condition TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 227 of 2389

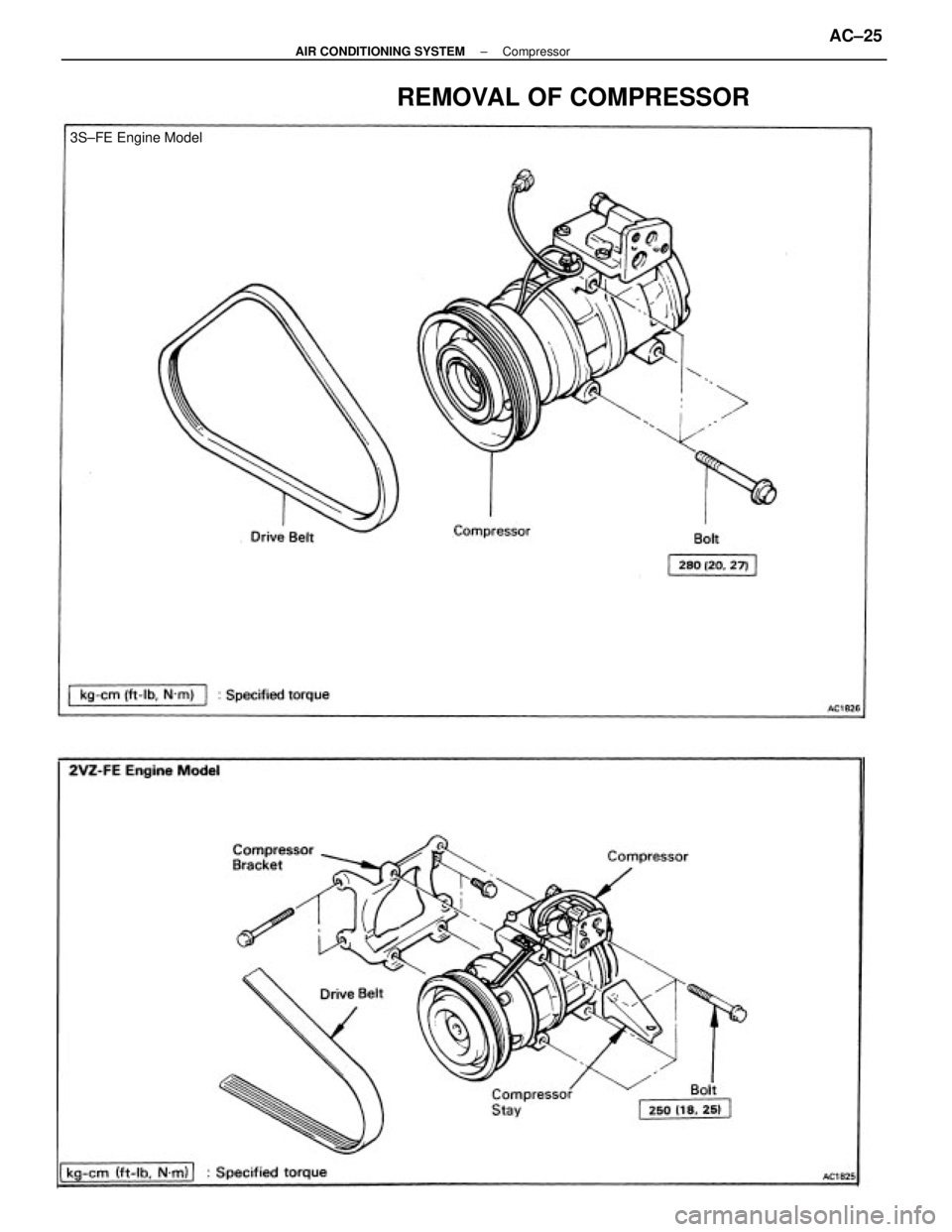

REMOVAL OF COMPRESSOR

3S±FE Engine Model

± AIR CONDITIONING SYSTEMCompressorAC±25

Page 228 of 2389

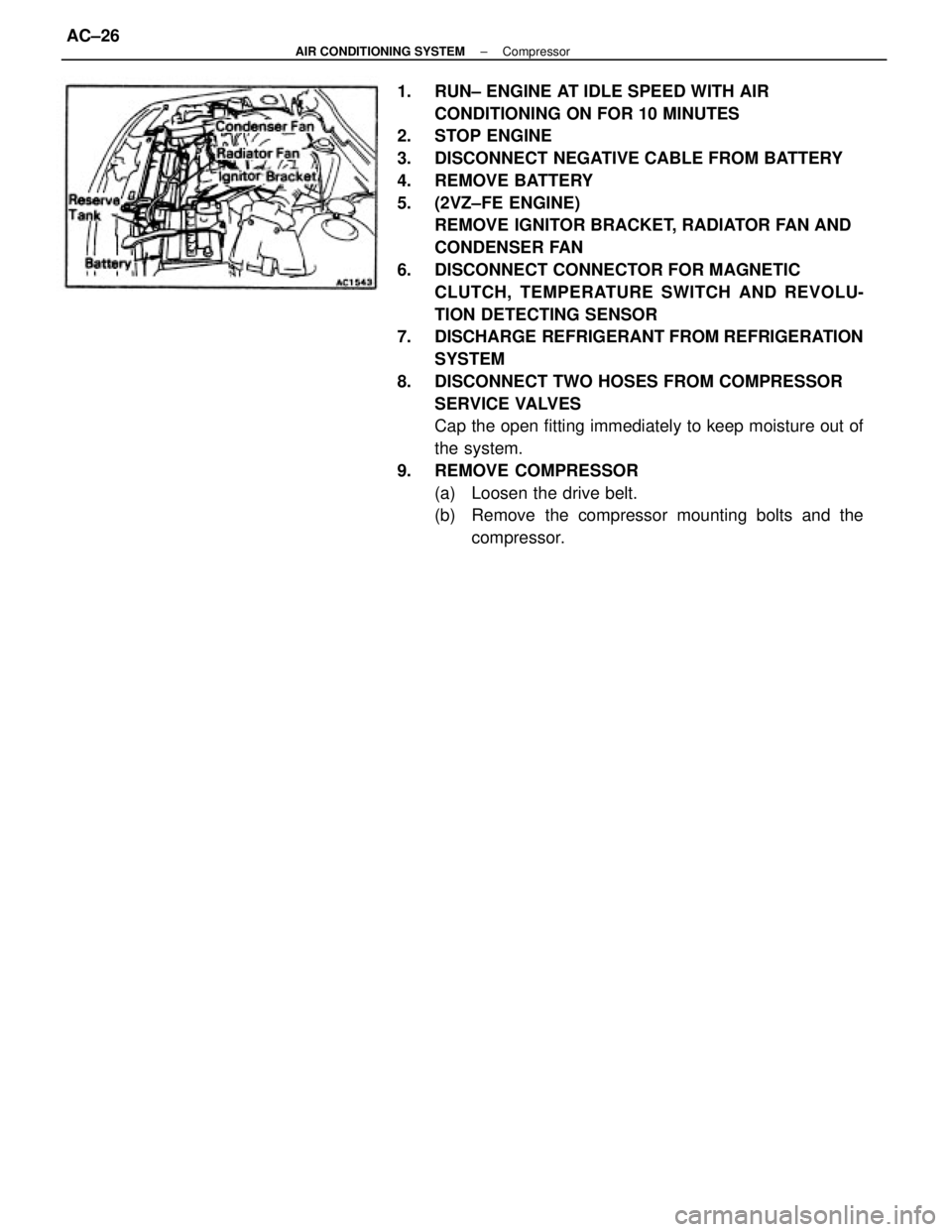

1. RUN± ENGINE AT IDLE SPEED WITH AIR

CONDITIONING ON FOR 10 MINUTES

2. STOP ENGINE

3. DISCONNECT NEGATIVE CABLE FROM BATTERY

4. REMOVE BATTERY

5. (2VZ±FE ENGINE)

REMOVE IGNITOR BRACKET, RADIATOR FAN AND

CONDENSER FAN

6. DISCONNECT CONNECTOR FOR MAGNETIC

CLUTCH, TEMPERATURE SWITCH AND REVOLU-

