sensor TOYOTA CAMRY 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2000, Model line: CAMRY, Model: TOYOTA CAMRY 2000Pages: 4770, PDF Size: 86.41 MB

Page 137 of 4770

17. M/T:

REMOVE CLUTCH RELEASE CYLINDER WITHOUT

DISCONNECTING TUBE

Remove the 4 bolts, release cylinder and tube from

the transaxle.15. DISCONNECT FUEL INLET HOSE

CAUTION: Catch leaking fuel in a container.

16. M/T:

REMOVE STARTER

19. DISCONNECT VACUUM HOSES

(a) MAP sensor hose from air intake chamber

(b) Brake booster vacuum hose from air intake chamber 18. DISCONNECT TRANSAXLE CONTROL CABLE (S)

FROM TRANSAXLE

± 5S±FE ENGINEENGINE MECHANICALEG1±87

Page 143 of 4770

9. REMOVE TIMING BELT AND PULLEYS

10. REMOVE CYLINDER HEAD

11. REMOVE WATER PUMP AND GENERATOR

ADJUSTING BAR

12. REMOVE OIL PAN AND OIL PUMP

13. REMOVE OIL FILTER

14. w/ OIL COOLER:

REMOVE OIL COOLER 4. REMOVE REAR END PLATE

Remove the bolt and end plate.

