panel TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 732 of 2389

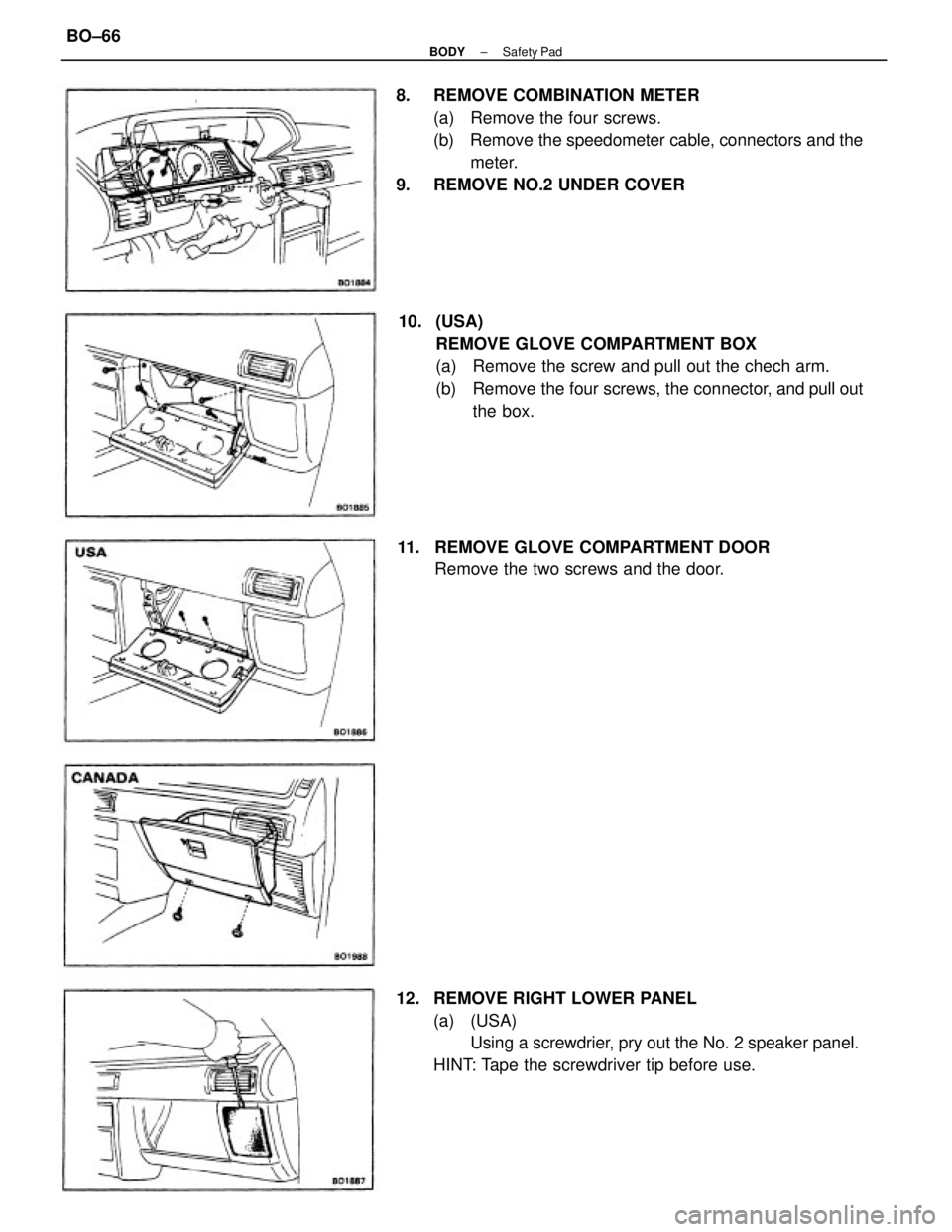

8. REMOVE COMBINATION METER

(a) Remove the four screws.

(b) Remove the speedometer cable, connectors and the

meter.

9. REMOVE NO.2 UNDER COVER

10. (USA)

REMOVE GLOVE COMPARTMENT BOX

(a) Remove the screw and pull out the chech arm.

(b) Remove the four screws, the connector, and pull out

the box.

12. REMOVE RIGHT LOWER PANEL

(a) (USA)

Using a screwdrier, pry out the No. 2 speaker panel.

HINT: Tape the screwdriver tip before use. 11. REMOVE GLOVE COMPARTMENT DOOR

Remove the two screws and the door.