TION DETECTING SENSOR

7. DISCHARGE REFRIGERANT FROM REFRIGERATION

SYSTEM

8. DISCONNECT TWO HOSES FROM COMPRESSOR

SERVICE VALVES

Cap the open fitting immediately to keep moisture out of

the system.

9. REMOVE COMPRESSOR

(a) Loosen the drive belt.

(b) Remove the compressor mounting bolts and the

compressor.

± AIR CONDITIONING SYSTEMCompressorAC±26

Page 229 of 2389

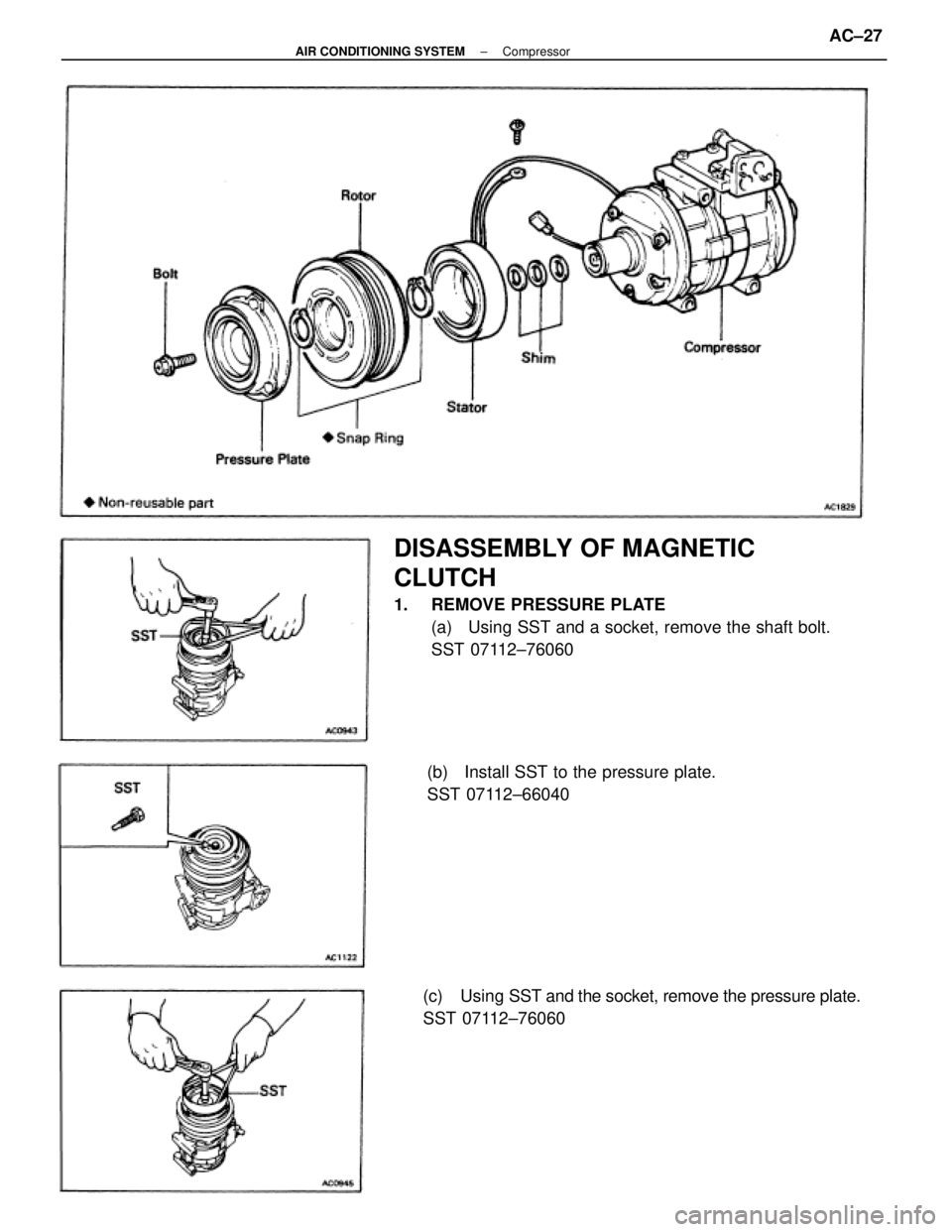

DISASSEMBLY OF MAGNETIC

CLUTCH

1. REMOVE PRESSURE PLATE

(a) Using SST and a socket, remove the shaft bolt.

