panel TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 979 of 2389

REMOVAL OF MASTER CYLINDER

1. DRAW OUT FLUID WITH SYRINGE

2. DISCONNECT CLUTCH LINE TUBE

3. REMOVE INSTRUMENT LOWER FINISH PANEL

Remove the lower instrument lower finish panel and disconnect

the air duct from the instrument lower finish panel.

4. REMOVE CLEVIS PIN AND CLIP WITH SPRING

WASHER

Remove the clip and clevis pin with the spring washer.

5. REMOVE MOUNTING NUTS AND PULL OUT MASTER

CYLINDER

DISASSEMBLY OF MASTER CYLINDER

1. REMOVE RESERVOIR TANK

2. REMOVE PUSH ROD AND PISTON

(a) Pull back the boot and, using snap ring pliers, remove the snap

ring.

(b) Pull out the push rod.

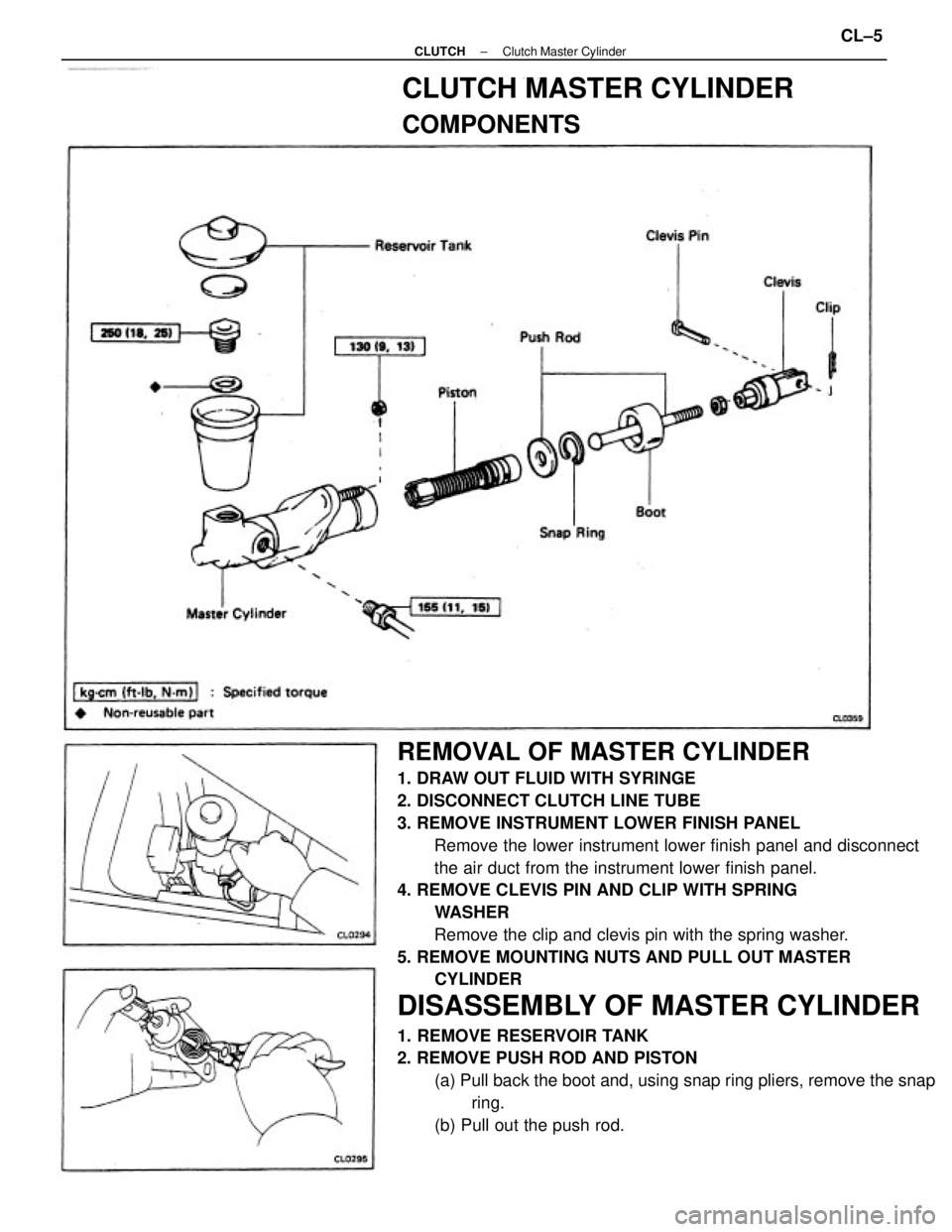

CLUTCH MASTER CYLINDER

COMPONENTS

± CLUTCHClutch Master CylinderCL±5

Page 980 of 2389

INSPECTION OF MASTER CYLINDER

HINT: Clean the disassembled parts with compressed air.

1. INSPECT MASTER CYLINDER BORE FOR SCORING

OR CORROSION

If a problem is found, clean or replace the cylinder.

2. INSPECT PISTON AND CUPS FOR WEAR, SCORING,

CRACKS OR SWELLING

If either one requires replacement, use the parts from the

cylinder kit.

3. INSPECT PUSH ROD FOR WEAR OR DAMAGE

If necessary, replace the push rod.

ASSEMBLY OF MASTER CYLINDER

(See page CL±5)

