spark plugs TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1024 of 2389

TROUBLESHOOTING

TROUBLESHOOTING HINTS

1. Engine troubles is usually not caused by the EFI system.

When troubleshooting, always first check the condition of

the other systems.

(a) Electronic source

wBattery

wFusible links

wFuses

(b) Body ground

(e) Fuel supply

wFuel leakage

wFuel filter

wFuel pump

(d) Ignition system

wSpark plugs

wHigh±tension cords

wDistributor

wIgnition coil

wIgniter

(e) Air induction system

wVacuum leaks

(f) Emission control system

wPCV system

wEGR system

(g) Others

wIgnition timing (ESA system)

wdle speed (ISC system)

wetc.

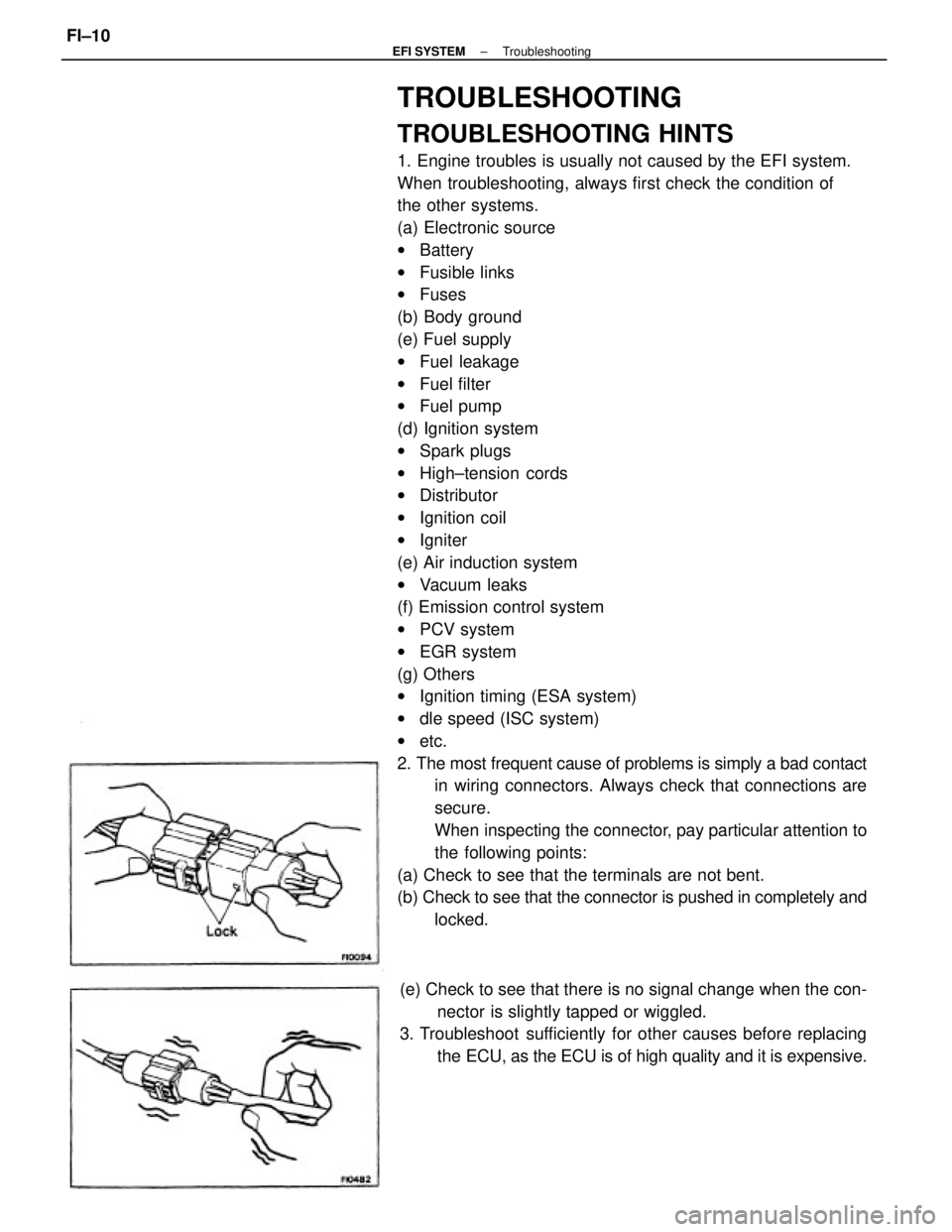

2. The most frequent cause of problems is simply a bad contact

in wiring connectors. Always check that connections are

secure.

When inspecting the connector, pay particular attention to

the following points:

(a) Check to see that the terminals are not bent.

(b) Check to see that the connector is pushed in completely and

locked.

(e) Check to see that there is no signal change when the con-

nector is slightly tapped or wiggled.

3. Troubleshoot sufficiently for other causes before replacing

the ECU, as the ECU is of high quality and it is expensive.

± EFI SYSTEMTroubleshootingFI±10

Page 1026 of 2389

1. Spark plugs

2. Compression pressure

Minimum: 10.0 kg/cm2

(142 psi, 981 kPa)

at 250 rpm

3. Valve clearance

Standard:

3F±FE I N 0.19 ± 0.29 mm

(0.007 ± 0.011 in.)

EX 0.28 ± 0.38 mm

(0.011 ± 0.015 in.)

2VZ±FE IN 0.13 0.23 mm

(0±005 ± 0.009 in.)

EX 0.27± 0.37 mm

(0.011 ± 0.015 in.)