5. INSTALL ENGINE TO ENGINE STAND FOR

DISASSEMBLY

6. REMOVE GENERATOR

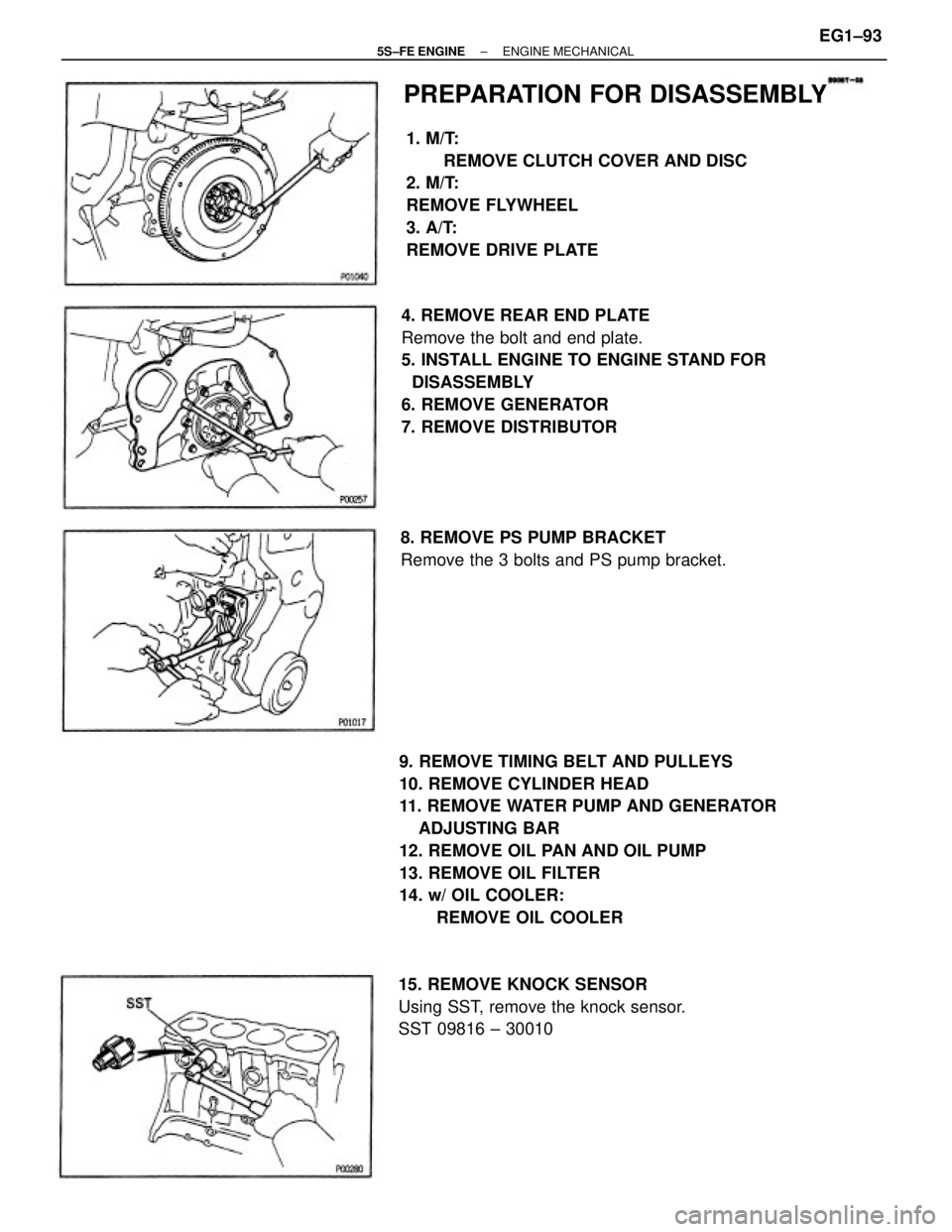

7. REMOVE DISTRIBUTOR1. M/T:

REMOVE CLUTCH COVER AND DISC

2. M/T:

REMOVE FLYWHEEL

3. A/T:

REMOVE DRIVE PLATE

15. REMOVE KNOCK SENSOR

Using SST, remove the knock sensor.

SST 09816 ± 300108. REMOVE PS PUMP BRACKET

Remove the 3 bolts and PS pump bracket.