± BODYSafety PadBO±66

Page 733 of 2389

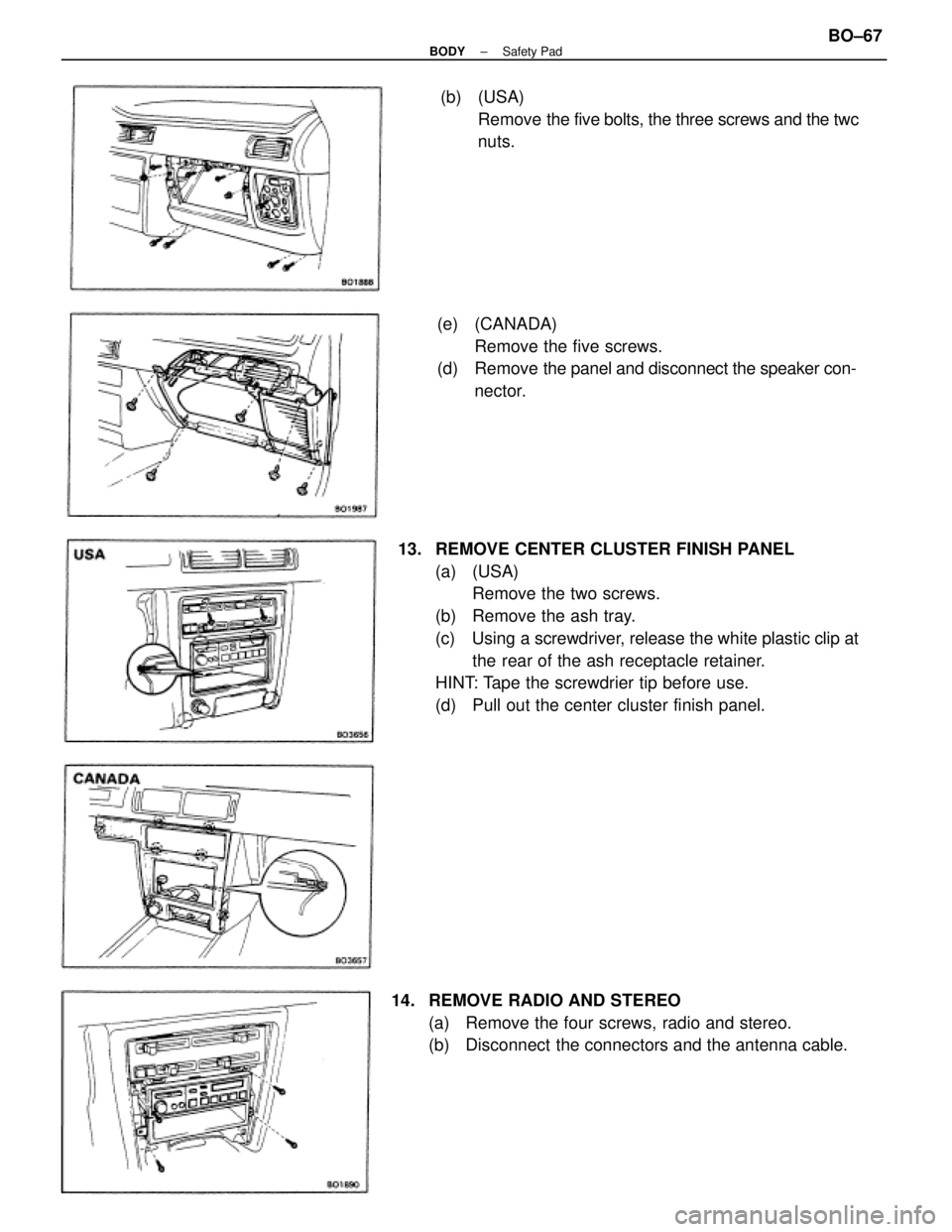

13. REMOVE CENTER CLUSTER FINISH PANEL

(a) (USA)

Remove the two screws.

(b) Remove the ash tray.

(c) Using a screwdriver, release the white plastic clip at

the rear of the ash receptacle retainer.

HINT: Tape the screwdrier tip before use.

(d) Pull out the center cluster finish panel.(e) (CANADA)

Remove the five screws.

(d) Remove the panel and disconnect the speaker con-

nector.

14. REMOVE RADIO AND STEREO

(a) Remove the four screws, radio and stereo.

(b) Disconnect the connectors and the antenna cable.(b) (USA)

Remove the five bolts, the three screws and the twc

nuts.

± BODYSafety PadBO±67

Page 734 of 2389

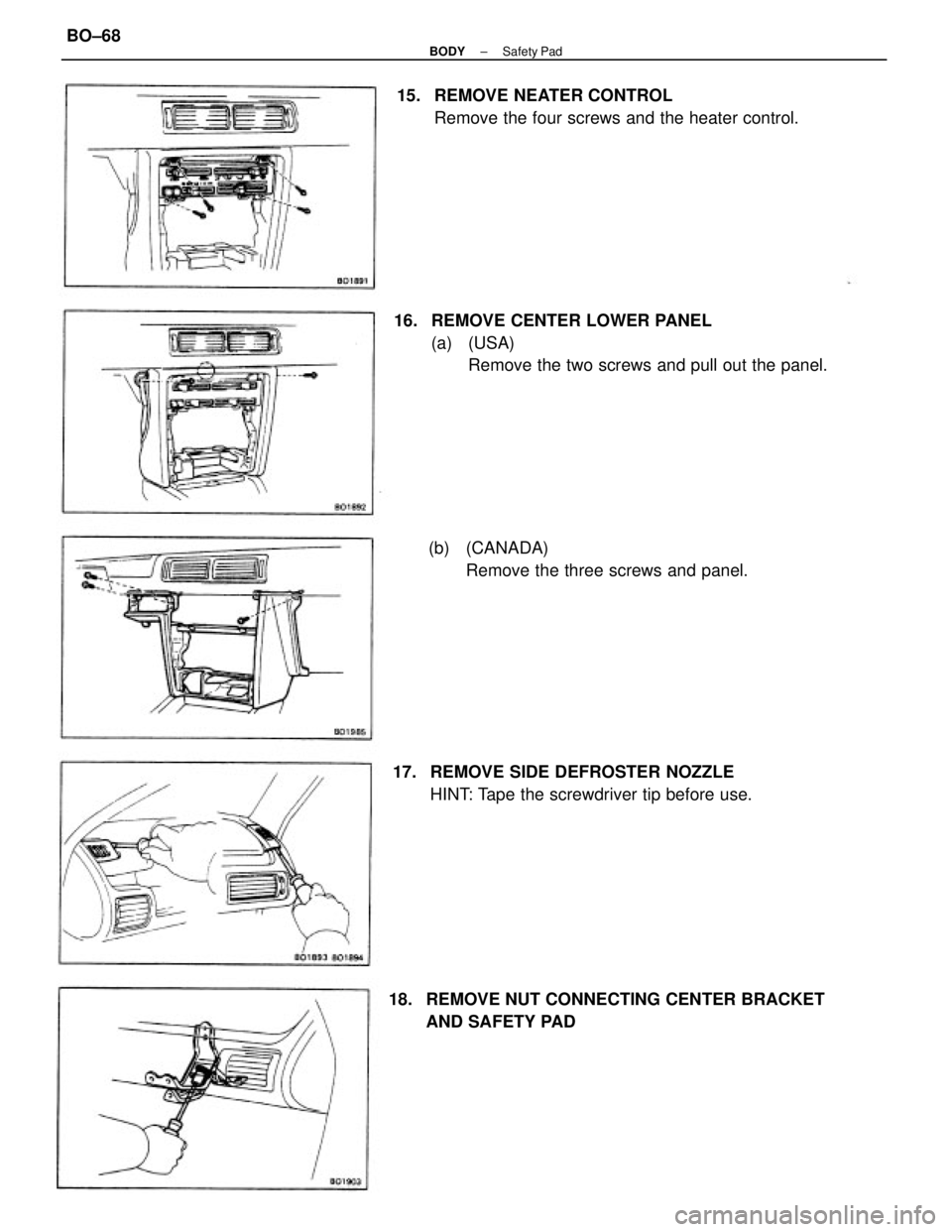

16. REMOVE CENTER LOWER PANEL

(a) (USA)

Remove the two screws and pull out the panel. 15. REMOVE NEATER CONTROL

Remove the four screws and the heater control.