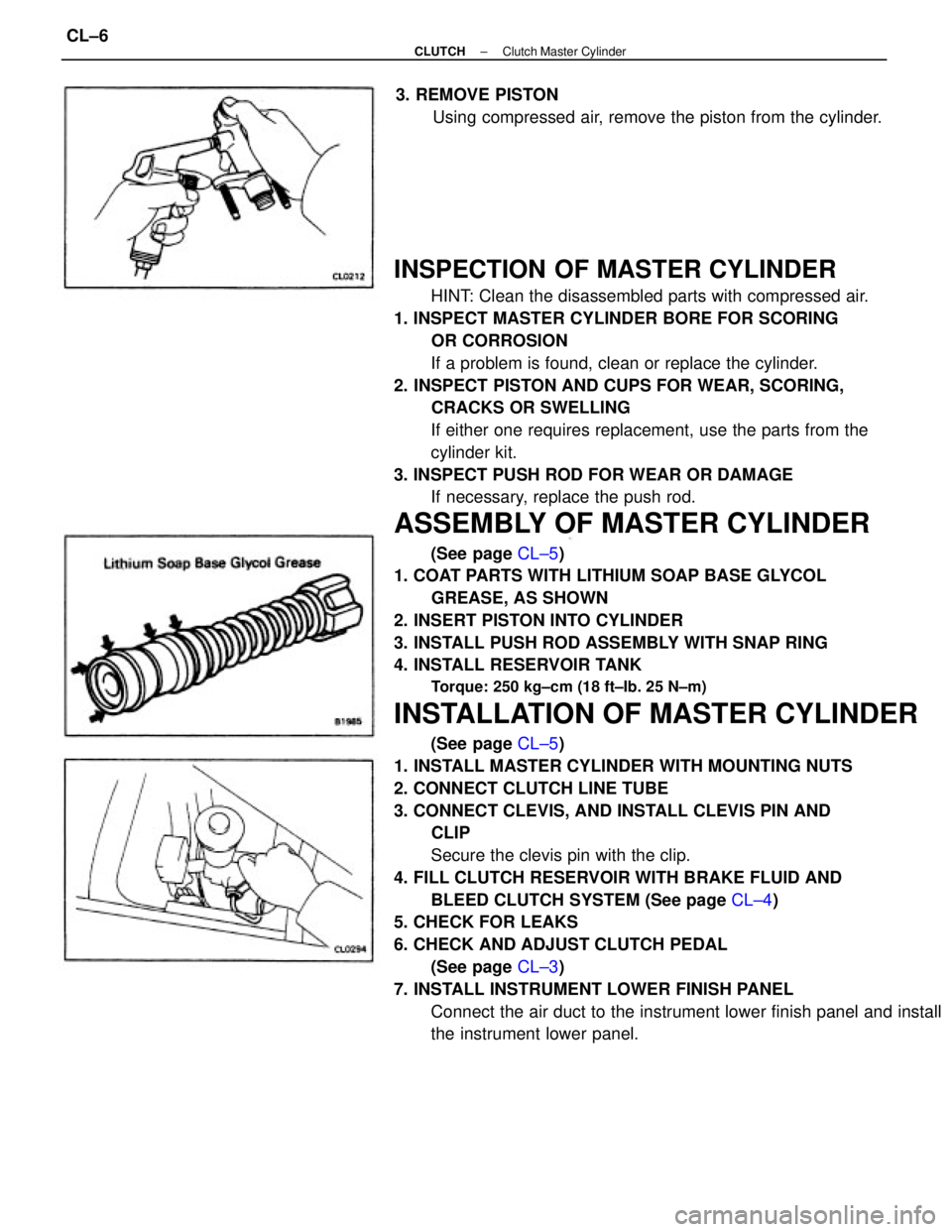

1. COAT PARTS WITH LITHIUM SOAP BASE GLYCOL

GREASE, AS SHOWN

2. INSERT PISTON INTO CYLINDER

3. INSTALL PUSH ROD ASSEMBLY WITH SNAP RING

4. INSTALL RESERVOIR TANK

Torque: 250 kg±cm (18 ft±Ib. 25 N±m)

INSTALLATION OF MASTER CYLINDER

(See page CL±5)

1. INSTALL MASTER CYLINDER WITH MOUNTING NUTS

2. CONNECT CLUTCH LINE TUBE

3. CONNECT CLEVIS, AND INSTALL CLEVIS PIN AND

CLIP

Secure the clevis pin with the clip.

4. FILL CLUTCH RESERVOIR WITH BRAKE FLUID AND

BLEED CLUTCH SYSTEM (See page CL±4)

5. CHECK FOR LEAKS

6. CHECK AND ADJUST CLUTCH PEDAL

(See page CL±3)

7. INSTALL INSTRUMENT LOWER FINISH PANEL

Connect the air duct to the instrument lower finish panel and install

the instrument lower panel. 3. REMOVE PISTON

Using compressed air, remove the piston from the cylinder.

± CLUTCHClutch Master CylinderCL±6

Page 1017 of 2389

The ER system is composed of there basic sub±systems: Fuel, Air Induction and Electronic Control Systems.

FUEL SYSTEM

Fuel is supplied under constant pressure to the EFI injectors by an electric fuel pump. The injectors inject a

metered quantity of fuel into the intake manifold in a accordance with signals from the ECU (Electronic Control

Unit).

AIR INDUCTION SYSTEM

The air induction system provides sufficient air for engine operation.

ELECTRONIC CONTROL SYSTEM

The Camry 3S±FE and 2V1±FE engines are equipped with a Toyota Computer Control System (TCCS) which

centrally controls the EFI, ESA, ISC, Diagnosis systems etc. by means of an Electronic Control Unit (ECU±

formerly ER computer) employing a microcomputer.

By means of the ECU, the TCCS controls the following functions:

1. Electronic Fuel Injection (EFI)

The ECU receives signals from various sensors indicating changing engine operation conditions such as:

Intake air volume

Intake air temperature

Coolant temperature

Engine rpm

Acceleration/deceleration

Exhaust oxygen content etc.

The signals are utilized by the ECU to determine the injection duration necessary for an optimum air±fuel ratio.

2. Electronic Spark Advance (ESA)

The ECU is programmed with data for optimum ignition timing under any and all operating conditions.

Using data provided by sensors which monitor various engine functions (rpm, coolant temperature, etc.), the

microcomputer (ECU) triggers the spark at precisely the right instant. (See IG section)

3. Idle Speed Control (ISC)

The ECU is programmed with target idling speed values to respond to different engine conditions (coolant

temperature, air conditioner ON/OFF, etc.). Sensors transmit signals to the ECU which control the flow of air

through the by±pass of the throttle valve and adjust idle speed to the target value. (See page FI±45,115

or 62, 117)

4. Diagnosis

The ECU detects any malfunctions or abnormalities in the sensor network and lights a ºCHECKº engine warn-

ing light on the instrument panel. At the same time, the trouble is identified and a diagnosis code is recorded

by the ECU. The diagnosis code can be read by the number of blinks of the ºCHECKº engine warning light

when terminals TE1 and E1 are connected. The diagnostic codes are refer to the later page.

(See page FI±25 or 27)

5. Fail±safe Function

In the event of the sensor malfunctioning, a back±up circuit will take over to provide minimal drivability, and

the ºCHECKº engine warning light.