SST 07112±76060

(c) Using SST and the socket, remove the pressure plate.

SST 07112±76060(b) Install SST to the pressure plate.

SST 07112±66040

± AIR CONDITIONING SYSTEMCompressorAC±27

Page 230 of 2389

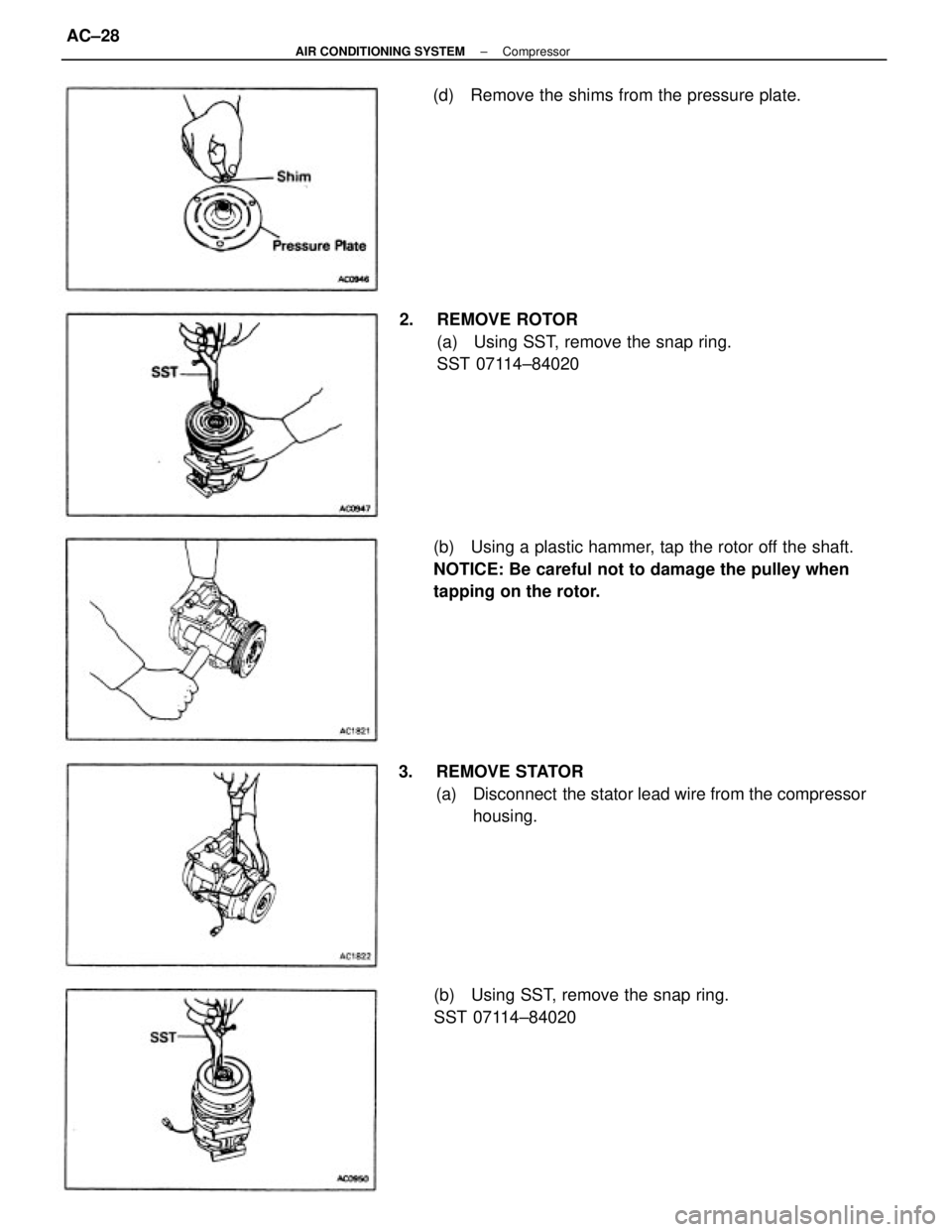

3. REMOVE STATOR

(a) Disconnect the stator lead wire from the compressor

housing. (b) Using a plastic hammer, tap the rotor off the shaft.

NOTICE: Be careful not to damage the pulley when

tapping on the rotor. 2. REMOVE ROTOR

(a) Using SST, remove the snap ring.

SST 07114±84020

(b) Using SST, remove the snap ring.

SST 07114±84020 (d) Remove the shims from the pressure plate.

