belt TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 779 of 2389

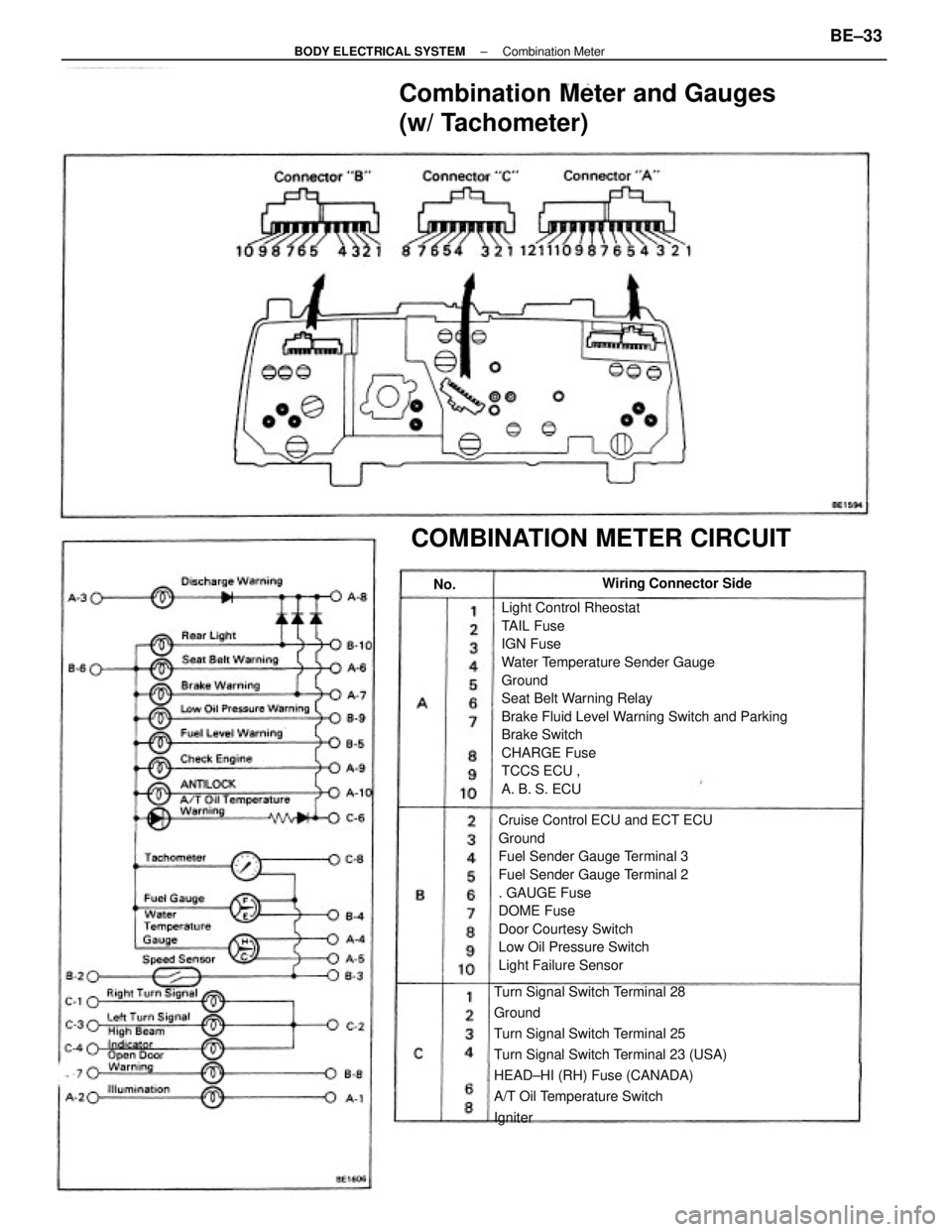

Light Control Rheostat

TAIL Fuse

IGN Fuse

Water Temperature Sender Gauge

Ground

Seat Belt Warning Relay

Brake Fluid Level Warning Switch and Parking

Brake Switch

CHARGE Fuse

TCCS ECU ,

A. B. S. ECU

Cruise Control ECU and ECT ECU

Ground

Fuel Sender Gauge Terminal 3

Fuel Sender Gauge Terminal 2

. GAUGE Fuse

DOME Fuse

Door Courtesy Switch

Low Oil Pressure Switch

Light Failure Sensor

Turn Signal Switch Terminal 28

Ground

Turn Signal Switch Terminal 25

Turn Signal Switch Terminal 23 (USA)

HEAD±HI (RH) Fuse (CANADA)

A/T Oil Temperature Switch

Igniter

Combination Meter and Gauges

(w/ Tachometer)

COMBINATION METER CIRCUIT

Wiring Connector Side

No.

