manual transmission TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1 of 2389

Pub. NamePub. No.

'91 Camry Repair ManualRM199U Automatic TransmissionApplicable Model

A540E

A540H'91 Camry

FOREWORD

This repair manual covers Disassembly, Inspection and As-

sembly procedures for the following Automatic Transaxles:

For On-vehicle Servicing (Inspection, Adjustment, Trouble-

shooting, Removal and Installation) of Automatic Transaxle,

refer to the repair manual for the applicable vehicle model.

All information contained in this manual is the most up-to-data

at the time of publication. However, specifications and proce-

dures are subject to change without notice.

TOYOTA MOTOR CORPORATION

Page 6 of 2389

ABBREVIATIONS USED IN THIS MANUAL

A/T ATM Automatic Transmission

ATF Automatic Transmission Fluid

B

0 Overdrive Brake

B

1 Second Coast Brake

B

2 Second Brake

B

3 First and Reverse Brake

C

0 Overdrive Clutch

C

1 Forward Clutch

C

2 Direct Clutch

D Disc

D/F Differential

LH Left

MP Multipurpose

O/D Overdrive

P Plate

RH Right

SSM Special Service Materials

SST Special Service Tools

IN-6- INTRODUCTIONAbbreviations Used in This Manual

Page 145 of 2389

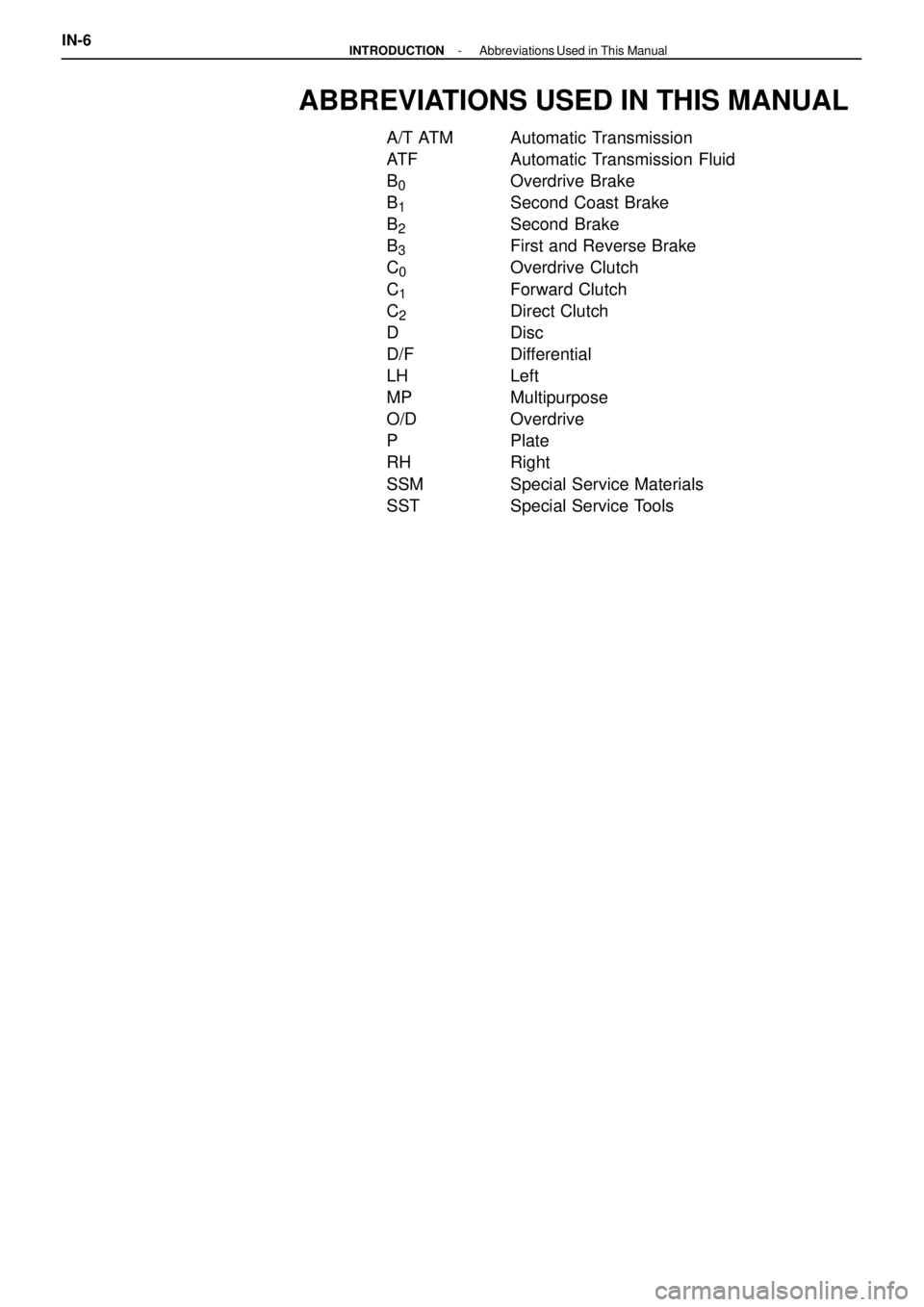

AT7759

AT0090

AT3576

Manual

Valve LeverParking

Lock Rod

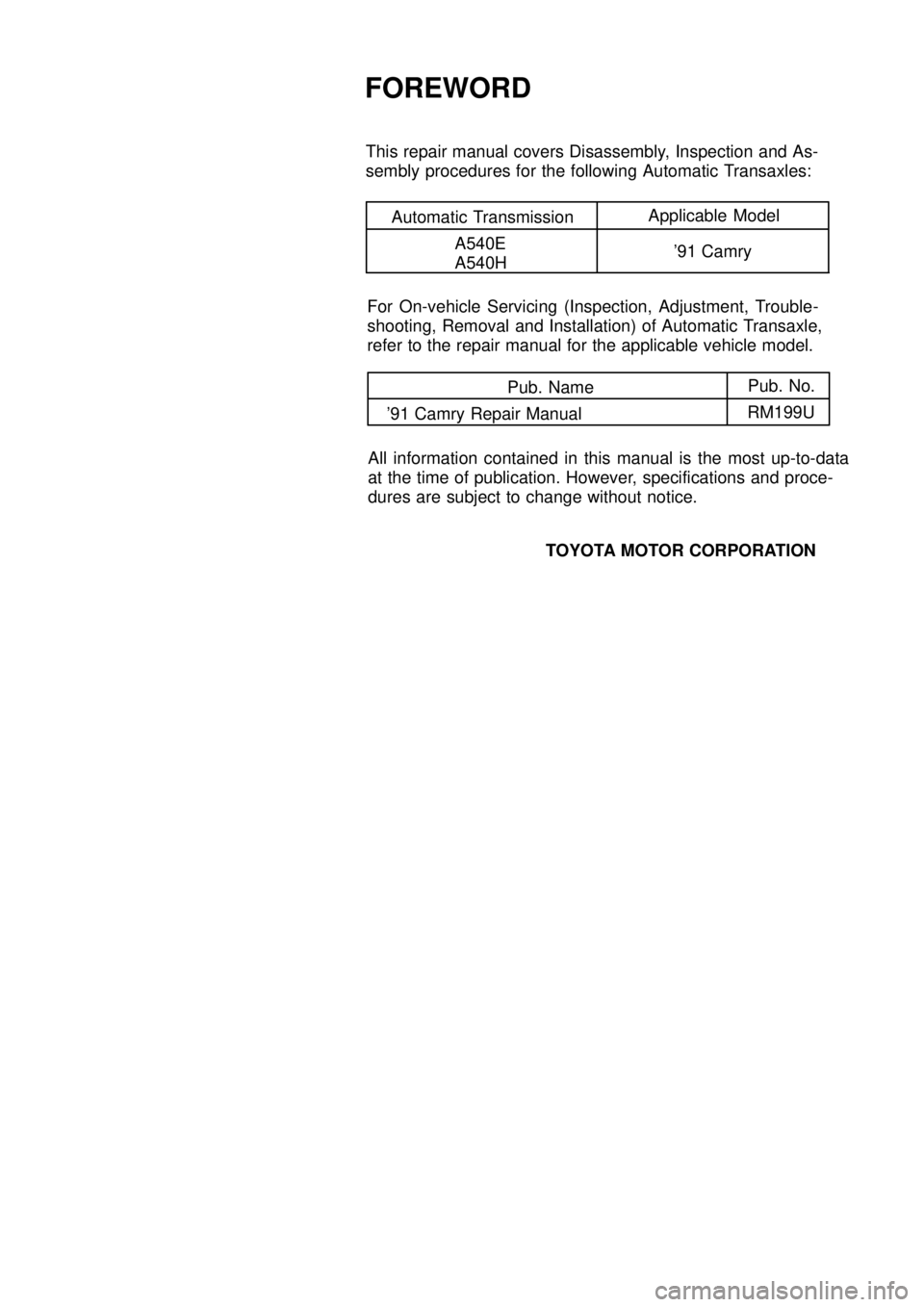

AT3574 AT2731

Lock PawlPin

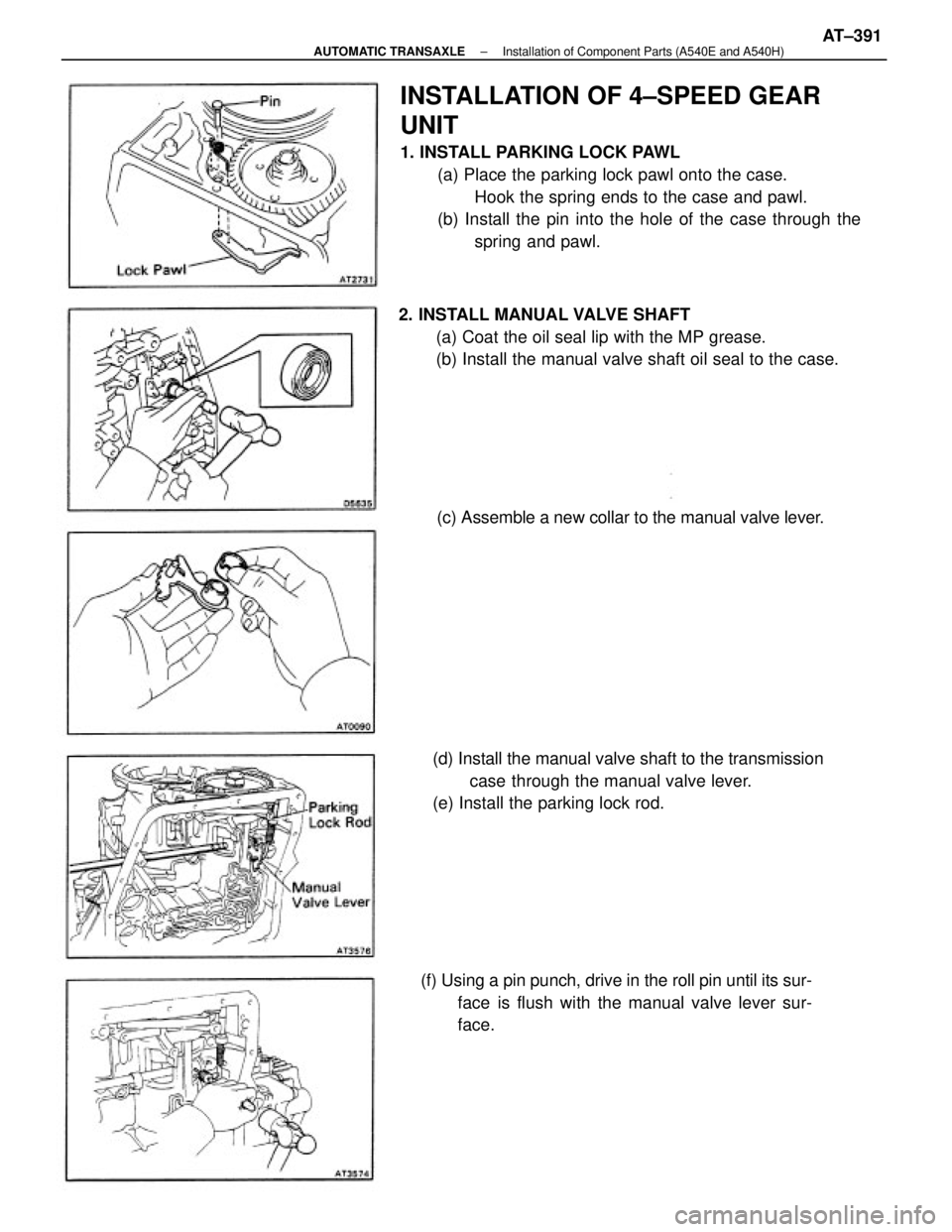

INSTALLATION OF 4-SPEED GEAR UNIT

1. INSTALL PARKING LOCK PAWL

(a) Place the parking lock pawl onto the case.

Hook the spring ends to the case and pawl.

(b) Install the pin into the hole of the case through the

spring and pawl.

2. INSTALL MANUAL VALVE SHAFT

(a) Coat the oil seal lip with the MP grease.

(b) Install the manual valve shaft oil seal to the case.

(c) Assemble a new collar to the manual valve lever.

(d) Install the manual valve shaft to the transmission

case through the manual valve lever.

(e) Install the parking lock rod.

(f) Using a pin punch, drive in the roll pin until its sur-

face is flush with the manual valve lever surface.

