coolant TOYOTA CELICA 1987 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 121 of 346

EFI SYSTEM - Fuel System

-.

REMOVAL OF. INJECTOR

FI-87

1.

2.

3.

I A k DISCONNECT FOLLOWING CONNECTORS:

5.

8.

7. DISCONNECT CABLE FROM NEGATIVE TERMINAL

OF BATTERY

DRAIN COOLANT

DISCONNECT FOLLOWING HOSES:

l Water hoses from throttle body (7-M-GE) or water by-

pass pipe (‘IM-GTE)

0 Vacuum hoses from throttle body

0 ISC valve hoses from throttle body

0 Vacuum sensing hose from pressure regulator

0 Throttle position sensor connector

0 ISC valve connector

0 (‘IM-GE)

Cold start injector connector

REMOVE AIR INTAKE CONNECTOR

(7M-GE)

(a) Disconnect the air cleaner hose from the throttle

body.

(b) Remove the throttle body and air intake connector

brackets.

(c) Remove the four bolts and two nuts, intake connec-

tor and gasket.

(7M-GTE)

(See steps 1 to 3 on page EM-121

(‘IM-GTE)

REMOVE THROTTLE BODY (See page Fi-104)

REMOVE ISC VALVE

(a) Disconnect the No. 2 water by-pass hose from the

ISC valve.

Page 137 of 346

EFI SYSTEM - Air Inductioi System

PI-1 03

-

1 7M-GE

I 7M-GTE

d

c q-rEA

vc

1

I I

in-7.h

IDL VTA VC ’

s --I

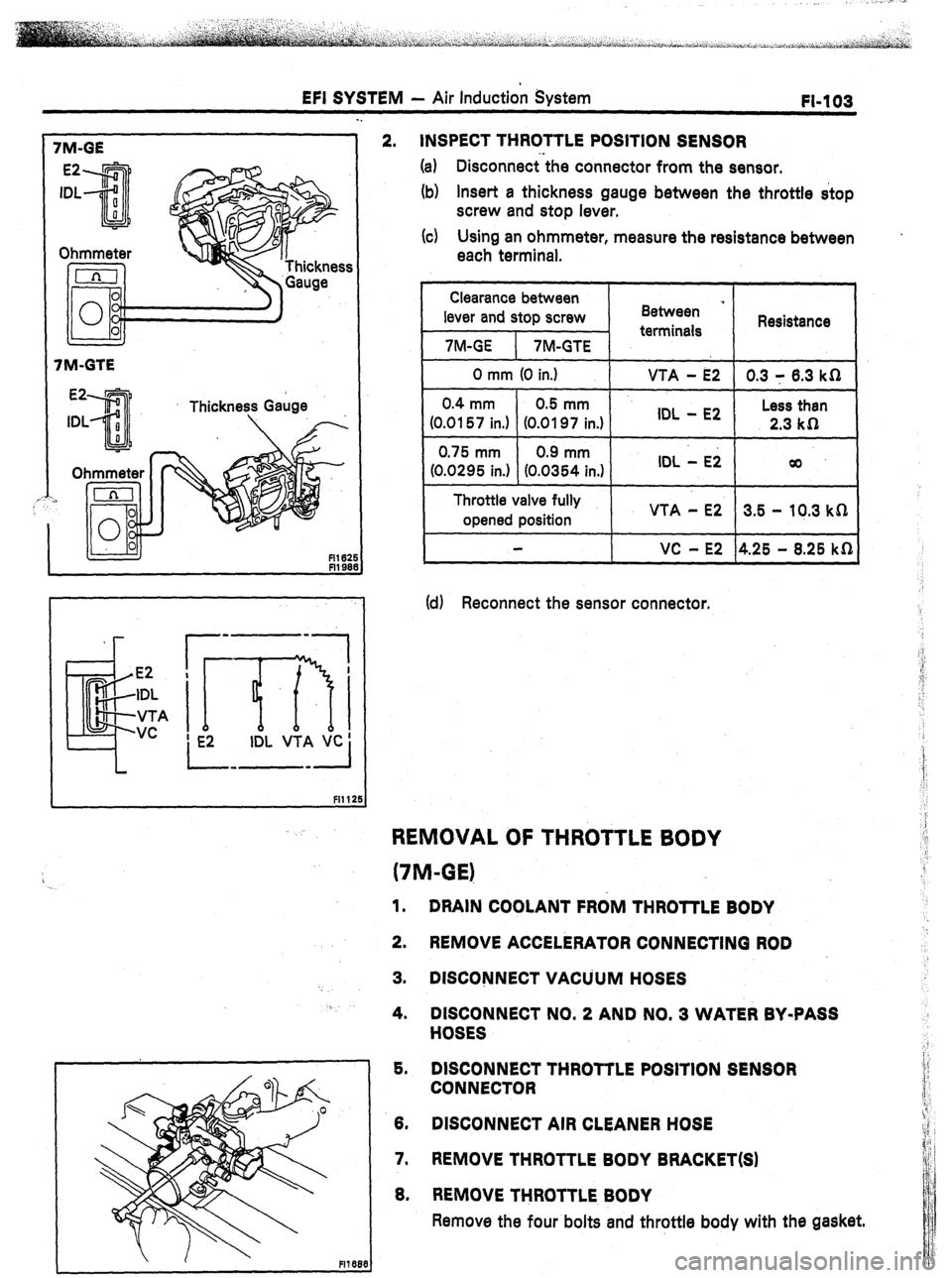

2. INSPECT THROTTLE POSITION SENSOR

(a) Disconnectthe connector from the sensor.