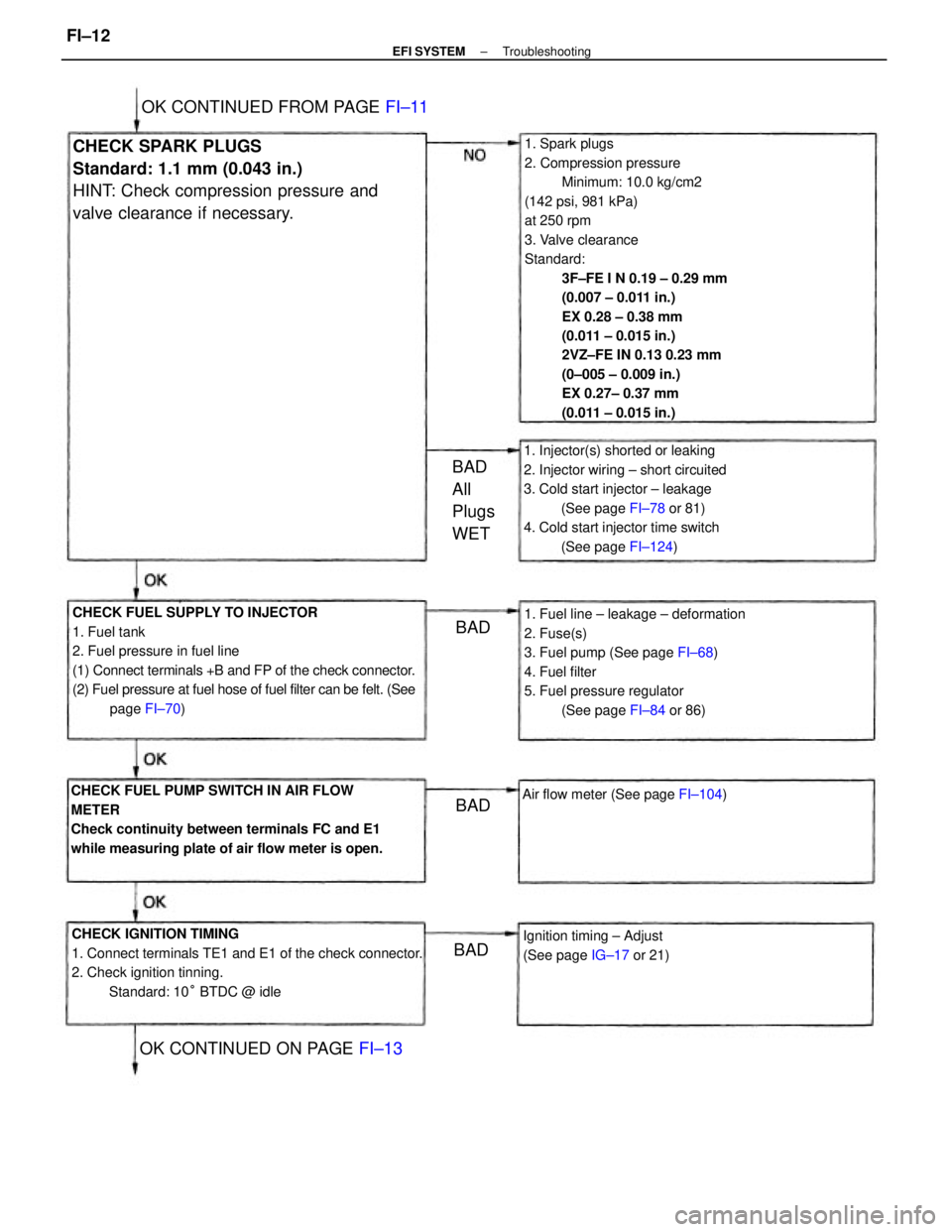

CHECK FUEL SUPPLY TO INJECTOR

1. Fuel tank

2. Fuel pressure in fuel line

(1) Connect terminals +B and FP of the check connector.

(2) Fuel pressure at fuel hose of fuel filter can be felt. (See

page FI±70)

CHECK IGNITION TIMING

1. Connect terminals TE1 and E1 of the check connector.

2. Check ignition tinning.

Standard: 10° BTDC @ idle CHECK FUEL PUMP SWITCH IN AIR FLOW

METER

Check continuity between terminals FC and E1

while measuring plate of air flow meter is open.1. Fuel line ± leakage ± deformation

2. Fuse(s)

3. Fuel pump (See page FI±68)

4. Fuel filter

5. Fuel pressure regulator

(See page FI±84 or 86) 1. Injector(s) shorted or leaking

2. Injector wiring ± short circuited

3. Cold start injector ± leakage

(See page FI±78 or 81)

4. Cold start injector time switch

(See page FI±124)CHECK SPARK PLUGS

Standard: 1.1 mm (0.043 in.)

HINT: Check compression pressure and

valve clearance if necessary.

Ignition timing ± Adjust

(See page IG±17 or 21)

OK CONTINUED FROM PAGE FI±11

OK CONTINUED ON PAGE FI±13

Air flow meter (See page FI±104)

BAD

All

Plugs

WET

BAD

BADBAD

± EFI SYSTEMTroubleshootingFI±12

Page 1028 of 2389

1. Spark plugs

2. Compression pressure

Minimum: 10.0 kg/cm 2

(142 psi, 981 kPa)

at 250 rpm

3. Valve clearance

Standard:

3F±FE IN 0.19 ± 0.29 mm

(0.007 ± 0.011 in.)

EX 0.28 ± 0.38 mm

(0.011 ± 0.015 in.)

2VZ±FE IN 0.13 ± 0.23 mm

(0.005 ± 0.009 in.)

EX 0.27± 0.37 mm

(0.011 ± 0.015 in.)

1. Wiring connection

2. Power to ECU

(1) Fusible link(s)

(2) Fuse(s)

(3) ER main relay (See page FI±121)