- AUTOMATIC TRANSAXLEInstallation of Component PartsAT-129

Page 146 of 2389

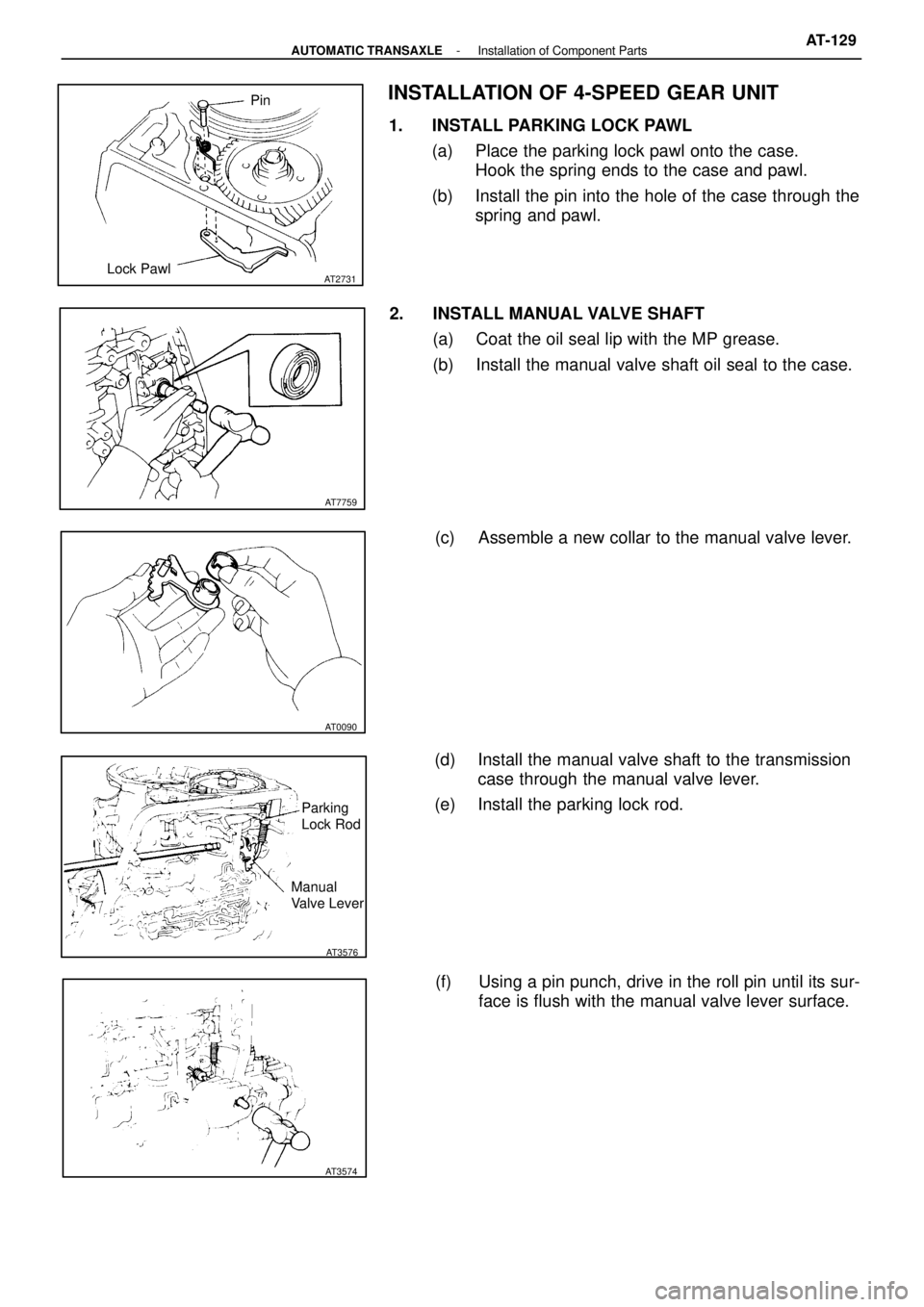

AT5025

Retaining

Spring

AT0312

AT0969

AT2757AT0093

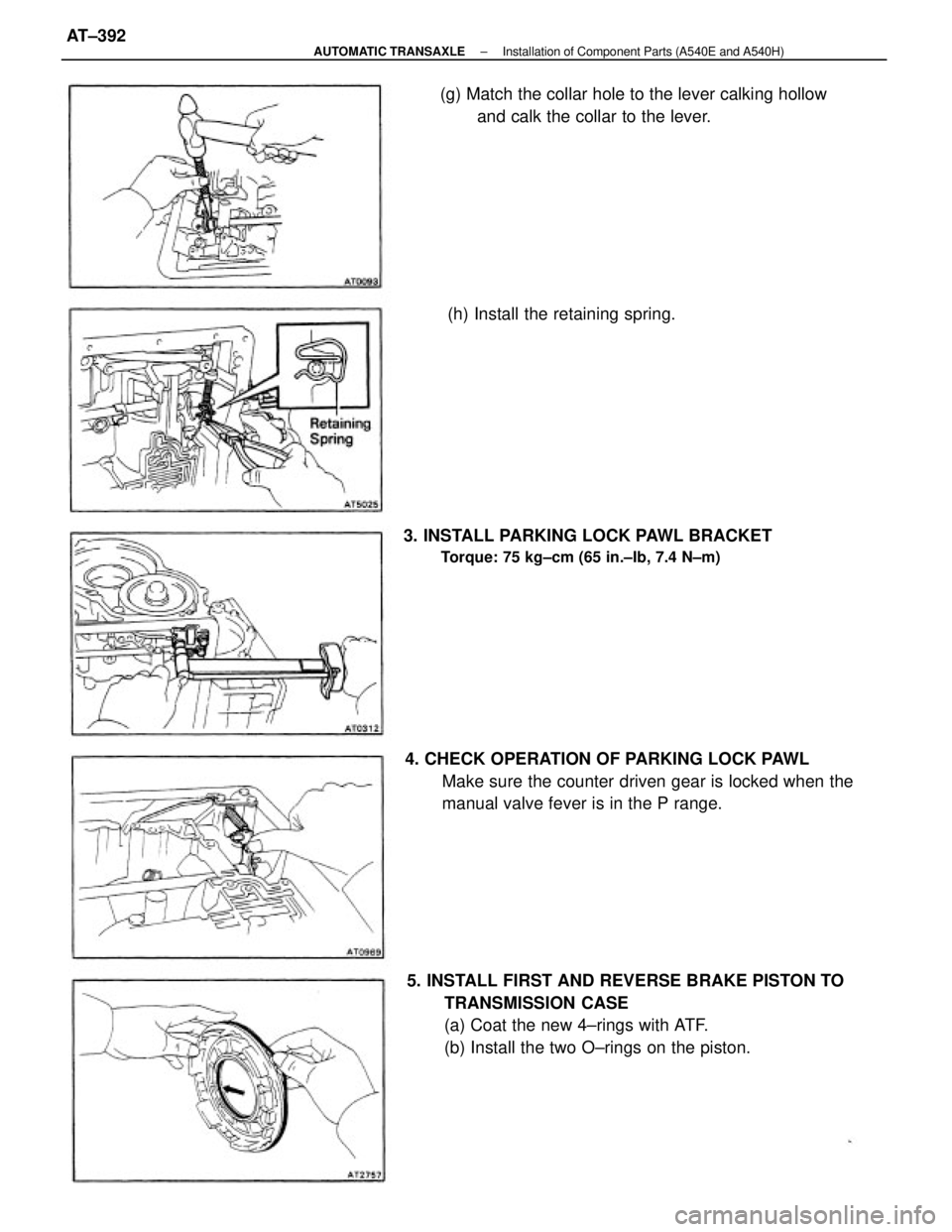

(g) Match the collar hole to the lever calking hollow

and calk the collar to the lever.

(h) Install the retaining spring.

