check engine light TOYOTA CAMRY 2000 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2000, Model line: CAMRY, Model: TOYOTA CAMRY 2000Pages: 4770, PDF Size: 86.41 MB

Page 145 of 4770

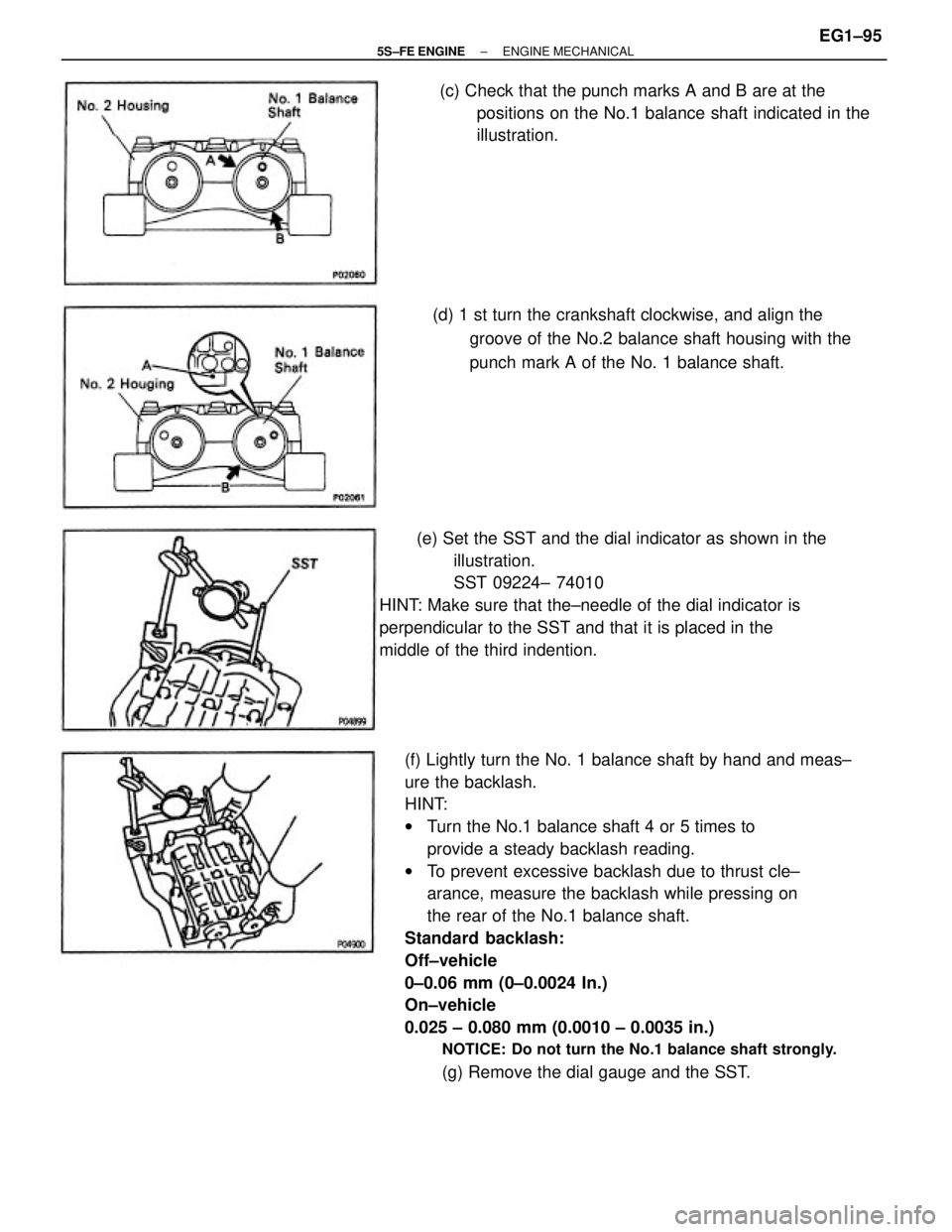

(f) Lightly turn the No. 1 balance shaft by hand and meas±

ure the backlash.

HINT:

wTurn the No.1 balance shaft 4 or 5 times to

provide a steady backlash reading.

wTo prevent excessive backlash due to thrust cle±

arance, measure the backlash while pressing on

the rear of the No.1 balance shaft.

Standard backlash:

Off±vehicle

0±0.06 mm (0±0.0024 In.)

On±vehicle

0.025 ± 0.080 mm (0.0010 ± 0.0035 in.)

NOTICE: Do not turn the No.1 balance shaft strongly.

(g) Remove the dial gauge and the SST. (e) Set the SST and the dial indicator as shown in the

illustration.

SST 09224± 74010

HINT: Make sure that the±needle of the dial indicator is

perpendicular to the SST and that it is placed in the

middle of the third indention.(d) 1 st turn the crankshaft clockwise, and align the

groove of the No.2 balance shaft housing with the

punch mark A of the No. 1 balance shaft. (c) Check that the punch marks A and B are at the

positions on the No.1 balance shaft indicated in the

illustration.

