lock TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 2349 of 2389

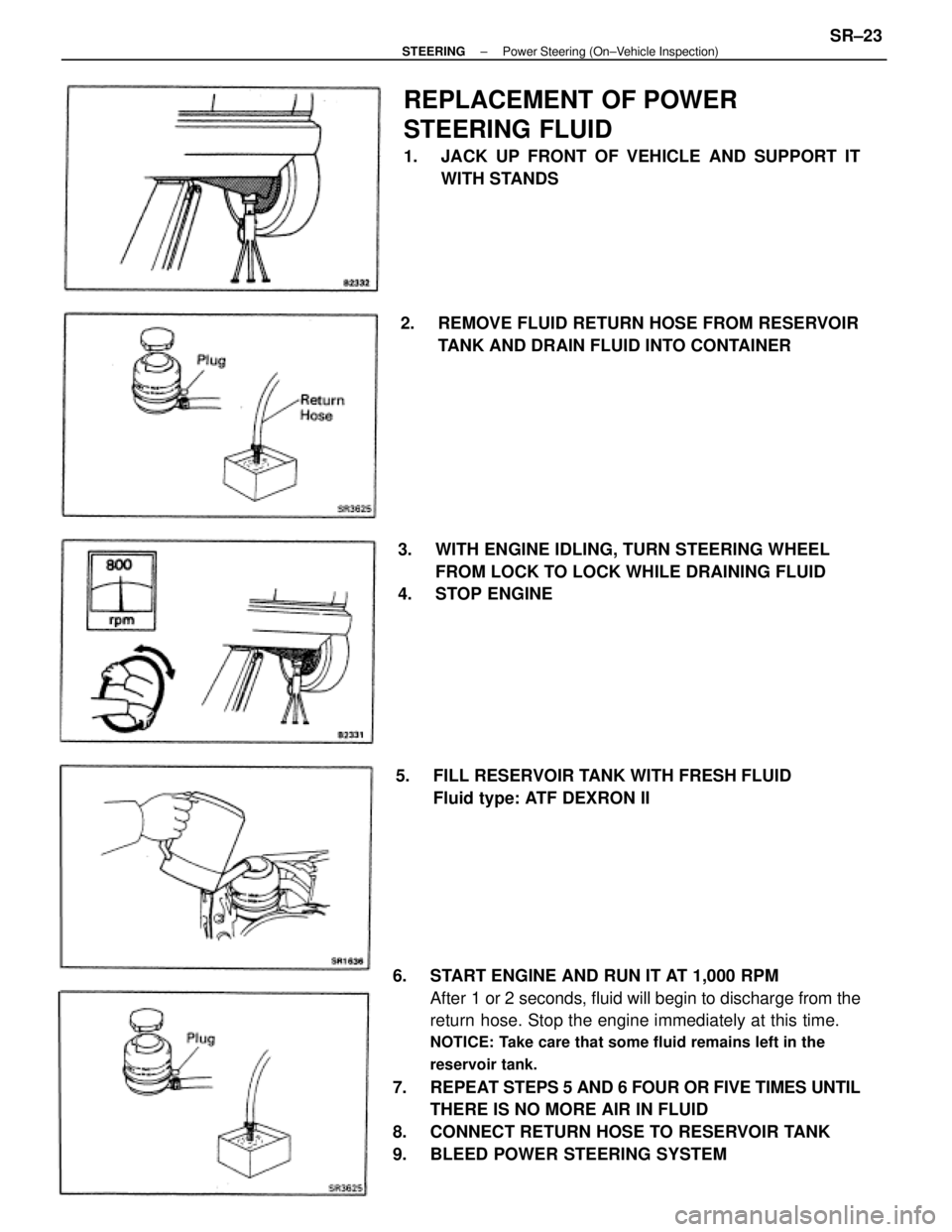

6. START ENGINE AND RUN IT AT 1,000 RPM

After 1 or 2 seconds, fluid will begin to discharge from the

return hose. Stop the engine immediately at this time.

NOTICE: Take care that some fluid remains left in the

reservoir tank.