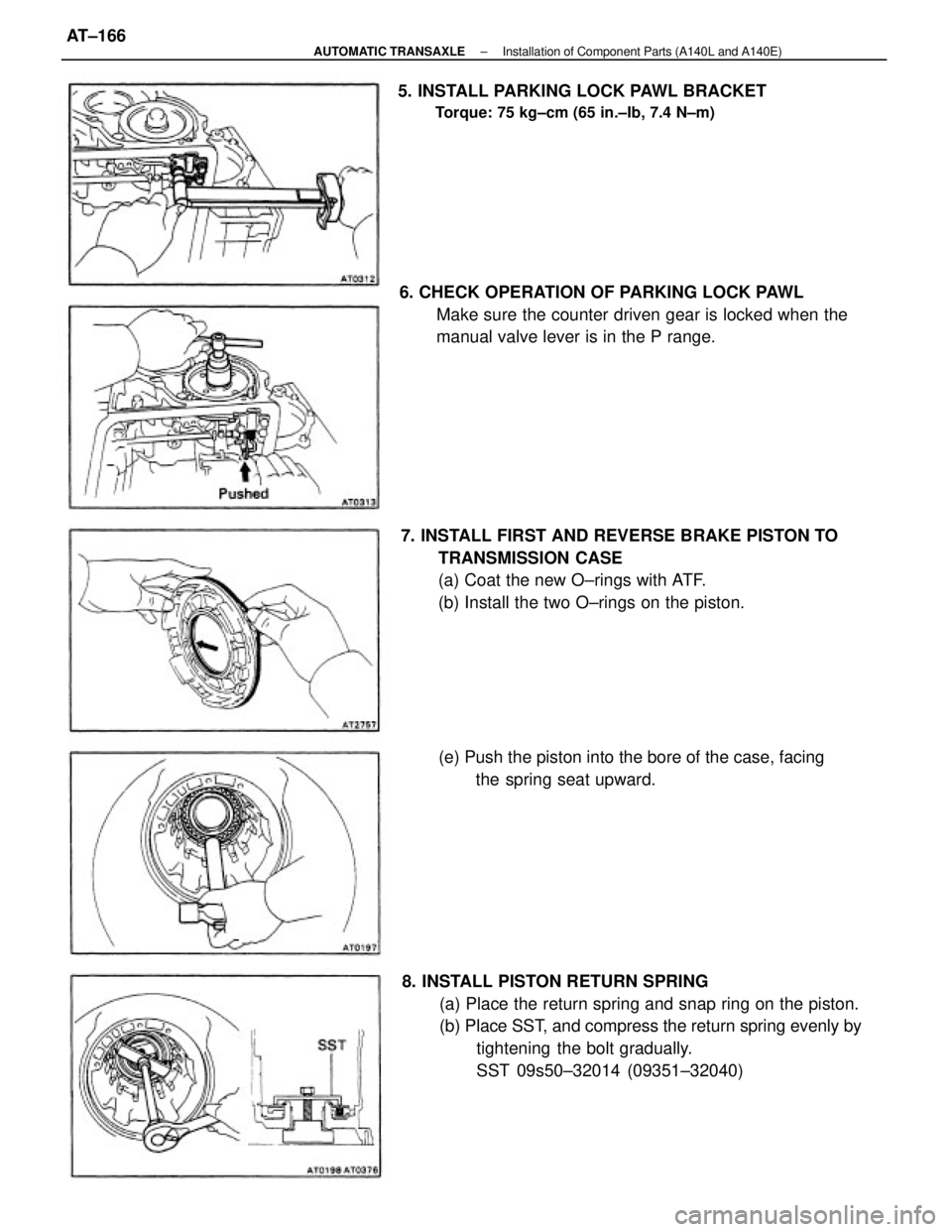

3. INSTALL PARKING LOCK PAWL BRACKET

Torque: 75 kg-cm (65 in.-lb, 7.4 N-m)

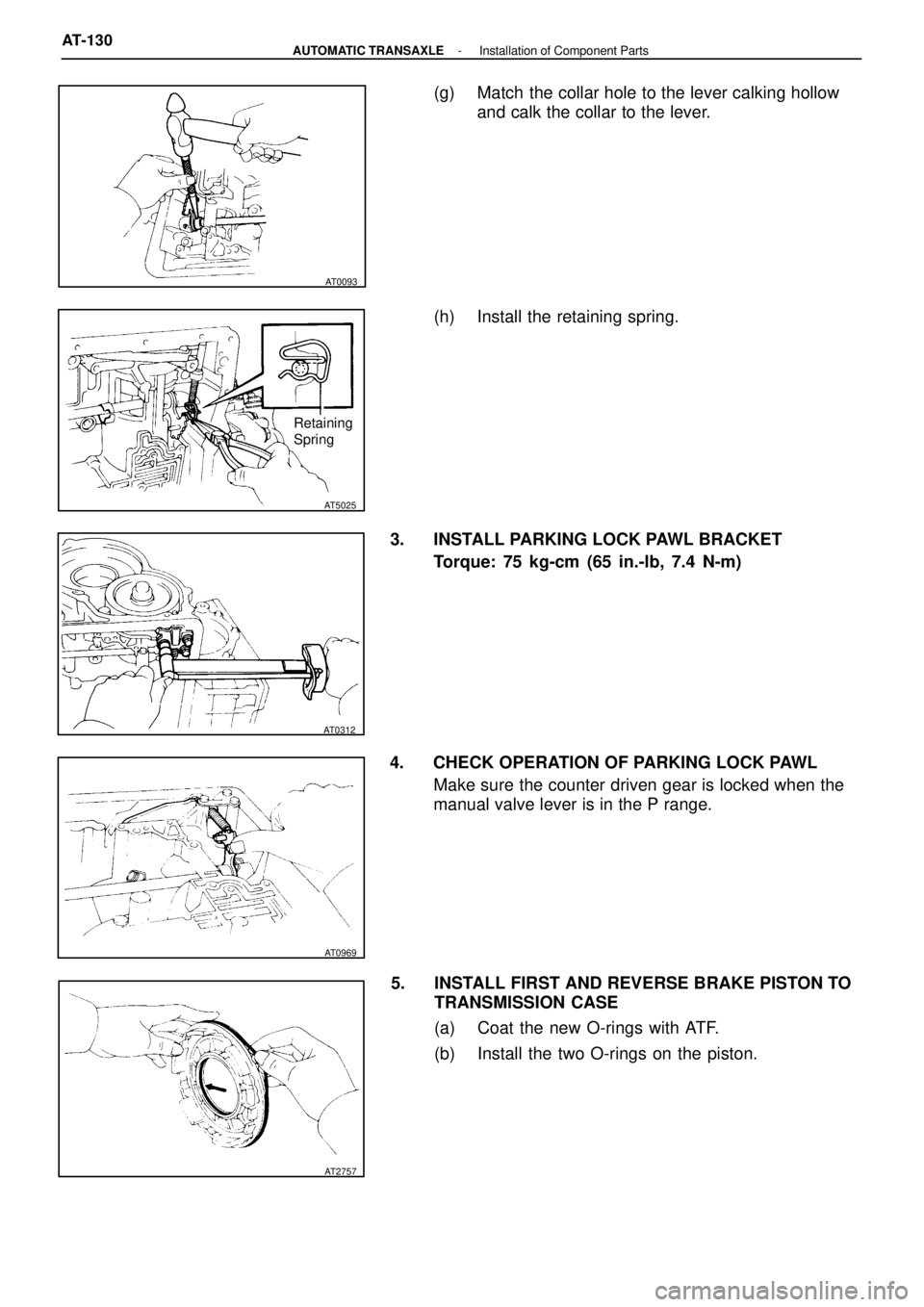

4. CHECK OPERATION OF PARKING LOCK PAWL

Make sure the counter driven gear is locked when the

manual valve lever is in the P range.

5. INSTALL FIRST AND REVERSE BRAKE PISTON TO

TRANSMISSION CASE

(a) Coat the new O-rings with ATF.

(b) Install the two O-rings on the piston.

AT-130- AUTOMATIC TRANSAXLEInstallation of Component Parts

Page 306 of 2389

2. REMOVE NEUTRAL START SWITCH

(a) Remove the clips and, disconnect the transmission

control cable from manual shift lever.