± 5S±FE ENGINEENGINE MECHANICALEG1±95

Page 148 of 4770

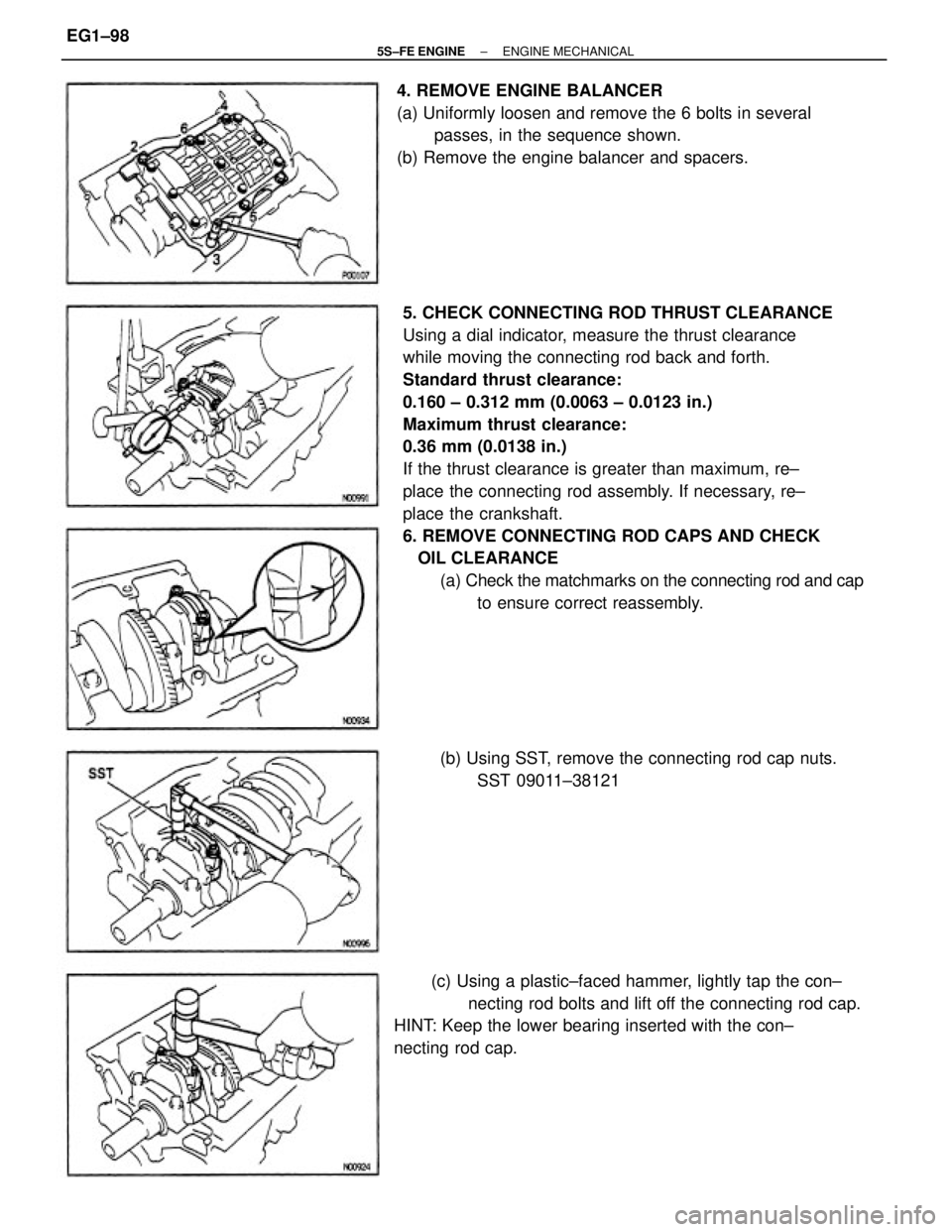

5. CHECK CONNECTING ROD THRUST CLEARANCE

Using a dial indicator, measure the thrust clearance

while moving the connecting rod back and forth.

Standard thrust clearance:

0.160 ± 0.312 mm (0.0063 ± 0.0123 in.)

Maximum thrust clearance:

0.36 mm (0.0138 in.)

If the thrust clearance is greater than maximum, re±

place the connecting rod assembly. If necessary, re±

place the crankshaft.

6. REMOVE CONNECTING ROD CAPS AND CHECK

OIL CLEARANCE

(a) Check the matchmarks on the connecting rod and cap

to ensure correct reassembly.

(c) Using a plastic±faced hammer, lightly tap the con±

necting rod bolts and lift off the connecting rod cap.

HINT: Keep the lower bearing inserted with the con±

necting rod cap.4. REMOVE ENGINE BALANCER

(a) Uniformly loosen and remove the 6 bolts in several

passes, in the sequence shown.

(b) Remove the engine balancer and spacers.

(b) Using SST, remove the connecting rod cap nuts.