3. Air flow meter (See page FI±104)

4. Water temp. sensor (See page FI±125)

5. Air temp. sensor (See page FI±104j

6. Injection signal circuit

(1) Injector wiring

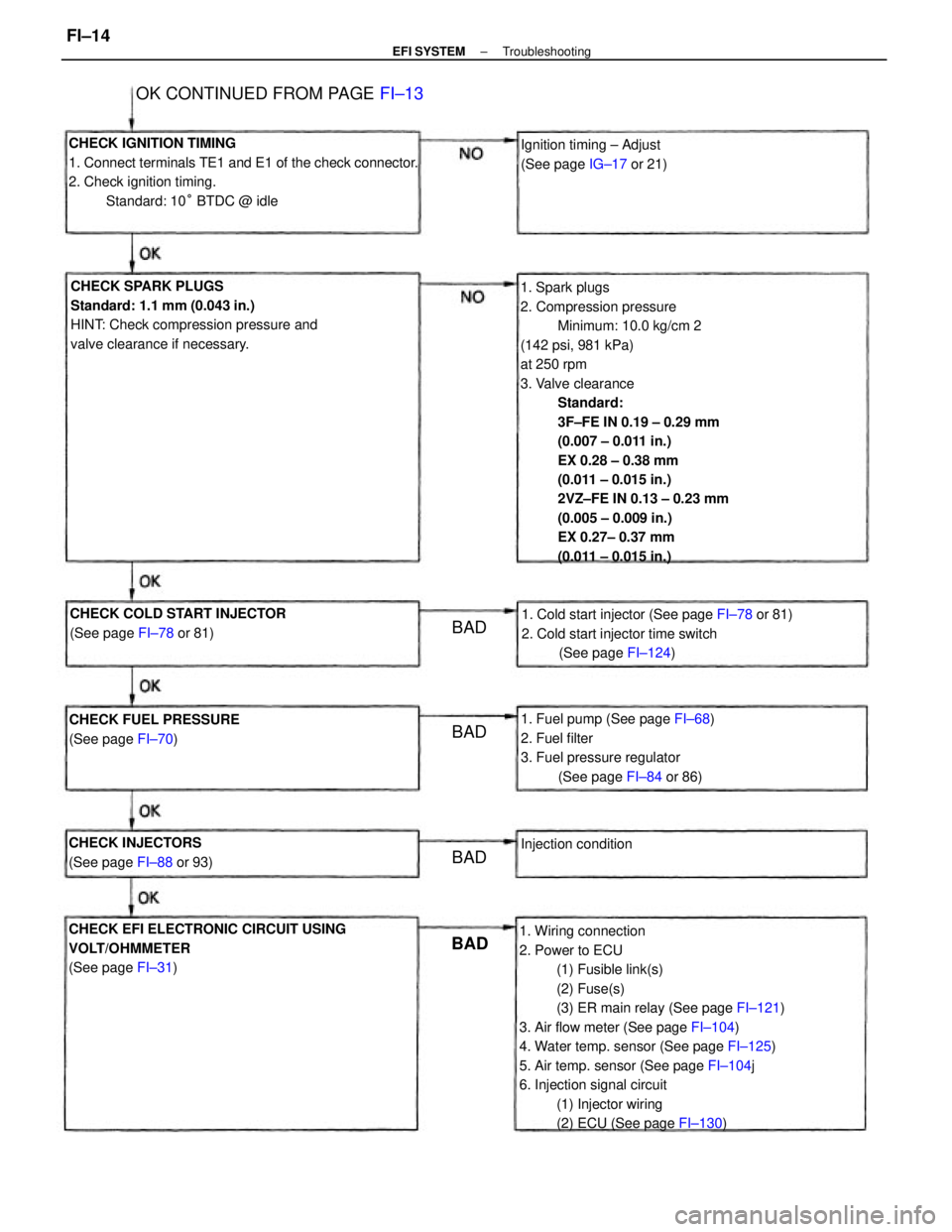

(2) ECU (See page FI±130) CHECK IGNITION TIMING

1. Connect terminals TE1 and E1 of the check connector.

2. Check ignition timing.

Standard: 10° BTDC @ idle

CHECK SPARK PLUGS

Standard: 1.1 mm (0.043 in.)

HINT: Check compression pressure and

valve clearance if necessary.

CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See page FI±31)1. Cold start injector (See page FI±78 or 81)

2. Cold start injector time switch

(See page FI±124)

1. Fuel pump (See page FI±68)

2. Fuel filter

3. Fuel pressure regulator

(See page FI±84 or 86) CHECK COLD START INJECTOR

(See page FI±78 or 81)

OK CONTINUED FROM PAGE FI±13

CHECK FUEL PRESSURE

(See page FI±70)Ignition timing ± Adjust

(See page IG±17 or 21)

