check engine light TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1213 of 2389

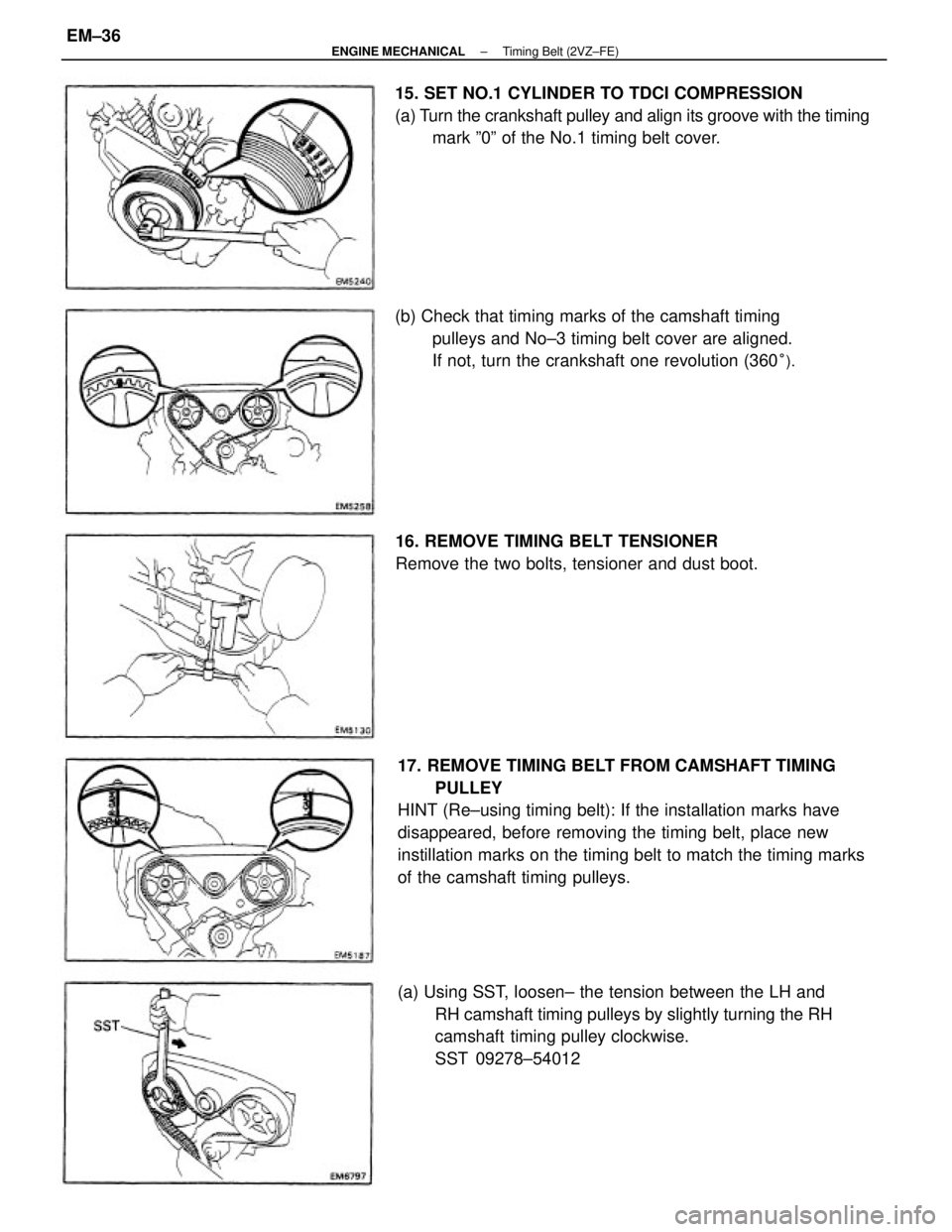

17. REMOVE TIMING BELT FROM CAMSHAFT TIMING

PULLEY

HINT (Re±using timing belt): If the installation marks have

disappeared, before removing the timing belt, place new

instillation marks on the timing belt to match the timing marks

of the camshaft timing pulleys.

(a) Using SST, loosen± the tension between the LH and

RH camshaft timing pulleys by slightly turning the RH

camshaft timing pulley clockwise.

SST 09278±54012 15. SET NO.1 CYLINDER TO TDCI COMPRESSION

(a) Turn the crankshaft pulley and align its groove with the timing

mark º0º of the No.1 timing belt cover.

(b) Check that timing marks of the camshaft timing

pulleys and No±3 timing belt cover are aligned.

If not, turn the crankshaft one revolution (360

°).

16. REMOVE TIMING BELT TENSIONER

Remove the two bolts, tensioner and dust boot.