SST 09011±38121

± 5S±FE ENGINEENGINE MECHANICALEG1±98

Page 171 of 4770

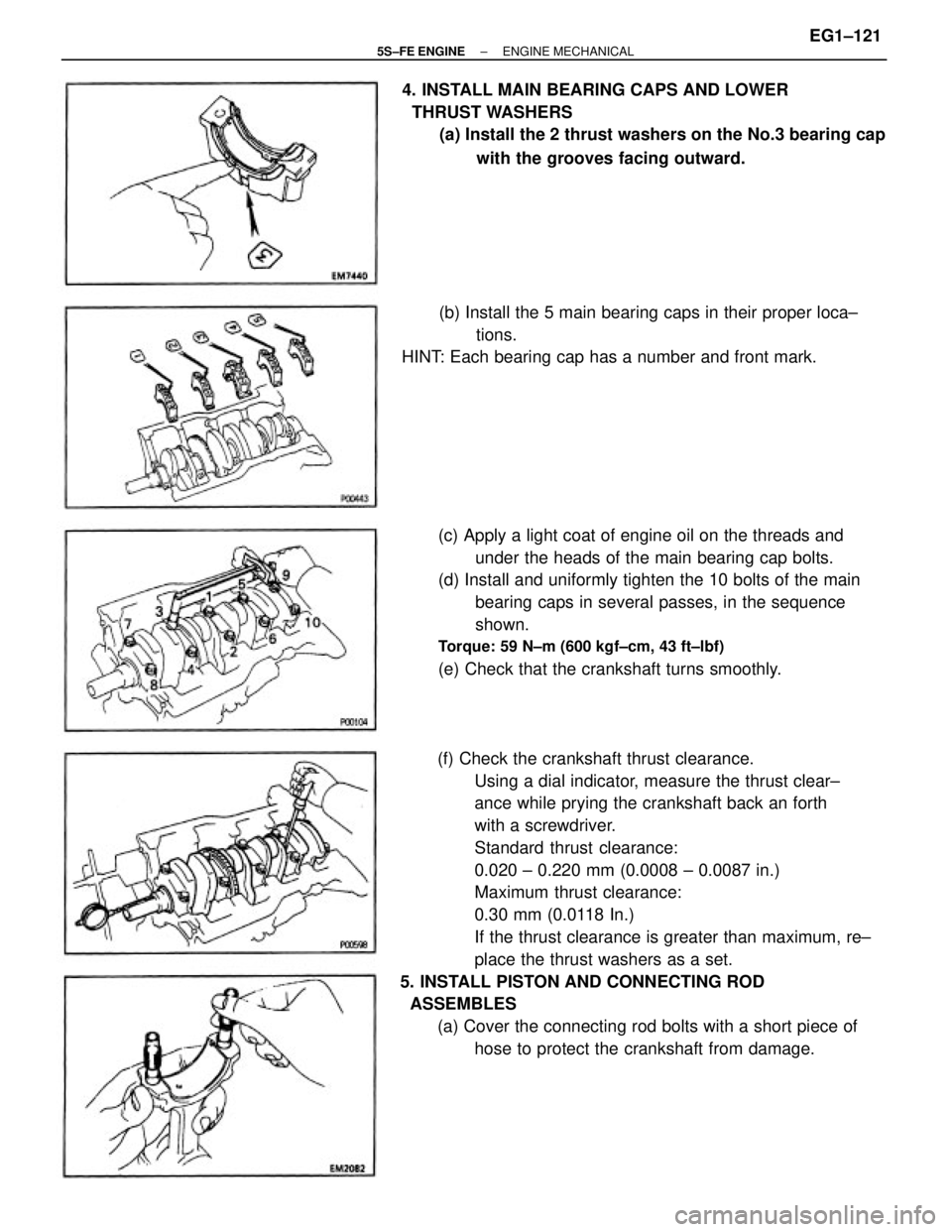

(f) Check the crankshaft thrust clearance.

Using a dial indicator, measure the thrust clear±

ance while prying the crankshaft back an forth

with a screwdriver.

Standard thrust clearance:

0.020 ± 0.220 mm (0.0008 ± 0.0087 in.)

Maximum thrust clearance:

0.30 mm (0.0118 In.)

If the thrust clearance is greater than maximum, re±

place the thrust washers as a set.

5. INSTALL PISTON AND CONNECTING ROD

ASSEMBLES

(a) Cover the connecting rod bolts with a short piece of

hose to protect the crankshaft from damage. (c) Apply a light coat of engine oil on the threads and

under the heads of the main bearing cap bolts.

(d) Install and uniformly tighten the 10 bolts of the main

bearing caps in several passes, in the sequence

shown.

Torque: 59 N±m (600 kgf±cm, 43 ft±lbf)

(e) Check that the crankshaft turns smoothly. 4. INSTALL MAIN BEARING CAPS AND LOWER

THRUST WASHERS

(a) Install the 2 thrust washers on the No.3 bearing cap

with the grooves facing outward.

(b) Install the 5 main bearing caps in their proper loca±

tions.

HINT: Each bearing cap has a number and front mark.

± 5S±FE ENGINEENGINE MECHANICALEG1±121

Page 204 of 4770

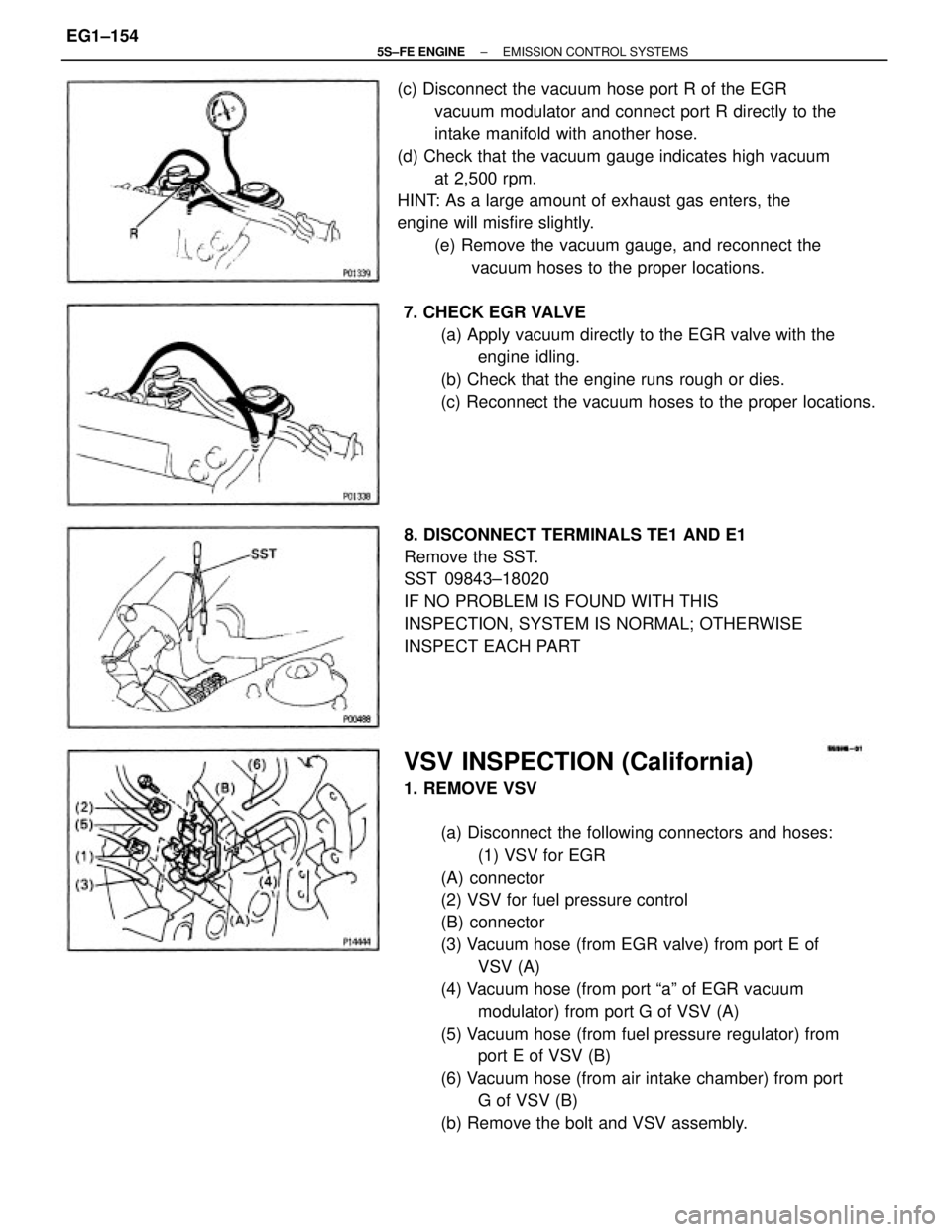

VSV INSPECTION (California)

1. REMOVE VSV

(a) Disconnect the following connectors and hoses:

(1) VSV for EGR

(A) connector

(2) VSV for fuel pressure control

(B) connector

(3) Vacuum hose (from EGR valve) from port E of

VSV (A)

(4) Vacuum hose (from port ªaº of EGR vacuum

modulator) from port G of VSV (A)

(5) Vacuum hose (from fuel pressure regulator) from

port E of VSV (B)

(6) Vacuum hose (from air intake chamber) from port

G of VSV (B)

(b) Remove the bolt and VSV assembly. (c) Disconnect the vacuum hose port R of the EGR

vacuum modulator and connect port R directly to the

intake manifold with another hose.

