oil pressure TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 852 of 2389

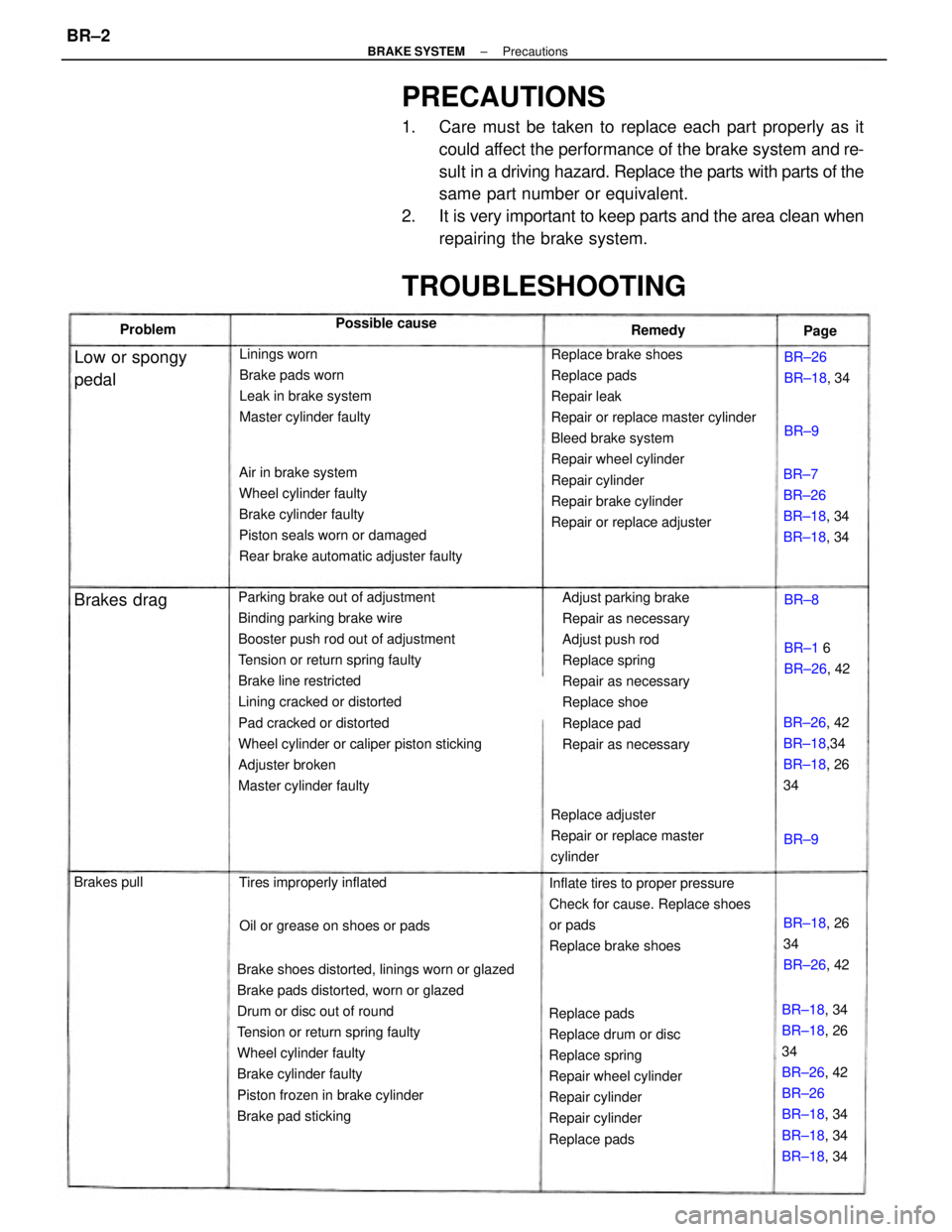

PRECAUTIONS

1. Care must be taken to replace each part properly as it

could affect the performance of the brake system and re-

sult in a driving hazard. Replace the parts with parts of the

same part number or equivalent.

2. It is very important to keep parts and the area clean when

repairing the brake system.

Parking brake out of adjustment

Binding parking brake wire

Booster push rod out of adjustment

Tension or return spring faulty

Brake line restricted

Lining cracked or distorted

Pad cracked or distorted

Wheel cylinder or caliper piston sticking

Adjuster broken

Master cylinder faulty

Brake shoes distorted, linings worn or glazed

Brake pads distorted, worn or glazed

Drum or disc out of round

Tension or return spring faulty

Wheel cylinder faulty

Brake cylinder faulty

Piston frozen in brake cylinder

Brake pad stickingReplace brake shoes

Replace pads

Repair leak

Repair or replace master cylinder

Bleed brake system

Repair wheel cylinder

Repair cylinder

Repair brake cylinder

Repair or replace adjuster Air in brake system

Wheel cylinder faulty

Brake cylinder faulty

Piston seals worn or damaged

Rear brake automatic adjuster faulty

Adjust parking brake

Repair as necessary

Adjust push rod

Replace spring

Repair as necessary

Replace shoe

Replace pad

Repair as necessary

Replace pads

Replace drum or disc

Replace spring

Repair wheel cylinder

Repair cylinder

Repair cylinder

Replace padsInflate tires to proper pressure

Check for cause. Replace shoes

or pads

Replace brake shoes Linings worn

Brake pads worn

Leak in brake system

Master cylinder faulty

BR±18, 34

BR±18, 26

34

BR±26, 42

BR±26

BR±18, 34

BR±18, 34

BR±18, 34 Replace adjuster

Repair or replace master

cylinder

TROUBLESHOOTING

BR±7

BR±26

BR±18, 34

BR±18, 34

BR±26, 42

BR±18,34

BR±18, 26

34

Oil or grease on shoes or pads Tires improperly inflated

BR±18, 26

34

BR±26, 42

Low or spongy

pedalBR±26

BR±18, 34

BR±1 6

BR±26, 42 Possible cause

Brakes drag

Brakes pullRemedy Problem

Page

BR±8

BR±9BR±9

± BRAKE SYSTEMPrecautionsBR±2

Page 853 of 2389

PRECAUTIONS

1. Care must be taken to replace each part properly as it

could affect the performance of the brake system and re-

sult in a driving hazard. Replace the parts with parts of the

same part number or equivalent.

2. It is very important to keep parts and the area clean when

repairing the brake system.

