timing belt TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1315 of 2389

32. INSTALL BATTERY

33. FILL WITH ENGINE COOLANT (See page CO±5)

Capacity (w/ Heater):

M/T 6.4 liters (6.8 US qts, 5.6 Imp. qts)

A/T (2WD) 6.3 liters (6.7 US qts, 5.5 Imp. qts)

A/T (4WD) 6.8 liters (7.2 US qts, 6.0 Imp. qts)

34. FILL WITH ENGINE OIL (See page LU±8)

Capacity:

Drain and refill

w/ Oil filter change

3.9 liters (4.1 US qts, 3.4 Imp. qts)

w/o Oil filter change

3.7 liters (3.9 US qts, 3.3 Imp. qts)

Dry fill 4.3 liters (4.5 US qts, 3.8 Imp. qts)

35. START ENGINE AND CHECK FOR LEAKS

36. PERFORM ENGINE ADJUSTMENT

(a) Adjust the alternator drive belt.

(See page CH±3)

Drive belt tension:

w/ A/C New belt 175 + 5 lb

Used belt 130 + 10 lb

w/o A/C New belt 125 + 25 lb

Used belt 95 + 20 lb

(b) Adjust the PS drive belt.

Drive belt tension: New belt 125 + 25 lb

Used belt 80 + 20 lb

(c) Adjust the ignition timing.

(See steps 7 to 10 on pages IG±16 and 17)

Ignition timing:

10° BTDC @ idle

(w/ Terminals TE 1 and E1 connected)

(d) Adjust the valve. clearance. (See page EM±11)

Valve clearance:

Intake 0.19 ± 0.29 mm (0.007 ± 0.011 in.)

Exhaust 0.28 ± 0.38 mm (0.011 ± 0.015 in.)

37. INSTALL HOOD

38. PERFORM ROAD TEST

Check for abnormal noise, shock, slippage, correct shift

points and smooth operation.

39. RECHECK ENGINE COOLANT AND ENGINE OIL

LEVELS

± ENGINE MECHANICALCylinder Block (3S±FE)EM±138

Page 1323 of 2389

PREPARATION FOR DISASSEMBLY

1. (M/T)

REMOVE CLUTCH COVER AND DISC

2. (M/T)

REMOVE FLYWHEEL

3. (A/T)

REMOVE DRIVE PLATE

4 REMOVE REAR END PLATE

Remove the bolt and end plate.

5. INSTALL ENGINE TO ENGINE STAND FOR

DISASSEMBLY

6. REMOVE DISTRIBUTOR (See page IG±18)

7. REMOVE TIMING BELT AND PULLEYS

(See page EM±34)

8. REMOVE CYLINDER HEADS (See page EM±76)

9. REMOVE WATER PUMP (See page CO±9)

10. REMOVE OIL PAN AND OIL PUMP

(See page LU±17)

