lock TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 6 of 346

IN-4 Identification Information,

INTRODUCTION - General Repair Instructions

IDENTIFICATION INFORMATION

ENGINE SERIAL NUMBER

The engine serial number is stamped on the right side of the

cylinder block.

Seal Lock Adhesive

GENERAL REPAIR INSTRUCTIONS

1. Use fender, seat and floor covers to keep the vehicle clean

and prevent damage.

2.

3. During disassembly, keep parts in order to facilitate

reassembly.

Observe the following:

(a)

(b) Before performing electrical work, disconnect ‘the

negative (-1 cable from the battery terminal.

If it is necessary to disconnect the battery for inspec-

tion or repair, always disconnect the cable from the

negative (-) terminal which is grounded to the vehi-

cle body.

(c) To prevent damage to the battery terminal post,

loosen the terminal nut and raise the cable straight up

without twisting or prying it.

(d) Clean the battery terminal posts and cable terminals

with a shop rag. Do not scrape them with a file or

other abrasive object.

(e)

(f) Install the cable terminal to the battery post with the

nut loose, and tighten the nut after installation. Do

not use a hammer to tap the terminal onto the post.

Be sure the cover for the positive (+I terminal is pro-

perly in place.

4.

5. Check hose and wiring connectors to make sure that they

are secure and correct.

Non-reusable parts

(a)’ Always replace cotter pins gaskets, O-rings, oil seals,

etc. with new ones.

(b) Non-reusable parts are indicated in the component

illustrations by the “+” symbol.