± BODY ELECTRICAL SYSTEMCombination MeterBE±33

Page 787 of 2389

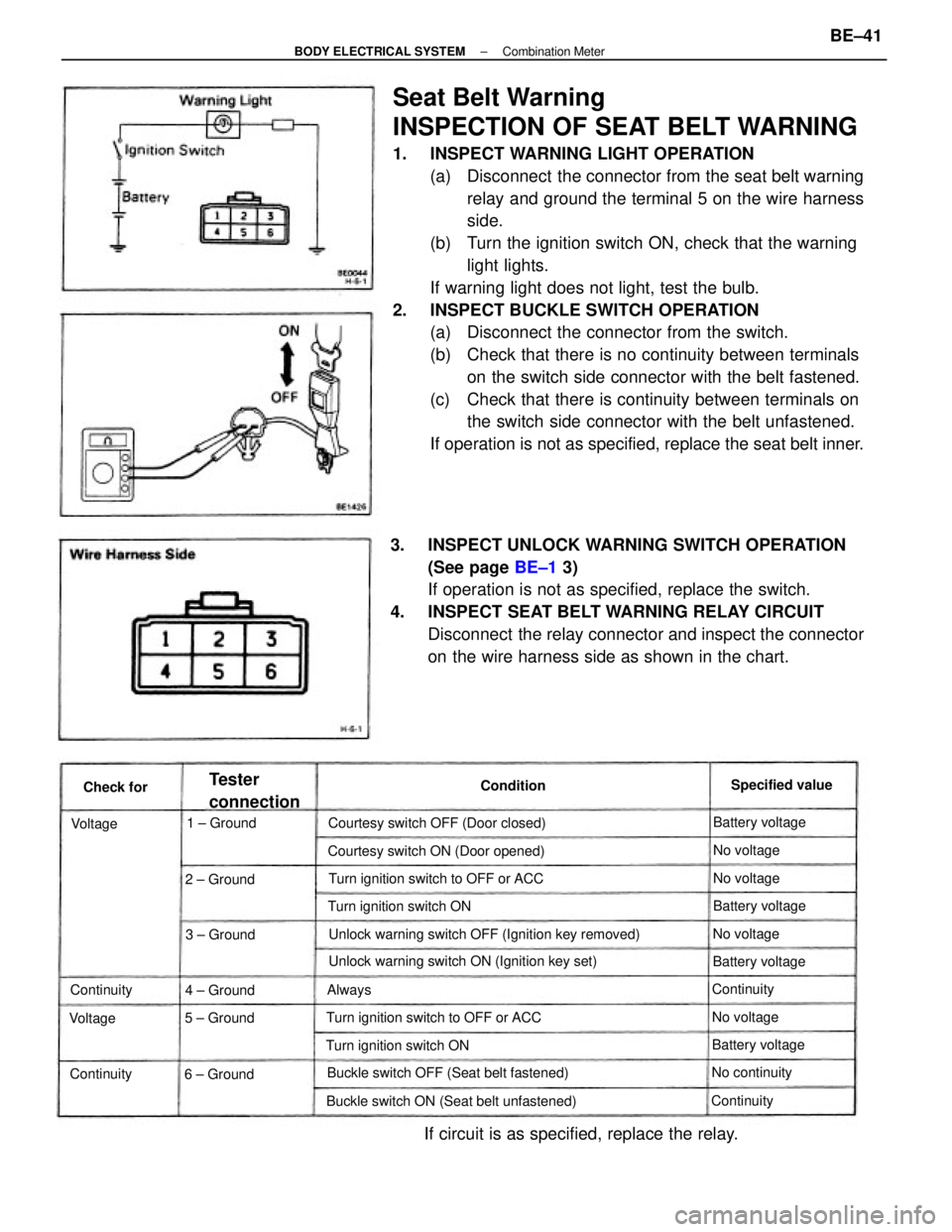

Seat Belt Warning

INSPECTION OF SEAT BELT WARNING

1. INSPECT WARNING LIGHT OPERATION

(a) Disconnect the connector from the seat belt warning

relay and ground the terminal 5 on the wire harness

side.

(b) Turn the ignition switch ON, check that the warning

light lights.

If warning light does not light, test the bulb.

2. INSPECT BUCKLE SWITCH OPERATION

(a) Disconnect the connector from the switch.

(b) Check that there is no continuity between terminals

on the switch side connector with the belt fastened.

(c) Check that there is continuity between terminals on

the switch side connector with the belt unfastened.

If operation is not as specified, replace the seat belt inner.

3. INSPECT UNLOCK WARNING SWITCH OPERATION

(See page BE±1 3)

If operation is not as specified, replace the switch.

4. INSPECT SEAT BELT WARNING RELAY CIRCUIT

Disconnect the relay connector and inspect the connector

on the wire harness side as shown in the chart.

Unlock warning switch OFF (Ignition key removed)

If circuit is as specified, replace the relay.

Unlock warning switch ON (Ignition key set)

Buckle switch ON (Seat belt unfastened)Buckle switch OFF (Seat belt fastened)Courtesy switch ON (Door opened)

Turn ignition switch to OFF or ACCTurn ignition switch to OFF or ACC Courtesy switch OFF (Door closed)

