steering TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1396 of 2389

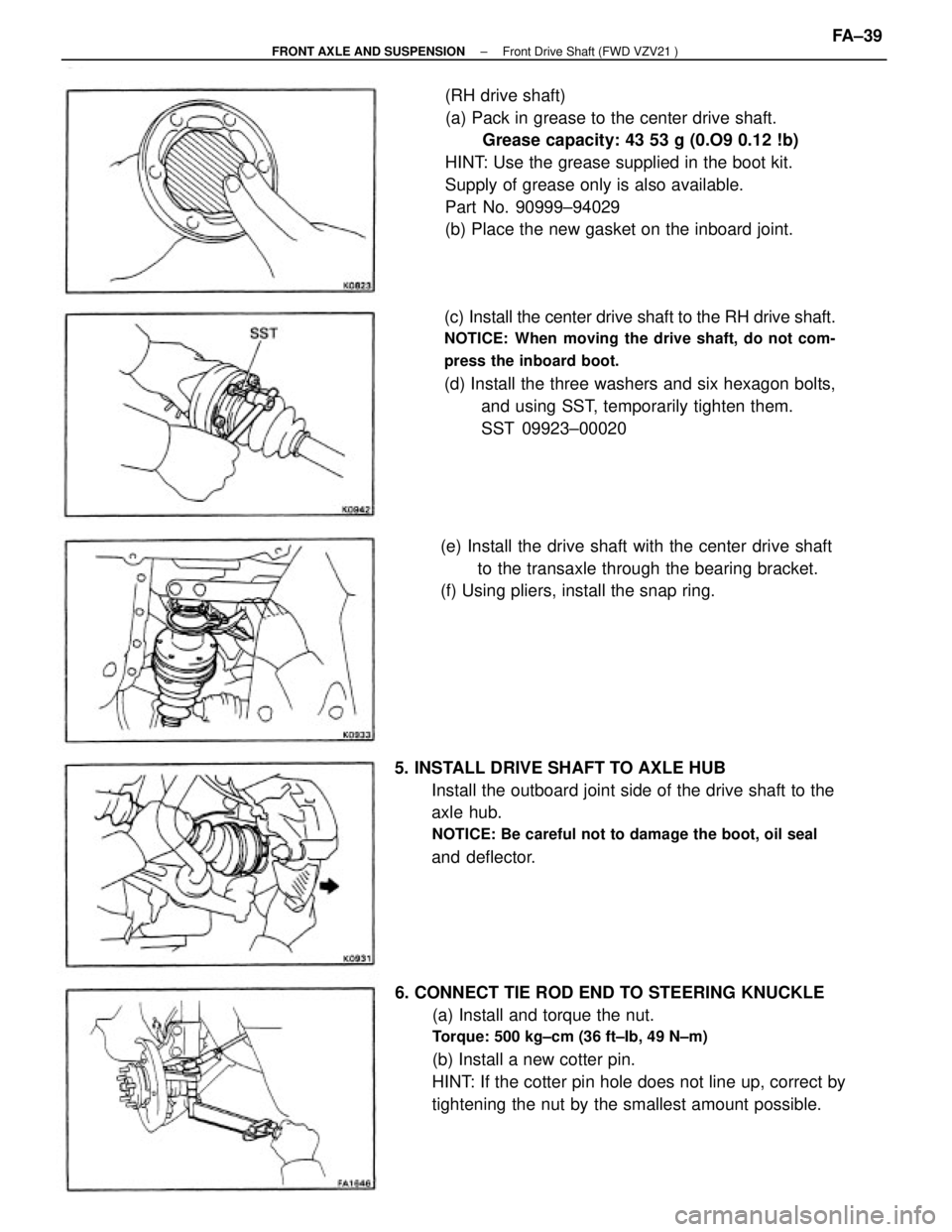

(RH drive shaft)

(a) Pack in grease to the center drive shaft.

Grease capacity: 43 53 g (0.O9 0.12 !b)

HINT: Use the grease supplied in the boot kit.

Supply of grease only is also available.

Part No. 90999±94029

(b) Place the new gasket on the inboard joint.

6. CONNECT TIE ROD END TO STEERING KNUCKLE

(a) Install and torque the nut.

Torque: 500 kg±cm (36 ft±Ib, 49 N±m)

(b) Install a new cotter pin.

HINT: If the cotter pin hole does not line up, correct by

tightening the nut by the smallest amount possible.(c) Install the center drive shaft to the RH drive shaft.

NOTICE: When moving the drive shaft, do not com-

press the inboard boot.

(d) Install the three washers and six hexagon bolts,

and using SST, temporarily tighten them.

SST 09923±00020

5. INSTALL DRIVE SHAFT TO AXLE HUB

Install the outboard joint side of the drive shaft to the

axle hub.

NOTICE: Be careful not to damage the boot, oil seal

and deflector.(e) Install the drive shaft with the center drive shaft

to the transaxle through the bearing bracket.

(f) Using pliers, install the snap ring.

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (FWD VZV21 )FA±39

Page 1397 of 2389

9. INSTALL BEARING LOCK NUT, LOCK NUT CAP AND

NEW COTTER PIN

(a) Torque the bearing lock nut while depressing the brake

pedal.

Torque: 1,900 kg±cm (137 ft±Ib, 186 N±m)

(b) Install the lock nut cap and, using pliers, install a new

cotter pin. 8. TIGHTEN SIX HEXAGON BOLTS

Using SST, tighten the six hexagon bolts while depress-

ing the brake pedal.