(b) Insert a thickness gauge between the throttle stop

screw and stop lever.

(c) Using an ohmmeter, measure the resistance between

each terminal.

(d) Reconnect the sensor connector.

./ !’

REMOVAL OF THROTTLE BODY ‘.

/ (7M-GE)

1. DRAIN COOLANT FRdM THROTTLE BODY

2. REMOVE ACCELERATOR CONNECTING ROD

3. DISCONNECT VACUUM HOSES

4.

DISCONNECT NO. 2 AND NO. 3 WATER BY-PASS

HOSES

. 1 5. DISCONNECT THROTTLE POSITION SEI

7.

REMOVE THROTTLE BODY BRACKET(S)

6. REMOVE THROTTLE BODY

Remove the four bolts and throttle body with the gasket,

Page 138 of 346

Fl-104 EFI SYSTEM - Air Induction Svstem

;i7M-GTE)

1.

2.

3. thAIhi COOLANT -kROM THROTTLE BODY

DISCONNECT ACCELERATOR CONNECTING ROD

REMOVE AIR INTAKE CONNECTOR

(See steps 1 to 3 on page EM-121

4.

5.

/A-.( /w /

Trottle Stop Screw

DISCONNECT VACUUM HOSES

*

DISCONNECT THROTTLE POSITION SENSOR

CONNECTOR

REMOVE THROTTLE BODY

(a) Disconnect the tko water by-pass hoses from the

ISC valve and water pipe.

(b) Remove the four bolts, throttle body and gasket.

(cl Remove the two water by-pass hoses.

INSPECTION OF THROTTLE BODY

1. CLEAN THROTTLE BODY

(a) Using a soft brush and carburetor cleaner, clean the

cast parts.

(d) Using compressed air, clean all passages and aper-

tures.

CAUTION: To prevent deterioration, do not clean the

throttle position sensor and dash pot.