± EFI SYSTEMSystem DescriptionFI±4

Page 1036 of 2389

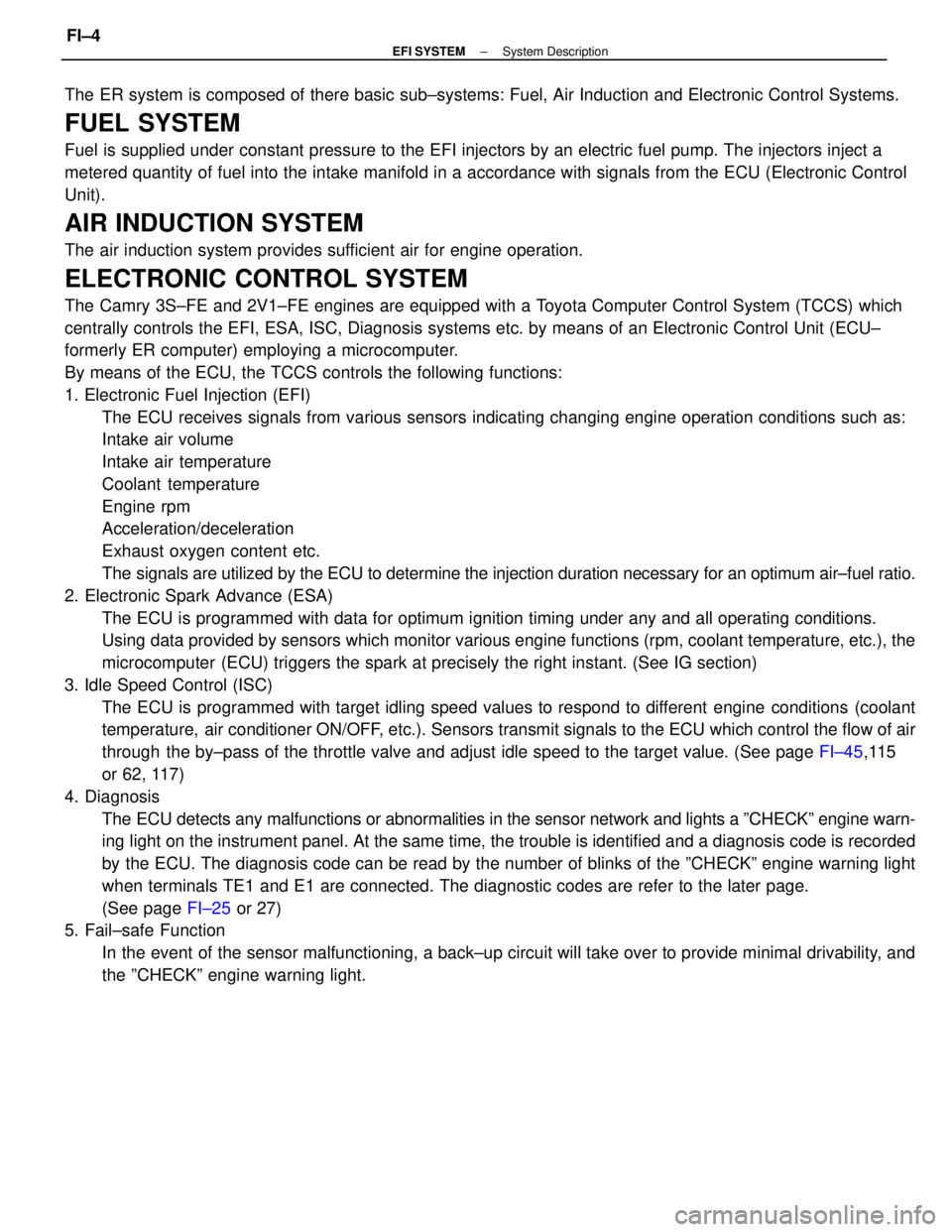

DIAGNOSIS SYSTEM

DESCRIPTION

The ECU contains a built±in, self±diagnosis system which de-

tects troubles within the engine signal network and then flashed

a

warning on the ºCHECKº engine warning light on the instrument

panel flashes.

By analyzing various signals shown in the tables (See pages FI±

25 or 27) the ECU detects system malfunctions which are re-

lated to the various operating parameter sensors or actuator.

The ECU

stores the failure code associated with the detected failure until

the diagnosis system is cleared by removing the EFI fuse with

the ignition switch OFF.

A ºCHECKº engine warning light on the instrument panel informs

the driver that a malfunction has been detected.

The light goes oft automatically when the malfunction has been

cleared.

