check engine TOYOTA CAMRY 2000 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2000, Model line: CAMRY, Model: TOYOTA CAMRY 2000Pages: 4770, PDF Size: 86.41 MB

Page 323 of 4770

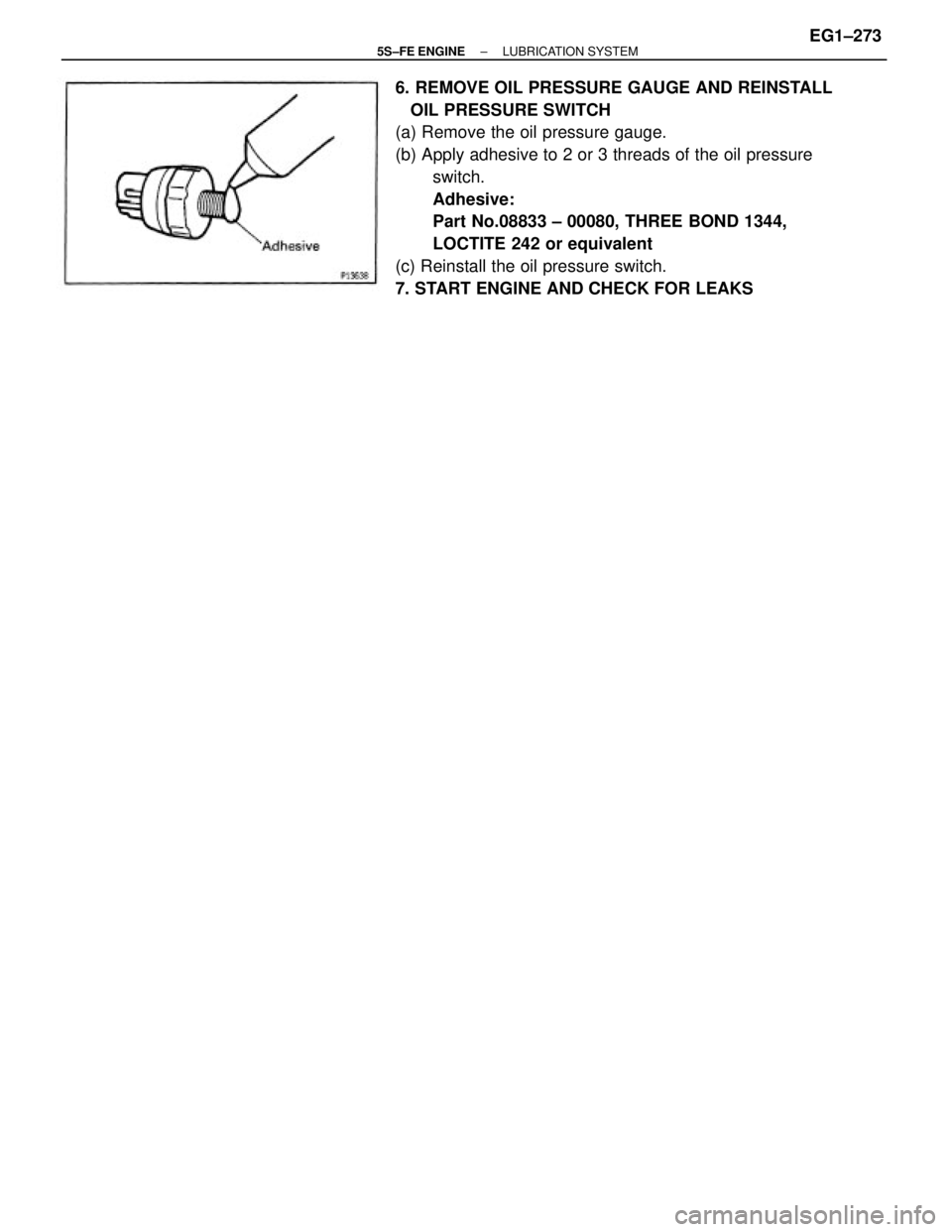

6. REMOVE OIL PRESSURE GAUGE AND REINSTALL

OIL PRESSURE SWITCH

(a) Remove the oil pressure gauge.

(b) Apply adhesive to 2 or 3 threads of the oil pressure

switch.

Adhesive:

Part No.08833 ± 00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(c) Reinstall the oil pressure switch.

7. START ENGINE AND CHECK FOR LEAKS

± 5S±FE ENGINELUBRICATION SYSTEMEG1±273

Page 324 of 4770

OIL AND FILTER REPLACEMENT

CAUTION:

wProlonged and repeated contact with mineral oil will

result in the removal of natural fats from the skin,

leading to dryness, irritation and dermatitis. In addi±

tion, used engine oil contains potentially harmful

contaminants which may cause skin cancer.

wCare should be taken, therefore, when changing

engine, oil to minimize the frequency and length of

time your skin is exposed to used engine oil. Protec±

tive clothing and gloves that cannot be penetrated

by oil should be worn. The skin should be thorought±

hly washed with soap and water, or use water±less

hand cleaner, to remove any used engine oil. Do not

use gasoline, thinners, or solvents.

wIn order to preserve the environment, used oil and

used oil filter must be disposed of only at designated

disposal sites.