(d) Check that the vacuum gauge indicates high vacuum

at 2,500 rpm.

HINT: As a large amount of exhaust gas enters, the

engine will misfire slightly.

(e) Remove the vacuum gauge, and reconnect the

vacuum hoses to the proper locations.

8. DISCONNECT TERMINALS TE1 AND E1

Remove the SST.

SST 09843±18020

IF NO PROBLEM IS FOUND WITH THIS

INSPECTION, SYSTEM IS NORMAL; OTHERWISE

INSPECT EACH PART 7. CHECK EGR VALVE

(a) Apply vacuum directly to the EGR valve with the

engine idling.

(b) Check that the engine runs rough or dies.

(c) Reconnect the vacuum hoses to the proper locations.

± 5S±FE ENGINEEMISSION CONTROL SYSTEMSEG1±154

Page 222 of 4770

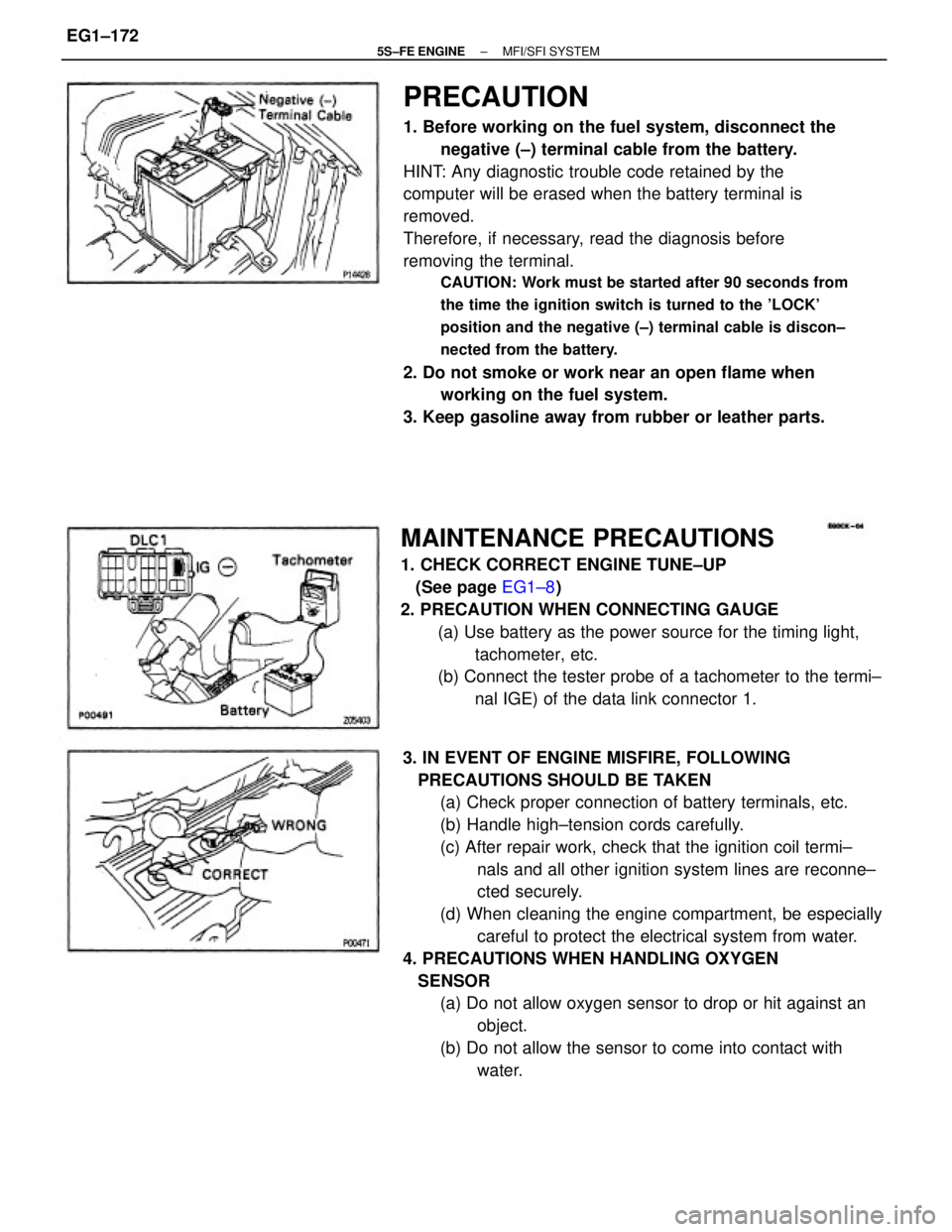

PRECAUTION

1. Before working on the fuel system, disconnect the

negative (±) terminal cable from the battery.

HINT: Any diagnostic trouble code retained by the

computer will be erased when the battery terminal is

removed.

Therefore, if necessary, read the diagnosis before

removing the terminal.

CAUTION: Work must be started after 90 seconds from

the time the ignition switch is turned to the 'LOCK'

position and the negative (±) terminal cable is discon±

nected from the battery.

2. Do not smoke or work near an open flame when

working on the fuel system.

3. Keep gasoline away from rubber or leather parts.

3. IN EVENT OF ENGINE MISFIRE, FOLLOWING

PRECAUTIONS SHOULD BE TAKEN

(a) Check proper connection of battery terminals, etc.

(b) Handle high±tension cords carefully.

(c) After repair work, check that the ignition coil termi±

nals and all other ignition system lines are reconne±

cted securely.

(d) When cleaning the engine compartment, be especially

careful to protect the electrical system from water.

4. PRECAUTIONS WHEN HANDLING OXYGEN

SENSOR

(a) Do not allow oxygen sensor to drop or hit against an

object.

(b) Do not allow the sensor to come into contact with

water.