PREPARATION FOR DISASSEMBLY

± 5S±FE ENGINEENGINE MECHANICALEG1±93

Page 175 of 4770

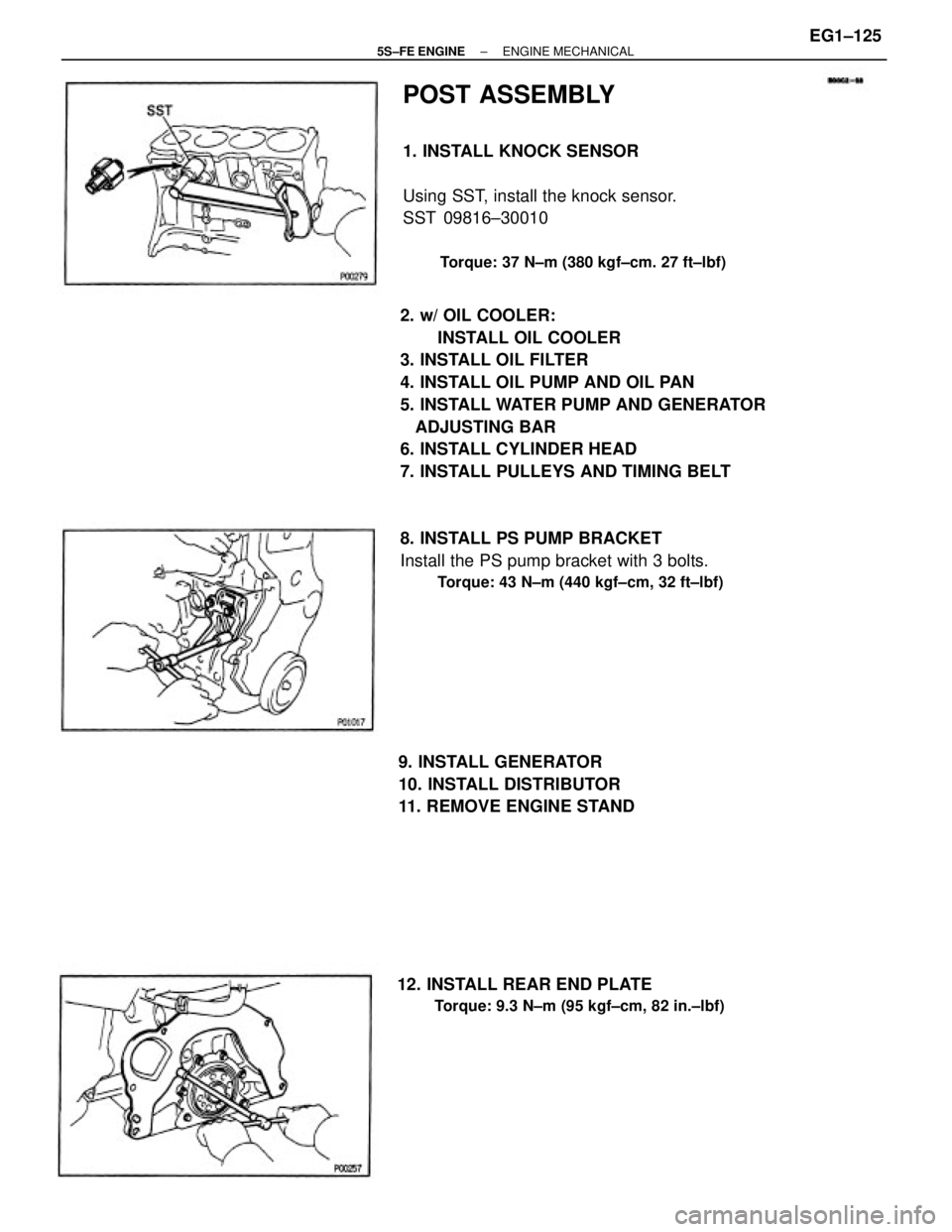

2. w/ OIL COOLER:

INSTALL OIL COOLER

3. INSTALL OIL FILTER

4. INSTALL OIL PUMP AND OIL PAN

5. INSTALL WATER PUMP AND GENERATOR

ADJUSTING BAR

6. INSTALL CYLINDER HEAD

7. INSTALL PULLEYS AND TIMING BELT

POST ASSEMBLY

1. INSTALL KNOCK SENSOR

Using SST, install the knock sensor.

SST 09816±30010

Torque: 37 N±m (380 kgf±cm. 27 ft±lbf)

8. INSTALL PS PUMP BRACKET

Install the PS pump bracket with 3 bolts.

Torque: 43 N±m (440 kgf±cm, 32 ft±lbf)

9. INSTALL GENERATOR

10. INSTALL DISTRIBUTOR

11. REMOVE ENGINE STAND

12. INSTALL REAR END PLATE

Torque: 9.3 N±m (95 kgf±cm, 82 in.±lbf)

± 5S±FE ENGINEENGINE MECHANICALEG1±125

Page 181 of 4770

19. M/T:

INSTALL CLUTCH RELEASE CYLINDER

Install the release cylinder and tube with the 4 bolts.