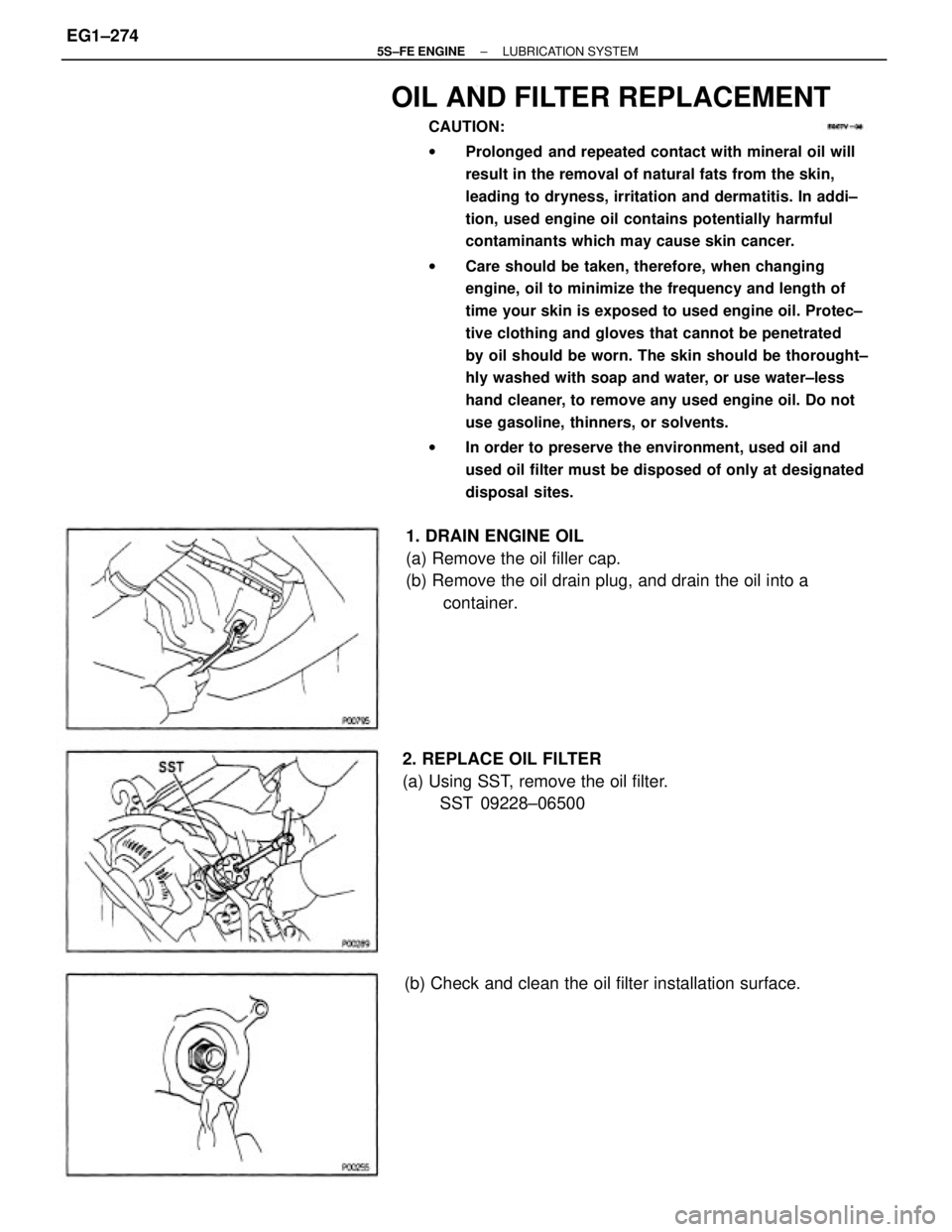

1. DRAIN ENGINE OIL

(a) Remove the oil filler cap.

(b) Remove the oil drain plug, and drain the oil into a

container.

2. REPLACE OIL FILTER

(a) Using SST, remove the oil filter.

SST 09228±06500

(b) Check and clean the oil filter installation surface.

± 5S±FE ENGINELUBRICATION SYSTEMEG1±274

Page 325 of 4770

3. FILL WITH ENGINE OIL

(a) Clean and install the oil drain plug with a new gasket.

Torque: 39 N±m (400 kgf±cm, 29 ft±lbf)

(b) Fill with new engine oil.

Oil grade: (See step 1 on page EG1±272)

Capacity (M/T):

Drain and refill

w/ Oil filter change

3.6 liters (3.8 US qts, 3.2 Imp. qts)

w/o Oil filter change

3.4 liters (3.6 US qts, 3.0 Imp. qts)

Dry fill

4.2 liters (4.4 US qts, 3.7 Imp. qts)

Capacity (A/T):

Drain and refill

w/ Oil filter change

3.6 liters (3.8 US qts, 3.2 Imp. qts)

w/o Oil filter change

3.4 liters (3.6 US qts, 3.0 Imp. qts)

Dry fill

4.3 liters (4.5 US qts, 3.8 Imp. qts)

(c) Reinstall the oil filler cap.