11. REMOVE OIL FILTER (See page LU±7)

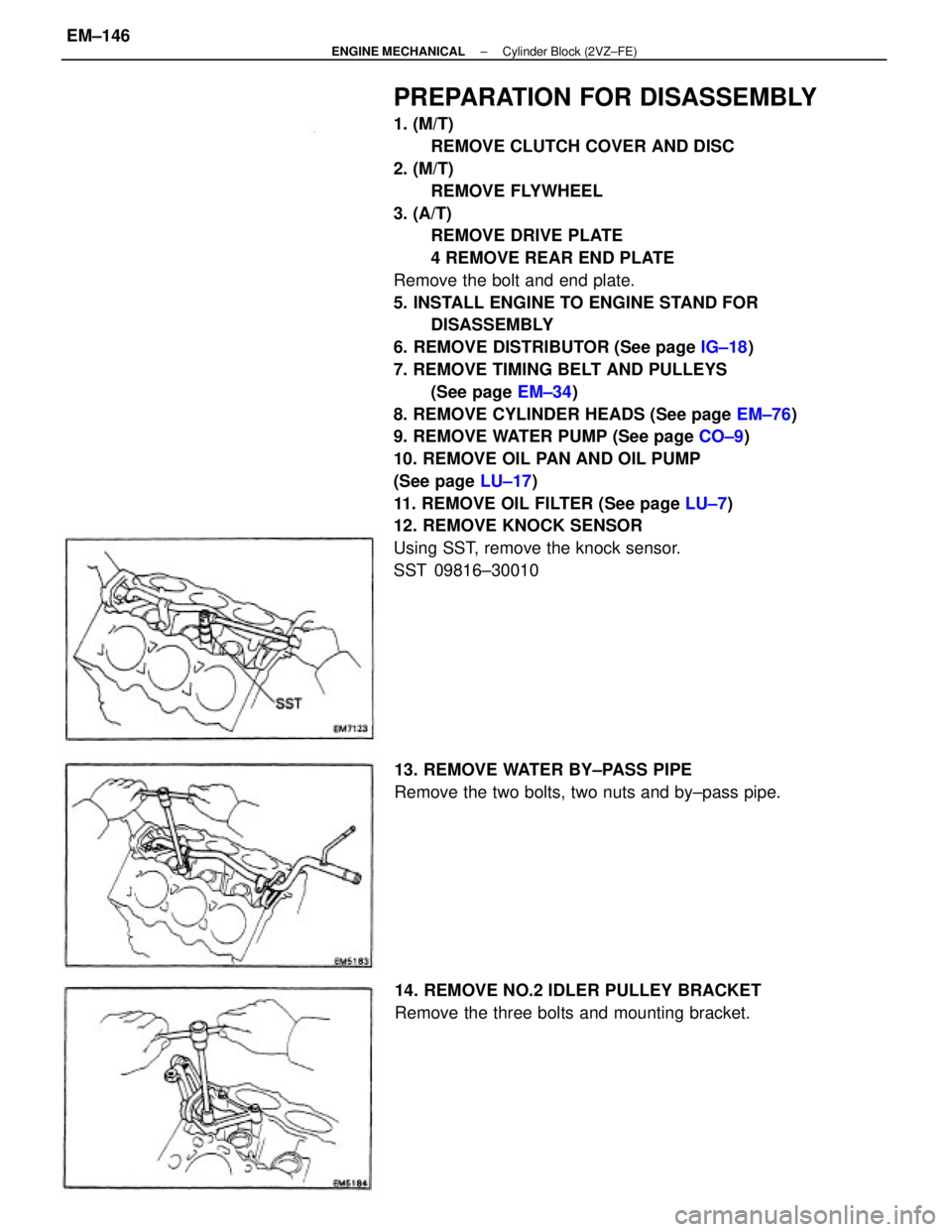

12. REMOVE KNOCK SENSOR

Using SST, remove the knock sensor.

SST 09816±30010

13. REMOVE WATER BY±PASS PIPE

Remove the two bolts, two nuts and by±pass pipe.

14. REMOVE NO.2 IDLER PULLEY BRACKET

Remove the three bolts and mounting bracket.

± ENGINE MECHANICALCylinder Block (2VZ±FE)EM±146

Page 1345 of 2389

4. INSTALL OIL FILTER (See page LU±7)

5. INSTALL OIL PUMP AND OIL PAN

(See page LU±14)

6. INSTALL WATER PUMP (See page CO±6)

7. INSTALL CYLINDER HEADS

(See pages EM±96 to 106)

8. INSTALL PULLEYS AND TIMING BELT

(See pages EM±42 to 47)

9. INSTALL DISTRIBUTOR (See page IG±19)

10. REMOVE ENGINE STAND

11. INSTALL REAR END PLATE

Install the end plate with the bolt.

Torque: 75 kg±cm (65 in.±Ib, 7.4 N±m)

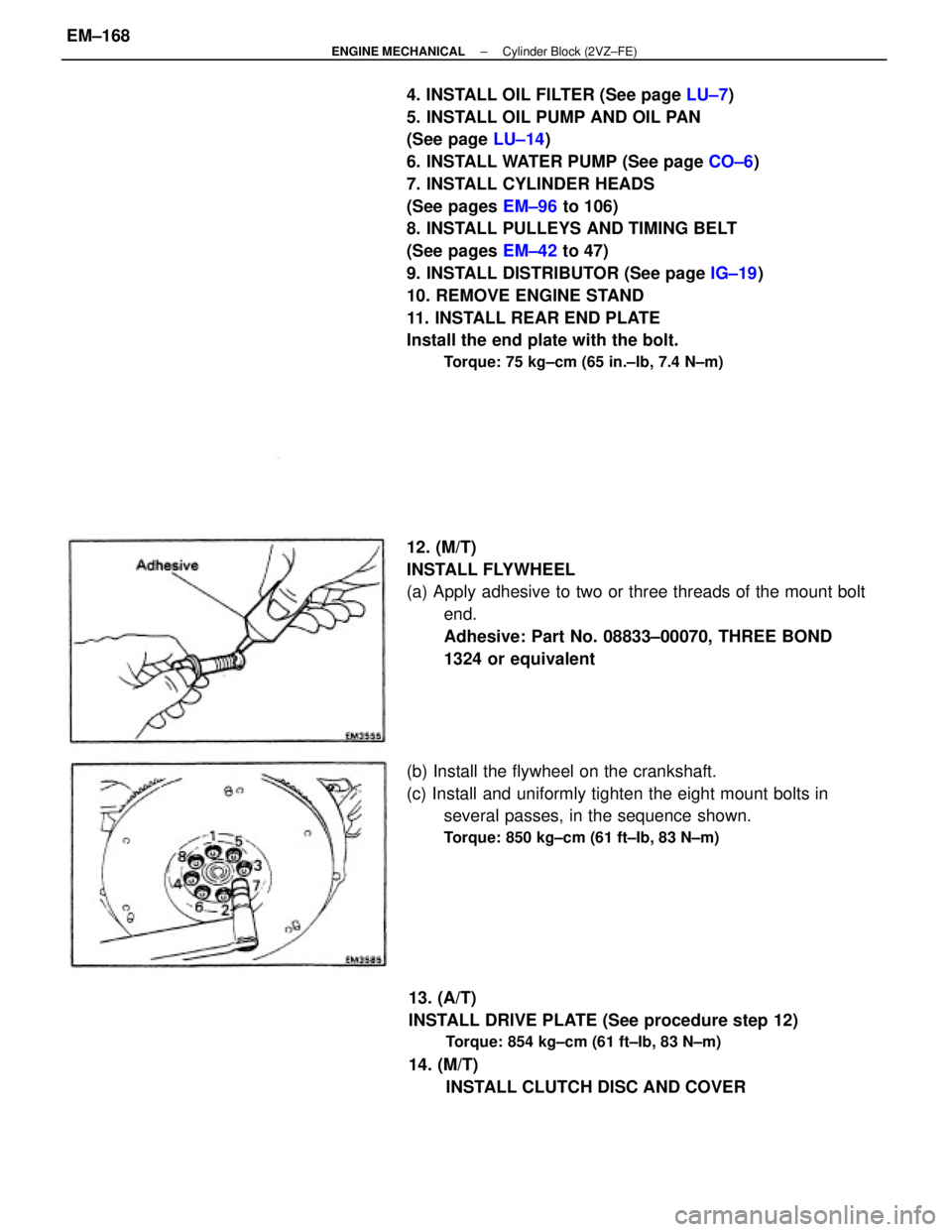

12. (M/T)

INSTALL FLYWHEEL

(a) Apply adhesive to two or three threads of the mount bolt

end.

