sensor TOYOTA CAMRY 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2000, Model line: CAMRY, Model: TOYOTA CAMRY 2000Pages: 4770, PDF Size: 86.41 MB

Page 96 of 4770

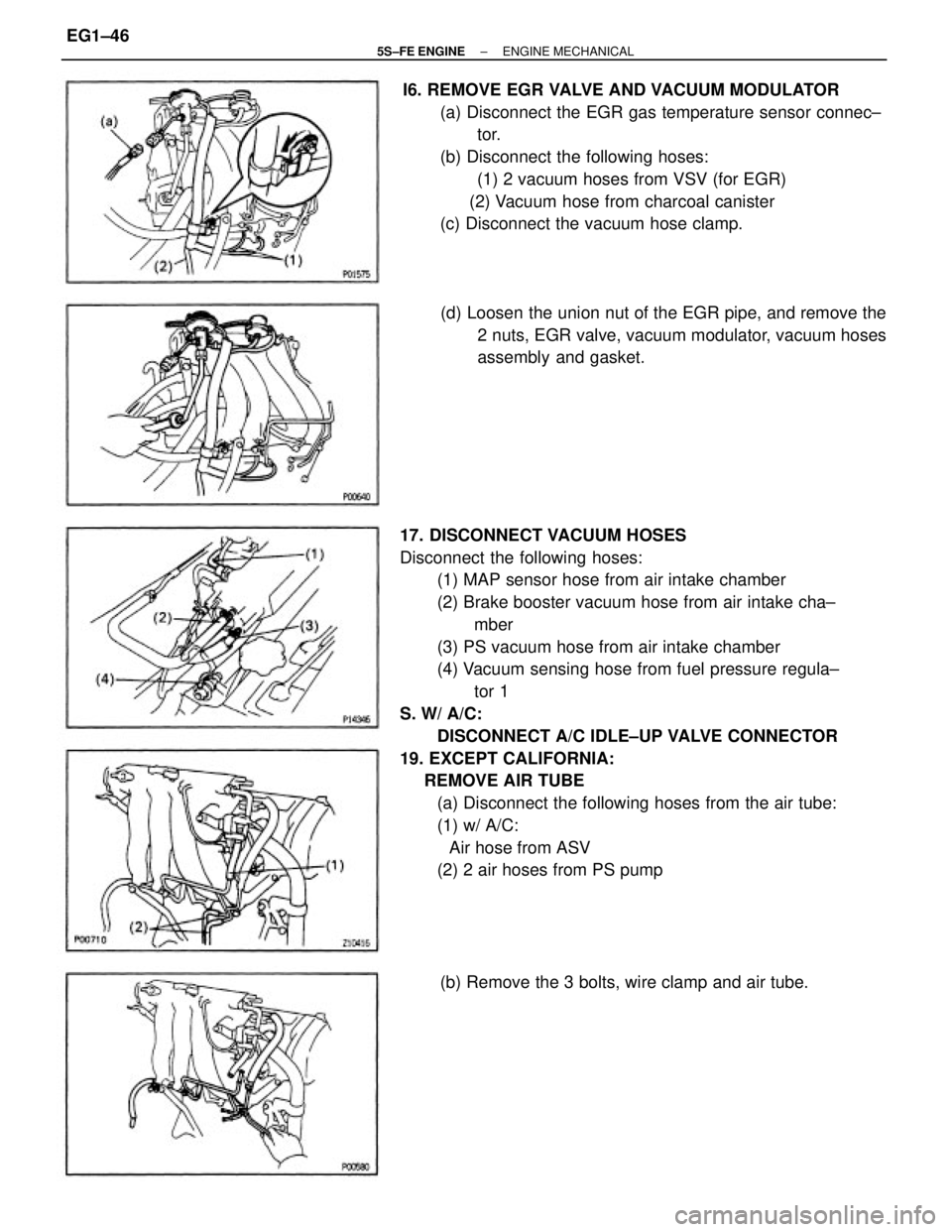

17. DISCONNECT VACUUM HOSES

Disconnect the following hoses:

(1) MAP sensor hose from air intake chamber

(2) Brake booster vacuum hose from air intake cha±

mber

(3) PS vacuum hose from air intake chamber

(4) Vacuum sensing hose from fuel pressure regula±

tor 1

S. W/ A/C:

DISCONNECT A/C IDLE±UP VALVE CONNECTOR

19. EXCEPT CALIFORNIA:

REMOVE AIR TUBE

(a) Disconnect the following hoses from the air tube:

(1) w/ A/C:

Air hose from ASV

(2) 2 air hoses from PS pump I6. REMOVE EGR VALVE AND VACUUM MODULATOR

(a) Disconnect the EGR gas temperature sensor connec±

tor.

(b) Disconnect the following hoses:

(1) 2 vacuum hoses from VSV (for EGR)

(2) Vacuum hose from charcoal canister

(c) Disconnect the vacuum hose clamp.

(d) Loosen the union nut of the EGR pipe, and remove the

2 nuts, EGR valve, vacuum modulator, vacuum hoses

assembly and gasket.

(b) Remove the 3 bolts, wire clamp and air tube.