± ENGINE MECHANICALTiming Belt (2VZ±FE)EM±36

Page 1221 of 2389

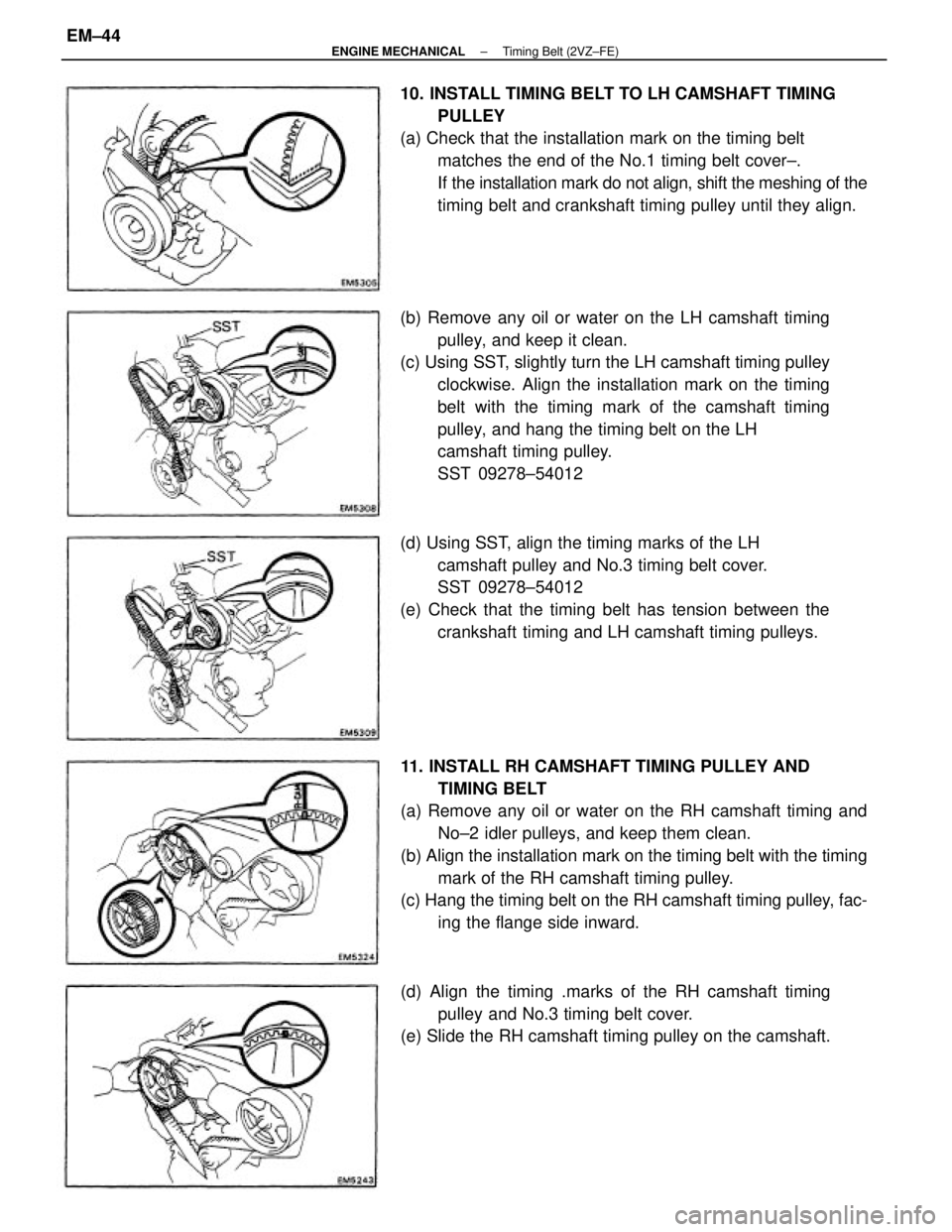

11. INSTALL RH CAMSHAFT TIMING PULLEY AND

TIMING BELT

(a) Remove any oil or water on the RH camshaft timing and

No±2 idler pulleys, and keep them clean.

(b) Align the installation mark on the timing belt with the timing

mark of the RH camshaft timing pulley.

(c) Hang the timing belt on the RH camshaft timing pulley, fac-

ing the flange side inward. (b) Remove any oil or water on the LH camshaft timing

pulley, and keep it clean.

(c) Using SST, slightly turn the LH camshaft timing pulley

clockwise. Align the installation mark on the timing

belt with the timing mark of the camshaft timing

pulley, and hang the timing belt on the LH

camshaft timing pulley.

SST 09278±54012 10. INSTALL TIMING BELT TO LH CAMSHAFT TIMING

PULLEY

(a) Check that the installation mark on the timing belt

matches the end of the No.1 timing belt cover±.

If the installation mark do not align, shift the meshing of the

timing belt and crankshaft timing pulley until they align.

(d) Using SST, align the timing marks of the LH

camshaft pulley and No.3 timing belt cover.

SST 09278±54012

(e) Check that the timing belt has tension between the

crankshaft timing and LH camshaft timing pulleys.

(d) Align the timing .marks of the RH camshaft timing

pulley and No.3 timing belt cover.

(e) Slide the RH camshaft timing pulley on the camshaft.