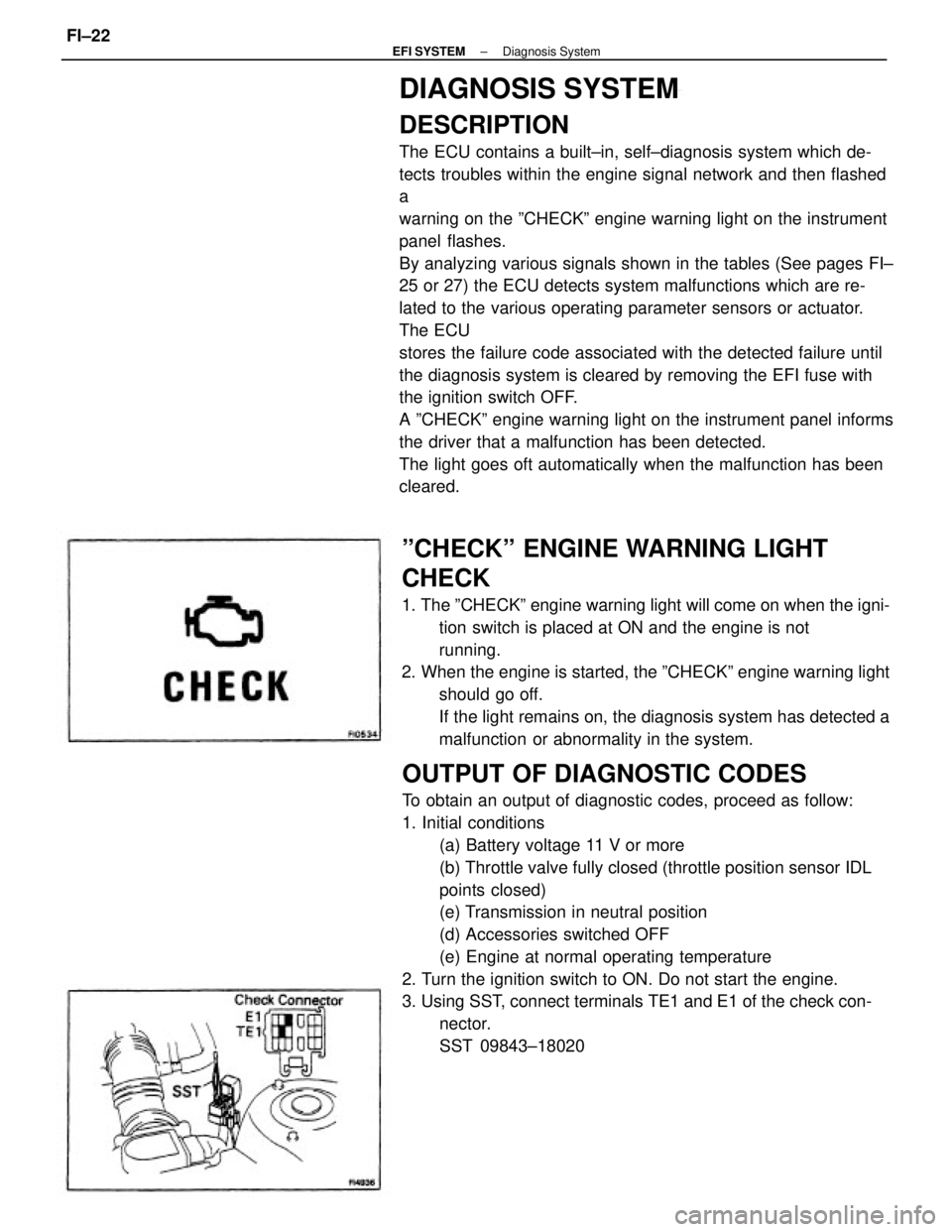

OUTPUT OF DIAGNOSTIC CODES

To obtain an output of diagnostic codes, proceed as follow:

1. Initial conditions

(a) Battery voltage 11 V or more

(b) Throttle valve fully closed (throttle position sensor IDL

points closed)

(e) Transmission in neutral position

(d) Accessories switched OFF

(e) Engine at normal operating temperature

2. Turn the ignition switch to ON. Do not start the engine.

3. Using SST, connect terminals TE1 and E1 of the check con-

nector.

SST 09843±18020

ºCHECKº ENGINE WARNING LIGHT

CHECK

1. The ºCHECKº engine warning light will come on when the igni-

tion switch is placed at ON and the engine is not

running.

2. When the engine is started, the ºCHECKº engine warning light

should go off.

If the light remains on, the diagnosis system has detected a

malfunction or abnormality in the system.

± EFI SYSTEMDiagnosis SystemFI±22

Page 1038 of 2389

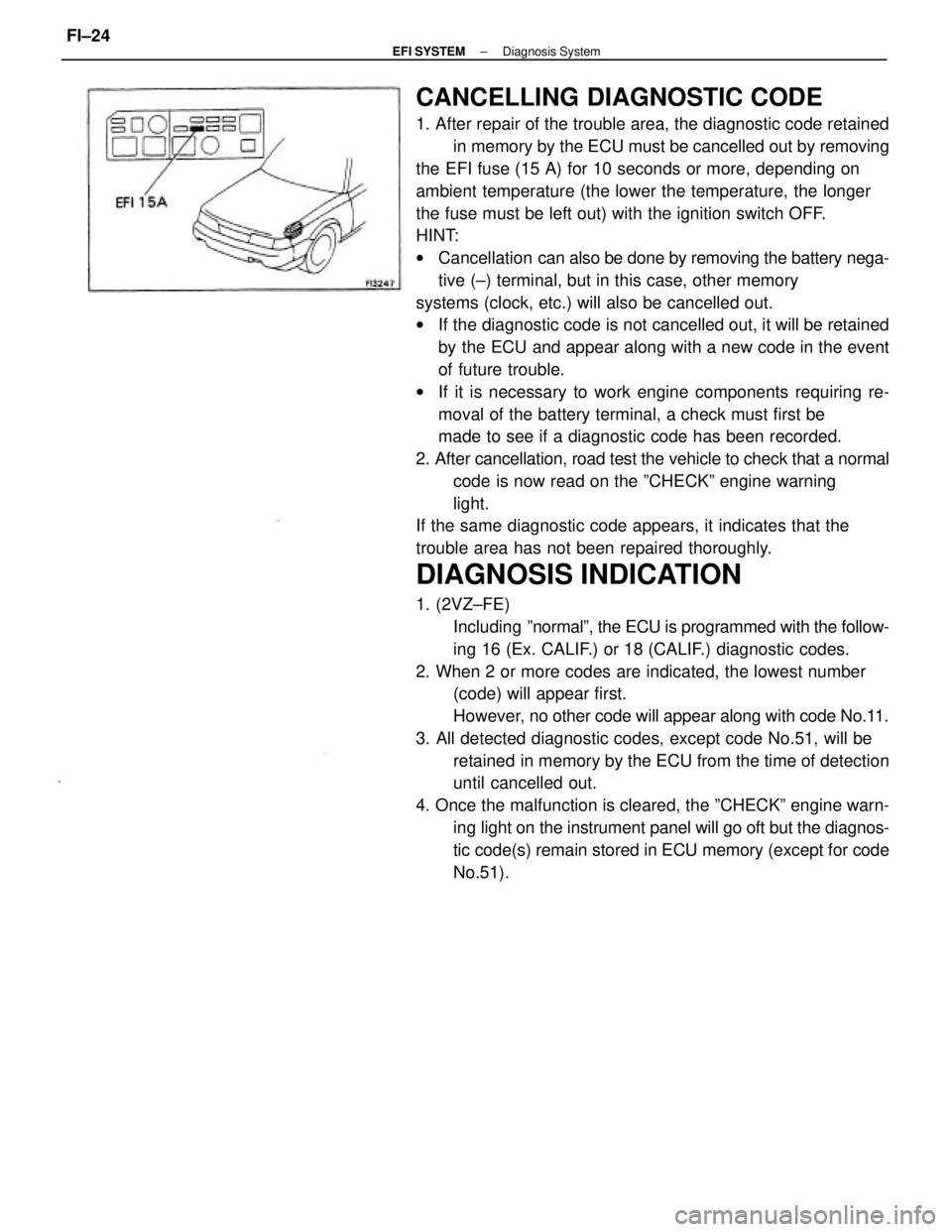

CANCELLING DIAGNOSTIC CODE

1. After repair of the trouble area, the diagnostic code retained

in memory by the ECU must be cancelled out by removing

the EFI fuse (15 A) for 10 seconds or more, depending on

ambient temperature (the lower the temperature, the longer

the fuse must be left out) with the ignition switch OFF.

HINT:

wCancellation can also be done by removing the battery nega-

tive (±) terminal, but in this case, other memory

systems (clock, etc.) will also be cancelled out.

wIf the diagnostic code is not cancelled out, it will be retained

by the ECU and appear along with a new code in the event

of future trouble.

wIf it is necessary to work engine components requiring re-

moval of the battery terminal, a check must first be

made to see if a diagnostic code has been recorded.

2. After cancellation, road test the vehicle to check that a normal

code is now read on the ºCHECKº engine warning

light.

If the same diagnostic code appears, it indicates that the

trouble area has not been repaired thoroughly.

DIAGNOSIS INDICATION

1. (2VZ±FE)

Including ºnormalº, the ECU is programmed with the follow-

ing 16 (Ex. CALIF.) or 18 (CALIF.) diagnostic codes.

