timing belt TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1221 of 2389

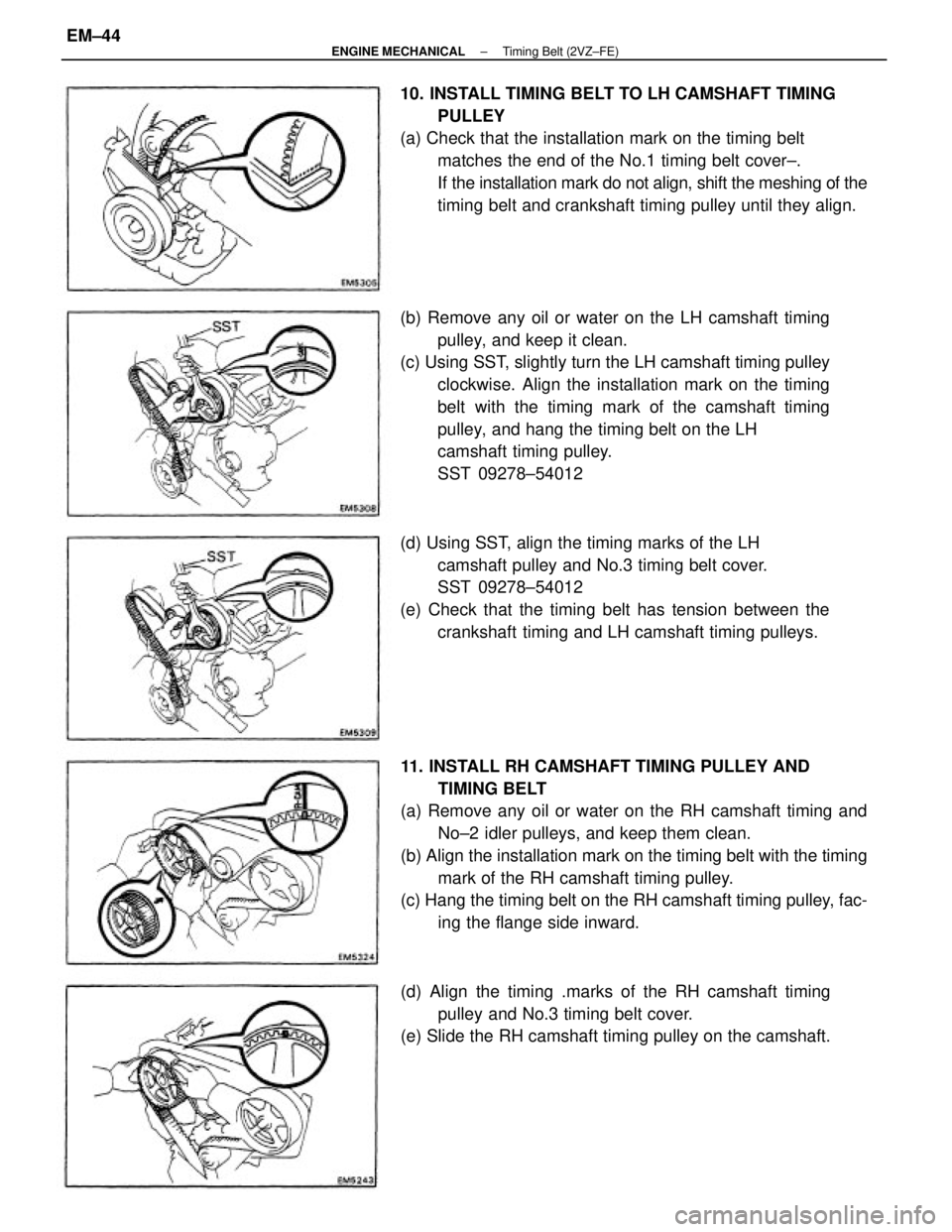

11. INSTALL RH CAMSHAFT TIMING PULLEY AND

TIMING BELT

(a) Remove any oil or water on the RH camshaft timing and

No±2 idler pulleys, and keep them clean.

(b) Align the installation mark on the timing belt with the timing

mark of the RH camshaft timing pulley.

(c) Hang the timing belt on the RH camshaft timing pulley, fac-

ing the flange side inward. (b) Remove any oil or water on the LH camshaft timing

pulley, and keep it clean.

(c) Using SST, slightly turn the LH camshaft timing pulley

clockwise. Align the installation mark on the timing

belt with the timing mark of the camshaft timing

pulley, and hang the timing belt on the LH

camshaft timing pulley.

SST 09278±54012 10. INSTALL TIMING BELT TO LH CAMSHAFT TIMING

PULLEY

(a) Check that the installation mark on the timing belt

matches the end of the No.1 timing belt cover±.

If the installation mark do not align, shift the meshing of the

timing belt and crankshaft timing pulley until they align.

(d) Using SST, align the timing marks of the LH

camshaft pulley and No.3 timing belt cover.

SST 09278±54012

(e) Check that the timing belt has tension between the

crankshaft timing and LH camshaft timing pulleys.

(d) Align the timing .marks of the RH camshaft timing

pulley and No.3 timing belt cover.

(e) Slide the RH camshaft timing pulley on the camshaft.