Parking brake out of adjustment

Binding parking brake wire

Booster push rod out of adjustment

Tension or return spring faulty

Brake line restricted

Lining cracked or distorted

Pad cracked or distorted

Wheel cylinder or caliper piston sticking

Adjuster broken

Master cylinder faulty

Brake shoes distorted, linings worn or glazed

Brake pads distorted, worn or glazed

Drum or disc out of round

Tension or return spring faulty

Wheel cylinder faulty

Brake cylinder faulty

Piston frozen in brake cylinder

Brake pad stickingReplace brake shoes

Replace pads

Repair leak

Repair or replace master cylinder

Bleed brake system

Repair wheel cylinder

Repair cylinder

Repair brake cylinder

Repair or replace adjuster Air in brake system

Wheel cylinder faulty

Brake cylinder faulty

Piston seals worn or damaged

Rear brake automatic adjuster faulty

Adjust parking brake

Repair as necessary

Adjust push rod

Replace spring

Repair as necessary

Replace shoe

Replace pad

Repair as necessary

Replace pads

Replace drum or disc

Replace spring

Repair wheel cylinder

Repair cylinder

Repair cylinder

Replace padsInflate tires to proper pressure

Check for cause. Replace shoes

or pads

Replace brake shoes Linings worn

Brake pads worn

Leak in brake system

Master cylinder faulty

BR±18, 34

BR±18, 26

34

BR±26, 42

BR±26

BR±18, 34

BR±18, 34

BR±18, 34 Replace adjuster

Repair or replace master

cylinder

TROUBLESHOOTING

BR±7

BR±26

BR±18, 34

BR±18, 34

BR±26, 42

BR±18,34

BR±18, 26

34

Oil or grease on shoes or pads Tires improperly inflated

BR±18, 26

34

BR±26, 42

Low or spongy

pedalBR±26

BR±18, 34

BR±16

BR±26, 42 Possible cause

Brakes drag

Brakes pullRemedy Problem

Page

BR±8

BR±9BR±9

± BRAKE SYSTEMTroubleshootingBR±2

Page 975 of 2389

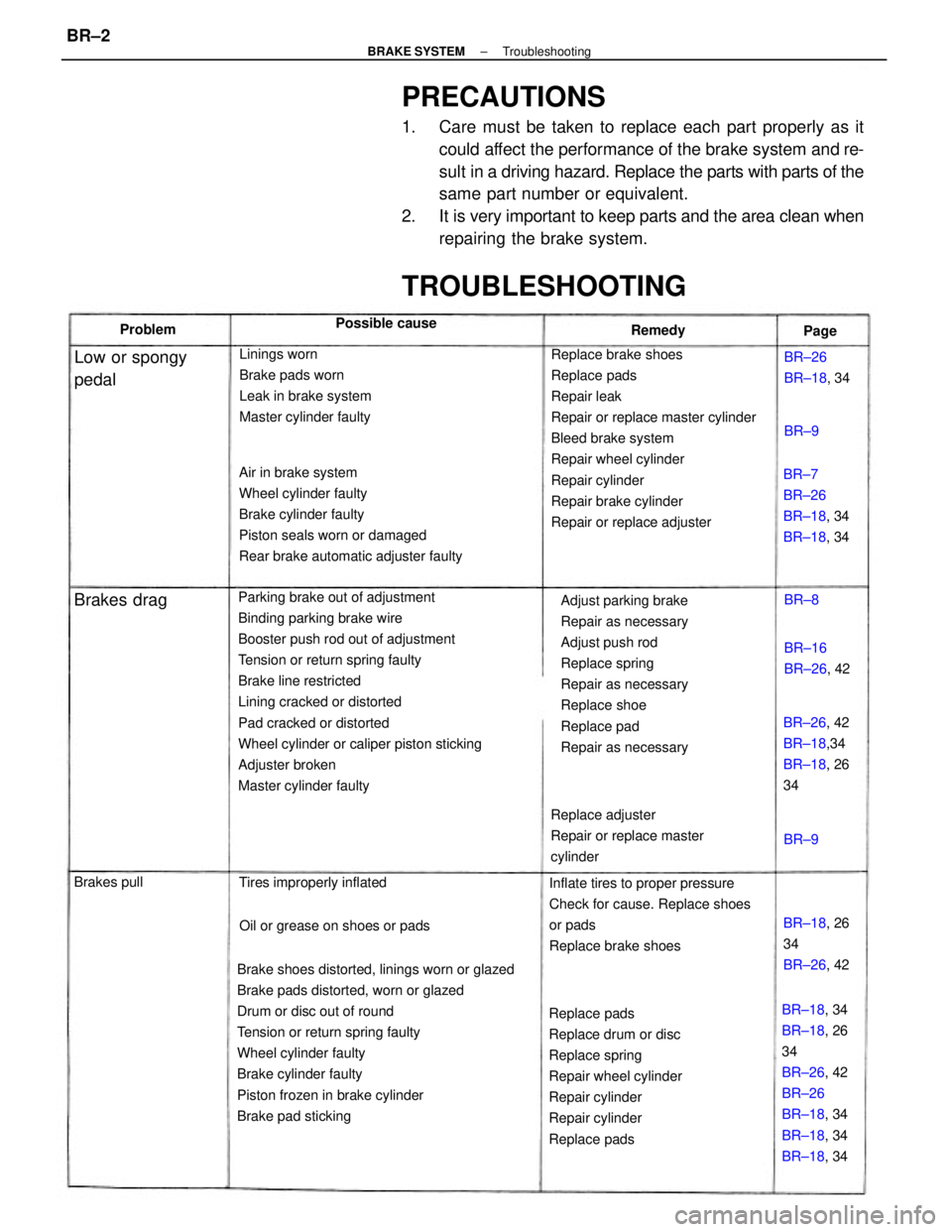

Clutch pedal freeplay excessive