CHECK INJECTORS

(See page FI±88 or 93)Injection condition

BADBAD

BAD BAD

± EFI SYSTEMTroubleshootingFI±14

Page 1030 of 2389

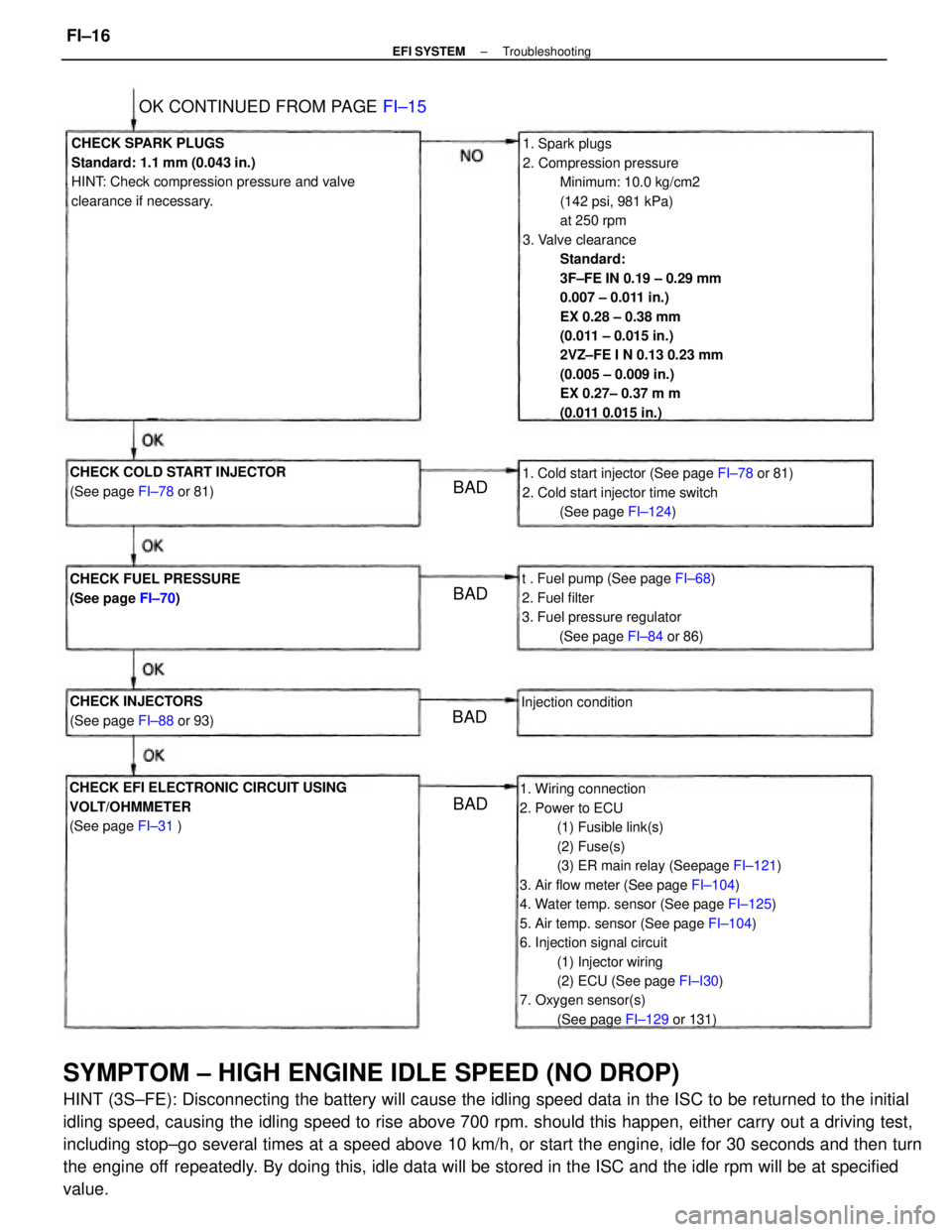

SYMPTOM ± HIGH ENGINE IDLE SPEED (NO DROP)

HINT (3S±FE): Disconnecting the battery will cause the idling speed data in the ISC to be returned to the initial

idling speed, causing the idling speed to rise above 700 rpm. should this happen, either carry out a driving test,

including stop±go several times at a speed above 10 km/h, or start the engine, idle for 30 seconds and then turn

the engine off repeatedly. By doing this, idle data will be stored in the ISC and the idle rpm will be at specified

value.

1. Spark plugs

2. Compression pressure

Minimum: 10.0 kg/cm2

(142 psi, 981 kPa)

at 250 rpm

3. Valve clearance

Standard:

3F±FE IN 0.19 ± 0.29 mm

0.007 ± 0.011 in.)

EX 0.28 ± 0.38 mm

(0.011 ± 0.015 in.)

2VZ±FE I N 0.13 0.23 mm

(0.005 ± 0.009 in.)

EX 0.27± 0.37 m m

(0.011 0.015 in.)

1. Wiring connection

2. Power to ECU

(1) Fusible link(s)

(2) Fuse(s)

(3) ER main relay (Seepage FI±121)

3. Air flow meter (See page FI±104)

4. Water temp. sensor (See page FI±125)

5. Air temp. sensor (See page FI±104)

6. Injection signal circuit

(1) Injector wiring

(2) ECU (See page FI±I30)

7. Oxygen sensor(s)

(See page FI±129 or 131) CHECK SPARK PLUGS

Standard: 1.1 mm (0.043 in.)

HINT: Check compression pressure and valve

clearance if necessary.

CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See page FI±31 )1. Cold start injector (See page FI±78 or 81)

2. Cold start injector time switch

(See page FI±124)

t . Fuel pump (See page FI±68)

2. Fuel filter

3. Fuel pressure regulator

(See page FI±84 or 86) CHECK COLD START INJECTOR

(See page FI±78 or 81)

CHECK FUEL PRESSURE

(See page FI±70)

OK CONTINUED FROM PAGE FI±15

CHECK INJECTORS

(See page FI±88 or 93)Injection condition

BADBAD

BAD

BAD

± EFI SYSTEMTroubleshootingFI±16

Page 1033 of 2389

1. Spark plugs

2. Compression pressure

Minimum: 10.0 kg/cm

2

(142 psi, 981 kPa)

at 250 rpm

3. Valve clearance

Standard:

3F±FE 1N 0.19 ± 0.29 mm

(0.007 ± 0.011 in.)

EX 0.28 ± 0.38 mm

(0.011 0.015 in.)

2VZ±FE I N 0.13 ± 0.23 mm

(0.005 ± 0.009 in.)

EX 0.27± 0.37 mm

(0.011 ± 0.015 in.)