18. REMOVE NUT CONNECTING CENTER BRACKET

AND SAFETY PAD 17. REMOVE SIDE DEFROSTER NOZZLE

HINT: Tape the screwdriver tip before use. (b) (CANADA)

Remove the three screws and panel.

± BODYSafety PadBO±68

Page 736 of 2389

21. REMOVE NO.1 HEATER REGISTER DUCT

Pry out the clip and remove the duct.

22. REMOVE NO.3 HEATER REGISTER DUCT

Remove the three screws and duct.

23. REMOVE DEFROSTER NOZZLE

Remove the five screws and nozzle.

24. REMOVE NO.1 INSTRUMENT PANEL REGISTER

Remove the two screws and register.

25. REMOVE NO.3 INSTRUMENT PANEL REGISTER

Remove the three screws and register.

26. REMOVE NO.2 INSTRUMENT PANEL REGISTER

Remove the screws and register.

27. REMOVE SAFETY PAD GARNISH

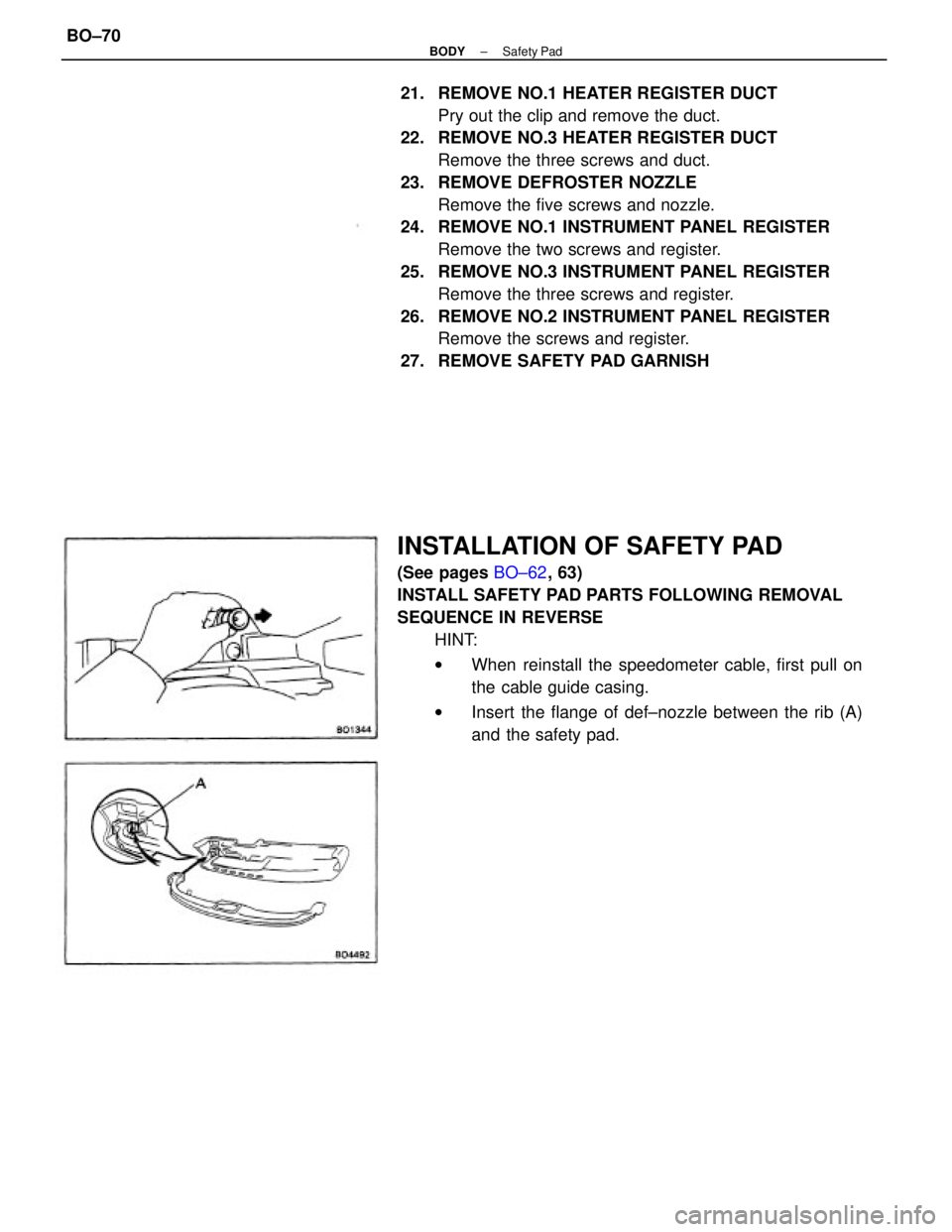

INSTALLATION OF SAFETY PAD

(See pages BO±62, 63)

INSTALL SAFETY PAD PARTS FOLLOWING REMOVAL

SEQUENCE IN REVERSE

HINT:

wWhen reinstall the speedometer cable, first pull on

the cable guide casing.

wInsert the flange of def±nozzle between the rib (A)

and the safety pad.