Air in clutch lines

Clutch release cylinder faulty

Clutch master cylinder faulty

Clutch disc out of true, runout is excessive or

lining broken

Splines on input shaft or clutch disc dirty or

burred

Clutch pressure plate faulty

Clutch disc lining oily or worn out

Pressure plate faulty

Clutch diaphragm spring bent

Engine mounts looseClutch pedal freeplay insufficient

Clutch disc lining oily or worn out

Pressure plate faulty

Release fork binding

Inspect clutch disc

Replace clutch cover

Align clutch diaphragm spring

Repair as necessaryAdjust pedal freeplay

Bleed clutch system

Repair release cylinder

Repair master cylinder

Inspect clutch disc

Air in clutch lines

Clutch release cylinder faulty

Clutch master cylinder faultyAdjust pedal freeplay

inspect clutch disc

Replace clutch cover

inspect release fork

Bleed clutch system

Repair release cylinder

Repair master cylinder

Loose part inside housing

Release bearing worn or dirtyRepair as necessary

Replace clutch cover

TROUBLESHOOTING

Repair as necessary

Replace release bearing Hard to shift or will not

shiftCL±3

CL±4

CL±7

CL±5

CL±9

Clutch pedal spongyClutch grabs/

chattersCL±3

CL±9

CL±9

CL±9

CL±9

CL±9

CL±9

CL±4

CL±7

CL±5 Possible cause

Clutch noisy Clutch slipsProblem

RemedyPage

± CLUTCHTroubleshootingCL±2

Page 989 of 2389

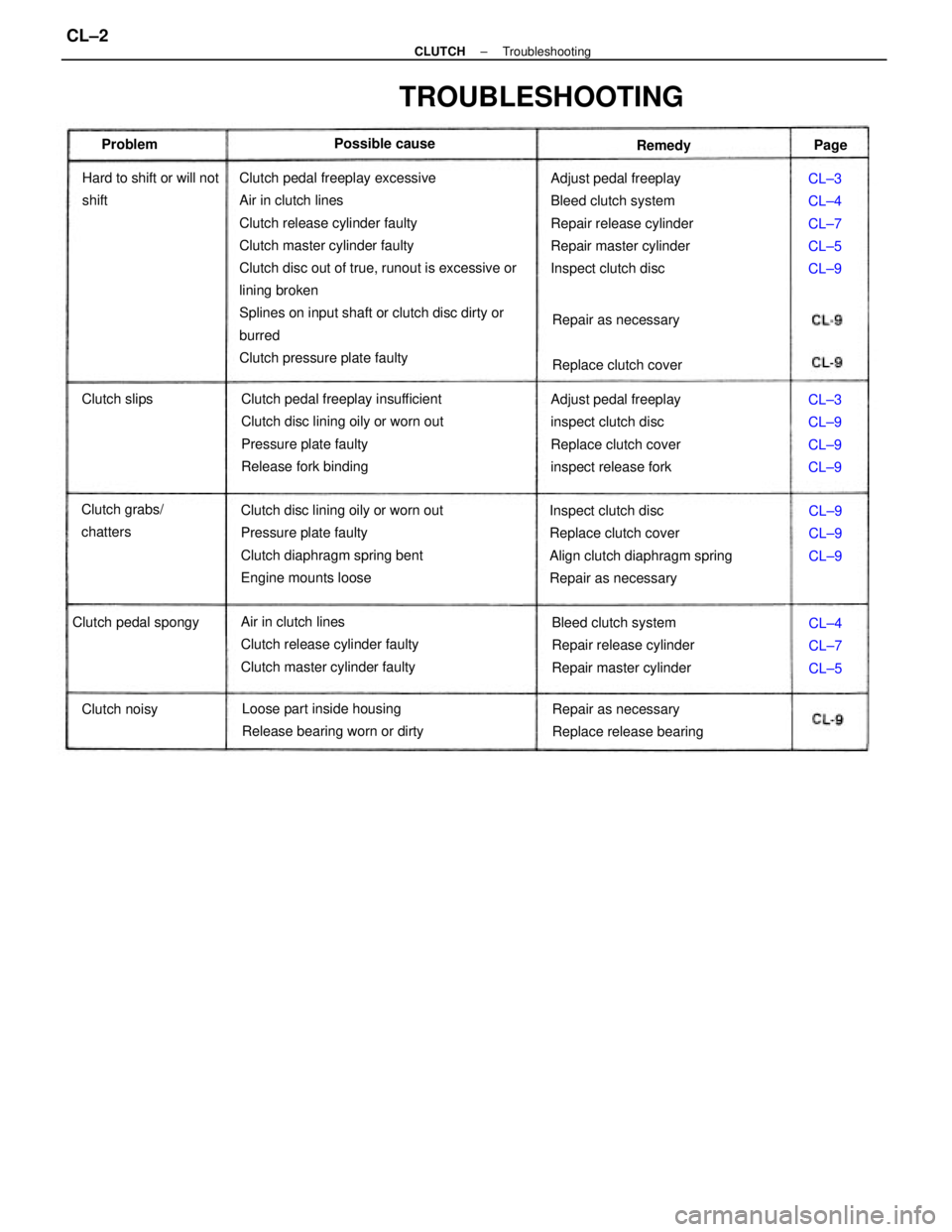

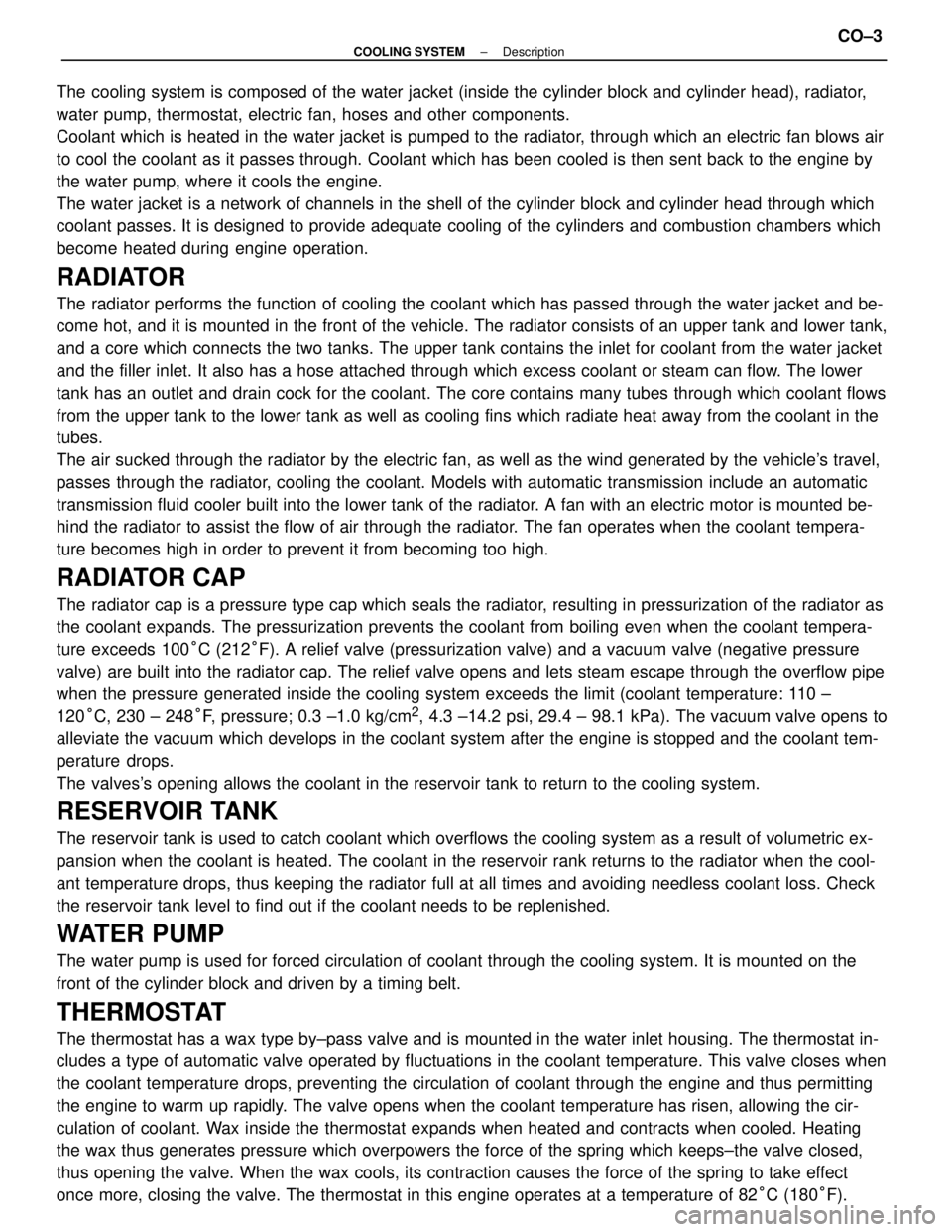

The cooling system is composed of the water jacket (inside the cylinder block and cylinder head), radiator,

water pump, thermostat, electric fan, hoses and other components.

Coolant which is heated in the water jacket is pumped to the radiator, through which an electric fan blows air

to cool the coolant as it passes through. Coolant which has been cooled is then sent back to the engine by

the water pump, where it cools the engine.