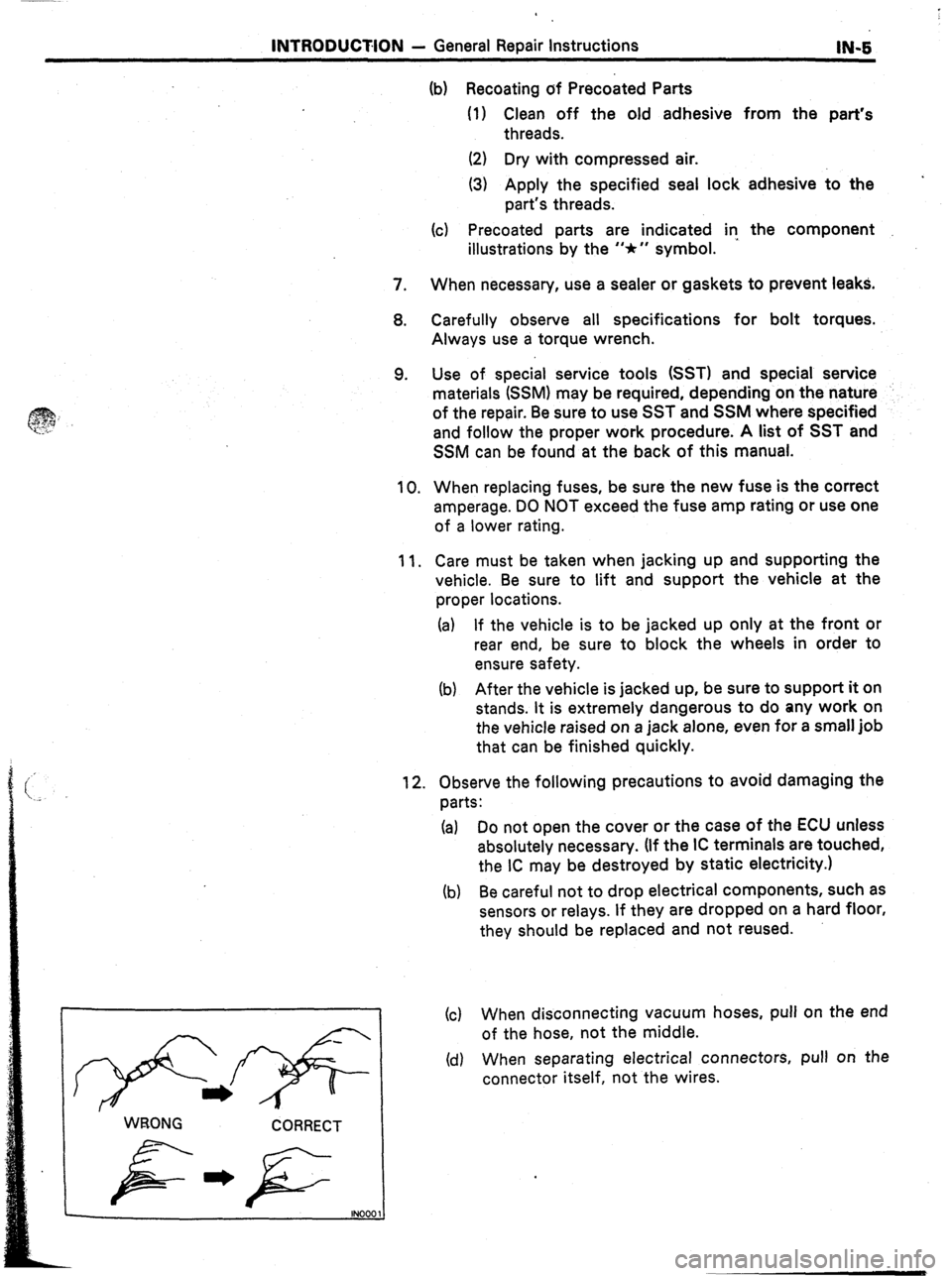

6. Precoated Parts

Precoated parts are the bolts, nuts, etc. which are coated

with a seal lock adhesive at the factory.

(a) If a precoated part is retightened, loosened or caused

to move in any way, it must be recoated with the

specified adhesive.

Page 7 of 346

INTRODUCTION - General Repair Instructions

IN-S

(b) Recoating of Precoated Parts

(1) Clean off the old adhesive from the part’s

threads.

(2) Dry with compressed air.

(3) Apply the specified seal lock adhesive to the

part’s threads.

(c) Precoated parts are indicated in the component

illustrations by the “*” symbol.

7. When necessary, use a sealer or gaskets to prevent leaks.

8. Carefully observe all specifications for bolt torques.

Always use a torque wrench.

9. Use of special service tools (SST) and special service

materials (SSM) may be required, depending on the nature

of the repair. Be sure to use SST and SSM where specified

and follow the proper work procedure. A list of SST and

SSM can be found at the back of this manual.

10. When replacing fuses, be sure the new fuse is the correct

amperage. DO NOT exceed the fuse amp rating or use one

of a lower rating.

11. Care must be taken when jacking up and supporting the

vehicle. Be sure to lift and support the vehicle at the

proper locations.

(a) If the vehicle is to be jacked up only at the front or

rear end, be sure to block the wheels in order to

ensure safety.

(b) After the vehicle is jacked up, be sure to support it on

stands. It is extremely dangerous to do any work on

the vehicle raised on a jack alone, even for a small job

that can be finished quickly.