Turn ignition switch ONTurn ignition switch ON

6 ± Ground

Tester

connectionSpecified value

Battery voltage

Battery voltage

Battery voltageBattery voltage

No continuity 1 ± Ground

2 ± Ground

3 ± Ground

5 ± Ground4 ± GroundContinuity

Continuity

ContinuityNo voltageNo voltageNo voltage

No voltage

Continuity Condition

Check for

VoltageVoltage

Always

± BODY ELECTRICAL SYSTEMCombination MeterBE±41

Page 811 of 2389

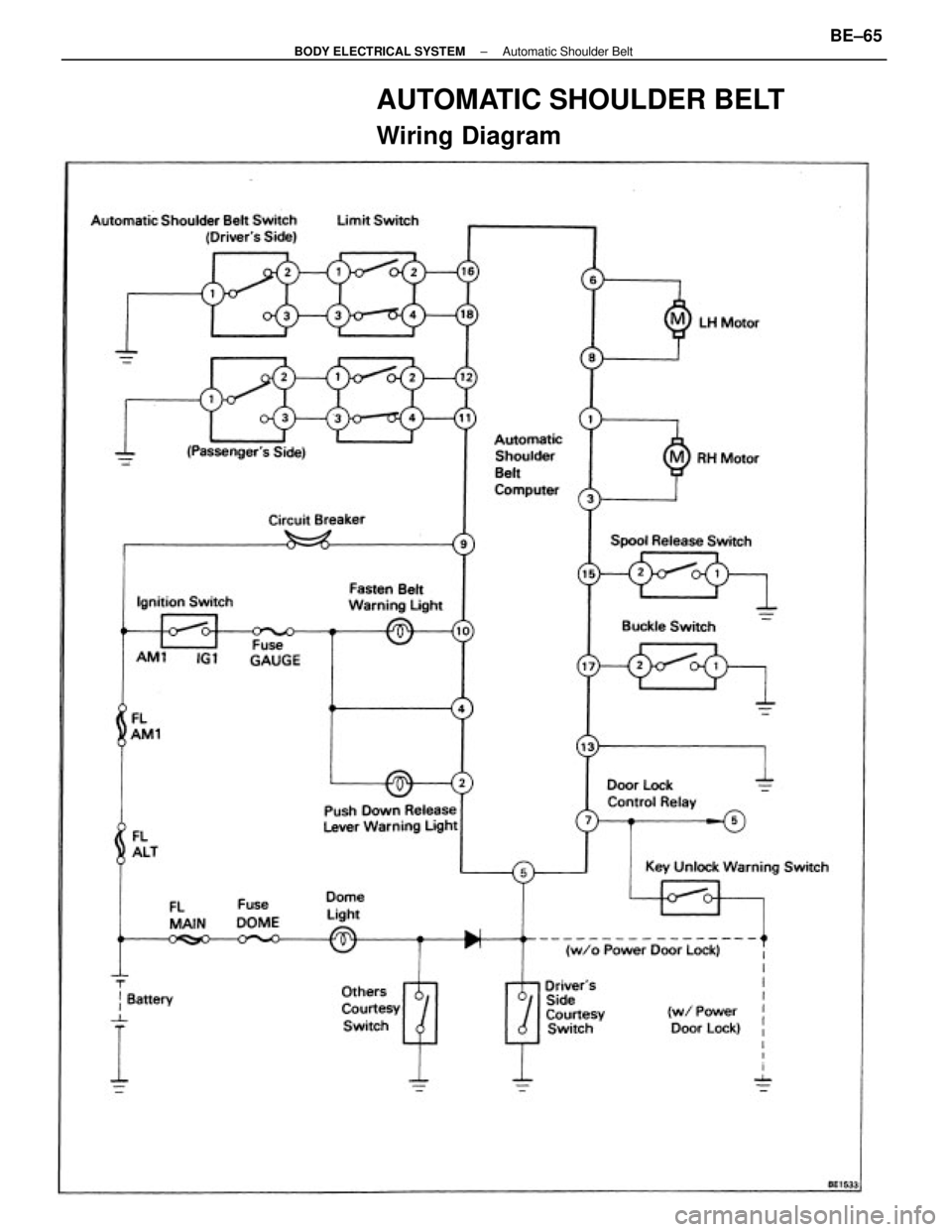

AUTOMATIC SHOULDER BELT

Wiring Diagram

± BODY ELECTRICAL SYSTEMAutomatic Shoulder BeltBE±65

Page 812 of 2389

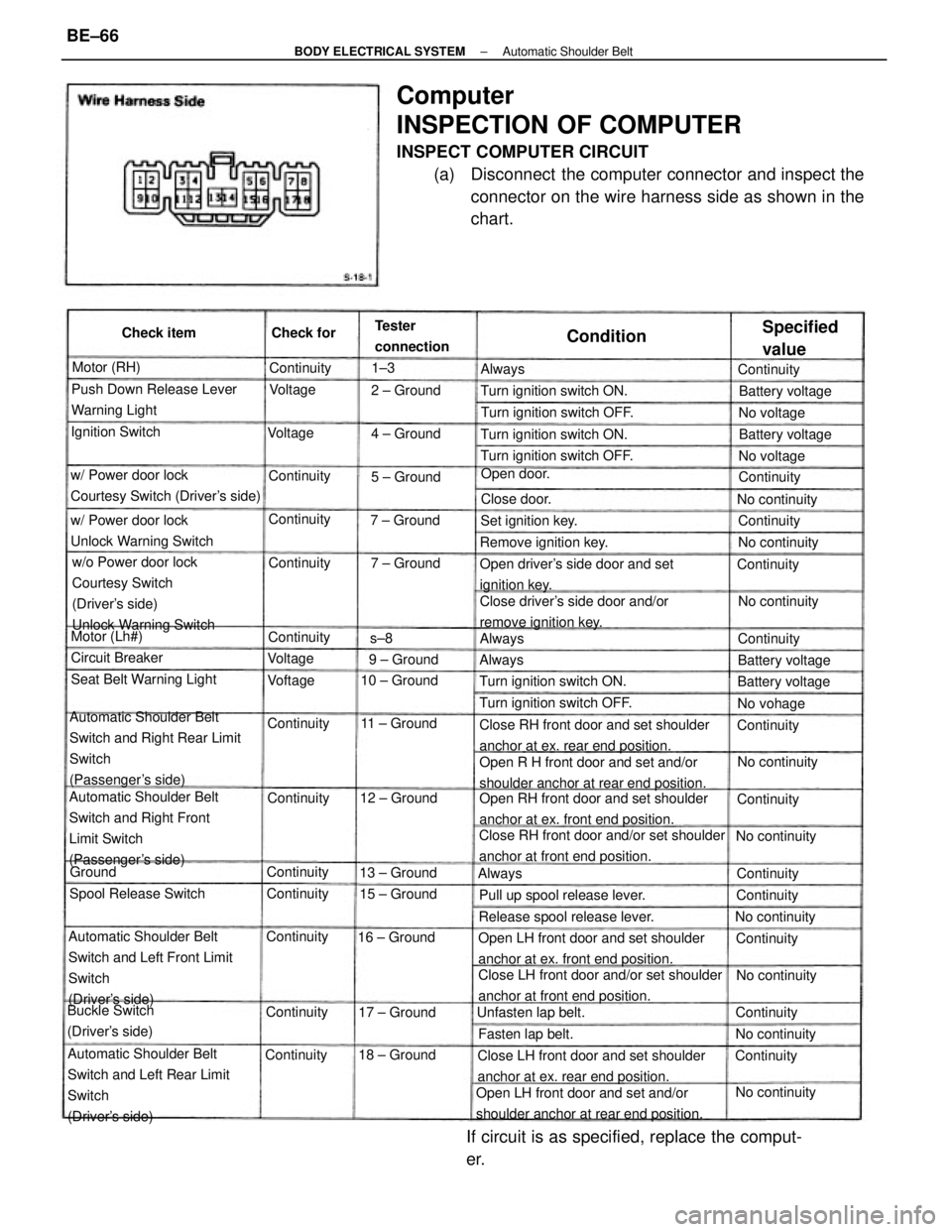

Computer

INSPECTION OF COMPUTER

INSPECT COMPUTER CIRCUIT

(a) Disconnect the computer connector and inspect the

connector on the wire harness side as shown in the

chart.