SST 09043±88010

Torque: 660 kg±cm (48 ft±Ib, 65 N±m)

10. FILL TRANSAXLE WITH GEAR OIL

(See page MT±45)

11. INSTALL ENGINE UNDER COVERS

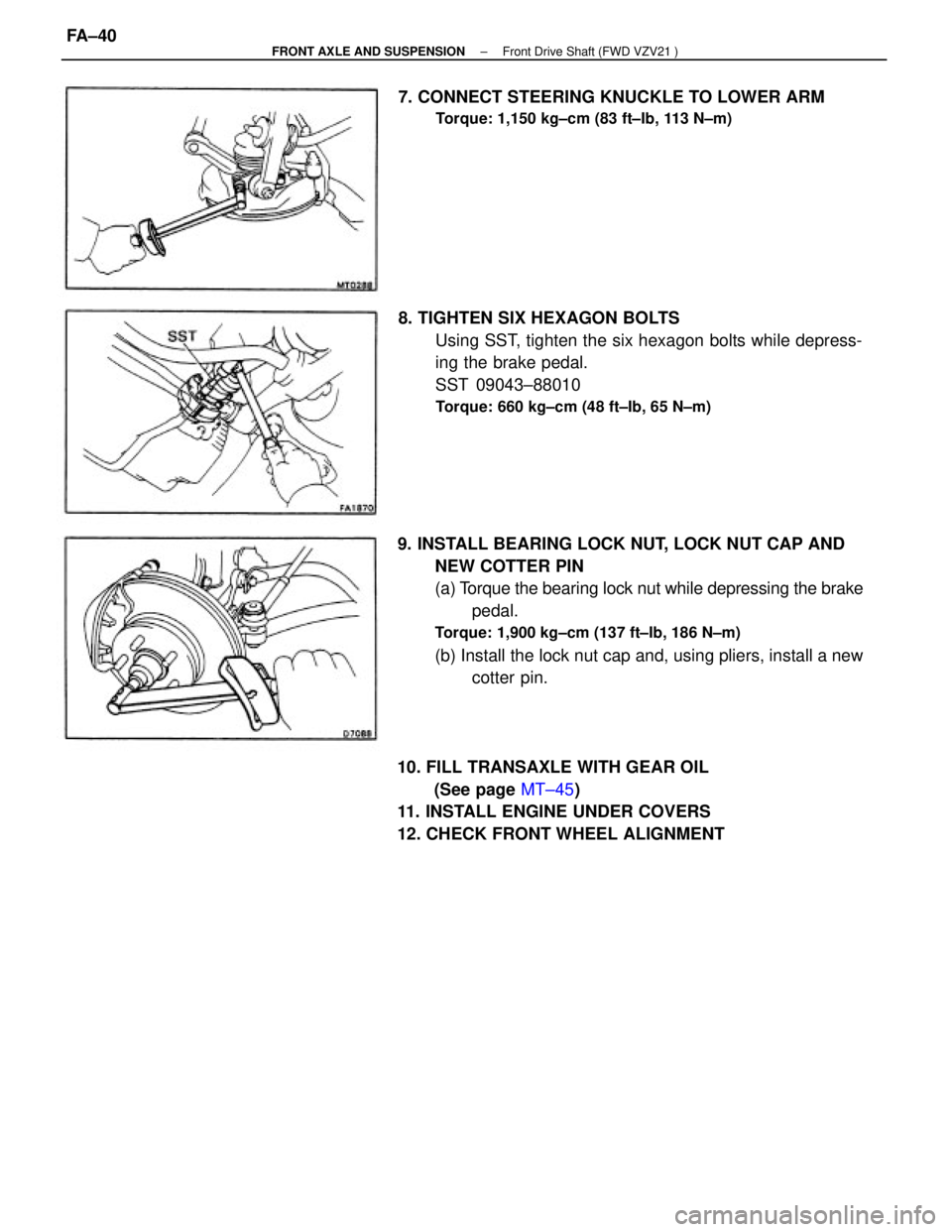

12. CHECK FRONT WHEEL ALIGNMENT7. CONNECT STEERING KNUCKLE TO LOWER ARM

Torque: 1,150 kg±cm (83 ft±Ib, 113 N±m)

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (FWD VZV21 )FA±40

Page 1399 of 2389

REMOVAL OF FRONT DRIVE SHAFT

(See page FA±41)

1. REMOVE COTTER PIN, LOCK NUT CAP AND LOCK

NUT

(a) Remove the cotter pin and lock nut cap.

(b) Loosen the bearing lock nut while depressing the

brake pedal.

2. REMOVE ENGINE UNDER COVER RH AND LH

3. DISCONNECT TIE ROD END

(a) Remove the cotter pin and nut from the tie rod end.

(b) Using SST, disconnect the tie rod end from the steering

knuckle.