± 5S±FE ENGINEENGINE MECHANICALEG1±46

Page 97 of 4770

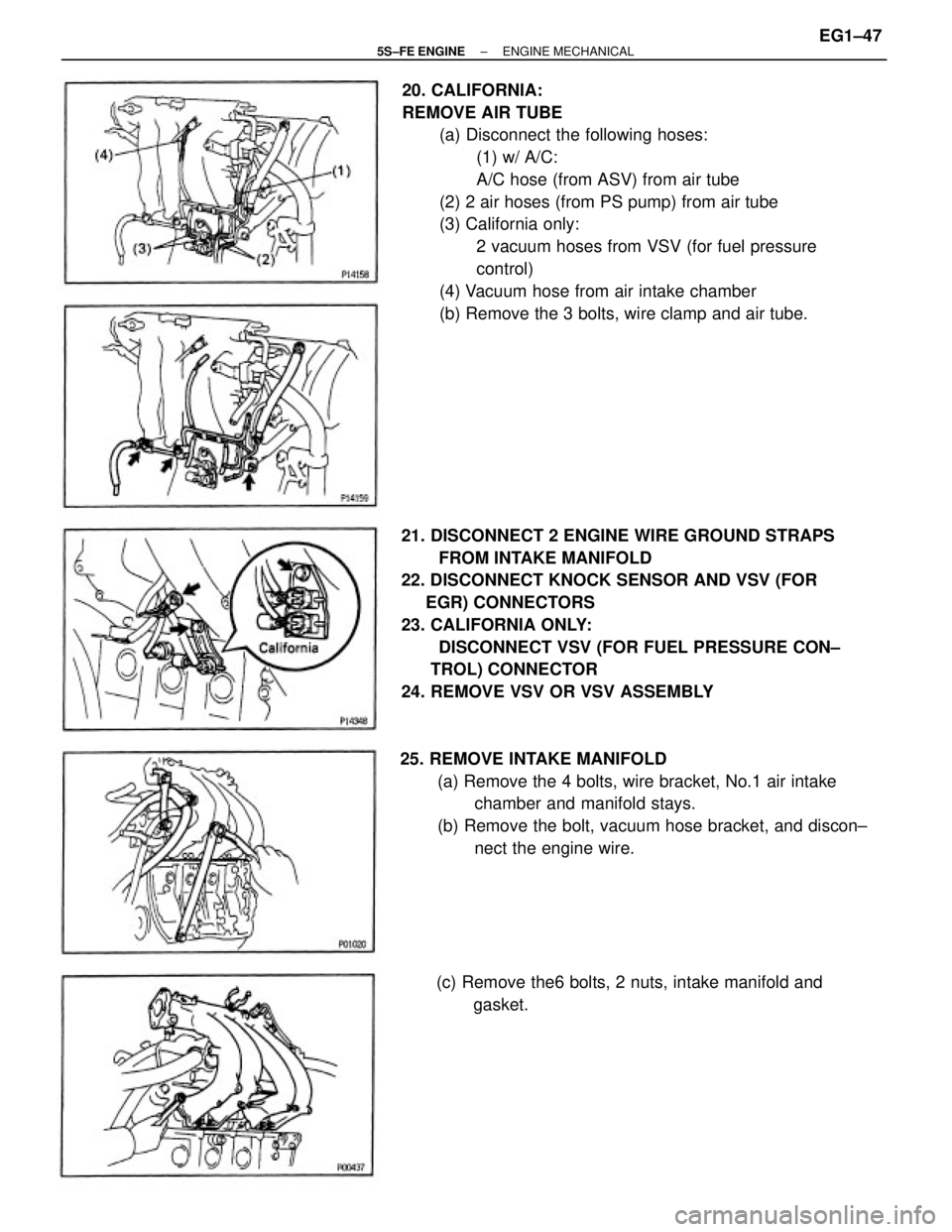

20. CALIFORNIA:

REMOVE AIR TUBE

(a) Disconnect the following hoses:

(1) w/ A/C:

A/C hose (from ASV) from air tube

(2) 2 air hoses (from PS pump) from air tube

(3) California only:

2 vacuum hoses from VSV (for fuel pressure

control)

(4) Vacuum hose from air intake chamber

(b) Remove the 3 bolts, wire clamp and air tube.

21. DISCONNECT 2 ENGINE WIRE GROUND STRAPS

FROM INTAKE MANIFOLD

22. DISCONNECT KNOCK SENSOR AND VSV (FOR

EGR) CONNECTORS

23. CALIFORNIA ONLY:

DISCONNECT VSV (FOR FUEL PRESSURE CON±

TROL) CONNECTOR

24. REMOVE VSV OR VSV ASSEMBLY

25. REMOVE INTAKE MANIFOLD

(a) Remove the 4 bolts, wire bracket, No.1 air intake

chamber and manifold stays.

(b) Remove the bolt, vacuum hose bracket, and discon±

nect the engine wire.

(c) Remove the6 bolts, 2 nuts, intake manifold and

gasket.