4. START ENGINE AND CHECK FOR LEAKS

5. RECHECK ENGINE OIL LEVEL

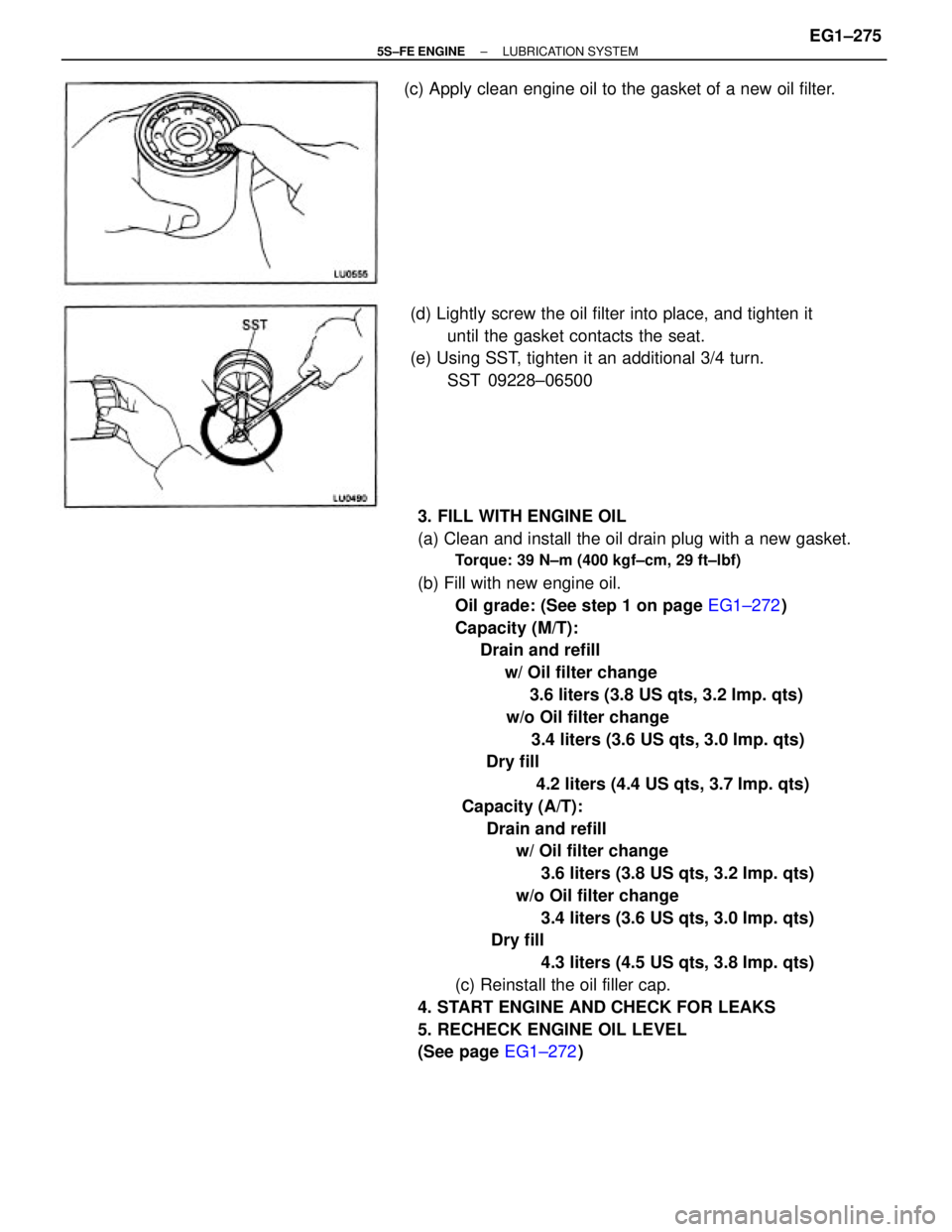

(See page EG1±272) (d) Lightly screw the oil filter into place, and tighten it

until the gasket contacts the seat.

(e) Using SST, tighten it an additional 3/4 turn.

SST 09228±06500 (c) Apply clean engine oil to the gasket of a new oil filter.