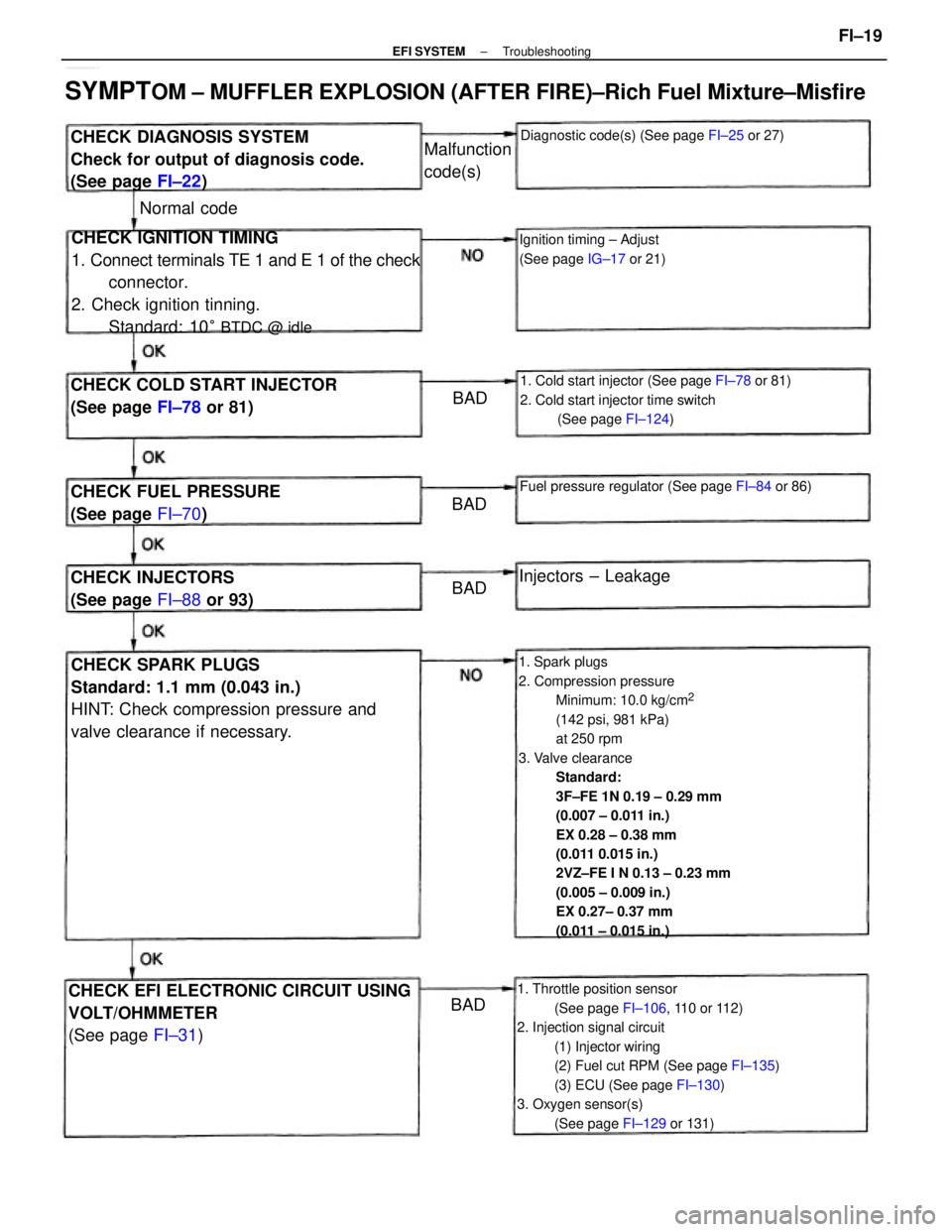

1. Throttle position sensor

(See page FI±106, 110 or 112)

2. Injection signal circuit

(1) Injector wiring

(2) Fuel cut RPM (See page FI±135)

(3) ECU (See page FI±130)

3. Oxygen sensor(s)

(See page FI±129 or 131)

CHECK IGNITION TIMING

1. Connect terminals TE 1 and E 1 of the check

connector.

2. Check ignition tinning.

Standard: 10

° BTDC @ idle

CHECK SPARK PLUGS

Standard: 1.1 mm (0.043 in.)

HINT: Check compression pressure and

valve clearance if necessary.

SYMPTOM ± MUFFLER EXPLOSION (AFTER FIRE)±Rich Fuel Mixture±Misfire

CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See page FI±31)

1. Cold start injector (See page FI±78 or 81)

2. Cold start injector time switch

(See page FI±124)

CHECK DIAGNOSIS SYSTEM

Check for output of diagnosis code.

(See page FI±22)

CHECK COLD START INJECTOR

(See page FI±78 or 81)

Fuel pressure regulator (See page FI±84 or 86)CHECK FUEL PRESSURE

(See page FI±70)

Diagnostic code(s) (See page FI±25 or 27)

Ignition timing ± Adjust

(See page IG±17 or 21)

CHECK INJECTORS

(See page FI±88 or 93)Injectors ± Leakage Malfunction

code(s)