± 5S±FE ENGINEENGINE MECHANICALEG1±47

Page 126 of 4770

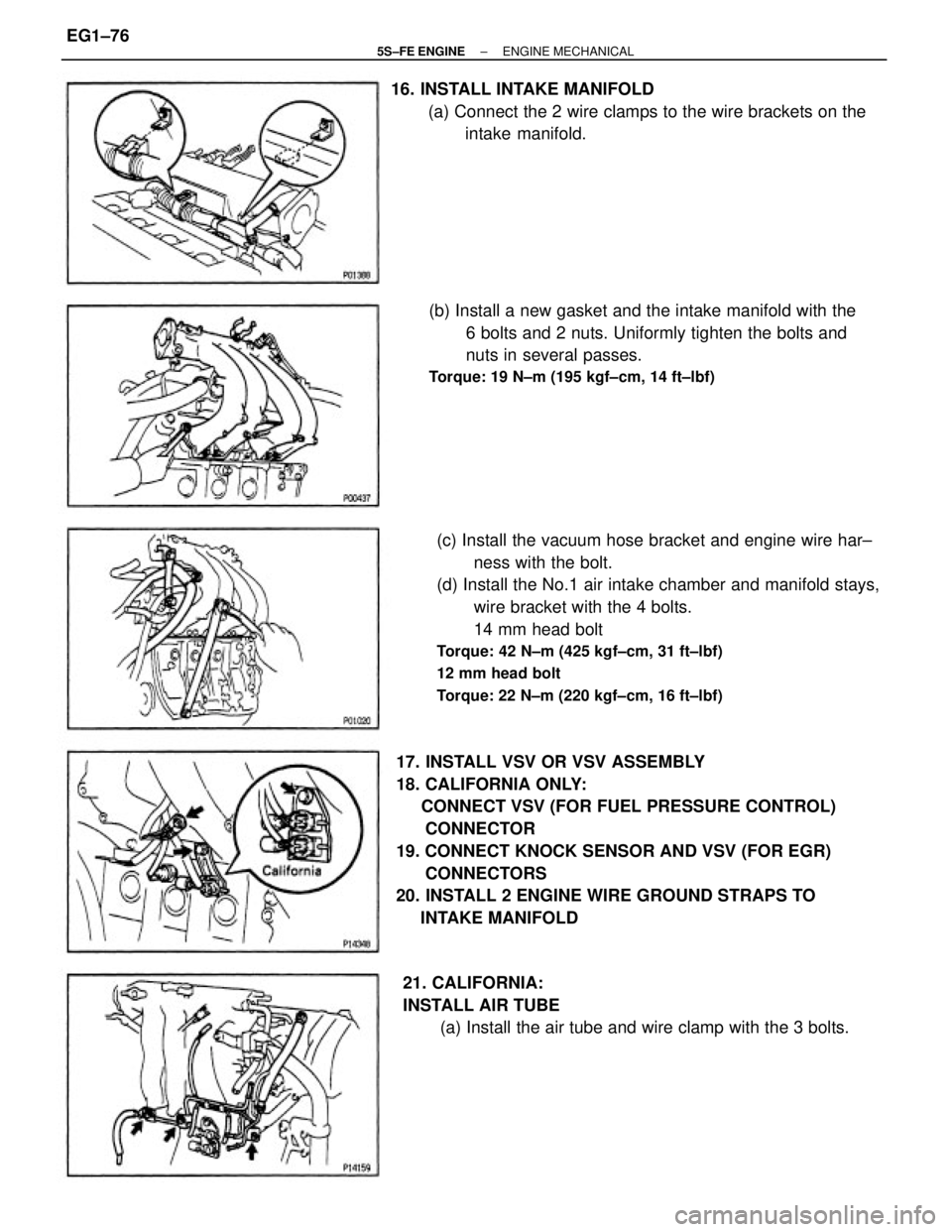

(c) Install the vacuum hose bracket and engine wire har±

ness with the bolt.

(d) Install the No.1 air intake chamber and manifold stays,

wire bracket with the 4 bolts.

14 mm head bolt

Torque: 42 N±m (425 kgf±cm, 31 ft±lbf)

12 mm head bolt

Torque: 22 N±m (220 kgf±cm, 16 ft±lbf)

17. INSTALL VSV OR VSV ASSEMBLY

18. CALIFORNIA ONLY:

CONNECT VSV (FOR FUEL PRESSURE CONTROL)

CONNECTOR

19. CONNECT KNOCK SENSOR AND VSV (FOR EGR)

CONNECTORS

20. INSTALL 2 ENGINE WIRE GROUND STRAPS TO

INTAKE MANIFOLD(b) Install a new gasket and the intake manifold with the

6 bolts and 2 nuts. Uniformly tighten the bolts and

nuts in several passes.

Torque: 19 N±m (195 kgf±cm, 14 ft±lbf)

16. INSTALL INTAKE MANIFOLD

(a) Connect the 2 wire clamps to the wire brackets on the

intake manifold.

21. CALIFORNIA:

INSTALL AIR TUBE

(a) Install the air tube and wire clamp with the 3 bolts.

± 5S±FE ENGINEENGINE MECHANICALEG1±76

Page 127 of 4770

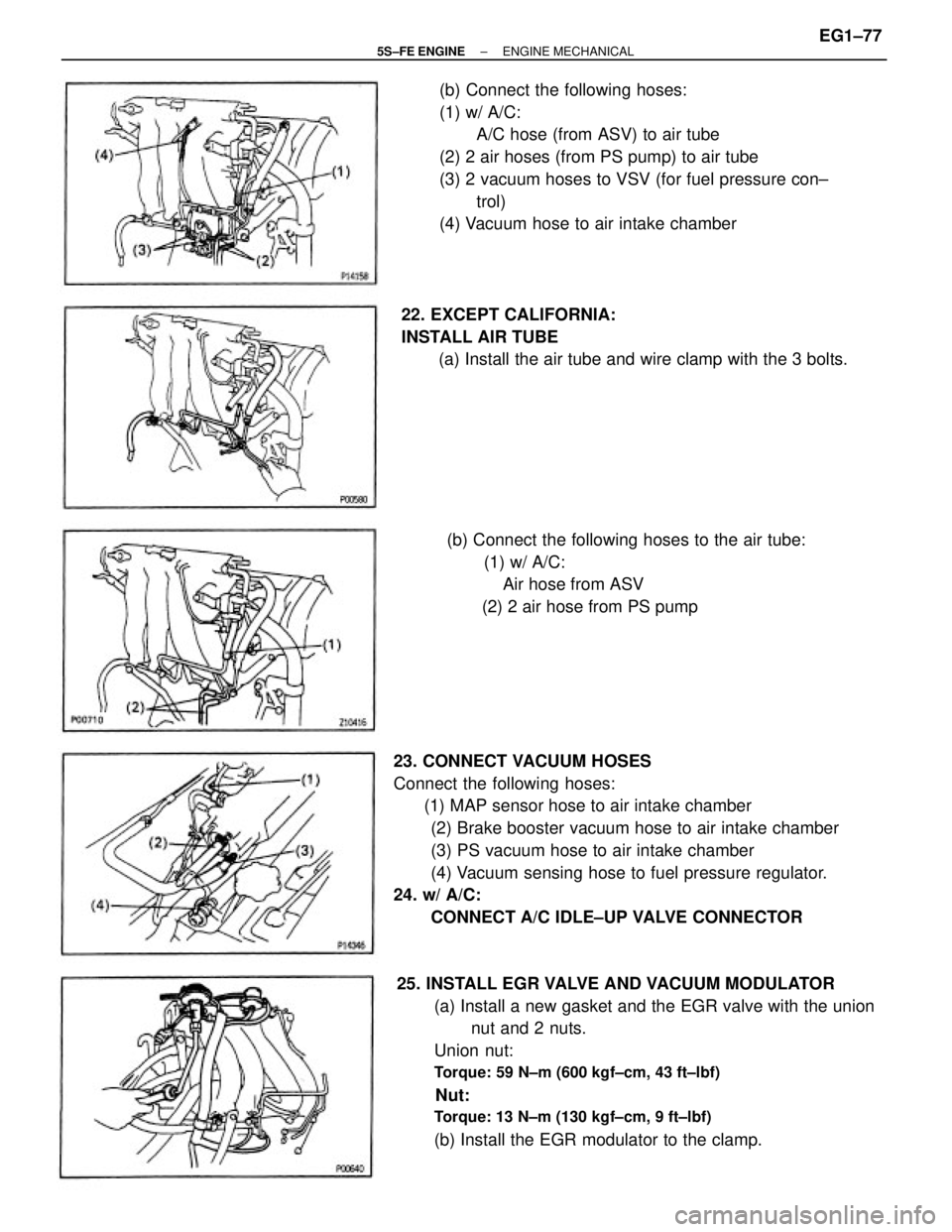

25. INSTALL EGR VALVE AND VACUUM MODULATOR

(a) Install a new gasket and the EGR valve with the union

nut and 2 nuts.