Adhesive: Part No. 08833±00070, THREE BOND

1324 or equivalent

13. (A/T)

INSTALL DRIVE PLATE (See procedure step 12)

Torque: 854 kg±cm (61 ft±Ib, 83 N±m)

14. (M/T)

INSTALL CLUTCH DISC AND COVER (b) Install the flywheel on the crankshaft.

(c) Install and uniformly tighten the eight mount bolts in

several passes, in the sequence shown.

Torque: 850 kg±cm (61 ft±Ib, 83 N±m)

± ENGINE MECHANICALCylinder Block (2VZ±FE)EM±168

Page 1352 of 2389

39. PERFORM ENGINE ADJUSTMENT

(a) Adjust the alternator drive belt.

(See page CH±3)

Drive belt tension: New belt 175 + 5 Ib

Used belt 115 + 20 Ib

(b) Adjust PS pump drive belt.

Drive belt tension: New belt 125 + 25 Ib

Used belt 80 + 20 lb

(c) Adjust the ignition timing.

(See page IG±21 )

Ignition timing:

10°BTDC @ idle

(w/ Terminals TE1 and E1 connected)

(d) Adjust the valve clearance.

Valve clearance:

Intake 0.13 ± 0.23 mm (0. 005 ± 0.009 in.)

Exhaust 0.27 ± 0.37 mm l0.011 ± 0.015 in.)

40. INSTALL HOOD

41. PERFORM ROAD TEST

Check for abnormal noise, shock, slippage, correct shift

points and smooth operation.

42. RECHECK ENGINE COOLANT AND ENGINE OIL

LEVELS

± ENGINE MECHANICALCylinder Block (2VZ±FE)EM±175

Page 1895 of 2389

(c) Insert the blade of SST between the cylinder block and

oil pan, cut off applied sealer and remove the oil pan.

SST 09032±04100

NOTICE:

wDo not use SST for the oil pump body side and rear oil

seal retainer.

wBe careful not to damage the oil pan flange.

11. SUSPEND ENGINE WITH ENGINE HOIST CHAIN

12. REMOVE TIMING BELT AND PULLEYS

(See pages EM±23 to 26) 10. REMOVE OIL STRAINER

Remove the two bolts, two nuts, oil strainer, baffle plate and

gasket. 9. REMOVE OIL PAN

(a) Remove the dipstick.