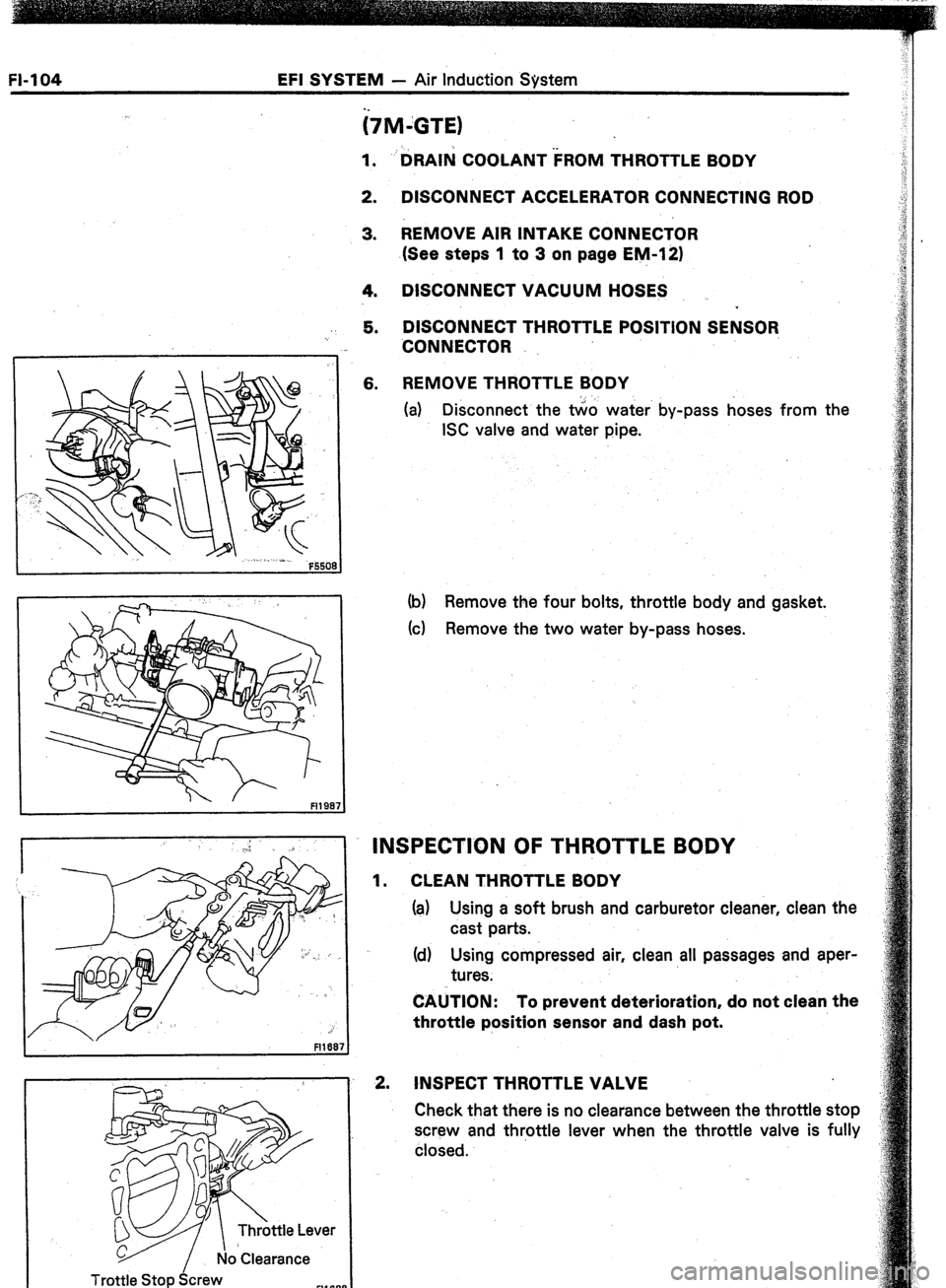

2. INSPECT THROTTLE VALVE

Check that there is no clearance between the throttle stop

screw and throttle lever when the throttle valve is fully

closed.

Page 140 of 346

FI-106 EFI SYSTEM - Air Induction S&m

-.

@ls,TAL&ATION OF THROTTLE BODY

(?M-QE)

I FIlW

I-

/

1.

2.

3.

4.

6.

6.

7.

6. INSTALL THROTTLE BODY

Install the gasket-and throttle body with the four bolts.

Torque: 130 kg-cm (9 ft-lb, 13 Narn)

CONNECT THROTTLE BODY BRACKET@

CONNECT AIR CLEANER HOSE

CONNECT THROTTLE POSITiON SENSOR

CONNECTOR

CONNECT VACUUM HOSES

CONNECT WATER HOSES

CONNECT ACCELERATOR CONNECTING ROD

REFILL WITH COOLANT

(‘/M-GTE)

1. INSTALL THROTTLE BOPY

(a) Install the two water by-pass hoses.

(b) Install a new gasket and throttle body with the four

bolts.

(c) Connect the two water by-pass hoses to the ISC

valve and water pipe.

Page 141 of 346

EFI SYSTEM - Air Induction System

FI-107

. .

2. CONNECT THROTTLE POSITION SENSOR

CONNiXTOR .-

3. CONNECT VACUUM HOSES

4. INSTALL AiR INTAKE CONNECTOR

:

(See steps 13 to 15 on page EM-141

5. INSTALL ACCELERATOR CONNECTING ROD

6. REFILL WITH COOLANT

Page 142 of 346

FI-108 EFI SYSTEM - Air Induction System

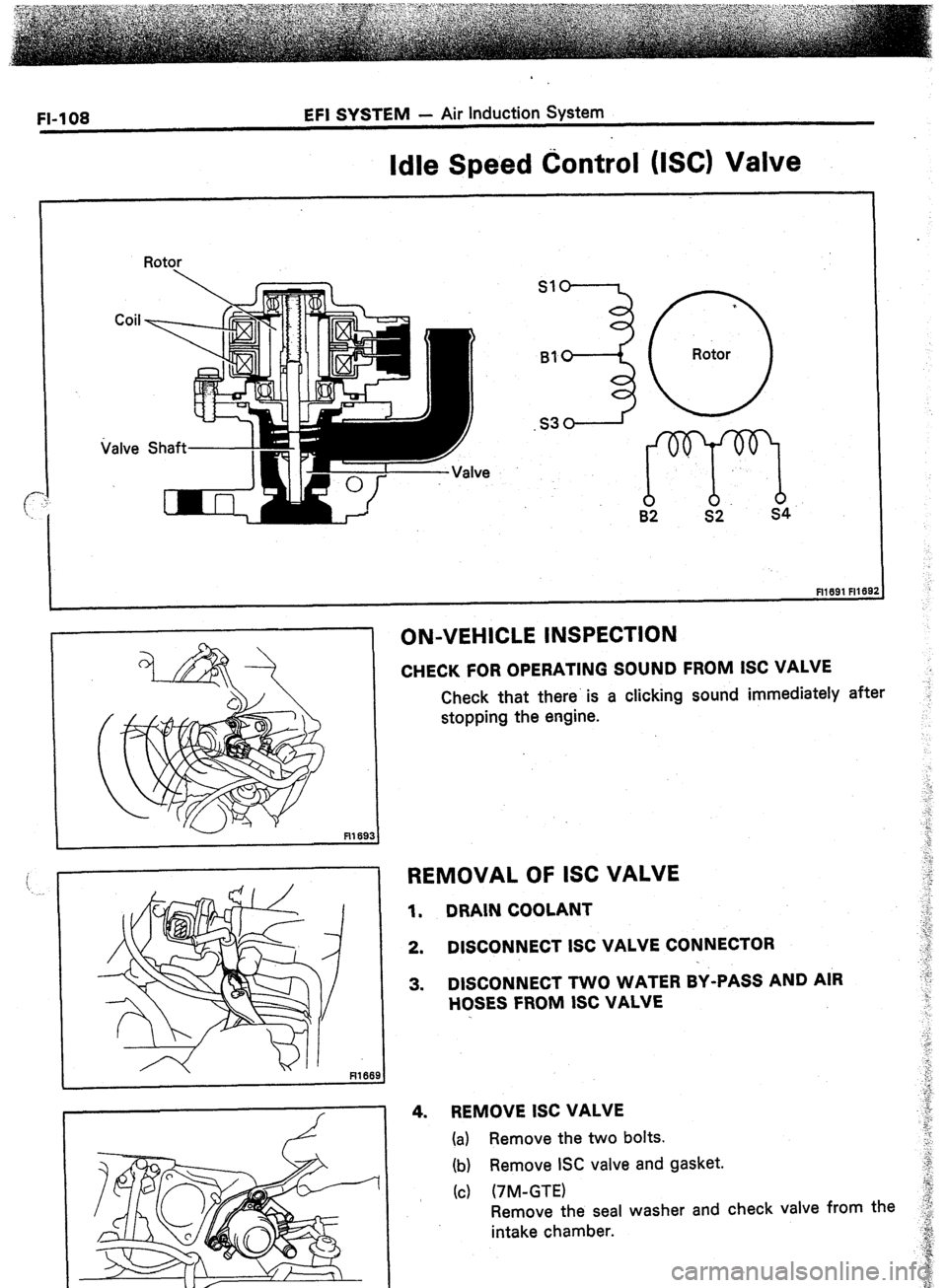

Idle Speed Control (EC) Valve

Rotor

Bl

Q-4

*

0

Rotor

m B2 s2. s4

Fll99lFH6.

,

ON-VEHICLE INSPECTION

CHECK FOR OPERATING SOUND FROM ISC VALVE

Check that there’ is a clicking sound immediately after

stopping the engine.

REMOVAL OF ISC VALVE

1. DRAIN COOLANT

2. DISCONNECT ISC VALVE CONNECTOR

3. DISCONNECT TWO WATER BY-PASS AND AIR

HOSES FROM ISC VALVE

4. REMOVE ISC VALVE

(a) Remove the two bolts.

(b)

Remove ISC valve and gasket.

(cd (7M-GTE)

Remove the seal washer and check valve from the

intake chamber.

Page 143 of 346

EFI SYSTEM - Air Induction System

FI-‘I 09

-.

!