(b) Remove the manual shift lever.

(c) Remove the neutral start switch.

3. REMOVE VALVE BODY (See page AT±61, AT±62)

INSTALLATION OF THROTTLE CABLE

1. INSTALL CABLE IN TRANSMISSION CASE

(a) Be sure to push it in all the way.

(b) Install the retaining plate and one bolt.

2. INSTALL VALVE BODY (See page AT±177, AT±178)

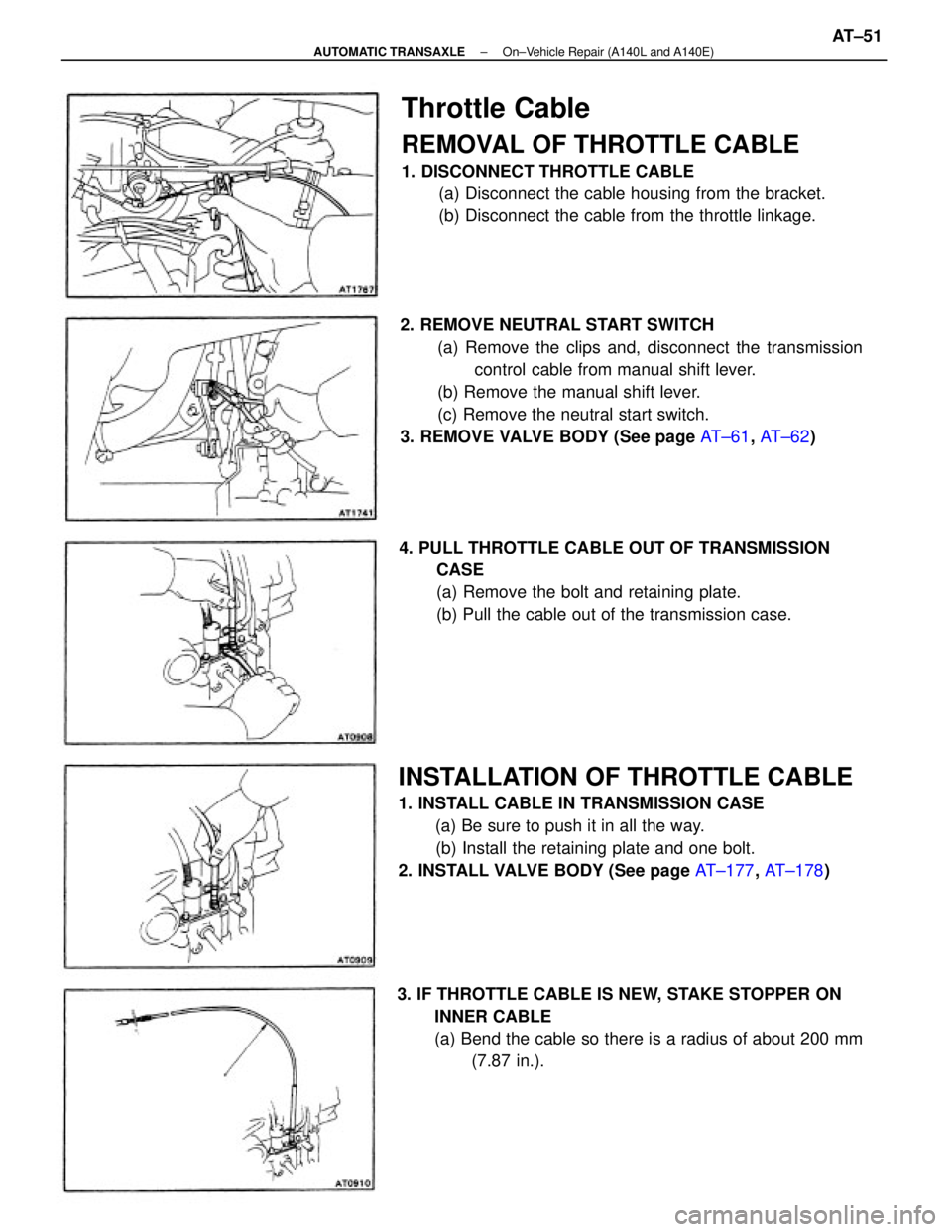

Throttle Cable

REMOVAL OF THROTTLE CABLE

1. DISCONNECT THROTTLE CABLE

(a) Disconnect the cable housing from the bracket.

(b) Disconnect the cable from the throttle linkage.

4. PULL THROTTLE CABLE OUT OF TRANSMISSION

CASE

(a) Remove the bolt and retaining plate.

(b) Pull the cable out of the transmission case.

3. IF THROTTLE CABLE IS NEW, STAKE STOPPER ON

INNER CABLE

(a) Bend the cable so there is a radius of about 200 mm

(7.87 in.).

