checking oil TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1406 of 2389

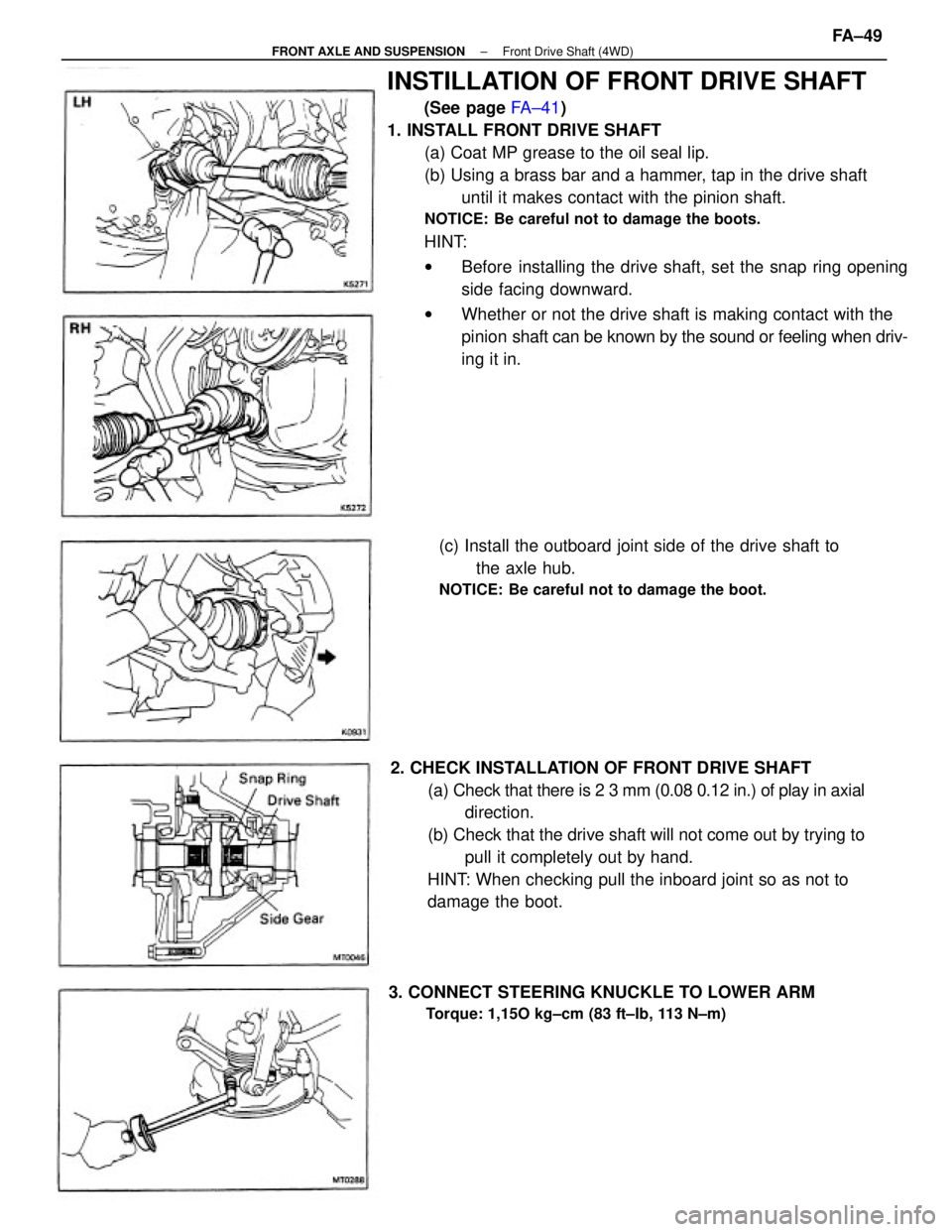

INSTILLATION OF FRONT DRIVE SHAFT

(See page FA±41)

1. INSTALL FRONT DRIVE SHAFT

(a) Coat MP grease to the oil seal lip.

(b) Using a brass bar and a hammer, tap in the drive shaft

until it makes contact with the pinion shaft.

NOTICE: Be careful not to damage the boots.

HINT:

wBefore installing the drive shaft, set the snap ring opening

side facing downward.

wWhether or not the drive shaft is making contact with the

pinion shaft can be known by the sound or feeling when driv-

ing it in.

2. CHECK INSTALLATION OF FRONT DRIVE SHAFT

(a) Check that there is 2 3 mm (0.08 0.12 in.) of play in axial

direction.

(b) Check that the drive shaft will not come out by trying to

pull it completely out by hand.

HINT: When checking pull the inboard joint so as not to

damage the boot.(c) Install the outboard joint side of the drive shaft to

the axle hub.

NOTICE: Be careful not to damage the boot.

3. CONNECT STEERING KNUCKLE TO LOWER ARM

Torque: 1,15O kg±cm (83 ft±Ib, 113 N±m)

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (4WD)FA±49

Page 1861 of 2389

PRECAUTIONS FOR VEHICLES EQUIPPED WITH A

CATALYTIC CONVERTER

CAUTION: If large amounts of unburned gasoline flow into the converter, it may overheat

and create a fire hazard. To prevent this, observe the following precautions and

explain them to your customer.

1. Use only unleaded gasoline.

2. Avoid prolonged idling.

Avoid running the engine at idle speed for more than 20

minutes.

3. Avoid spark jump test.

(a) Spark jump test only when absolutely necessary. Perform this test as rapidly as pos-

sible.

(b) While testing, never race the engine.

4. Avoid prolonged engine compression measurement.

Engine compression tests must be made as rapidly as possible.