The water jacket is a network of channels in the shell of the cylinder block and cylinder head through which

coolant passes. It is designed to provide adequate cooling of the cylinders and combustion chambers which

become heated during engine operation.

RADIATOR

The radiator performs the function of cooling the coolant which has passed through the water jacket and be-

come hot, and it is mounted in the front of the vehicle. The radiator consists of an upper tank and lower tank,

and a core which connects the two tanks. The upper tank contains the inlet for coolant from the water jacket

and the filler inlet. It also has a hose attached through which excess coolant or steam can flow. The lower

tank has an outlet and drain cock for the coolant. The core contains many tubes through which coolant flows

from the upper tank to the lower tank as well as cooling fins which radiate heat away from the coolant in the

tubes.

The air sucked through the radiator by the electric fan, as well as the wind generated by the vehicle's travel,

passes through the radiator, cooling the coolant. Models with automatic transmission include an automatic

transmission fluid cooler built into the lower tank of the radiator. A fan with an electric motor is mounted be-

hind the radiator to assist the flow of air through the radiator. The fan operates when the coolant tempera-

ture becomes high in order to prevent it from becoming too high.

RADIATOR CAP

The radiator cap is a pressure type cap which seals the radiator, resulting in pressurization of the radiator as

the coolant expands. The pressurization prevents the coolant from boiling even when the coolant tempera-

ture exceeds 100°C (212°F). A relief valve (pressurization valve) and a vacuum valve (negative pressure

valve) are built into the radiator cap. The relief valve opens and lets steam escape through the overflow pipe

when the pressure generated inside the cooling system exceeds the limit (coolant temperature: 110 ±

120°C, 230 ± 248°F, pressure; 0.3 ±1.0 kg/cm

2, 4.3 ±14.2 psi, 29.4 ± 98.1 kPa). The vacuum valve opens to

alleviate the vacuum which develops in the coolant system after the engine is stopped and the coolant tem-

perature drops.

The valves's opening allows the coolant in the reservoir tank to return to the cooling system.

RESERVOIR TANK

The reservoir tank is used to catch coolant which overflows the cooling system as a result of volumetric ex-

pansion when the coolant is heated. The coolant in the reservoir rank returns to the radiator when the cool-

ant temperature drops, thus keeping the radiator full at all times and avoiding needless coolant loss. Check

the reservoir tank level to find out if the coolant needs to be replenished.

WATER PUMP

The water pump is used for forced circulation of coolant through the cooling system. It is mounted on the

front of the cylinder block and driven by a timing belt.

THERMOSTAT

The thermostat has a wax type by±pass valve and is mounted in the water inlet housing. The thermostat in-

cludes a type of automatic valve operated by fluctuations in the coolant temperature. This valve closes when

the coolant temperature drops, preventing the circulation of coolant through the engine and thus permitting

the engine to warm up rapidly. The valve opens when the coolant temperature has risen, allowing the cir-

culation of coolant. Wax inside the thermostat expands when heated and contracts when cooled. Heating

the wax thus generates pressure which overpowers the force of the spring which keeps±the valve closed,

thus opening the valve. When the wax cools, its contraction causes the force of the spring to take effect

once more, closing the valve. The thermostat in this engine operates at a temperature of 82°C (180°F).

± COOLING SYSTEMDescriptionCO±3

Page 990 of 2389

3. (3S±FE)

REPLACE ENGINE COOLANT

(a) Remove the radiator cap.

CAUTION: To avoid the danger of being burned, do not re-

move it while the engine and radiator are still hot

as fluid and steam can be blown out under pressure.

(b) Drain the coolant from the .radiator and engine drain cocks.

(Engine drain cock at the right rear of engine block.)

(c) Close the drain cocks.

Torque (Engine drain cock):

130 kg±cm (9 ft±Ib, 13 N±m) HINT: If the engine tends to overheat, removal of the

thermostat will adversely effect cooling efficiency.

CHECK AND REPLACEMENT OF

ENGINE COOLANT

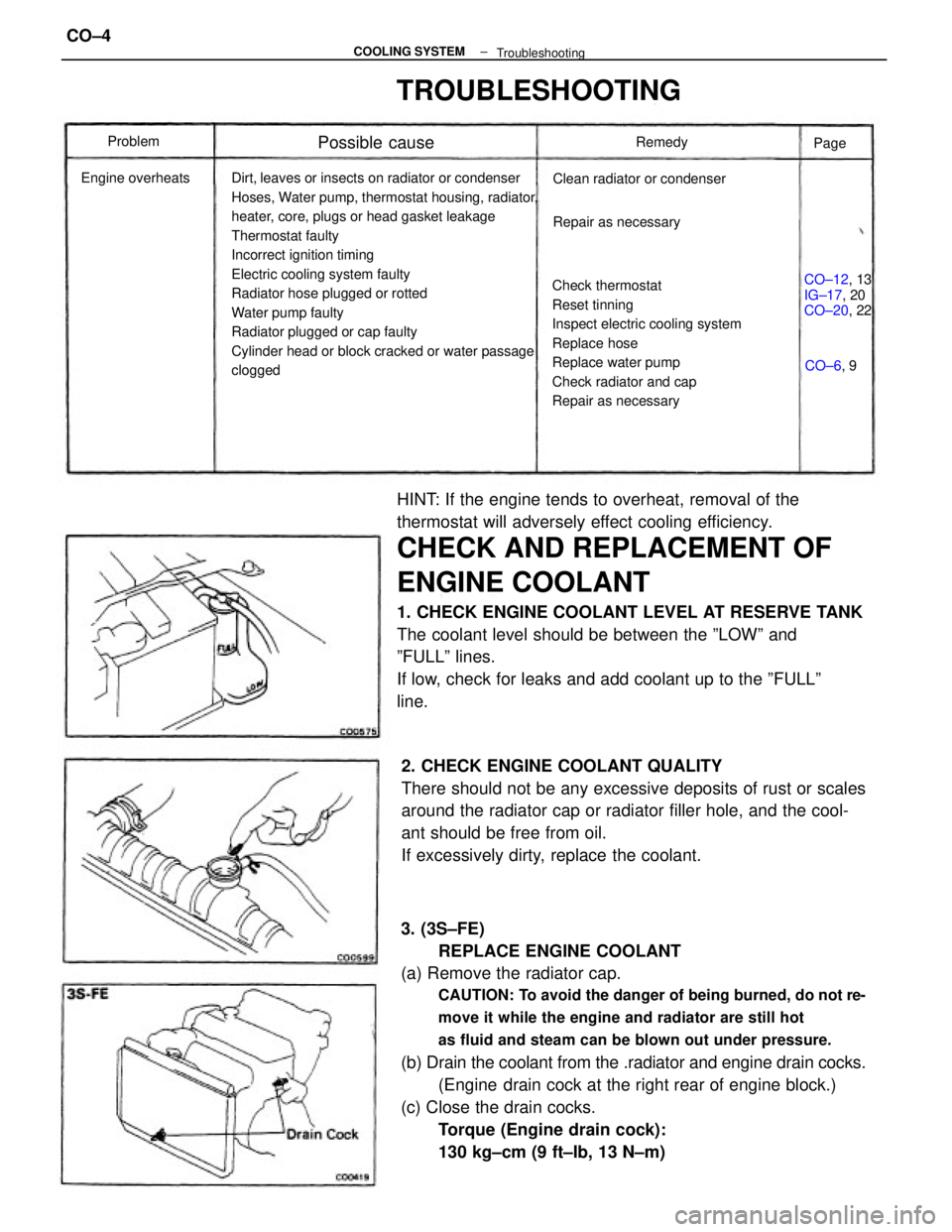

1. CHECK ENGINE COOLANT LEVEL AT RESERVE TANK

The coolant level should be between the ºLOWº and

ºFULLº lines.