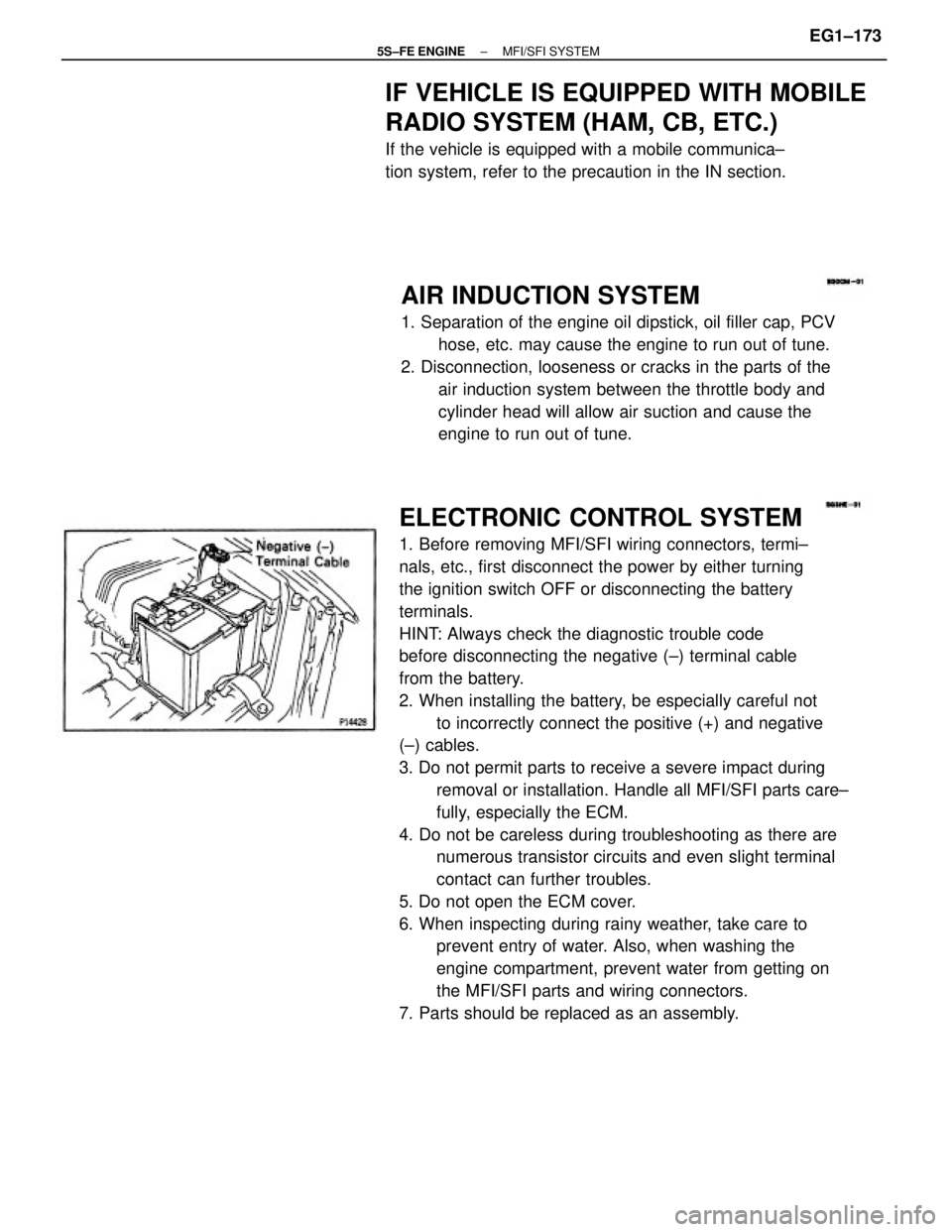

MAINTENANCE PRECAUTIONS

1. CHECK CORRECT ENGINE TUNE±UP

(See page EG1±8)

2. PRECAUTION WHEN CONNECTING GAUGE

(a) Use battery as the power source for the timing light,

tachometer, etc.

(b) Connect the tester probe of a tachometer to the termi±

nal IGE) of the data link connector 1.

± 5S±FE ENGINEMFI/SFI SYSTEMEG1±172

Page 223 of 4770

ELECTRONIC CONTROL SYSTEM

1. Before removing MFI/SFI wiring connectors, termi±

nals, etc., first disconnect the power by either turning

the ignition switch OFF or disconnecting the battery

terminals.

HINT: Always check the diagnostic trouble code

before disconnecting the negative (±) terminal cable

from the battery.

2. When installing the battery, be especially careful not

to incorrectly connect the positive (+) and negative

(±) cables.

3. Do not permit parts to receive a severe impact during

removal or installation. Handle all MFI/SFI parts care±

fully, especially the ECM.

4. Do not be careless during troubleshooting as there are

numerous transistor circuits and even slight terminal

contact can further troubles.

5. Do not open the ECM cover.

6. When inspecting during rainy weather, take care to

prevent entry of water. Also, when washing the

engine compartment, prevent water from getting on

the MFI/SFI parts and wiring connectors.

7. Parts should be replaced as an assembly.

AIR INDUCTION SYSTEM

1. Separation of the engine oil dipstick, oil filler cap, PCV

hose, etc. may cause the engine to run out of tune.

2. Disconnection, looseness or cracks in the parts of the

air induction system between the throttle body and

cylinder head will allow air suction and cause the

engine to run out of tune.

IF VEHICLE IS EQUIPPED WITH MOBILE

RADIO SYSTEM (HAM, CB, ETC.)

If the vehicle is equipped with a mobile communica±

tion system, refer to the precaution in the IN section.