± 5S±FE ENGINELUBRICATION SYSTEMEG1±275

Page 330 of 4770

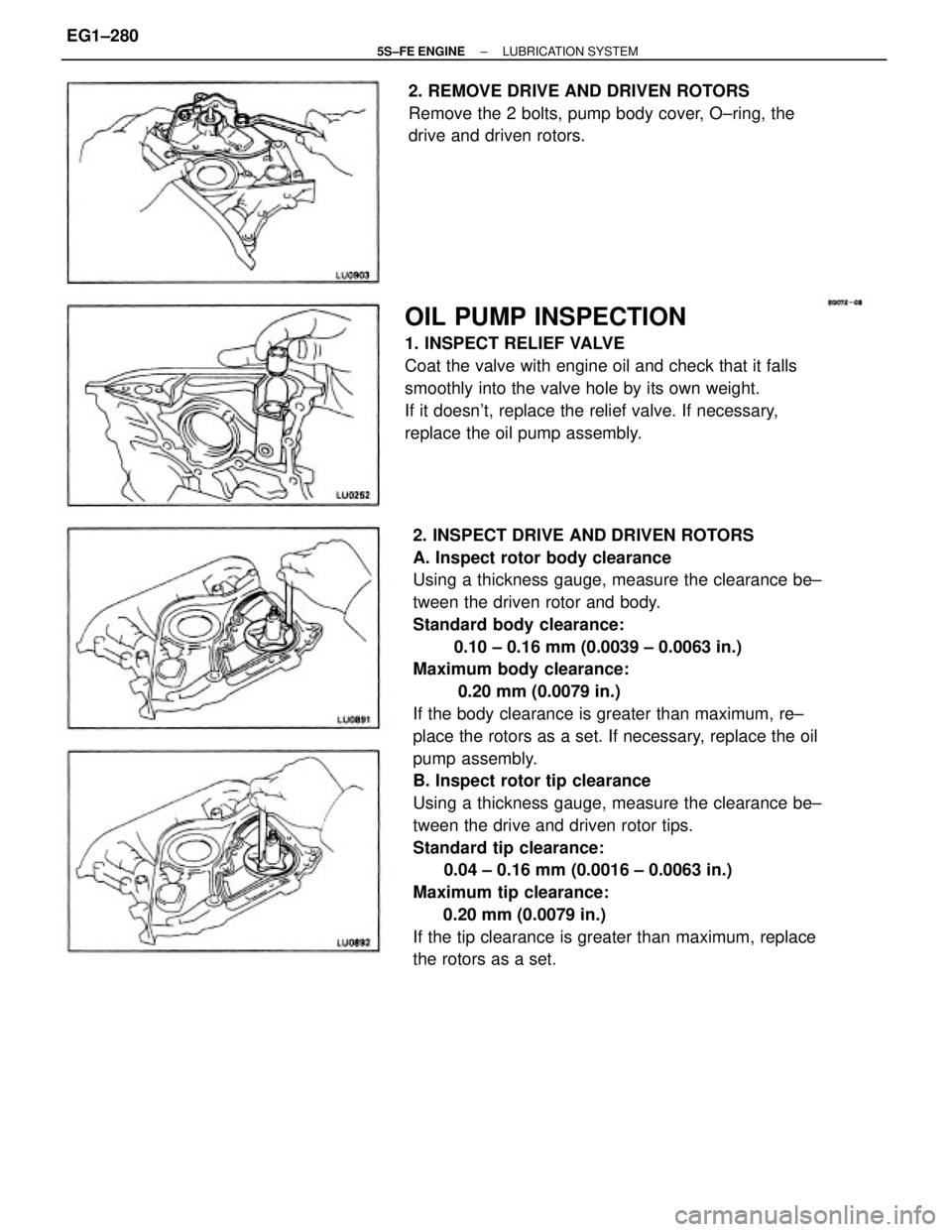

2. INSPECT DRIVE AND DRIVEN ROTORS

A. Inspect rotor body clearance

Using a thickness gauge, measure the clearance be±

tween the driven rotor and body.

Standard body clearance:

0.10 ± 0.16 mm (0.0039 ± 0.0063 in.)

Maximum body clearance:

0.20 mm (0.0079 in.)

If the body clearance is greater than maximum, re±

place the rotors as a set. If necessary, replace the oil

pump assembly.

B. Inspect rotor tip clearance

Using a thickness gauge, measure the clearance be±

tween the drive and driven rotor tips.

Standard tip clearance:

0.04 ± 0.16 mm (0.0016 ± 0.0063 in.)

Maximum tip clearance:

0.20 mm (0.0079 in.)

If the tip clearance is greater than maximum, replace

the rotors as a set.

OIL PUMP INSPECTION

1. INSPECT RELIEF VALVE

Coat the valve with engine oil and check that it falls

smoothly into the valve hole by its own weight.

If it doesn't, replace the relief valve. If necessary,

replace the oil pump assembly.2. REMOVE DRIVE AND DRIVEN ROTORS

Remove the 2 bolts, pump body cover, O±ring, the

drive and driven rotors.