7. REPEAT STEPS 5 AND 6 FOUR OR FIVE TIMES UNTIL

THERE IS NO MORE AIR IN FLUID

8. CONNECT RETURN HOSE TO RESERVOIR TANK

9. BLEED POWER STEERING SYSTEM

REPLACEMENT OF POWER

STEERING FLUID

1. JACK UP FRONT OF VEHICLE AND SUPPORT IT

WITH STANDS

3. WITH ENGINE IDLING, TURN STEERING WHEEL

FROM LOCK TO LOCK WHILE DRAINING FLUID

4. STOP ENGINE2. REMOVE FLUID RETURN HOSE FROM RESERVOIR

TANK AND DRAIN FLUID INTO CONTAINER

5. FILL RESERVOIR TANK WITH FRESH FLUID

Fluid type: ATF DEXRON II

± STEERINGPower Steering (On±Vehicle Inspection)SR±23

Page 2350 of 2389

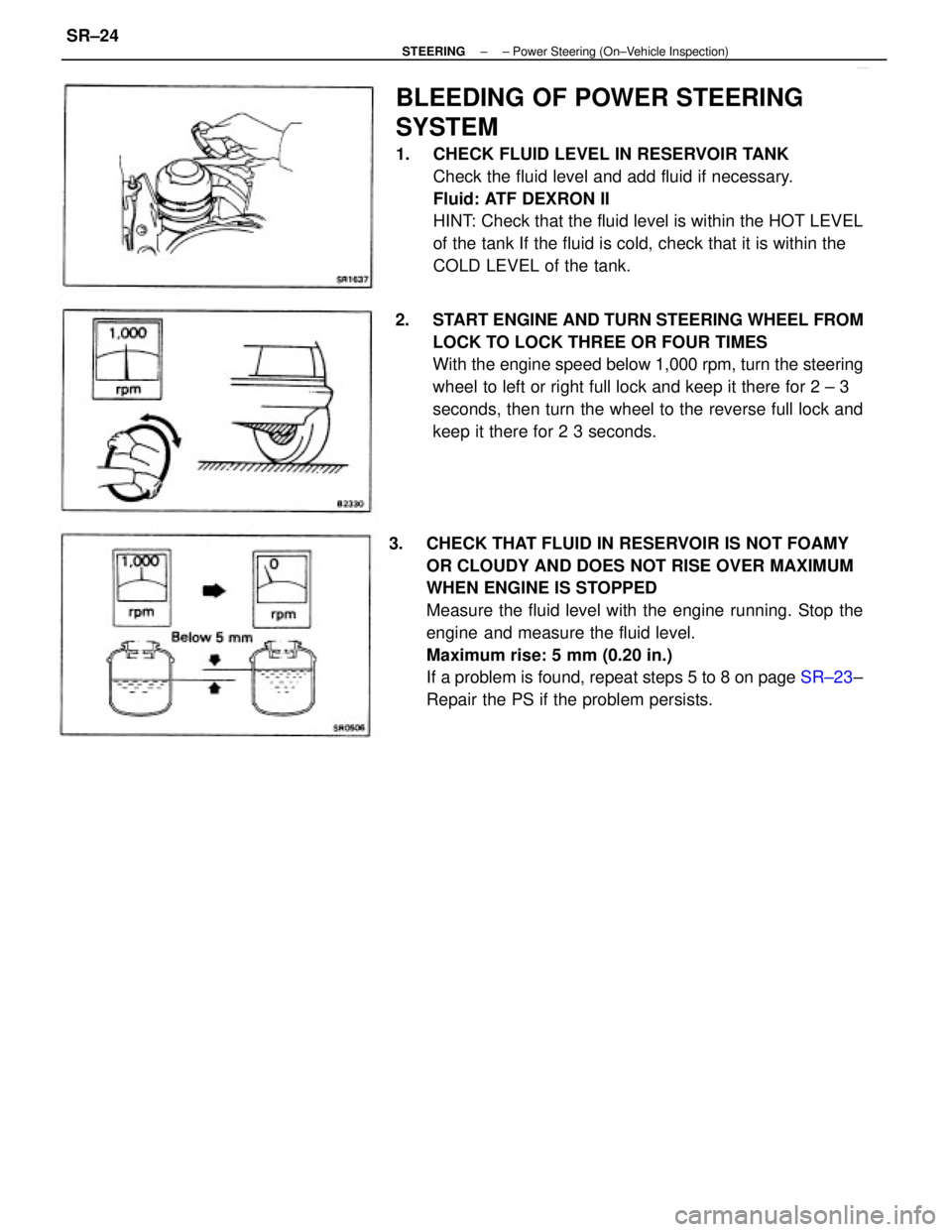

3. CHECK THAT FLUID IN RESERVOIR IS NOT FOAMY

OR CLOUDY AND DOES NOT RISE OVER MAXIMUM

WHEN ENGINE IS STOPPED

Measure the fluid level with the engine running. Stop the

engine and measure the fluid level.

Maximum rise: 5 mm (0.20 in.)

If a problem is found, repeat steps 5 to 8 on page SR±23±

Repair the PS if the problem persists.

BLEEDING OF POWER STEERING

SYSTEM

1. CHECK FLUID LEVEL IN RESERVOIR TANK

Check the fluid level and add fluid if necessary.

Fluid: ATF DEXRON II

HINT: Check that the fluid level is within the HOT LEVEL

of the tank If the fluid is cold, check that it is within the

COLD LEVEL of the tank.

2. START ENGINE AND TURN STEERING WHEEL FROM

LOCK TO LOCK THREE OR FOUR TIMES

With the engine speed below 1,000 rpm, turn the steering

wheel to left or right full lock and keep it there for 2 ± 3

seconds, then turn the wheel to the reverse full lock and

keep it there for 2 3 seconds.