± BODYSafety PadBO±70

Page 741 of 2389

BODY DIMENSIONS

General Information

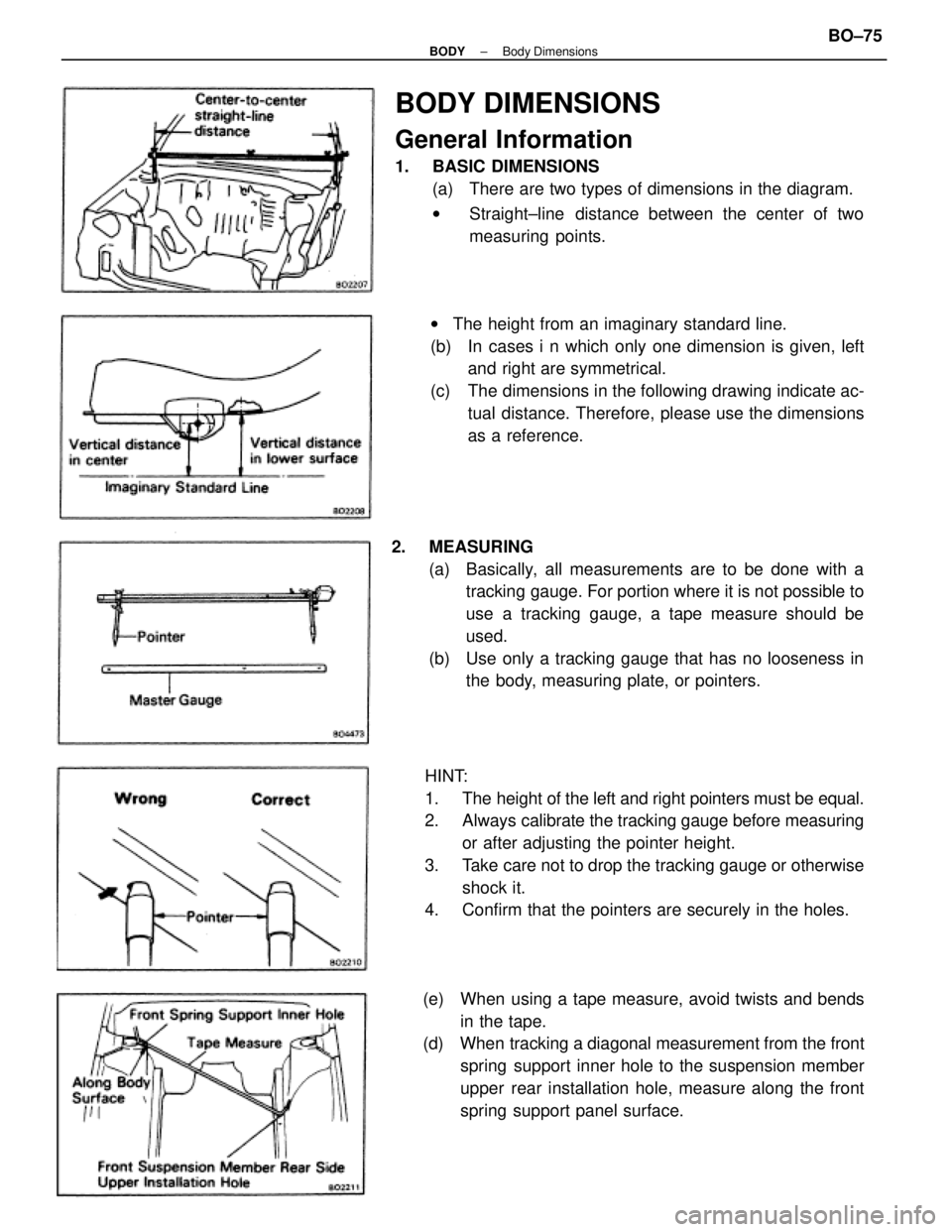

1. BASIC DIMENSIONS

(a) There are two types of dimensions in the diagram.

wStraight±line distance between the center of two

measuring points.

HINT:

1. The height of the left and right pointers must be equal.

2. Always calibrate the tracking gauge before measuring

or after adjusting the pointer height.

3. Take care not to drop the tracking gauge or otherwise

shock it.

4. Confirm that the pointers are securely in the holes. 2. MEASURING

(a) Basically, all measurements are to be done with a

tracking gauge. For portion where it is not possible to

use a tracking gauge, a tape measure should be

used.

(b) Use only a tracking gauge that has no looseness in

the body, measuring plate, or pointers. wThe height from an imaginary standard line.

(b) In cases i n which only one dimension is given, left

and right are symmetrical.

(c) The dimensions in the following drawing indicate ac-

tual distance. Therefore, please use the dimensions

as a reference.

(e) When using a tape measure, avoid twists and bends

in the tape.

(d) When tracking a diagonal measurement from the front

spring support inner hole to the suspension member

upper rear installation hole, measure along the front

spring support panel surface.