± 5S±FE ENGINELUBRICATION SYSTEMEG1±280

Page 334 of 4770

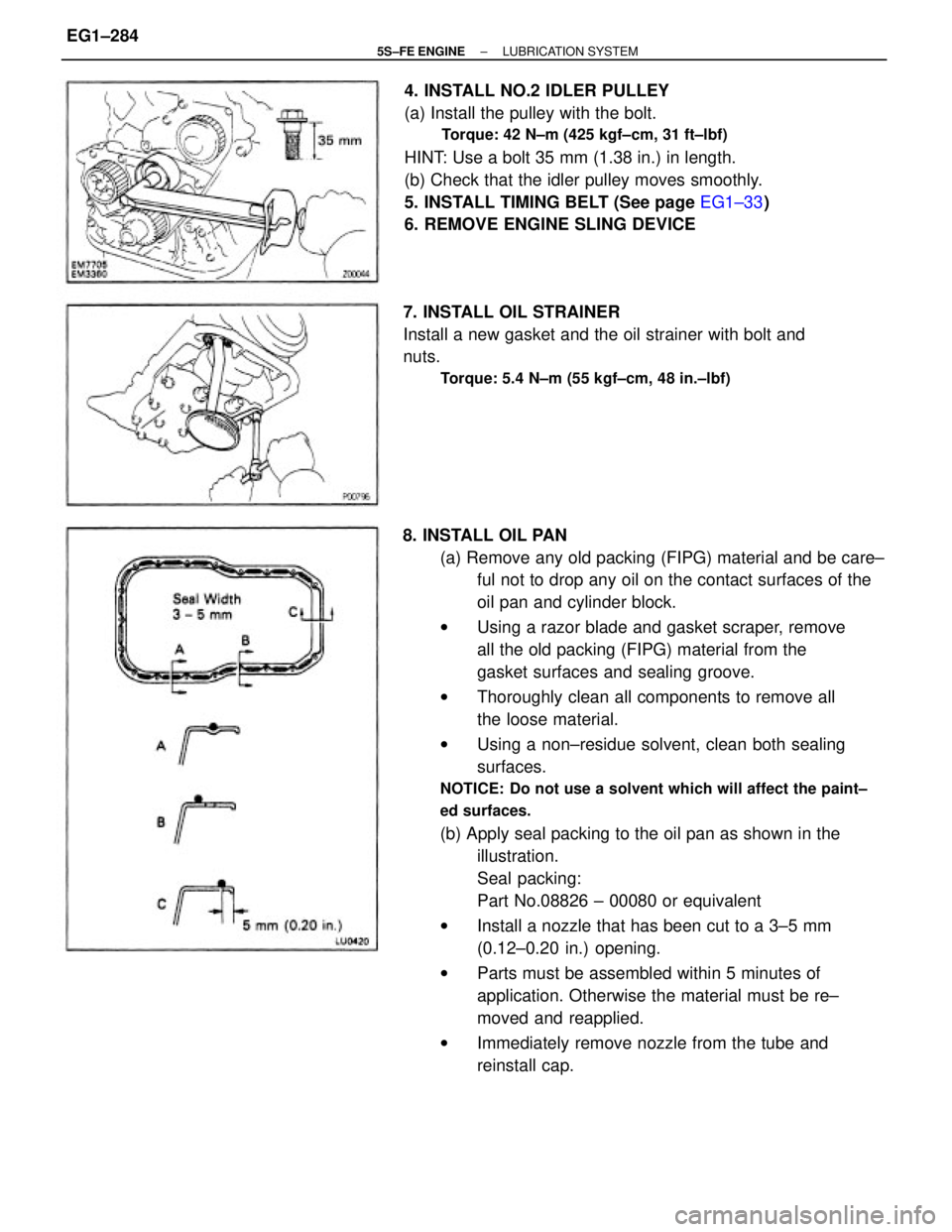

8. INSTALL OIL PAN

(a) Remove any old packing (FIPG) material and be care±

ful not to drop any oil on the contact surfaces of the

oil pan and cylinder block.

wUsing a razor blade and gasket scraper, remove

all the old packing (FIPG) material from the

gasket surfaces and sealing groove.

wThoroughly clean all components to remove all

the loose material.

wUsing a non±residue solvent, clean both sealing

surfaces.

NOTICE: Do not use a solvent which will affect the paint±

ed surfaces.

(b) Apply seal packing to the oil pan as shown in the

illustration.

Seal packing:

Part No.08826 ± 00080 or equivalent

wInstall a nozzle that has been cut to a 3±5 mm

(0.12±0.20 in.) opening.

wParts must be assembled within 5 minutes of

application. Otherwise the material must be re±

moved and reapplied.

wImmediately remove nozzle from the tube and

reinstall cap. 4. INSTALL NO.2 IDLER PULLEY

(a) Install the pulley with the bolt.

Torque: 42 N±m (425 kgf±cm, 31 ft±lbf)

HINT: Use a bolt 35 mm (1.38 in.) in length.

(b) Check that the idler pulley moves smoothly.

5. INSTALL TIMING BELT (See page EG1±33)

6. REMOVE ENGINE SLING DEVICE

7. INSTALL OIL STRAINER

Install a new gasket and the oil strainer with bolt and

nuts.

Torque: 5.4 N±m (55 kgf±cm, 48 in.±lbf)

± 5S±FE ENGINELUBRICATION SYSTEMEG1±284

Page 335 of 4770

10. INSTALL FRONT EXHAUST PIPE

(a) Place 2 new gaskets on the front and rear of the front

exhaust pipe.

(b) Temporarily install the 2 bolts and 2 new nuts holding

front exhaust pipe to the center exhaust pipe.

(c) Using a 14 mm deep socket wrench, install the 3 new

nuts holding the front exhaust pipe to the WU±TWC.

Torque: 62 N±m (630 kgf±cm, 46 ft±lbf)

(d) Tighten the 2 bolts and 2 nuts holding front exhaust

pipe to the center exhaust pipe.

Torque: 56 N±m (570 kgf±cm, 41 ft±lbf)

(e) Install the bracket with the 2 bolts.

