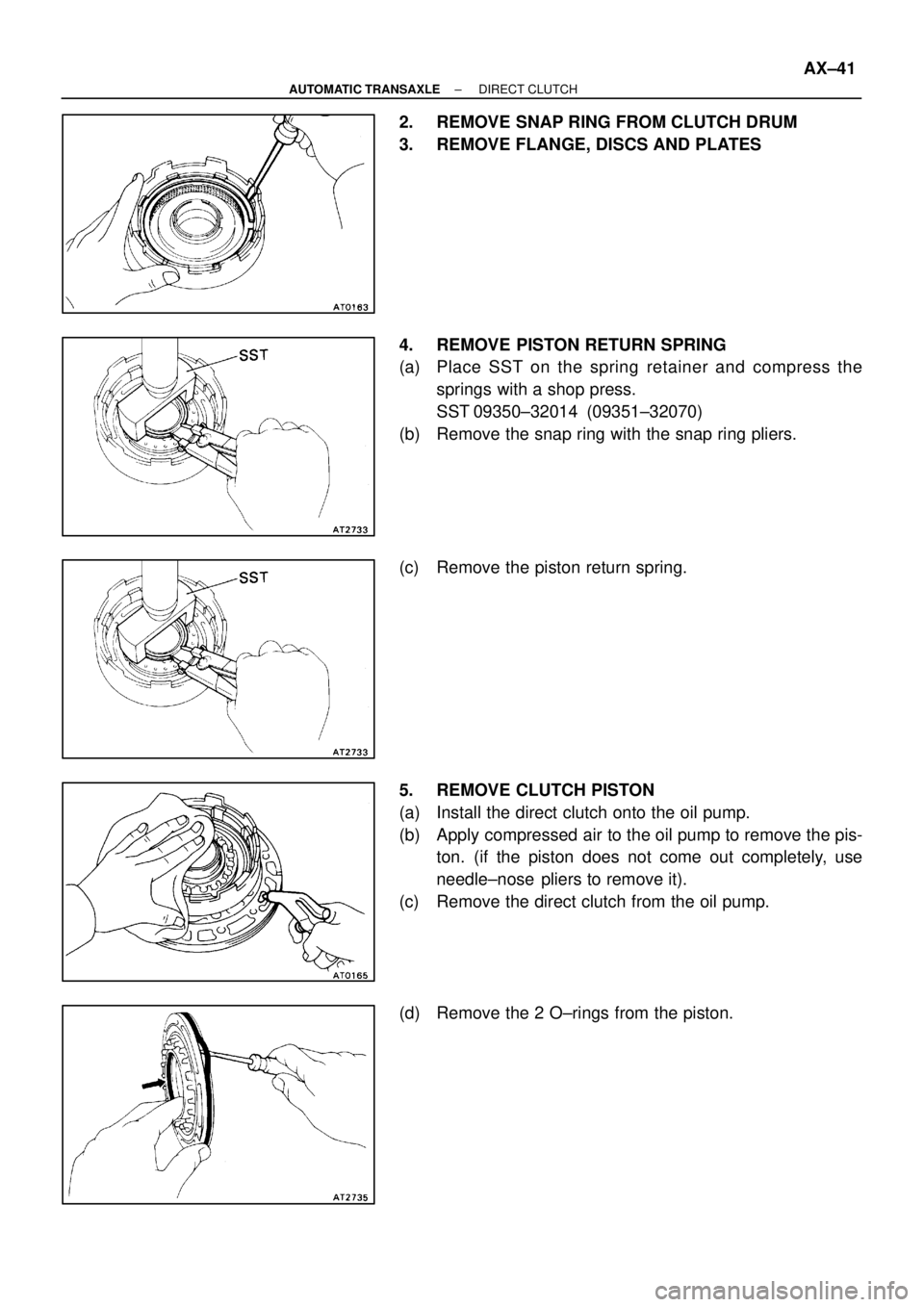

2. REMOVE SNAP RING FROM CLUTCH DRUM

3. REMOVE FLANGE, DISCS AND PLATES

4. REMOVE PISTON RETURN SPRING

(a) Place SST on the spring retainer and compress the

springs with a shop press.

SST 09350±32014 (09351±32070)

(b) Remove the snap ring with the snap ring pliers.

(c) Remove the piston return spring.

5. REMOVE CLUTCH PISTON

(a) Install the direct clutch onto the oil pump.

(b) Apply compressed air to the oil pump to remove the pis-

ton. (if the piston does not come out completely, use

needle±nose pliers to remove it).

(c) Remove the direct clutch from the oil pump.

(d) Remove the 2 O±rings from the piston.