5. Do not run engine when fuel tank is nearly empty.

This may cause the engine to misfire and create an extra

load on the converter.

6. Avoid coasting with ignition turned off and prolonged braking.

7. Do not dispose of used catalyst along with parts contaminated with gasoline or oil.(f) When steam cleaning an engine, protect the distribu-

tor, air filter and VCV from water.

(g) Never use an impact wrench to remove or install tem-

perature switches or temperature sensors.

(h) When checking continuity at the wire connector, insert

the tester probe carefully to prevent terminals from

bending.

(i) When using a vacuum gauge, never force the hose

onto a connector that is too large. Use a step±down

adapter instead. Once the hose has been stretched,

it may leak.

13. Tag hoses before disconnecting them:

(a) When disconnecting vacuum hoses, use tags to iden-

tify how they should be reconnected.

(b) After completing a job, double check that the vacuum

hoses are properly connected. A label under the

hood shows the proper layout.

± INTRODUCTIONIN±6General Repair Instructions

Page 1862 of 2389

PRECAUTIONS FOR VEHICLES EQUIPPED WITH A

CATALYTIC CONVERTER

CAUTION: If large amounts of unburned gasoline flow into the converter, it may overheat

and create a fire hazard. To prevent this, observe the following precautions and

explain them to your customer.

1. Use only unleaded gasoline.

2. Avoid prolonged idling.

Avoid running the engine at idle speed for more than 20

minutes.

3. Avoid spark jump test.

(a) Spark jump test only when absolutely necessary. Perform this test as rapidly as pos-

sible.

(b) While testing, never race the engine.

4. Avoid prolonged engine compression measurement.

Engine compression tests must be made as rapidly as possible.

5. Do not run engine when fuel tank is nearly empty.

This may cause the engine to misfire and create an extra

load on the converter.

6. Avoid coasting with ignition turned off and prolonged braking.

7. Do not dispose of used catalyst along with parts contaminated with gasoline or oil.(f) When steam cleaning an engine, protect the distribu-

tor, air filter and VCV from water.

(g) Never use an impact wrench to remove or install tem-

perature switches or temperature sensors.

(h) When checking continuity at the wire connector, insert

the tester probe carefully to prevent terminals from

bending.

(i) When using a vacuum gauge, never force the hose

onto a connector that is too large. Use a step±down

adapter instead. Once the hose has been stretched,

it may leak.

13. Tag hoses before disconnecting them:

(a) When disconnecting vacuum hoses, use tags to iden-

tify how they should be reconnected.

(b) After completing a job, double check that the vacuum

hoses are properly connected. A label under the

hood shows the proper layout.

± INTRODUCTIONPrecautions for Vehicles Equipped with a Catalytic ConverterIN±6

Page 1914 of 2389

GENERAL MAINTENANCE

These are the maintenance and inspection items

which are considered to be the owner's responsibility,

They can be performed by the owner or he

can have then done at a service shop. These items

include those which should be checked on a daily ba-

sis, those which, in most cases, do not require

(special) tools and those which are considered to be

reasonable for the owner to perform.

Items and procedures for general maintenance are as

follows:

OUTSIDE VEHICLE

1. TIRES

(a) Check the pressure with a gauge. Adjust

if necessary.

(b) Check for cuts, damage or excessive wear.

2. WHEEL NUTS

When checking the tires, check the nuts for looseness

or for missing nuts. If necessary,

tighten them.

3. TIRE ROTATION

It is recommended that tires be rotated every

7,500 miles (12,000 km).

4. WINDSHIELD WIPER BLADES

Check for wear or cracks whenever they do not wipe

clean. Replace if necessary.

5. FLUID LEAKS

(a) Check underneath for leaking fuel, oil, water or

other fluid.

(b) If you smell gasoline fumes or notice any leak,

have the cause found and corrected.

6. DOORS AND ENGINE HOOD

(a) Check that all doors including the trunk lid and

back door operate smoothly, and that all

latches lock securely.

(b) Check that the engine hood secondary latch se-

cures the hood from opening when the prima-

ry latch is released.

INSIDE VEHICLE

7. LIGHTS

(a) Check that the headlights, stop lights, taillights,

turn signal lights, and other

lights are all working.

(b) Check the headlight aiming.8. WARNING LIGHTS AND BUZZERS

Check that all warning lights and buzzers func-

tion properly.

9. HORN

Check that it is working.

10. WINDSHIELD GLASS

Check for scratches, pits or abrasions.

11. WINDSHIELD WIPER AND WASHER

(a) Check operation of the wipers and washer.

(b) Check that the wipers do not streak.

12. WINDSHIELD DEFROSTER

Check that air comes out from the defroster out-

let when operating the heater or air conditioner

at defroster mode.

13. REAR VIEW MIRROR

Check that it is mounted securely.

14. SUN VISORS

Check that they move freely and are mounted

securely.

15. STEERING WHEEL

Check that it has the specified freeplay. Be alert

for changes in steering condition, such as hard

steering, excessive freeplay or strange noise.

16. SEATS

(a) Check that all front seat controls such as

seat adjusters, seatback recliner, etc.

operate smoothly.

(b) Check that a11 latches lock securely in

any position.

(c) Check that the locks hold securely in any

latched position.

(d) Check that the head restraints move up

and down smoothly and that the locks

hold securely in any latched position.

(e) For folding±down rear seat backs, check

that the latches lock securely.

17. SEAT BELTS

(a) Check that the seat belt system such as

buckles, retractors and anchors operate

properly and smoothly.

(b) Check that the belt webbing is not cut,

frayed, worn or damaged.

± MAINTENANCEGeneral MaintenanceMA±16