Automatic Shoulder Belt

Switch and Right Rear Limit

Switch

(Passenger's side)

Automatic Shoulder Belt

Switch and Left Front Limit

Switch

(Driver's side)

Automatic Shoulder Belt

Switch and Left Rear Limit

Switch

(Driver's side)Automatic Shoulder Belt

Switch and Right Front

Limit Switch

(Passenger's side)w/o Power door lock

Courtesy Switch

(Driver's side)

Unlock Warning Switch

Open RH front door and set shoulder

anchor at ex. front end position.

Close LH front door and/or set shoulder

anchor at front end position.Close RH front door and/or set shoulder

anchor at front end position.Close RH front door and set shoulder

anchor at ex. rear end position.

Open R H front door and set and/or

shoulder anchor at rear end position.

Open LH front door and set shoulder

anchor at ex. front end position.

Open LH front door and set and/or

shoulder anchor at rear end position.Close LH front door and set shoulder

anchor at ex. rear end position.

If circuit is as specified, replace the comput-

er.

Close driver's side door and/or

remove ignition key. Open driver's side door and set

ignition key. w/ Power door lock

Courtesy Switch (Driver's side)Push Down Release Lever

Warning Light

w/ Power door lock

Unlock Warning Switch

Release spool release lever.Pull up spool release lever.Turn ignition switch ON.

Seat Belt Warning LightTurn ignition switch OFF.

Turn ignition switch OFF.Turn ignition switch OFF.

Turn ignition switch ON.Turn ignition switch ON.

Buckle Switch

(Driver's side)Spool Release SwitchRemove ignition key. Tester

connection

Unfasten lap belt.

Specified

value

Set ignition key.

Battery voltage Ignition Switch

Battery voltage Battery voltage

Battery voltage

Fasten lap belt. Circuit Breaker

No continuity

No continuityNo continuity

No continuity No continuity

No continuity

No continuity

No continuity 15 ± Ground

No continuity 11 ± Ground 10 ± Ground

12 ± Ground

16 ± Ground

18 ± Ground13 ± Ground

17 ± GroundOpen door. Check item

7 ± Ground4 ± Ground

9 ± Ground7 ± Ground2 ± Ground

5 ± Ground Motor (RH)

Motor (Lh#)

Continuity

ContinuityNo voltage No voltage

No vohage Continuity

Continuity Continuity

ContinuityContinuity Continuity

Continuity

ContinuityContinuity Check for

Continuity ContinuityContinuity

Continuity Close door.

Continuity

ContinuityContinuityContinuity

ContinuityContinuity

Continuity

ContinuityContinuity

Condition

Voltage Voltage

VoftageVoltageAlways

AlwaysAlways

Always

Ground1±3

s±8

± BODY ELECTRICAL SYSTEMAutomatic Shoulder BeltBE±66

Page 813 of 2389

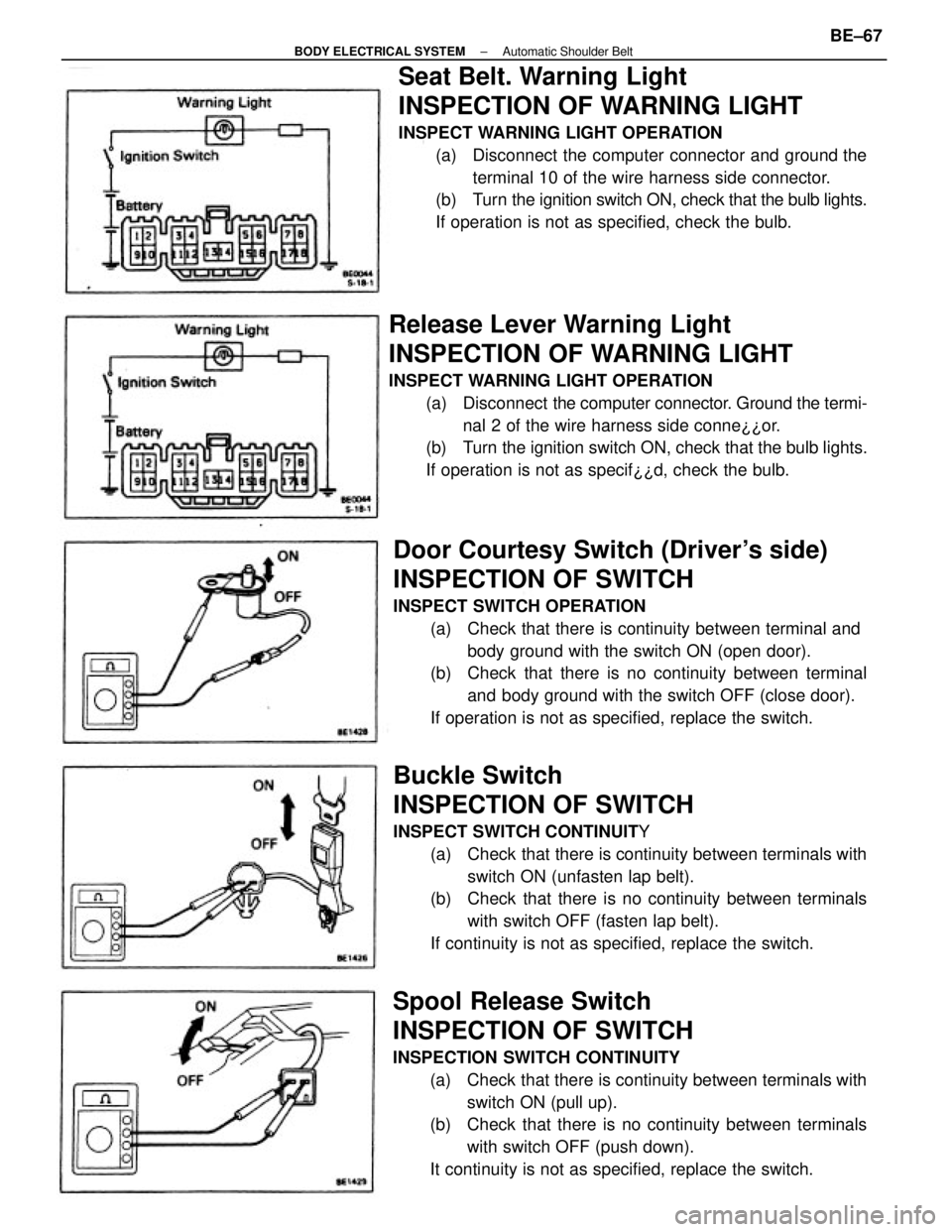

Seat Belt. Warning Light

INSPECTION OF WARNING LIGHT

INSPECT WARNING LIGHT OPERATION

(a) Disconnect the computer connector and ground the

terminal 10 of the wire harness side connector.

