flat tire TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 781 of 2389

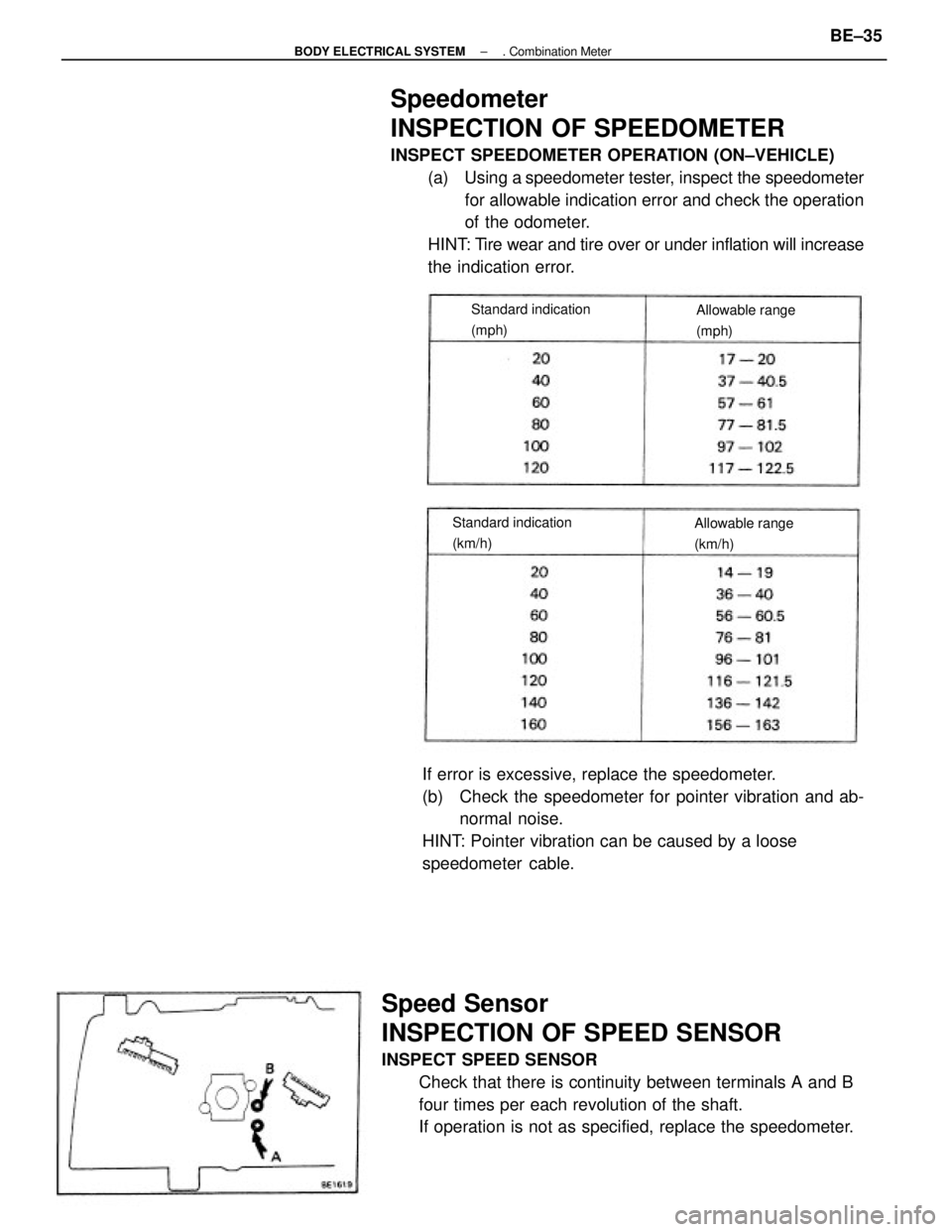

Speedometer

INSPECTION OF SPEEDOMETER

INSPECT SPEEDOMETER OPERATION (ON±VEHICLE)

(a) Using a speedometer tester, inspect the speedometer

for allowable indication error and check the operation

of the odometer.

HINT: Tire wear and tire over or under inflation will increase

the indication error.

Speed Sensor

INSPECTION OF SPEED SENSOR

INSPECT SPEED SENSOR

Check that there is continuity between terminals A and B

four times per each revolution of the shaft.

If operation is not as specified, replace the speedometer.If error is excessive, replace the speedometer.

(b) Check the speedometer for pointer vibration and ab-

normal noise.

HINT: Pointer vibration can be caused by a loose

speedometer cable.

Standard indication

(km/h)Standard indication

(mph)Allowable range

(mph)

Allowable range

(km/h)