Normal code

BAD

BAD

BADBAD

± EFI SYSTEMTroubleshootingFI±19

Page 1035 of 2389

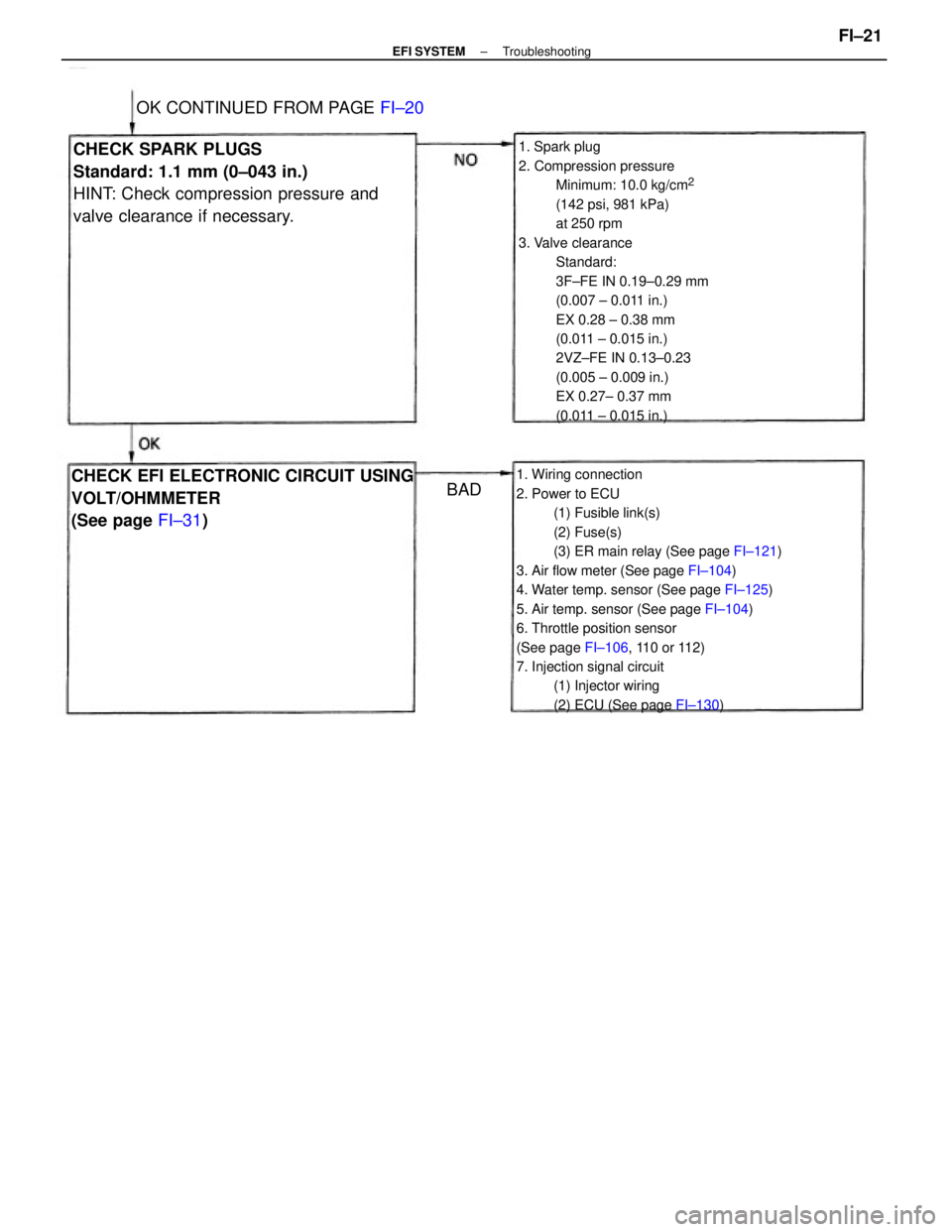

1. Spark plug

2. Compression pressure

Minimum: 10.0 kg/cm

2

(142 psi, 981 kPa)

at 250 rpm

3. Valve clearance

Standard:

3F±FE IN 0.19±0.29 mm

(0.007 ± 0.011 in.)

EX 0.28 ± 0.38 mm

(0.011 ± 0.015 in.)

2VZ±FE IN 0.13±0.23

(0.005 ± 0.009 in.)

EX 0.27± 0.37 mm

(0.011 ± 0.015 in.)

1. Wiring connection

2. Power to ECU

(1) Fusible link(s)

(2) Fuse(s)

(3) ER main relay (See page FI±121)

3. Air flow meter (See page FI±104)

4. Water temp. sensor (See page FI±125)

5. Air temp. sensor (See page FI±104)

6. Throttle position sensor

(See page FI±106, 110 or 112)

7. Injection signal circuit

(1) Injector wiring

(2) ECU (See page FI±130)

CHECK SPARK PLUGS

Standard: 1.1 mm (0±043 in.)

HINT: Check compression pressure and

valve clearance if necessary.

CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See page FI±31) OK CONTINUED FROM PAGE FI±20

BAD

± EFI SYSTEMTroubleshootingFI±21

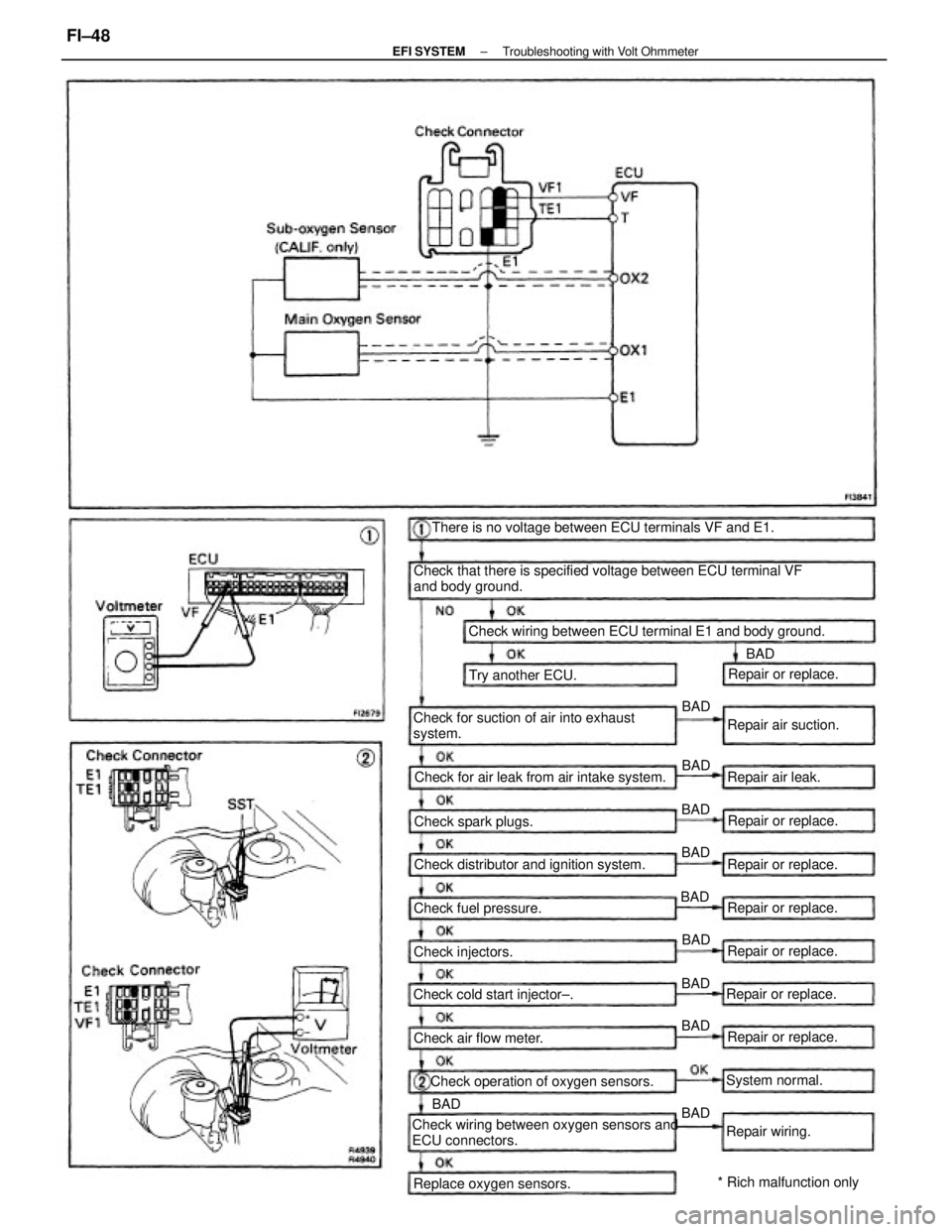

Page 1072 of 2389

Check that there is specified voltage between ECU terminal VF

and body ground.