± ENGINE MECHANICALTiming Belt (2VZ±FE)EM±44

Page 1238 of 2389

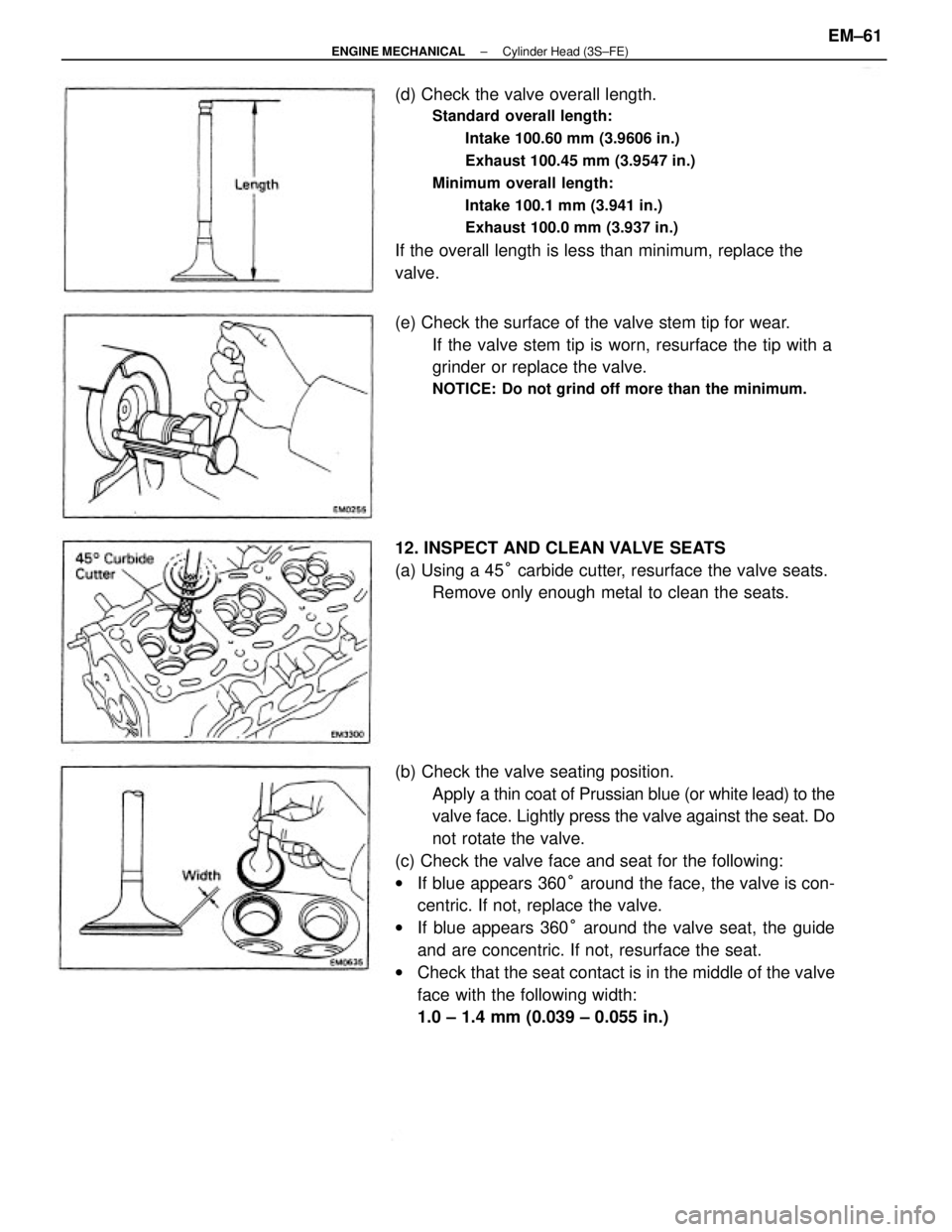

(b) Check the valve seating position.

Apply a thin coat of Prussian blue (or white lead) to the

valve face. Lightly press the valve against the seat. Do

not rotate the valve.

(c) Check the valve face and seat for the following:

wIf blue appears 360° around the face, the valve is con-

centric. If not, replace the valve.

wIf blue appears 360° around the valve seat, the guide

and are concentric. If not, resurface the seat.

wCheck that the seat contact is in the middle of the valve

face with the following width:

1.0 ± 1.4 mm (0.039 ± 0.055 in.) (d) Check the valve overall length.

Standard overall length:

Intake 100.60 mm (3.9606 in.)

Exhaust 100.45 mm (3.9547 in.)

Minimum overall length:

Intake 100.1 mm (3.941 in.)

Exhaust 100.0 mm (3.937 in.)

If the overall length is less than minimum, replace the

valve.

(e) Check the surface of the valve stem tip for wear.

If the valve stem tip is worn, resurface the tip with a

grinder or replace the valve.

NOTICE: Do not grind off more than the minimum.

12. INSPECT AND CLEAN VALVE SEATS

(a) Using a 45° carbide cutter, resurface the valve seats.

Remove only enough metal to clean the seats.