± BODY ELECTRICAL SYSTEM. Combination MeterBE±35

Page 852 of 2389

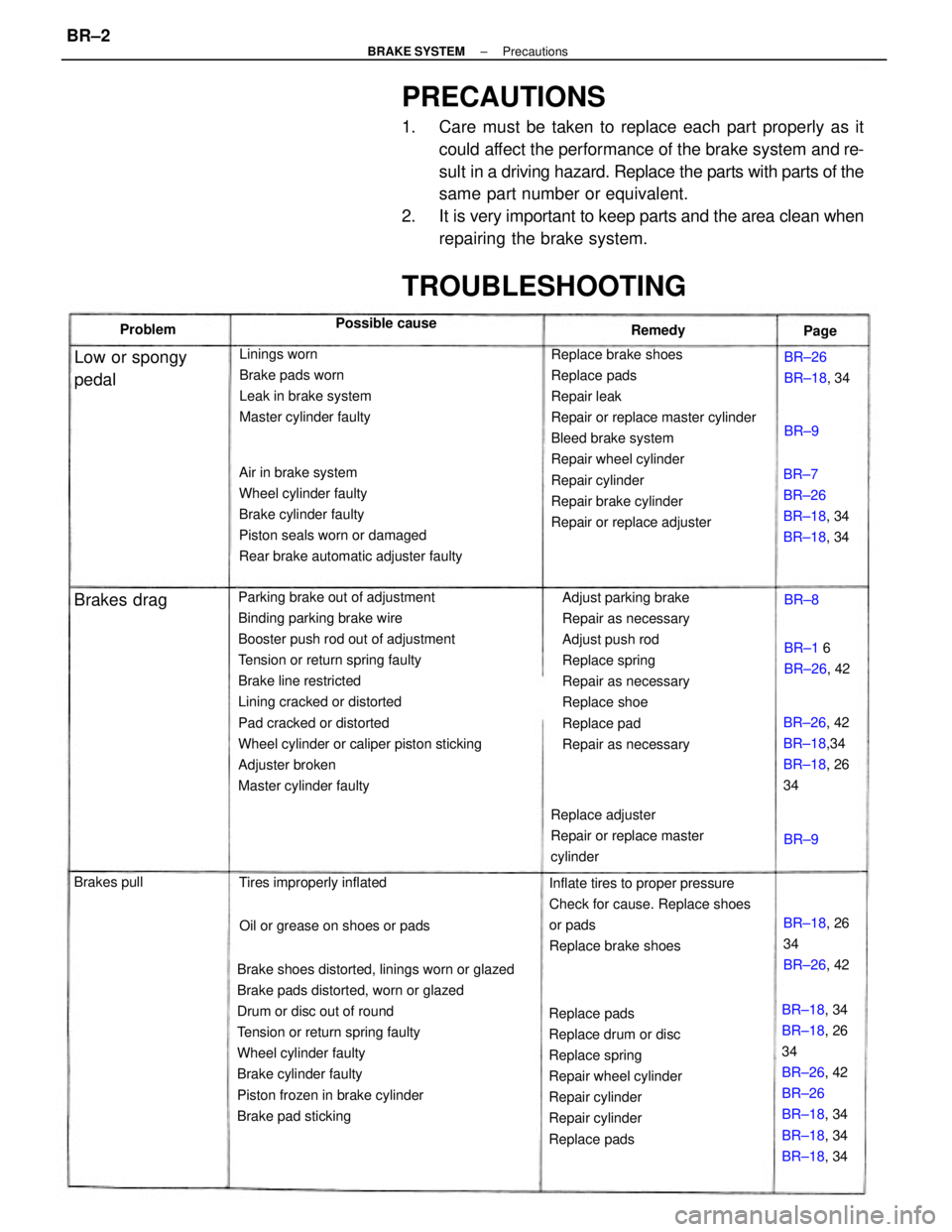

PRECAUTIONS

1. Care must be taken to replace each part properly as it

could affect the performance of the brake system and re-

sult in a driving hazard. Replace the parts with parts of the

same part number or equivalent.

2. It is very important to keep parts and the area clean when

repairing the brake system.