± AUTOMATIC TRANSAXLEOn±Vehicle Repair (A140L and A140E)AT±51

Page 307 of 2389

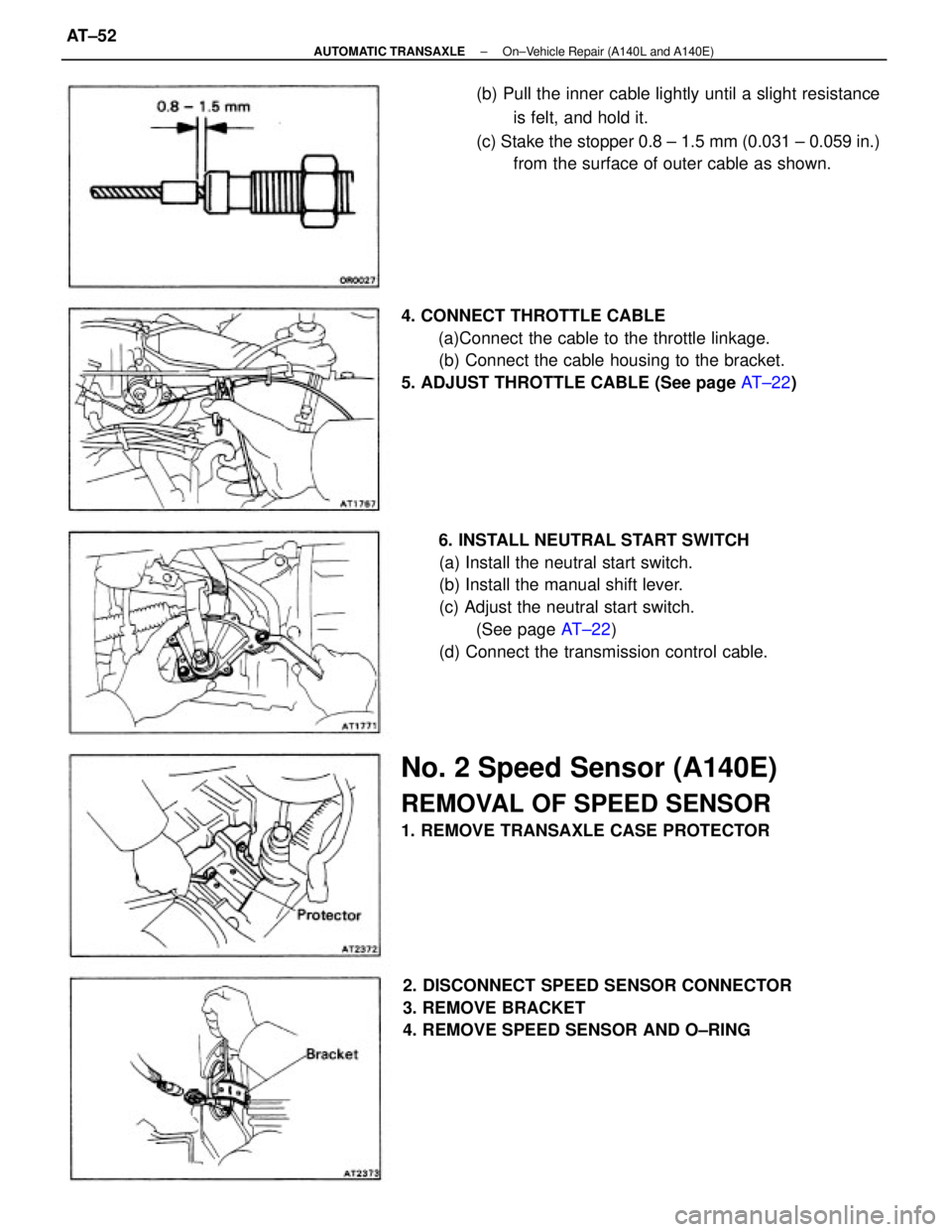

6. INSTALL NEUTRAL START SWITCH

(a) Install the neutral start switch.

(b) Install the manual shift lever.

(c) Adjust the neutral start switch.

(See page AT±22)

(d) Connect the transmission control cable. 4. CONNECT THROTTLE CABLE

(a)Connect the cable to the throttle linkage.

(b) Connect the cable housing to the bracket.

5. ADJUST THROTTLE CABLE (See page AT±22) (b) Pull the inner cable lightly until a slight resistance

is felt, and hold it.

(c) Stake the stopper 0.8 ± 1.5 mm (0.031 ± 0.059 in.)

from the surface of outer cable as shown.

No. 2 Speed Sensor (A140E)

REMOVAL OF SPEED SENSOR

1. REMOVE TRANSAXLE CASE PROTECTOR

2. DISCONNECT SPEED SENSOR CONNECTOR

3. REMOVE BRACKET

4. REMOVE SPEED SENSOR AND O±RING

± AUTOMATIC TRANSAXLEOn±Vehicle Repair (A140L and A140E)AT±52

Page 421 of 2389

8. INSTALL PISTON RETURN SPRING

(a) Place the return spring and snap ring on the piston.

(b) Place SST, and compress the return spring evenly by

tightening the bolt gradually.

SST 09s50±32014 (09351±32040) 6. CHECK OPERATION OF PARKING LOCK PAWL

Make sure the counter driven gear is locked when the

manual valve lever is in the P range.

7. INSTALL FIRST AND REVERSE BRAKE PISTON TO

TRANSMISSION CASE

(a) Coat the new O±rings with ATF.

(b) Install the two O±rings on the piston.

(e) Push the piston into the bore of the case, facing

the spring seat upward. 5. INSTALL PARKING LOCK PAWL BRACKET

Torque: 75 kg±cm (65 in.±Ib, 7.4 N±m)

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±166

Page 649 of 2389

INSTALLATION OF 4±SPEED GEAR

UNIT

1. INSTALL PARKING LOCK PAWL

(a) Place the parking lock pawl onto the case.

Hook the spring ends to the case and pawl.

(b) Install the pin into the hole of the case through the

spring and pawl.

2. INSTALL MANUAL VALVE SHAFT

(a) Coat the oil seal lip with the MP grease.

(b) Install the manual valve shaft oil seal to the case.

(d) Install the manual valve shaft to the transmission

case through the manual valve lever.

(e) Install the parking lock rod.

(f) Using a pin punch, drive in the roll pin until its sur-

face is flush with the manual valve lever sur-

face. (c) Assemble a new collar to the manual valve lever.

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A540E and A540H)AT±391

Page 650 of 2389

5. INSTALL FIRST AND REVERSE BRAKE PISTON TO

TRANSMISSION CASE

(a) Coat the new 4±rings with ATF.

(b) Install the two O±rings on the piston. 4. CHECK OPERATION OF PARKING LOCK PAWL

Make sure the counter driven gear is locked when the

manual valve fever is in the P range. 3. INSTALL PARKING LOCK PAWL BRACKET

Torque: 75 kg±cm (65 in.±Ib, 7.4 N±m)

(g) Match the collar hole to the lever calking hollow

and calk the collar to the lever.

(h) Install the retaining spring.