± ENGINE MECHANICALTiming Belt (2VZ±FE)EM±44

Page 1222 of 2389

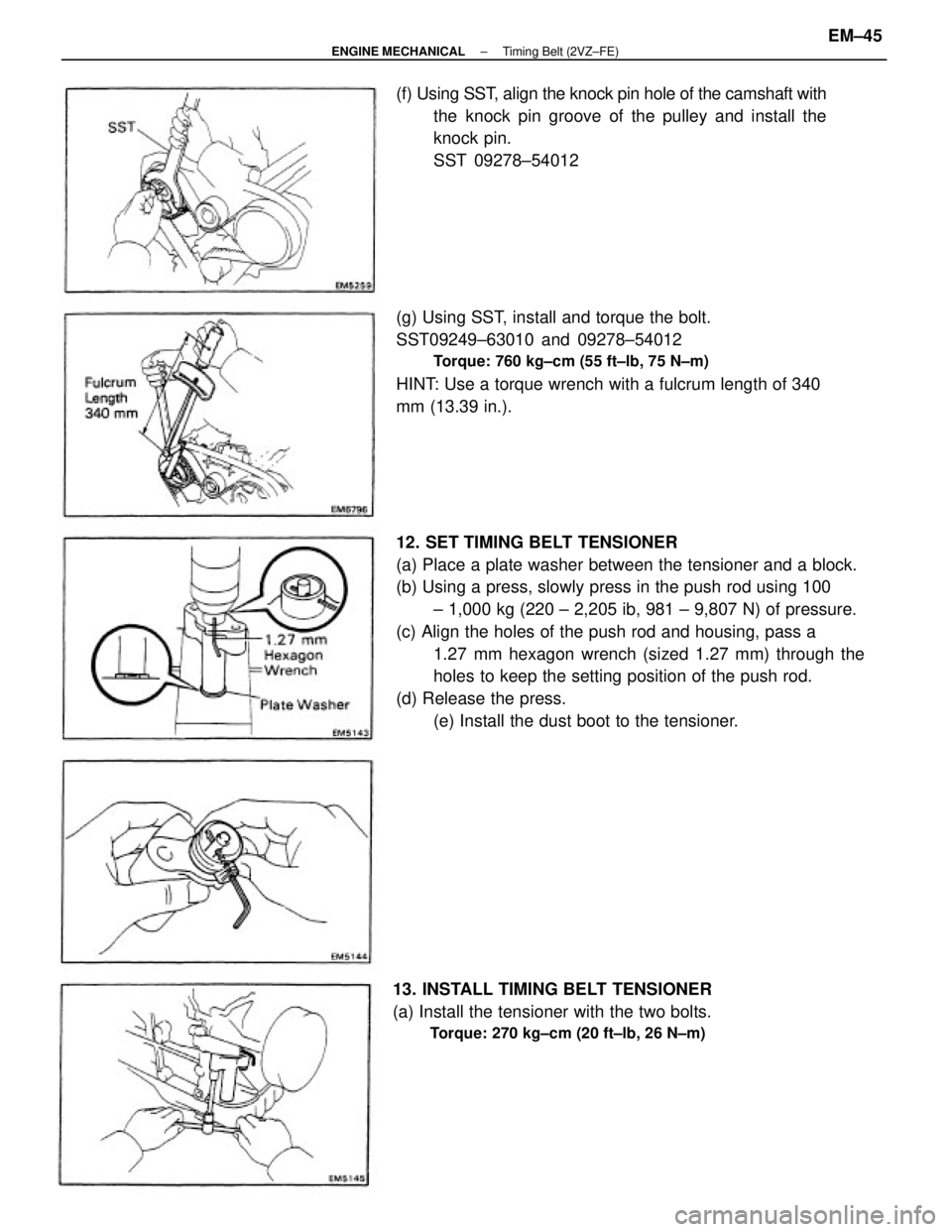

12. SET TIMING BELT TENSIONER

(a) Place a plate washer between the tensioner and a block.

(b) Using a press, slowly press in the push rod using 100

± 1,000 kg (220 ± 2,205 ib, 981 ± 9,807 N) of pressure.

(c) Align the holes of the push rod and housing, pass a

1.27 mm hexagon wrench (sized 1.27 mm) through the

holes to keep the setting position of the push rod.

(d) Release the press.

(e) Install the dust boot to the tensioner. (g) Using SST, install and torque the bolt.

SST09249±63010 and 09278±54012

Torque: 760 kg±cm (55 ft±lb, 75 N±m)

HINT: Use a torque wrench with a fulcrum length of 340

mm (13.39 in.). (f) Using SST, align the knock pin hole of the camshaft with

the knock pin groove of the pulley and install the

knock pin.

SST 09278±54012

13. INSTALL TIMING BELT TENSIONER

(a) Install the tensioner with the two bolts.

Torque: 270 kg±cm (20 ft±lb, 26 N±m)