Parking brake out of adjustment

Binding parking brake wire

Booster push rod out of adjustment

Tension or return spring faulty

Brake line restricted

Lining cracked or distorted

Pad cracked or distorted

Wheel cylinder or caliper piston sticking

Adjuster broken

Master cylinder faulty

Brake shoes distorted, linings worn or glazed

Brake pads distorted, worn or glazed

Drum or disc out of round

Tension or return spring faulty

Wheel cylinder faulty

Brake cylinder faulty

Piston frozen in brake cylinder

Brake pad stickingReplace brake shoes

Replace pads

Repair leak

Repair or replace master cylinder

Bleed brake system

Repair wheel cylinder

Repair cylinder

Repair brake cylinder

Repair or replace adjuster Air in brake system

Wheel cylinder faulty

Brake cylinder faulty

Piston seals worn or damaged

Rear brake automatic adjuster faulty

Adjust parking brake

Repair as necessary

Adjust push rod

Replace spring

Repair as necessary

Replace shoe

Replace pad

Repair as necessary

Replace pads

Replace drum or disc

Replace spring

Repair wheel cylinder

Repair cylinder

Repair cylinder

Replace padsInflate tires to proper pressure

Check for cause. Replace shoes

or pads

Replace brake shoes Linings worn

Brake pads worn

Leak in brake system

Master cylinder faulty

BR±18, 34

BR±18, 26

34

BR±26, 42

BR±26

BR±18, 34

BR±18, 34

BR±18, 34 Replace adjuster

Repair or replace master

cylinder

TROUBLESHOOTING

BR±7

BR±26

BR±18, 34

BR±18, 34

BR±26, 42

BR±18,34

BR±18, 26

34

Oil or grease on shoes or pads Tires improperly inflated

BR±18, 26

34

BR±26, 42

Low or spongy

pedalBR±26

BR±18, 34

BR±1 6

BR±26, 42 Possible cause

Brakes drag

Brakes pullRemedy Problem

Page

BR±8

BR±9BR±9

± BRAKE SYSTEMPrecautionsBR±2

Page 853 of 2389

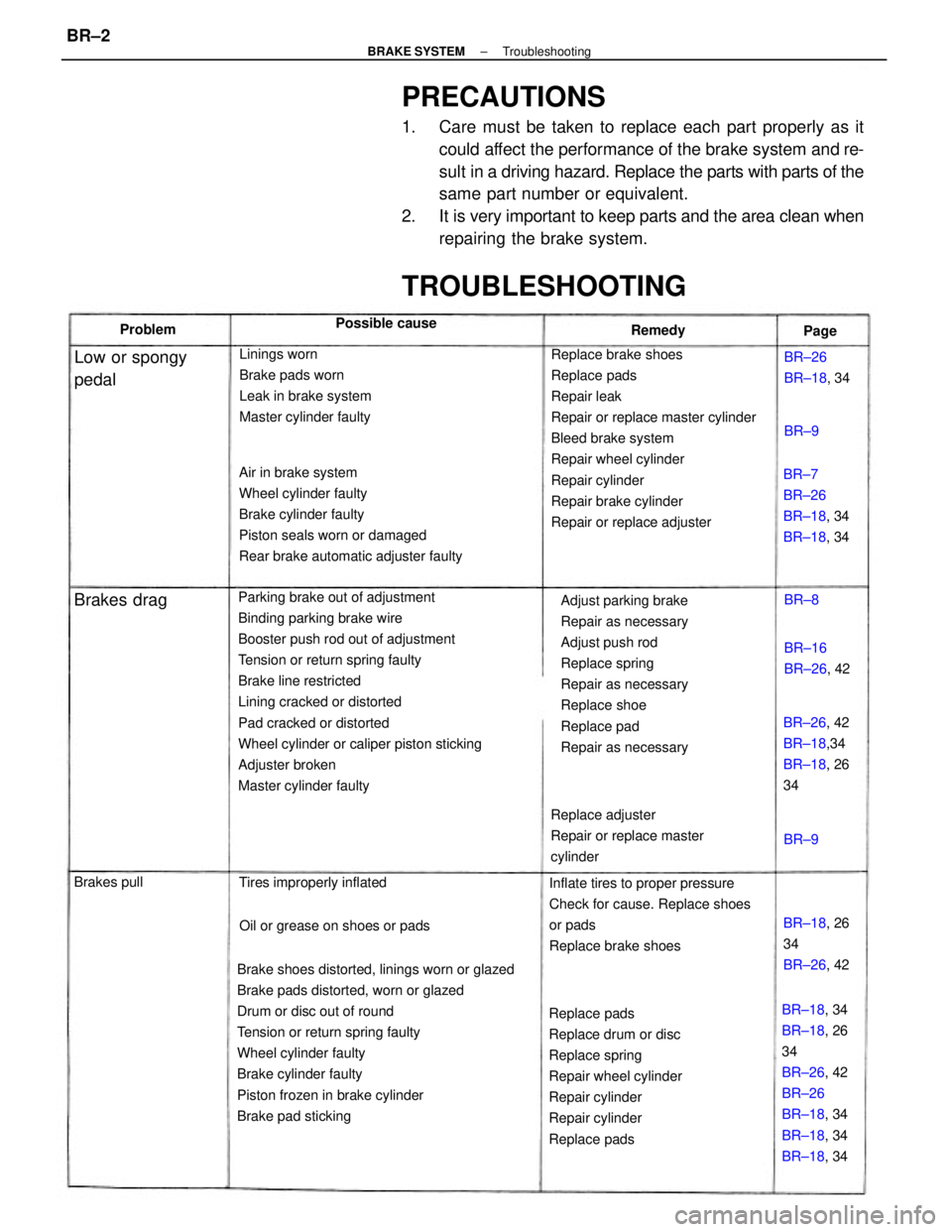

PRECAUTIONS

1. Care must be taken to replace each part properly as it

could affect the performance of the brake system and re-

sult in a driving hazard. Replace the parts with parts of the

same part number or equivalent.

2. It is very important to keep parts and the area clean when

repairing the brake system.