Union nut:

Torque: 59 N±m (600 kgf±cm, 43 ft±lbf)

Nut:

Torque: 13 N±m (130 kgf±cm, 9 ft±lbf)

(b) Install the EGR modulator to the clamp. 23. CONNECT VACUUM HOSES

Connect the following hoses:

(1) MAP sensor hose to air intake chamber

(2) Brake booster vacuum hose to air intake chamber

(3) PS vacuum hose to air intake chamber

(4) Vacuum sensing hose to fuel pressure regulator.

24. w/ A/C:

CONNECT A/C IDLE±UP VALVE CONNECTOR(b) Connect the following hoses:

(1) w/ A/C:

A/C hose (from ASV) to air tube

(2) 2 air hoses (from PS pump) to air tube

(3) 2 vacuum hoses to VSV (for fuel pressure con±

trol)

(4) Vacuum hose to air intake chamber

22. EXCEPT CALIFORNIA:

INSTALL AIR TUBE

(a) Install the air tube and wire clamp with the 3 bolts.

(b) Connect the following hoses to the air tube:

(1) w/ A/C:

Air hose from ASV

(2) 2 air hose from PS pump

± 5S±FE ENGINEENGINE MECHANICALEG1±77

Page 128 of 4770

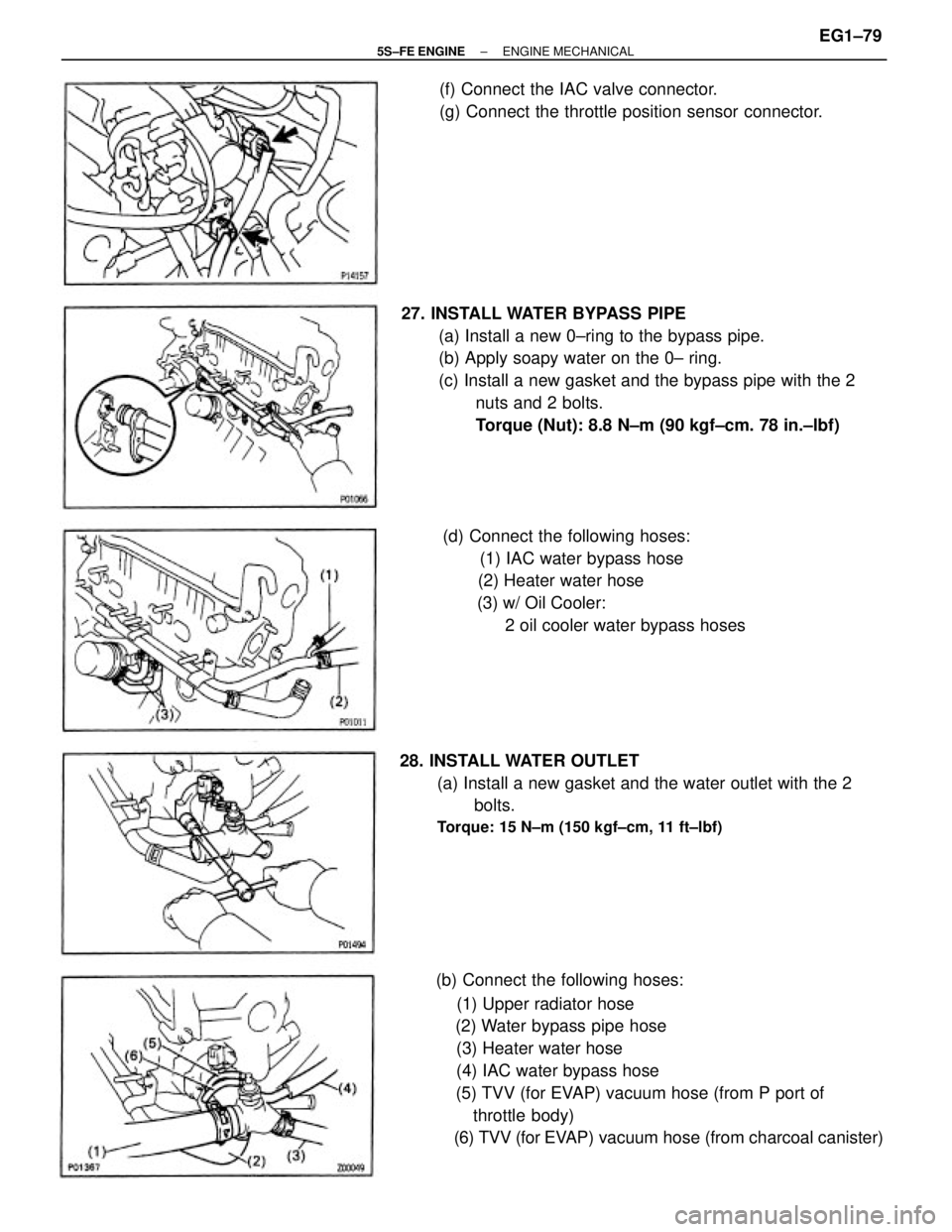

(c) Type A:

Install the throttle body with the 4 bolts.

Torque: 19 N±m (195 kgf±cm, 14 ft±lbf)

HINT: Each bolt is indicated in the illustration.

Bolt length:

A 45 mm (1.77 in.)

B 55 mm (2.17 in.)

(d) Type e:

Install the throttle body with the 2 bolts and 2 nuts.