Check for suction of air into exhaust

system.Check wiring between ECU terminal E1 and body ground.

Check wiring between oxygen sensors and

ECU connectors.There is no voltage between ECU terminals VF and E1.

Check for air leak from air intake system.

Check distributor and ignition system.

Check operation of oxygen sensors. Check cold start injector±.

Replace oxygen sensors.* Rich malfunction only Check fuel pressure.

Check air flow meter.Check spark plugs.Repair or replace.

Repair air suction.

Repair or replace.

Repair or replace. Repair or replace.

Repair or replace.

Repair or replace. Repair or replace. Try another ECU.

Check injectors.

System normal.Repair air leak.

Repair wiring. BAD

BADBADBADBAD

BADBAD

BAD BADBAD

BAD

± EFI SYSTEMTroubleshooting with Volt OhmmeterFI±48

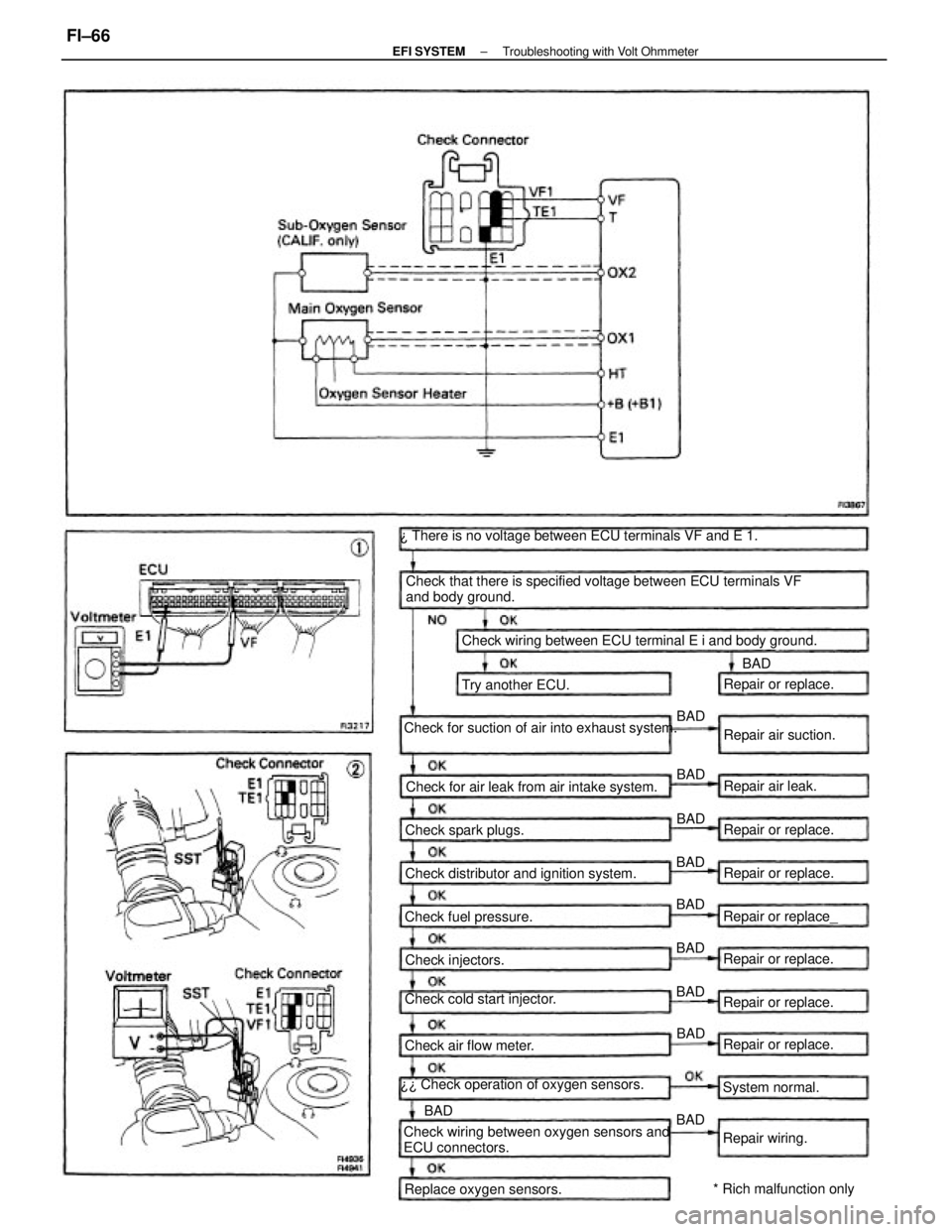

Page 1090 of 2389

Check that there is specified voltage between ECU terminals VF

and body ground. ¿ There is no voltage between ECU terminals VF and E 1.

Check wiring between ECU terminal E i and body ground.

Check for suction of air into exhaust system.

Check wiring between oxygen sensors and

ECU connectors. ¿¿ Check operation of oxygen sensors.Check for air leak from air intake system.

Check cold start injector.Check distributor and ignition system.

Replace oxygen sensors.* Rich malfunction only Check fuel pressure.

Check air flow meter.Check spark plugs.Repair air suction.

Repair or replace. Repair or replace_Repair or replace.

Repair or replace.

Repair or replace.Repair or replace.

Repair or replace. Try another ECU.

Check injectors.

System normal.Repair air leak.

Repair wiring. BAD

BAD

BADBADBAD BAD

BAD

BAD

BAD BADBAD

± EFI SYSTEMTroubleshooting with Volt OhmmeterFI±66

Page 1180 of 2389

The 3S±FE engine is an in±line 4±cylinder engine with the cylinders numbered 1 ± 2 ± 3 ± 4 from the

front.