Parking brake out of adjustment

Binding parking brake wire

Booster push rod out of adjustment

Tension or return spring faulty

Brake line restricted

Lining cracked or distorted

Pad cracked or distorted

Wheel cylinder or caliper piston sticking

Adjuster broken

Master cylinder faulty

Brake shoes distorted, linings worn or glazed

Brake pads distorted, worn or glazed

Drum or disc out of round

Tension or return spring faulty

Wheel cylinder faulty

Brake cylinder faulty

Piston frozen in brake cylinder

Brake pad stickingReplace brake shoes

Replace pads

Repair leak

Repair or replace master cylinder

Bleed brake system

Repair wheel cylinder

Repair cylinder

Repair brake cylinder

Repair or replace adjuster Air in brake system

Wheel cylinder faulty

Brake cylinder faulty

Piston seals worn or damaged

Rear brake automatic adjuster faulty

Adjust parking brake

Repair as necessary

Adjust push rod

Replace spring

Repair as necessary

Replace shoe

Replace pad

Repair as necessary

Replace pads

Replace drum or disc

Replace spring

Repair wheel cylinder

Repair cylinder

Repair cylinder

Replace padsInflate tires to proper pressure

Check for cause. Replace shoes

or pads

Replace brake shoes Linings worn

Brake pads worn

Leak in brake system

Master cylinder faulty

BR±18, 34

BR±18, 26

34

BR±26, 42

BR±26

BR±18, 34

BR±18, 34

BR±18, 34 Replace adjuster

Repair or replace master

cylinder

TROUBLESHOOTING

BR±7

BR±26

BR±18, 34

BR±18, 34

BR±26, 42

BR±18,34

BR±18, 26

34

Oil or grease on shoes or pads Tires improperly inflated

BR±18, 26

34

BR±26, 42

Low or spongy

pedalBR±26

BR±18, 34

BR±16

BR±26, 42 Possible cause

Brakes drag

Brakes pullRemedy Problem

Page

BR±8

BR±9BR±9

± BRAKE SYSTEMTroubleshootingBR±2

Page 1186 of 2389

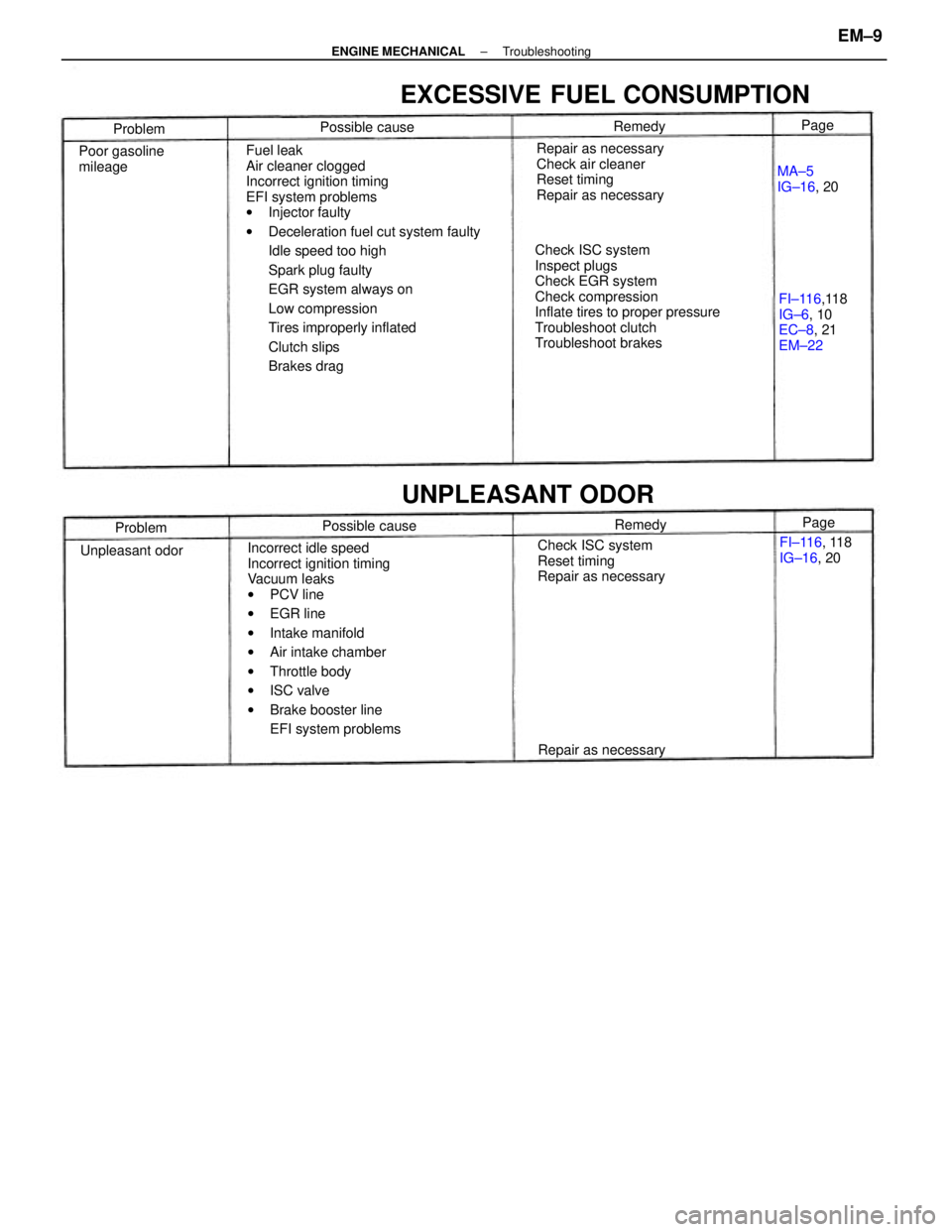

Fuel leak

Air cleaner clogged

Incorrect ignition timing

EFI system problems

wInjector faulty

wDeceleration fuel cut system faulty

Idle speed too high

Spark plug faulty

EGR system always on

Low compression

Tires improperly inflated