(b) Turn the ignition switch ON, check that the bulb lights.

If operation is not as specified, check the bulb.

Buckle Switch

INSPECTION OF SWITCH

INSPECT SWITCH CONTINUITY

(a) Check that there is continuity between terminals with

switch ON (unfasten lap belt).

(b) Check that there is no continuity between terminals

with switch OFF (fasten lap belt).

If continuity is not as specified, replace the switch.

Door Courtesy Switch (Driver's side)

INSPECTION OF SWITCH

INSPECT SWITCH OPERATION

(a) Check that there is continuity between terminal and

body ground with the switch ON (open door).

(b) Check that there is no continuity between terminal

and body ground with the switch OFF (close door).

If operation is not as specified, replace the switch.

Spool Release Switch

INSPECTION OF SWITCH

INSPECTION SWITCH CONTINUITY

(a) Check that there is continuity between terminals with

switch ON (pull up).

(b) Check that there is no continuity between terminals

with switch OFF (push down).

It continuity is not as specified, replace the switch.

Release Lever Warning Light

INSPECTION OF WARNING LIGHT

INSPECT WARNING LIGHT OPERATION

(a) Disconnect the computer connector. Ground the termi-

nal 2 of the wire harness side conne¿¿or.

(b) Turn the ignition switch ON, check that the bulb lights.

If operation is not as specif¿¿d, check the bulb.

± BODY ELECTRICAL SYSTEMAutomatic Shoulder BeltBE±67

Page 814 of 2389

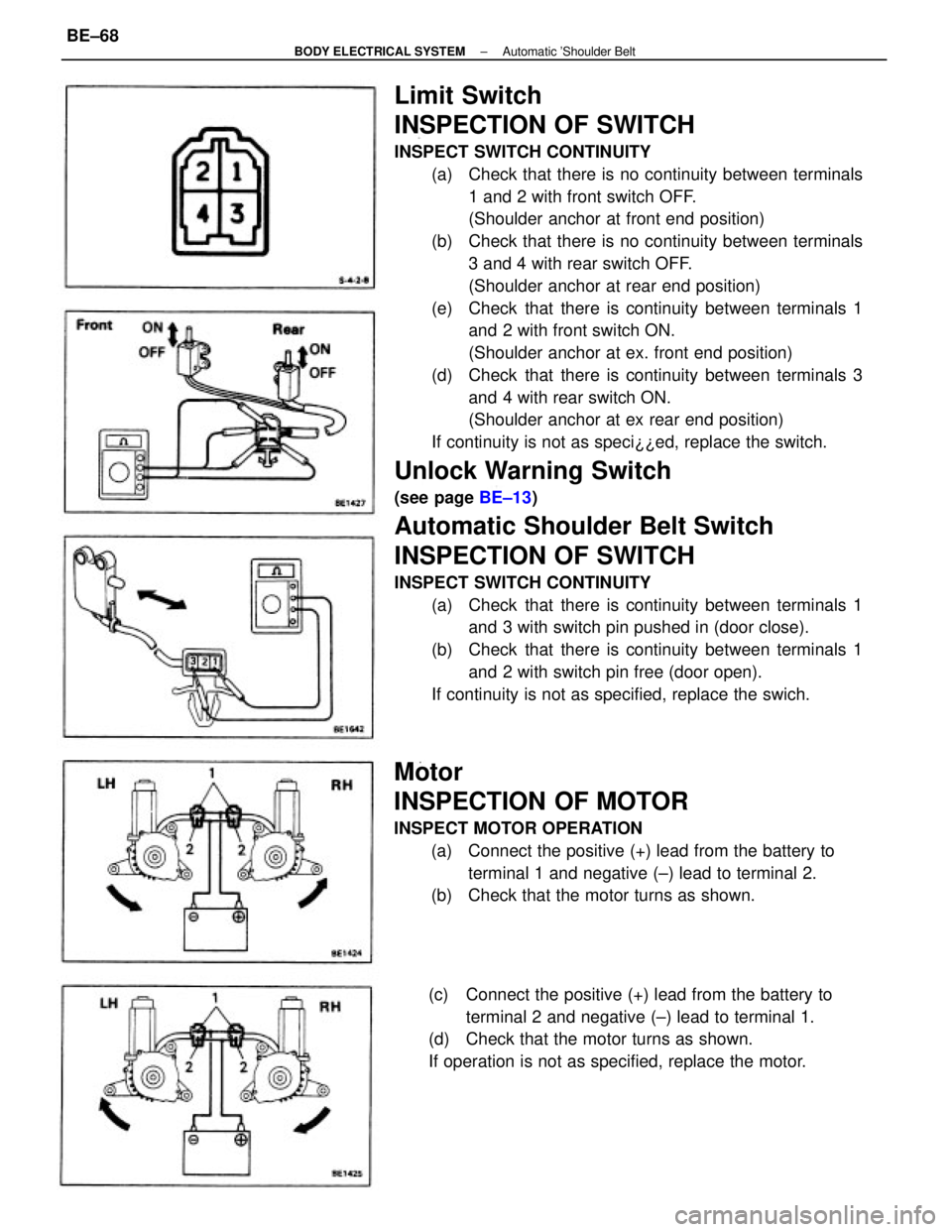

Limit Switch

INSPECTION OF SWITCH

INSPECT SWITCH CONTINUITY

(a) Check that there is no continuity between terminals

1 and 2 with front switch OFF.