SST 09610±55021

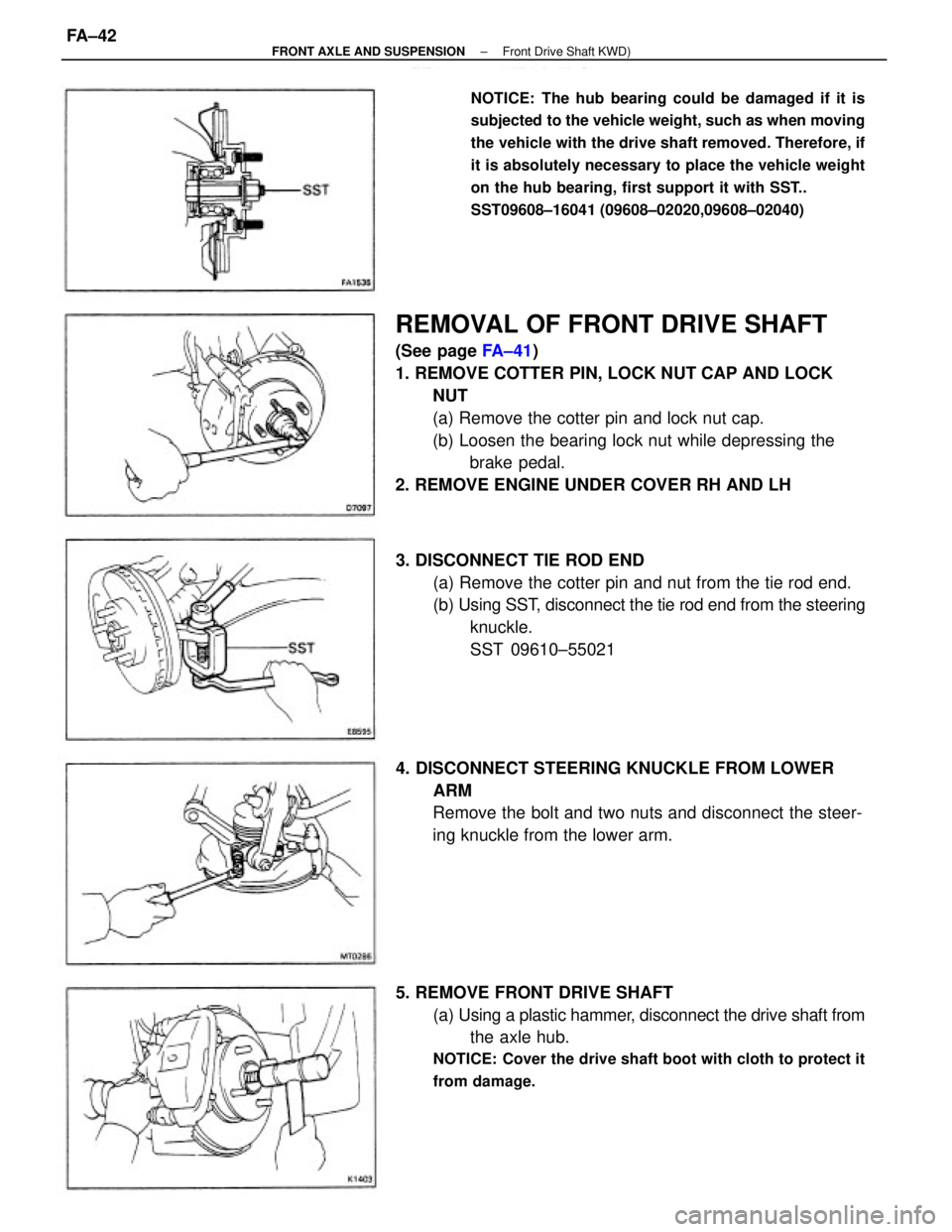

NOTICE: The hub bearing could be damaged if it is

subjected to the vehicle weight, such as when moving

the vehicle with the drive shaft removed. Therefore, if

it is absolutely necessary to place the vehicle weight

on the hub bearing, first support it with SST..

SST09608±16041 (09608±02020,09608±02040)

5. REMOVE FRONT DRIVE SHAFT

(a) Using a plastic hammer, disconnect the drive shaft from

the axle hub.

NOTICE: Cover the drive shaft boot with cloth to protect it

from damage.

4. DISCONNECT STEERING KNUCKLE FROM LOWER

ARM

Remove the bolt and two nuts and disconnect the steer-

ing knuckle from the lower arm.

± FRONT AXLE AND SUSPENSIONFront Drive Shaft KWD)FA±42

Page 1406 of 2389

INSTILLATION OF FRONT DRIVE SHAFT

(See page FA±41)

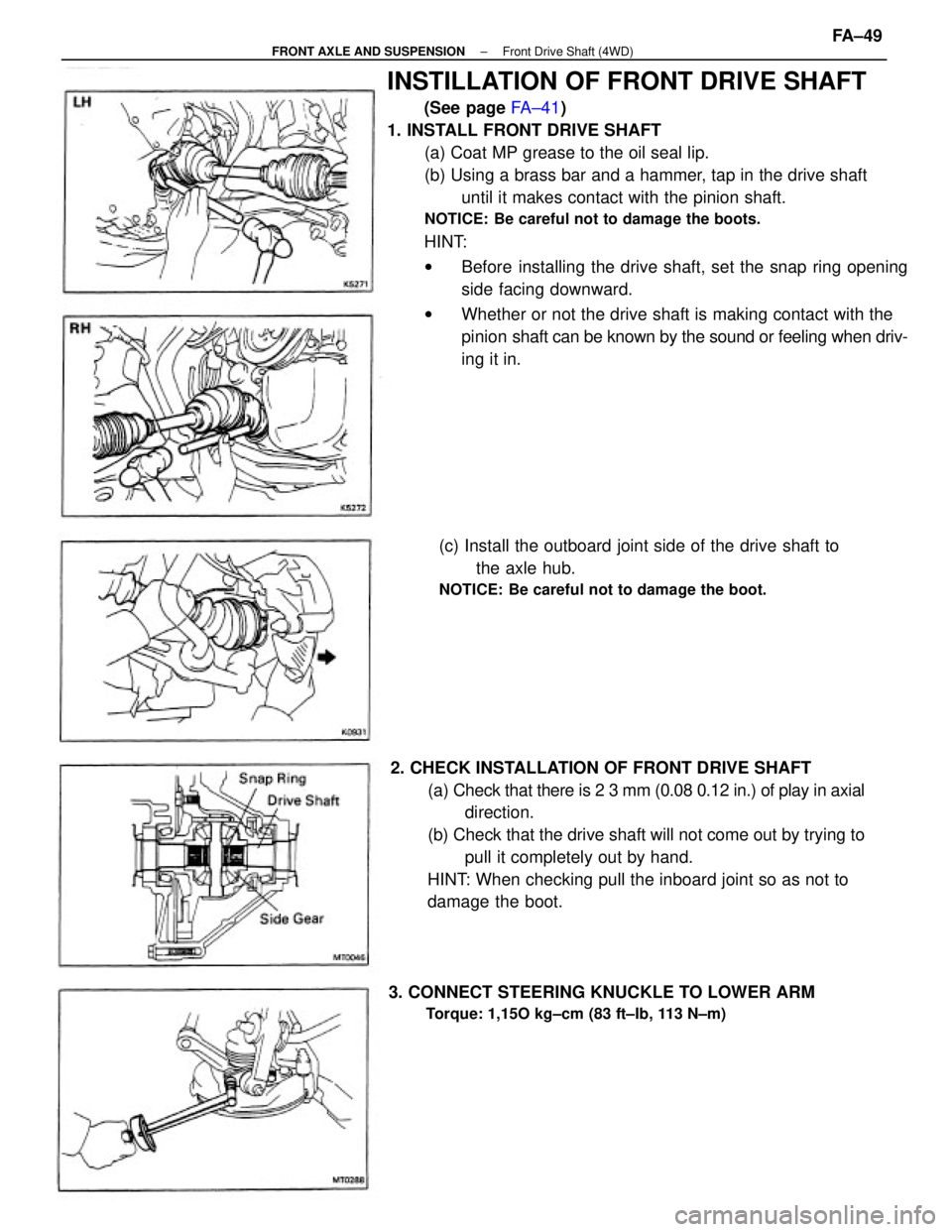

1. INSTALL FRONT DRIVE SHAFT

(a) Coat MP grease to the oil seal lip.