± 5S±FE ENGINEMFI/SFI SYSTEMEG1±173

Page 238 of 4770

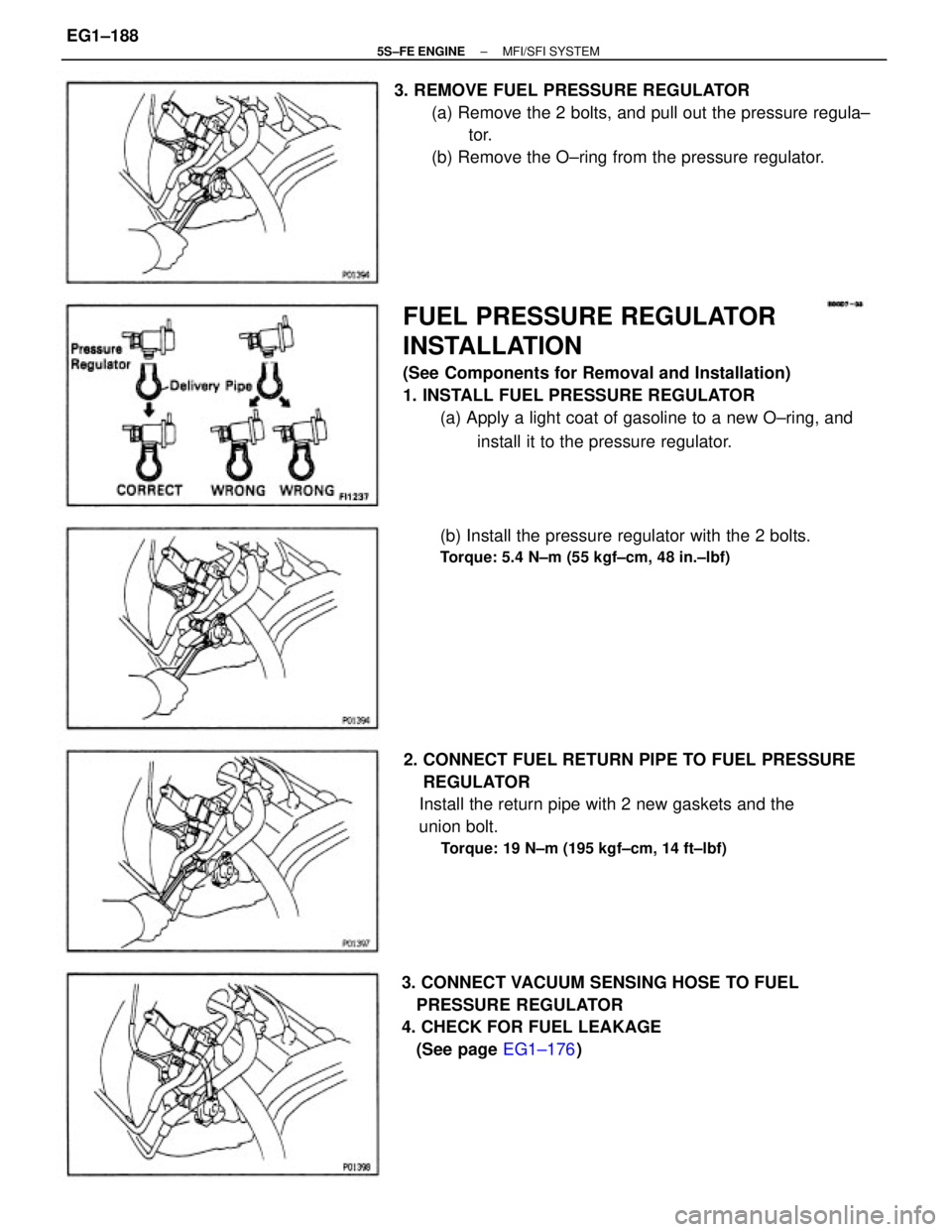

FUEL PRESSURE REGULATOR

INSTALLATION

(See Components for Removal and Installation)

1. INSTALL FUEL PRESSURE REGULATOR

(a) Apply a light coat of gasoline to a new O±ring, and

install it to the pressure regulator.

2. CONNECT FUEL RETURN PIPE TO FUEL PRESSURE

REGULATOR

Install the return pipe with 2 new gaskets and the

union bolt.

Torque: 19 N±m (195 kgf±cm, 14 ft±lbf)

3. REMOVE FUEL PRESSURE REGULATOR

(a) Remove the 2 bolts, and pull out the pressure regula±

tor.

(b) Remove the O±ring from the pressure regulator.

3. CONNECT VACUUM SENSING HOSE TO FUEL

PRESSURE REGULATOR

4. CHECK FOR FUEL LEAKAGE

(See page EG1±176) (b) Install the pressure regulator with the 2 bolts.

Torque: 5.4 N±m (55 kgf±cm, 48 in.±lbf)