± STEERING± Power Steering (On±Vehicle Inspection)SR±24

Page 2351 of 2389

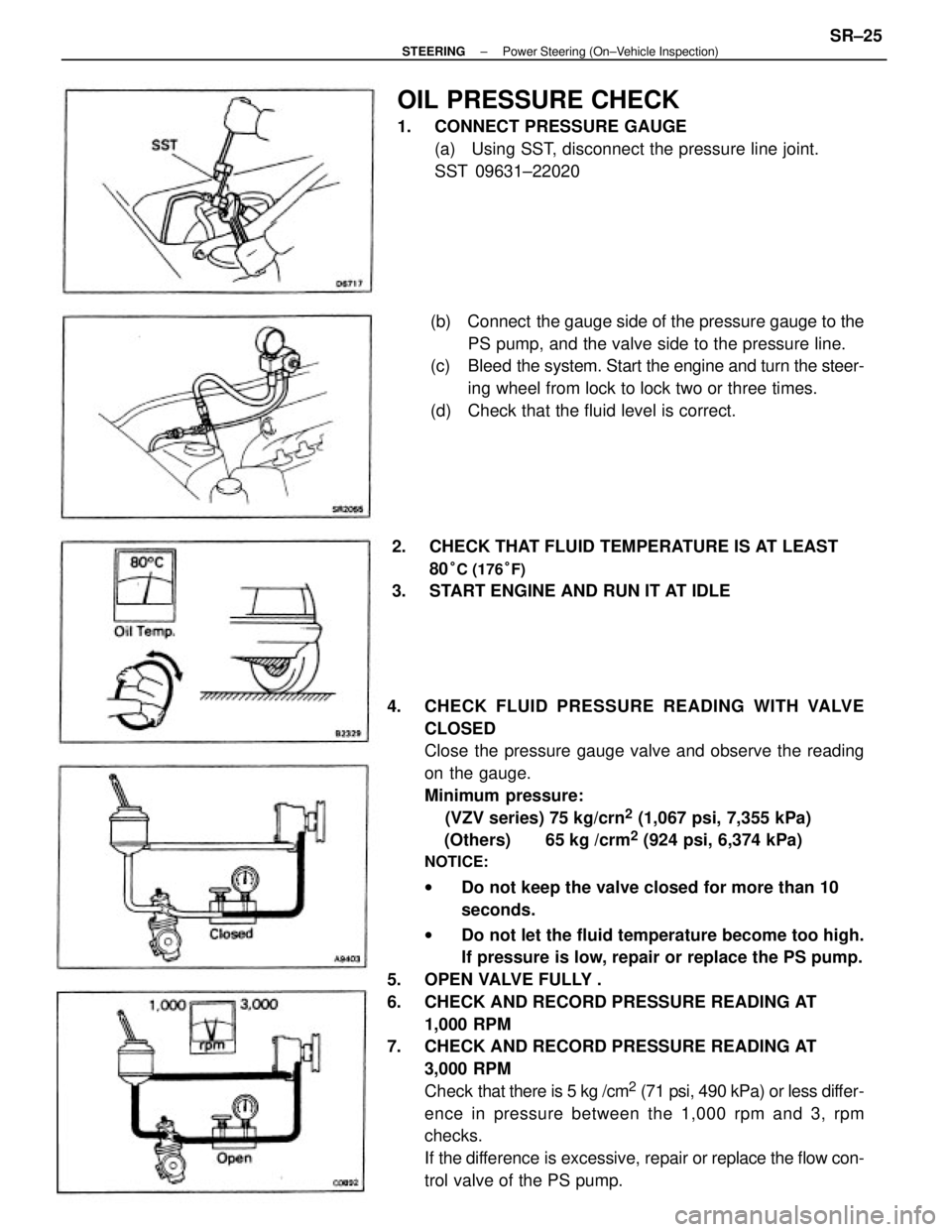

4. CHECK FLUID PRESSURE READING WITH VALVE

CLOSED

Close the pressure gauge valve and observe the reading

on the gauge.

Minimum pressure:

(VZV series) 75 kg/crn

2 (1,067 psi, 7,355 kPa)

(Others) 65 kg /crm

2 (924 psi, 6,374 kPa)

NOTICE:

wDo not keep the valve closed for more than 10

seconds.

wDo not let the fluid temperature become too high.

If pressure is low, repair or replace the PS pump.

5. OPEN VALVE FULLY .

6. CHECK AND RECORD PRESSURE READING AT

1,000 RPM

7. CHECK AND RECORD PRESSURE READING AT

3,000 RPM

Check that there is 5 kg /cm

2 (71 psi, 490 kPa) or less differ-

ence in pressure between the 1,000 rpm and 3, rpm

checks.

If the difference is excessive, repair or replace the flow con-

trol valve of the PS pump.(b) Connect the gauge side of the pressure gauge to the

PS pump, and the valve side to the pressure line.

(c) Bleed the system. Start the engine and turn the steer-

ing wheel from lock to lock two or three times.

(d) Check that the fluid level is correct.

OIL PRESSURE CHECK

1. CONNECT PRESSURE GAUGE

(a) Using SST, disconnect the pressure line joint.

SST 09631±22020

2. CHECK THAT FLUID TEMPERATURE IS AT LEAST

80

°C (176°F)

3. START ENGINE AND RUN IT AT IDLE

± STEERINGPower Steering (On±Vehicle Inspection)SR±25

Page 2352 of 2389

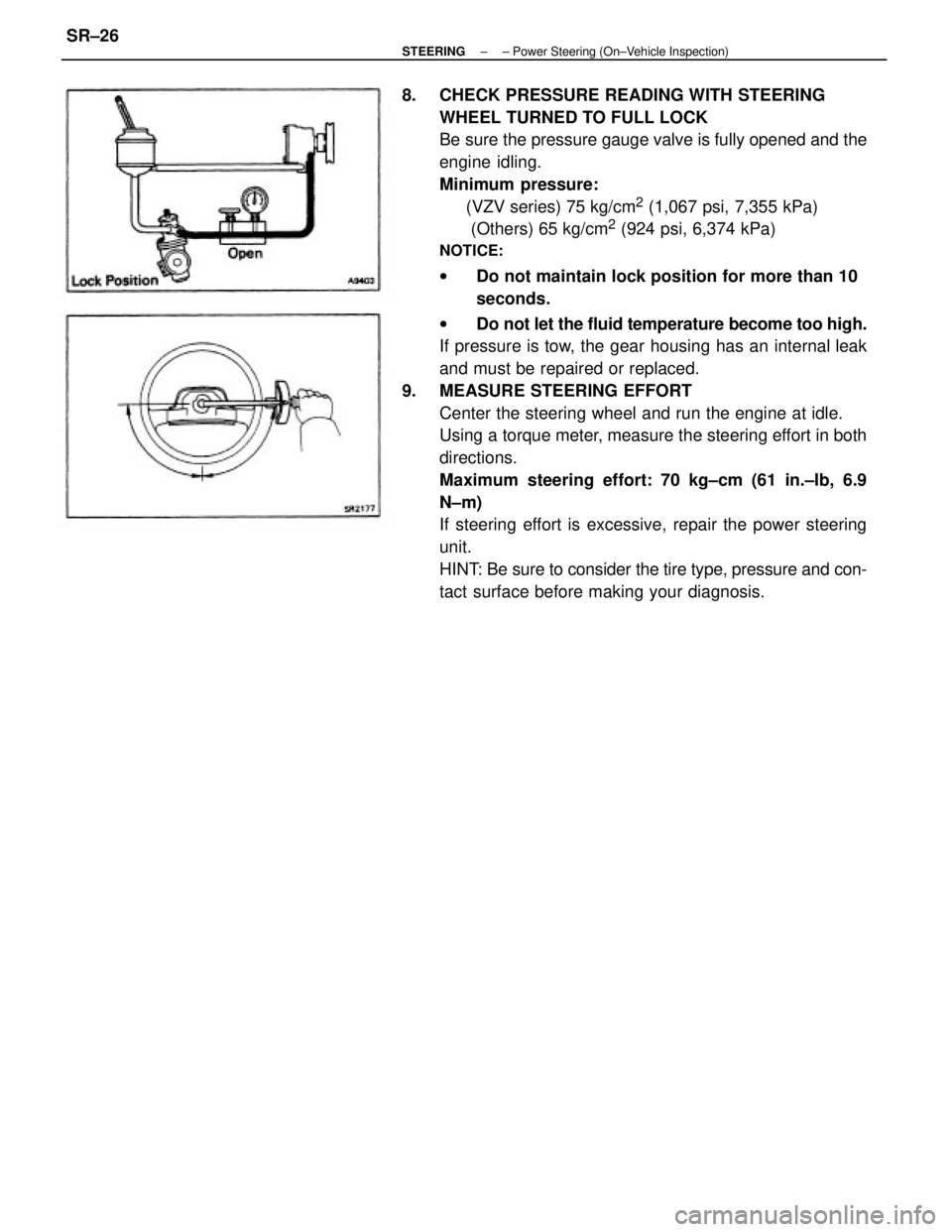

8. CHECK PRESSURE READING WITH STEERING

WHEEL TURNED TO FULL LOCK

Be sure the pressure gauge valve is fully opened and the

engine idling.