(b) Using a brass bar and a hammer, tap in the drive shaft

until it makes contact with the pinion shaft.

NOTICE: Be careful not to damage the boots.

HINT:

wBefore installing the drive shaft, set the snap ring opening

side facing downward.

wWhether or not the drive shaft is making contact with the

pinion shaft can be known by the sound or feeling when driv-

ing it in.

2. CHECK INSTALLATION OF FRONT DRIVE SHAFT

(a) Check that there is 2 3 mm (0.08 0.12 in.) of play in axial

direction.

(b) Check that the drive shaft will not come out by trying to

pull it completely out by hand.

HINT: When checking pull the inboard joint so as not to

damage the boot.(c) Install the outboard joint side of the drive shaft to

the axle hub.

NOTICE: Be careful not to damage the boot.

3. CONNECT STEERING KNUCKLE TO LOWER ARM

Torque: 1,15O kg±cm (83 ft±Ib, 113 N±m)

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (4WD)FA±49

Page 1407 of 2389

6. FILL TRANSAXLE WITH GEAR OIL OR FLUID

M/T (See page MT±1 17)

A/T Fluid type: ATF DEXRON) II

7. INSTALL ENGINE UNDER COVERS

8. INSTALL WHEELS

9. CHECK FRONT WHEEL ALIGNMENT

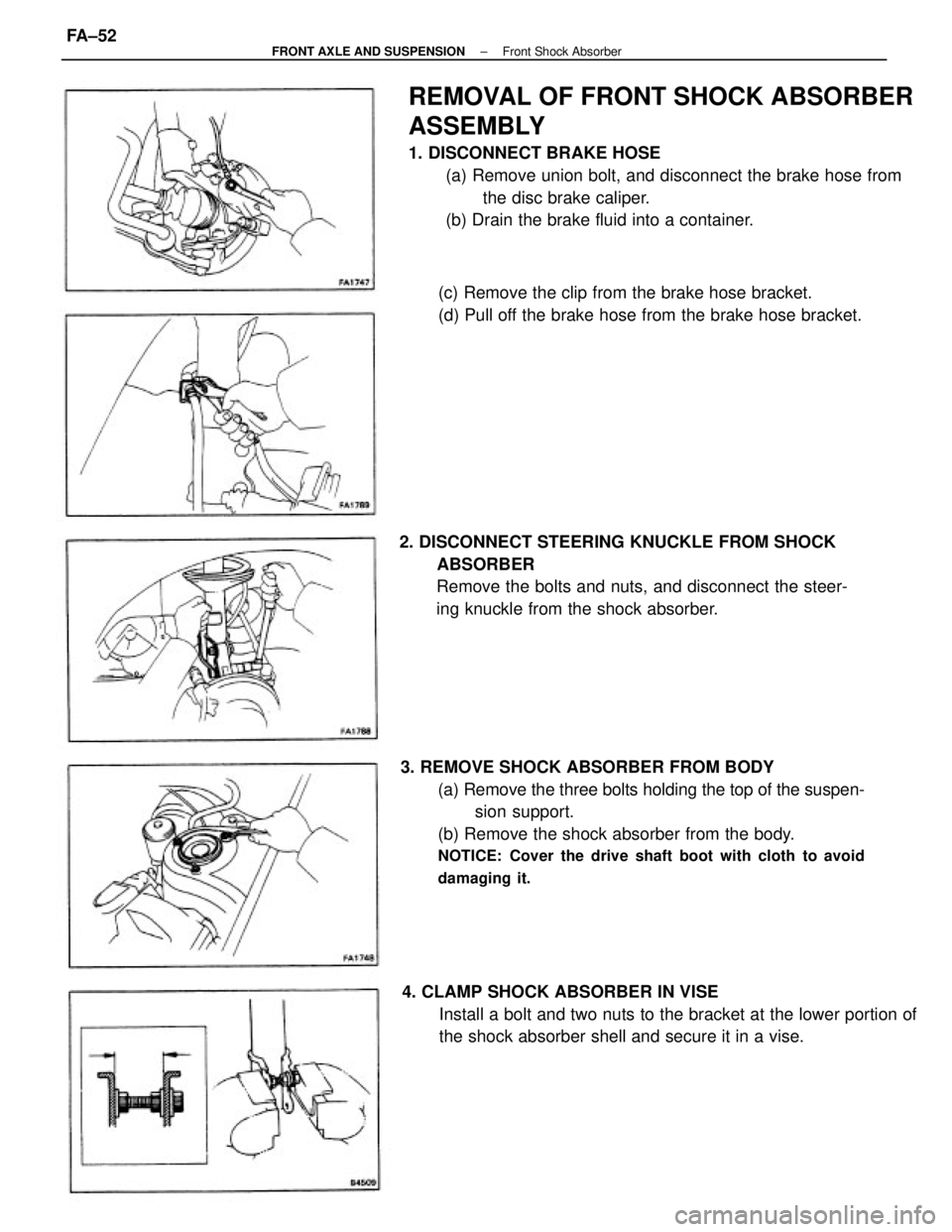

(See page FA ± 3) 5. INSTALL BEARING LOCK NUT, LOCK NUT CAP AND

COTTER PIN

(a) Torque the bearing lock nut while depressing the brake

pedal.