2. When 2 or more codes are indicated, the lowest number

(code) will appear first.

However, no other code will appear along with code No.11.

3. All detected diagnostic codes, except code No.51, will be

retained in memory by the ECU from the time of detection

until cancelled out.

4. Once the malfunction is cleared, the ºCHECKº engine warn-

ing light on the instrument panel will go oft but the diagnos-

tic code(s) remain stored in ECU memory (except for code

No.51).

± EFI SYSTEMDiagnosis SystemFI±24

Page 1287 of 2389

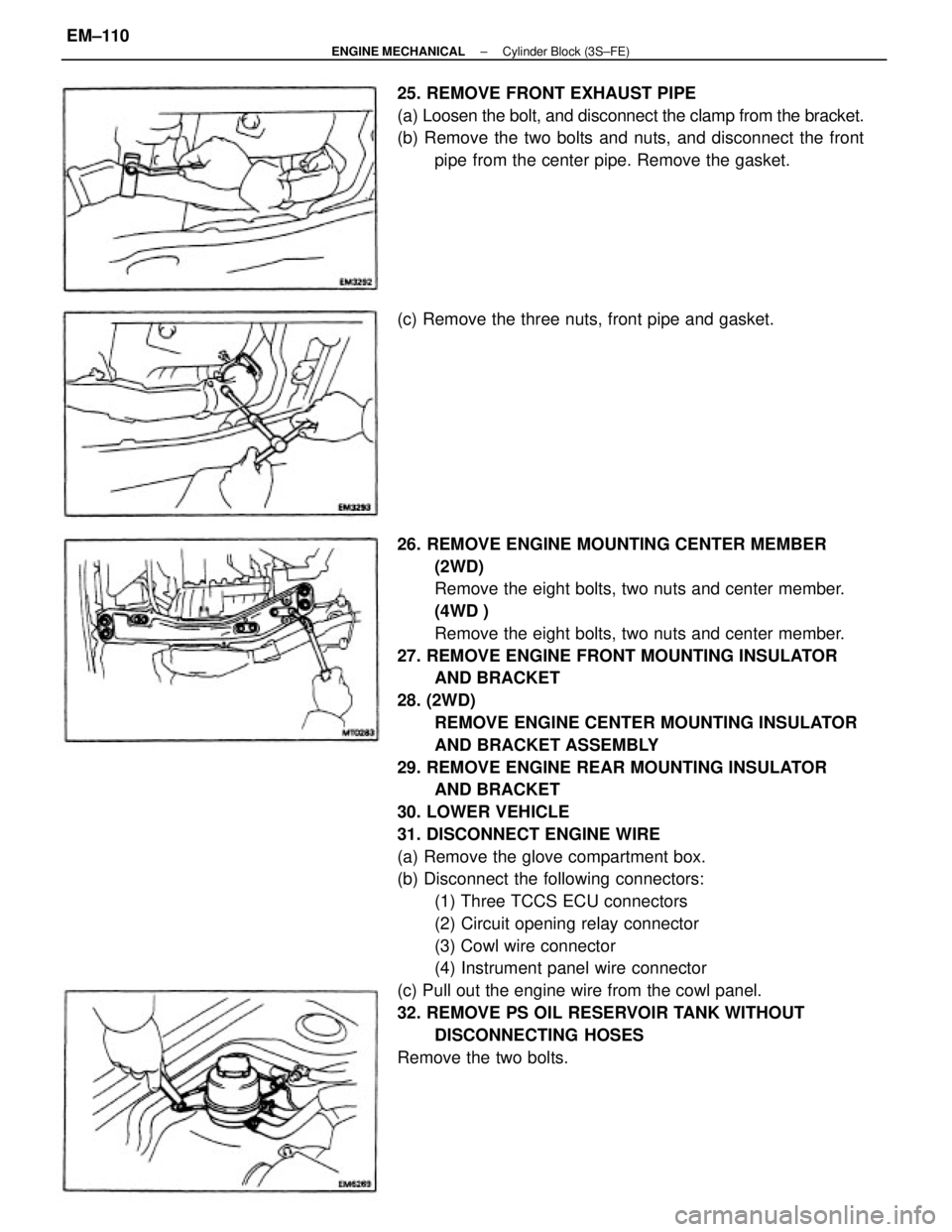

26. REMOVE ENGINE MOUNTING CENTER MEMBER

(2WD)

Remove the eight bolts, two nuts and center member.

(4WD )

Remove the eight bolts, two nuts and center member.

27. REMOVE ENGINE FRONT MOUNTING INSULATOR

AND BRACKET

28. (2WD)

REMOVE ENGINE CENTER MOUNTING INSULATOR

AND BRACKET ASSEMBLY

29. REMOVE ENGINE REAR MOUNTING INSULATOR

AND BRACKET

30. LOWER VEHICLE

31. DISCONNECT ENGINE WIRE

(a) Remove the glove compartment box.

(b) Disconnect the following connectors:

(1) Three TCCS ECU connectors

(2) Circuit opening relay connector

(3) Cowl wire connector

(4) Instrument panel wire connector

(c) Pull out the engine wire from the cowl panel.

32. REMOVE PS OIL RESERVOIR TANK WITHOUT

DISCONNECTING HOSES

Remove the two bolts. 25. REMOVE FRONT EXHAUST PIPE

(a) Loosen the bolt, and disconnect the clamp from the bracket.

(b) Remove the two bolts and nuts, and disconnect the front

pipe from the center pipe. Remove the gasket.

(c) Remove the three nuts, front pipe and gasket.