11. CONNECT NEGATIVE (±) TERMINAL CABLE TO

BATTERY

12. FILL WITH ENGINE OIL (See page EG1±275)

13. START ENGINE AND CHECK FOR LEAKS

14. RECHECK ENGINE OIL LEVEL

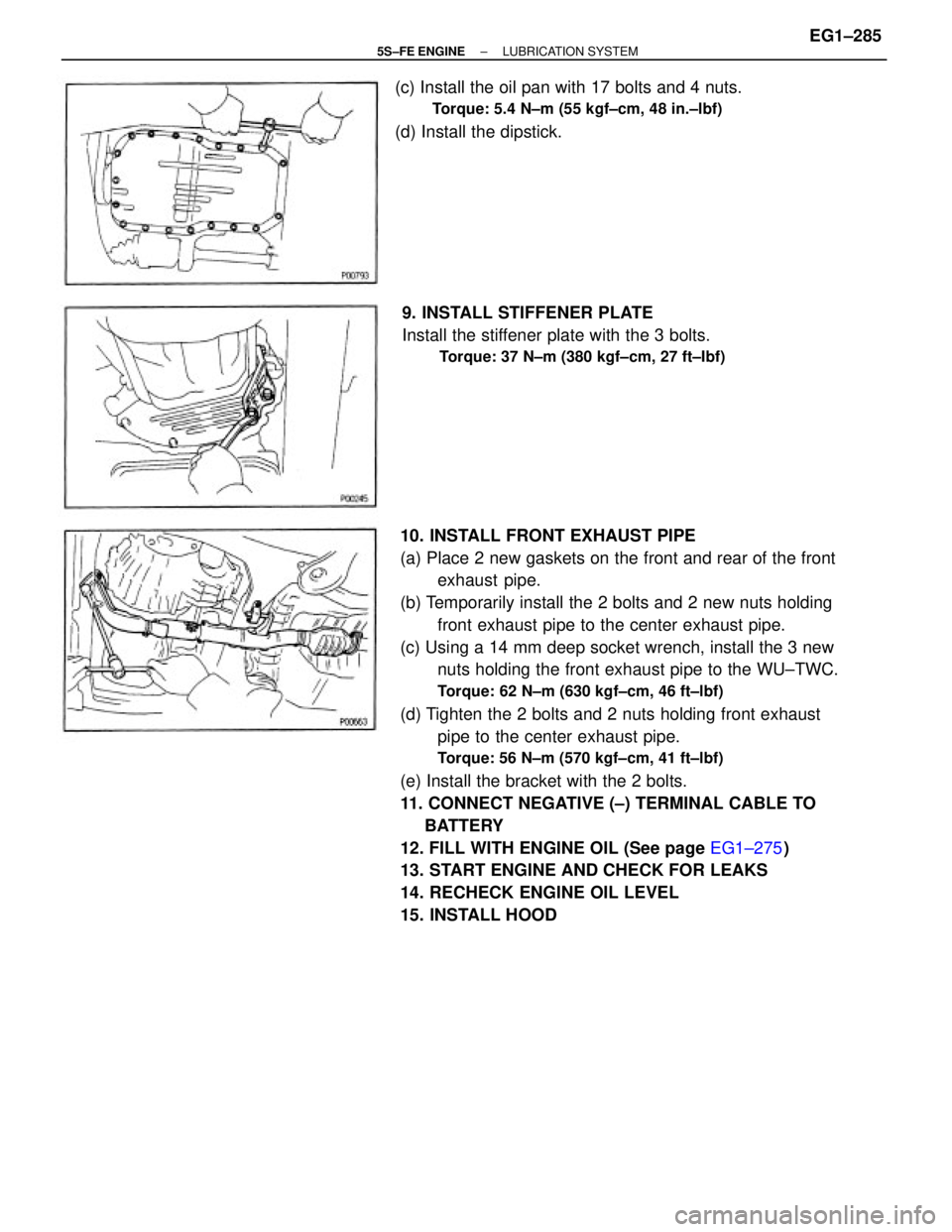

15. INSTALL HOOD (c) Install the oil pan with 17 bolts and 4 nuts.

Torque: 5.4 N±m (55 kgf±cm, 48 in.±lbf)

(d) Install the dipstick.

9. INSTALL STIFFENER PLATE

Install the stiffener plate with the 3 bolts.

Torque: 37 N±m (380 kgf±cm, 27 ft±Ibf)

± 5S±FE ENGINELUBRICATION SYSTEMEG1±285

Page 337 of 4770

(b) Apply a light coat of engine oil on the threads and

under the head of the relief valve.

(c) Temporarily install the oil cooler with the nut.

(d) Install the plate washer and relief valve.

Torque: 78 N±m (800 kgf±cm, 58 ft±lbf)

(e) Tighten the nut.

Torque: 7.8 N±m (80 kgf±cm, 69 In.±lbf)