Torque: 19 N±m (195 kgf±cm, 14 ft±lbf)

(e) Connect the following hoses to the throttle body:

(1) PCV hose

(2) 2 vacuum hoses from EGR vacuum modulator

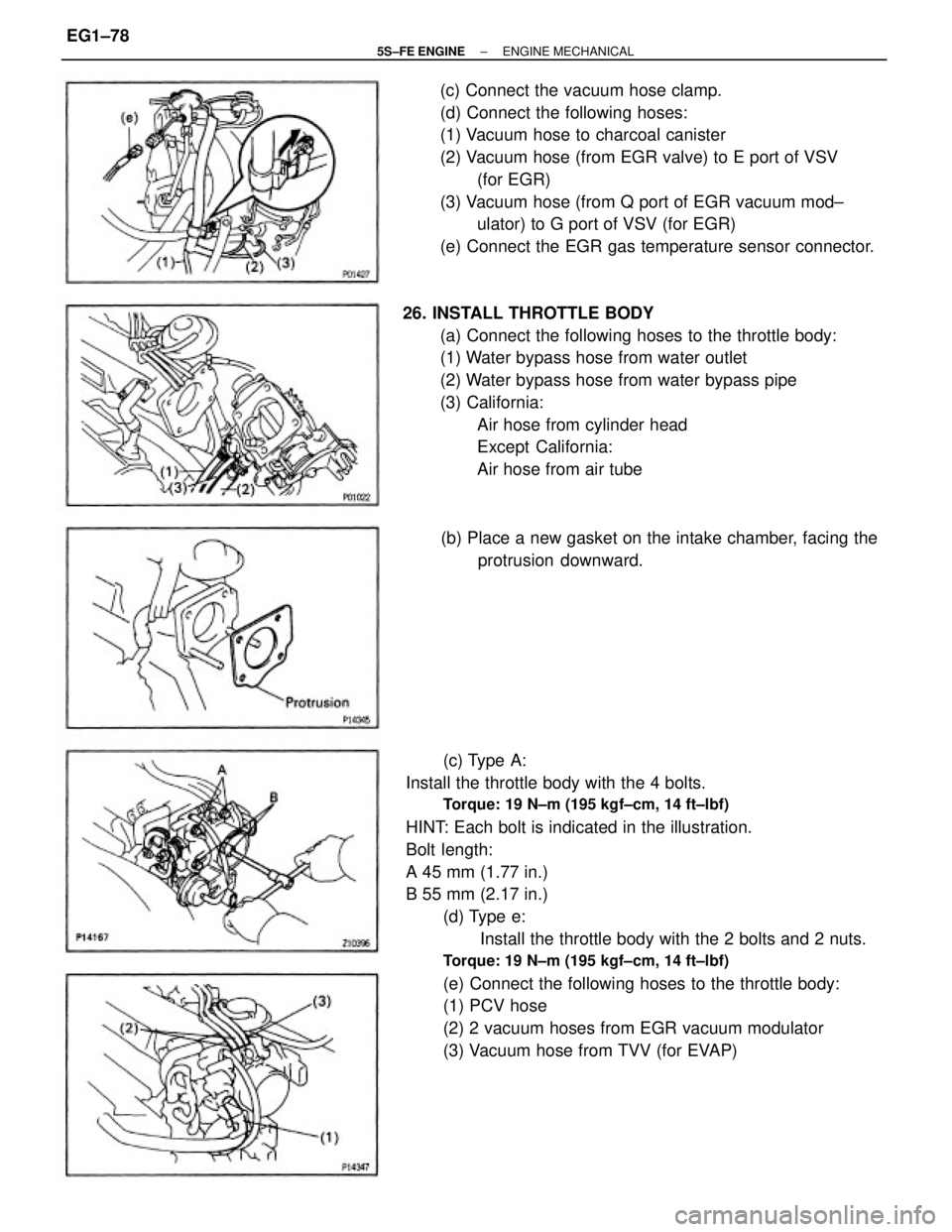

(3) Vacuum hose from TVV (for EVAP) (c) Connect the vacuum hose clamp.

(d) Connect the following hoses:

(1) Vacuum hose to charcoal canister

(2) Vacuum hose (from EGR valve) to E port of VSV

(for EGR)

(3) Vacuum hose (from Q port of EGR vacuum mod±

ulator) to G port of VSV (for EGR)

(e) Connect the EGR gas temperature sensor connector.

26. INSTALL THROTTLE BODY

(a) Connect the following hoses to the throttle body:

(1) Water bypass hose from water outlet

(2) Water bypass hose from water bypass pipe

(3) California:

Air hose from cylinder head

Except California:

Air hose from air tube

(b) Place a new gasket on the intake chamber, facing the

protrusion downward.