± ENGINE MECHANICALTiming Belt (2VZ±FE)EM±45

Page 1223 of 2389

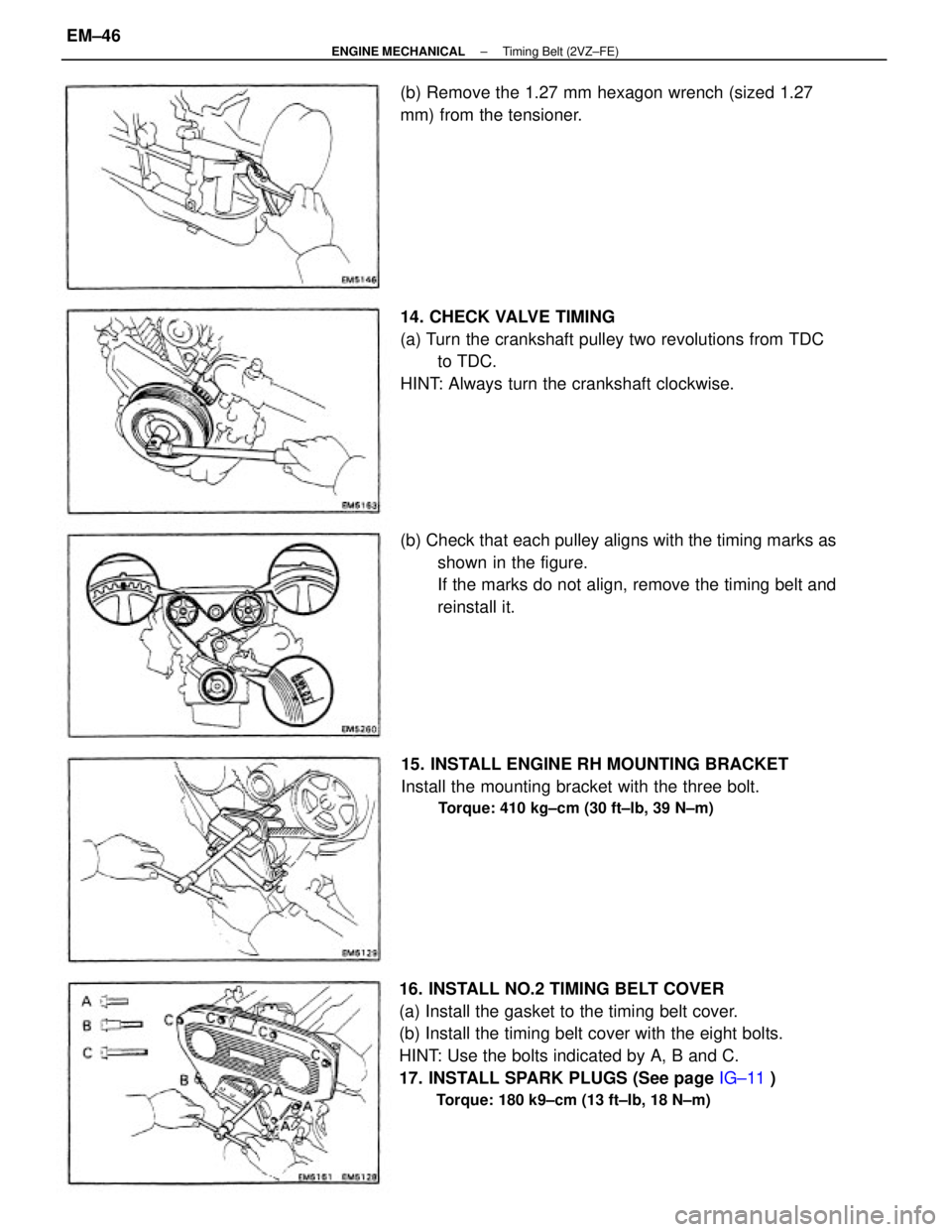

16. INSTALL NO.2 TIMING BELT COVER

(a) Install the gasket to the timing belt cover.

(b) Install the timing belt cover with the eight bolts.

HINT: Use the bolts indicated by A, B and C.

17. INSTALL SPARK PLUGS (See page IG±11 )

Torque: 180 k9±cm (13 ft±Ib, 18 N±m)

14. CHECK VALVE TIMING

(a) Turn the crankshaft pulley two revolutions from TDC

to TDC.

HINT: Always turn the crankshaft clockwise.

(b) Check that each pulley aligns with the timing marks as

shown in the figure.

If the marks do not align, remove the timing belt and

reinstall it.

15. INSTALL ENGINE RH MOUNTING BRACKET

Install the mounting bracket with the three bolt.

Torque: 410 kg±cm (30 ft±lb, 39 N±m)

(b) Remove the 1.27 mm hexagon wrench (sized 1.27

mm) from the tensioner.