Minimum pressure:

(VZV series) 75 kg/cm

2 (1,067 psi, 7,355 kPa)

(Others) 65 kg/cm

2 (924 psi, 6,374 kPa)

NOTICE:

wDo not maintain lock position for more than 10

seconds.

wDo not let the fluid temperature become too high.

If pressure is tow, the gear housing has an internal leak

and must be repaired or replaced.

9. MEASURE STEERING EFFORT

Center the steering wheel and run the engine at idle.

Using a torque meter, measure the steering effort in both

directions.

Maximum steering effort: 70 kg±cm (61 in.±Ib, 6.9

N±m)

If steering effort is excessive, repair the power steering

unit.

HINT: Be sure to consider the tire type, pressure and con-

tact surface before making your diagnosis.

± STEERING± Power Steering (On±Vehicle Inspection)SR±26

Page 2378 of 2389

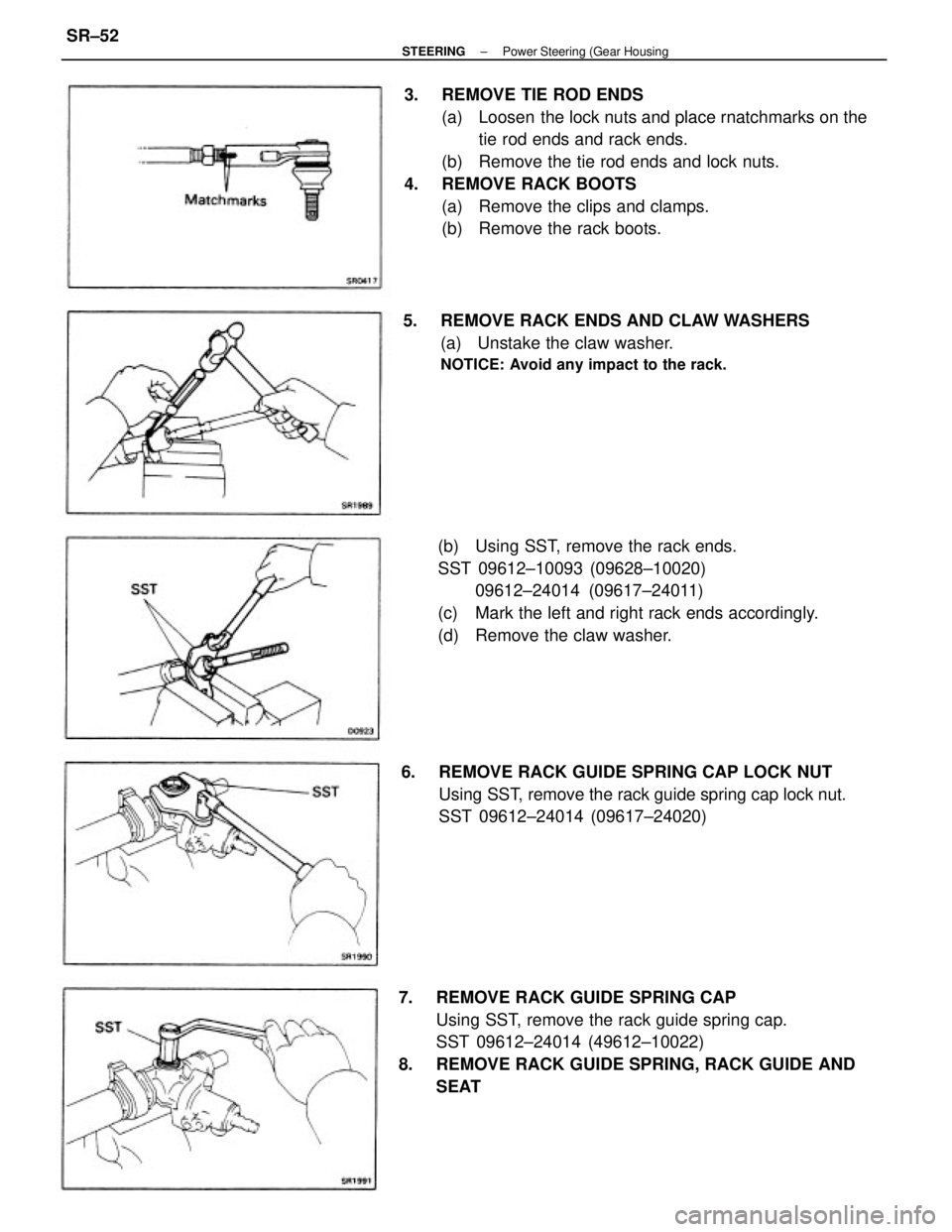

3. REMOVE TIE ROD ENDS

(a) Loosen the lock nuts and place rnatchmarks on the

tie rod ends and rack ends.

(b) Remove the tie rod ends and lock nuts.

4. REMOVE RACK BOOTS

(a) Remove the clips and clamps.

(b) Remove the rack boots.

7. REMOVE RACK GUIDE SPRING CAP

Using SST, remove the rack guide spring cap.