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A540E and A540H)AT±392

Page 1864 of 2389

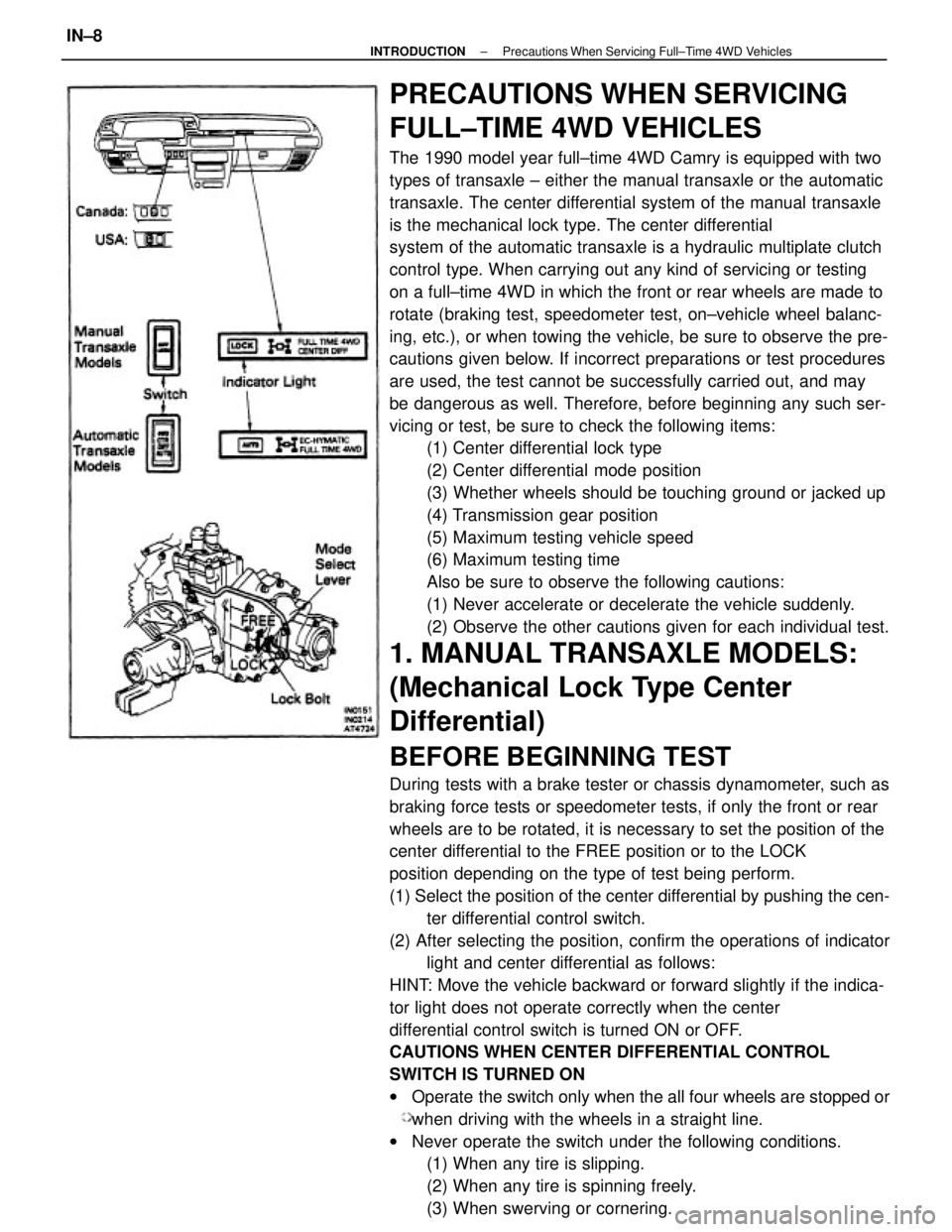

PRECAUTIONS WHEN SERVICING

FULL±TIME 4WD VEHICLES

The 1990 model year full±time 4WD Camry is equipped with two

types of transaxle ± either the manual transaxle or the automatic

transaxle. The center differential system of the manual transaxle

is the mechanical lock type. The center differential

system of the automatic transaxle is a hydraulic multiplate clutch

control type. When carrying out any kind of servicing or testing

on a full±time 4WD in which the front or rear wheels are made to

rotate (braking test, speedometer test, on±vehicle wheel balanc-

ing, etc.), or when towing the vehicle, be sure to observe the pre-

cautions given below. If incorrect preparations or test procedures

are used, the test cannot be successfully carried out, and may

be dangerous as well. Therefore, before beginning any such ser-

vicing or test, be sure to check the following items:

(1) Center differential lock type

(2) Center differential mode position

(3) Whether wheels should be touching ground or jacked up

(4) Transmission gear position

(5) Maximum testing vehicle speed

(6) Maximum testing time

Also be sure to observe the following cautions:

(1) Never accelerate or decelerate the vehicle suddenly.

(2) Observe the other cautions given for each individual test.

1. MANUAL TRANSAXLE MODELS:

(Mechanical Lock Type Center

Differential)

BEFORE BEGINNING TEST

During tests with a brake tester or chassis dynamometer, such as

braking force tests or speedometer tests, if only the front or rear

wheels are to be rotated, it is necessary to set the position of the

center differential to the FREE position or to the LOCK

position depending on the type of test being perform.

(1) Select the position of the center differential by pushing the cen-

ter differential control switch.

(2) After selecting the position, confirm the operations of indicator

light and center differential as follows:

HINT: Move the vehicle backward or forward slightly if the indica-

tor light does not operate correctly when the center

differential control switch is turned ON or OFF.

CAUTIONS WHEN CENTER DIFFERENTIAL CONTROL

SWITCH IS TURNED ON

wOperate the switch only when the all four wheels are stopped or

when driving with the wheels in a straight line.

wNever operate the switch under the following conditions.

(1) When any tire is slipping.

(2) When any tire is spinning freely.

(3) When swerving or cornering.

± INTRODUCTIONPrecautions When Servicing Full±Time 4WD VehiclesIN±8