The crankshaft is supported by 5 bearing inside the crankcase. These bearing are made of aluminum

alloy.

The crankshaft is integrated with 8 weights for balance. Oil holes are placed in the center of the crank-

shaft to supply oil to the connecting rods, bearing, pistons and other components.

This engine's ignition order is 1 ± 3 ± 4 ± 2. The cylinder head is made of aluminum alloy, with a cross

flow type intake and exhaust layout and with pent±roof type combustion chambers. The spark plugs are

located in the center of the combustion chamber.

The intake manifold has 8 independent long ports and utilizes the inertial supercharging effect to im-

prove engine torque at low and medium speeds.

Exhaust and intake valves are equipped with irregular pitch springs made of special valve spring carbon

steel which are capable of functioning no matter what the engine speed.

The intake side camshaft is driven by a timing belt, and a gear on the intake side camshaft engages with

a gear on the exhaust side camshaft to drive it. The cam journal is supported at 5 places between the

valve lifters of each cylinder and on the front end of the cylinder head. Lubrication of the cam journal and

gear is accomplished by oil being supplied through the oiler port in the center of the camshaft.

Adjustment of the valve clearance is done by means of outer shim type system, in which valve adjusting

shims are located above the valve lifters. This permits replacement of the shims without removal of the

camshafts.

The resin timing belt cover is made of 2 pieces. A service hole is provided in the No. 1 belt cover for ad-

justing the timing belt tension.

Piston are made of high temperature±resistant aluminum alloy, and a depression is built into the piston

head to prevent interference with the valves.

Piston pins are the semi±floating type, with the pins fastened to the connecting rods by pressure fitting,

allowing the pistons and pins to float.

The No. 1 compression ring is made of steel and the No. 2 compression ring is made of cast iron. The oil

ring is made of a combination of steel and stainless steel. The outer diameter of each piston ring is

slightly larger than the diameter of the piston and the flexibility of the rings allows them to hug the cylin-

der walls when they are mounted on the piston rings No. 1 and No. 2 work to prevent gas leakage from

the cylinder and oil ring works to clear oil off the cylinder walls to prevent it from entering the combustion

chambers.

The cylinder block is made of cast iron. It has 4 cylinders which are approximately 2 times the length of

the piston stroke. The top of the cylinders is closed off by the cylinder head and the lower end of the cyl-

inders becomes the crankcase, in which the crankshaft is installed. In .addition, the cylinder block con-

tains a water jacket, through which coolant is pumped to cool the cylinders.

The oil pan is bolted onto the bottom of the cylinder block. The oil pan is an oil reservoir made of

pressed steel shoot. A dividing plate is included inside the oil pan to keep sufficient oil in the bottom of

the pan even when the vehicle is tilted. This dividing plate also prevents the oil from making waves when

the vehicle is topped suddenly and thus shifting the oil away from the oil pump suction pipe.

± ENGINE MECHANICALDescription (3S±FE)EM±3

Page 1182 of 2389

The 2VZ±FE engine has 6 cylinder in a V arrangement at bank of 60°. From the front of the RH bank cylin-

ders are numbered 1 ± 3 ± 5, and from the front of the LH bank cylinders are numbered 2 ± 4 ±r 6. The crankshaft is

supported by 4 bearings inside the crankcase. These bearing are made of copper and lead alloy.

The crankshaft is integrated with 5 weights for balance. Oil holes are placed in the center of the crankshaft for sup-

plying oil to the connecting rods, pistons and other components.

This engine's ignition order is 1 ± 2 ± 3 ± 4 ± 5 ± 6. The cylinder head is made of aluminum alloy, with a cross flow

type intake and exhaust layout and with pent±roof type combustion chambers. The spark plugs are located in the

center of the combustion chambers.

At,the front and rear of the intake port of the intake manifold, a water passage has been provided which connects

the RH and LH cylinder heads.

Exhaust and intake valves are equipped with irregular pitch springs made of special valve spring carbon steel which

are capable of functioning no matter what the engine speed.

The RH and LH intake camshaft are driven by a single timing belt, and a gear on the intake side camshaft engages

with a gear on the exhaust side camshaft to drive it. The cam journal is supported at 5 (intake) or 4

(exhaust) places between the valve liters of each cylinder and on the front end of the cylinder head. Lubrication of

the cam journals and gears is accomplished by oil being supplied through the oiler port in the center of the camshaft.

Adjustment of the valve clearance is done by means of outer shim type system, in which valve adjusting shims are

located above the valve lifters. The permits replacement of the shims without removal of the camshafts.

The timing belt cover is composed of resin type No. 2 and No. 1 above and below the RH mounting bracket.

Piston are made high temperature±resistant aluminum alloy, and a depression is built into the piston head to prevent

interference with the valves.

Piston pins are the semi±floating type, with the pins fastened to the connecting rods by pressure fitting, allowing the

pistons and pins to float.

The No. 1 compression ring is made of steel and the No. 2 compression ring is made±of cast iron. The oil ring is

made of a combination of steel and stainless steel. The outer diameter of each piston ring is slightly larger than the

diameter of the piston and the flexibility of the rings allows them to hug the cylinder walls when they are mounted on

the piston. Compression rings No. 1 and No. 2 work to prevent gas leakage from the cylinder and oil ring works to

clear oil off the cylinder walls to prevent it from entering the combustion chambers.

The cylinder block is made of cast iron with a bank angle of 60°. It has 6 cylinders which are approximately 2

times the length of the piston stroke. The top of the cylinders is closed off by the cylinder heads and the lower end of

the cylinders becomes the crankcase, in which the crankshaft is installed. In addition, the cylinder block contains a

water jacket, through which coolant is pumped to cool the cylinders.

The oil pan is bolted onto the bottom of the cylinder block. The oil pan is an oil reservoir made of pressed steel

sheet. A dividing plate is included inside the oil pan to keep sufficient oil in the bottom of the pan even when the ve-

hicle is tilted. This dividing plate also prevents the oil from making waves when the vehicle is stopped suddenly and

thus shifting the oil away from the oil pump suction pipe.

± ENGINE MECHANICALDescription (2VZ±FE)EM±5