If low, check for leaks and add coolant up to the ºFULLº

line.

Dirt, leaves or insects on radiator or condenser

Hoses, Water pump, thermostat housing, radiator,

heater, core, plugs or head gasket leakage

Thermostat faulty

Incorrect ignition timing

Electric cooling system faulty

Radiator hose plugged or rotted

Water pump faulty

Radiator plugged or cap faulty

Cylinder head or block cracked or water passage

clogged

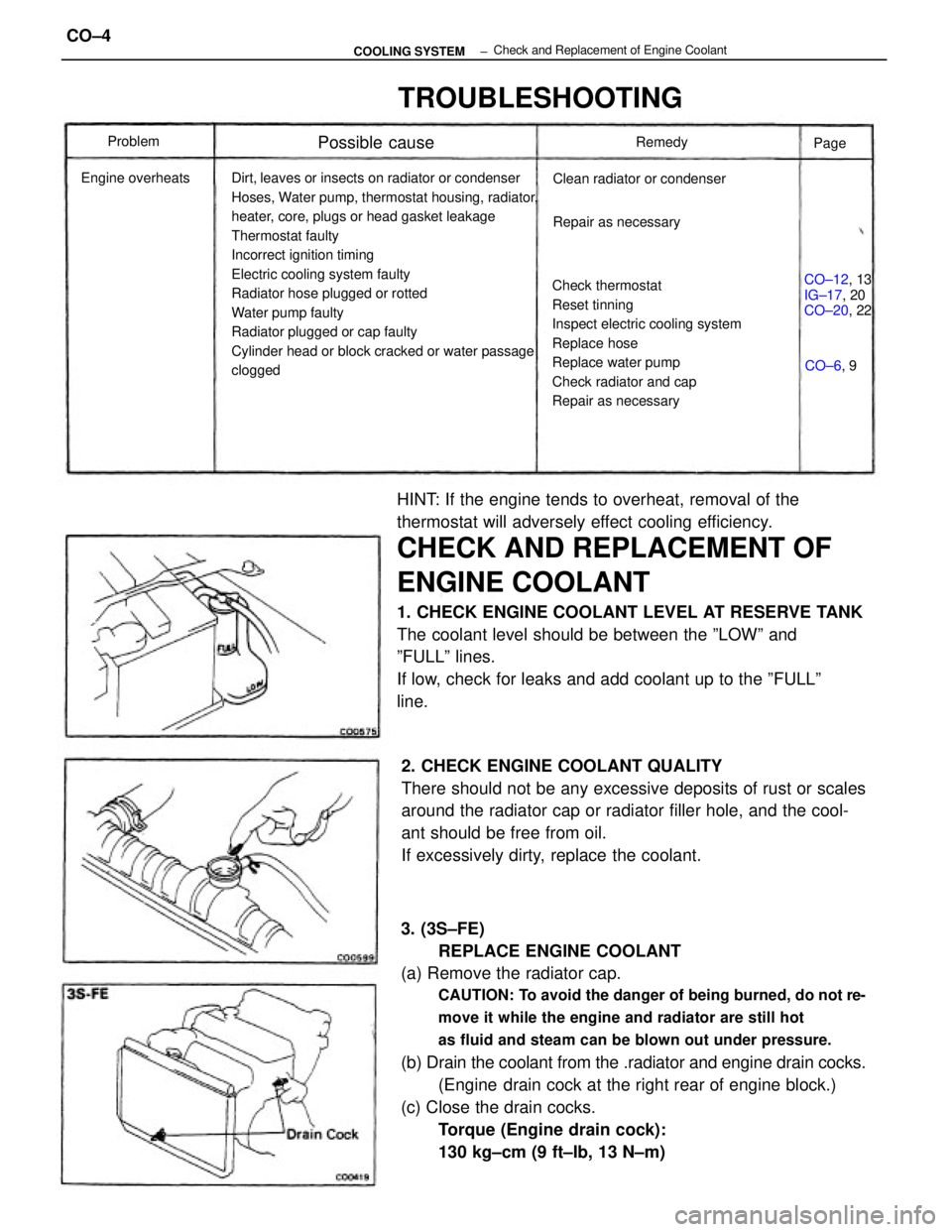

2. CHECK ENGINE COOLANT QUALITY

There should not be any excessive deposits of rust or scales

around the radiator cap or radiator filler hole, and the cool-

ant should be free from oil.

If excessively dirty, replace the coolant.

Check thermostat

Reset tinning

Inspect electric cooling system

Replace hose

Replace water pump

Check radiator and cap

Repair as necessary

TROUBLESHOOTING

CO±12, 13

IG±17, 20

CO±20, 22 Clean radiator or condenser

Repair as necessary Engine overheats

Possible causeRemedy Problem

CO±6, 9 Page

± COOLING SYSTEM

TroubleshootingCO±4

Page 991 of 2389

3. (3S±FE)

REPLACE ENGINE COOLANT

(a) Remove the radiator cap.

CAUTION: To avoid the danger of being burned, do not re-

move it while the engine and radiator are still hot

as fluid and steam can be blown out under pressure.

(b) Drain the coolant from the .radiator and engine drain cocks.

(Engine drain cock at the right rear of engine block.)

(c) Close the drain cocks.

Torque (Engine drain cock):

130 kg±cm (9 ft±Ib, 13 N±m) HINT: If the engine tends to overheat, removal of the

thermostat will adversely effect cooling efficiency.

CHECK AND REPLACEMENT OF

ENGINE COOLANT

1. CHECK ENGINE COOLANT LEVEL AT RESERVE TANK

The coolant level should be between the ºLOWº and

ºFULLº lines.

If low, check for leaks and add coolant up to the ºFULLº

line.

Dirt, leaves or insects on radiator or condenser

Hoses, Water pump, thermostat housing, radiator,

heater, core, plugs or head gasket leakage

Thermostat faulty

Incorrect ignition timing

Electric cooling system faulty

Radiator hose plugged or rotted

Water pump faulty

Radiator plugged or cap faulty

Cylinder head or block cracked or water passage

clogged

2. CHECK ENGINE COOLANT QUALITY

There should not be any excessive deposits of rust or scales

around the radiator cap or radiator filler hole, and the cool-

ant should be free from oil.

If excessively dirty, replace the coolant.