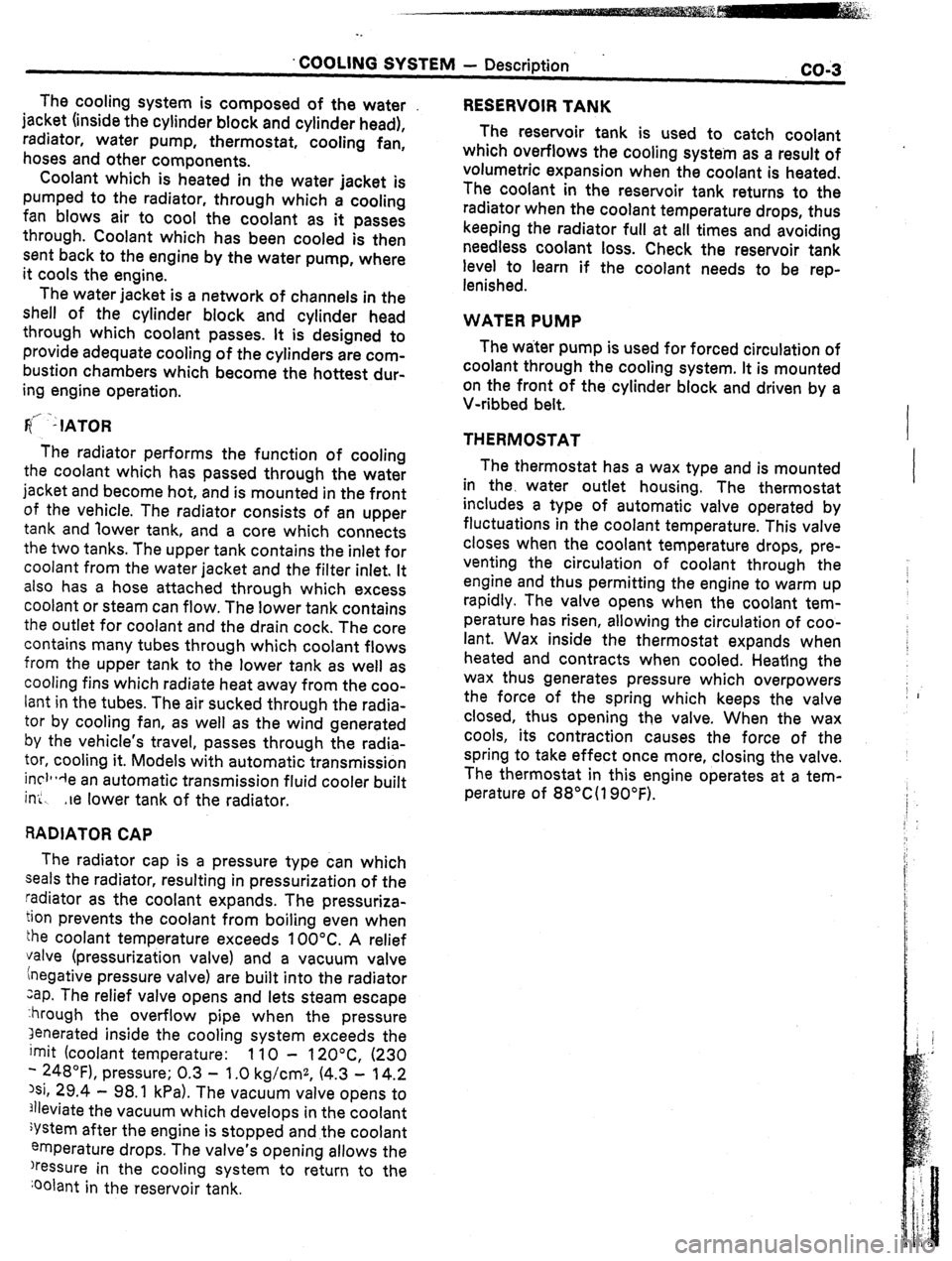

WRONG

CORRECT 12. Observe the following precautions to avoid damaging the

parts:

(a) Do not open the cover or the case of the ECU unless

absolutely necessary. (If the IC terminals are touched,

the IC may be destroyed by static electricity.)

(b) Be careful not to drop electrical components, such as

sensors or relays. If they are dropped on a hard floor,

they should be replaced and not reused.

(c) When disconnecting vacuum hoses, pull on the end

of the hose, not the middle.

(d) When separating electrical connectors, pull on the

connector itself, not the wires.

Page 23 of 346

. COOLING SYSTEM - Description

co;3

RESERVOIR TANK

The reservoir tank is used to catch coolant

which overflows the cooling systein as a result of

volumetric expansion when the coolant is heated.

The coolant in the reservoir tank returns to the

radiator when the coolant temperature drops, thus

keeping the radiator full at all times and avoiding

needless coolant loss. Check the reservoir tank

level to learn if the coolant needs to be rep-

lenished.