Clutch slips

Brakes drag

Incorrect idle speed

Incorrect ignition timing

Vacuum leaks

wPCV line

wEGR line

wIntake manifold

wAir intake chamber

wThrottle body

wISC valve

wBrake booster line

EFI system problemsCheck ISC system

Inspect plugs

Check EGR system

Check compression

Inflate tires to proper pressure

Troubleshoot clutch

Troubleshoot brakesRepair as necessary

Check air cleaner

Reset timing

Repair as necessary

EXCESSIVE FUEL CONSUMPTION

Check ISC system

Reset timing

Repair as necessaryFI±116,118

IG±6, 10

EC±8, 21

EM±22

UNPLEASANT ODOR

Poor gasoline

mileage

FI±116, 118

IG±16, 20

Repair as necessaryMA±5

IG±16, 20

Unpleasant odorPossible cause Possible cause

Problem

ProblemRemedy

RemedyPage Page

± ENGINE MECHANICALTroubleshootingEM±9

Page 1359 of 2389

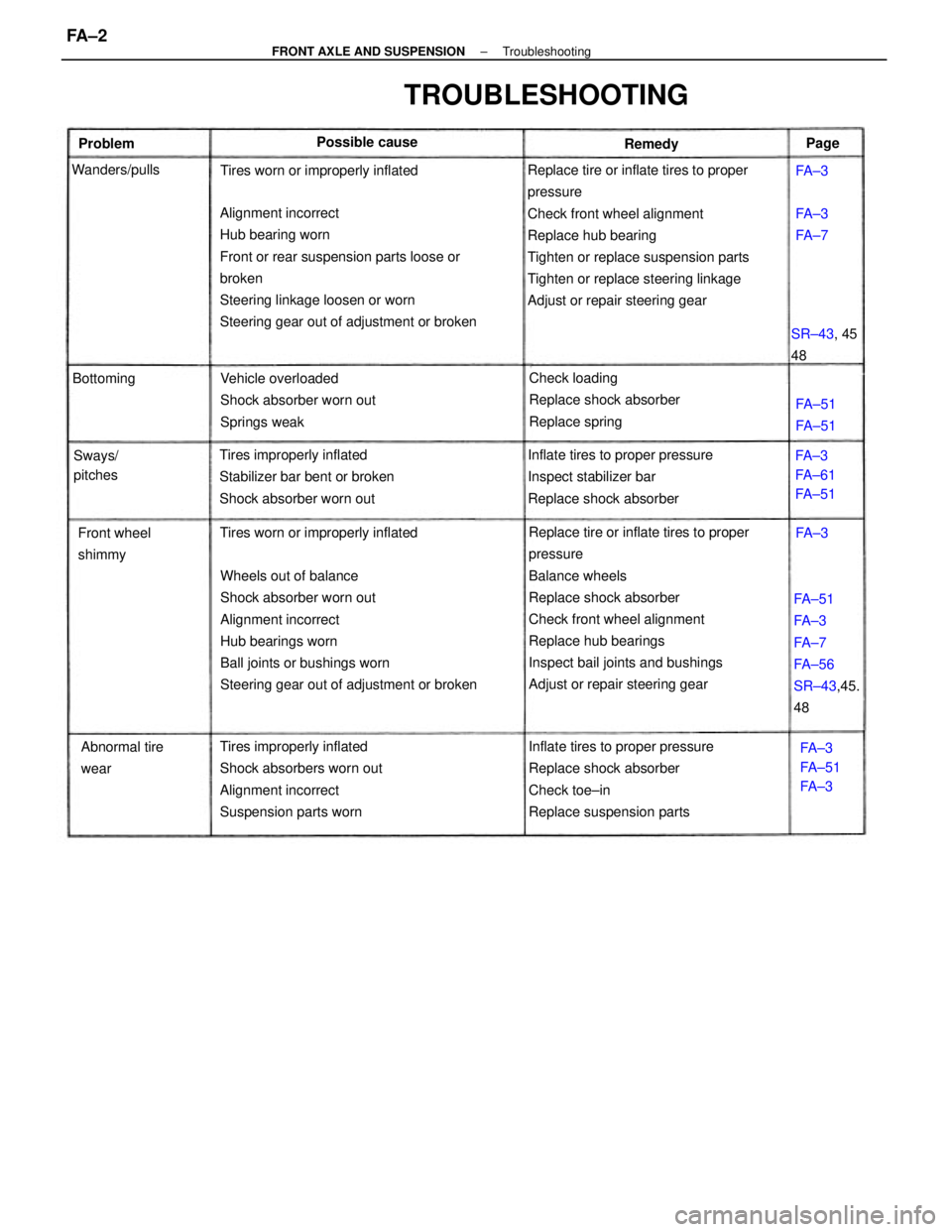

Replace tire or inflate tires to proper

pressure

Check front wheel alignment

Replace hub bearing

Tighten or replace suspension parts

Tighten or replace steering linkage

Adjust or repair steering gear

Replace tire or inflate tires to proper

pressure

Balance wheels

Replace shock absorber

Check front wheel alignment

Replace hub bearings

Inspect bail joints and bushings

Adjust or repair steering gear Wheels out of balance

Shock absorber worn out

Alignment incorrect

Hub bearings worn

Ball joints or bushings worn

Steering gear out of adjustment or broken Alignment incorrect

Hub bearing worn

Front or rear suspension parts loose or

broken

Steering linkage loosen or worn

Steering gear out of adjustment or broken

Inflate tires to proper pressure

Replace shock absorber

Check toe±in

Replace suspension parts Tires improperly inflated

Shock absorbers worn out

Alignment incorrect

Suspension parts wornInflate tires to proper pressure

Inspect stabilizer bar

Replace shock absorber Tires improperly inflated

Stabilizer bar bent or broken

Shock absorber worn outVehicle overloaded

Shock absorber worn out

Springs weakCheck loading

Replace shock absorber

Replace spring

FA±51

FA±3

FA±7

FA±56

SR±43,45.