± ENGINE MECHANICALCylinder Head (3S±FE)EM±61

Page 1243 of 2389

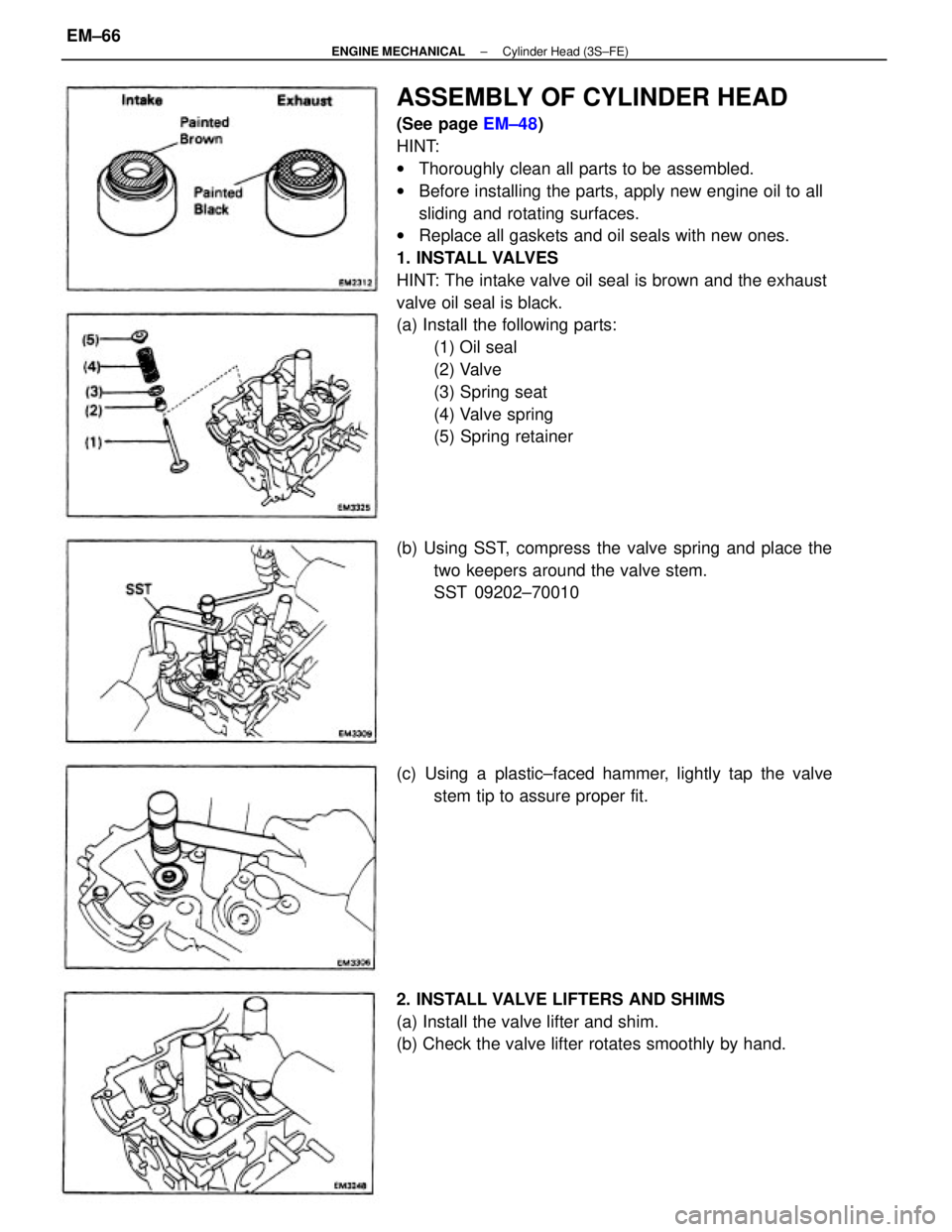

ASSEMBLY OF CYLINDER HEAD

(See page EM±48)

HINT:

wThoroughly clean all parts to be assembled.

wBefore installing the parts, apply new engine oil to all

sliding and rotating surfaces.

wReplace all gaskets and oil seals with new ones.

1. INSTALL VALVES

HINT: The intake valve oil seal is brown and the exhaust

valve oil seal is black.

(a) Install the following parts:

(1) Oil seal

(2) Valve

(3) Spring seat

(4) Valve spring

(5) Spring retainer

2. INSTALL VALVE LIFTERS AND SHIMS

(a) Install the valve lifter and shim.

(b) Check the valve lifter rotates smoothly by hand. (b) Using SST, compress the valve spring and place the

two keepers around the valve stem.

SST 09202±70010

(c) Using a plastic±faced hammer, lightly tap the valve

stem tip to assure proper fit.