SST 09612±24014 (49612±10022)

8. REMOVE RACK GUIDE SPRING, RACK GUIDE AND

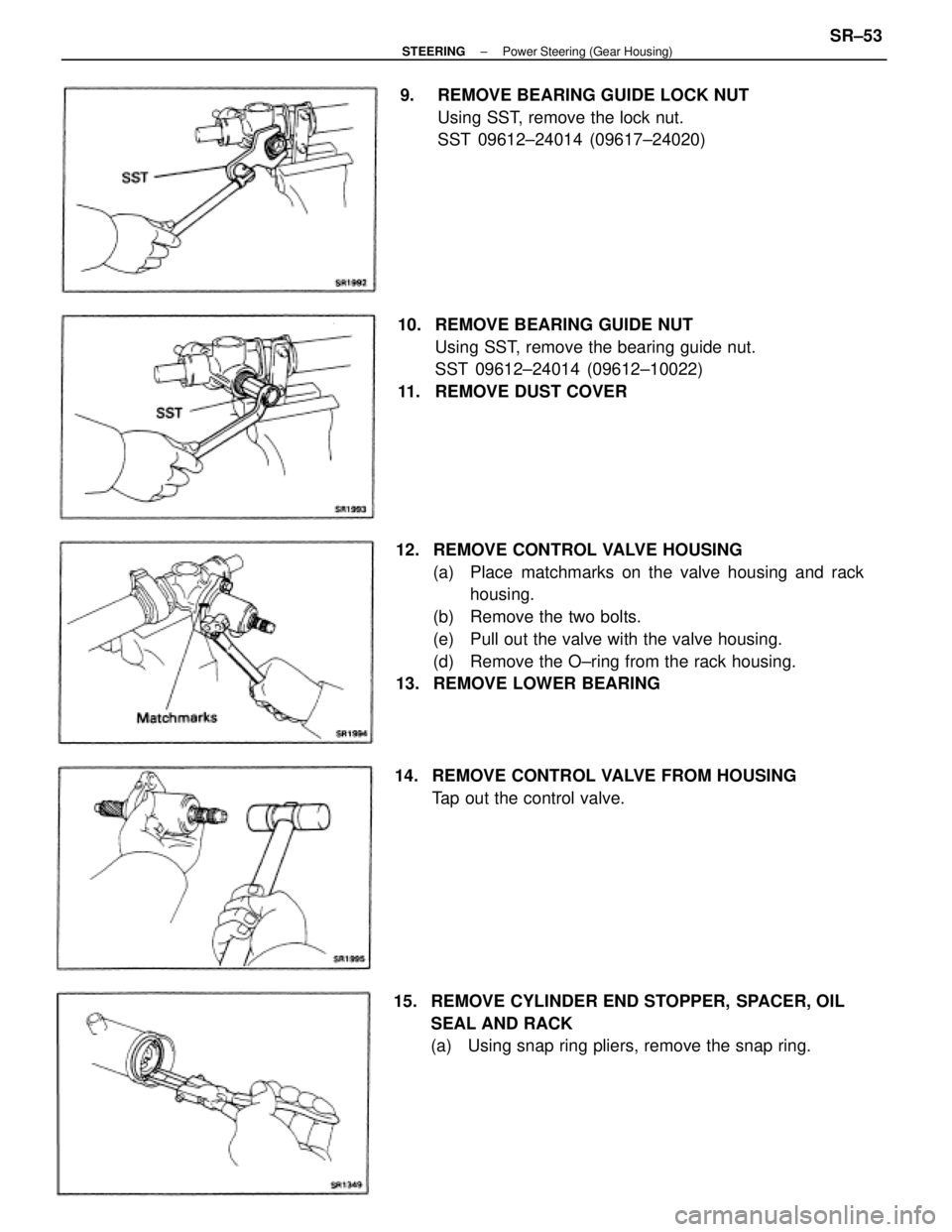

SEAT(b) Using SST, remove the rack ends.

SST 09612±10093 (09628±10020)

09612±24014 (09617±24011)

(c) Mark the left and right rack ends accordingly.

(d) Remove the claw washer.

6. REMOVE RACK GUIDE SPRING CAP LOCK NUT

Using SST, remove the rack guide spring cap lock nut.

SST 09612±24014 (09617±24020) 5. REMOVE RACK ENDS AND CLAW WASHERS

(a) Unstake the claw washer.

NOTICE: Avoid any impact to the rack.

± STEERINGPower Steering (Gear HousingSR±52

Page 2379 of 2389

12. REMOVE CONTROL VALVE HOUSING

(a) Place matchmarks on the valve housing and rack

housing.

(b) Remove the two bolts.

(e) Pull out the valve with the valve housing.

(d) Remove the O±ring from the rack housing.

13. REMOVE LOWER BEARING10. REMOVE BEARING GUIDE NUT

Using SST, remove the bearing guide nut.

SST 09612±24014 (09612±10022)