± AIR CONDITIONING SYSTEMCompressorAC±28

Page 231 of 2389

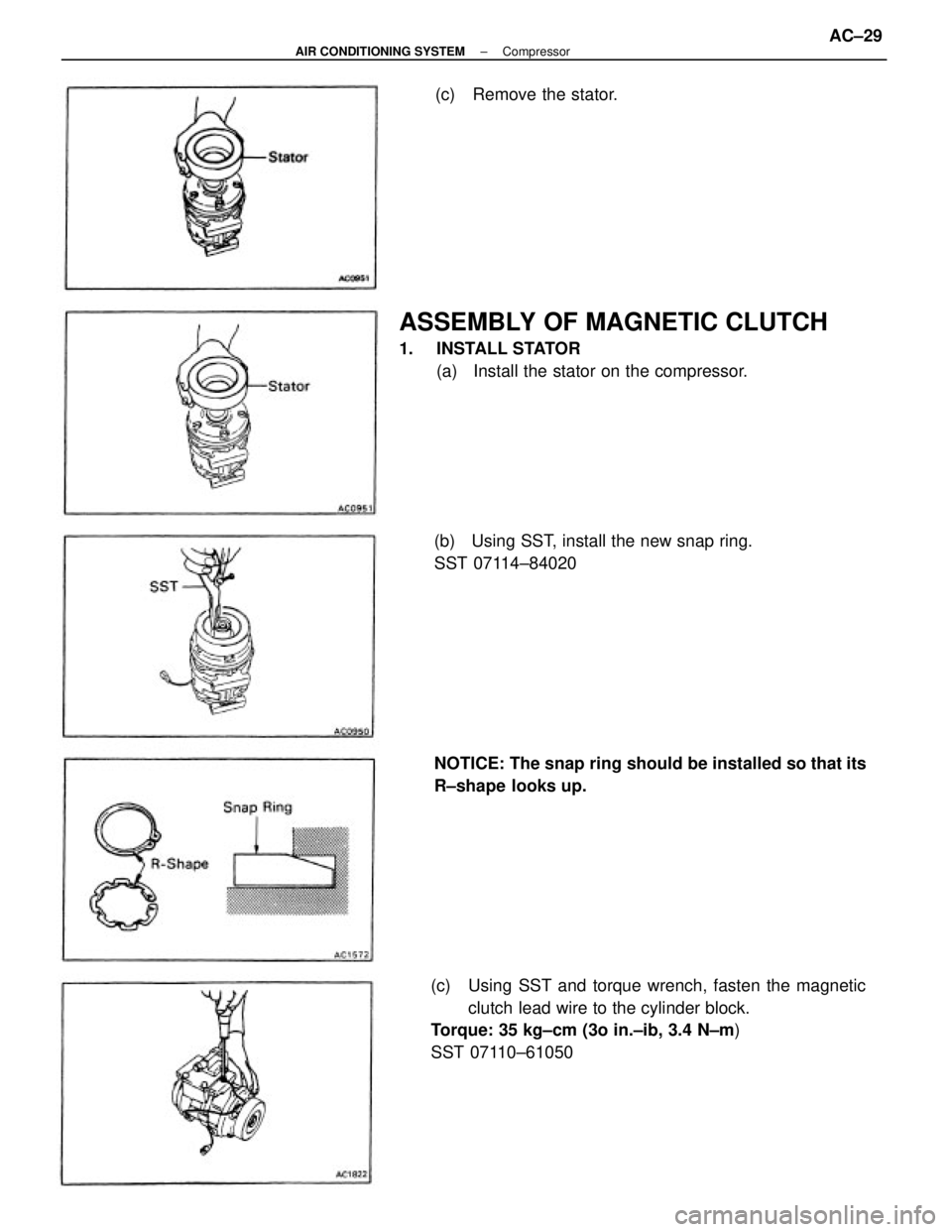

(c) Using SST and torque wrench, fasten the magnetic

clutch lead wire to the cylinder block.

Torque: 35 kg±cm (3o in.±ib, 3.4 N±m)

SST 07110±61050

ASSEMBLY OF MAGNETIC CLUTCH

1. INSTALL STATOR

(a) Install the stator on the compressor.

NOTICE: The snap ring should be installed so that its

R±shape looks up. (b) Using SST, install the new snap ring.

SST 07114±84020(c) Remove the stator.