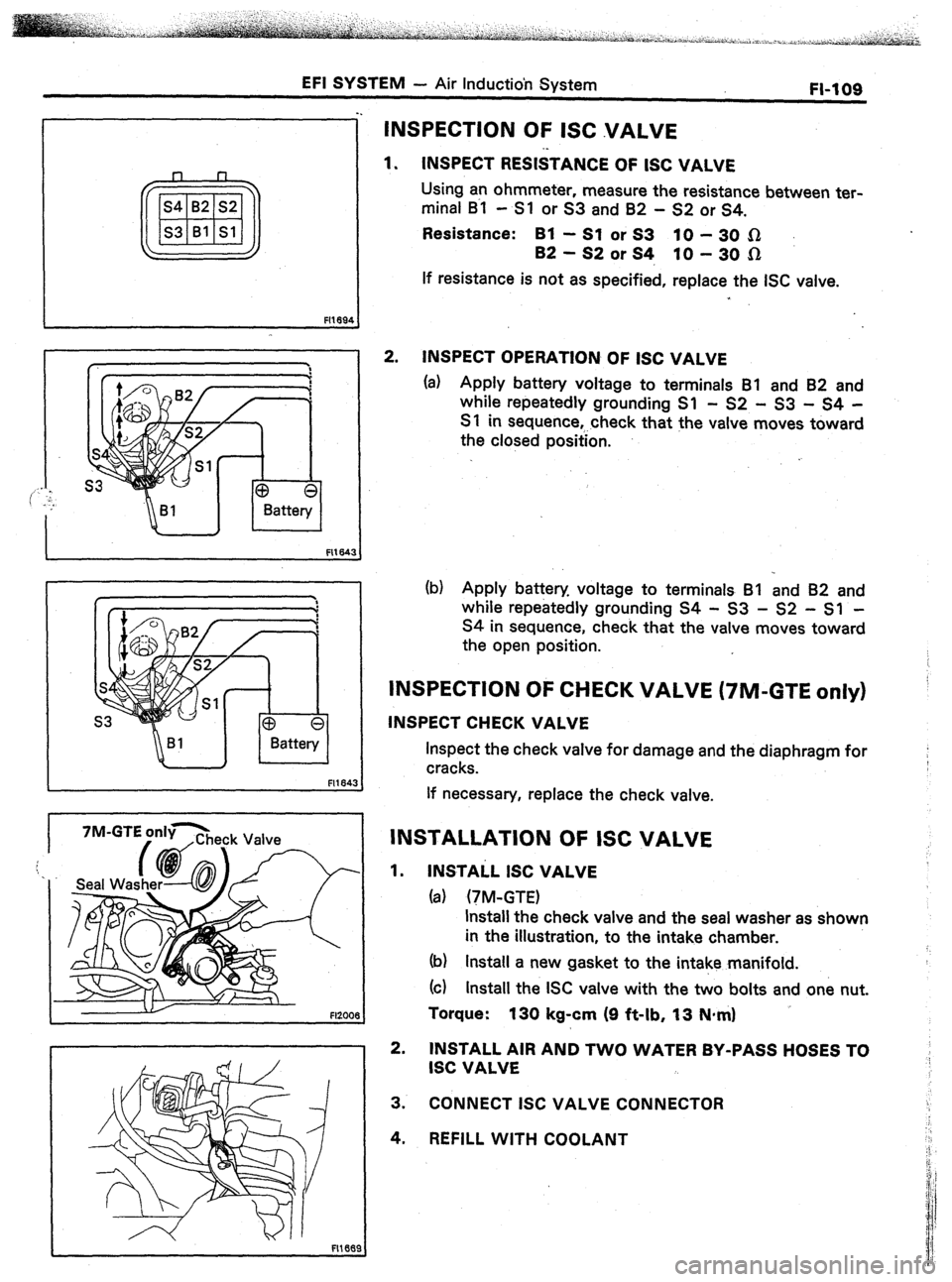

INSPECTION OF ISC VALVE

1. INSPECT RESISTANCE OF ISC VALVE

Using an ohmmeter, measure the resistance between ter-

minal B~l - Sl or S3 and 82 - S2 or S4.

Resistance: Bl -SlorS3 PO-3051

B2-S2orS4, lo-30n

If resistance is not as specified, replace the ISC valve.

2. INSPECT OPERATION OF ISC VALVE

(a) Apply battery voltage to terminals Bl and 82 and

while repeatedly grounding Sl - S2 - 53 - S4 -

S 1 in sequence,.. check that the valve moves toward

the closed position.

(b) Apply battery voltage to terminals Bl and 82 and

while repeatedly grounding S4 - S3 - S2 - Sl -

S4 in sequence, check that the valve moves toward

the open position.

INSPECTION OF CHECK VALVE (7M-GTE only)

INSPECT CHECK VALVE

Inspect the check valve for damage and the diaphragm for

cracks.

If necessary, replace the check valve.

INSTALLATION OF ISC VALVE

1. INSTAiL ISC VALVE

(a) (TM-GTE)

Install the check valve and the seal washer as shown

in the illustration, to the intake chamber.

(b) Install a new gasket to the intake manifold.

(cl Install the ISC valve with the two bolts and one nut.

Torque:

130 kg-cm (9 ft-lb, 13 N-m)