± ENGINE MECHANICALTiming Belt (2VZ±FE)EM±46

Page 1224 of 2389

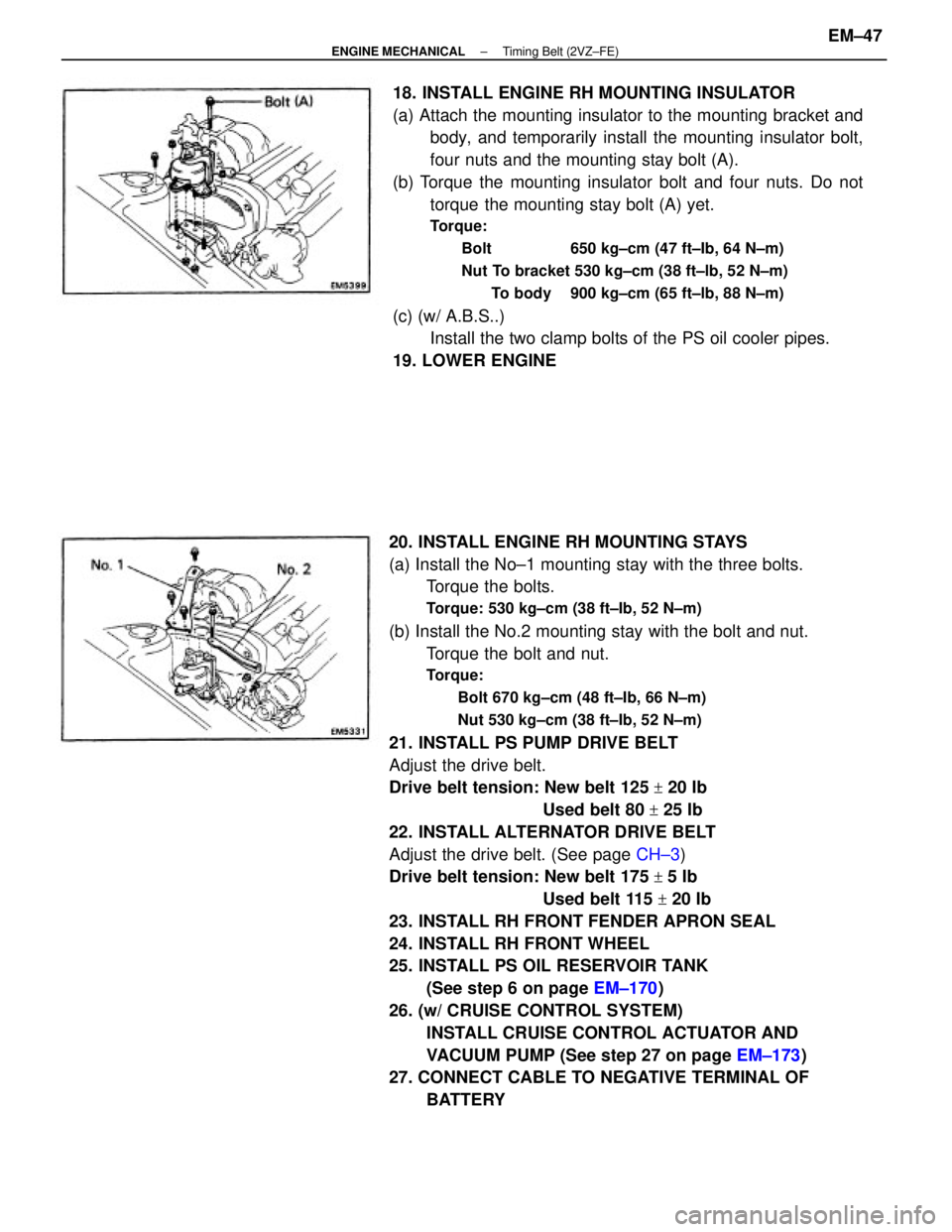

20. INSTALL ENGINE RH MOUNTING STAYS

(a) Install the No±1 mounting stay with the three bolts.

Torque the bolts.

Torque: 530 kg±cm (38 ft±Ib, 52 N±m)

(b) Install the No.2 mounting stay with the bolt and nut.

Torque the bolt and nut.

Torque:

Bolt 670 kg±cm (48 ft±Ib, 66 N±m)

Nut 530 kg±cm (38 ft±Ib, 52 N±m)

21. INSTALL PS PUMP DRIVE BELT

Adjust the drive belt.

Drive belt tension: New belt 125

+ 20 Ib

Used belt 80

+ 25 Ib

22. INSTALL ALTERNATOR DRIVE BELT

Adjust the drive belt. (See page CH±3)

Drive belt tension: New belt 175

+ 5 Ib

Used belt 115

+ 20 Ib

23. INSTALL RH FRONT FENDER APRON SEAL

24. INSTALL RH FRONT WHEEL

25. INSTALL PS OIL RESERVOIR TANK

(See step 6 on page EM±170)

26. (w/ CRUISE CONTROL SYSTEM)

INSTALL CRUISE CONTROL ACTUATOR AND

VACUUM PUMP (See step 27 on page EM±173)

27. CONNECT CABLE TO NEGATIVE TERMINAL OF

BATTERY 18. INSTALL ENGINE RH MOUNTING INSULATOR

(a) Attach the mounting insulator to the mounting bracket and

body, and temporarily install the mounting insulator bolt,

four nuts and the mounting stay bolt (A).

(b) Torque the mounting insulator bolt and four nuts. Do not

torque the mounting stay bolt (A) yet.

Torque:

Bolt 650 kg±cm (47 ft±Ib, 64 N±m)

Nut To bracket 530 kg±cm (38 ft±lb, 52 N±m)

To body 900 kg±cm (65 ft±lb, 88 N±m)

(c) (w/ A.B.S..)

Install the two clamp bolts of the PS oil cooler pipes.