± ENGINE MECHANICALCylinder Block (3S±FE)EM±110

Page 1311 of 2389

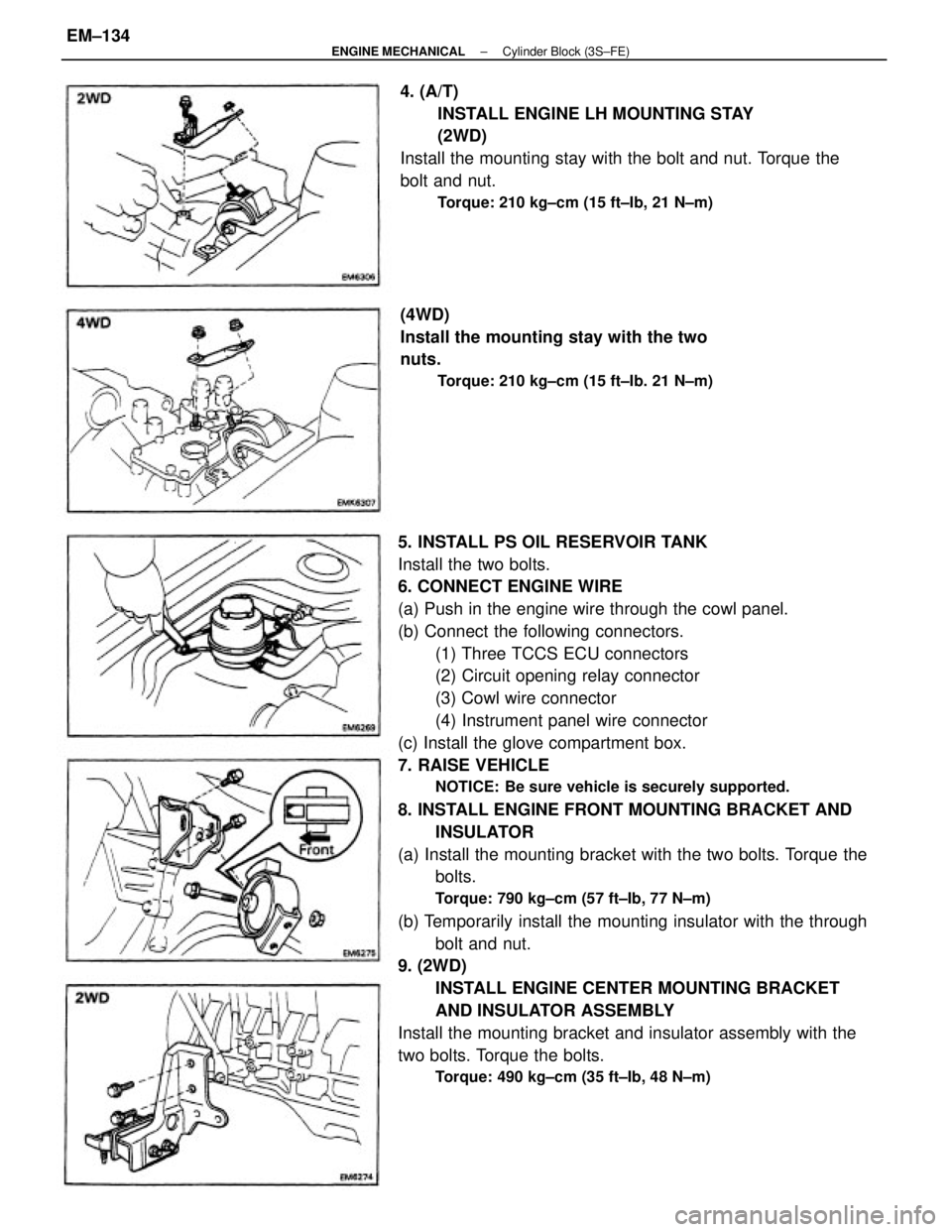

5. INSTALL PS OIL RESERVOIR TANK

Install the two bolts.

6. CONNECT ENGINE WIRE

(a) Push in the engine wire through the cowl panel.

(b) Connect the following connectors.

(1) Three TCCS ECU connectors

(2) Circuit opening relay connector

(3) Cowl wire connector

(4) Instrument panel wire connector

(c) Install the glove compartment box.

7. RAISE VEHICLE

NOTICE: Be sure vehicle is securely supported.

8. INSTALL ENGINE FRONT MOUNTING BRACKET AND

INSULATOR

(a) Install the mounting bracket with the two bolts. Torque the

bolts.

Torque: 790 kg±cm (57 ft±Ib, 77 N±m)

(b) Temporarily install the mounting insulator with the through

bolt and nut.

9. (2WD)

INSTALL ENGINE CENTER MOUNTING BRACKET

AND INSULATOR ASSEMBLY

Install the mounting bracket and insulator assembly with the

two bolts. Torque the bolts.

Torque: 490 kg±cm (35 ft±Ib, 48 N±m)

4. (A/T)

INSTALL ENGINE LH MOUNTING STAY

(2WD)

Install the mounting stay with the bolt and nut. Torque the

bolt and nut.

Torque: 210 kg±cm (15 ft±Ib, 21 N±m)

(4WD)

Install the mounting stay with the two

nuts.

Torque: 210 kg±cm (15 ft±Ib. 21 N±m)