Torque: 1, 900 kg±cm (137 ft±Ib, 186 N±m )

(b) Install the lock nut cap and, using pliers, install a new

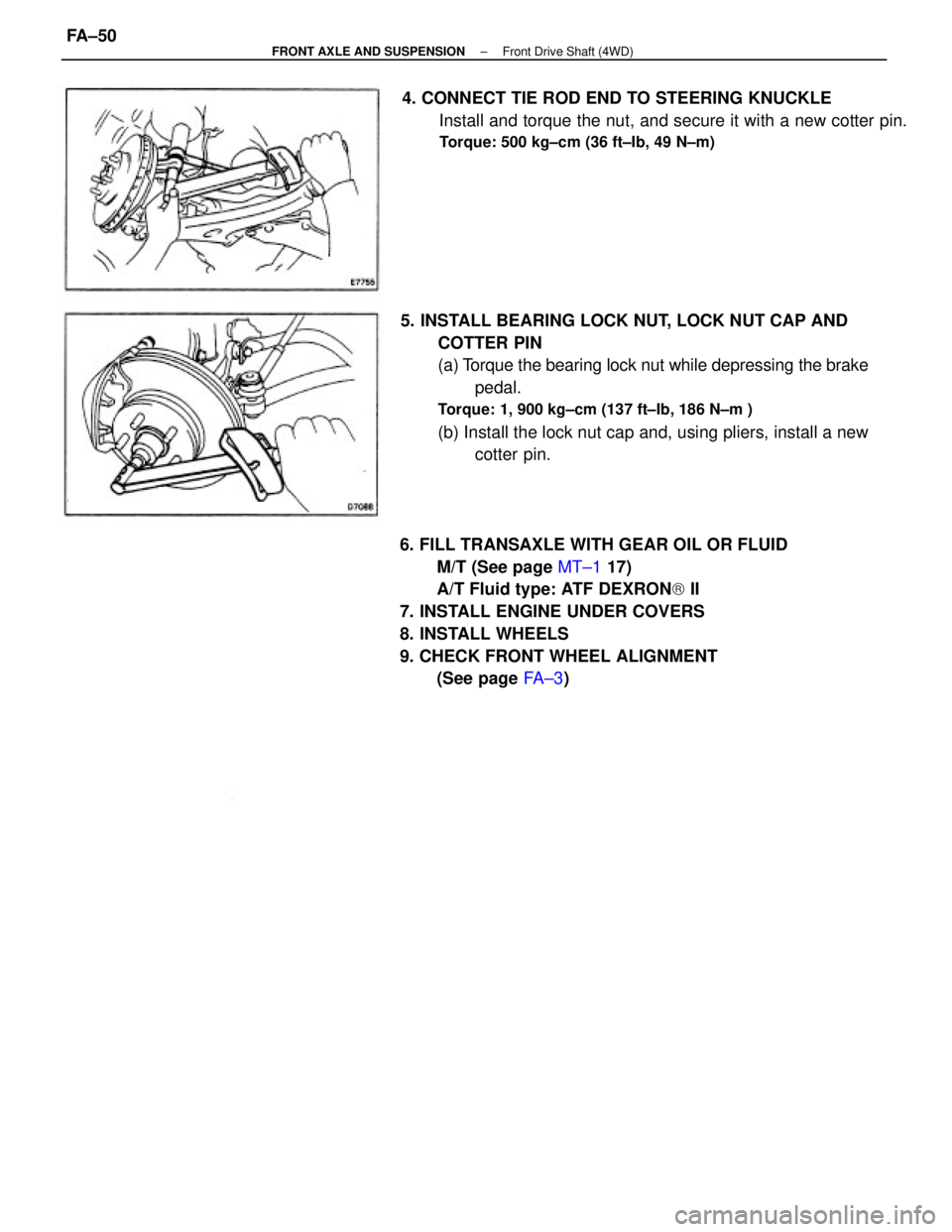

cotter pin. 4. CONNECT TIE ROD END TO STEERING KNUCKLE

Install and torque the nut, and secure it with a new cotter pin.

Torque: 500 kg±cm (36 ft±Ib, 49 N±m)