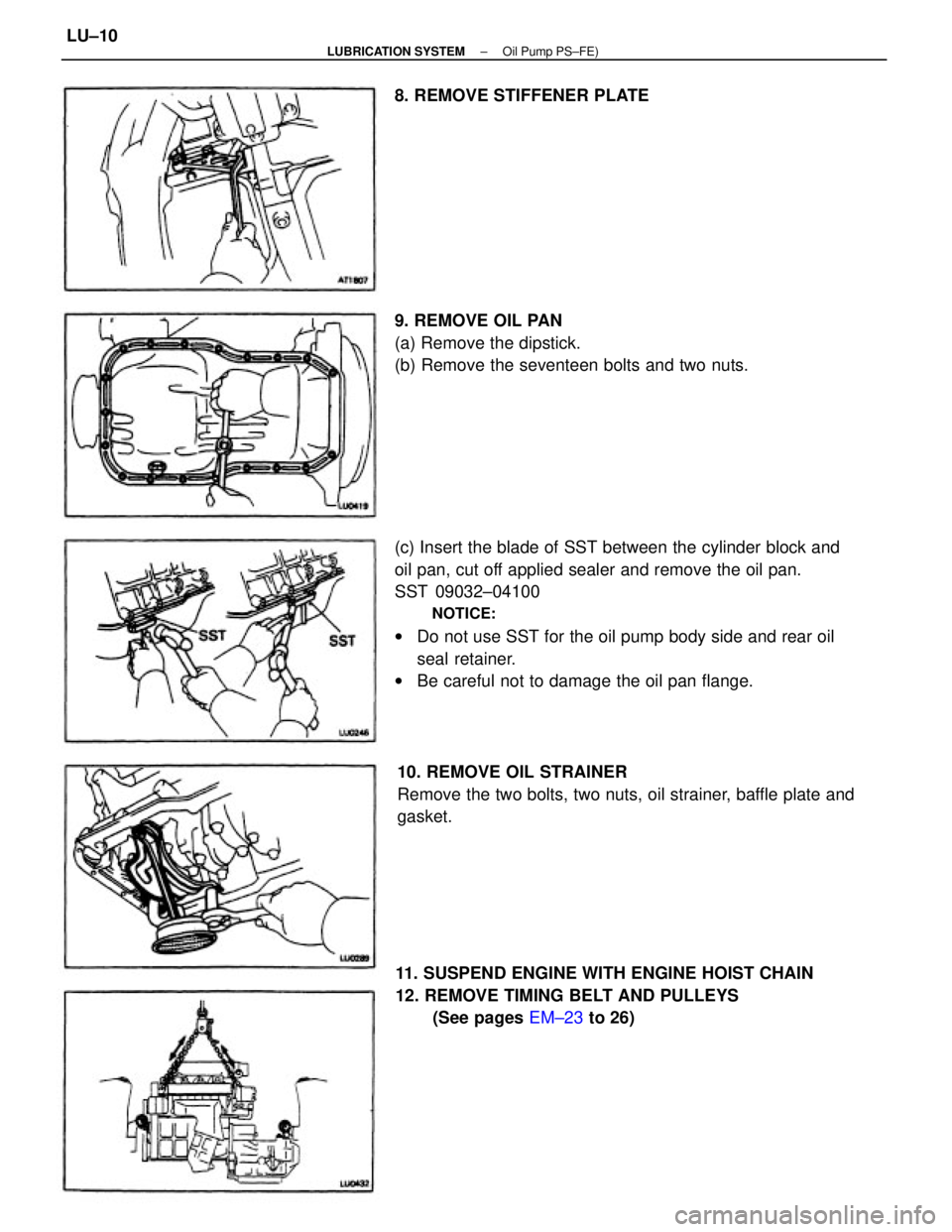

(b) Remove the seventeen bolts and two nuts. 8. REMOVE STIFFENER PLATE

± LUBRICATION SYSTEMOil Pump PS±FE)LU±10

Page 1899 of 2389

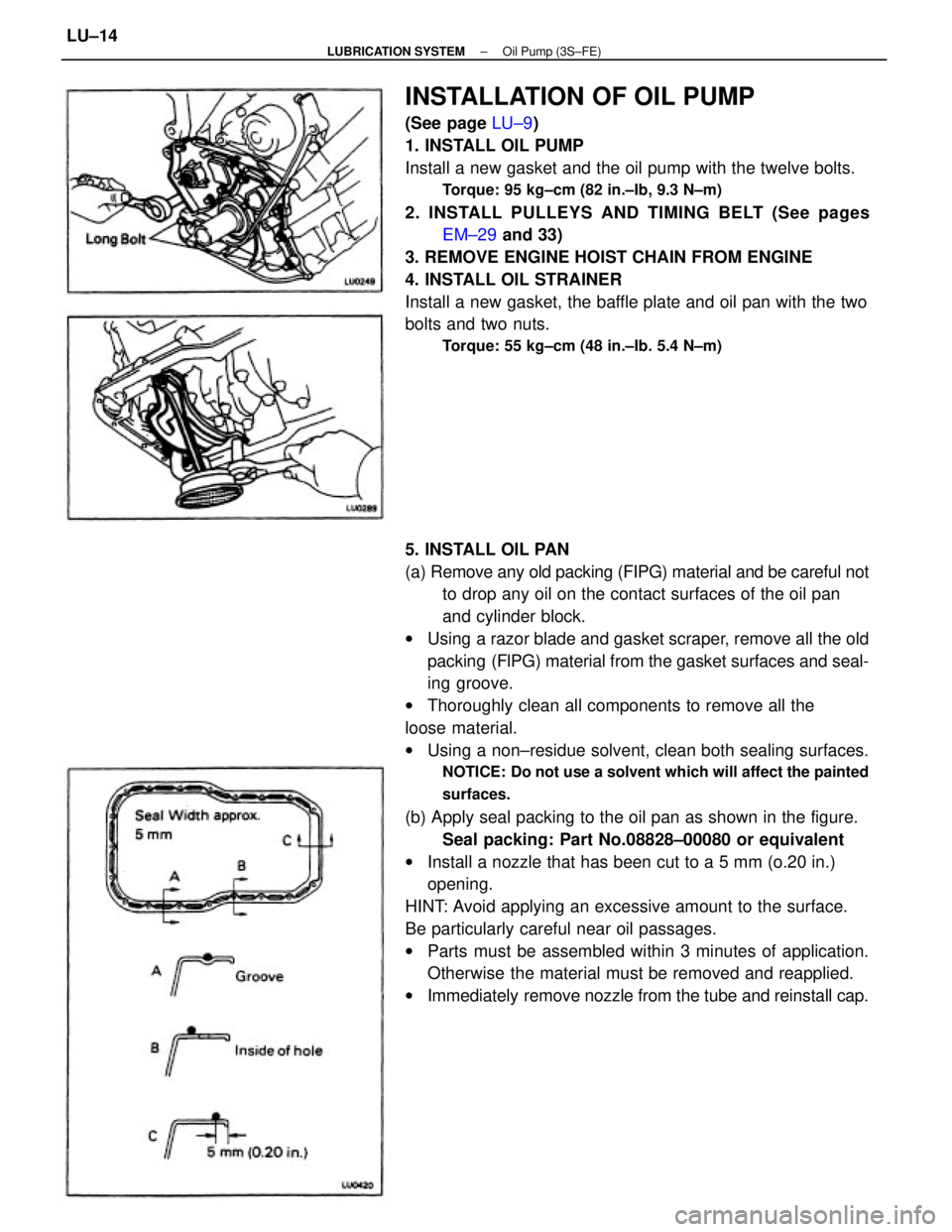

5. INSTALL OIL PAN

(a) Remove any old packing (FIPG) material and be careful not

to drop any oil on the contact surfaces of the oil pan

and cylinder block.

wUsing a razor blade and gasket scraper, remove all the old

packing (FlPG) material from the gasket surfaces and seal-

ing groove.

wThoroughly clean all components to remove all the

loose material.

wUsing a non±residue solvent, clean both sealing surfaces.

NOTICE: Do not use a solvent which will affect the painted

surfaces.

(b) Apply seal packing to the oil pan as shown in the figure.