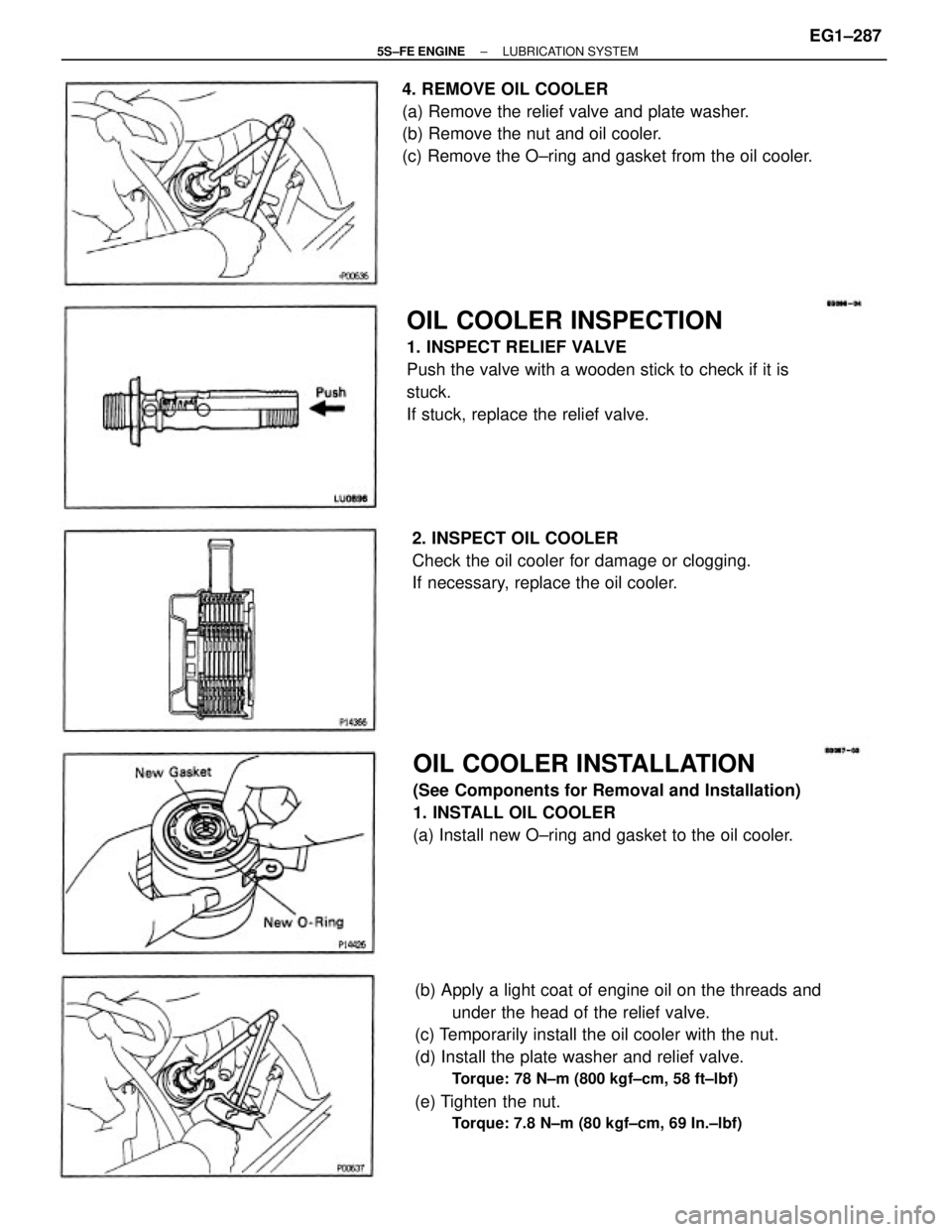

OIL COOLER INSPECTION

1. INSPECT RELIEF VALVE

Push the valve with a wooden stick to check if it is

stuck.

If stuck, replace the relief valve.

OIL COOLER INSTALLATION

(See Components for Removal and Installation)

1. INSTALL OIL COOLER

(a) Install new O±ring and gasket to the oil cooler. 4. REMOVE OIL COOLER

(a) Remove the relief valve and plate washer.

(b) Remove the nut and oil cooler.

(c) Remove the O±ring and gasket from the oil cooler.

2. INSPECT OIL COOLER

Check the oil cooler for damage or clogging.

If necessary, replace the oil cooler.