2. INSTALL All? AND TWO WATER BY-PASS HOSES TO

ISC VALVE

3. CONNECT ISC VALVE CONNECTOR

4. REFILL WITH COOLANT

Page 149 of 346

EFI SYSTEM

- Electronic Co?troi System

FI-116

To ignition Switch

(ST11

1 To ECU (STA)

-- : Cold Start Injector Time Switch

._

To ECi

Time Switch

FH37

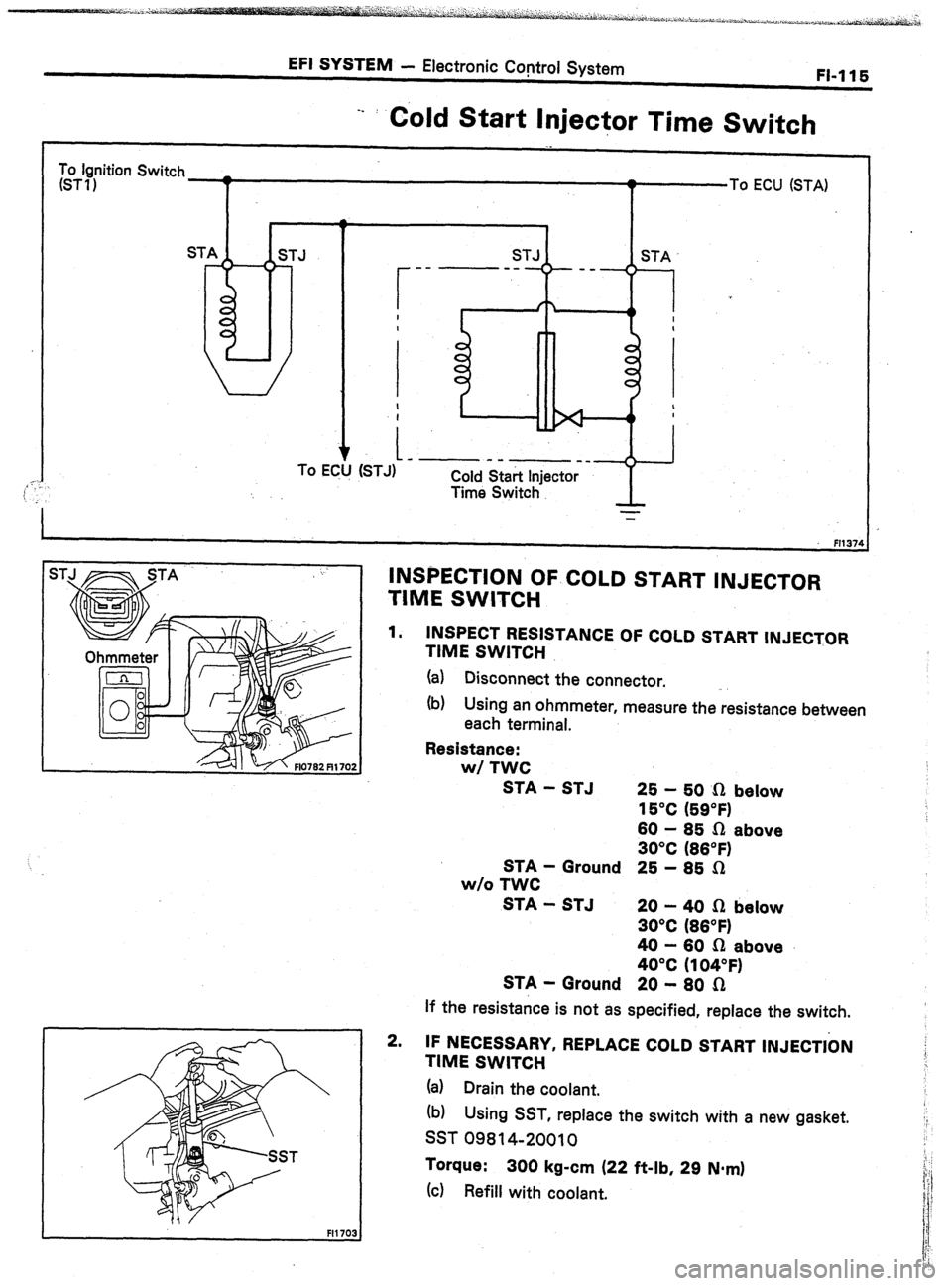

INSPECTION OF COLD START INJECTOR

TIME SWITCH

1. INSPECT RESISTANCE OF COLD START INJECTOR

TIME SWITCH

(a) Disconnect the connector.

(b) Using an ohmmeter, measure the resistance between

each terminal.

Resistance:

w/ TWC

STA - STJ

25 - 50 Cl below

15°C (59°F)

60 - 85 Cl above

30~ (860~)

STA - Ground 25 - 85 Q

w/o TWC

STA - STJ

20 - 40 n below

30°C (86OFI

40 - 60 i2 above

40°C (104’FI

STA - Ground 20 - 80 $I

If the resistance is not as specified, replace the switch.

2.

IF NECESSARY, REPLACE COLD START INJECTlbN

TIME SWITCH

(a) Drain the coolant.

(b) Using SST, replace the switch with a new gasket.

SST 09814-20010

Torque: 300 kg-cm (22 f&lb, 29 Narn)

(cl Refill with coolant.