± 5S±FE ENGINEMFI/SFI SYSTEMEG1±188

Page 306 of 4770

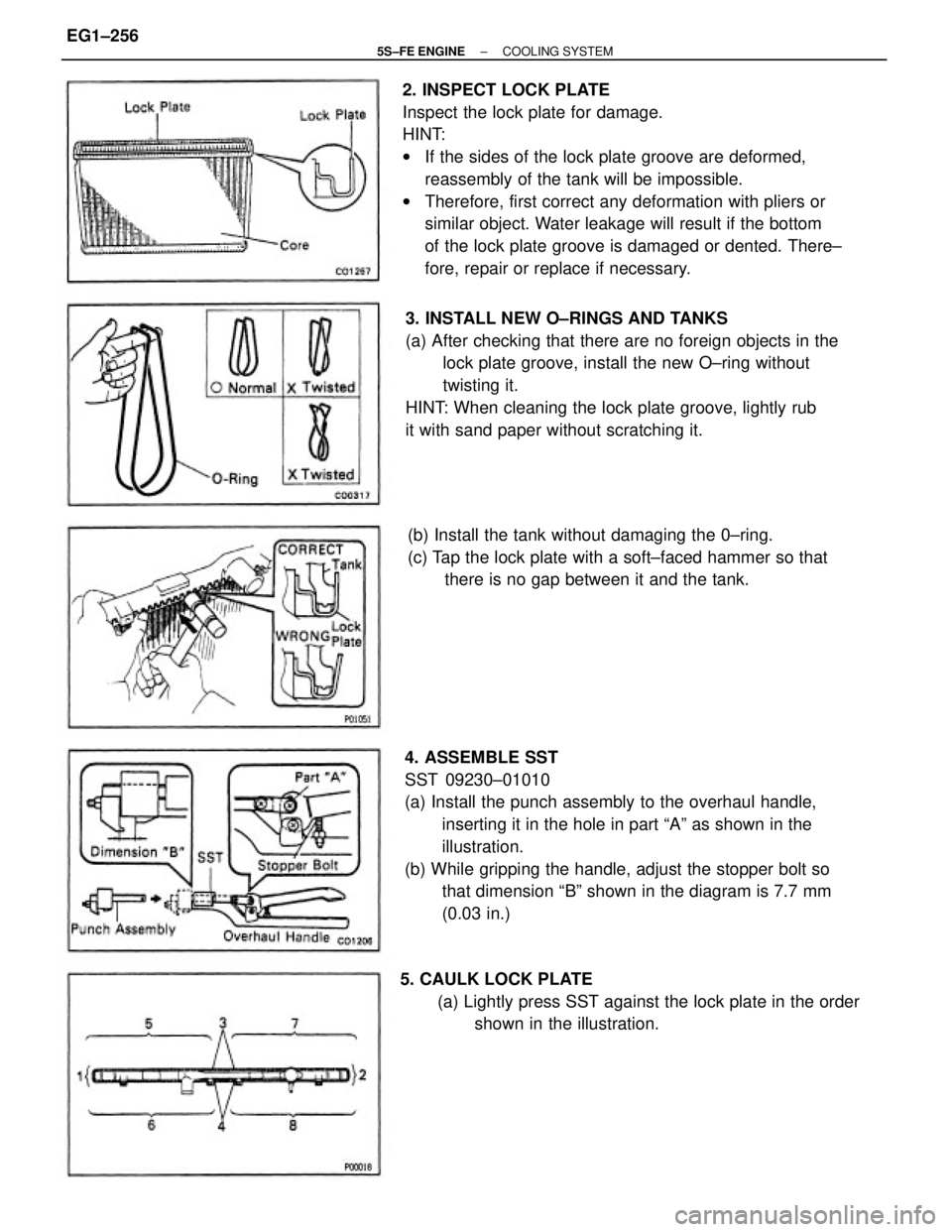

2. INSPECT LOCK PLATE

Inspect the lock plate for damage.

HINT:

wIf the sides of the lock plate groove are deformed,

reassembly of the tank will be impossible.

wTherefore, first correct any deformation with pliers or

similar object. Water leakage will result if the bottom

of the lock plate groove is damaged or dented. There±

fore, repair or replace if necessary.

4. ASSEMBLE SST

SST 09230±01010

(a) Install the punch assembly to the overhaul handle,

inserting it in the hole in part ªAº as shown in the

illustration.

(b) While gripping the handle, adjust the stopper bolt so

that dimension ªBº shown in the diagram is 7.7 mm

(0.03 in.) 3. INSTALL NEW O±RINGS AND TANKS

(a) After checking that there are no foreign objects in the

lock plate groove, install the new O±ring without

twisting it.

HINT: When cleaning the lock plate groove, lightly rub

it with sand paper without scratching it.

(b) Install the tank without damaging the 0±ring.

(c) Tap the lock plate with a soft±faced hammer so that

there is no gap between it and the tank.

5. CAULK LOCK PLATE

(a) Lightly press SST against the lock plate in the order

shown in the illustration.

± 5S±FE ENGINECOOLING SYSTEMEG1±256

Page 325 of 4770

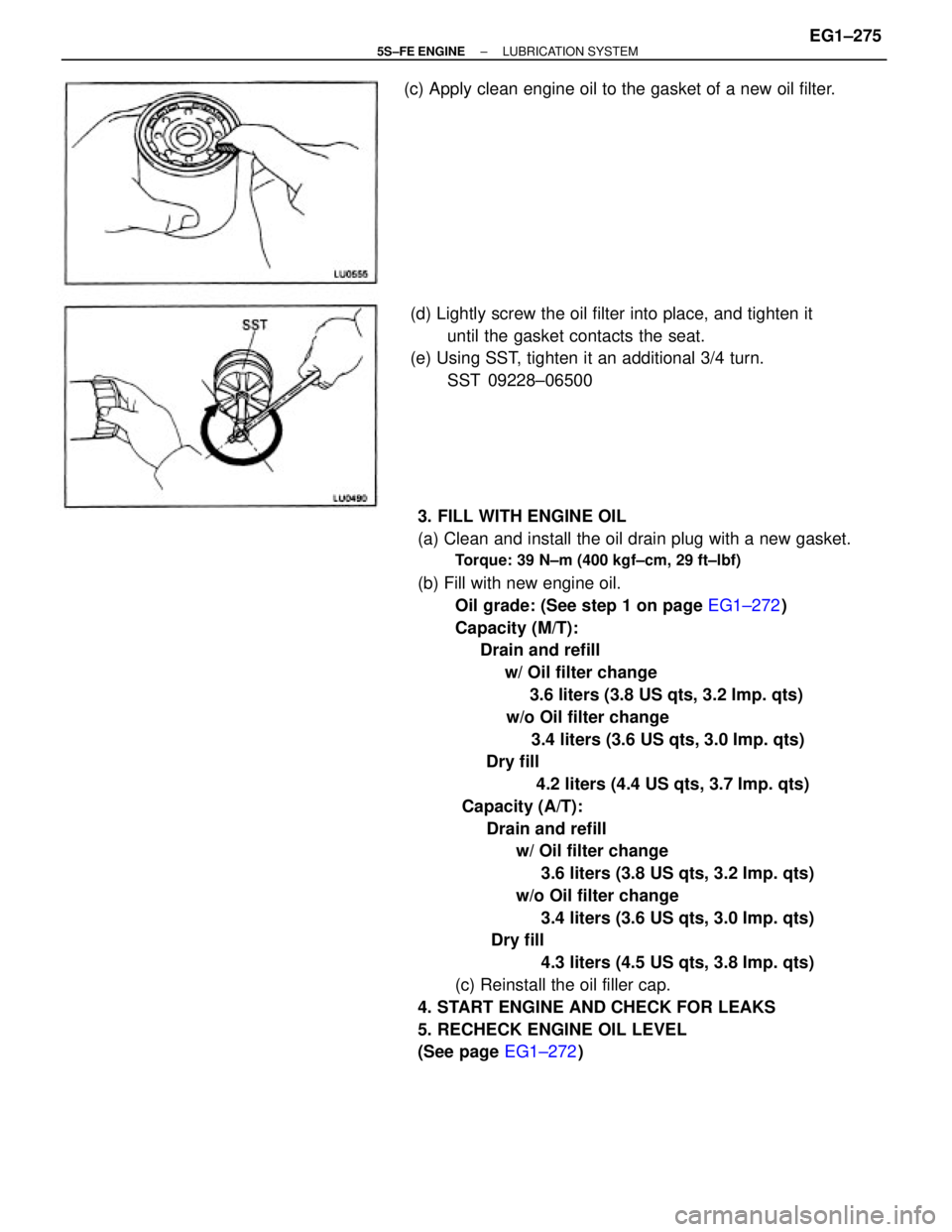

3. FILL WITH ENGINE OIL

(a) Clean and install the oil drain plug with a new gasket.