(Shoulder anchor at front end position)

(b) Check that there is no continuity between terminals

3 and 4 with rear switch OFF.

(Shoulder anchor at rear end position)

(e) Check that there is continuity between terminals 1

and 2 with front switch ON.

(Shoulder anchor at ex. front end position)

(d) Check that there is continuity between terminals 3

and 4 with rear switch ON.

(Shoulder anchor at ex rear end position)

If continuity is not as speci¿¿ed, replace the switch.

Unlock Warning Switch

(see page BE±13)

Automatic Shoulder Belt Switch

INSPECTION OF SWITCH

INSPECT SWITCH CONTINUITY

(a) Check that there is continuity between terminals 1

and 3 with switch pin pushed in (door close).

(b) Check that there is continuity between terminals 1

and 2 with switch pin free (door open).

If continuity is not as specified, replace the swich.

Motor

INSPECTION OF MOTOR

INSPECT MOTOR OPERATION

(a) Connect the positive (+) lead from the battery to

terminal 1 and negative (±) lead to terminal 2.

(b) Check that the motor turns as shown.

(c) Connect the positive (+) lead from the battery to

terminal 2 and negative (±) lead to terminal 1.

(d) Check that the motor turns as shown.

If operation is not as specified, replace the motor.

± BODY ELECTRICAL SYSTEMAutomatic 'Shoulder BeltBE±68

Page 958 of 2389

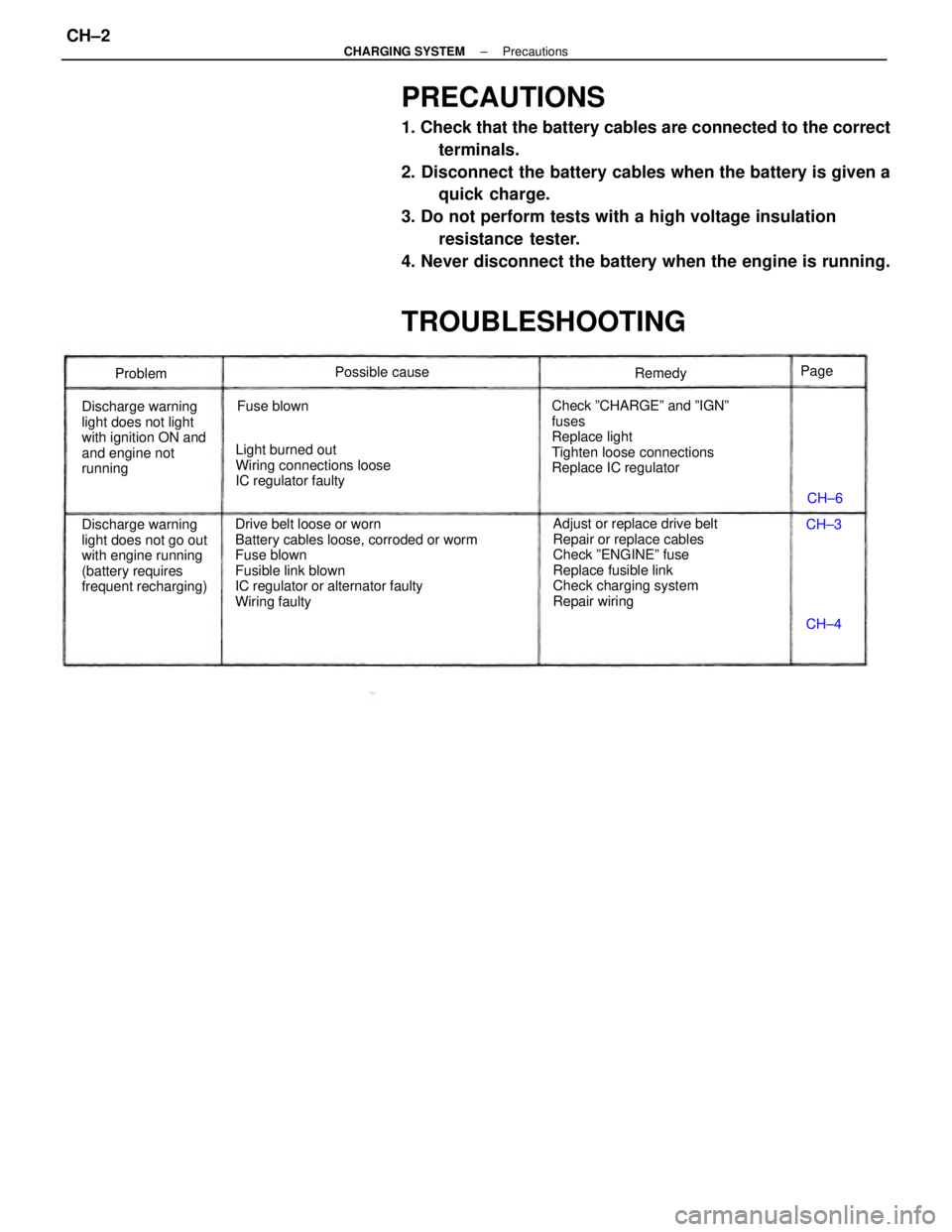

PRECAUTIONS

1. Check that the battery cables are connected to the correct

terminals.

2. Disconnect the battery cables when the battery is given a

quick charge.

3. Do not perform tests with a high voltage insulation

resistance tester.

4. Never disconnect the battery when the engine is running.

TROUBLESHOOTING

Drive belt loose or worn

Battery cables loose, corroded or worm

Fuse blown

Fusible link blown

IC regulator or alternator faulty

Wiring faultyAdjust or replace drive belt

Repair or replace cables

Check ºENGINEº fuse

Replace fusible link

Check charging system

Repair wiring Check ºCHARGEº and ºIGNº

fuses

Replace light

Tighten loose connections

Replace IC regulator

Discharge warning

light does not go out

with engine running

(battery requires

frequent recharging) Discharge warning

light does not light

with ignition ON and

and engine not

runningLight burned out

Wiring connections loose

IC regulator faultyPossible cause

Fuse blownRemedy

Problem

CH±6

CH±4 CH±3 Page

± CHARGING SYSTEMPrecautionsCH±2

Page 959 of 2389

PRECAUTIONS

1. Check that the battery cables are connected to the correct

terminals.