19. LOWER ENGINE

± ENGINE MECHANICALTiming Belt (2VZ±FE)EM±47

Page 1229 of 2389

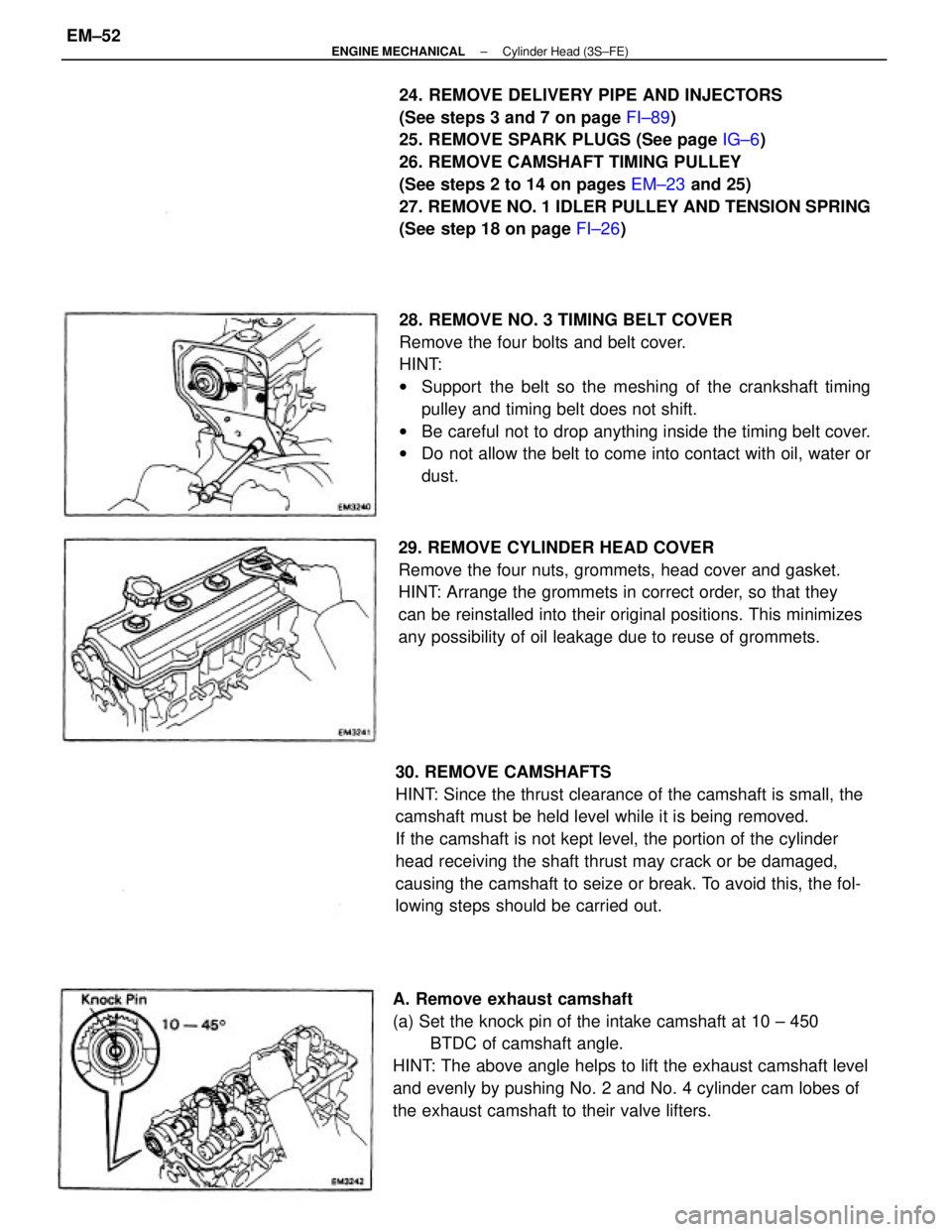

28. REMOVE NO. 3 TIMING BELT COVER

Remove the four bolts and belt cover.

HINT:

wSupport the belt so the meshing of the crankshaft timing

pulley and timing belt does not shift.

wBe careful not to drop anything inside the timing belt cover.

wDo not allow the belt to come into contact with oil, water or

dust. 24. REMOVE DELIVERY PIPE AND INJECTORS

(See steps 3 and 7 on page FI±89)

25. REMOVE SPARK PLUGS (See page IG±6)

26. REMOVE CAMSHAFT TIMING PULLEY

(See steps 2 to 14 on pages EM±23 and 25)

27. REMOVE NO. 1 IDLER PULLEY AND TENSION SPRING

(See step 18 on page FI±26)

30. REMOVE CAMSHAFTS

HINT: Since the thrust clearance of the camshaft is small, the

camshaft must be held level while it is being removed.

If the camshaft is not kept level, the portion of the cylinder

head receiving the shaft thrust may crack or be damaged,

causing the camshaft to seize or break. To avoid this, the fol-

lowing steps should be carried out.

A. Remove exhaust camshaft

(a) Set the knock pin of the intake camshaft at 10 ± 450

BTDC of camshaft angle.

HINT: The above angle helps to lift the exhaust camshaft level

and evenly by pushing No. 2 and No. 4 cylinder cam lobes of

the exhaust camshaft to their valve lifters.29. REMOVE CYLINDER HEAD COVER

Remove the four nuts, grommets, head cover and gasket.

HINT: Arrange the grommets in correct order, so that they

can be reinstalled into their original positions. This minimizes

any possibility of oil leakage due to reuse of grommets.

± ENGINE MECHANICALCylinder Head (3S±FE)EM±52

Page 1248 of 2389

6. INSTALL N0.3 TIMING BELT COVER

Install the timing belt cover with the four bolts.

7. INSTALL NO.1 IDLER PULLEY AND TENSION SPRING

(See step 4 on page EM±29)

8. INSTALL CAMSHAFT TIMING PULLEY

(See steps 9 to 13 on pages EM±30 to 32)

9. INSTALL SPARK PLUGS (See page IG±7)

Torque: 180 kg±cm (13 ft±lb, 18 N±m)

10. INSTALL INJECTOR AND DELIVERY PIPE

(See steps 1 and 5 on pages FI±91 to 92)

11. INSTALL INTAKE MANIFOLD

(a) Install a new gasket and the intake manifold with the six bolts

and two nuts.

Torque: 195 kg±cm (14 ft±lb, 19 N±m)

12. INSTALL AIR TUBE

(a) Install the air tube with the two bolts.

lbf Connect the following air hoses:

(1) Air intake chamber air hose

(2) Throttle body air hose

(3) (w/ PS)

PS pump air hose

13. INSTALL COLD START INJECTOR PIPE

(See steps 2 and 3 on page FI±80)