11. REMOVE DUST COVER

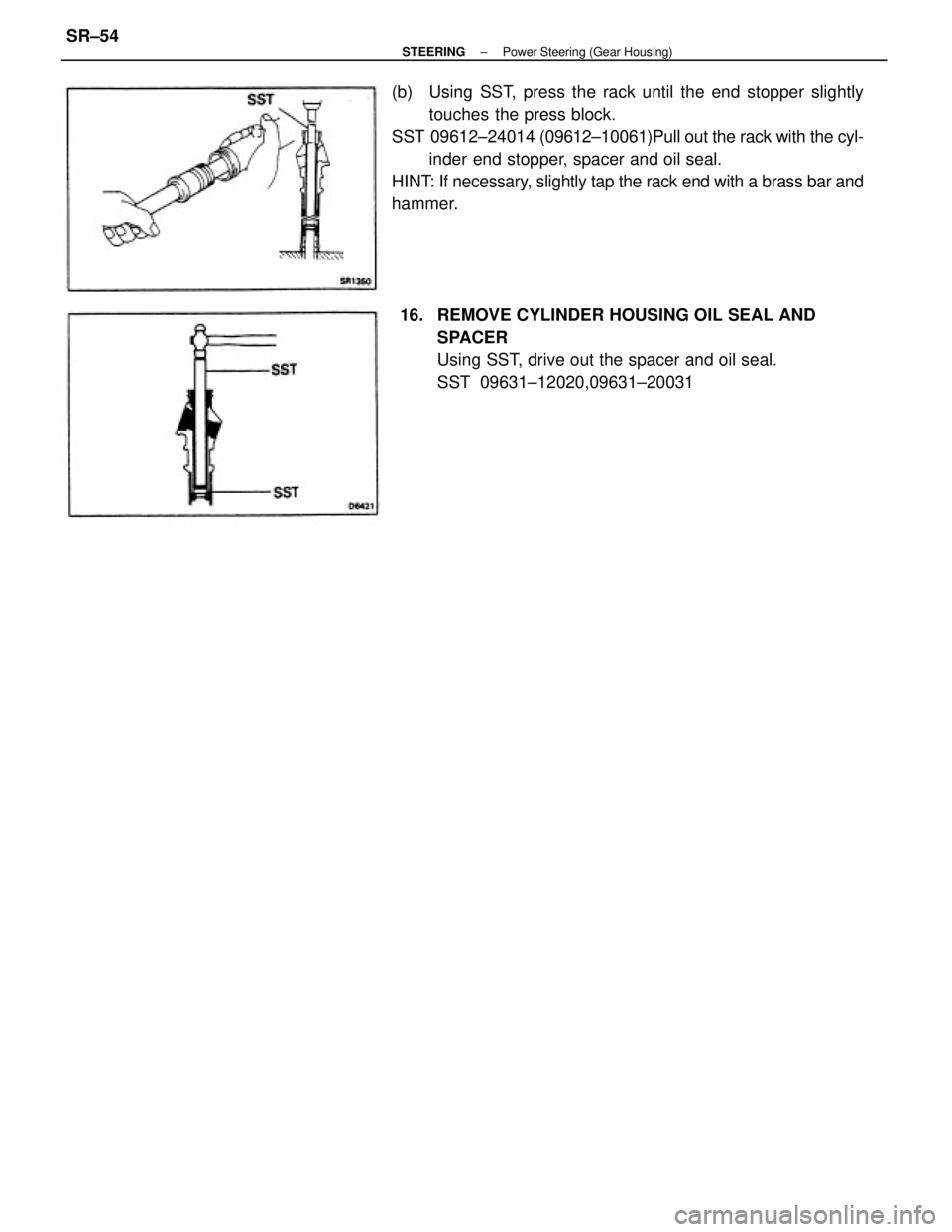

15. REMOVE CYLINDER END STOPPER, SPACER, OIL

SEAL AND RACK

(a) Using snap ring pliers, remove the snap ring. 9. REMOVE BEARING GUIDE LOCK NUT

Using SST, remove the lock nut.

SST 09612±24014 (09617±24020)

14. REMOVE CONTROL VALVE FROM HOUSING

Tap out the control valve.

± STEERINGPower Steering (Gear Housing)SR±53

Page 2380 of 2389

(b) Using SST, press the rack until the end stopper slightly

touches the press block.

SST 09612±24014 (09612±10061)Pull out the rack with the cyl-

inder end stopper, spacer and oil seal.

HINT: If necessary, slightly tap the rack end with a brass bar and

hammer.

16. REMOVE CYLINDER HOUSING OIL SEAL AND

SPACER

Using SST, drive out the spacer and oil seal.