± BODYBody DimensionsBO±75

Page 742 of 2389

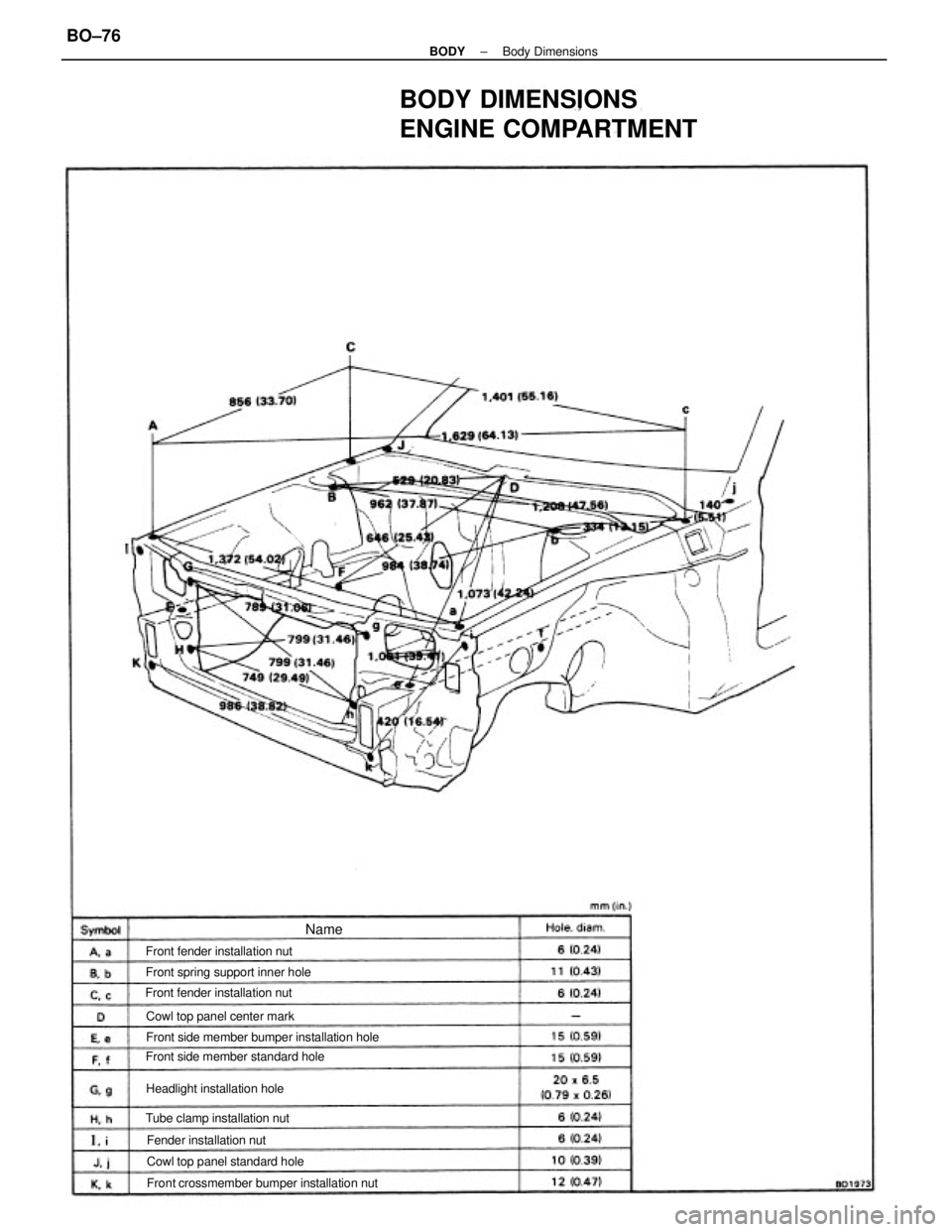

BODY DIMENSIONS

ENGINE COMPARTMENT

Front crossmember bumper installation nut Front side member bumper installation hole