± ENGINE MECHANICALCylinder Block (3S±FE)EM±134

Page 1319 of 2389

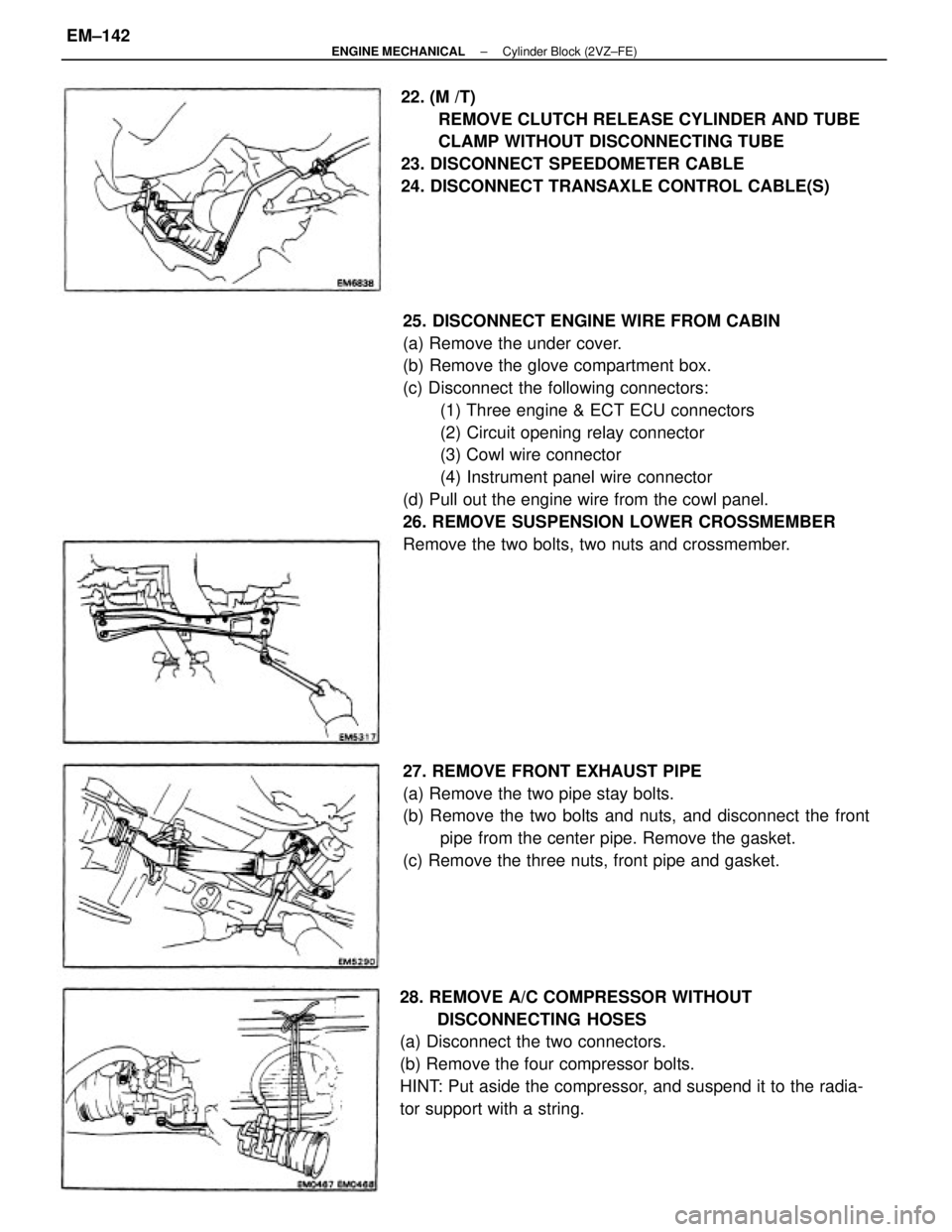

25. DISCONNECT ENGINE WIRE FROM CABIN

(a) Remove the under cover.

(b) Remove the glove compartment box.

(c) Disconnect the following connectors:

(1) Three engine & ECT ECU connectors

(2) Circuit opening relay connector

(3) Cowl wire connector

(4) Instrument panel wire connector

(d) Pull out the engine wire from the cowl panel.

26. REMOVE SUSPENSION LOWER CROSSMEMBER

Remove the two bolts, two nuts and crossmember.

28. REMOVE A/C COMPRESSOR WITHOUT

DISCONNECTING HOSES

(a) Disconnect the two connectors.

(b) Remove the four compressor bolts.

HINT: Put aside the compressor, and suspend it to the radia-

tor support with a string.22. (M /T)

REMOVE CLUTCH RELEASE CYLINDER AND TUBE

CLAMP WITHOUT DISCONNECTING TUBE

23. DISCONNECT SPEEDOMETER CABLE

24. DISCONNECT TRANSAXLE CONTROL CABLE(S)

27. REMOVE FRONT EXHAUST PIPE

(a) Remove the two pipe stay bolts.

(b) Remove the two bolts and nuts, and disconnect the front

pipe from the center pipe. Remove the gasket.

(c) Remove the three nuts, front pipe and gasket.

± ENGINE MECHANICALCylinder Block (2VZ±FE)EM±142

Page 1349 of 2389

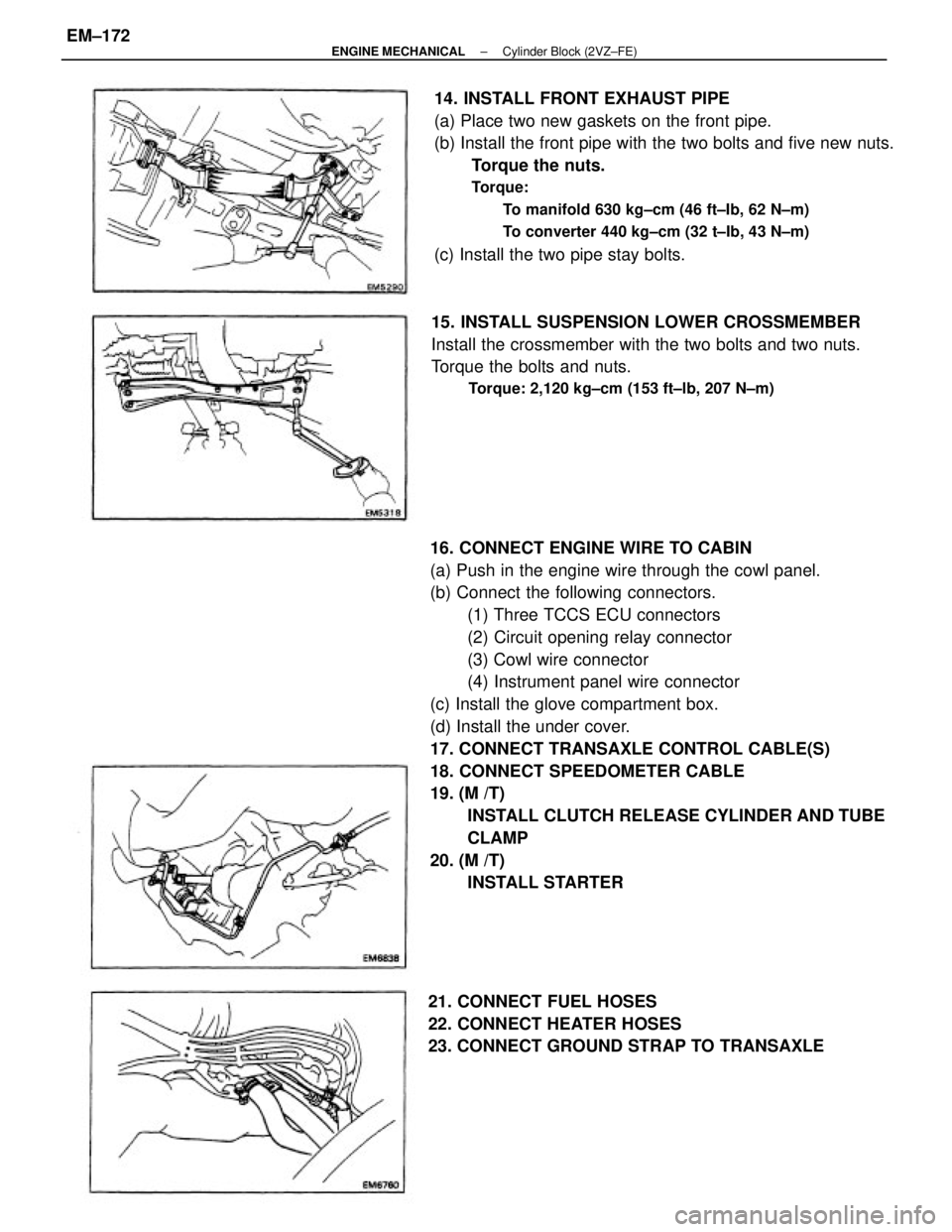

16. CONNECT ENGINE WIRE TO CABIN

(a) Push in the engine wire through the cowl panel.

(b) Connect the following connectors.