20. M/T:

INSTALL STARTER17. CONNECT VACUUM HOSES

(a) MAP sensor hose to air intake chamber

(b) Brake booster vacuum hose to air intake chamber

18. CONNECT TRANSAXLE CONTROL CABLE

(S) TO TRANSAXLE (c) Charcoal canister vacuum hose

± 5S±FE ENGINEENGINE MECHANICALEG1±131

Page 183 of 4770

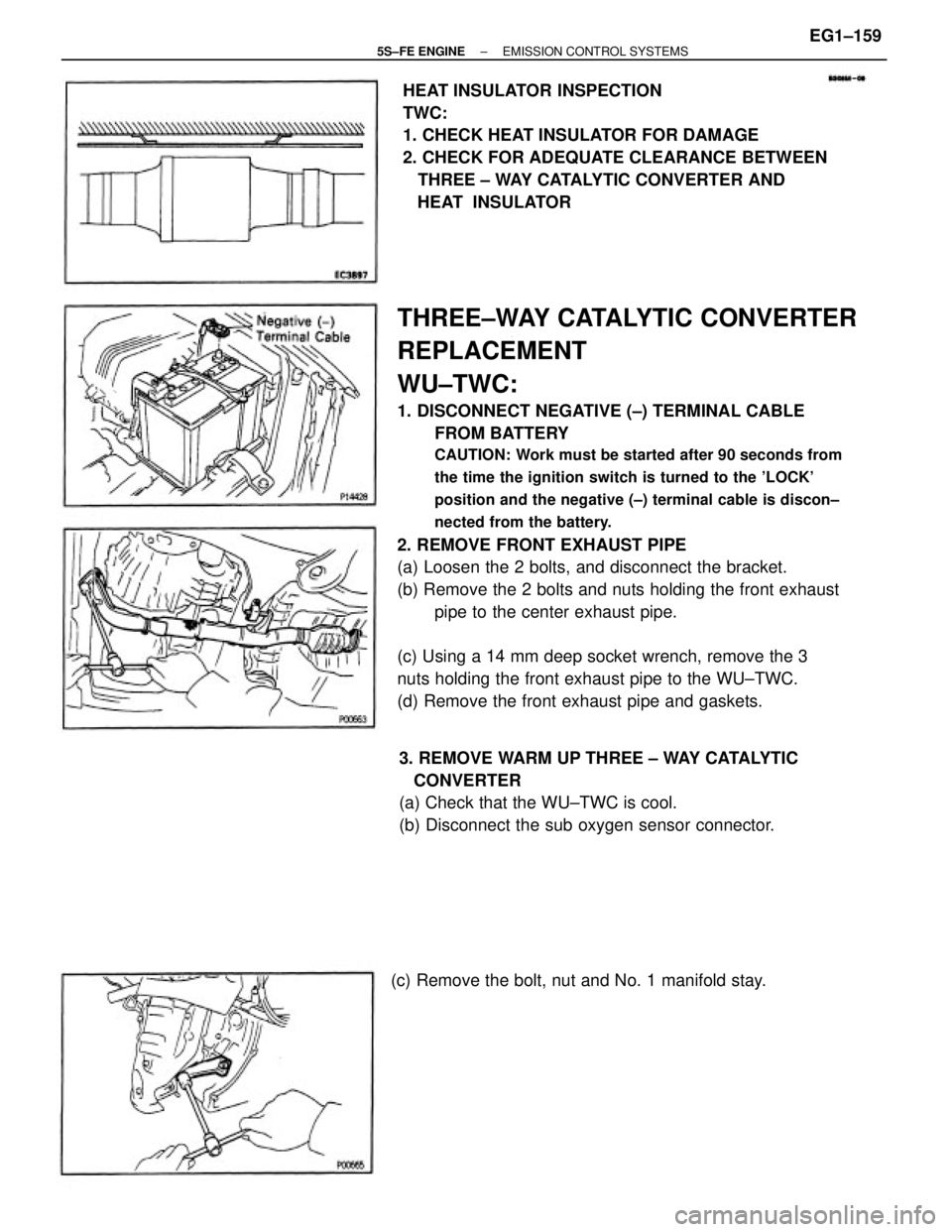

27. INSTALL AIR CLEANER ASSEMBLY, RESONATOR

AND AIR CLEANER HOSE

(a) Install the air cleaner case with 3 bolts.

(b) Install the element.

(c) Connect the air cleaner hose to the throttle body.

(d) Install the air cleaner cap together with the resonator

and air cleaner hose.

(e) California only:

Connect the air hose to the air cleaner hose.

(f) Connect the intake air temperature sensor connector.

28. A/T:

CONNECT AND ADJUST THROTTLE CABLE

29. CONNECT AND ADJUST ACCELERATOR CABLE

30. FILL WITH ENGINE COOLANT

31. FILL WITH ENGINE OIL

32. CONNECT NEGATIVE (±) TERMINAL CABLE TO

BATTERY

33. START ENGINE AND CHECK FOR LEAKS

34. PREFORM ENGINE ADJUSTMENT

35. INSTALL ENGINE UNDER COVERS

36. INSTALL HOOD

37. PERFORM ROAD TEST

Check for abnormal noises, shock, slippage, correct

shift points and smooth operation.