14. INSTALL THROTTLE BODY

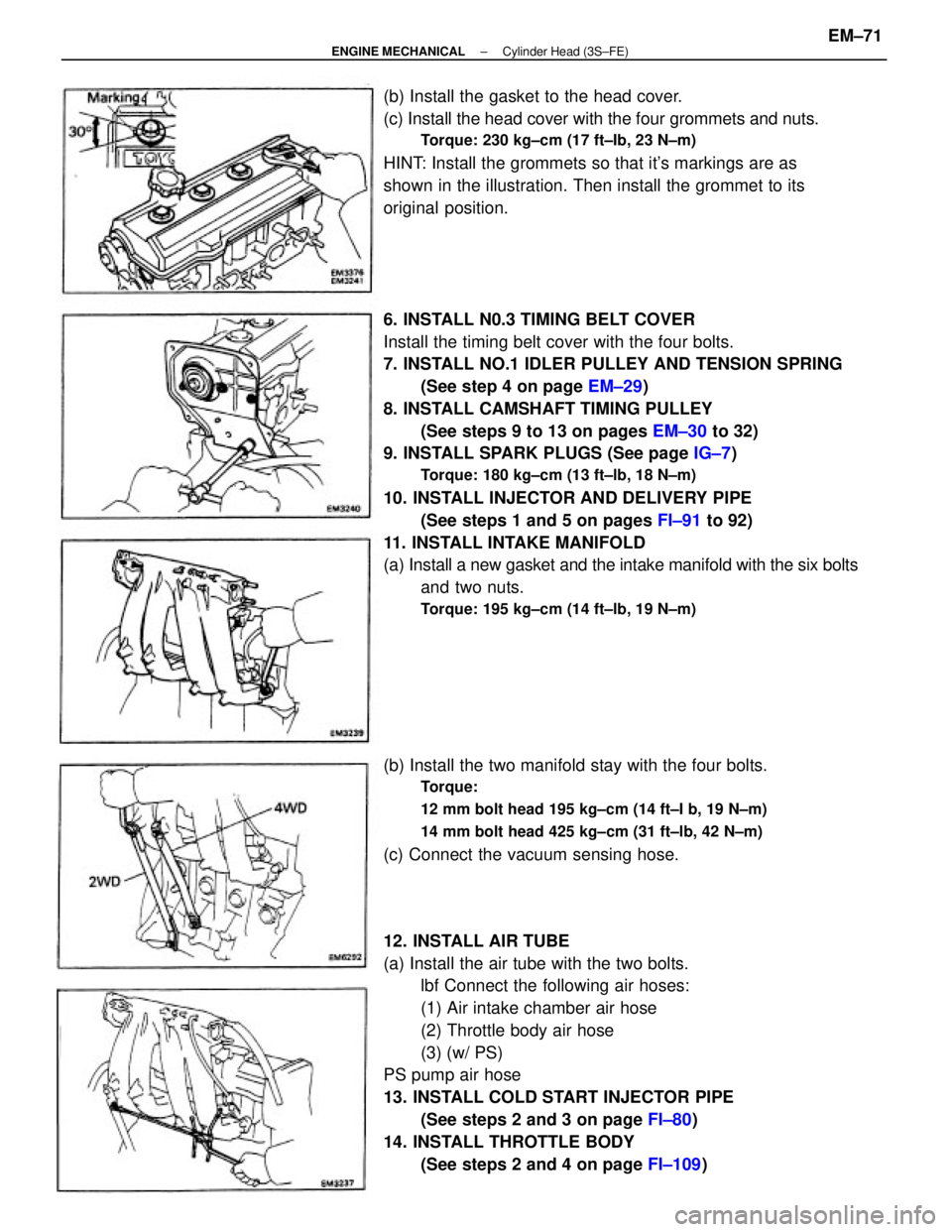

(See steps 2 and 4 on page FI±109) (b) Install the gasket to the head cover.

(c) Install the head cover with the four grommets and nuts.

Torque: 230 kg±cm (17 ft±Ib, 23 N±m)

HINT: Install the grommets so that it's markings are as

shown in the illustration. Then install the grommet to its

original position.

(b) Install the two manifold stay with the four bolts.

Torque:

12 mm bolt head 195 kg±cm (14 ft±I b, 19 N±m)

14 mm bolt head 425 kg±cm (31 ft±lb, 42 N±m)

(c) Connect the vacuum sensing hose.

± ENGINE MECHANICALCylinder Head (3S±FE)EM±71

Page 1256 of 2389

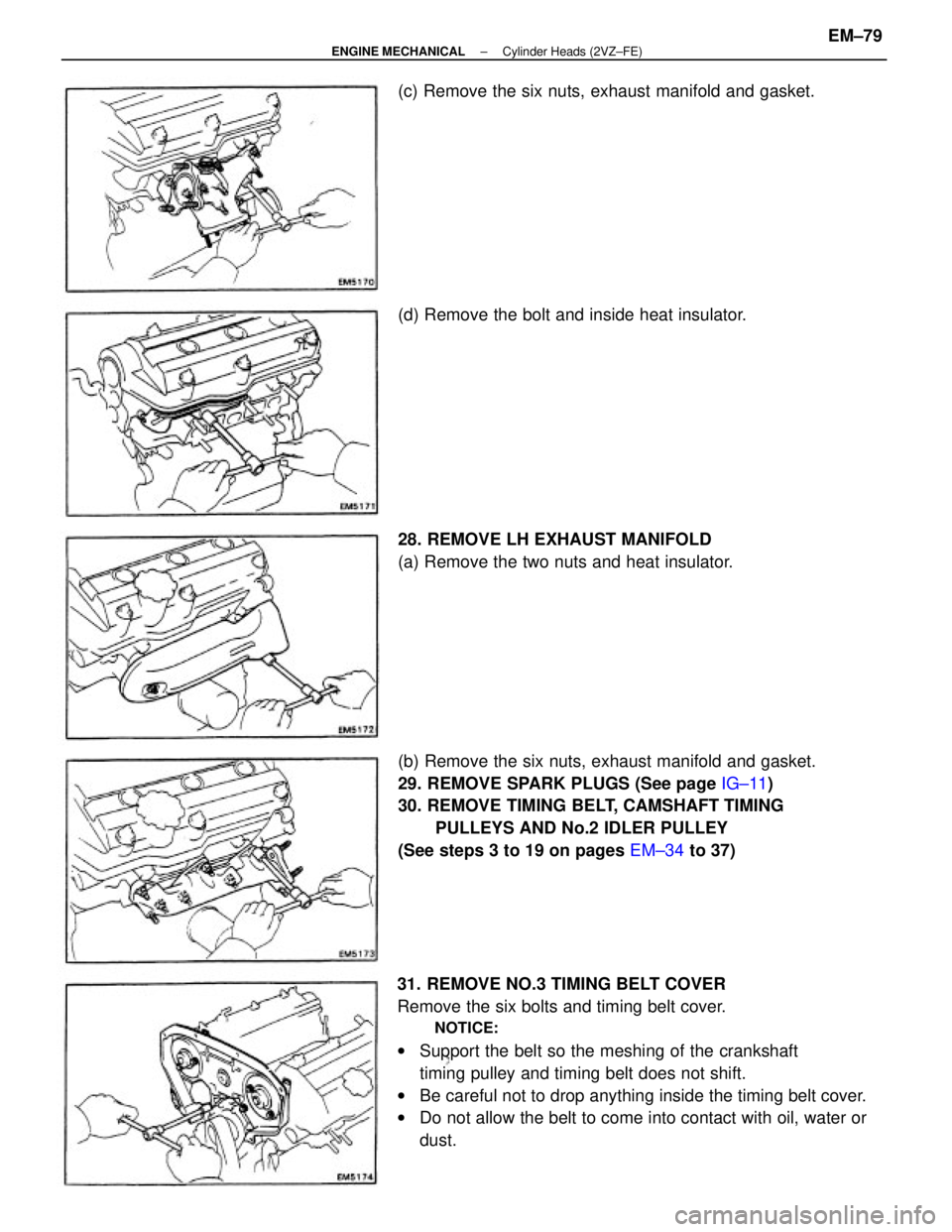

31. REMOVE NO.3 TIMING BELT COVER

Remove the six bolts and timing belt cover.