WATER PUMP

The water pump is used for forced circulation of

coolant through the cooling system. It is mounted

on the front of the cylinder block and driven by a

V-ribbed belt,

THERMOSTAT I The cooling system is composed of the water

jacket (inside the cylinder block and cylinder head),

radiator, water pump, thermostat, cooling fan,

hoses and other components.

Coolant which is heated in the water

jacket is

pumped to the radiator, through which a cooling

fan blows air to cool the coolant as it passes

through. Coolant which has been cooled is then

sent back to the engine by the water pump, where

it cools the engine.

The water jacket is a network of channels in the

shell of the cylinder block and cylinder head

through which coolant passes. It is designed to

provide adequate cooling of the cylinders are com-

bustion chambers which become the hottest dur-

ing engine operation.

F(/ “ IATOR

The radiator performs the function of cooling

the coolant which has passed through the water

jacket and become hot, and is mounted in the front

of the vehicle. The radiator consists of an upper

tank and ‘lower tank, and a core which connects

the two tanks. The upper tank contains the inlet for

coolant from the water jacket and the filter inlet. It

also has a hose attached through which excess

coolant or steam can flow. The lower tank contains

the outlet for coolant and the drain cock. The core

contains many tubes through which coolant flows

from the upper tank to the lower tank as well as

cooling fins which radiate heat away from the coo-

lant in the tubes. The air sucked through the radia-

tor by cooling fan, as well as the wind generated

by the vehicle’s travel, passes through the radia-

tor, cooling it. Models with automatic transmission

incrl*-le an automatic transmission fluid cooler built

in:.

.le lower tank of the radiator.

RADIATOR CAP

The radiator cap is a pressure type can which

seals the radiator, resulting in pressurization of the

radiator as the coolant expands. The pressuriza-

tion prevents the coolant from boiling even when

the coolant temperature exceeds 100°C. A relief

valve (pressurization valve) and a vacuum valve

(negative pressure valve) are built into the radiator

zap. The relief valve opens and lets steam escape

:hrough the overflow pipe when the pressure

3enerated inside the cooling system exceeds the

imit (coolant temperature:

110 - 1 20°C, (230

- 248”F), pressure; 0.3 - 1 .O kg/cmz, (4.3 - 14.2

)si, 29.4 - 98.1 kPa). The vacuum valve opens to

3ljeviate the vacuum which develops in the coolant

system after the engine is stopped and the coolant

emperature drops. The valve’s opening allows the

)ressure in the cooling system to return to the

Qclant in the reservoir tank. The thermostat has a wax type and is mounted

in the. water outlet housing. The thermostat

includes a type of automatic valve operated by

fluctuations in the coolant temperature. This valve

closes when the coolant temperature drops, pre-

venting the circulation of coolant through the

engine and thus permitting the engine to warm up

rapidly. The valve opens when the coolant tem-

perature has risen, allowing the circulation of coo-

lant. Wax inside the thermostat expands when

heated and contracts when cooled. Heating the

wax thus generates pressure which overpowers

the force of the spring which keeps the valve

closed, thus opening the valve. When the wax

cools, its contraction causes the force of the

spring to take effect once more, closing the valve.

The thermostat in this engine operates at a tem-

perature of 88”C(19O”F).