± AIR CONDITIONING SYSTEMCompressorAC±29

Page 232 of 2389

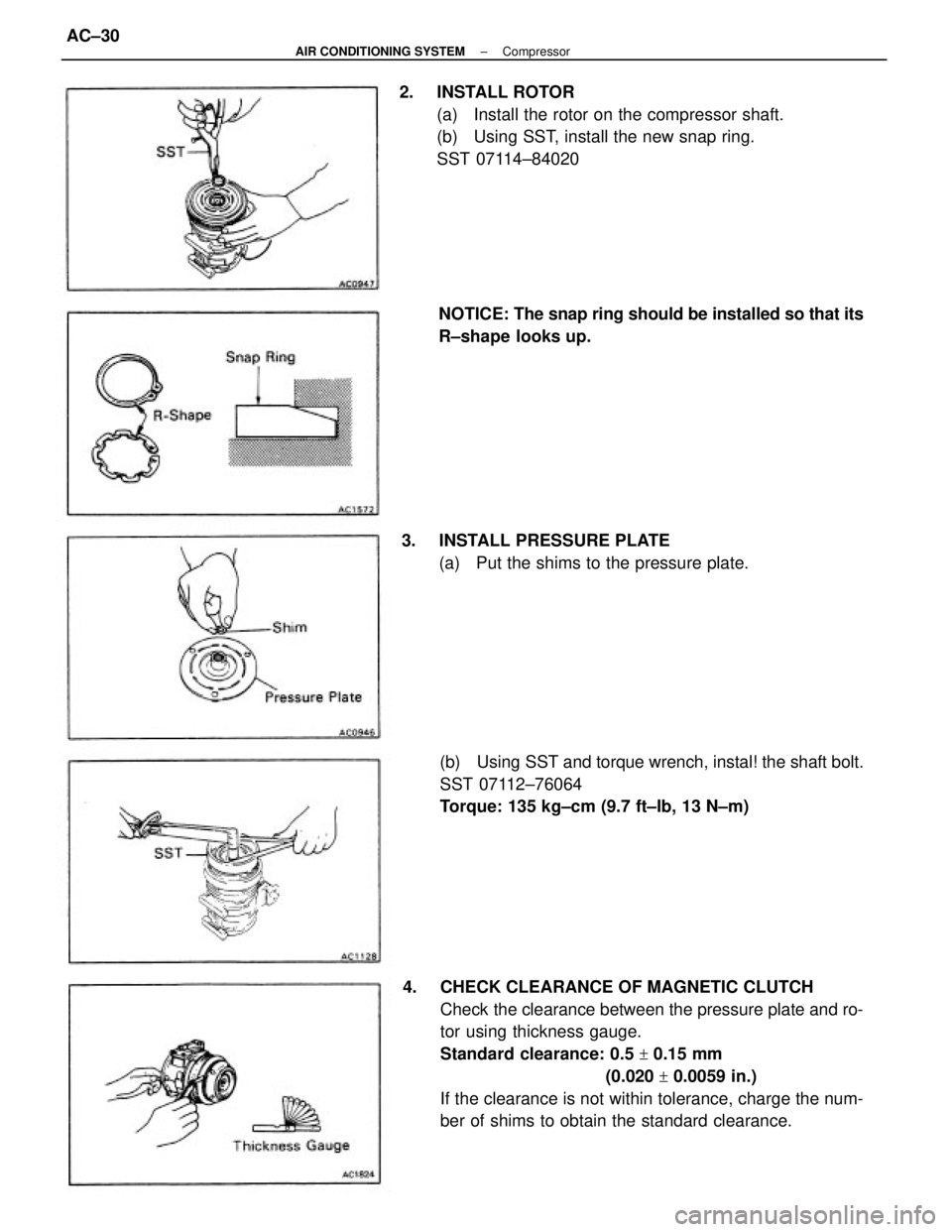

4. CHECK CLEARANCE OF MAGNETIC CLUTCH

Check the clearance between the pressure plate and ro-

tor using thickness gauge.

Standard clearance: 0.5

+ 0.15 mm

(0.020

+ 0.0059 in.)

If the clearance is not within tolerance, charge the num-

ber of shims to obtain the standard clearance. 2. INSTALL ROTOR

(a) Install the rotor on the compressor shaft.

(b) Using SST, install the new snap ring.

SST 07114±84020

(b) Using SST and torque wrench, instal! the shaft bolt.

SST 07112±76064

Torque: 135 kg±cm (9.7 ft±Ib, 13 N±m) NOTICE: The snap ring should be installed so that its

R±shape looks up.

3. INSTALL PRESSURE PLATE

(a) Put the shims to the pressure plate.

± AIR CONDITIONING SYSTEMCompressorAC±30

Page 233 of 2389

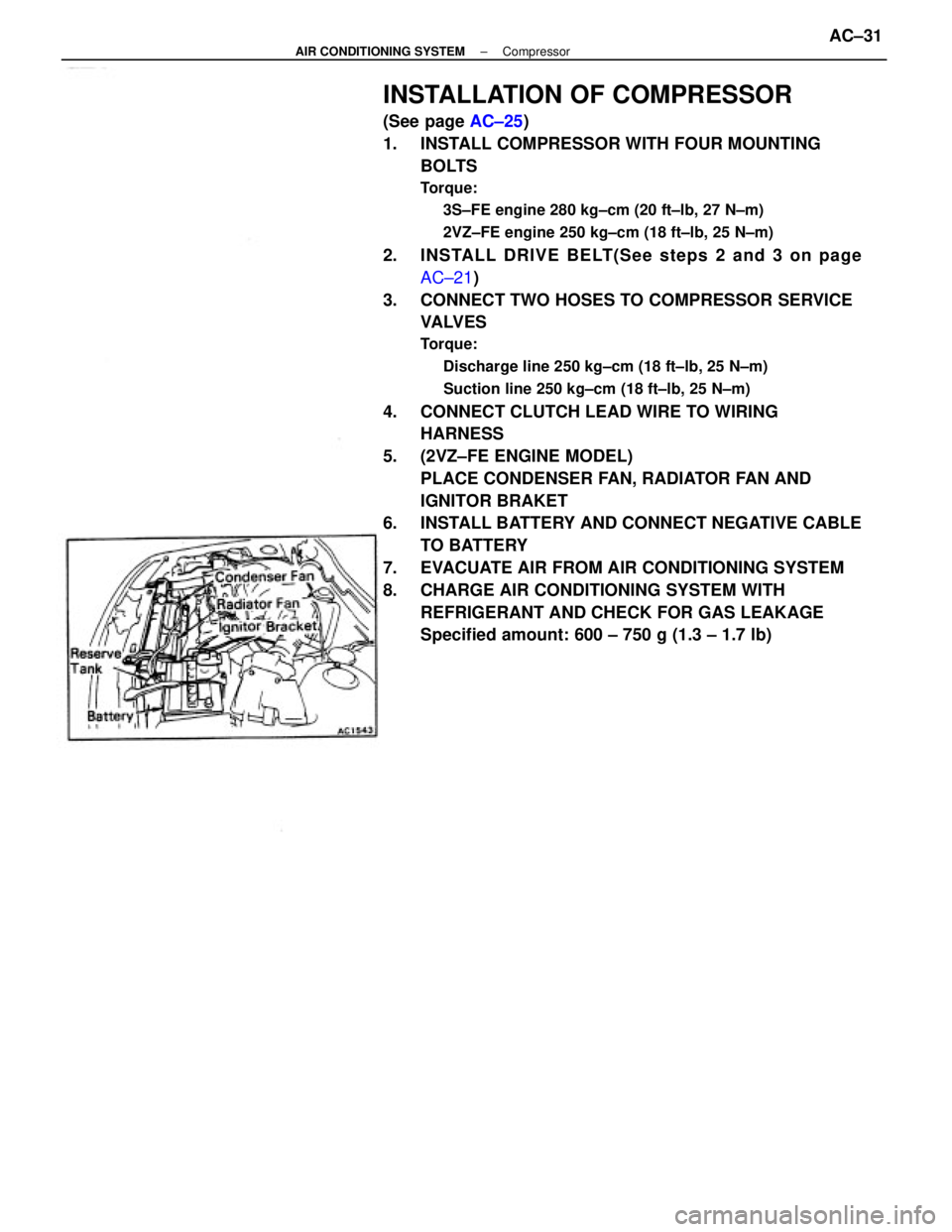

INSTALLATION OF COMPRESSOR

(See page AC±25)