Check thermostat

Reset tinning

Inspect electric cooling system

Replace hose

Replace water pump

Check radiator and cap

Repair as necessary

TROUBLESHOOTING

CO±12, 13

IG±17, 20

CO±20, 22 Clean radiator or condenser

Repair as necessary Engine overheats

Possible causeRemedy Problem

CO±6, 9 Page

± COOLING SYSTEMCheck and Replacement of Engine CoolantCO±4

Page 1003 of 2389

REMOVAL OF RADIATO

1. DRAIN ENGINE COOLANT (See page CO±4 or 5)

2. REMOVE BATTERY

3. REMOVE IGNITION COIL (2VZ±FE), IGNITER AND

BRACKET ASSEMBLY

4. DISCONNECT COOLANT RESERVOIR HOSE

5. DISCONNECT RADIATOR NOSE

6. DISCONNECT COOLING FAN MOTOR

CONNECTOR(S)

7. (A/T)

DISCONNECT OIL COOLER HOSES

8. REMOVE RADIATOR AND ELECTRIC COOLING

FAN(S)

Remove the two bolts, supports and radiator.

9. REMOVE ELECTRIC COOLING FANS FROM RADIATOR

DISASSEMBLY OF RADIATOR

(See page CO±15)

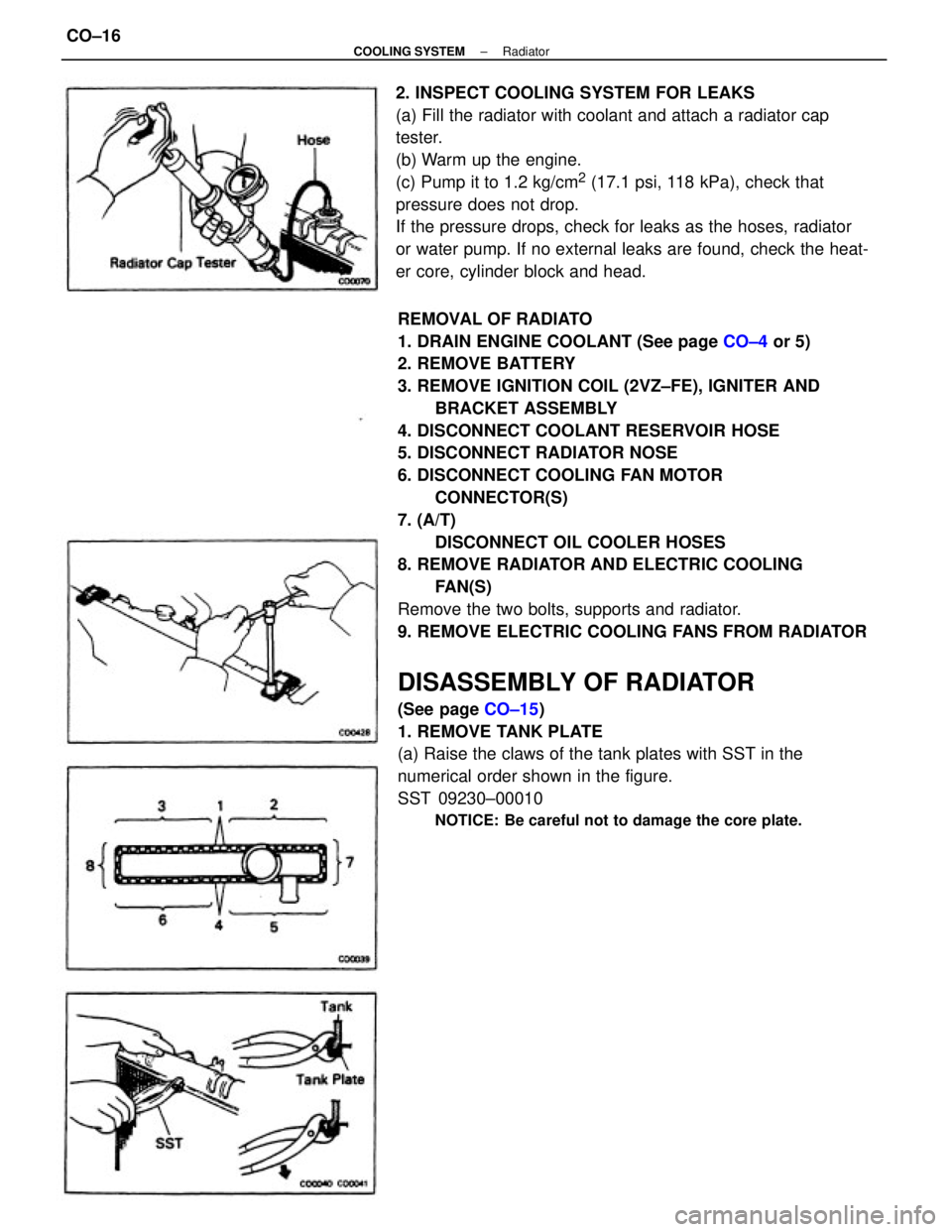

1. REMOVE TANK PLATE

(a) Raise the claws of the tank plates with SST in the

numerical order shown in the figure.

SST 09230±00010

NOTICE: Be careful not to damage the core plate.

2. INSPECT COOLING SYSTEM FOR LEAKS

(a) Fill the radiator with coolant and attach a radiator cap

tester.

(b) Warm up the engine.

(c) Pump it to 1.2 kg/cm

2 (17.1 psi, 118 kPa), check that

pressure does not drop.

If the pressure drops, check for leaks as the hoses, radiator

or water pump. If no external leaks are found, check the heat-

er core, cylinder block and head.