NOTICE:

wSupport the belt so the meshing of the crankshaft

timing pulley and timing belt does not shift.

wBe careful not to drop anything inside the timing belt cover.

wDo not allow the belt to come into contact with oil, water or

dust. (b) Remove the six nuts, exhaust manifold and gasket.

29. REMOVE SPARK PLUGS (See page IG±11)

30. REMOVE TIMING BELT, CAMSHAFT TIMING

PULLEYS AND No.2 IDLER PULLEY

(See steps 3 to 19 on pages EM±34 to 37) 28. REMOVE LH EXHAUST MANIFOLD

(a) Remove the two nuts and heat insulator. (c) Remove the six nuts, exhaust manifold and gasket.

(d) Remove the bolt and inside heat insulator.

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±79

Page 1279 of 2389

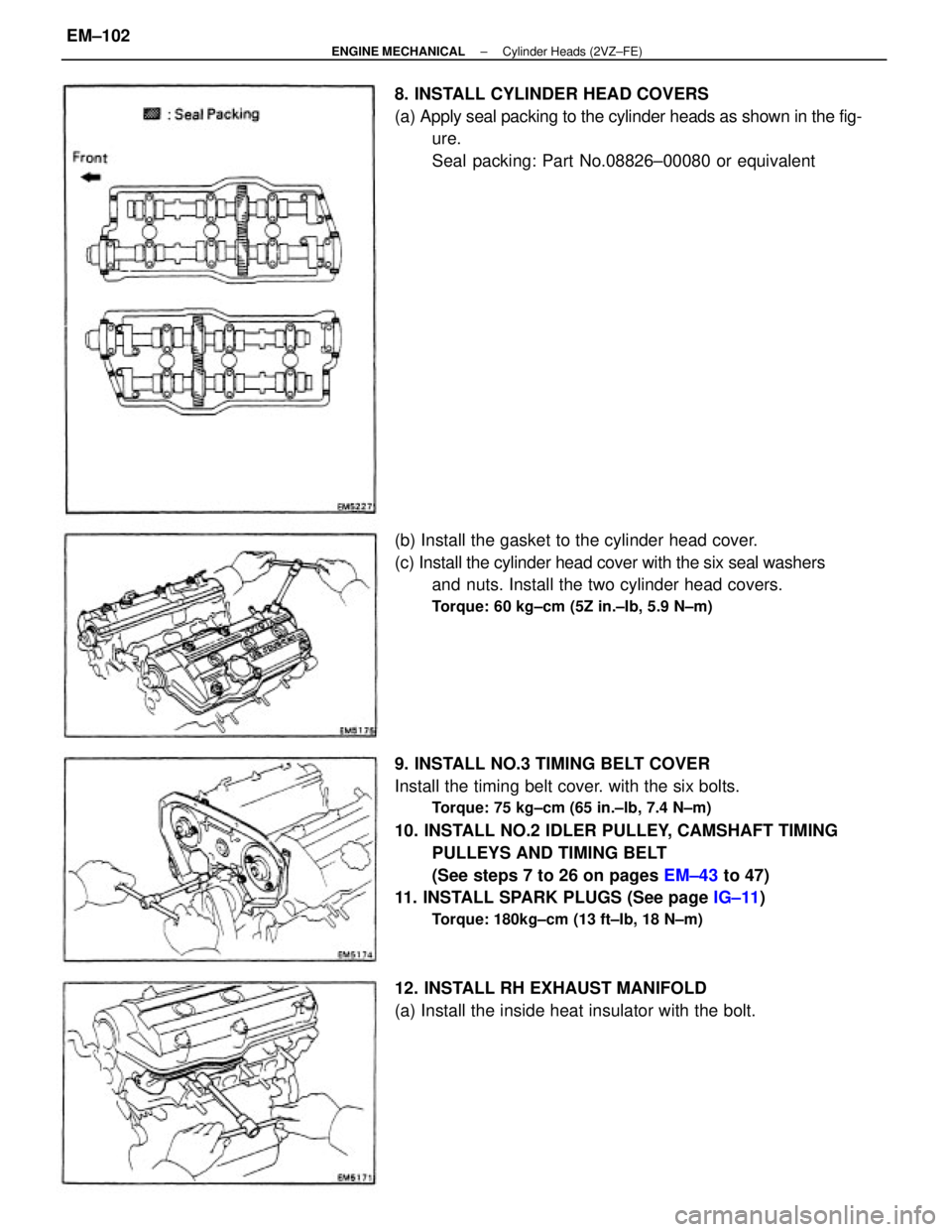

9. INSTALL NO.3 TIMING BELT COVER

Install the timing belt cover. with the six bolts.

Torque: 75 kg±cm (65 in.±lb, 7.4 N±m)

10. INSTALL NO.2 IDLER PULLEY, CAMSHAFT TIMING

PULLEYS AND TIMING BELT

(See steps 7 to 26 on pages EM±43 to 47)

11. INSTALL SPARK PLUGS (See page IG±11)

Torque: 180kg±cm (13 ft±Ib, 18 N±m)

8. INSTALL CYLINDER HEAD COVERS

(a) Apply seal packing to the cylinder heads as shown in the fig-

ure.

Seal packing: Part No.08826±00080 or equivalent

(b) Install the gasket to the cylinder head cover.

(c) Install the cylinder head cover with the six seal washers

and nuts. Install the two cylinder head covers.

Torque: 60 kg±cm (5Z in.±Ib, 5.9 N±m)

12. INSTALL RH EXHAUST MANIFOLD

(a) Install the inside heat insulator with the bolt.