38. RECHECK ENGINE COOLANT AND ENGINE OIL

LEVELS26. w/ CRUISE CONTROL SYSTEM:

INSTALL CRUISE CONTROL ACTUATOR

(a) Install the actuator and bracket with the 3 bolts.

(b) Connect the actuator connector.

(c) Install the actuator cover.(6) Data link connector 1

(7) 2 ground straps from RH fender apron

(e) Connect the MAP sensor connector.

25. INSTALL RADIATOR

± 5S±FE ENGINEENGINE MECHANICALEG1±133

Page 194 of 4770

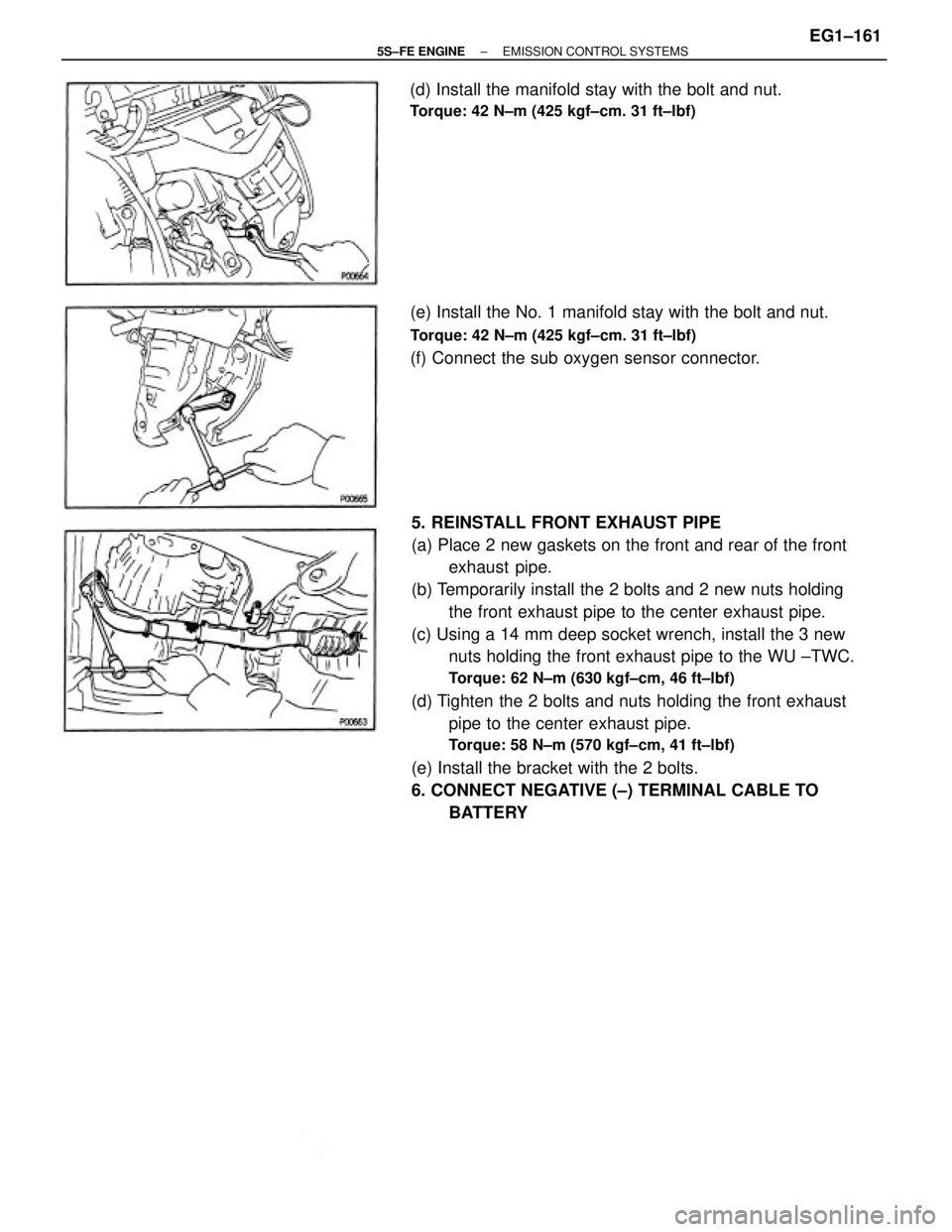

No. 1 balance shaft housing x No. 2 balance shaft housing (1st)