Seal packing: Part No.08828±00080 or equivalent

wInstall a nozzle that has been cut to a 5 mm (o.20 in.)

opening.

HINT: Avoid applying an excessive amount to the surface.

Be particularly careful near oil passages.

wParts must be assembled within 3 minutes of application.

Otherwise the material must be removed and reapplied.

wImmediately remove nozzle from the tube and reinstall cap.

INSTALLATION OF OIL PUMP

(See page LU±9)

1. INSTALL OIL PUMP

Install a new gasket and the oil pump with the twelve bolts.

Torque: 95 kg±cm (82 in.±Ib, 9.3 N±m)

2. INSTALL PULLEYS AND TIMING BELT (See pages

EM±29 and 33)

3. REMOVE ENGINE HOIST CHAIN FROM ENGINE

4. INSTALL OIL STRAINER

Install a new gasket, the baffle plate and oil pan with the two

bolts and two nuts.

Torque: 55 kg±cm (48 in.±Ib. 5.4 N±m)

± LUBRICATION SYSTEMOil Pump (3S±FE)LU±14

Page 1903 of 2389

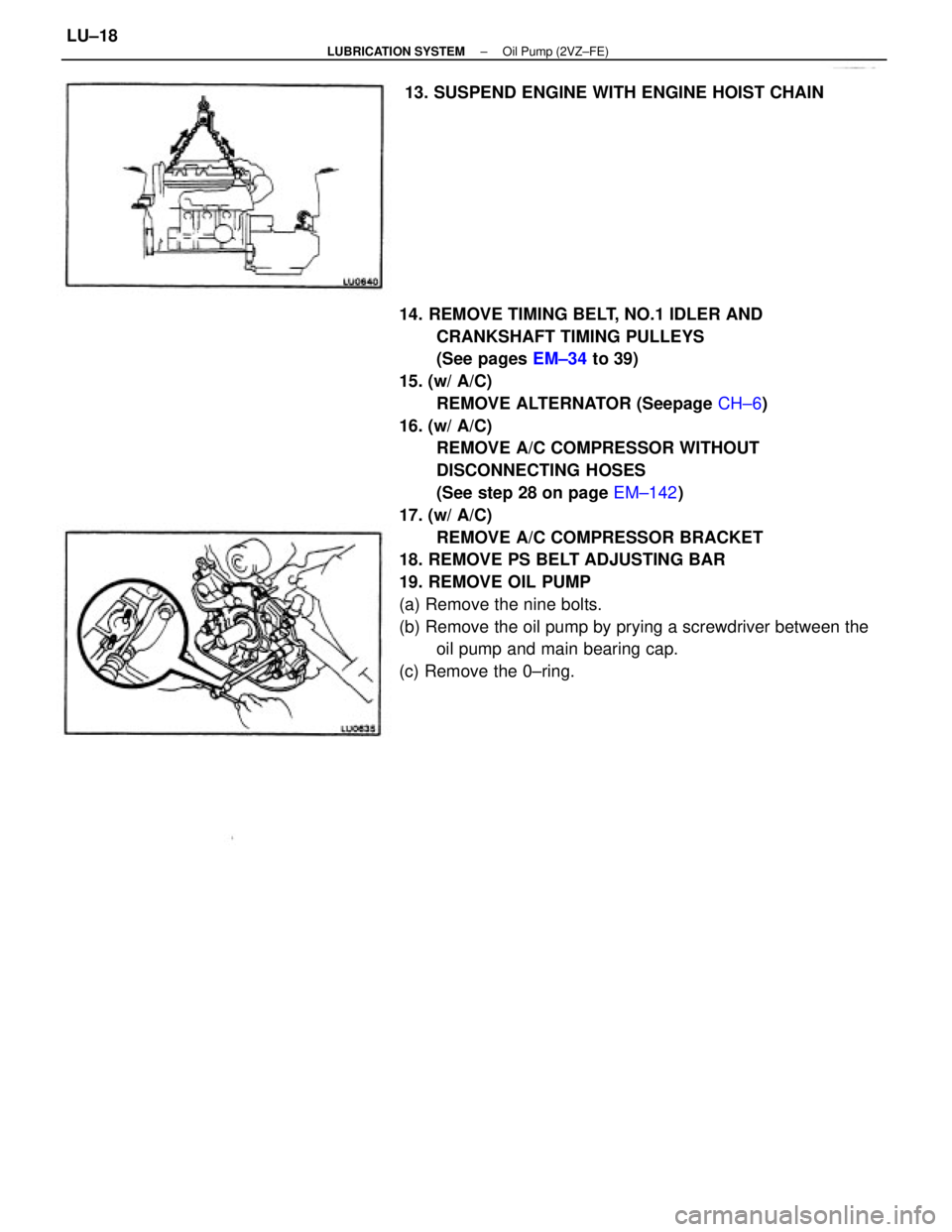

14. REMOVE TIMING BELT, NO.1 IDLER AND

CRANKSHAFT TIMING PULLEYS

(See pages EM±34 to 39)

15. (w/ A/C)

REMOVE ALTERNATOR (Seepage CH±6)

16. (w/ A/C)

REMOVE A/C COMPRESSOR WITHOUT

DISCONNECTING HOSES

(See step 28 on page EM±142)

17. (w/ A/C)

REMOVE A/C COMPRESSOR BRACKET

18. REMOVE PS BELT ADJUSTING BAR

19. REMOVE OIL PUMP

(a) Remove the nine bolts.

(b) Remove the oil pump by prying a screwdriver between the

oil pump and main bearing cap.