1. INSTALL COMPRESSOR WITH FOUR MOUNTING

BOLTS

Torque:

3S±FE engine 280 kg±cm (20 ft±lb, 27 N±m)

2VZ±FE engine 250 kg±cm (18 ft±lb, 25 N±m)

2. INS TALL DRIV E BE LT(S e e ste ps 2 and 3 on pa ge

AC±21)

3. CONNECT TWO HOSES TO COMPRESSOR SERVICE

VALVES

Torque:

Discharge line 250 kg±cm (18 ft±lb, 25 N±m)

Suction line 250 kg±cm (18 ft±lb, 25 N±m)

4. CONNECT CLUTCH LEAD WIRE TO WIRING

HARNESS

5. (2VZ±FE ENGINE MODEL)

PLACE CONDENSER FAN, RADIATOR FAN AND

IGNITOR BRAKET

6. INSTALL BATTERY AND CONNECT NEGATIVE CABLE

TO BATTERY

7. EVACUATE AIR FROM AIR CONDITIONING SYSTEM

8. CHARGE AIR CONDITIONING SYSTEM WITH

REFRIGERANT AND CHECK FOR GAS LEAKAGE

Specified amount: 600 ± 750 g (1.3 ± 1.7 lb)

± AIR CONDITIONING SYSTEMCompressorAC±31

Page 234 of 2389

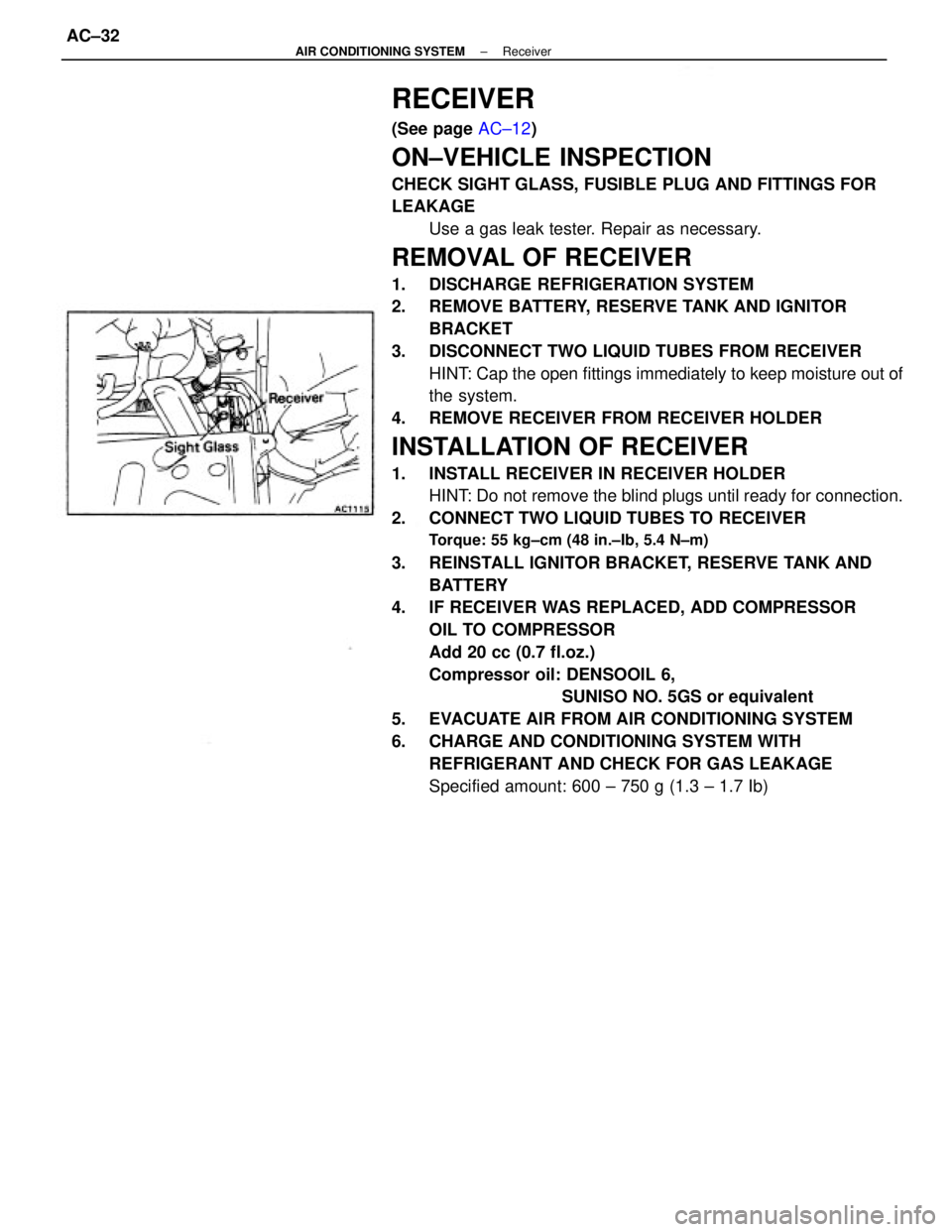

RECEIVER

(See page AC±12)

ON±VEHICLE INSPECTION

CHECK SIGHT GLASS, FUSIBLE PLUG AND FITTINGS FOR

LEAKAGE

Use a gas leak tester. Repair as necessary.