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±102

Page 1290 of 2389

PREPARATION FOR DISASSEMBLY

1. ( M /T)

REMOVE CLUTCH COVER AND DISC

2. ( M /T)

REMOVE FLYWHEEL

3. 1A/T)

REMOVE DRIVE PLATE

4. REMOVE REAR END PLATE

5. INSTALL ENGINE TO ENGINE STAND FOR

DISASSEMBLY

6. REMOVE ALTERNATOR (See page CH±6)

7 REMOVE DISTRIBUTOR (See page IG±13)

8. REMOVE TIMING BELT AND PULLEYS

(See page EM±23)

9. REMOVE CYLINDER HEAD (See page EM±48)

10. REMOVE WATER PUMP (See page CO±6)

11. REMOVE OIL PAN AND OIL PUMP

(See page LU±9)

± ENGINE MECHANICALCylinder Block (3S±FE)EM±113

Page 1308 of 2389

POST ASSEMBLY

1. INSTALL OIL PUMP AND OIL PAN

(See page LU±14)

2. INSTALL WATER PUMP (See page CO±7)

3. INSTALL CYLINDER HEAD (See page EM±67)

4. INSTALL PULLEYS AND TIMING BELT

(See page EM±29)

5. INSTALL ALTERNATOR (See page CH±14)

6. INSTALL DISTRIBUTOR (See page IG±16)

7. REMOVE ENGINE STAND

8. INSTALL REAR END PLATE

Torque: 95 kg±cm (82 ft±Ib, 9.3 N±m)

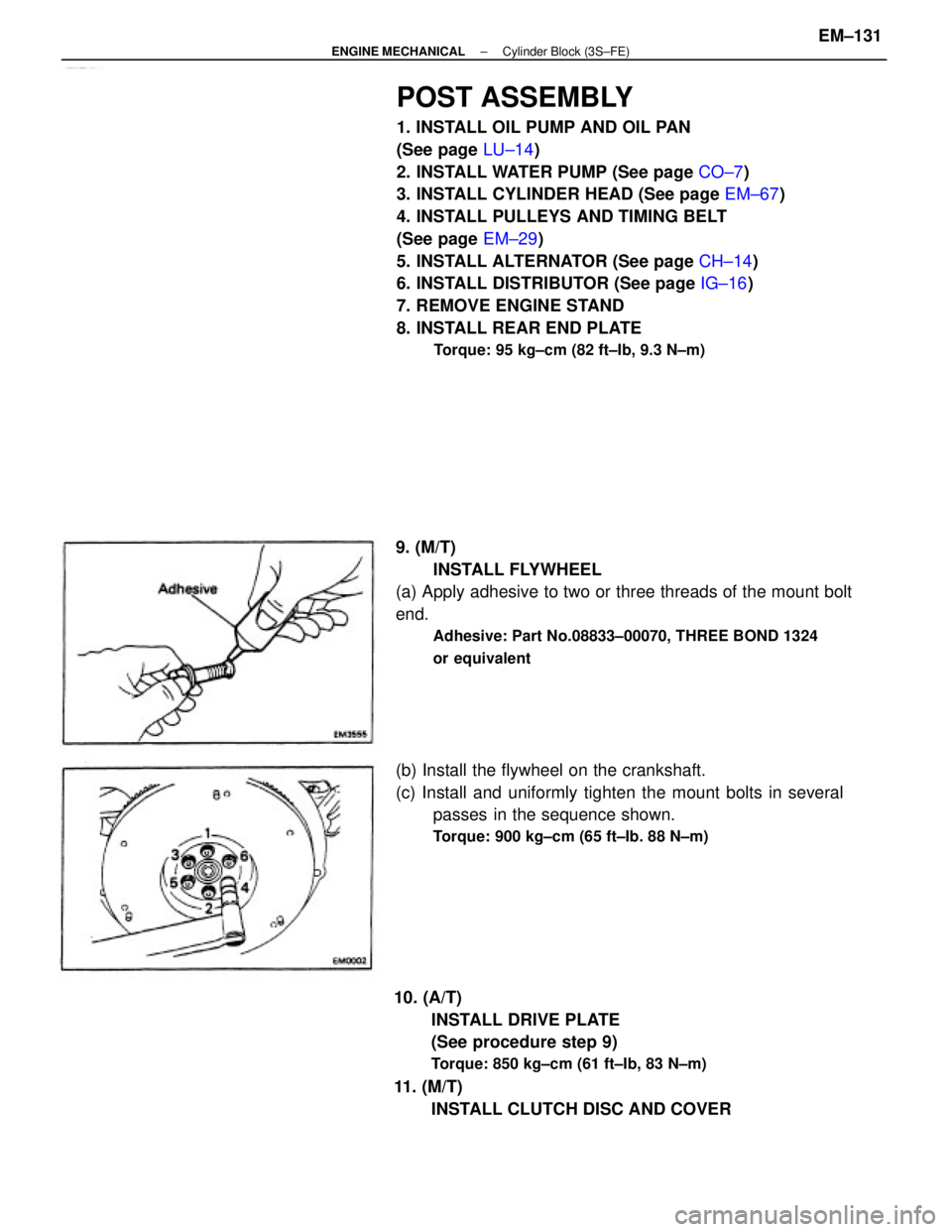

9. (M/T)

INSTALL FLYWHEEL

(a) Apply adhesive to two or three threads of the mount bolt

end.

Adhesive: Part No.08833±00070, THREE BOND 1324

or equivalent

10. (A/T)

INSTALL DRIVE PLATE

(See procedure step 9)

Torque: 850 kg±cm (61 ft±Ib, 83 N±m)

11. (M/T)

INSTALL CLUTCH DISC AND COVER (b) Install the flywheel on the crankshaft.

(c) Install and uniformly tighten the mount bolts in several

passes in the sequence shown.

Torque: 900 kg±cm (65 ft±Ib. 88 N±m)

± ENGINE MECHANICALCylinder Block (3S±FE)EM±131