± 5S±FE ENGINEENGINE MECHANICALEG1±78

Page 129 of 4770

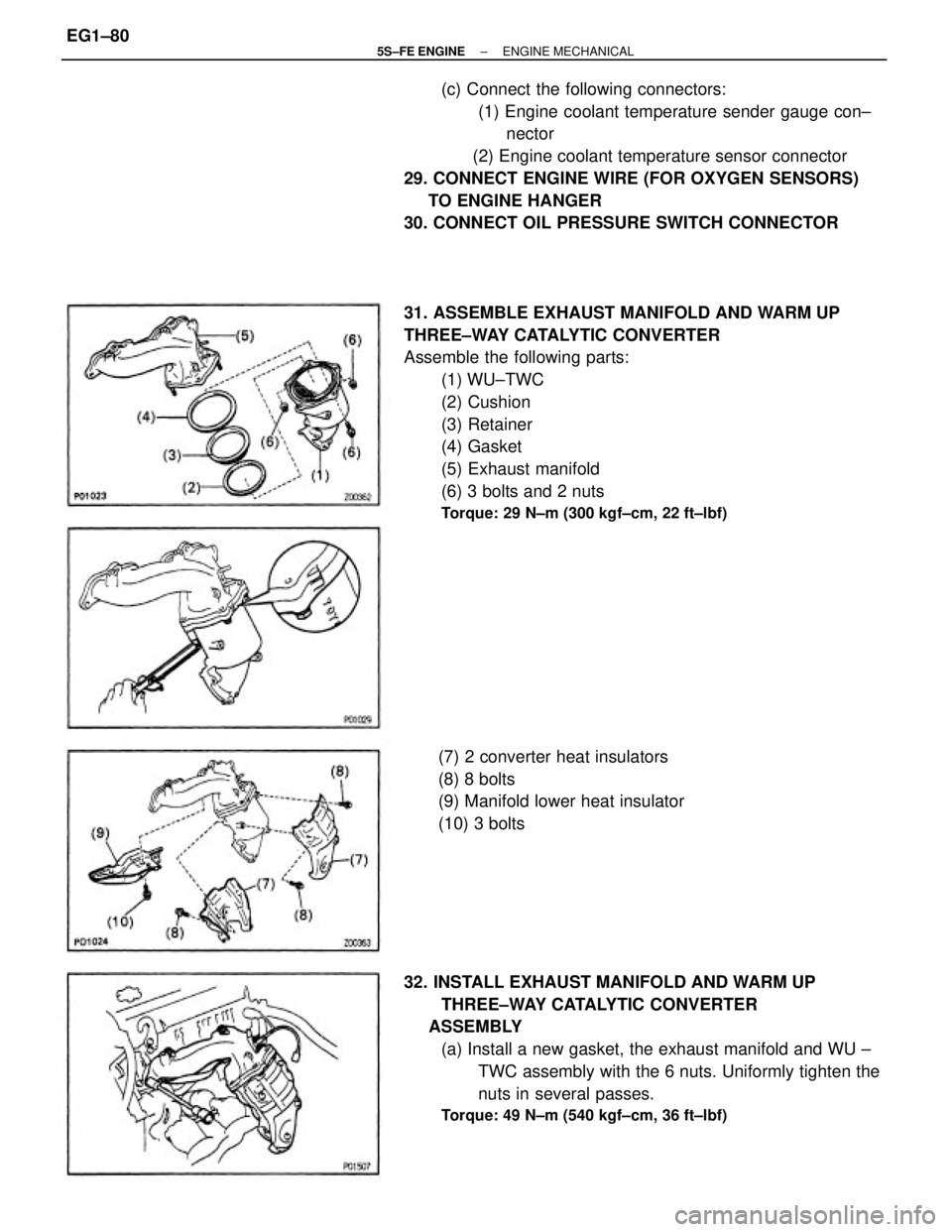

(b) Connect the following hoses:

(1) Upper radiator hose

(2) Water bypass pipe hose

(3) Heater water hose

(4) IAC water bypass hose

(5) TVV (for EVAP) vacuum hose (from P port of

throttle body)

(6) TVV (for EVAP) vacuum hose (from charcoal canister) 27. INSTALL WATER BYPASS PIPE

(a) Install a new 0±ring to the bypass pipe.

(b) Apply soapy water on the 0± ring.

(c) Install a new gasket and the bypass pipe with the 2

nuts and 2 bolts.

Torque (Nut): 8.8 N±m (90 kgf±cm. 78 in.±lbf)

28. INSTALL WATER OUTLET

(a) Install a new gasket and the water outlet with the 2

bolts.

Torque: 15 N±m (150 kgf±cm, 11 ft±lbf)

(d) Connect the following hoses:

(1) IAC water bypass hose

(2) Heater water hose

(3) w/ Oil Cooler:

2 oil cooler water bypass hoses (f) Connect the IAC valve connector.

(g) Connect the throttle position sensor connector.

± 5S±FE ENGINEENGINE MECHANICALEG1±79

Page 130 of 4770

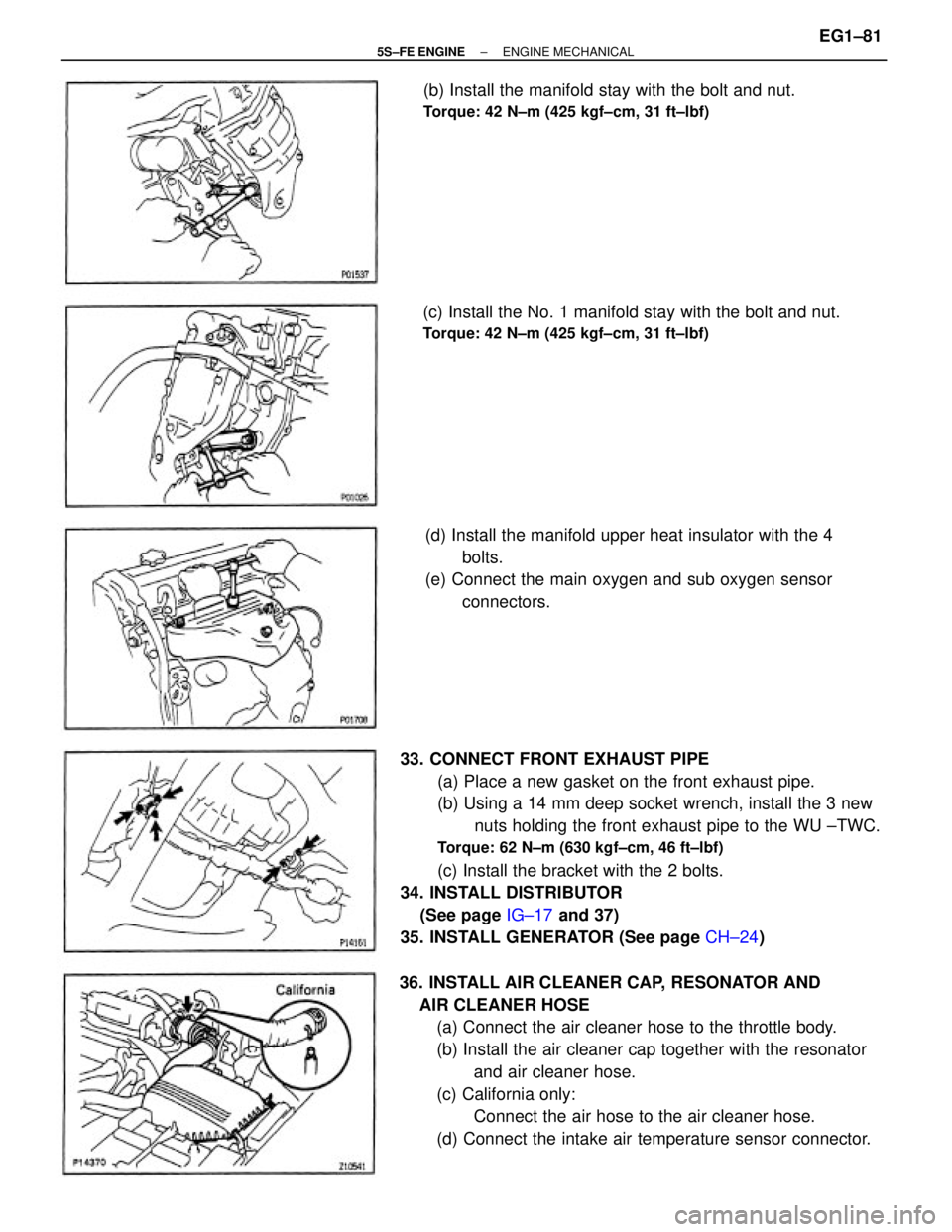

31. ASSEMBLE EXHAUST MANIFOLD AND WARM UP

THREE±WAY CATALYTIC CONVERTER

Assemble the following parts:

(1) WU±TWC

(2) Cushion

(3) Retainer

(4) Gasket

(5) Exhaust manifold

(6) 3 bolts and 2 nuts

Torque: 29 N±m (300 kgf±cm, 22 ft±lbf)

(c) Connect the following connectors:

(1) Engine coolant temperature sender gauge con±

nector

(2) Engine coolant temperature sensor connector

29. CONNECT ENGINE WIRE (FOR OXYGEN SENSORS)

TO ENGINE HANGER

30. CONNECT OIL PRESSURE SWITCH CONNECTOR

32. INSTALL EXHAUST MANIFOLD AND WARM UP

THREE±WAY CATALYTIC CONVERTER

ASSEMBLY

(a) Install a new gasket, the exhaust manifold and WU ±

TWC assembly with the 6 nuts. Uniformly tighten the

nuts in several passes.

Torque: 49 N±m (540 kgf±cm, 36 ft±lbf)

(7) 2 converter heat insulators

(8) 8 bolts

(9) Manifold lower heat insulator

(10) 3 bolts

± 5S±FE ENGINEENGINE MECHANICALEG1±80

Page 131 of 4770

33. CONNECT FRONT EXHAUST PIPE

(a) Place a new gasket on the front exhaust pipe.

(b) Using a 14 mm deep socket wrench, install the 3 new

nuts holding the front exhaust pipe to the WU ±TWC.

Torque: 62 N±m (630 kgf±cm, 46 ft±lbf)

(c) Install the bracket with the 2 bolts.

34. INSTALL DISTRIBUTOR

(See page IG±17 and 37)

35. INSTALL GENERATOR (See page CH±24)

36. INSTALL AIR CLEANER CAP, RESONATOR AND

AIR CLEANER HOSE

(a) Connect the air cleaner hose to the throttle body.

(b) Install the air cleaner cap together with the resonator

and air cleaner hose.

(c) California only:

Connect the air hose to the air cleaner hose.

(d) Connect the intake air temperature sensor connector. (d) Install the manifold upper heat insulator with the 4

bolts.

(e) Connect the main oxygen and sub oxygen sensor

connectors. (c) Install the No. 1 manifold stay with the bolt and nut.

Torque: 42 N±m (425 kgf±cm, 31 ft±lbf)

(b) Install the manifold stay with the bolt and nut.

Torque: 42 N±m (425 kgf±cm, 31 ft±lbf)

± 5S±FE ENGINEENGINE MECHANICALEG1±81

Page 135 of 4770

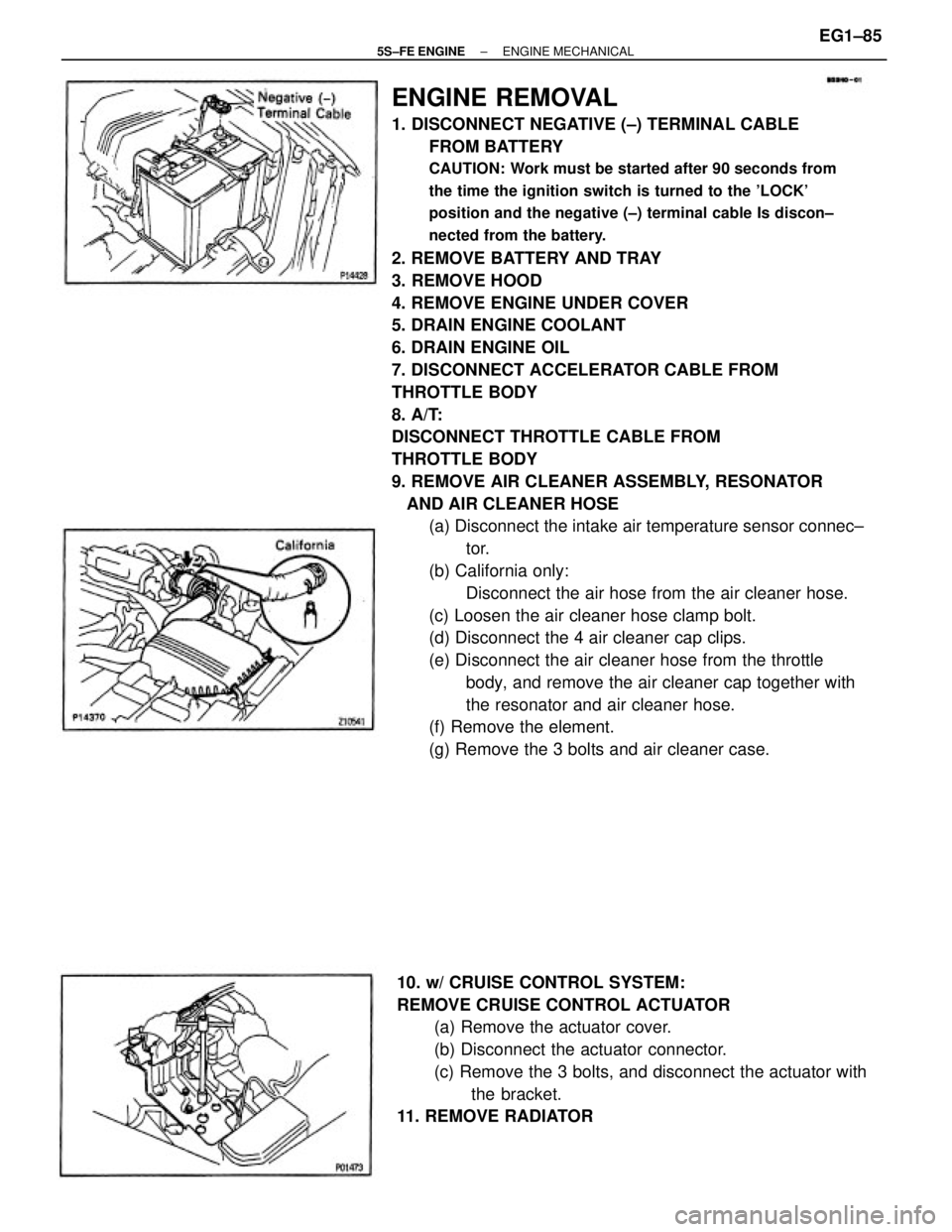

ENGINE REMOVAL

1. DISCONNECT NEGATIVE (±) TERMINAL CABLE

FROM BATTERY

CAUTION: Work must be started after 90 seconds from

the time the ignition switch is turned to the 'LOCK'

position and the negative (±) terminal cable Is discon±

nected from the battery.