2. Disconnect the battery cables when the battery is given a

quick charge.

3. Do not perform tests with a high voltage insulation

resistance tester.

4. Never disconnect the battery when the engine is running.

TROUBLESHOOTING

Drive belt loose or worn

Battery cables loose, corroded or worm

Fuse blown

Fusible link blown

IC regulator or alternator faulty

Wiring faultyAdjust or replace drive belt

Repair or replace cables

Check ºENGINEº fuse

Replace fusible link

Check charging system

Repair wiring Check ºCHARGEº and ºIGNº

fuses

Replace light

Tighten loose connections

Replace IC regulator

Discharge warning

light does not go out

with engine running

(battery requires

frequent recharging) Discharge warning

light does not light

with ignition ON and

and engine not

runningLight burned out

Wiring connections loose

IC regulator faultyPossible cause

Fuse blownRemedy

Problem

CH±6

CH±4 CH±3 Page

± CHARGING SYSTEMTroubleshootingCH±2

Page 960 of 2389

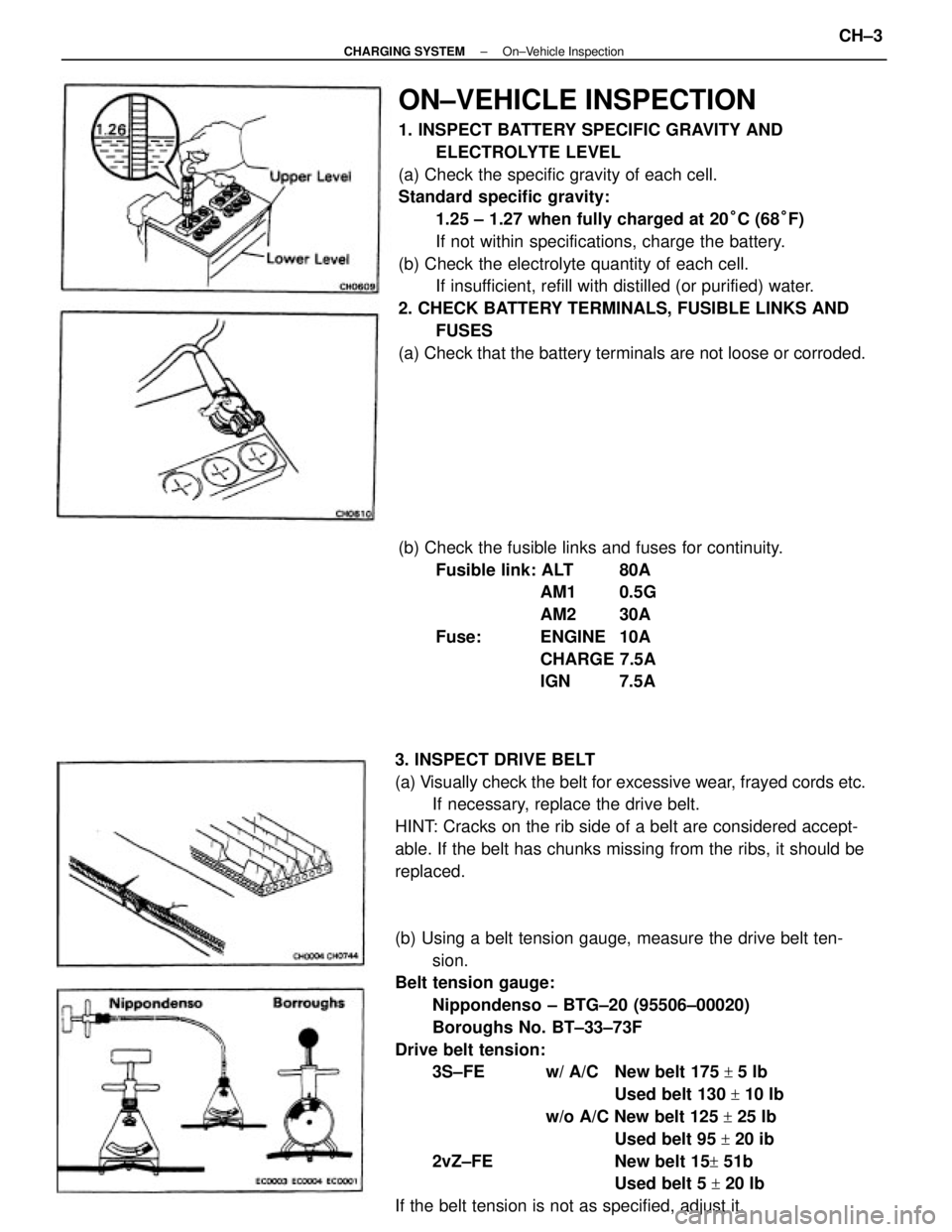

ON±VEHICLE INSPECTION

1. INSPECT BATTERY SPECIFIC GRAVITY AND

ELECTROLYTE LEVEL

(a) Check the specific gravity of each cell.

Standard specific gravity:

1.25 ± 1.27 when fully charged at 20°C (68°F)

If not within specifications, charge the battery.

(b) Check the electrolyte quantity of each cell.

If insufficient, refill with distilled (or purified) water.

2. CHECK BATTERY TERMINALS, FUSIBLE LINKS AND

FUSES

(a) Check that the battery terminals are not loose or corroded.

(b) Using a belt tension gauge, measure the drive belt ten-

sion.

Belt tension gauge:

Nippondenso ± BTG±20 (95506±00020)

Boroughs No. BT±33±73F

Drive belt tension:

3S±FE w/ A/C New belt 175

+ 5 Ib

Used belt 130

+ 10 Ib

w/o A/C New belt 125

+ 25 Ib

Used belt 95

+ 20 ib

2vZ±FE New belt 15

+ 51b

Used belt 5

+ 20 Ib

If the belt tension is not as specified, adjust it. 3. INSPECT DRIVE BELT

(a) Visually check the belt for excessive wear, frayed cords etc.