Front side member standard hole Front spring support inner hole

Cowl top panel standard hole Cowl top panel center mark

Tube clamp installation nut Front fender installation nut

Headlight installation hole Front fender installation nut

Fender installation nut

Name

± BODYBody DimensionsBO±76

Page 757 of 2389

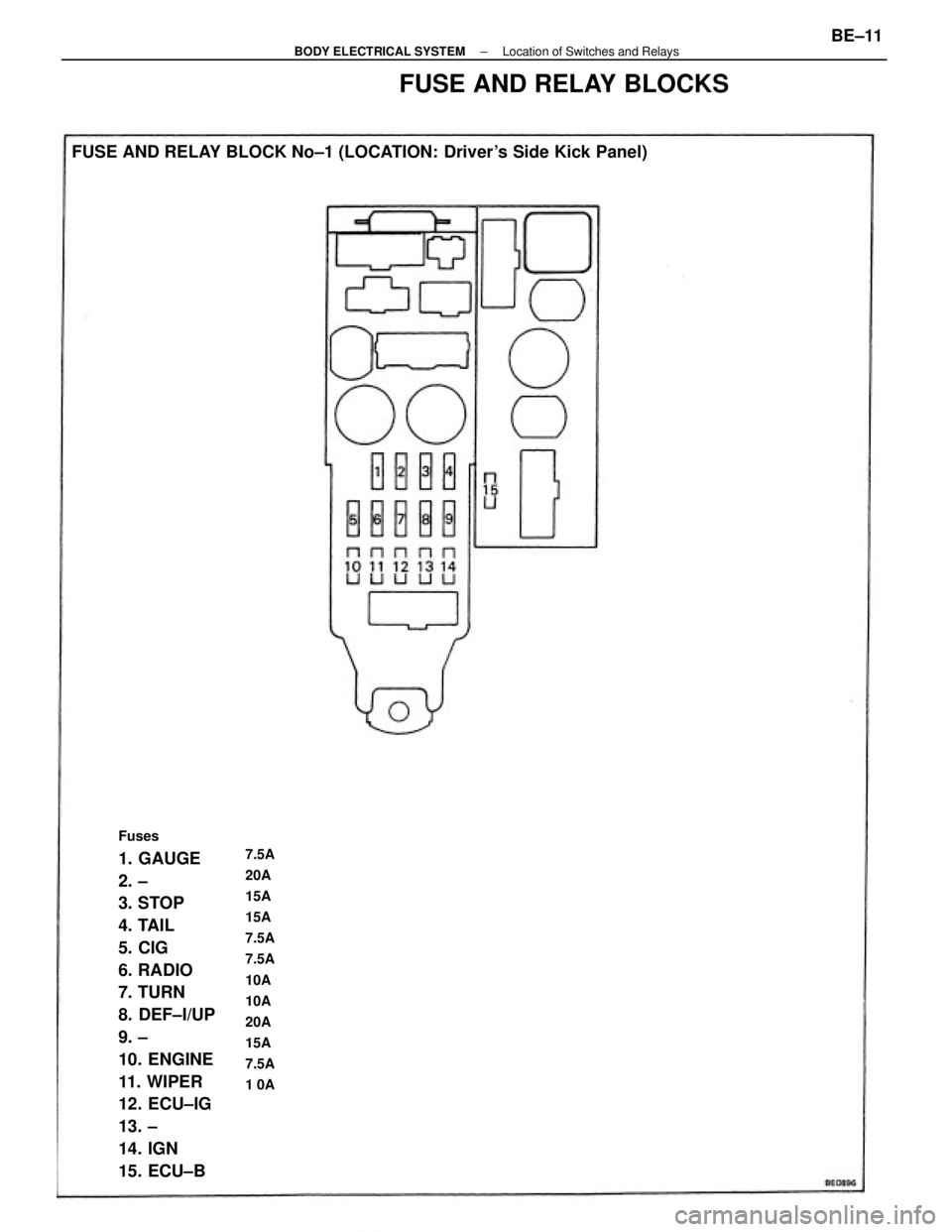

Fuses

1. GAUGE

2. ±

3. STOP

4. TAIL

5. CIG

6. RADIO

7. TURN

8. DEF±I/UP

9. ±

10. ENGINE

11. WIPER

12. ECU±IG

13. ±

14. IGN

15. ECU±B FUSE AND RELAY BLOCK No±1 (LOCATION: Driver's Side Kick Panel)7.5A

20A

15A

15A

7.5A

7.5A

10A

10A

20A

15A

7.5A

1 0A

FUSE AND RELAY BLOCKS

± BODY ELECTRICAL SYSTEMLocation of Switches and RelaysBE±11

Page 857 of 2389

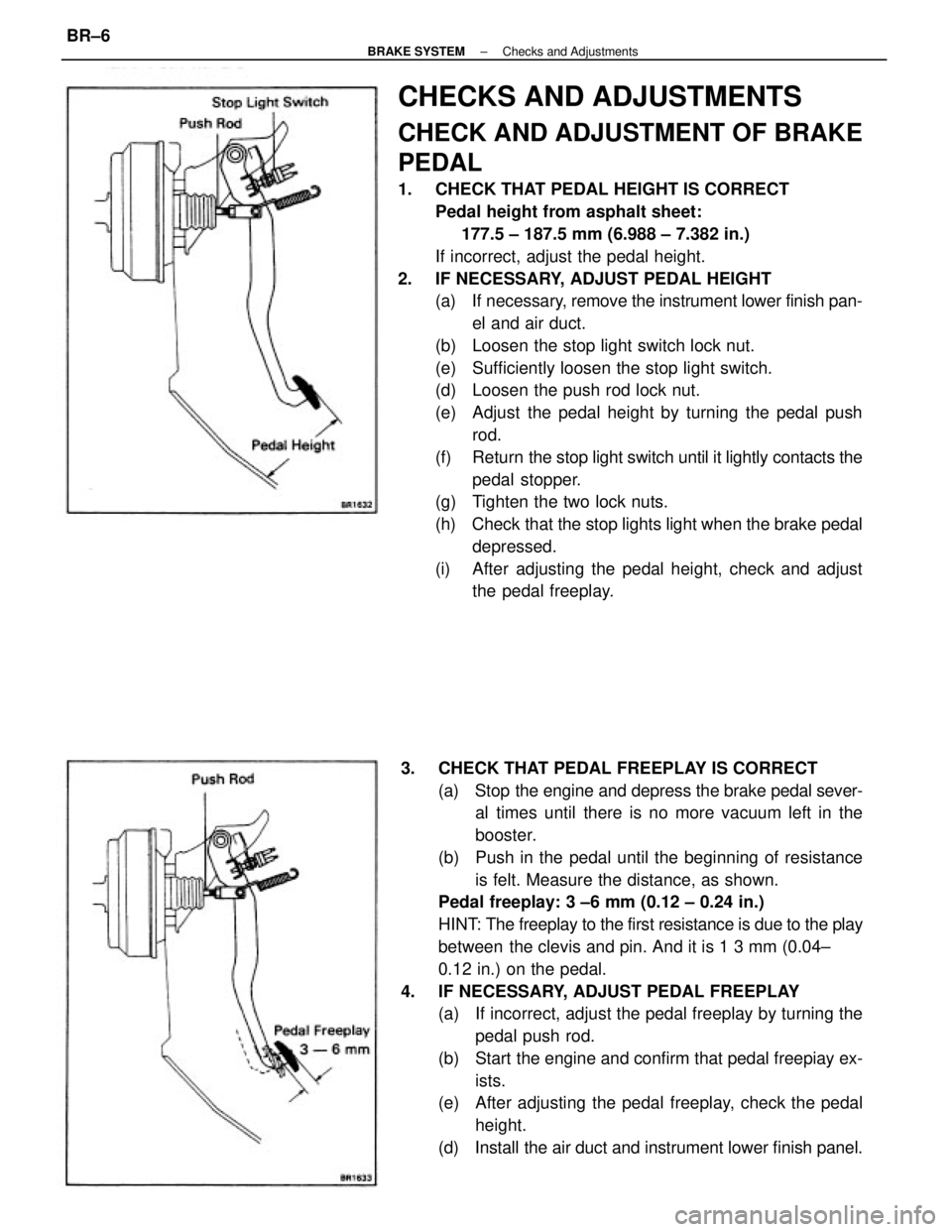

CHECKS AND ADJUSTMENTS

CHECK AND ADJUSTMENT OF BRAKE

PEDAL

1. CHECK THAT PEDAL HEIGHT IS CORRECT

Pedal height from asphalt sheet:

177.5 ± 187.5 mm (6.988 ± 7.382 in.)

If incorrect, adjust the pedal height.

2. IF NECESSARY, ADJUST PEDAL HEIGHT

(a) If necessary, remove the instrument lower finish pan-

el and air duct.

(b) Loosen the stop light switch lock nut.

(e) Sufficiently loosen the stop light switch.

(d) Loosen the push rod lock nut.

(e) Adjust the pedal height by turning the pedal push

rod.

(f) Return the stop light switch until it lightly contacts the

pedal stopper.