48

TROUBLESHOOTING

Tires worn or improperly inflatedTires worn or improperly inflated

Abnormal tire

wear Front wheel

shimmyFA±3

FA±61

FA±51

FA±3

FA±51

FA±3 SR±43, 45

48 Possible cause

Sways/

pitches Wanders/pulls

FA±51

FA±51 BottomingFA±3

FA±7 Problem

RemedyPage

FA±3

FA±3

± FRONT AXLE AND SUSPENSIONTroubleshootingFA ± 2

Page 1360 of 2389

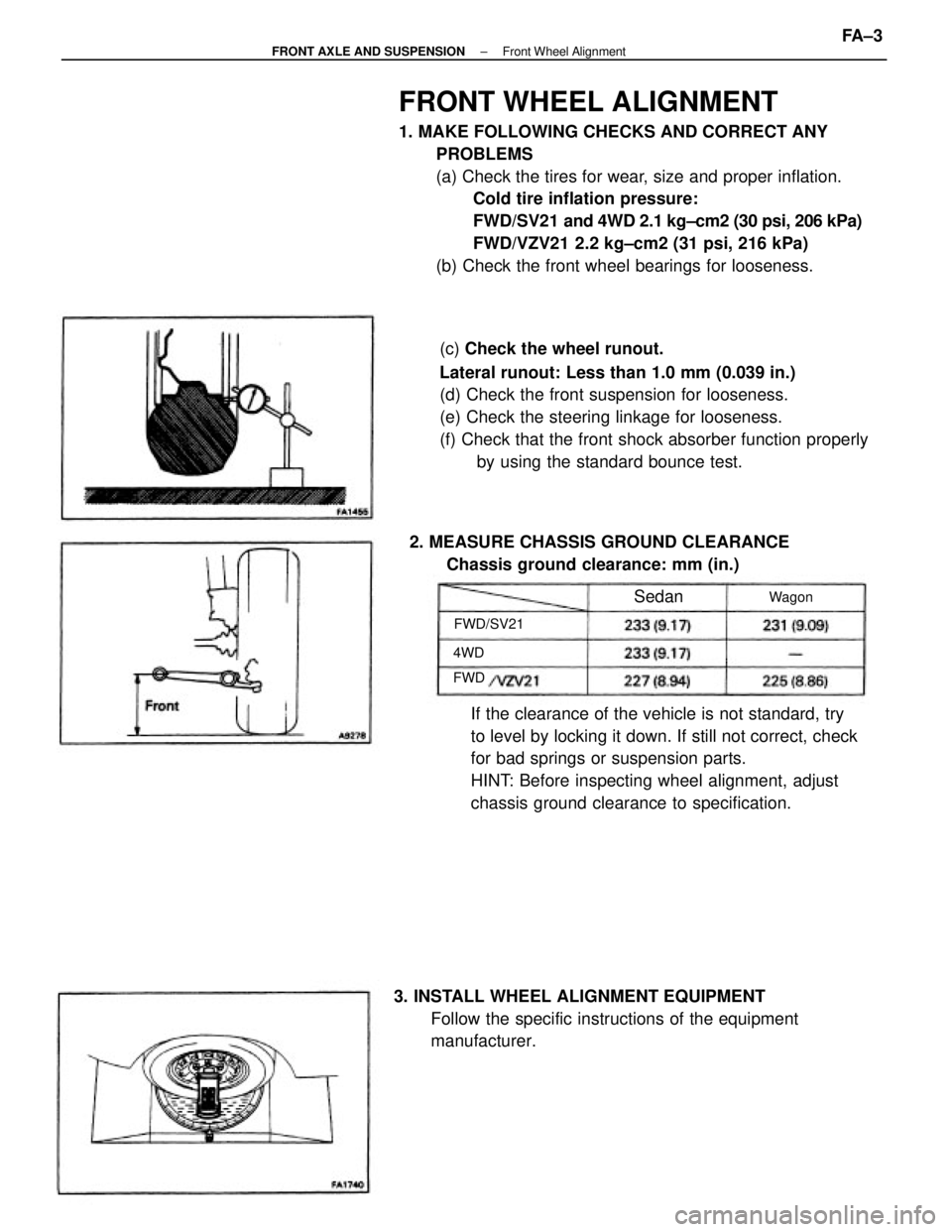

FRONT WHEEL ALIGNMENT

1. MAKE FOLLOWING CHECKS AND CORRECT ANY

PROBLEMS

(a) Check the tires for wear, size and proper inflation.

Cold tire inflation pressure:

FWD/SV21 and 4WD 2.1 kg±cm2 (30 psi, 206 kPa)

FWD/VZV21 2.2 kg±cm2 (31 psi, 216 kPa)

(b) Check the front wheel bearings for looseness.

(c) Check the wheel runout.

Lateral runout: Less than 1.0 mm (0.039 in.)

(d) Check the front suspension for looseness.

(e) Check the steering linkage for looseness.

(f) Check that the front shock absorber function properly

by using the standard bounce test.

If the clearance of the vehicle is not standard, try

to level by locking it down. If still not correct, check

for bad springs or suspension parts.

HINT: Before inspecting wheel alignment, adjust

chassis ground clearance to specification.

3. INSTALL WHEEL ALIGNMENT EQUIPMENT

Follow the specific instructions of the equipment

manufacturer. 2. MEASURE CHASSIS GROUND CLEARANCE

Chassis ground clearance: mm (in.)