± ENGINE MECHANICALCylinder Head (3S±FE)EM±66

Page 1244 of 2389

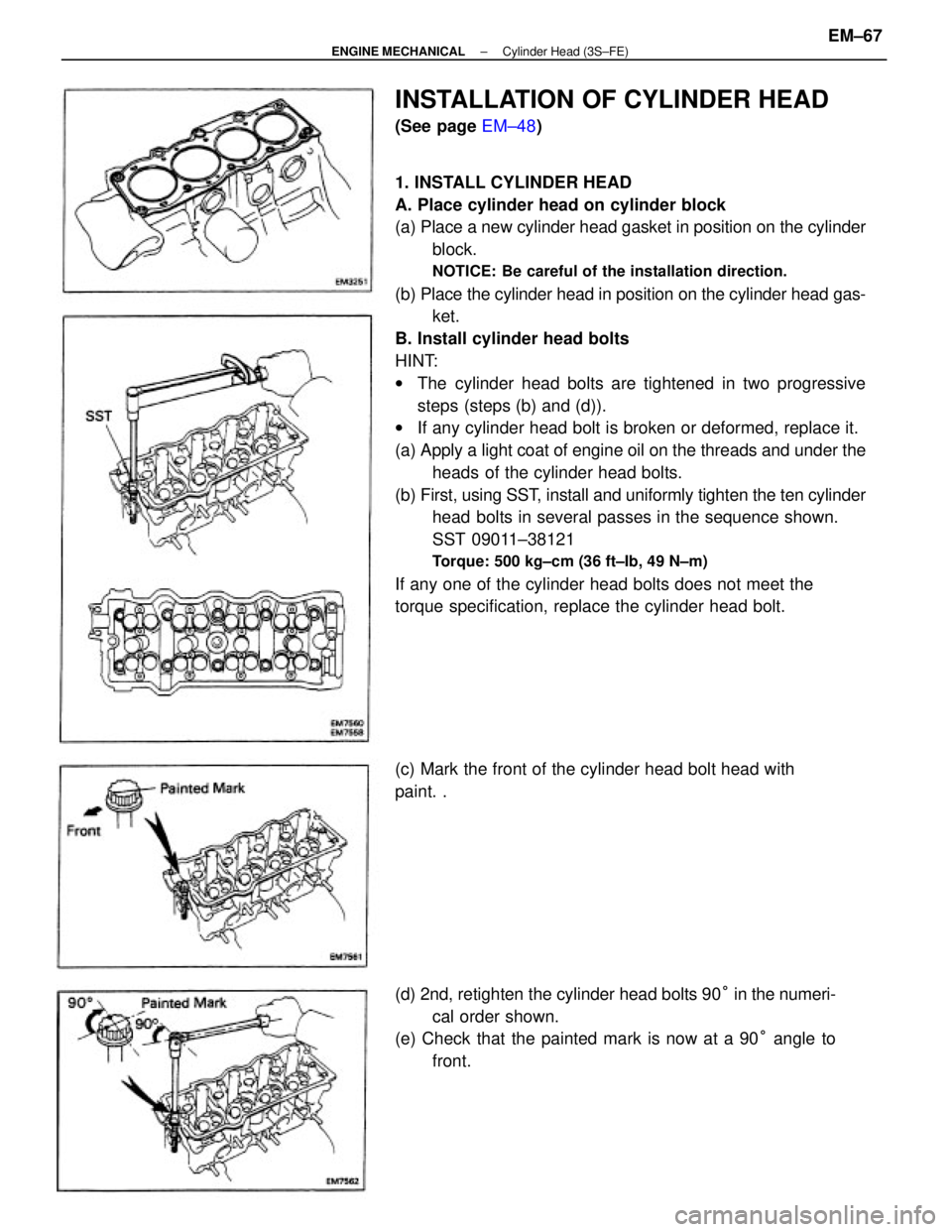

1. INSTALL CYLINDER HEAD

A. Place cylinder head on cylinder block

(a) Place a new cylinder head gasket in position on the cylinder

block.

NOTICE: Be careful of the installation direction.

(b) Place the cylinder head in position on the cylinder head gas-

ket.

B. Install cylinder head bolts

HINT:

wThe cylinder head bolts are tightened in two progressive

steps (steps (b) and (d)).

wIf any cylinder head bolt is broken or deformed, replace it.

(a) Apply a light coat of engine oil on the threads and under the

heads of the cylinder head bolts.

(b) First, using SST, install and uniformly tighten the ten cylinder

head bolts in several passes in the sequence shown.

SST 09011±38121

Torque: 500 kg±cm (36 ft±Ib, 49 N±m)

If any one of the cylinder head bolts does not meet the

torque specification, replace the cylinder head bolt.

(d) 2nd, retighten the cylinder head bolts 90° in the numeri-

cal order shown.

(e) Check that the painted mark is now at a 90° angle to

front.

INSTALLATION OF CYLINDER HEAD

(See page EM±48)

(c) Mark the front of the cylinder head bolt head with

paint. .

± ENGINE MECHANICALCylinder Head (3S±FE)EM±67

Page 1266 of 2389

(b) Check the valve seating position.

Apply a thin coat of Prussian blue (or white lead) to the

valve face. Lightly press the valve against the seat. Do

not rotate the valve.

(c) Check the valve face and seat for the following:

wIf blue appears 360° around the face, the valve is con-

centric. If not, replace the valve.

wIf blue appears 360° around the valve seat, the guide

and face are concentric. If not, resurface the seat.

wCheck that the seat contact is in the middle of the valve

face with the following width:

1.0 ± 1.4 mm (0.039 ± 0.055 in.) (d) Check the valve overall length.

Standard overall length:

Intake 96.1 mm (3.783 in.)

Exhaust 96.2 mm (3.787 in.)

Minimum overall length:

Intake 95.6 mm (3.754 in.)

Exhaust 95.7 mm (3.768 in.)

If the overall length is less than minimum, replace the

valve. (c) Check the valve head margin thickness.

Standard margin thickness: 1.0 mm (0.039 in.)

Minimum margin thickness: 0.5 mm (0.020 in.)

If the margin thickness is less than minimum, replace

the valve.

(e) Check the surface of the valve stem tip for wear.

If the valve stem tip is worn, resurface the tip with a

grinder or replace the valve.

NOTICE: Do not grind off more than the minimum.

12. INSPECT AND CLEAN VALVE SEATS

(a) Using a 455 carbide cutter, resurface the valve seats.

Remove only enough metal to clean the seats.