± COOLING SYSTEMRadiatorCO±16

Page 1022 of 2389

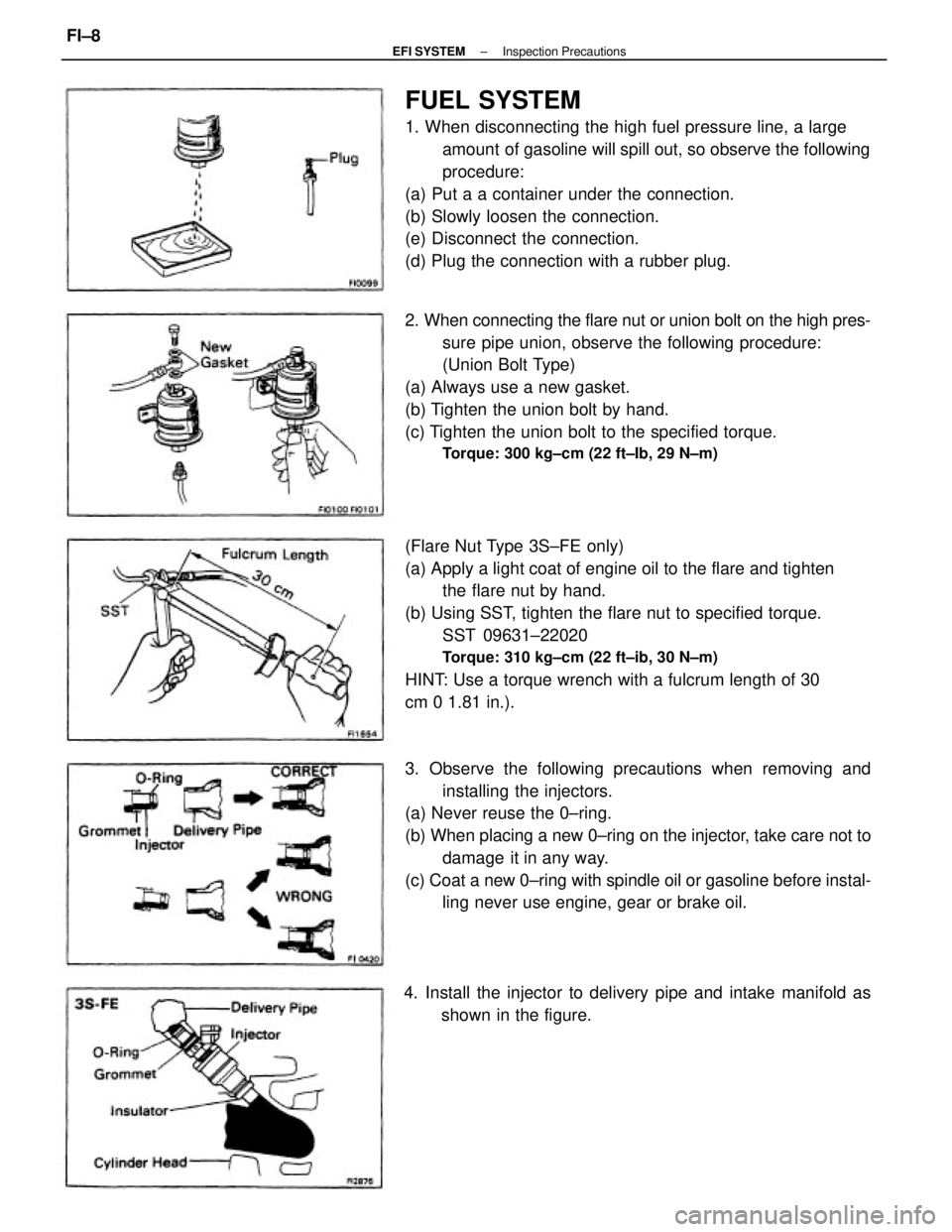

FUEL SYSTEM

1. When disconnecting the high fuel pressure line, a large

amount of gasoline will spill out, so observe the following

procedure:

(a) Put a a container under the connection.

(b) Slowly loosen the connection.

(e) Disconnect the connection.

(d) Plug the connection with a rubber plug.

(Flare Nut Type 3S±FE only)

(a) Apply a light coat of engine oil to the flare and tighten

the flare nut by hand.

(b) Using SST, tighten the flare nut to specified torque.

SST 09631±22020

Torque: 310 kg±cm (22 ft±ib, 30 N±m)

HINT: Use a torque wrench with a fulcrum length of 30

cm 0 1.81 in.). 2. When connecting the flare nut or union bolt on the high pres-

sure pipe union, observe the following procedure:

(Union Bolt Type)

(a) Always use a new gasket.

(b) Tighten the union bolt by hand.

(c) Tighten the union bolt to the specified torque.

Torque: 300 kg±cm (22 ft±Ib, 29 N±m)

3. Observe the following precautions when removing and

installing the injectors.

(a) Never reuse the 0±ring.

(b) When placing a new 0±ring on the injector, take care not to

damage it in any way.

(c) Coat a new 0±ring with spindle oil or gasoline before instal-

ling never use engine, gear or brake oil.

4. Install the injector to delivery pipe and intake manifold as

shown in the figure.

± EFI SYSTEMInspection PrecautionsFI±8

Page 1027 of 2389

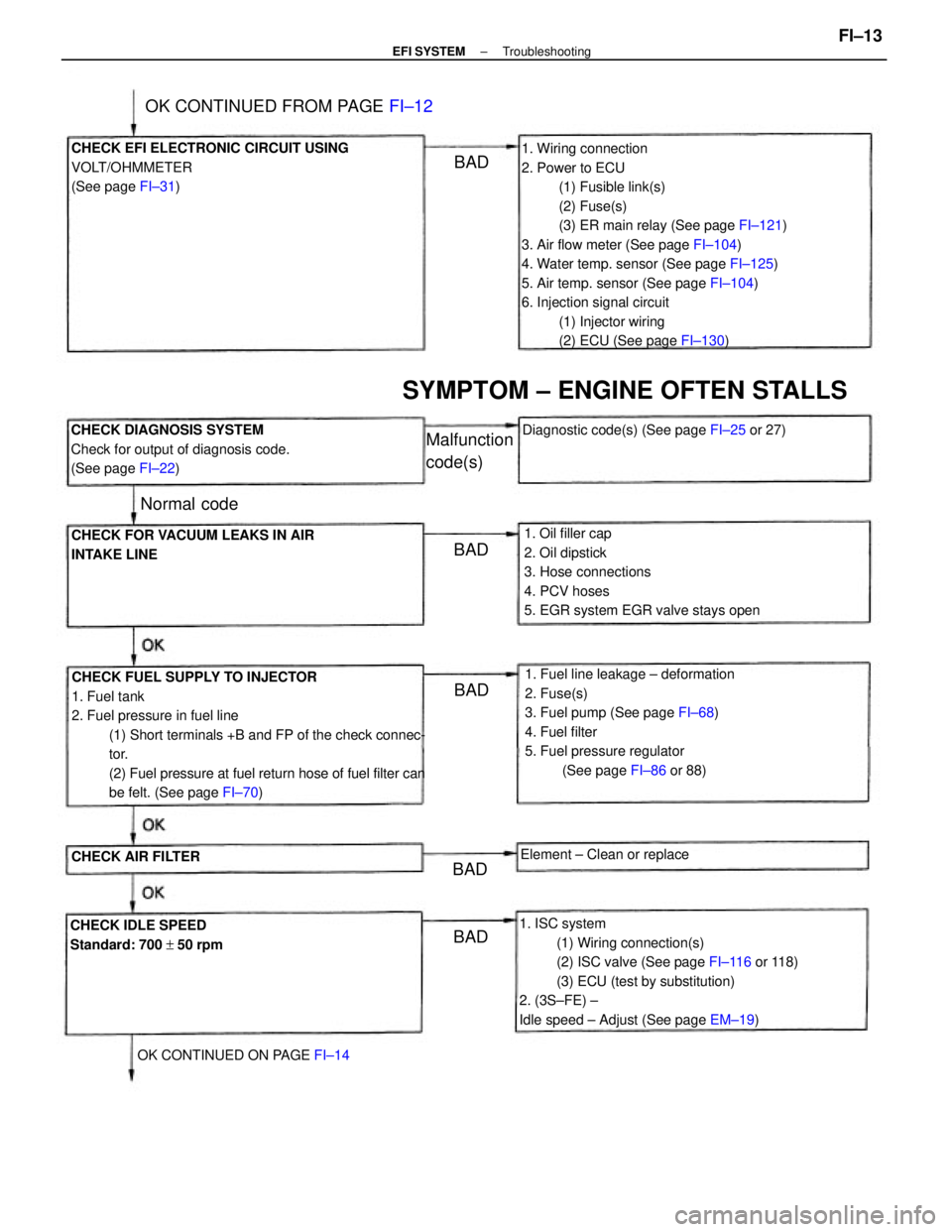

1. Wiring connection

2. Power to ECU

(1) Fusible link(s)

(2) Fuse(s)

(3) ER main relay (See page FI±121)

3. Air flow meter (See page FI±104)

4. Water temp. sensor (See page FI±125)

5. Air temp. sensor (See page FI±104)

6. Injection signal circuit

(1) Injector wiring

(2) ECU (See page FI±130)

CHECK FUEL SUPPLY TO INJECTOR

1. Fuel tank

2. Fuel pressure in fuel line

(1) Short terminals +B and FP of the check connec-

tor.