FWD/SV21Wagon

Sedan

4WD

FWD

± FRONT AXLE AND SUSPENSIONFront Wheel AlignmentFA ± 3

Page 2148 of 2389

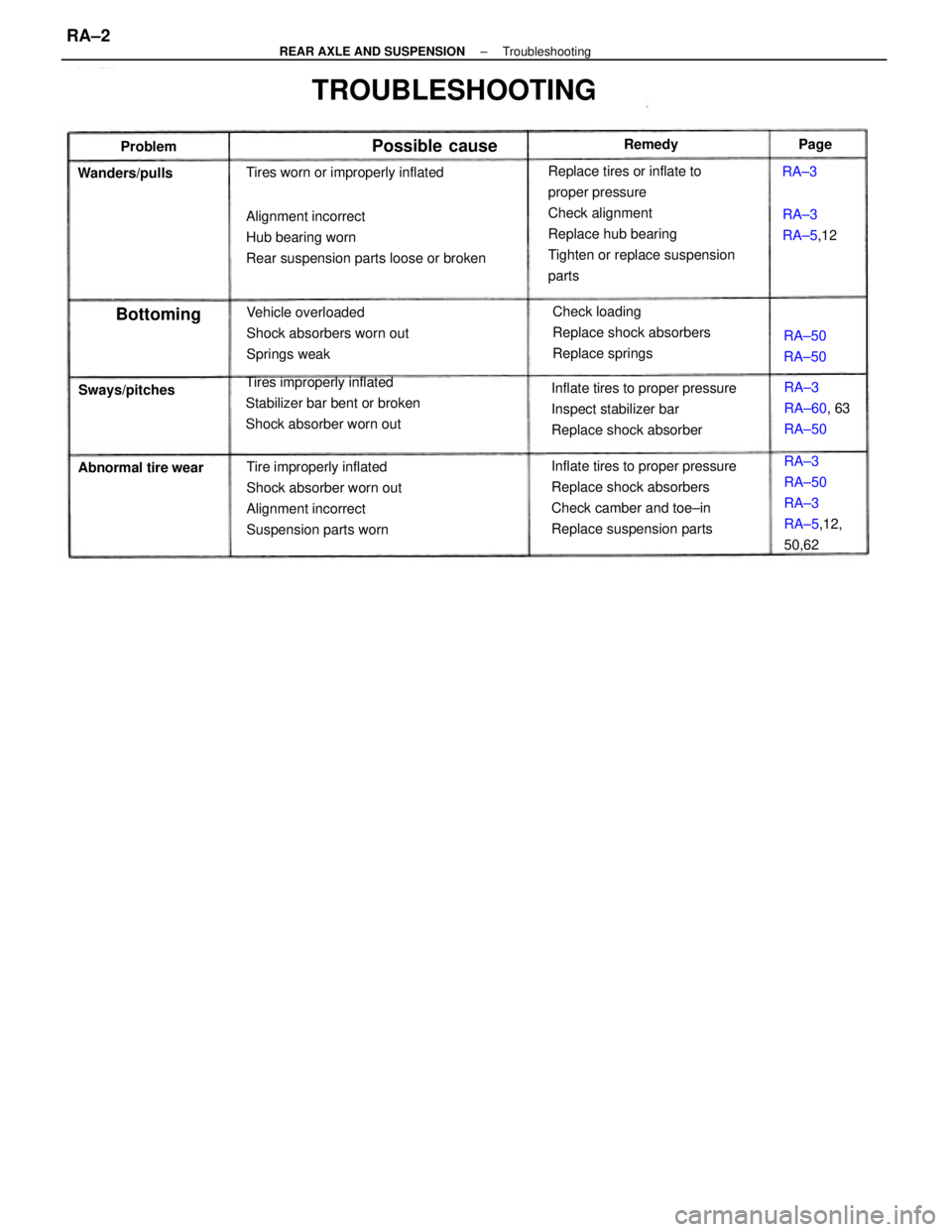

Replace tires or inflate to

proper pressure

Check alignment

Replace hub bearing

Tighten or replace suspension

parts

Inflate tires to proper pressure

Replace shock absorbers

Check camber and toe±in

Replace suspension parts Alignment incorrect

Hub bearing worn

Rear suspension parts loose or broken

Tire improperly inflated

Shock absorber worn out

Alignment incorrect

Suspension parts worn Tires improperly inflated

Stabilizer bar bent or broken

Shock absorber worn outInflate tires to proper pressure

Inspect stabilizer bar

Replace shock absorber

TROUBLESHOOTING

Vehicle overloaded

Shock absorbers worn out

Springs weakCheck loading

Replace shock absorbers

Replace springs

RA±3

RA±50

RA±3

RA±5,12,

50,62 Tires worn or improperly inflated

RA±3

RA±60, 63

RA±50

Abnormal tire wearRA±3

RA±5,12 Wanders/pulls

Sways/pitches

Possible cause

RA±50

RA±50

Bottoming

Remedy

ProblemPage

RA±3

± REAR AXLE AND SUSPENSIONTroubleshootingRA±2

Page 2149 of 2389

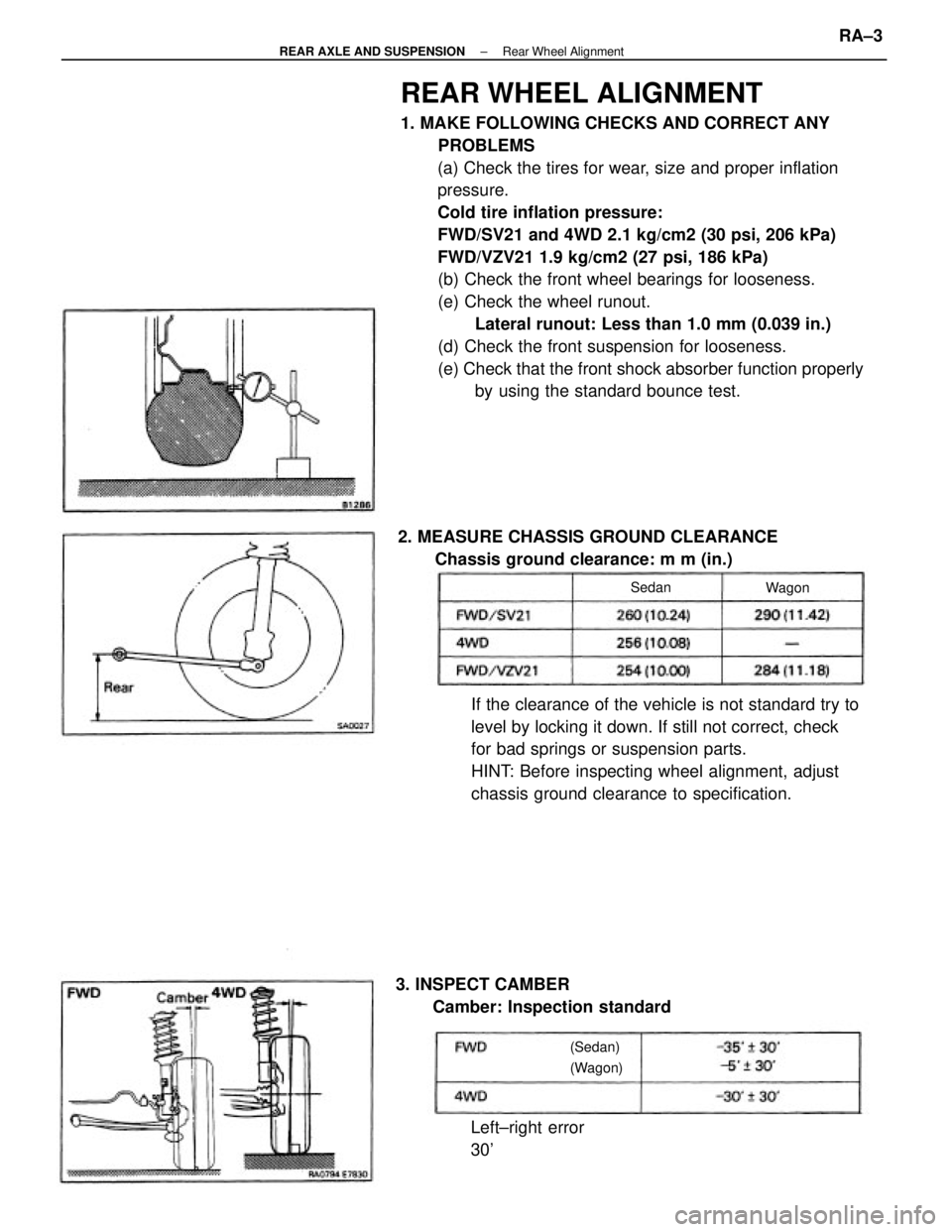

REAR WHEEL ALIGNMENT

1. MAKE FOLLOWING CHECKS AND CORRECT ANY

PROBLEMS

(a) Check the tires for wear, size and proper inflation

pressure.

Cold tire inflation pressure:

FWD/SV21 and 4WD 2.1 kg/cm2 (30 psi, 206 kPa)

FWD/VZV21 1.9 kg/cm2 (27 psi, 186 kPa)

(b) Check the front wheel bearings for looseness.

(e) Check the wheel runout.

Lateral runout: Less than 1.0 mm (0.039 in.)

(d) Check the front suspension for looseness.

(e) Check that the front shock absorber function properly

by using the standard bounce test.

If the clearance of the vehicle is not standard try to

level by locking it down. If still not correct, check

for bad springs or suspension parts.

HINT: Before inspecting wheel alignment, adjust

chassis ground clearance to specification. 2. MEASURE CHASSIS GROUND CLEARANCE

Chassis ground clearance: m m (in.)

3. INSPECT CAMBER

Camber: Inspection standard

Left±right error

30'

(Sedan)

(Wagon)Wagon Sedan

± REAR AXLE AND SUSPENSIONRear Wheel AlignmentRA±3

Page 2269 of 2389

Wheel lateral runout

Tie rod end left±right error

Hub bearing axial direction play

Ball joint vertial play

Ball joint rotation condition

Drive shaft standard length

(FWD/SV21 /TOYOTA type/LH)

(FWD/SV21 /TOYOTA type/RH)

(FWD/SV21 /GKN type/LH)

(FWD/SV21 /GKN type/RH)

( FVIJD/VZV21)

(4WD/M/T/LH)

(4WD/A/T/LH)

(4WD/M/T/RH)