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±89

Page 1272 of 2389

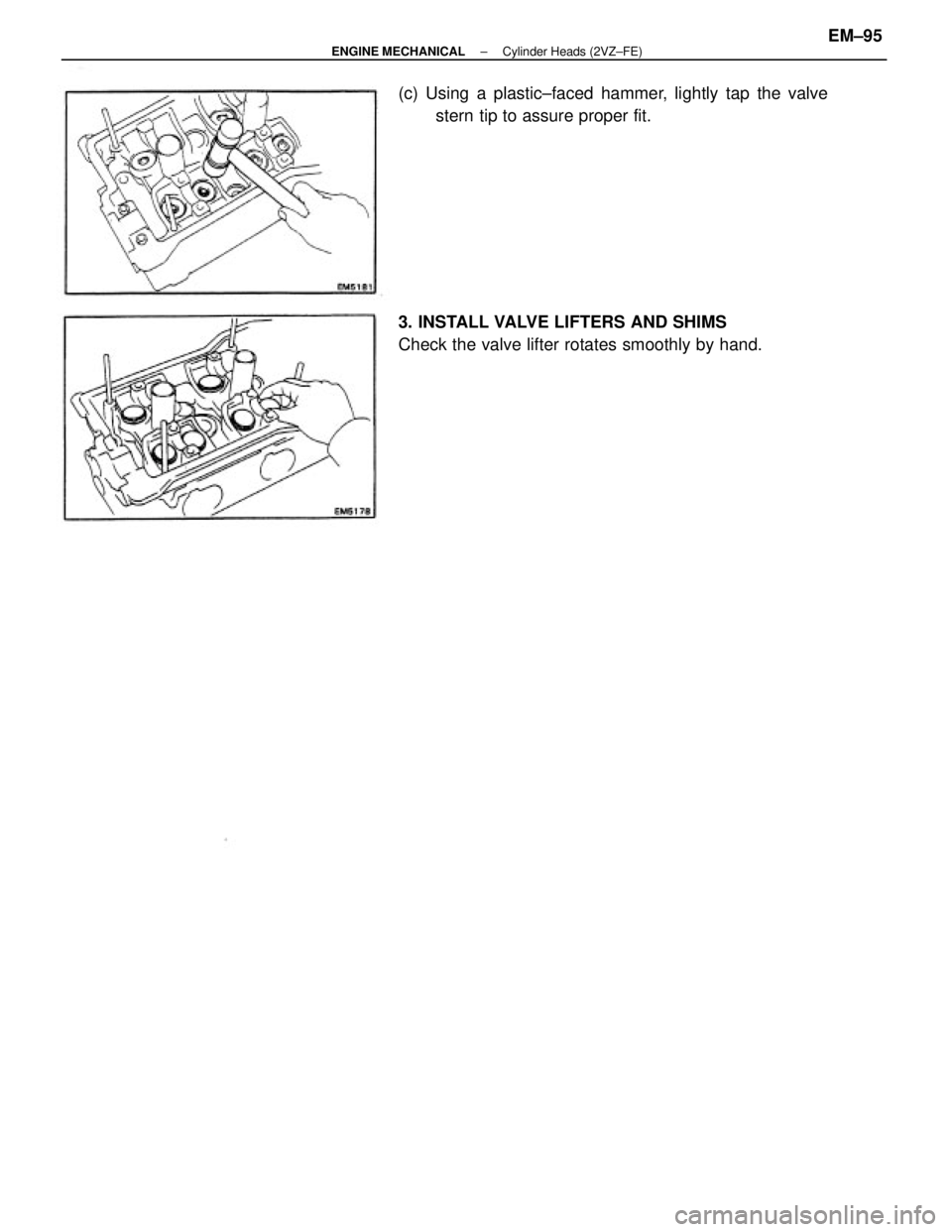

(c) Using a plastic±faced hammer, lightly tap the valve

stern tip to assure proper fit.

3. INSTALL VALVE LIFTERS AND SHIMS

Check the valve lifter rotates smoothly by hand.

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±95

Page 1273 of 2389

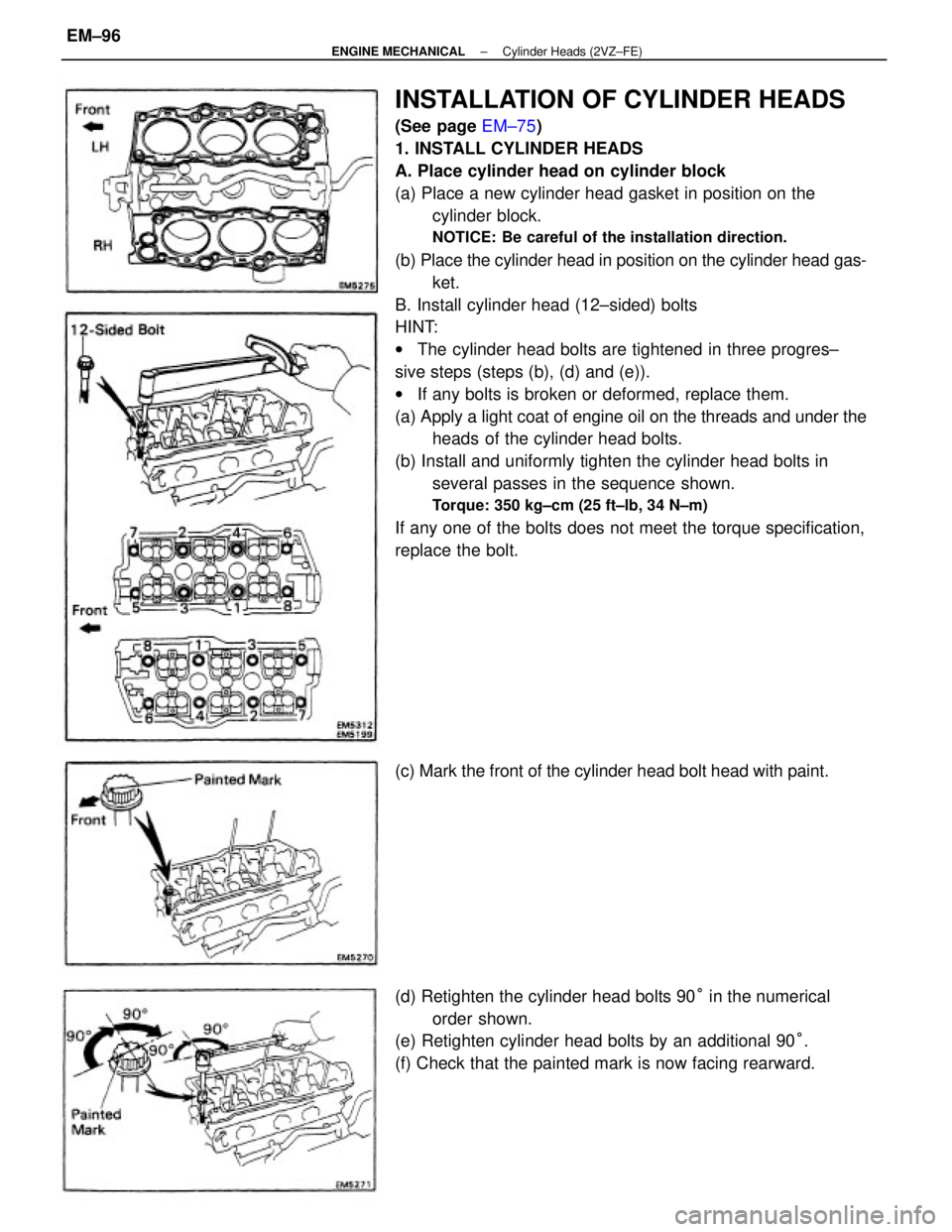

INSTALLATION OF CYLINDER HEADS

(See page EM±75)

1. INSTALL CYLINDER HEADS

A. Place cylinder head on cylinder block

(a) Place a new cylinder head gasket in position on the

cylinder block.