(2) Fuel pressure at fuel return hose of fuel filter can

be felt. (See page FI±70)

1. ISC system

(1) Wiring connection(s)

(2) ISC valve (See page FI±116 or 118)

(3) ECU (test by substitution)

2. (3S±FE) ±

Idle speed ± Adjust (See page EM±19) 1. Fuel line leakage ± deformation

2. Fuse(s)

3. Fuel pump (See page FI±68)

4. Fuel filter

5. Fuel pressure regulator

(See page FI±86 or 88) 1. Oil filler cap

2. Oil dipstick

3. Hose connections

4. PCV hoses

5. EGR system EGR valve stays open CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See page FI±31)

CHECK DIAGNOSIS SYSTEM

Check for output of diagnosis code.

(See page FI±22)

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE

SYMPTOM ± ENGINE OFTEN STALLS

CHECK IDLE SPEED

Standard: 700 + 50 rpmDiagnostic code(s) (See page FI±25 or 27)

OK CONTINUED FROM PAGE FI±12

OK CONTINUED ON PAGE FI±14Element ± Clean or replace

CHECK AIR FILTER

Malfunction

code(s)

Normal code

BADBAD

BAD

BADBAD

± EFI SYSTEMTroubleshootingFI±13

Page 1032 of 2389

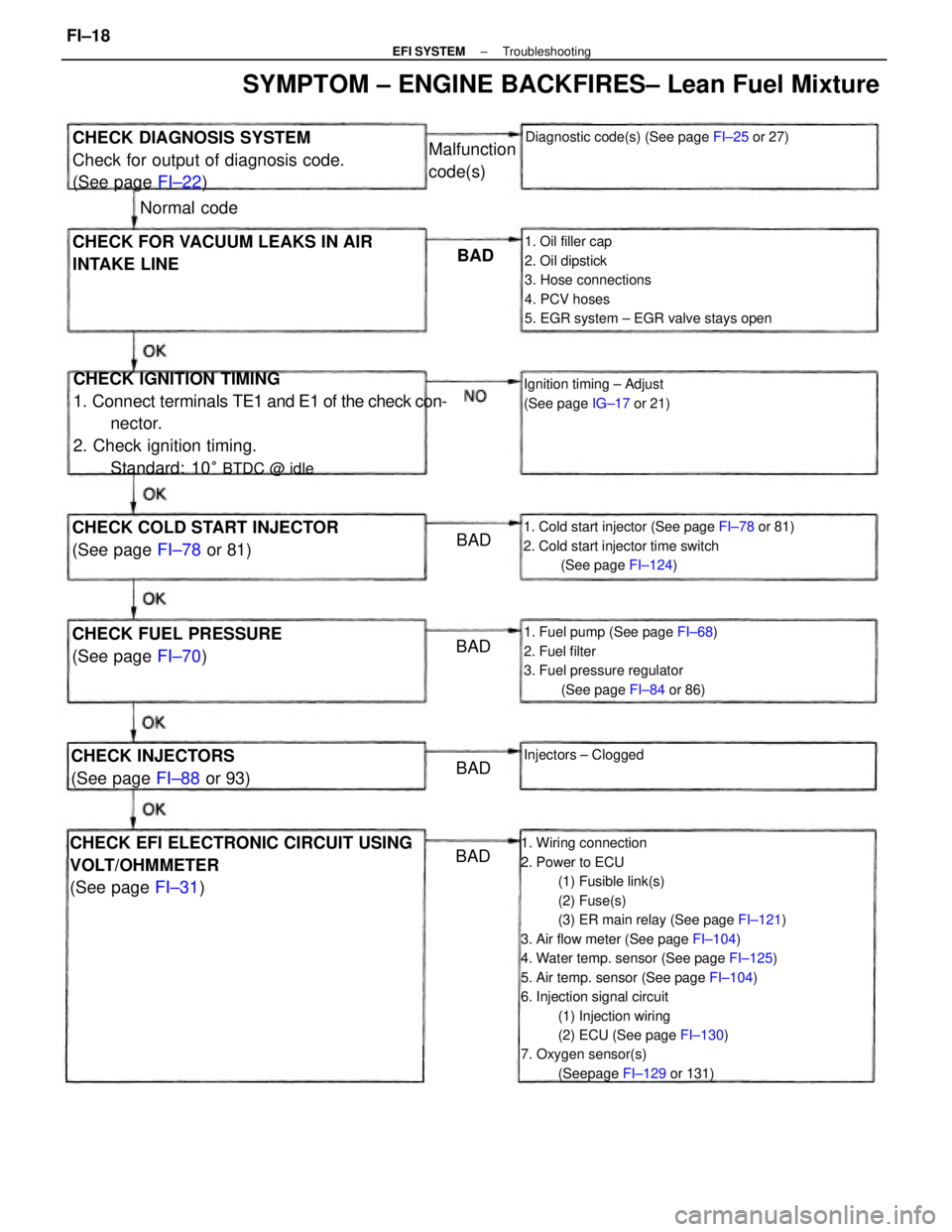

1. Wiring connection

2. Power to ECU

(1) Fusible link(s)

(2) Fuse(s)

(3) ER main relay (See page FI±121)

3. Air flow meter (See page FI±104)

4. Water temp. sensor (See page FI±125)

5. Air temp. sensor (See page FI±104)

6. Injection signal circuit

(1) Injection wiring

(2) ECU (See page FI±130)

7. Oxygen sensor(s)

(Seepage FI±129 or 131)

CHECK IGNITION TIMING

1. Connect terminals TE1 and E1 of the check con-

nector.

2. Check ignition timing.

Standard: 10

° BTDC @ idle

1. Oil filler cap

2. Oil dipstick

3. Hose connections

4. PCV hoses

5. EGR system ± EGR valve stays open

CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See page FI±31)

1. Cold start injector (See page FI±78 or 81)

2. Cold start injector time switch

(See page FI±124)

1. Fuel pump (See page FI±68)

2. Fuel filter

3. Fuel pressure regulator

(See page FI±84 or 86)

CHECK DIAGNOSIS SYSTEM

Check for output of diagnosis code.

(See page FI±22)

SYMPTOM ± ENGINE BACKFIRES± Lean Fuel Mixture

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE

CHECK COLD START INJECTOR

(See page FI±78 or 81)

CHECK FUEL PRESSURE

(See page FI±70)

Diagnostic code(s) (See page FI±25 or 27)

Ignition timing ± Adjust

(See page IG±17 or 21)

CHECK INJECTORS

(See page FI±88 or 93)Injectors ± Clogged

Malfunction

code(s)

Normal code

BAD

BAD

BAD BAD

BAD

± EFI SYSTEMTroubleshootingFI±18