SST 09631±12020,09631±20031

± STEERINGPower Steering (Gear Housing)SR±54

Page 2387 of 2389

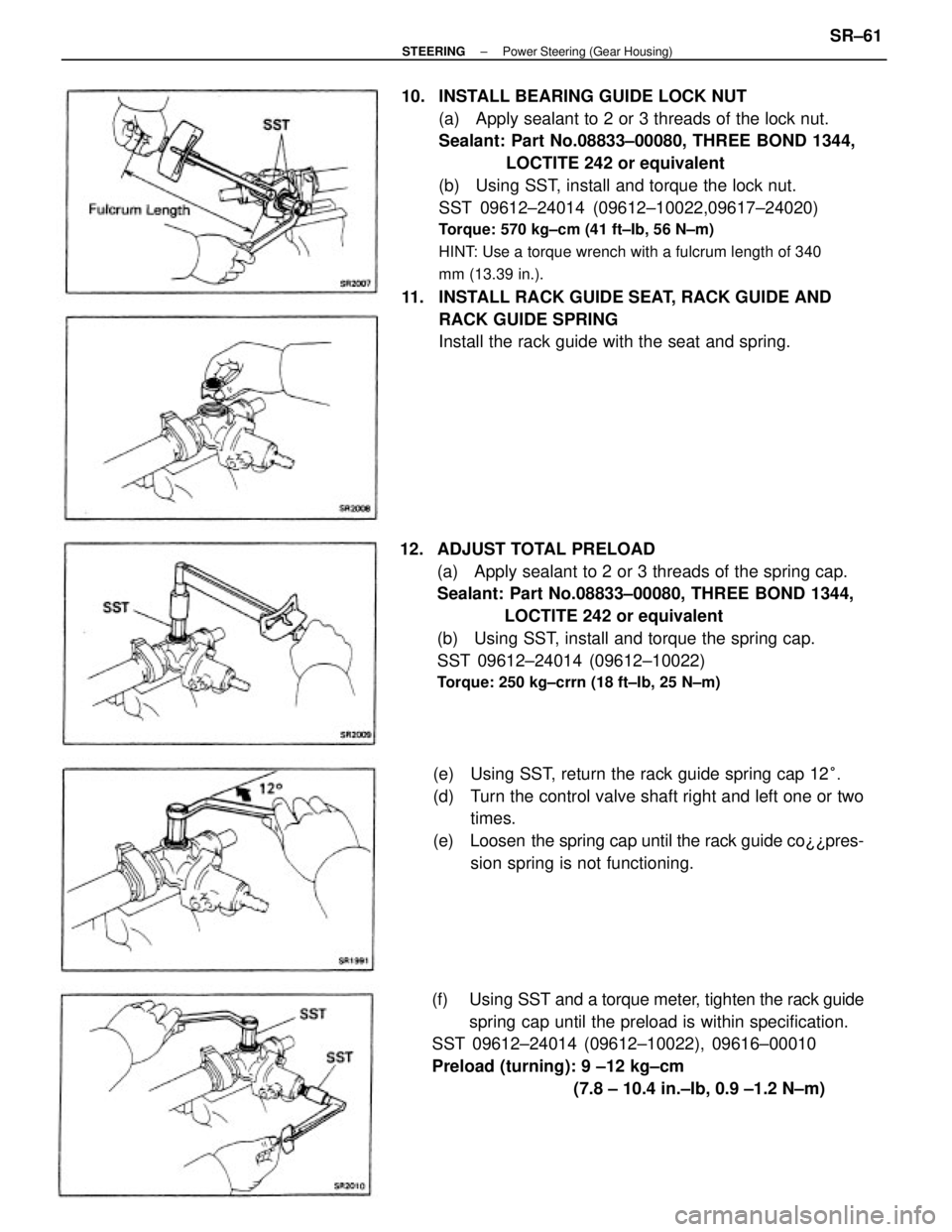

10. INSTALL BEARING GUIDE LOCK NUT

(a) Apply sealant to 2 or 3 threads of the lock nut.

Sealant: Part No.08833±00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(b) Using SST, install and torque the lock nut.

SST 09612±24014 (09612±10022,09617±24020)

Torque: 570 kg±cm (41 ft±Ib, 56 N±m)

HINT: Use a torque wrench with a fulcrum length of 340

mm (13.39 in.).

11. INSTALL RACK GUIDE SEAT, RACK GUIDE AND

RACK GUIDE SPRING

Install the rack guide with the seat and spring.

12. ADJUST TOTAL PRELOAD

(a) Apply sealant to 2 or 3 threads of the spring cap.

Sealant: Part No.08833±00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(b) Using SST, install and torque the spring cap.

SST 09612±24014 (09612±10022)

Torque: 250 kg±crrn (18 ft±Ib, 25 N±m)

(e) Using SST, return the rack guide spring cap 12°.

(d) Turn the control valve shaft right and left one or two

times.

(e) Loosen the spring cap until the rack guide co¿¿pres-

sion spring is not functioning.

(f) Using SST and a torque meter, tighten the rack guide

spring cap until the preload is within specification.

SST 09612±24014 (09612±10022), 09616±00010

Preload (turning): 9 ±12 kg±cm

(7.8 ± 10.4 in.±Ib, 0.9 ±1.2 N±m)

± STEERINGPower Steering (Gear Housing)SR±61

Page 2388 of 2389

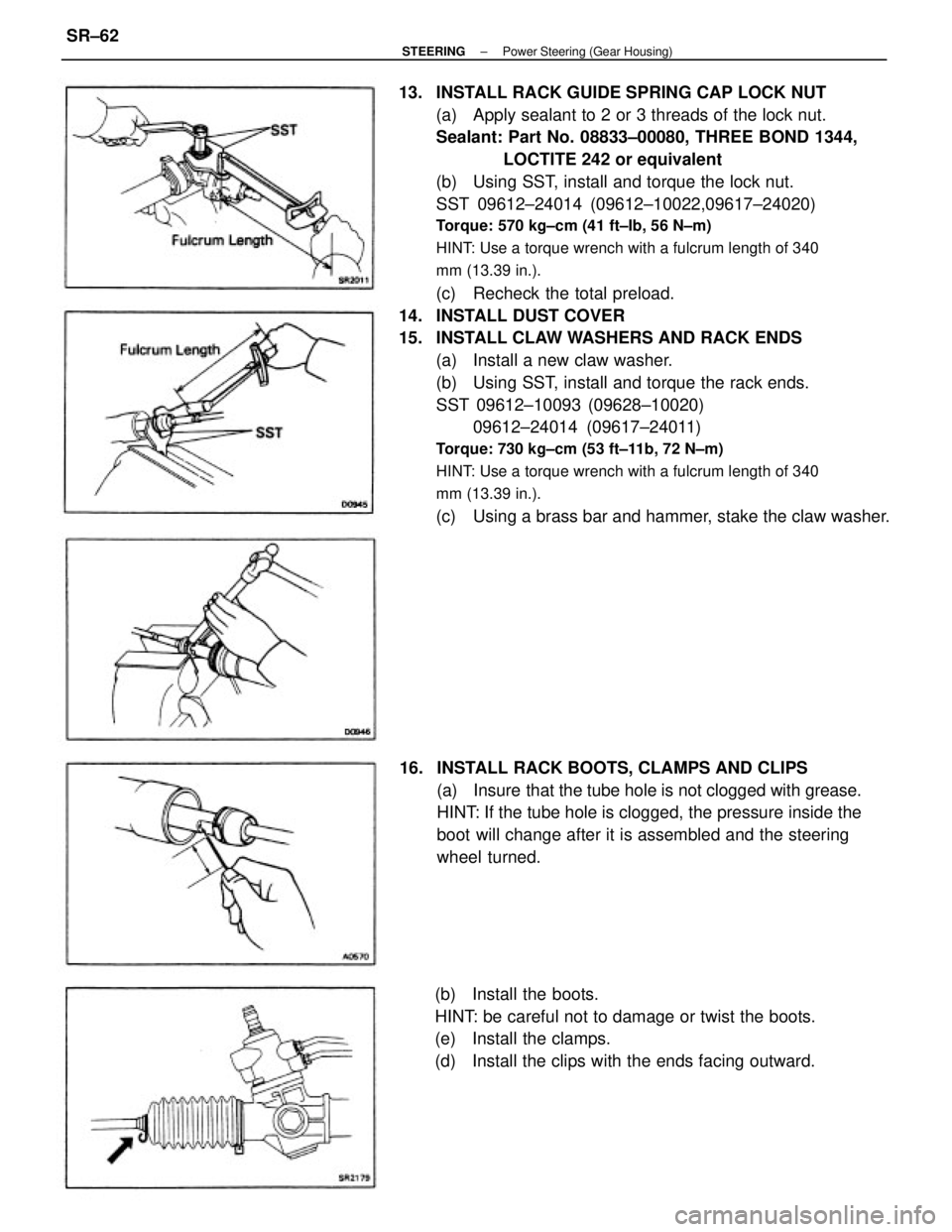

13. INSTALL RACK GUIDE SPRING CAP LOCK NUT

(a) Apply sealant to 2 or 3 threads of the lock nut.