Torque: 39 N±m (400 kgf±cm, 29 ft±lbf)

(b) Fill with new engine oil.

Oil grade: (See step 1 on page EG1±272)

Capacity (M/T):

Drain and refill

w/ Oil filter change

3.6 liters (3.8 US qts, 3.2 Imp. qts)

w/o Oil filter change

3.4 liters (3.6 US qts, 3.0 Imp. qts)

Dry fill

4.2 liters (4.4 US qts, 3.7 Imp. qts)

Capacity (A/T):

Drain and refill

w/ Oil filter change

3.6 liters (3.8 US qts, 3.2 Imp. qts)

w/o Oil filter change

3.4 liters (3.6 US qts, 3.0 Imp. qts)

Dry fill

4.3 liters (4.5 US qts, 3.8 Imp. qts)

(c) Reinstall the oil filler cap.

4. START ENGINE AND CHECK FOR LEAKS

5. RECHECK ENGINE OIL LEVEL

(See page EG1±272) (d) Lightly screw the oil filter into place, and tighten it

until the gasket contacts the seat.

(e) Using SST, tighten it an additional 3/4 turn.

SST 09228±06500 (c) Apply clean engine oil to the gasket of a new oil filter.

± 5S±FE ENGINELUBRICATION SYSTEMEG1±275

Page 337 of 4770

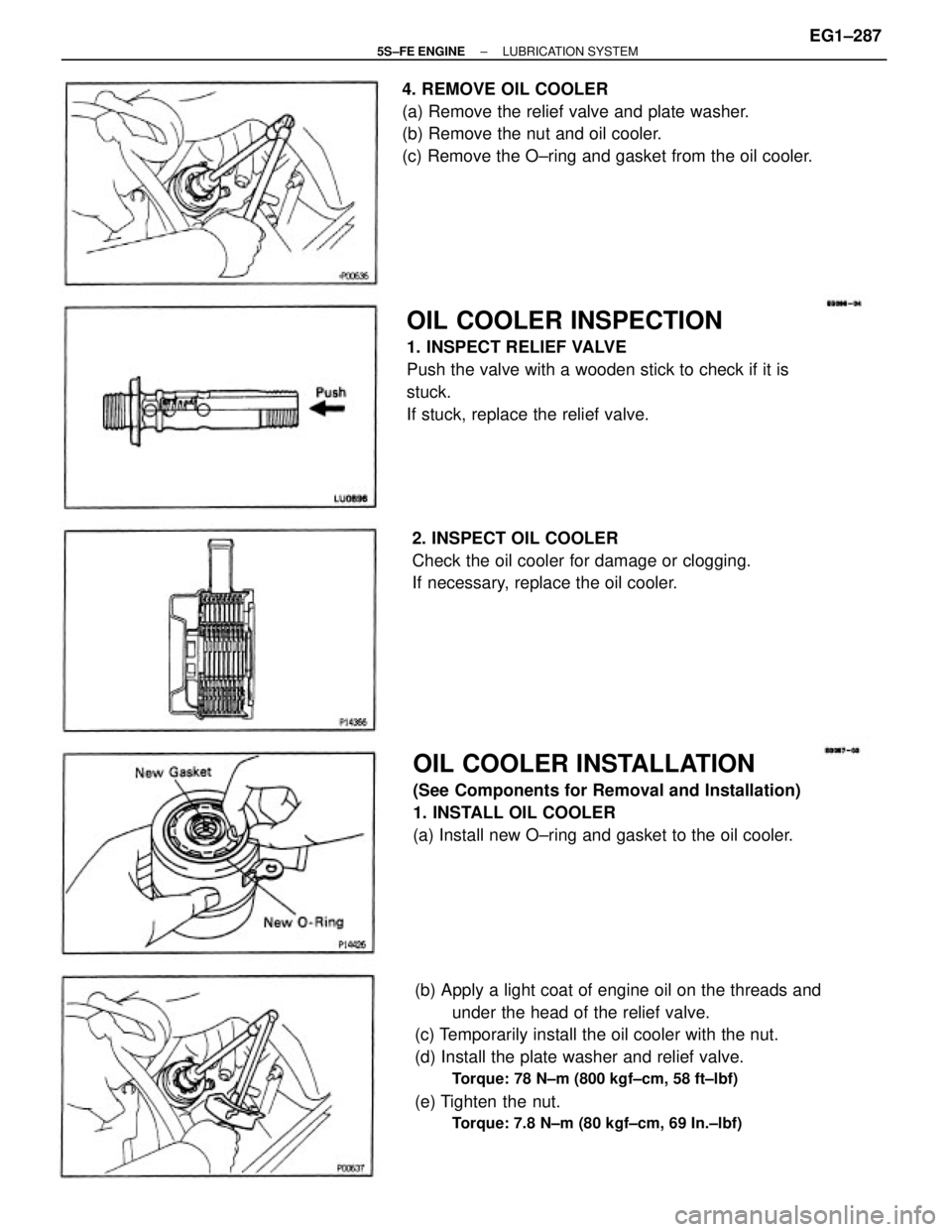

(b) Apply a light coat of engine oil on the threads and

under the head of the relief valve.

(c) Temporarily install the oil cooler with the nut.

(d) Install the plate washer and relief valve.

Torque: 78 N±m (800 kgf±cm, 58 ft±lbf)

(e) Tighten the nut.

Torque: 7.8 N±m (80 kgf±cm, 69 In.±lbf)

OIL COOLER INSPECTION

1. INSPECT RELIEF VALVE

Push the valve with a wooden stick to check if it is

stuck.

If stuck, replace the relief valve.

OIL COOLER INSTALLATION

(See Components for Removal and Installation)

1. INSTALL OIL COOLER

(a) Install new O±ring and gasket to the oil cooler. 4. REMOVE OIL COOLER

(a) Remove the relief valve and plate washer.

(b) Remove the nut and oil cooler.

(c) Remove the O±ring and gasket from the oil cooler.

2. INSPECT OIL COOLER

Check the oil cooler for damage or clogging.

If necessary, replace the oil cooler.

± 5S±FE ENGINELUBRICATION SYSTEMEG1±287