Page 159 of 346

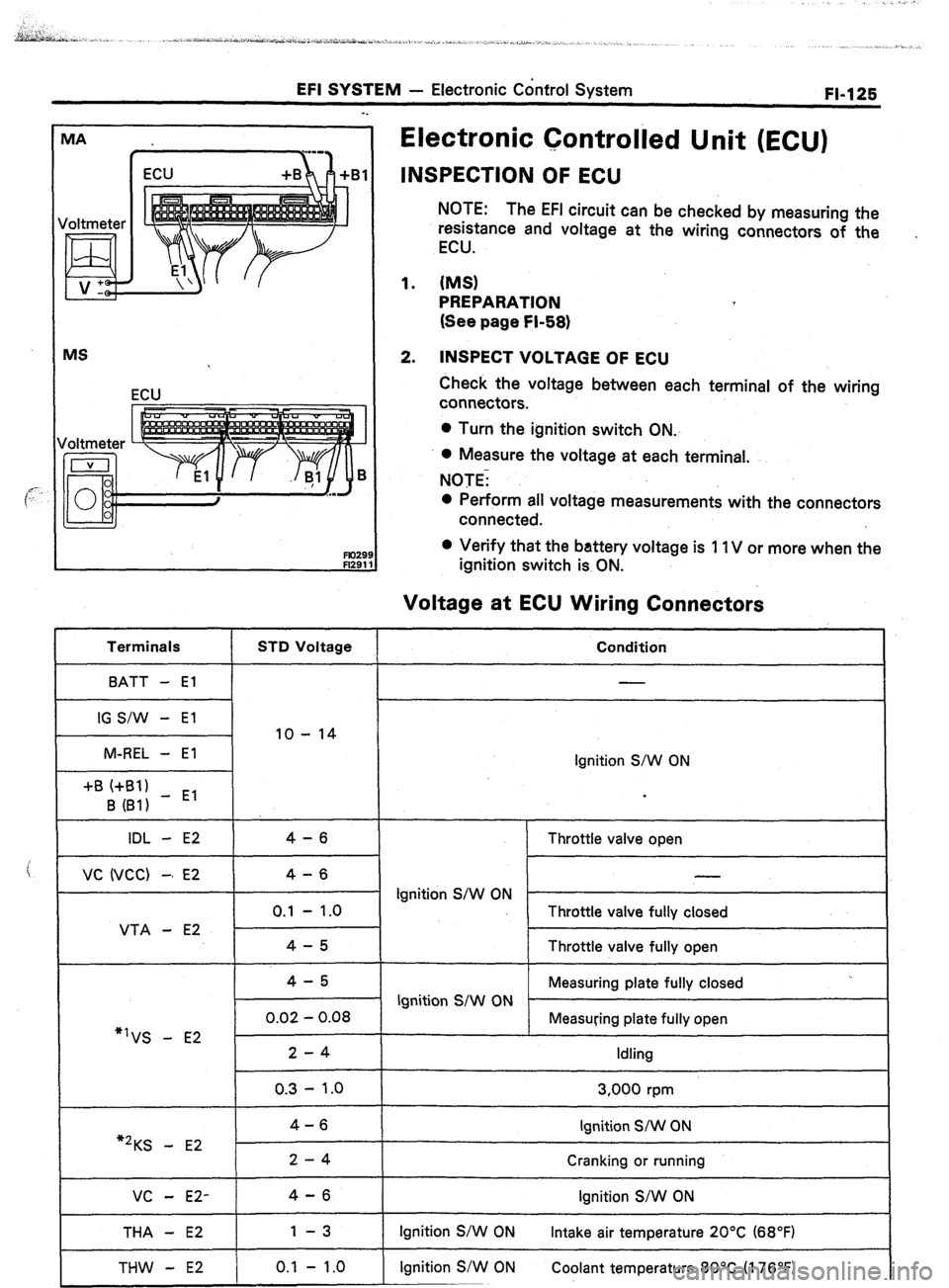

I ECU

ul +B +B

r

MS

ECU

Electronic Controlled Unit (ECU)

._

INSPECTION OF ECU

NOTE:

The EFI circuit can be checked by measuring the

resistance and voltage at the wiring connectors of the

ECU. .

1.

(MS)

PREPARATION

(See page FI-58)

2. INSPECT VOLTAGE OF ECU

Check the voltage between each terminal of the wiring

connectors.

0 Turn the ignition switch ON.

0 Measure the voltage at each terminal.

NOTE:

0 Perform all voltage measurements with the connectors

connected.

0 Verify that the battery voltage is 11 V or more when the

ignition switch is ON.

Voltage at ECU Wiring Connectors

I I I Terminals STD Voltage t Condition

I

BATT - El

IG S/W - El

10 - 14

M-REL - El

Ignition S/W ON

.

IDL - E2

VC (VCC) -. E2

VIA - E2 4-6 Throttle valve open

4-6

Ignition S/W ON

0.1 - 1.0 Throttle valve fully closed

4-5 Throttle valve fully open

4-5

Measuring plate fully closed

Ignition S/W ON

0.02 - 0.08

“‘vs Measuring plate fully open

- E2

2-4 Idling

0.3 - 1 .o 3,000 rpm

4-6

*2KS Ignition S/W ON

- E2

2-4 Cranking or running

VC - E2-

THA - E2 4-6 Ignition S/W ON

1 -3 Ignition S/W ON Intake air temperature 20°C (68°F)

THW - E2 0.1 - 1.0 Ignition S/W ON Coolant temperature 80°C (I 76°F)