REMOVAL OF RECEIVER

1. DISCHARGE REFRIGERATION SYSTEM

2. REMOVE BATTERY, RESERVE TANK AND IGNITOR

BRACKET

3. DISCONNECT TWO LIQUID TUBES FROM RECEIVER

HINT: Cap the open fittings immediately to keep moisture out of

the system.

4. REMOVE RECEIVER FROM RECEIVER HOLDER

INSTALLATION OF RECEIVER

1. INSTALL RECEIVER IN RECEIVER HOLDER

HINT: Do not remove the blind plugs until ready for connection.

2. CONNECT TWO LIQUID TUBES TO RECEIVER

Torque: 55 kg±cm (48 in.±Ib, 5.4 N±m)

3. REINSTALL IGNITOR BRACKET, RESERVE TANK AND

BATTERY

4. IF RECEIVER WAS REPLACED, ADD COMPRESSOR

OIL TO COMPRESSOR

Add 20 cc (0.7 fl.oz.)

Compressor oil: DENSOOIL 6,

SUNISO NO. 5GS or equivalent

5. EVACUATE AIR FROM AIR CONDITIONING SYSTEM

6. CHARGE AND CONDITIONING SYSTEM WITH

REFRIGERANT AND CHECK FOR GAS LEAKAGE

Specified amount: 600 ± 750 g (1.3 ± 1.7 Ib)

± AIR CONDITIONING SYSTEMReceiverAC±32

Page 235 of 2389

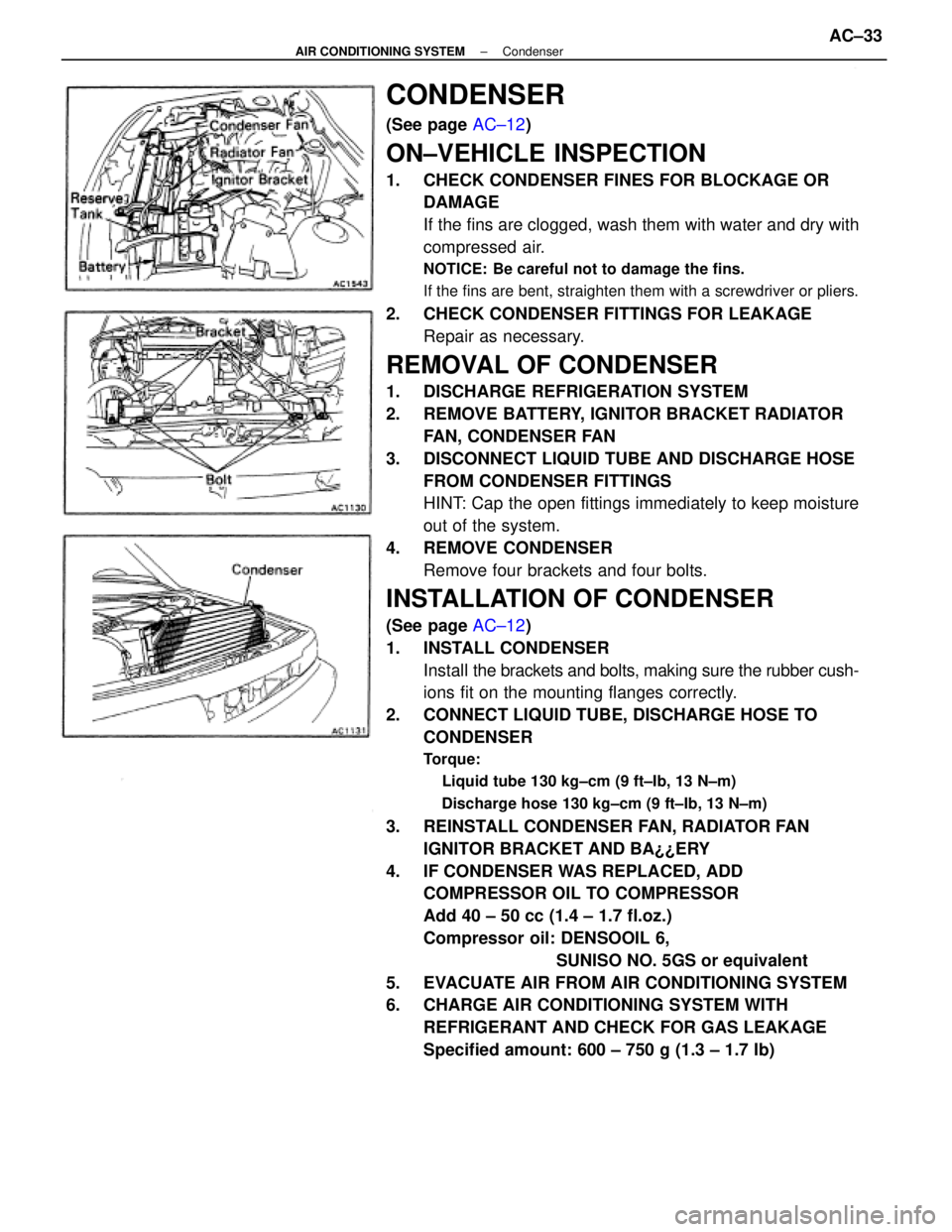

CONDENSER

(See page AC±12)

ON±VEHICLE INSPECTION

1. CHECK CONDENSER FINES FOR BLOCKAGE OR

DAMAGE

If the fins are clogged, wash them with water and dry with

compressed air.

NOTICE: Be careful not to damage the fins.

If the fins are bent, straighten them with a screwdriver or pliers.

2. CHECK CONDENSER FITTINGS FOR LEAKAGE

Repair as necessary.

REMOVAL OF CONDENSER

1. DISCHARGE REFRIGERATION SYSTEM

2. REMOVE BATTERY, IGNITOR BRACKET RADIATOR

FAN, CONDENSER FAN

3. DISCONNECT LIQUID TUBE AND DISCHARGE HOSE

FROM CONDENSER FITTINGS

HINT: Cap the open fittings immediately to keep moisture

out of the system.