NOTICE: Be careful of the installation direction.

(b) Place the cylinder head in position on the cylinder head gas-

ket.

B. Install cylinder head (12±sided) bolts

HINT:

wThe cylinder head bolts are tightened in three progres±

sive steps (steps (b), (d) and (e)).

wIf any bolts is broken or deformed, replace them.

(a) Apply a light coat of engine oil on the threads and under the

heads of the cylinder head bolts.

(b) Install and uniformly tighten the cylinder head bolts in

several passes in the sequence shown.

Torque: 350 kg±cm (25 ft±lb, 34 N±m)

If any one of the bolts does not meet the torque specification,

replace the bolt.

(d) Retighten the cylinder head bolts 90° in the numerical

order shown.

(e) Retighten cylinder head bolts by an additional 90°.

(f) Check that the painted mark is now facing rearward. (c) Mark the front of the cylinder head bolt head with paint.

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±96

Page 1278 of 2389

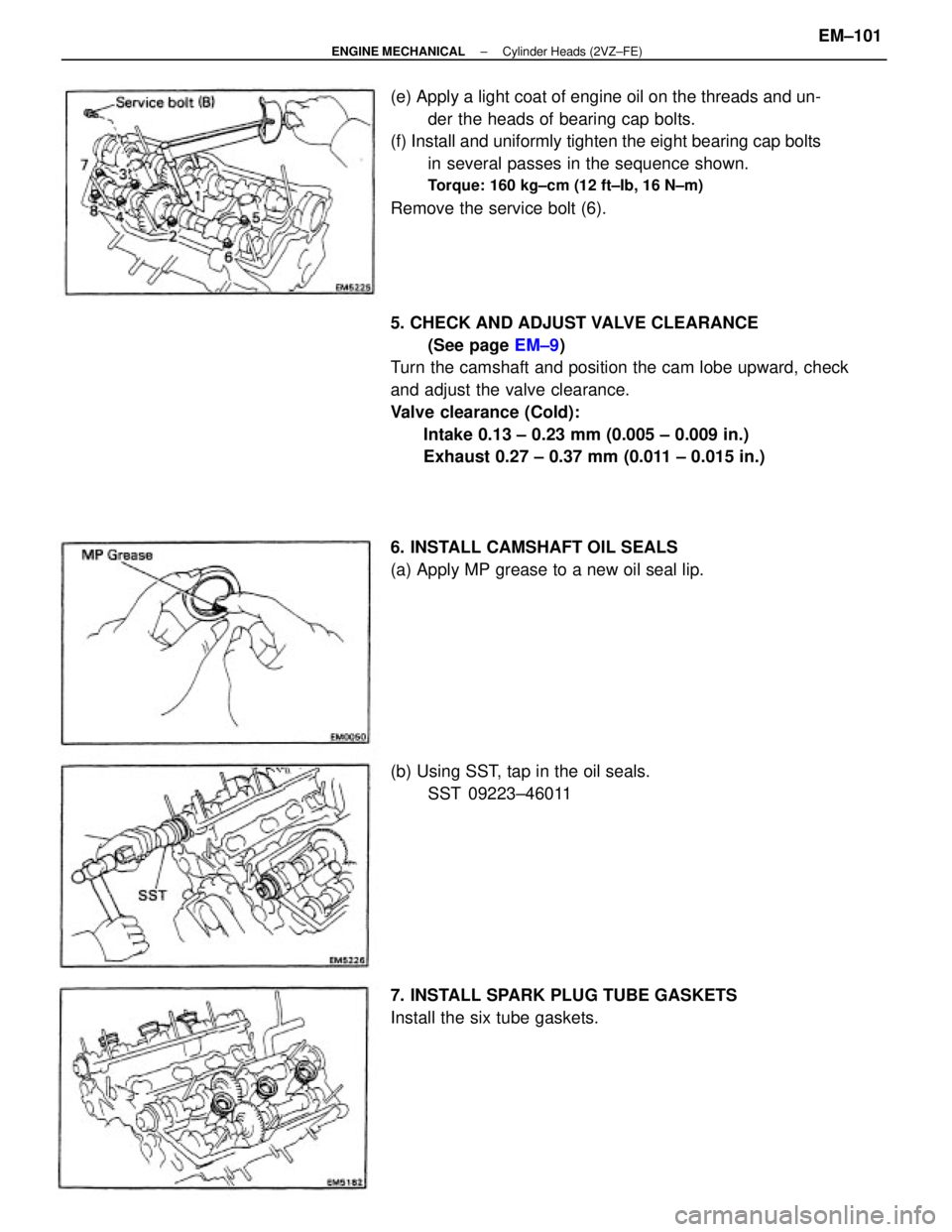

5. CHECK AND ADJUST VALVE CLEARANCE

(See page EM±9)

Turn the camshaft and position the cam lobe upward, check

and adjust the valve clearance.

Valve clearance (Cold):

Intake 0.13 ± 0.23 mm (0.005 ± 0.009 in.)