No. 1 balance shaft housing x No. 2 balance shaft housing (2nd)

FR engine mounting insulator x Front suspension member

RR engine mounting insulator x Front suspension member Exhaust manifold stay x FR engine mounting insulator No. 1 air intake chamber stay x Intake manifold

RR engine mounting insulator x Cylinder block

FR engine mounting insulator x Cylinder block No. 1 air intake chamber stay x Cylinder head

No. 1 exhaust manifold stay x Cylinder block

Connecting rod cap x Connecting rod (2nd) Connecting rod cap x Connecting rod (1 st)

LH engine mounting insulator x Transaxle No. 1 exhaust manifold stay x WU ±TWC Water bypass pipe x Water pump cover

Fuel inlet hose x Fuel filter (Union bolt) No. 3 timing belt cover x Cylinder head

Intake manifold stay x Intake manifoldCamshaft bearing cap x Cylinder head

Intake manifold stay x Cylinder blockCylinder head x Cylinder block (2nd)

Rear oil seal retainer x Cylinder block Exhaust manifold stay x WU ±TWC

PS pump bracket x Cylinder block Main bearing cap x Cylinder block Generator bracket x Cylinder head

A/C compressor x Cylinder block Pulsation damper x Delivery pipe

Exhaust manifold x Cylinder head

Engine balancer x Cylinder block

Front exhaust pipe x WU ±TWC Spark plug tube x Cylinder head

Rear end plate x Cylinder block Throttle body x Intake manifold Intake manifold x Cylinder heedEngine hanger x Cylinder head

Drive plate x Crankshaft (A/T)Knock sensor x Cylinder block Delivery pipe x Cylinder head

PS pump x PS pump bracketWU±TWC x Exhaust manifold

Flywheel x Crankshaft (M/T) Water outlet x Cylinder headEGR valve x intake manifold

EGR pipe x Cylinder head

± 5S±FE ENGINEENGINE MECHANICALEG1±144

Page 209 of 4770

THREE±WAY CATALYTIC CONVERTER

REPLACEMENT

WU±TWC:

1. DISCONNECT NEGATIVE (±) TERMINAL CABLE

FROM BATTERY

CAUTION: Work must be started after 90 seconds from

the time the ignition switch is turned to the 'LOCK'

position and the negative (±) terminal cable is discon±

nected from the battery.

2. REMOVE FRONT EXHAUST PIPE

(a) Loosen the 2 bolts, and disconnect the bracket.

(b) Remove the 2 bolts and nuts holding the front exhaust

pipe to the center exhaust pipe.

(c) Using a 14 mm deep socket wrench, remove the 3

nuts holding the front exhaust pipe to the WU±TWC.

(d) Remove the front exhaust pipe and gaskets.HEAT INSULATOR INSPECTION

TWC:

1. CHECK HEAT INSULATOR FOR DAMAGE

2. CHECK FOR ADEQUATE CLEARANCE BETWEEN

THREE ± WAY CATALYTIC CONVERTER AND

HEAT INSULATOR

3. REMOVE WARM UP THREE ± WAY CATALYTIC

CONVERTER

(a) Check that the WU±TWC is cool.

(b) Disconnect the sub oxygen sensor connector.

(c) Remove the bolt, nut and No. 1 manifold stay.

± 5S±FE ENGINEEMISSION CONTROL SYSTEMSEG1±159

Page 211 of 4770

5. REINSTALL FRONT EXHAUST PIPE

(a) Place 2 new gaskets on the front and rear of the front

exhaust pipe.

(b) Temporarily install the 2 bolts and 2 new nuts holding

the front exhaust pipe to the center exhaust pipe.