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (4WD)FA±50

Page 1409 of 2389

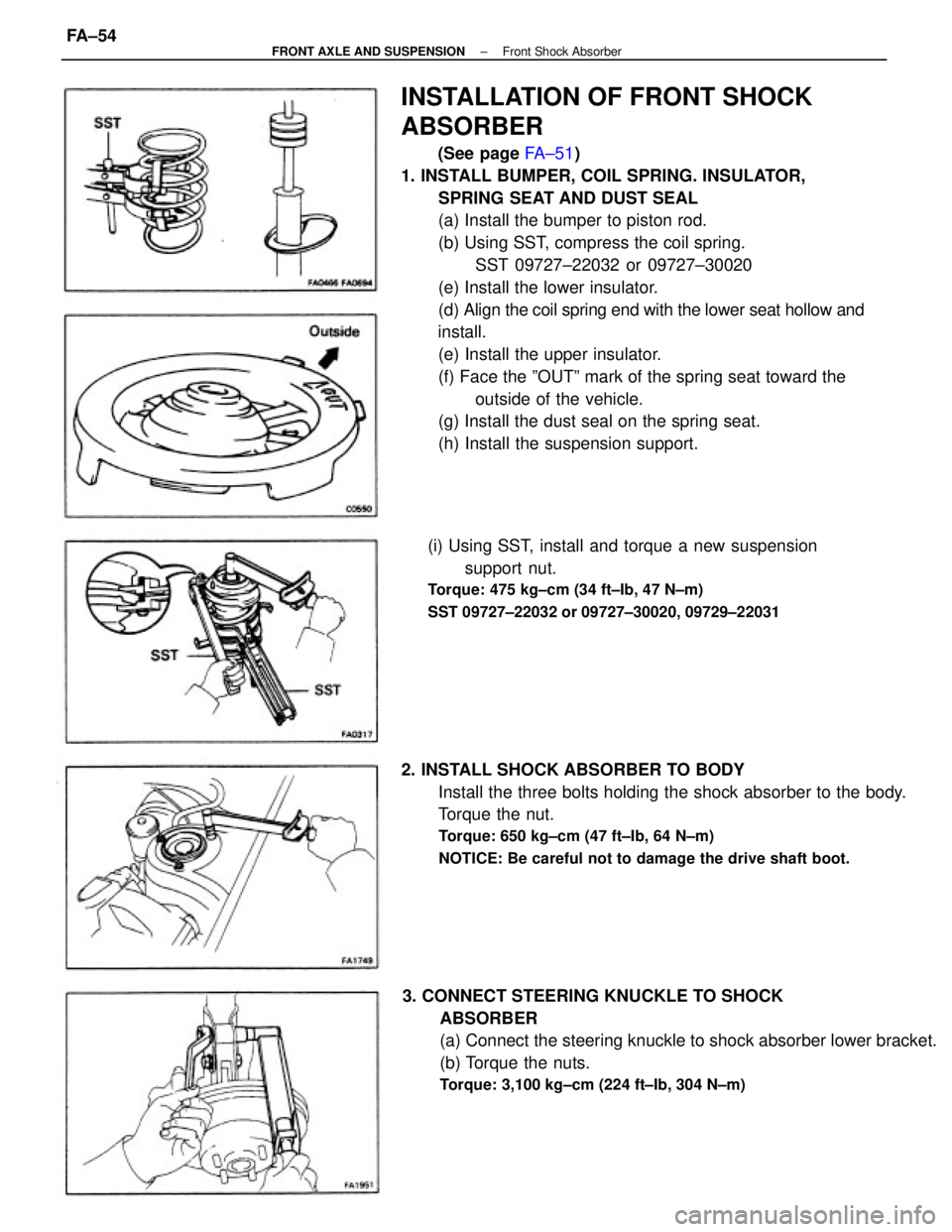

REMOVAL OF FRONT SHOCK ABSORBER

ASSEMBLY

1. DISCONNECT BRAKE HOSE

(a) Remove union bolt, and disconnect the brake hose from

the disc brake caliper.

(b) Drain the brake fluid into a container.

3. REMOVE SHOCK ABSORBER FROM BODY

(a) Remove the three bolts holding the top of the suspen-

sion support.

(b) Remove the shock absorber from the body.

NOTICE: Cover the drive shaft boot with cloth to avoid

damaging it.

2. DISCONNECT STEERING KNUCKLE FROM SHOCK

ABSORBER

Remove the bolts and nuts, and disconnect the steer-

ing knuckle from the shock absorber.

4. CLAMP SHOCK ABSORBER IN VISE

Install a bolt and two nuts to the bracket at the lower portion of

the shock absorber shell and secure it in a vise. (c) Remove the clip from the brake hose bracket.

(d) Pull off the brake hose from the brake hose bracket.

± FRONT AXLE AND SUSPENSIONFront Shock AbsorberFA±52

Page 1411 of 2389

INSTALLATION OF FRONT SHOCK

ABSORBER

(See page FA±51)

1. INSTALL BUMPER, COIL SPRING. INSULATOR,

SPRING SEAT AND DUST SEAL

(a) Install the bumper to piston rod.

(b) Using SST, compress the coil spring.

SST 09727±22032 or 09727±30020

(e) Install the lower insulator.

(d) Align the coil spring end with the lower seat hollow and

install.

(e) Install the upper insulator.

(f) Face the ºOUTº mark of the spring seat toward the

outside of the vehicle.

(g) Install the dust seal on the spring seat.

(h) Install the suspension support.

3. CONNECT STEERING KNUCKLE TO SHOCK

ABSORBER

(a) Connect the steering knuckle to shock absorber lower bracket.

(b) Torque the nuts.

Torque: 3,100 kg±cm (224 ft±Ib, 304 N±m)

2. INSTALL SHOCK ABSORBER TO BODY

Install the three bolts holding the shock absorber to the body.

Torque the nut.

Torque: 650 kg±cm (47 ft±Ib, 64 N±m)

NOTICE: Be careful not to damage the drive shaft boot.

(i) Using SST, install and torque a new suspension

support nut.

Torque: 475 kg±cm (34 ft±Ib, 47 N±m)