Exhaust 0.27 ± 0.37 mm (0.011 ± 0.015 in.) (e) Apply a light coat of engine oil on the threads and un-

der the heads of bearing cap bolts.

(f) Install and uniformly tighten the eight bearing cap bolts

in several passes in the sequence shown.

Torque: 160 kg±cm (12 ft±Ib, 16 N±m)

Remove the service bolt (6).

6. INSTALL CAMSHAFT OIL SEALS

(a) Apply MP grease to a new oil seal lip.

7. INSTALL SPARK PLUG TUBE GASKETS

Install the six tube gaskets. (b) Using SST, tap in the oil seals.

SST 09223±46011

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±101

Page 1291 of 2389

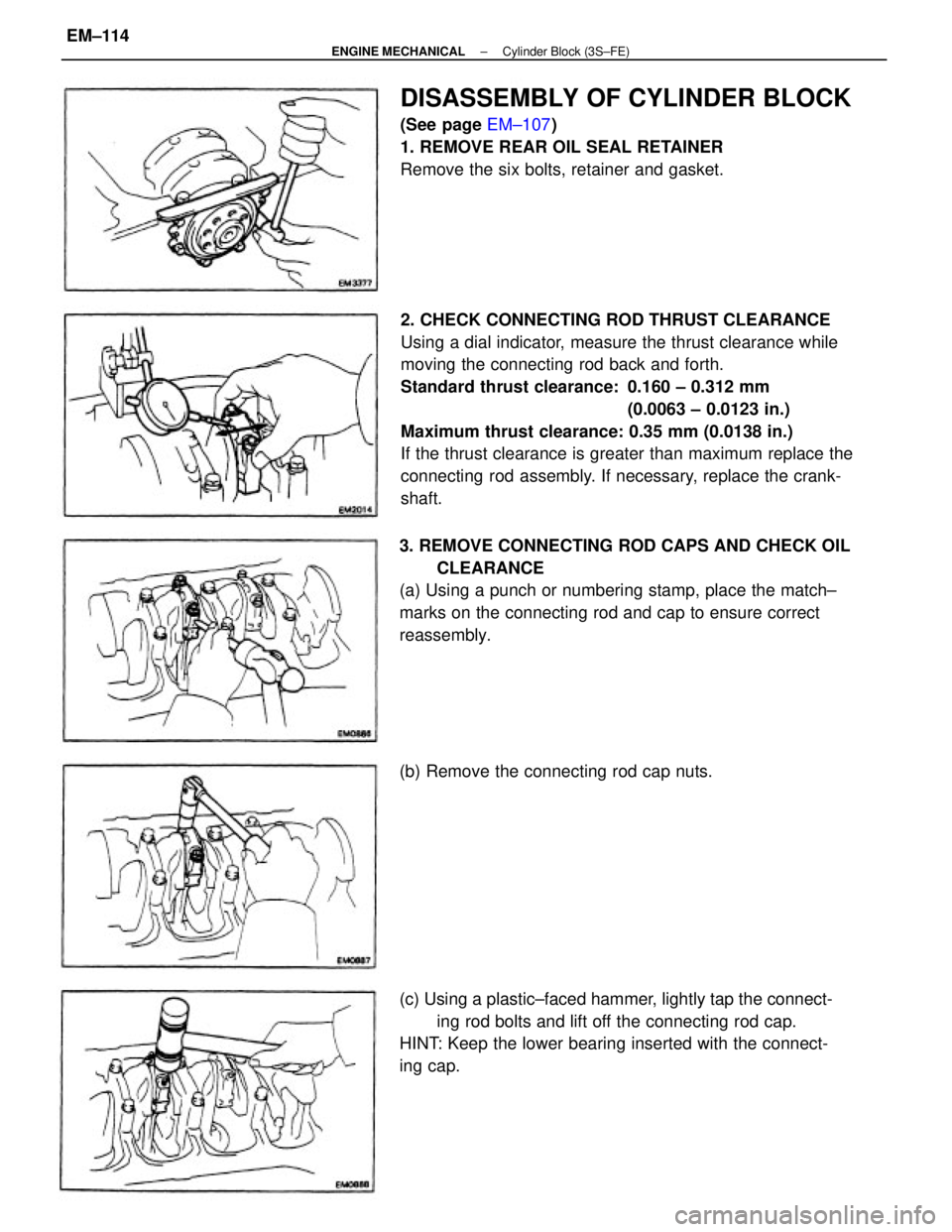

2. CHECK CONNECTING ROD THRUST CLEARANCE

Using a dial indicator, measure the thrust clearance while

moving the connecting rod back and forth.

Standard thrust clearance: 0.160 ± 0.312 mm

(0.0063 ± 0.0123 in.)

Maximum thrust clearance: 0.35 mm (0.0138 in.)

If the thrust clearance is greater than maximum replace the

connecting rod assembly. If necessary, replace the crank-

shaft.

3. REMOVE CONNECTING ROD CAPS AND CHECK OIL

CLEARANCE

(a) Using a punch or numbering stamp, place the match±

marks on the connecting rod and cap to ensure correct

reassembly.

(c) Using a plastic±faced hammer, lightly tap the connect-

ing rod bolts and lift off the connecting rod cap.

HINT: Keep the lower bearing inserted with the connect-

ing cap.

DISASSEMBLY OF CYLINDER BLOCK

(See page EM±107)

1. REMOVE REAR OIL SEAL RETAINER

Remove the six bolts, retainer and gasket.

(b) Remove the connecting rod cap nuts.

± ENGINE MECHANICALCylinder Block (3S±FE)EM±114