± 5S±FE ENGINELUBRICATION SYSTEMEG1±287

Page 338 of 4770

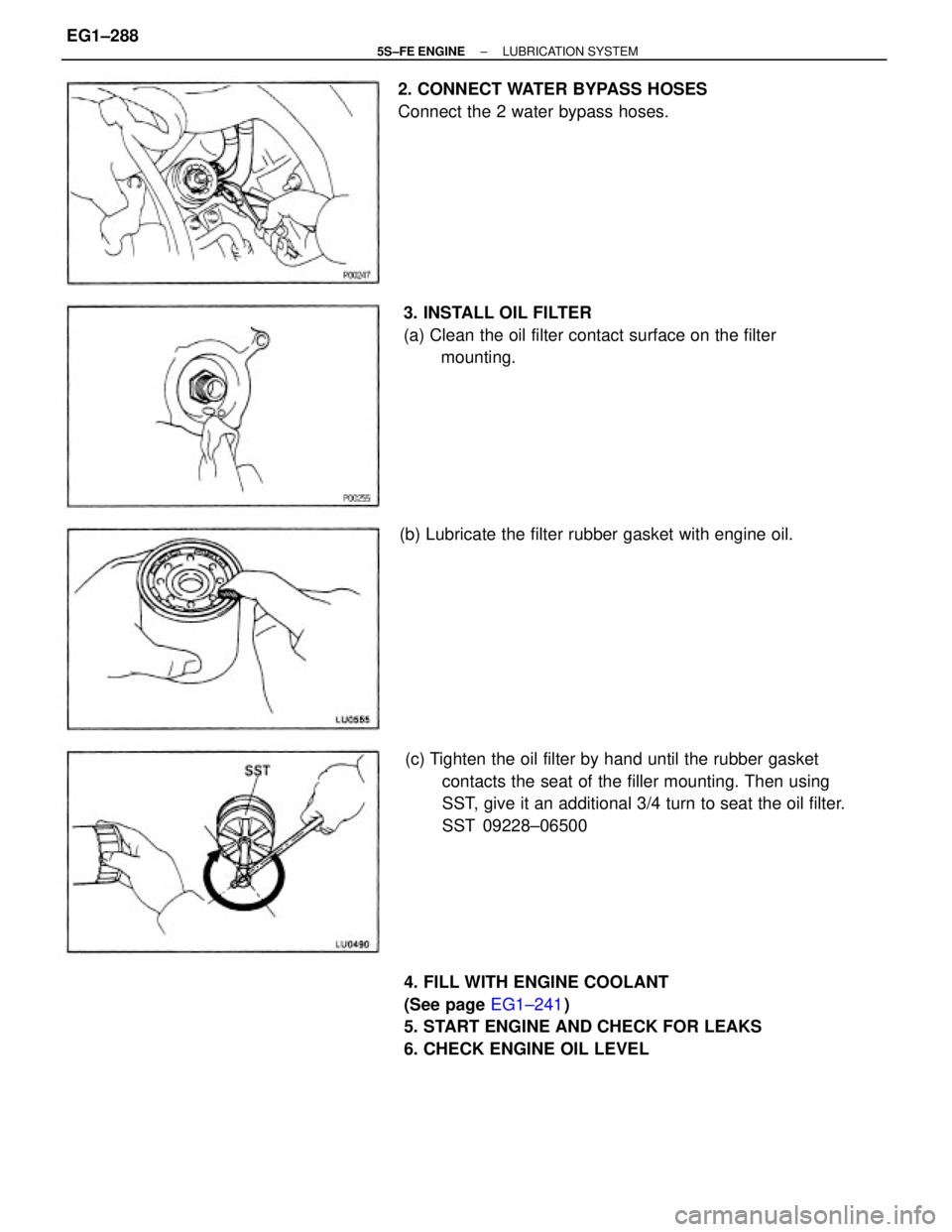

(c) Tighten the oil filter by hand until the rubber gasket

contacts the seat of the filler mounting. Then using

SST, give it an additional 3/4 turn to seat the oil filter.

SST 09228±06500

4. FILL WITH ENGINE COOLANT

(See page EG1±241)

5. START ENGINE AND CHECK FOR LEAKS

6. CHECK ENGINE OIL LEVEL 3. INSTALL OIL FILTER

(a) Clean the oil filter contact surface on the filter

mounting. 2. CONNECT WATER BYPASS HOSES

Connect the 2 water bypass hoses.

(b) Lubricate the filter rubber gasket with engine oil.

± 5S±FE ENGINELUBRICATION SYSTEMEG1±288

Page 342 of 4770

HOW TO PROCEED WITH TROUBLESHOOTING

The Engine Control System broadly consists of the sensors, Engine Control Module (ECM) and actuators.

The ECM receives signals from various sensors, judges the operating conditions and determines the

optimum injection duration, timing, ignition timing and idle speed.

In general, the Engine Control System is considered to be a very intricate system to troubleshoot. But, the

fact is that if you proceed to inspect the circuit one by one following the procedures directed in this manu-

al, troubleshooting of this system is not complex.

This section explains the most ideal method of troubleshooting and tells how to carry out the necessary

repairs.

1. CUSTOMER PROBLEM ANALYSIS

Using the customer problem analysis check sheet for reference, ask the customer in as much details

as possible about the problem.

2. CHECK AND CLEAR DIAGNOSTIC TROUBLE CODE (PRECHECK)

Before confirming the problem symptom, first check the diagnostic trouble code and make a note of

any malfunction code which is output, then clear the code.

HINT: Output of the malfunction code indicates that there is a malfunction in the circuit indicated.

However, it does not indicate whether the malfunction is still occurring or occurred in the past and

returned to normal. In order to determine this, the problem sym toms should be confirmed in step 4

first and the diagnostic trouble code be rechecked in step [6].

Accordingly, if troubleshooting is begun based on the malfunction code only in diagnostic trouble

code check in step [2], it could result in a misdiagnosis, leading to troubleshooting of circuits which

are normal and making it more difficult to locate the cause of the problem.

3. SETTING THE TEST MODE DIAGNOSIS, [4] PROBLEM SYMPTOM CONFIRMATION,

[5] SYMPTOM SIMULATION

In order to find out the trouble more quickly, set the diagnosis check in test mode and with higher

sensing ability of the ECM, confirm the problem symptoms. If the trouble does not reappear, use the

symptom simulation method to make sure the trouble is reproduced.

6. DIAGNOSTIC TROUBLE CODE CHECK IN TEST MODE

Check the diagnostic trouble code in test mode. If the malfunction code is output, proceed to step. If the

normal code is output, proceed to step [7].

7. BASIC INSPECTION

Carry out basic inspection such as the spark check and fuel pressure check, etc.

8. DIAGNOSTIC TROUBLE CODE CHART

If the malfunction code is displayed, proceed to inspect the circuit indicated by the chart for each

code.

9. MATRIX CHART OF PROBLEM SYMPTOMS

If the normal code is displayed in the diagnosis in test mode, perform troubleshooting according to

the inspection order in the Matrix Chart of Problem Symptoms.

10. PARTS INSPECTION

When the Matrix Chart of Problem Symptoms instructs to check the parts, proceed to parts inspection

section included in this manual.

11. CIRCUIT INSPECTION

Determine if the malfunction is the sensor, actuator, wire harness, connector or the ECM.

± 5S±FE ENGINEHOW TO PROCEED WITH TROUBLESHOOTINGEG1±292

Page 343 of 4770

CHECK FOR MOMENTARY INTERRUPTION

By performing the check for momentary interruption, the place where momentary interruptions or

momentary shorts are occurring due to poor contacts can be isolated.

ADJUSTMENT, REPAIR

After the cause of the problem is located, perform adjustment or repairs by following the inspection

and replacement procedures in this manual.

CONFIRMATION TEST

After completing adjustment or repairs, confirm not only that the malfunction is eliminated, but also

conduct a test drive, etc., to make sure the entire Engine Control System is operating normally.

± 5S±FE ENGINEHOW TO PROCEED WITH TROUBLESHOOTINGEG1±293