(c) Remove the 0±ring.13. SUSPEND ENGINE WITH ENGINE HOIST CHAIN

± LUBRICATION SYSTEMOil Pump (2VZ±FE)LU±18

Page 1908 of 2389

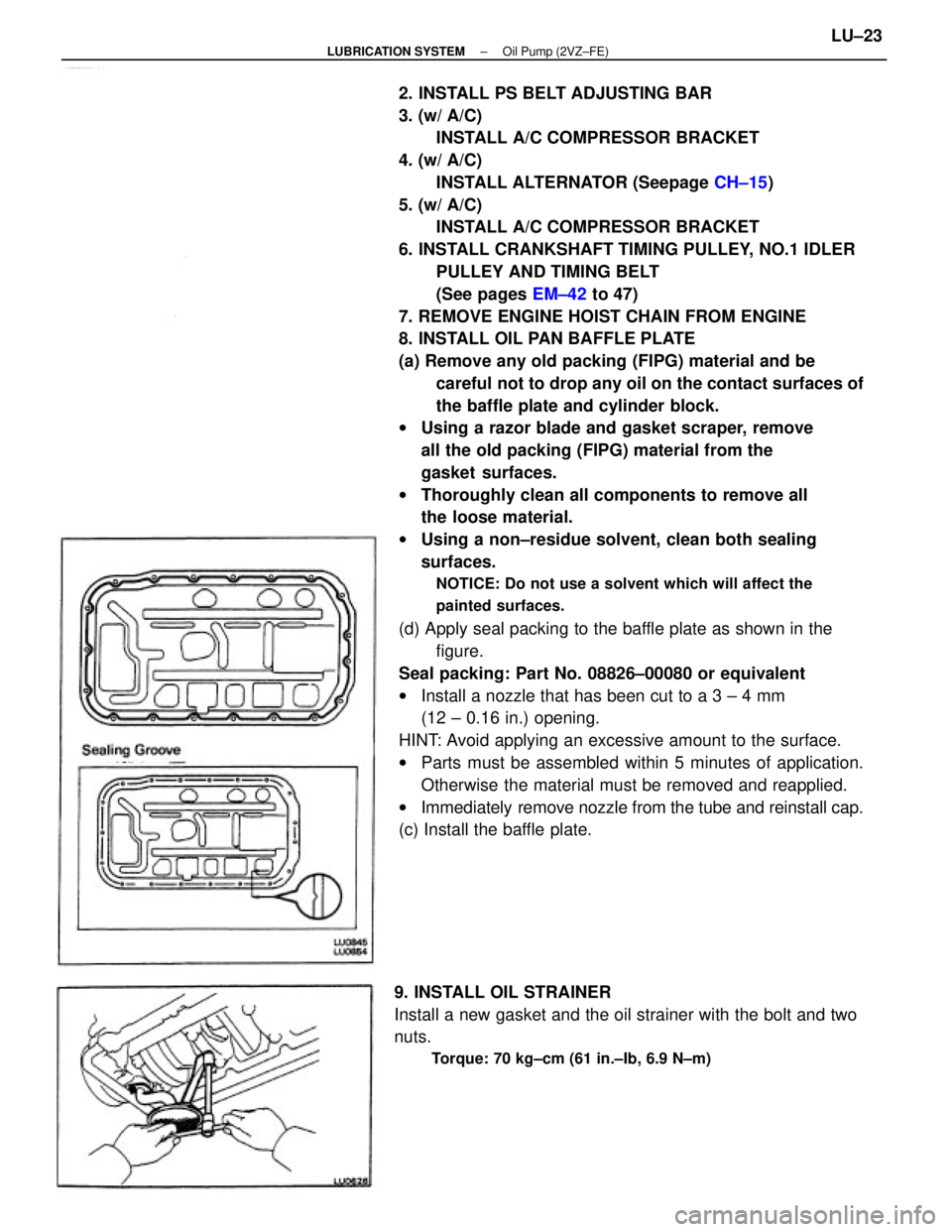

2. INSTALL PS BELT ADJUSTING BAR

3. (w/ A/C)

INSTALL A/C COMPRESSOR BRACKET

4. (w/ A/C)

INSTALL ALTERNATOR (Seepage CH±15)

5. (w/ A/C)

INSTALL A/C COMPRESSOR BRACKET

6. INSTALL CRANKSHAFT TIMING PULLEY, NO.1 IDLER

PULLEY AND TIMING BELT

(See pages EM±42 to 47)

7. REMOVE ENGINE HOIST CHAIN FROM ENGINE

8. INSTALL OIL PAN BAFFLE PLATE

(a) Remove any old packing (FIPG) material and be

careful not to drop any oil on the contact surfaces of

the baffle plate and cylinder block.

wUsing a razor blade and gasket scraper, remove

all the old packing (FIPG) material from the

gasket surfaces.

wThoroughly clean all components to remove all

the loose material.

wUsing a non±residue solvent, clean both sealing

surfaces.

NOTICE: Do not use a solvent which will affect the

painted surfaces.

(d) Apply seal packing to the baffle plate as shown in the

figure.

Seal packing: Part No. 08826±00080 or equivalent

wInstall a nozzle that has been cut to a 3 ± 4 mm

(12 ± 0.16 in.) opening.

HINT: Avoid applying an excessive amount to the surface.

wParts must be assembled within 5 minutes of application.

Otherwise the material must be removed and reapplied.

wImmediately remove nozzle from the tube and reinstall cap.

(c) Install the baffle plate.