SST 09727±22032 or 09727±30020, 09729±22031

± FRONT AXLE AND SUSPENSIONFront Shock AbsorberFA±54

Page 1414 of 2389

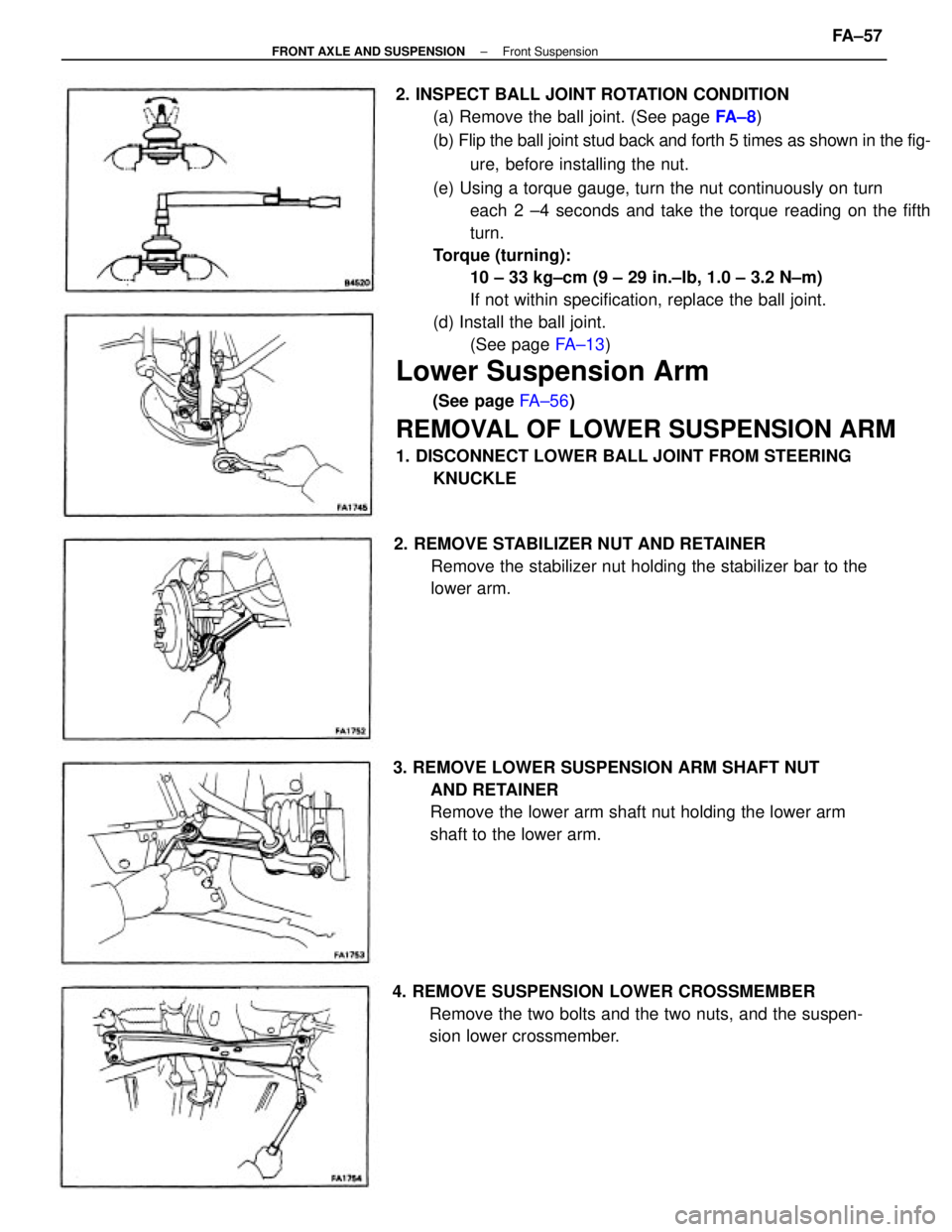

2. INSPECT BALL JOINT ROTATION CONDITION

(a) Remove the ball joint. (See page FA ± 8)

(b) Flip the ball joint stud back and forth 5 times as shown in the fig-

ure, before installing the nut.

(e) Using a torque gauge, turn the nut continuously on turn

each 2 ±4 seconds and take the torque reading on the fifth

turn.

Torque (turning):

10 ± 33 kg±cm (9 ± 29 in.±Ib, 1.0 ± 3.2 N±m)

If not within specification, replace the ball joint.

(d) Install the ball joint.

(See page FA±13)

Lower Suspension Arm

(See page FA±56)

REMOVAL OF LOWER SUSPENSION ARM

1. DISCONNECT LOWER BALL JOINT FROM STEERING

KNUCKLE

3. REMOVE LOWER SUSPENSION ARM SHAFT NUT

AND RETAINER

Remove the lower arm shaft nut holding the lower arm

shaft to the lower arm.

4. REMOVE SUSPENSION LOWER CROSSMEMBER

Remove the two bolts and the two nuts, and the suspen-

sion lower crossmember. 2. REMOVE STABILIZER NUT AND RETAINER

Remove the stabilizer nut holding the stabilizer bar to the

lower arm.

± FRONT AXLE AND SUSPENSIONFront SuspensionFA±57

Page 1416 of 2389

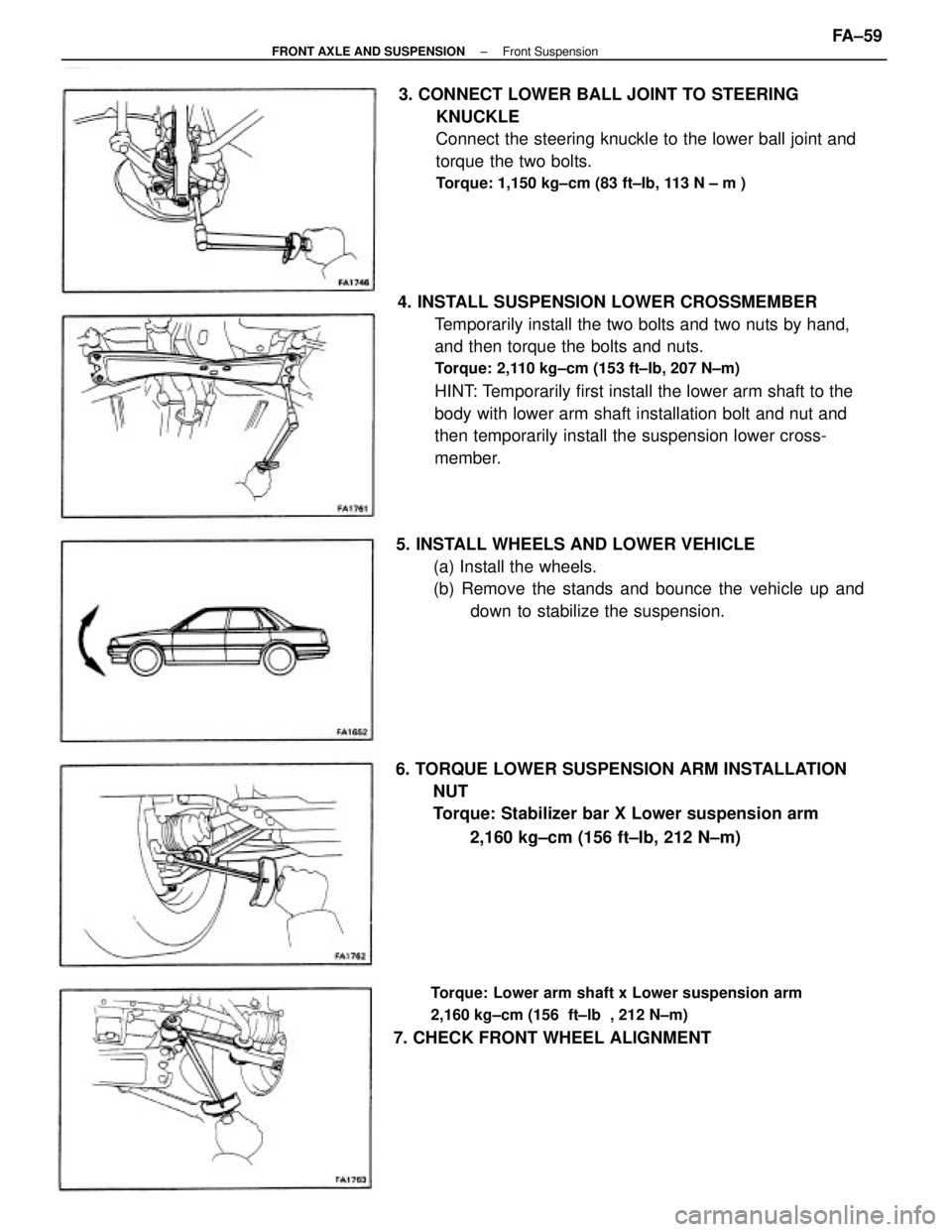

4. INSTALL SUSPENSION LOWER CROSSMEMBER

Temporarily install the two bolts and two nuts by hand,

and then torque the bolts and nuts.