(g) Tighten the two lock nuts.

(h) Check that the stop lights light when the brake pedal

depressed.

(i) After adjusting the pedal height, check and adjust

the pedal freeplay.

3. CHECK THAT PEDAL FREEPLAY IS CORRECT

(a) Stop the engine and depress the brake pedal sever-

al times until there is no more vacuum left in the

booster.

(b) Push in the pedal until the beginning of resistance

is felt. Measure the distance, as shown.

Pedal freeplay: 3 ±6 mm (0.12 ± 0.24 in.)

HINT: The freeplay to the first resistance is due to the play

between the clevis and pin. And it is 1 3 mm (0.04±

0.12 in.) on the pedal.

4. IF NECESSARY, ADJUST PEDAL FREEPLAY

(a) If incorrect, adjust the pedal freeplay by turning the

pedal push rod.

(b) Start the engine and confirm that pedal freepiay ex-

ists.

(e) After adjusting the pedal freeplay, check the pedal

height.

(d) Install the air duct and instrument lower finish panel.

± BRAKE SYSTEMChecks and AdjustmentsBR±6

Page 867 of 2389

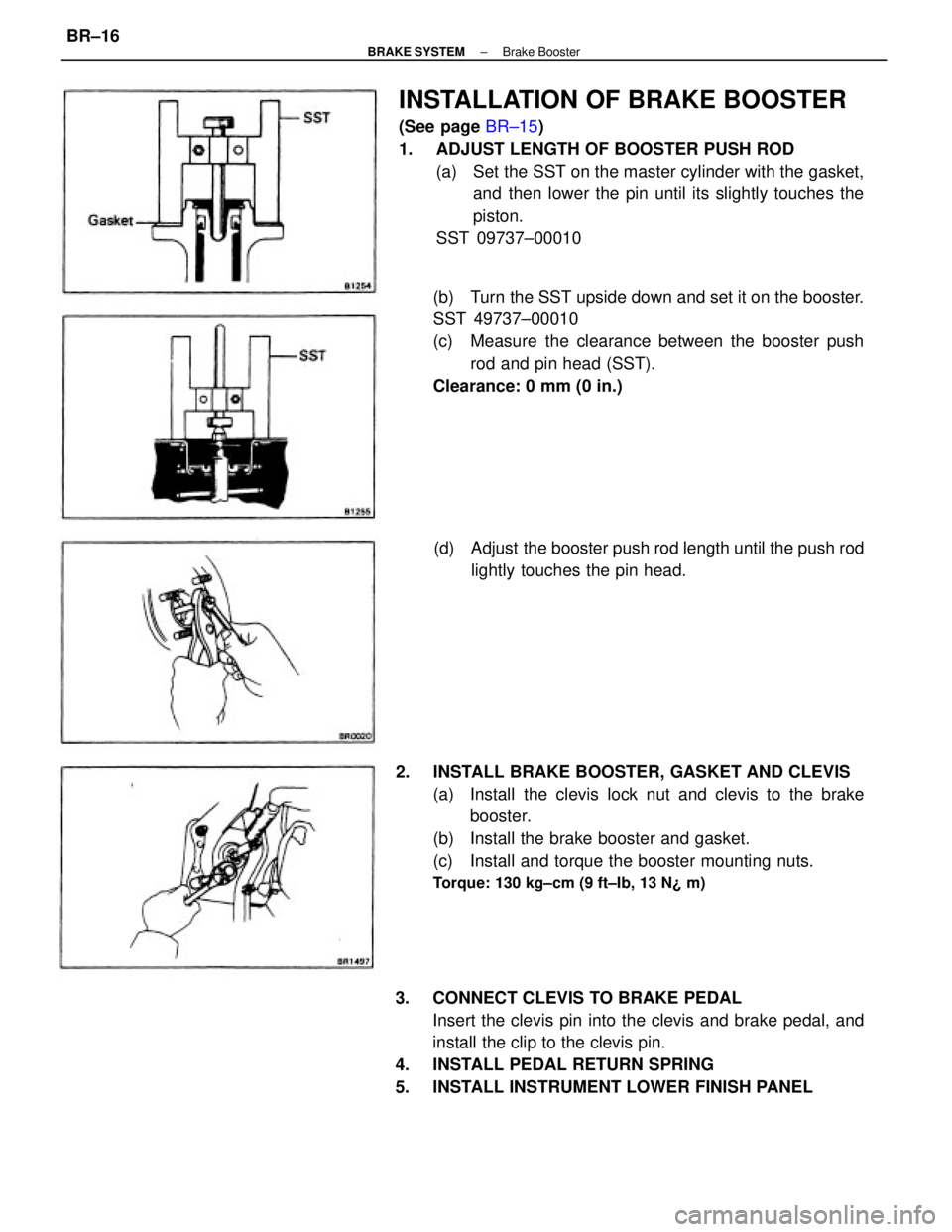

INSTALLATION OF BRAKE BOOSTER

(See page BR±15)

1. ADJUST LENGTH OF BOOSTER PUSH ROD

(a) Set the SST on the master cylinder with the gasket,

and then lower the pin until its slightly touches the

piston.

SST 09737±00010

3. CONNECT CLEVIS TO BRAKE PEDAL

Insert the clevis pin into the clevis and brake pedal, and

install the clip to the clevis pin.

4. INSTALL PEDAL RETURN SPRING

5. INSTALL INSTRUMENT LOWER FINISH PANEL(b) Turn the SST upside down and set it on the booster.

SST 49737±00010

(c) Measure the clearance between the booster push

rod and pin head (SST).

Clearance: 0 mm (0 in.)

2. INSTALL BRAKE BOOSTER, GASKET AND CLEVIS

(a) Install the clevis lock nut and clevis to the brake

booster.

(b) Install the brake booster and gasket.

(c) Install and torque the booster mounting nuts.

Torque: 130 kg±cm (9 ft±Ib, 13 N¿ m)

(d) Adjust the booster push rod length until the push rod

lightly touches the pin head.