(c) Using a 14 mm deep socket wrench, install the 3 new

nuts holding the front exhaust pipe to the WU ±TWC.

Torque: 62 N±m (630 kgf±cm, 46 ft±lbf)

(d) Tighten the 2 bolts and nuts holding the front exhaust

pipe to the center exhaust pipe.

Torque: 58 N±m (570 kgf±cm, 41 ft±lbf)

(e) Install the bracket with the 2 bolts.

6. CONNECT NEGATIVE (±) TERMINAL CABLE TO

BATTERY (e) Install the No. 1 manifold stay with the bolt and nut.

Torque: 42 N±m (425 kgf±cm. 31 ft±lbf)

(f) Connect the sub oxygen sensor connector. (d) Install the manifold stay with the bolt and nut.

Torque: 42 N±m (425 kgf±cm. 31 ft±lbf)

± 5S±FE ENGINEEMISSION CONTROL SYSTEMSEG1±161

Page 216 of 4770

ELECTRONIC CONTROL SYSTEM

The CAMRY 5S±FE engine is equipped with a TOYOTA Computer Controlled System (TCCS)

which centrally controls the MFI/SFI, ESA, IAC diagnosis systems etc. by means of an Engine

Control Module (ECM±formerly MFI/SFI computer) employing a microcomputer.

The ECM controls the following functions:

1. Multiport Fuel Injection (MFI)/Sequential Multiport Fuel Injection (SFI)

The ECM receives signals from various sensors indicating changing engine operation conditions

such as:

Intake manifold pressure

Intake air temperature

Engine coolant temperature

Engine speed

Throttle valve opening angle

Exhaust oxygen content etc.

The signals are utilized by the ECM to determine the injection duration necessary for an optimum

air±fuel ratio.

2. Electronic Spark Advance (ESA)

The ECM is programmed with data for optimum ignition timing under all operating conditions.

Using data provided by sensors which monitor various engine functions (RPM, engine coolant

temperature, etc.), the microcomputer (ECM) triggers the spark at precisely the right instant.

3. Idle Air Control (IAC)

The ECM is programmed with target idling speed values to respond to different engine conditions

(engine coolant temperature, air conditioning ON/OFF, etc.). Sensors transmit signals to the ECM

which controls the flow of air through the bypass of the throttle valve and adjusts idle speed to

the target value.

4. Diagnosis

The ECM detects any malfunctions and abnormalities in the sensor network and lights a

malfunction indicator lamp in the combination meter. At the same time, trouble is identified and

a diagnostic trouble code is recorded by the EC

5. The diagnostic trouble code can be read by the

number of blinks of the malfunction indicator lamp when terminals TE1 and E1 are connected.

The diagnostic trouble codes are referred to in later page. (See page EG1±300)

Fail±Safe Function

In the event of the sensor malfunction, a back±up circuit will take over to provide minimal

driveability, and the malfunction indicator lamp will illuminate. The MFI (Multiport Fuel Injection)/SFI (Sequential Multiport Fuel Injection) system is composed

of 3 basic sub±systems: Fuel, Air Induction and Electronic Control Systems.

FUEL SYSTEM

Fuel is supplied under constant pressure to the MFI/SFI injectors by an electric fuel pump. The

injectors inject a metered quantity of fuel into the intake port in accordance with signals from the

ECM (Engine Control Module).

AIR INDUCTION SYSTEM

The air induction system provides sufficient air for engine operation.