(1) Three TCCS ECU connectors

(2) Circuit opening relay connector

(3) Cowl wire connector

(4) Instrument panel wire connector

(c) Install the glove compartment box.

(d) Install the under cover.

17. CONNECT TRANSAXLE CONTROL CABLE(S)

18. CONNECT SPEEDOMETER CABLE

19. (M /T)

INSTALL CLUTCH RELEASE CYLINDER AND TUBE

CLAMP

20. (M /T)

INSTALL STARTER 14. INSTALL FRONT EXHAUST PIPE

(a) Place two new gaskets on the front pipe.

(b) Install the front pipe with the two bolts and five new nuts.

Torque the nuts.

Torque:

To manifold 630 kg±cm (46 ft±Ib, 62 N±m)

To converter 440 kg±cm (32 t±Ib, 43 N±m)

(c) Install the two pipe stay bolts.

15. INSTALL SUSPENSION LOWER CROSSMEMBER

Install the crossmember with the two bolts and two nuts.

Torque the bolts and nuts.

Torque: 2,120 kg±cm (153 ft±lb, 207 N±m)

21. CONNECT FUEL HOSES

22. CONNECT HEATER HOSES

23. CONNECT GROUND STRAP TO TRANSAXLE

± ENGINE MECHANICALCylinder Block (2VZ±FE)EM±172

Page 1858 of 2389

GENERAL REPAIR INSTRUCTIONS

1. Use fender seat and floor covers to keep the vehicle clean

and prevent damage.

2. During disassembly, keep parts in the appropriate order to

facilitate reassembly.

3. Observe the following:

(a) Before performing electrical work, disconnect the neg-

ative cable from the battery terminal.

(b) If it is necessary to disconnect the battery for inspection

or repair, always disconnect the cable from the nega-

tive H terminal which is grounded to the vehicle body.

(c) To prevent damage to the battery terminal post, loosen

the terminal nut and raise the cable straight up

without twisting or prying it.

(d) Clean the battery terminal posts and cable terminals

with a shop rag.

o not scrape them with a file or other

abrasive objects.

(e) Install the cable terminal to the battery post with

the nut loose, and tighten the nut after installation. Do

not use a hammer to tap the terminal onto the post.

(f) Be sure the cover for the positive (+) terminal is properly

in place.

4. Check hose and wiring connectors to make sure that they are

secure and correct.

5. Non±reusable parts

(a) Always replace cotter pins, gaskets, 0±rings and oil

seals etc. with new ones.

(b) Non±reusable parts are indicated in the component il-

lustrations by the ºrº symbol.

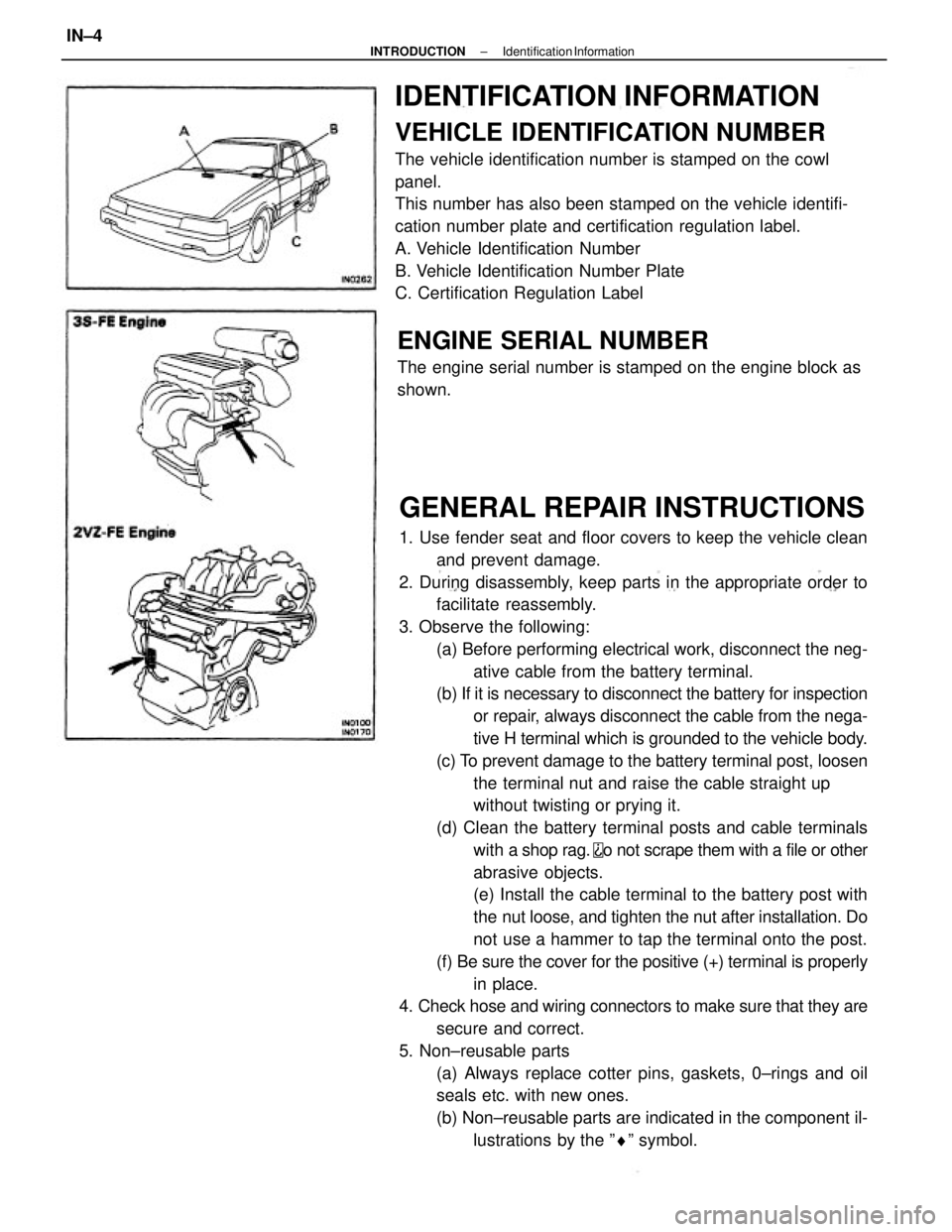

IDENTIFICATION INFORMATION

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number is stamped on the cowl

panel.

This number has also been stamped on the vehicle identifi-

cation number plate and certification regulation label.

A. Vehicle Identification Number

B. Vehicle Identification Number Plate

C. Certification Regulation Label

ENGINE SERIAL NUMBER

The engine serial number is stamped on the engine block as

shown.

± INTRODUCTIONIdentification InformationIN±4