9. INSTALL OIL STRAINER

Install a new gasket and the oil strainer with the bolt and two

nuts.

Torque: 70 kg±cm (61 in.±Ib, 6.9 N±m)

± LUBRICATION SYSTEMOil Pump (2VZ±FE)LU±23

Page 1912 of 2389

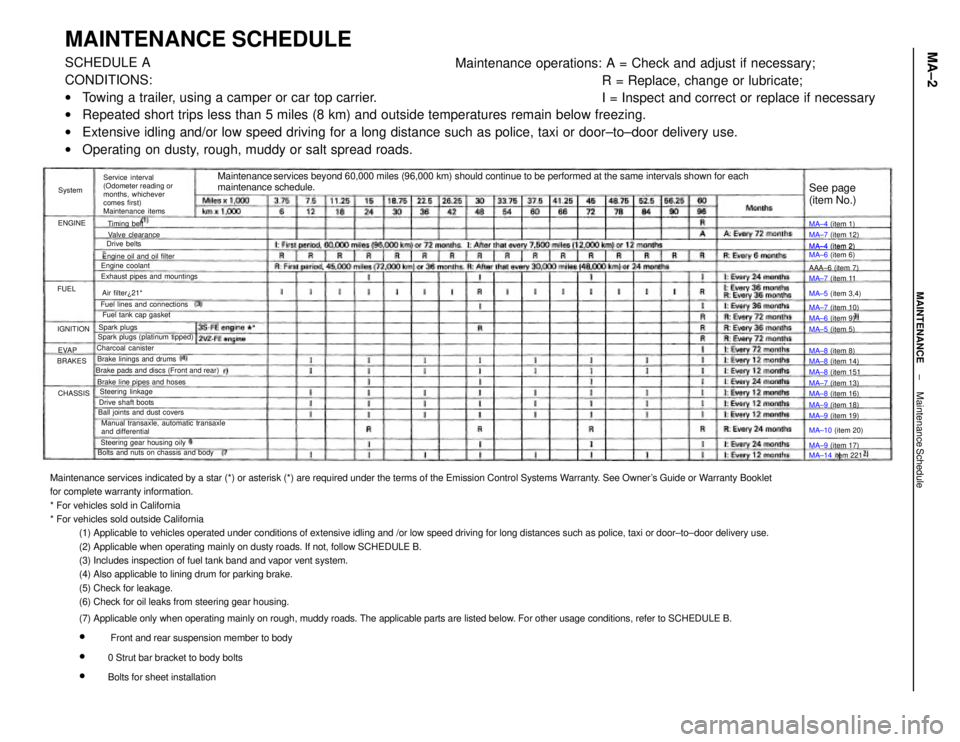

Maintenance services indicated by a star (*) or asterisk (*) are required under the terms of the Emission Control Systems Warranty. See Owner's Guide or Warranty Booklet

for complete warranty information.

* For vehicles sold in California

* For vehicles sold outside California

(1) Applicable to vehicles operated under conditions of extensive idling and /or low speed driving for long distances such as police, taxi or door±to±door delivery use.

(2) Applicable when operating mainly on dusty roads. If not, follow SCHEDULE B.

(3) Includes inspection of fuel tank band and vapor vent system.

(4) Also applicable to lining drum for parking brake.

(5) Check for leakage.

(6) Check for oil leaks from steering gear housing.

(7) Applicable only when operating mainly on rough, muddy roads. The applicable parts are listed below. For other usage conditions, refer to SCHEDULE B.

w

Front and rear suspension member to body

w

0 Strut bar bracket to body bolts

w

Bolts for sheet installation

MAINTENANCE SCHEDULESCHEDULE A

CONDITIONS:

wTowing a trailer, using a camper or car top carrier.

wRepeated short trips less than 5 miles (8 km) and outside temperatures remain below freezing.

wExtensive idling and/or low speed driving for a long distance such as police, taxi or door±to±door delivery use.

wOperating on dusty, rough, muddy or salt spread roads.Maintenance operations: A = Check and adjust if necessary;

R = Replace, change or lubricate;

I = Inspect and correct or replace if necessary

Maintenance services beyond 60,000 miles (96,000 km) should continue to be performed at the same intervals shown for each

maintenance schedule.

Service interval

(Odometer reading or

months, whichever

comes first)

Maintenance items

Manual transaxle, automatic transaxle

and differential Brake pads and discs (Front and rear)

Bolts and nuts on chassis and bodyExhaust pipes and mountings

Steering gear housing oily Brake line pipes and hosesFuel lines and connections

Ball joints and dust coversEngine oil and oil filter

Spark plugs (platinum tipped)MA±4 (item 2)

MA±6 (item 6)

Brake linings and drumsFuel tank cap gasket

Drive shaft boots

MA±14 item 221 MA±10 (item 20) MA±5 (item 3,4)

Steering linkageMA±7 (item 12)

MA±8 (item 14) Valve clearance

MA±8 (item 16)

MA±9 (item 19) MA±7 (item 13) MA±7 (item 11

MA±7 (item 10)

MA±9 (item 18) Charcoal canister

MA±9 (item 17) MA±8 (item 151

See page

(item No.)