Page 161 of 346

EFI SYSTEM - Electronic Control. System

FL127

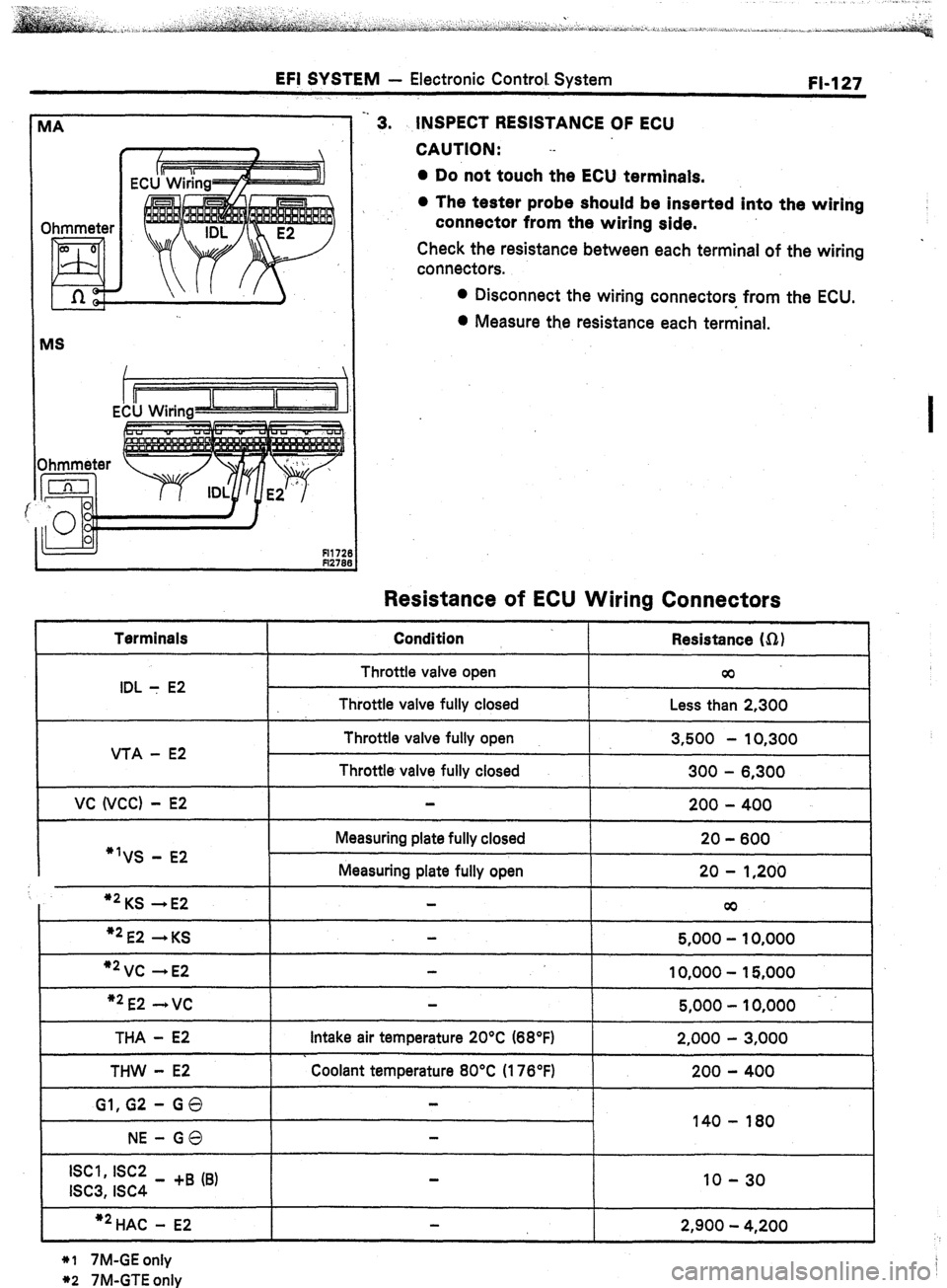

ECU Wiring . .

3.

INSPECT RESISTANCE OF ECU

CAUTION: .-

l Do not touch the ECU terminals.

0 The tester probe should be inserted into the wiring

connector from the wiring side.

Check the resistance between each terminal of the wiring

connectors.

l Disconnect the wiring connectors from the ECU.

0 Measure th.e resistance each terminal.

I

Resistance of ECU Wiring Connectors

Terminals Condition

. I Resistance Ifi)

I

IDL : E2

VTA - E2

VC WCC) - E2 Throttle valve open

Throttle valve fully closed

Throttle valve fully open

Throttle valve fully closed cc

Less than 2,300

3,500 - 10,300

300 - 6,300

200 - 400

*‘VS - E2 Measuring plate fully closed

Measuring plate fully open 20 - 600

20 - 1,200

I *2KS -E2 co I I I

“2E2 +KS -

5,000 - 10,000 I

I

“2VC -E2

10,000 - 15,000

I “2E2 -+VC

I I 5,000 - 10,000 I

THA - E2

THW - E2

Gl,G2 - GO

NE-GO Intake air temperature 20°C (68’FI

. Coolant temperature 80°C (176°F) 2,000 - 3,000

200 - 400

140 - 180

Iscl, I%2 _ +a (8)

ISC3, ISC4 10-30

+2 HAC - E2 2,900 - 4,200

*I 7M-GE only

*2 7M-GTE only