± 5S±FE ENGINEMFI/SFI SYSTEMEG1±166

Page 219 of 4770

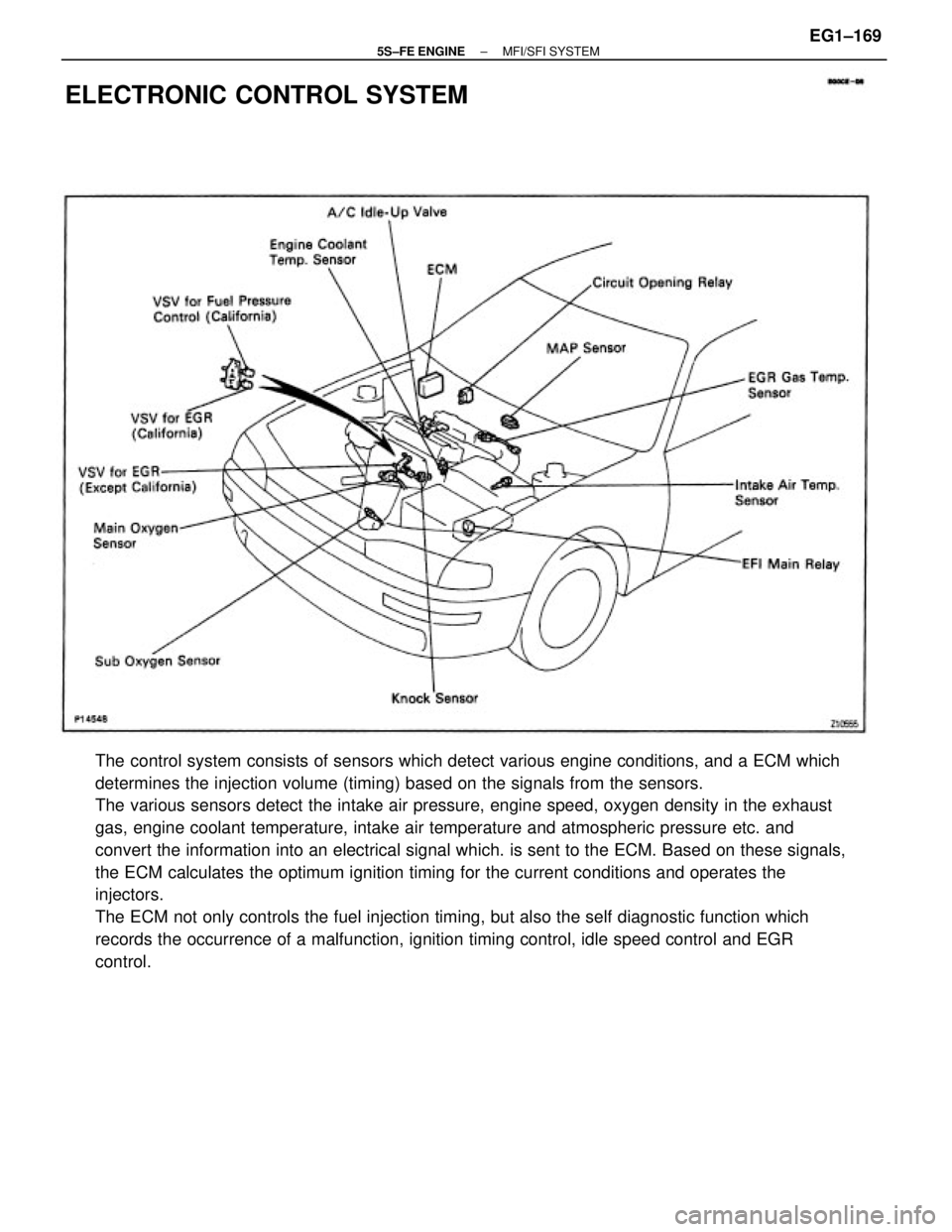

The control system consists of sensors which detect various engine conditions, and a ECM which

determines the injection volume (timing) based on the signals from the sensors.

The various sensors detect the intake air pressure, engine speed, oxygen density in the exhaust

gas, engine coolant temperature, intake air temperature and atmospheric pressure etc. and

convert the information into an electrical signal which. is sent to the ECM. Based on these signals,

the ECM calculates the optimum ignition timing for the current conditions and operates the

injectors.

The ECM not only controls the fuel injection timing, but also the self diagnostic function which

records the occurrence of a malfunction, ignition timing control, idle speed control and EGR

control.

ELECTRONIC CONTROL SYSTEM

± 5S±FE ENGINEMFI/SFI SYSTEMEG1±169