If necessary, replace the drive belt.

HINT: Cracks on the rib side of a belt are considered accept-

able. If the belt has chunks missing from the ribs, it should be

replaced.(b) Check the fusible links and fuses for continuity.

Fusible link: ALT 80A

AM1 0.5G

AM2 30A

Fuse: ENGINE 10A

CHARGE 7.5A

IGN 7.5A

± CHARGING SYSTEMOn±Vehicle InspectionCH±3

Page 961 of 2389

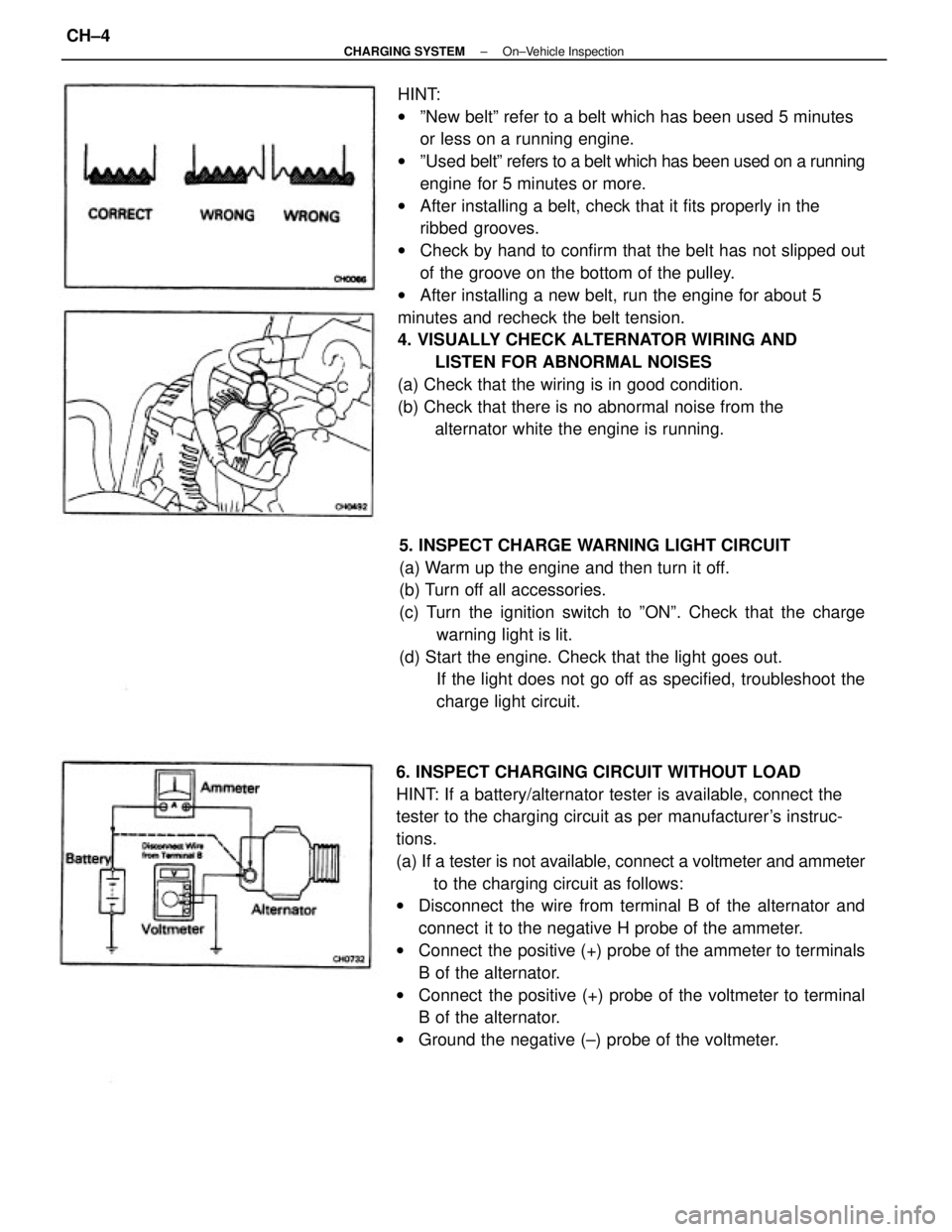

HINT:

wºNew beltº refer to a belt which has been used 5 minutes

or less on a running engine.

wºUsed beltº refers to a belt which has been used on a running

engine for 5 minutes or more.

wAfter installing a belt, check that it fits properly in the

ribbed grooves.

wCheck by hand to confirm that the belt has not slipped out

of the groove on the bottom of the pulley.

wAfter installing a new belt, run the engine for about 5

minutes and recheck the belt tension.

4. VISUALLY CHECK ALTERNATOR WIRING AND

LISTEN FOR ABNORMAL NOISES

(a) Check that the wiring is in good condition.

(b) Check that there is no abnormal noise from the

alternator white the engine is running.

6. INSPECT CHARGING CIRCUIT WITHOUT LOAD

HINT: If a battery/alternator tester is available, connect the

tester to the charging circuit as per manufacturer's instruc-

tions.

(a) If a tester is not available, connect a voltmeter and ammeter

to the charging circuit as follows:

wDisconnect the wire from terminal B of the alternator and

connect it to the negative H probe of the ammeter.

wConnect the positive (+) probe of the ammeter to terminals

B of the alternator.

wConnect the positive (+) probe of the voltmeter to terminal

B of the alternator.

wGround the negative (±) probe of the voltmeter. 5. INSPECT CHARGE WARNING LIGHT CIRCUIT

(a) Warm up the engine and then turn it off.

(b) Turn off all accessories.

(c) Turn the ignition switch to ºONº. Check that the charge

warning light is lit.

(d) Start the engine. Check that the light goes out.

If the light does not go off as specified, troubleshoot the

charge light circuit.

± CHARGING SYSTEMOn±Vehicle InspectionCH±4