± BRAKE SYSTEMBrake BoosterBR±16

Page 976 of 2389

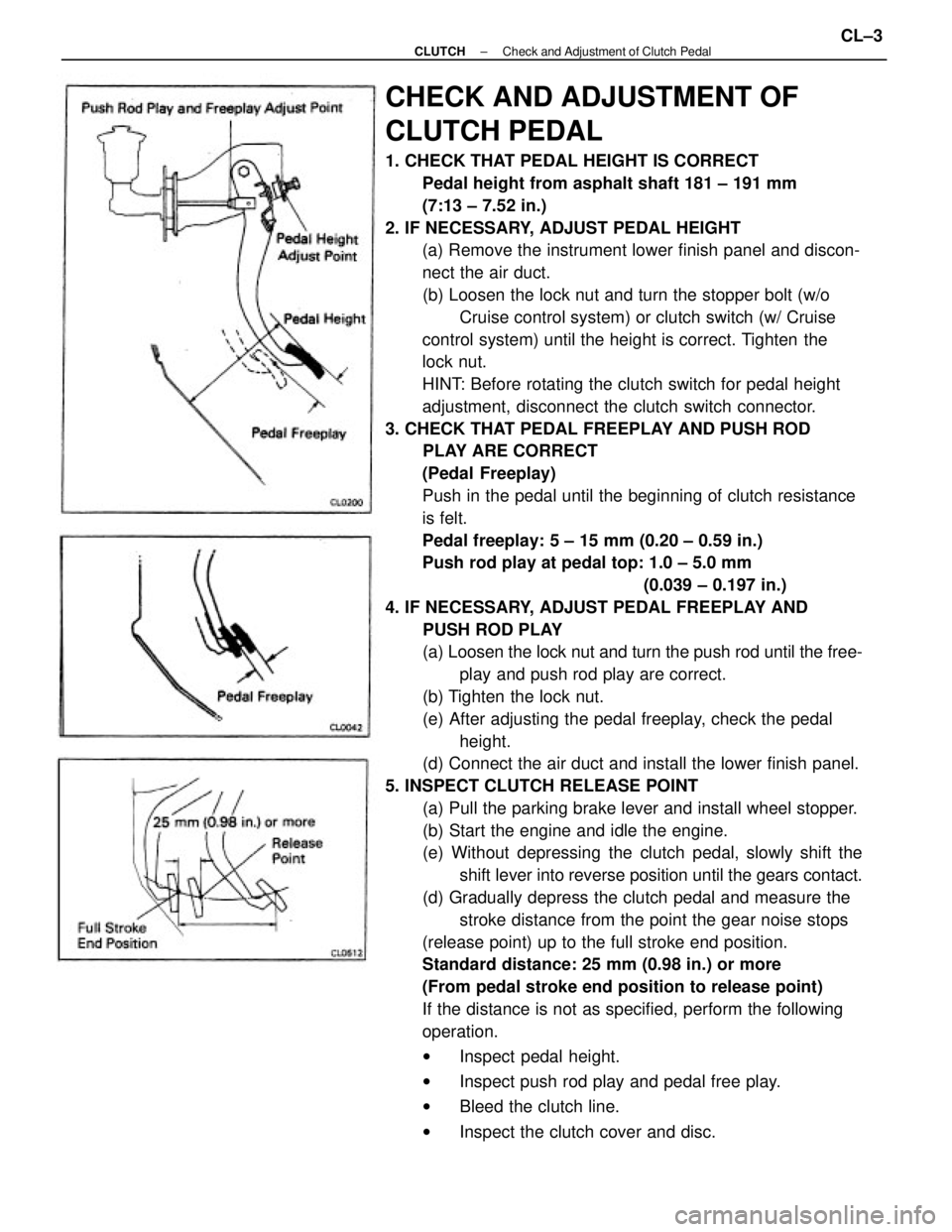

CHECK AND ADJUSTMENT OF

CLUTCH PEDAL

1. CHECK THAT PEDAL HEIGHT IS CORRECT

Pedal height from asphalt shaft 181 ± 191 mm

(7:13 ± 7.52 in.)

2. IF NECESSARY, ADJUST PEDAL HEIGHT

(a) Remove the instrument lower finish panel and discon-

nect the air duct.

(b) Loosen the lock nut and turn the stopper bolt (w/o

Cruise control system) or clutch switch (w/ Cruise

control system) until the height is correct. Tighten the

lock nut.

HINT: Before rotating the clutch switch for pedal height

adjustment, disconnect the clutch switch connector.

3. CHECK THAT PEDAL FREEPLAY AND PUSH ROD

PLAY ARE CORRECT

(Pedal Freeplay)

Push in the pedal until the beginning of clutch resistance

is felt.

Pedal freeplay: 5 ± 15 mm (0.20 ± 0.59 in.)

Push rod play at pedal top: 1.0 ± 5.0 mm

(0.039 ± 0.197 in.)

4. IF NECESSARY, ADJUST PEDAL FREEPLAY AND

PUSH ROD PLAY

(a) Loosen the lock nut and turn the push rod until the free-

play and push rod play are correct.

(b) Tighten the lock nut.

(e) After adjusting the pedal freeplay, check the pedal

height.

(d) Connect the air duct and install the lower finish panel.

5. INSPECT CLUTCH RELEASE POINT

(a) Pull the parking brake lever and install wheel stopper.

(b) Start the engine and idle the engine.

(e) Without depressing the clutch pedal, slowly shift the

shift lever into reverse position until the gears contact.

(d) Gradually depress the clutch pedal and measure the

stroke distance from the point the gear noise stops

(release point) up to the full stroke end position.

Standard distance: 25 mm (0.98 in.) or more

(From pedal stroke end position to release point)

If the distance is not as specified, perform the following

operation.

wInspect pedal height.

wInspect push rod play and pedal free play.

wBleed the clutch line.

wInspect the clutch cover and disc.

± CLUTCHCheck and Adjustment of Clutch PedalCL±3