Engine coolant

MA±6 (item 9) MA±4 (item 1)

MA±4 (item 2)

MA±5 (item 5)

MA±8 (item 8) AAA±6 (item 7)

Air filter¿21*

Spark plugsTiming belt

Drive belts

IGNITION

CHASSIS BRAKESENGINESystem

EVAP FUEL

± MAINTENANCEMaintenance ScheduleMA±2

Page 1916 of 2389

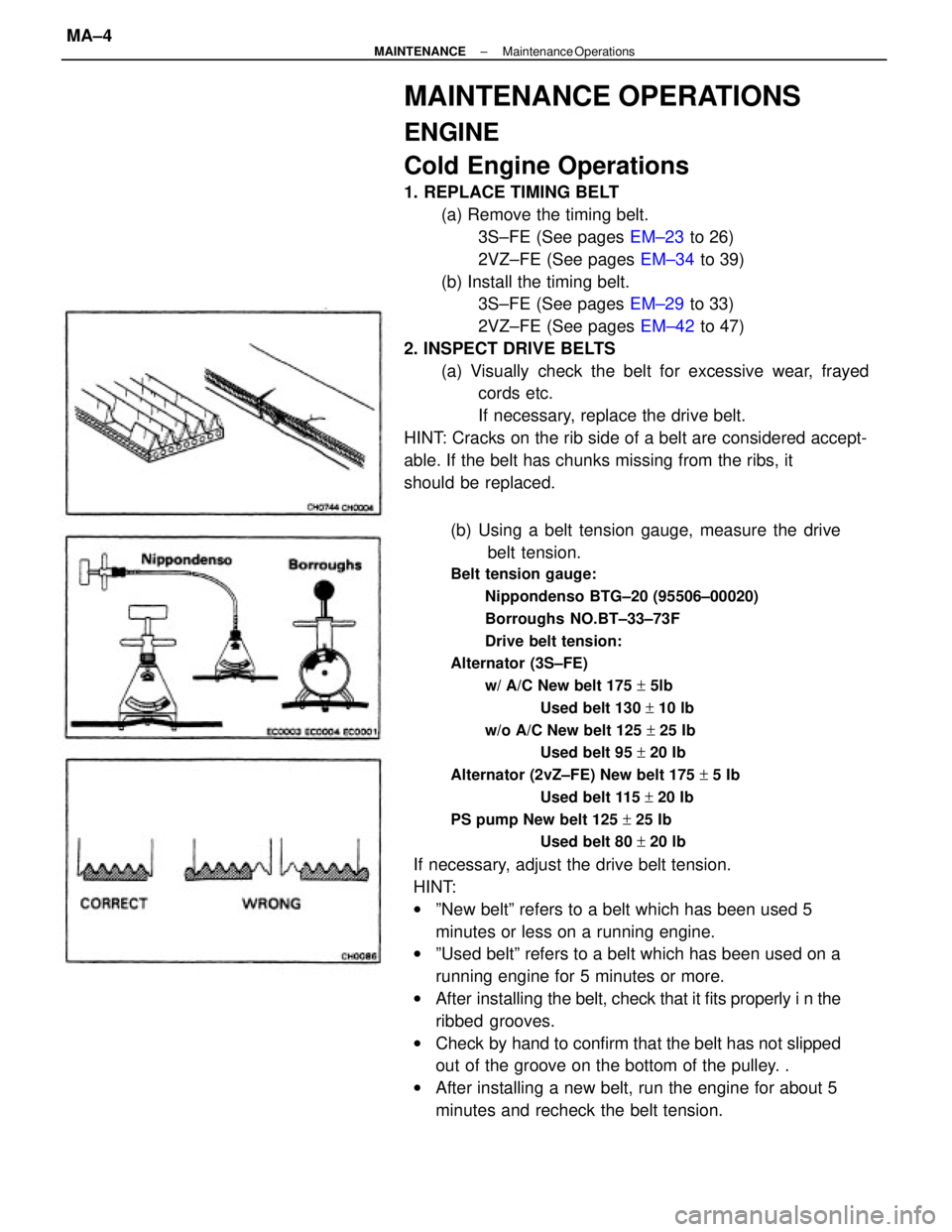

(b) Using a belt tension gauge, measure the drive

belt tension.

Belt tension gauge:

Nippondenso BTG±20 (95506±00020)

Borroughs NO.BT±33±73F

Drive belt tension:

Alternator (3S±FE)

w/ A/C New belt 175 + 5lb

Used belt 130 + 10 lb

w/o A/C New belt 125 + 25 Ib

Used belt 95 + 20 Ib

Alternator (2vZ±FE) New belt 175 + 5 Ib

Used belt 115 + 20 Ib

PS pump New belt 125 + 25 Ib

Used belt 80 + 20 lb

If necessary, adjust the drive belt tension.

HINT:

wºNew beltº refers to a belt which has been used 5

minutes or less on a running engine.

wºUsed beltº refers to a belt which has been used on a

running engine for 5 minutes or more.

wAfter installing the belt, check that it fits properly i n the

ribbed grooves.

wCheck by hand to confirm that the belt has not slipped

out of the groove on the bottom of the pulley. .

wAfter installing a new belt, run the engine for about 5

minutes and recheck the belt tension.

MAINTENANCE OPERATIONS

ENGINE

Cold Engine Operations

1. REPLACE TIMING BELT

(a) Remove the timing belt.

3S±FE (See pages EM±23 to 26)

2VZ±FE (See pages EM±34 to 39)

(b) Install the timing belt.

3S±FE (See pages EM±29 to 33)

2VZ±FE (See pages EM±42 to 47)

2. INSPECT DRIVE BELTS

(a) Visually check the belt for excessive wear, frayed

cords etc.

If necessary, replace the drive belt.

HINT: Cracks on the rib side of a belt are considered accept-

able. If the belt has chunks missing from the ribs, it

should be replaced.

± MAINTENANCEMaintenance OperationsMA±4