Torque: 2,110 kg±cm (153 ft±Ib, 207 N±m)

HINT: Temporarily first install the lower arm shaft to the

body with lower arm shaft installation bolt and nut and

then temporarily install the suspension lower cross-

member. 3. CONNECT LOWER BALL JOINT TO STEERING

KNUCKLE

Connect the steering knuckle to the lower ball joint and

torque the two bolts.

Torque: 1,150 kg±cm (83 ft±Ib, 113 N ± m )

5. INSTALL WHEELS AND LOWER VEHICLE

(a) Install the wheels.

(b) Remove the stands and bounce the vehicle up and

down to stabilize the suspension.

6. TORQUE LOWER SUSPENSION ARM INSTALLATION

NUT

Torque: Stabilizer bar X Lower suspension arm

2,160 kg±cm (156 ft±Ib, 212 N±m)

Torque: Lower arm shaft x Lower suspension arm

2,160 kg±cm (156 ft±lb , 212 N±m)

7. CHECK FRONT WHEEL ALIGNMENT

± FRONT AXLE AND SUSPENSIONFront SuspensionFA±59

Page 1912 of 2389

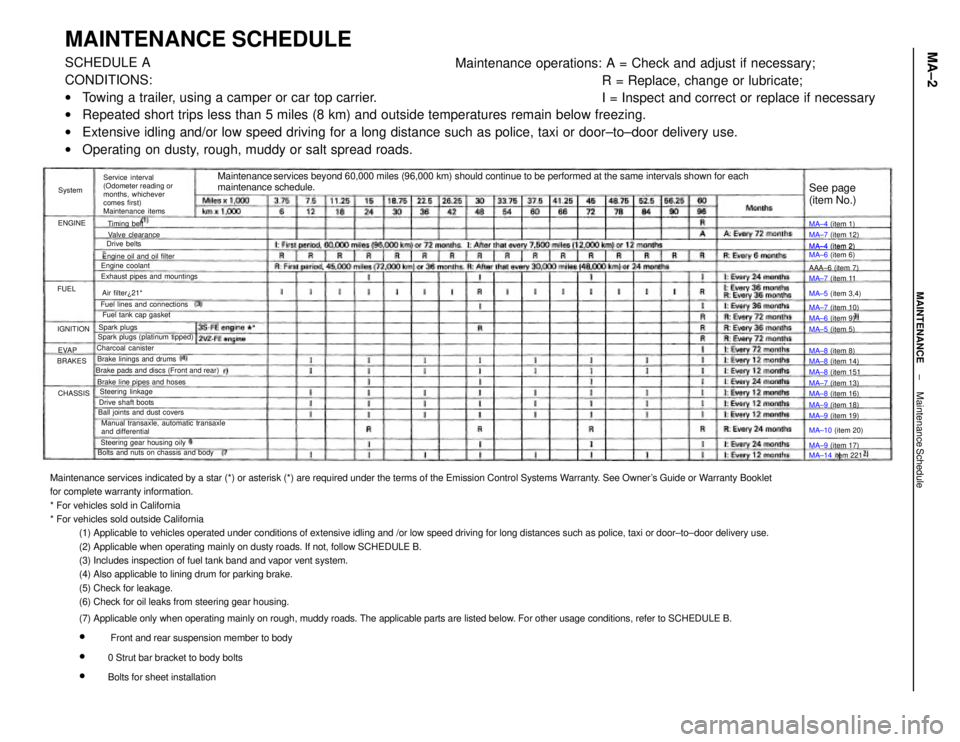

Maintenance services indicated by a star (*) or asterisk (*) are required under the terms of the Emission Control Systems Warranty. See Owner's Guide or Warranty Booklet

for complete warranty information.

* For vehicles sold in California

* For vehicles sold outside California

(1) Applicable to vehicles operated under conditions of extensive idling and /or low speed driving for long distances such as police, taxi or door±to±door delivery use.

(2) Applicable when operating mainly on dusty roads. If not, follow SCHEDULE B.

(3) Includes inspection of fuel tank band and vapor vent system.

(4) Also applicable to lining drum for parking brake.

(5) Check for leakage.

(6) Check for oil leaks from steering gear housing.

(7) Applicable only when operating mainly on rough, muddy roads. The applicable parts are listed below. For other usage conditions, refer to SCHEDULE B.

w

Front and rear suspension member to body

w

0 Strut bar bracket to body bolts

w

Bolts for sheet installation

MAINTENANCE SCHEDULESCHEDULE A

CONDITIONS:

wTowing a trailer, using a camper or car top carrier.

wRepeated short trips less than 5 miles (8 km) and outside temperatures remain below freezing.

wExtensive idling and/or low speed driving for a long distance such as police, taxi or door±to±door delivery use.

wOperating on dusty, rough, muddy or salt spread roads.Maintenance operations: A = Check and adjust if necessary;

R = Replace, change or lubricate;

I = Inspect and correct or replace if necessary

Maintenance services beyond 60,000 miles (96,000 km) should continue to be performed at the same intervals shown for each

maintenance schedule.

Service interval

(Odometer reading or

months, whichever

comes first)

Maintenance items

Manual transaxle, automatic transaxle

and differential Brake pads and discs (Front and rear)

Bolts and nuts on chassis and bodyExhaust pipes and mountings

Steering gear housing oily Brake line pipes and hosesFuel lines and connections

Ball joints and dust coversEngine oil and oil filter

Spark plugs (platinum tipped)MA±4 (item 2)

MA±6 (item 6)

Brake linings and drumsFuel tank cap gasket

Drive shaft boots

MA±14 item 221 MA±10 (item 20) MA±5 (item 3,4)

Steering linkageMA±7 (item 12)

MA±8 (item 14) Valve clearance

MA±8 (item 16)

MA±9 (item 19) MA±7 (item 13) MA±7 (item 11

MA±7 (item 10)

MA±9 (item 18) Charcoal canister

MA±9 (item 17) MA±8 (item 151

See page

(item No.)

Engine coolant

MA±6 (item 9) MA±4 (item 1)

MA±4 (item 2)

MA±5 (item 5)

MA±8 (item 8) AAA±6 (item 7)

Air filter¿21*

Spark plugsTiming belt

Drive belts

IGNITION

CHASSIS BRAKESENGINESystem

EVAP FUEL

± MAINTENANCEMaintenance ScheduleMA±2