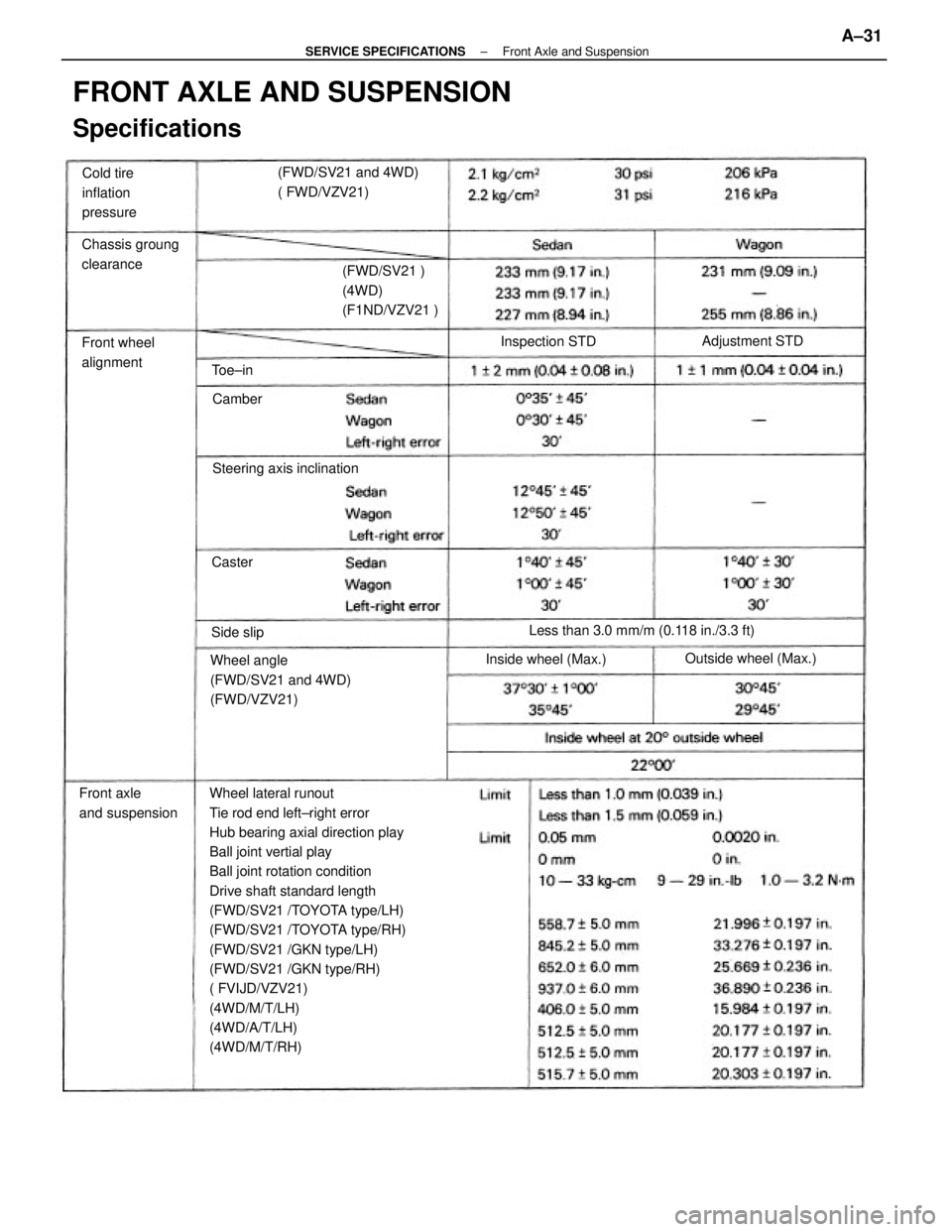

FRONT AXLE AND SUSPENSION

Specifications

Wheel angle

(FWD/SV21 and 4WD)

(FWD/VZV21)(FWD/SV21 and 4WD)

( FWD/VZV21)

Less than 3.0 mm/m (0.118 in./3.3 ft) (FWD/SV21 )

(4WD)

(F1ND/VZV21 )

Front axle

and suspensionChassis groung

clearance

Steering axis inclination Cold tire

inflation

pressure

Front wheel

alignment

Outside wheel (Max.)

Inside wheel (Max.)Adjustment STD

Inspection STD

Side slipCamber

Caster Toe±in

± SERVICE SPECIFICATIONSFront Axle and SuspensionA±31

Page 2271 of 2389

Limit Lateral runout

Radial runout

Ring gear installing temperature

Drive pinion oil seal drive in depth

Side gear oil seal drive in depth

Side gear thrust washer thicknessDrive pinion bearing preload at Starting

New bearing

Reused bearing

Drive pinion to ring gear backlash

Pinion gear to side gear backlash

Ring gear runout

Companion flange runout

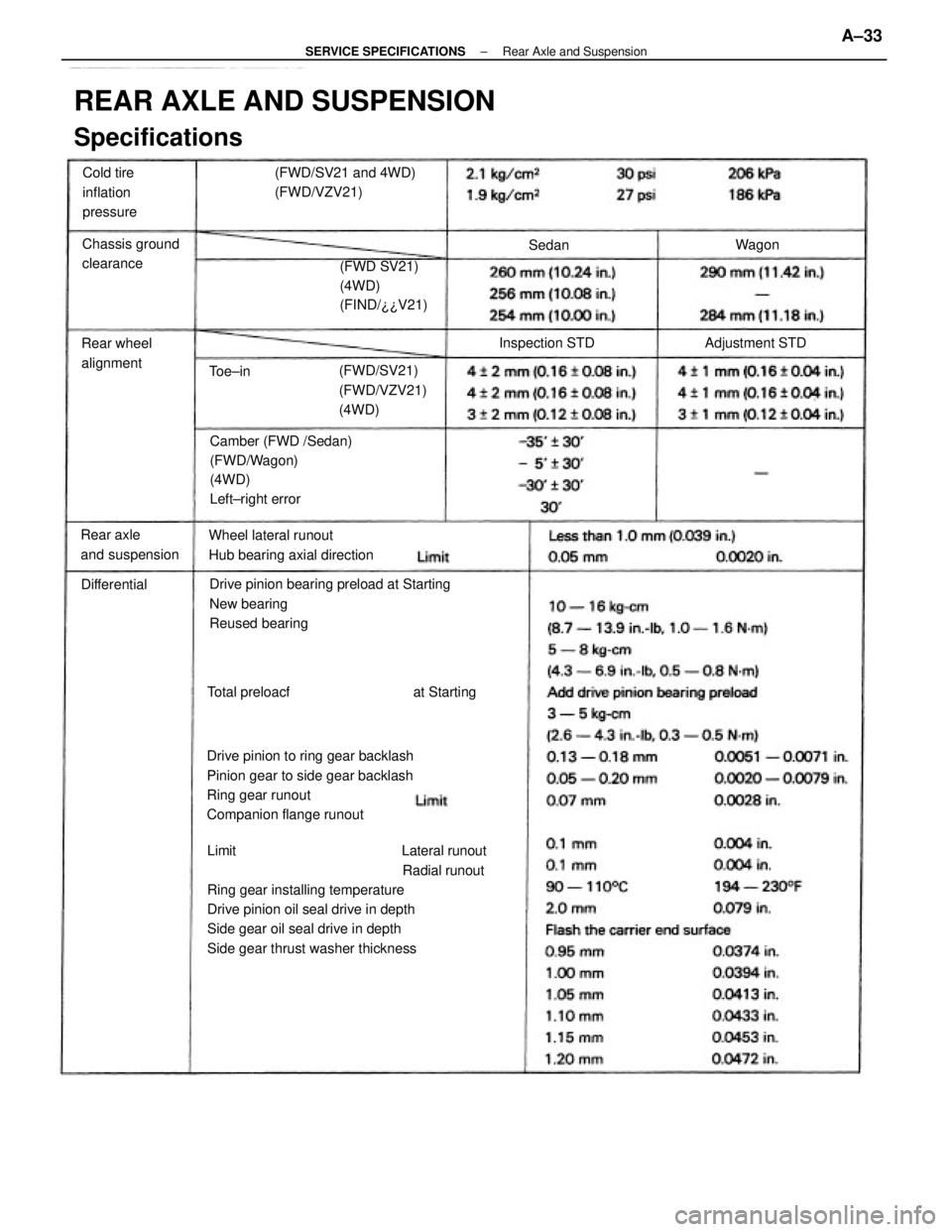

REAR AXLE AND SUSPENSION

Specifications

Camber (FWD /Sedan)

(FWD/Wagon)

(4WD)

Left±right error

Wheel lateral runout

Hub bearing axial direction(FWD/SV21 and 4WD)

(FWD/VZV21)

(FWD SV21)

(4WD)

(FIND/¿¿V21)

(FWD/SV21)

(FWD/VZV21)

(4WD)

Rear axle

and suspensionChassis ground

clearanceCold tire

inflation

pressure

Rear wheel

alignmentAdjustment STD Inspection STD

Total preloacf at Starting DifferentialWagon

Toe±inSedan

± SERVICE SPECIFICATIONSRear Axle and SuspensionA±33