4. REMOVE CONDENSER

Remove four brackets and four bolts.

INSTALLATION OF CONDENSER

(See page AC±12)

1. INSTALL CONDENSER

Install the brackets and bolts, making sure the rubber cush-

ions fit on the mounting flanges correctly.

2. CONNECT LIQUID TUBE, DISCHARGE HOSE TO

CONDENSER

Torque:

Liquid tube 130 kg±cm (9 ft±Ib, 13 N±m)

Discharge hose 130 kg±cm (9 ft±Ib, 13 N±m)

3. REINSTALL CONDENSER FAN, RADIATOR FAN

IGNITOR BRACKET AND BA¿¿ERY

4. IF CONDENSER WAS REPLACED, ADD

COMPRESSOR OIL TO COMPRESSOR

Add 40 ± 50 cc (1.4 ± 1.7 fl.oz.)

Compressor oil: DENSOOIL 6,

SUNISO NO. 5GS or equivalent

5. EVACUATE AIR FROM AIR CONDITIONING SYSTEM

6. CHARGE AIR CONDITIONING SYSTEM WITH

REFRIGERANT AND CHECK FOR GAS LEAKAGE

Specified amount: 600 ± 750 g (1.3 ± 1.7 Ib)

± AIR CONDITIONING SYSTEMCondenserAC±33

Page 236 of 2389

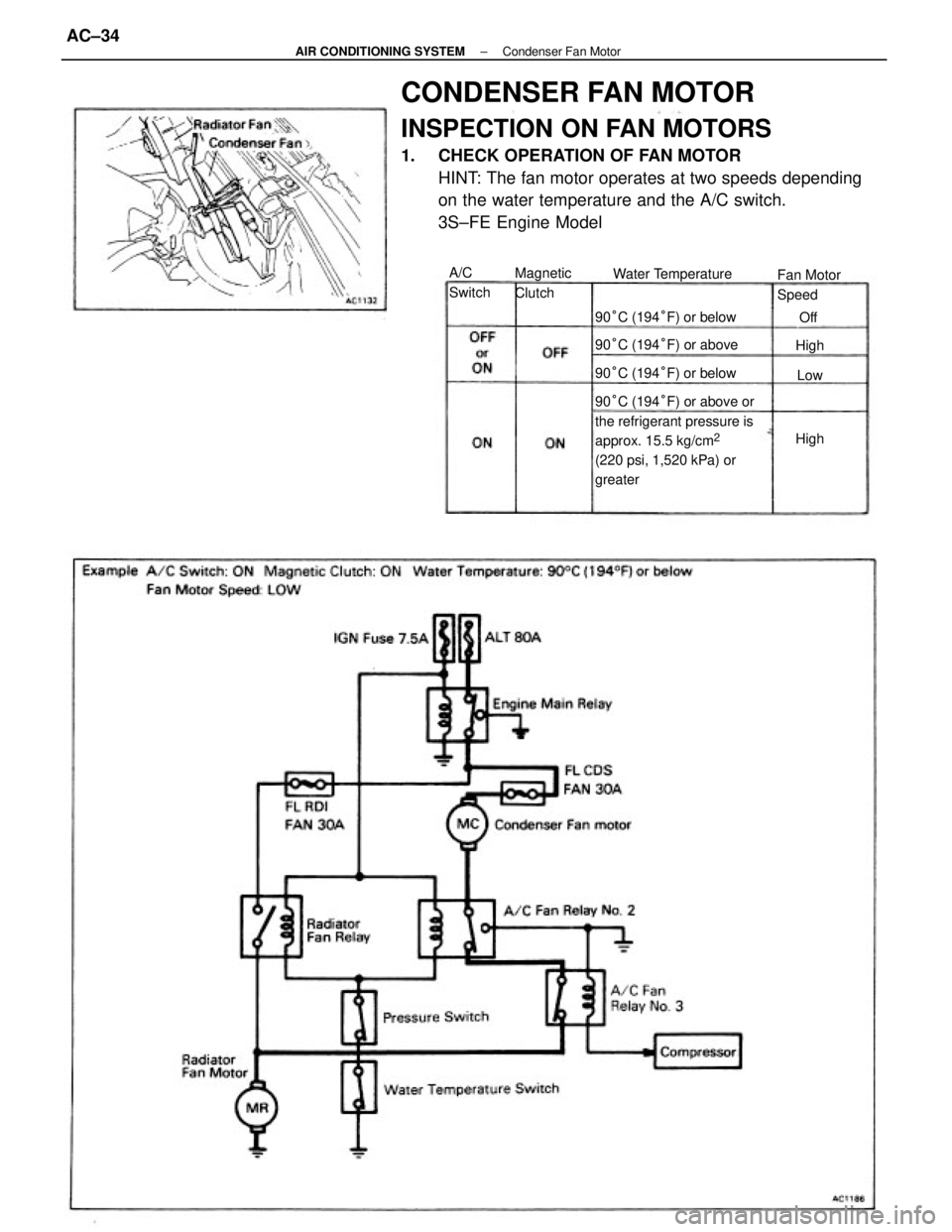

CONDENSER FAN MOTOR

INSPECTION ON FAN MOTORS

1. CHECK OPERATION OF FAN MOTOR

HINT: The fan motor operates at two speeds depending

on the water temperature and the A/C switch.

3S±FE Engine Model

90°C (194°F) or above or

the refrigerant pressure is

approx. 15.5 kg/cm

2

(220 psi, 1,520 kPa) or

greater 90°C (194°F) or below

90°C (194°F) or above

90°C (194°F) or below Water Temperature

Fan Motor

Speed Magnetic

Clutch A/C

Switch

High

HighLowOff

± AIR CONDITIONING SYSTEMCondenser Fan MotorAC±34