2. REMOVE BATTERY AND TRAY

3. REMOVE HOOD

4. REMOVE ENGINE UNDER COVER

5. DRAIN ENGINE COOLANT

6. DRAIN ENGINE OIL

7. DISCONNECT ACCELERATOR CABLE FROM

THROTTLE BODY

8. A/T:

DISCONNECT THROTTLE CABLE FROM

THROTTLE BODY

9. REMOVE AIR CLEANER ASSEMBLY, RESONATOR

AND AIR CLEANER HOSE

(a) Disconnect the intake air temperature sensor connec±

tor.

(b) California only:

Disconnect the air hose from the air cleaner hose.

(c) Loosen the air cleaner hose clamp bolt.

(d) Disconnect the 4 air cleaner cap clips.

(e) Disconnect the air cleaner hose from the throttle

body, and remove the air cleaner cap together with

the resonator and air cleaner hose.

(f) Remove the element.

(g) Remove the 3 bolts and air cleaner case.

10. w/ CRUISE CONTROL SYSTEM:

REMOVE CRUISE CONTROL ACTUATOR

(a) Remove the actuator cover.

(b) Disconnect the actuator connector.

(c) Remove the 3 bolts, and disconnect the actuator with

the bracket.

11. REMOVE RADIATOR

± 5S±FE ENGINEENGINE MECHANICALEG1±85

Page 136 of 4770

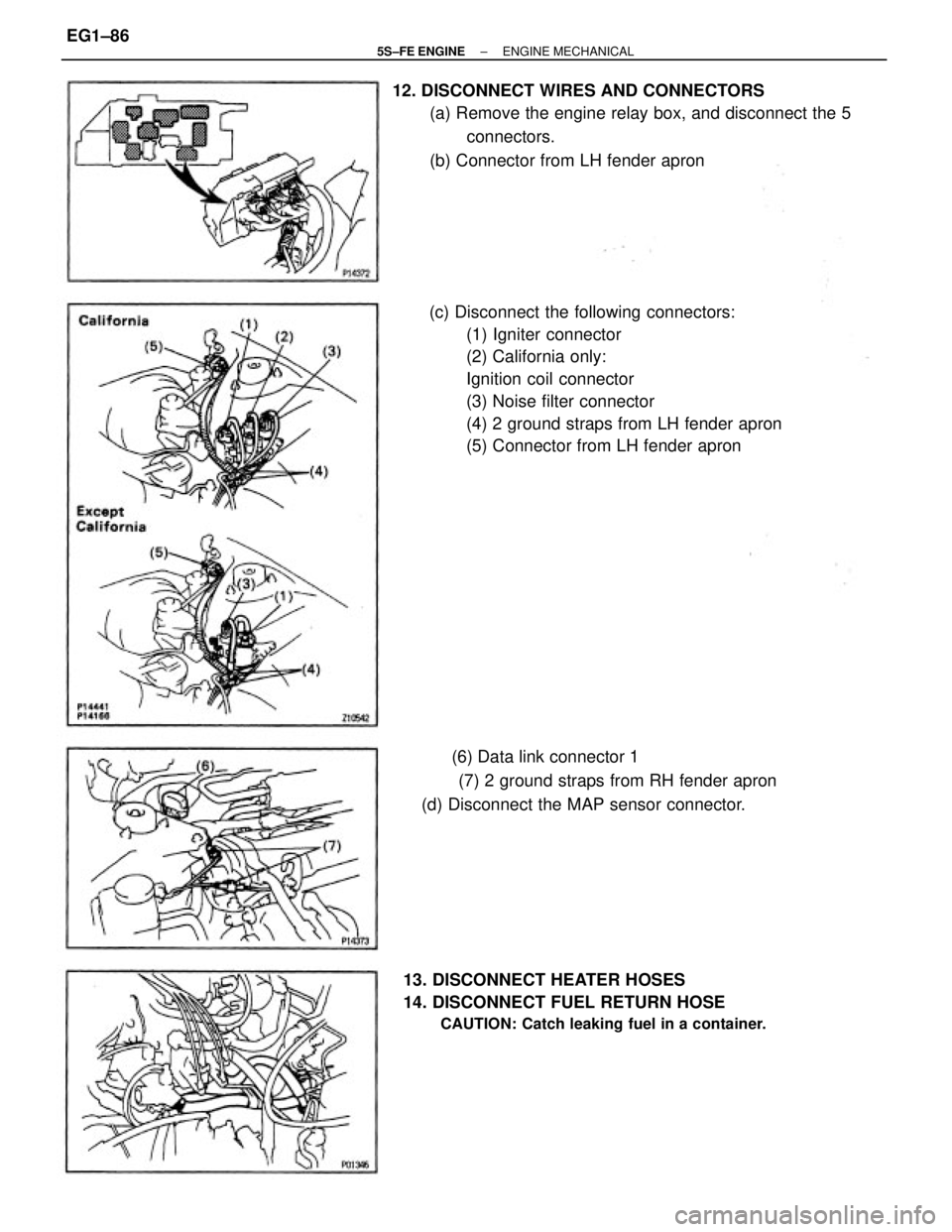

(c) Disconnect the following connectors:

(1) Igniter connector

(2) California only:

Ignition coil connector

(3) Noise filter connector

(4) 2 ground straps from LH fender apron

(5) Connector from LH fender apron 12. DISCONNECT WIRES AND CONNECTORS

(a) Remove the engine relay box, and disconnect the 5

connectors.

(b) Connector from LH fender apron

(6) Data link connector 1

(7) 2 ground straps from RH fender apron

(d) Disconnect the MAP sensor connector.

13. DISCONNECT HEATER HOSES

14. DISCONNECT FUEL RETURN HOSE

CAUTION: Catch leaking fuel in a container.

± 5S±FE ENGINEENGINE MECHANICALEG1±86