Sealant: Part No. 08833±00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(b) Using SST, install and torque the lock nut.

SST 09612±24014 (09612±10022,09617±24020)

Torque: 570 kg±cm (41 ft±Ib, 56 N±m)

HINT: Use a torque wrench with a fulcrum length of 340

mm (13.39 in.).

(c) Recheck the total preload.

14. INSTALL DUST COVER

15. INSTALL CLAW WASHERS AND RACK ENDS

(a) Install a new claw washer.

(b) Using SST, install and torque the rack ends.

SST 09612±10093 (09628±10020)

09612±24014 (09617±24011)

Torque: 730 kg±cm (53 ft±11b, 72 N±m)

HINT: Use a torque wrench with a fulcrum length of 340

mm (13.39 in.).

(c) Using a brass bar and hammer, stake the claw washer.

16. INSTALL RACK BOOTS, CLAMPS AND CLIPS

(a) Insure that the tube hole is not clogged with grease.

HINT: If the tube hole is clogged, the pressure inside the

boot will change after it is assembled and the steering

wheel turned.

(b) Install the boots.

HINT: be careful not to damage or twist the boots.

(e) Install the clamps.

(d) Install the clips with the ends facing outward.

± STEERINGPower Steering (Gear Housing)SR±62

Page 2389 of 2389

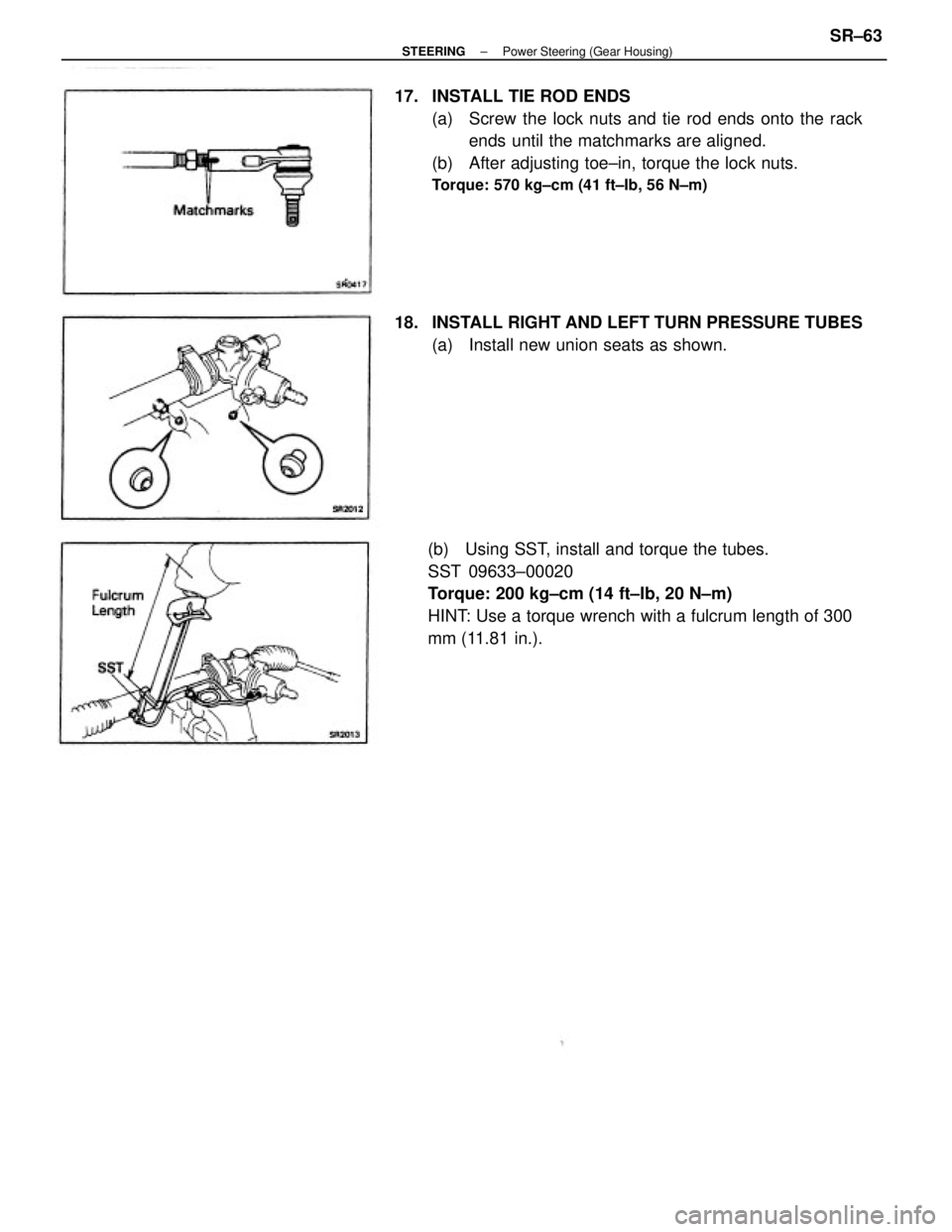

17. INSTALL TIE ROD ENDS

(a) Screw the lock nuts and tie rod ends onto the rack

ends until the matchmarks are aligned.

(b) After adjusting toe±in, torque the lock nuts.

Torque: 570 kg±cm (41 ft±Ib, 56 N±m)

(b) Using SST, install and torque the tubes.

SST 09633±00020

Torque: 200 kg±cm (14 ft±Ib, 20 N±m)

HINT: Use a torque wrench with a fulcrum length of 300

mm (11.81 in.). 18. INSTALL RIGHT AND LEFT TURN PRESSURE TUBES

(a) Install new union seats as shown.

± STEERINGPower Steering (Gear Housing)SR±63