I

I

Page 24 of 346

co-4 CQOLING SYSTEM - Troubleshootmg

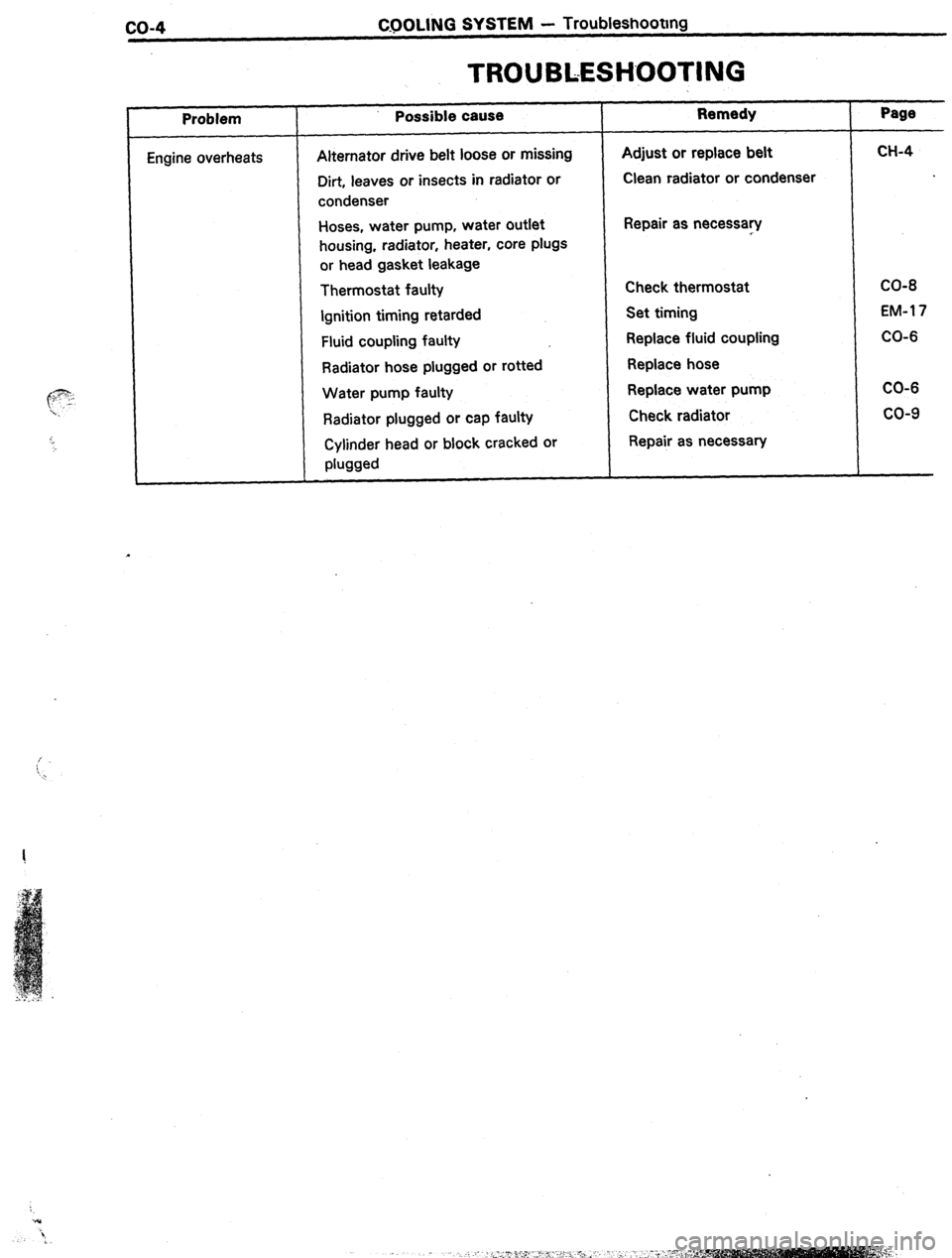

TROUBLESHOOTING

, Problem

Engine overheats Possible cause

Alternator drive belt loose or missing

Dirt, leaves or insects in radiator or

condenser

Hoses, water pump, water outlet

housing, radiator, heater, core plugs

or head gasket leakage

Thermostat faulty

Ignition timing

retarded

Fluid coupling faulty

Radiator hose plugged or rotted

Water pump faulty

Radiator plugged or cap faulty

Cylinder head or block cracked or

phwd Remedy

Adjust or replace belt

Clean radiator or condenser

Repair as necessary

Check thermostat

Set timing

Replace fluid coupling

Replace hose

Replace water pump

Check radiator

Repair as necessary Page

CH-4

CO-8

EM-l 7

CO-6

CO-6

co-9

Page 25 of 346

COOLING SYSTEM i Check and Replacement of Engine Coolant

co-5

._

CHECK AND REPLACEMENT OF

ENGINE COOLANT

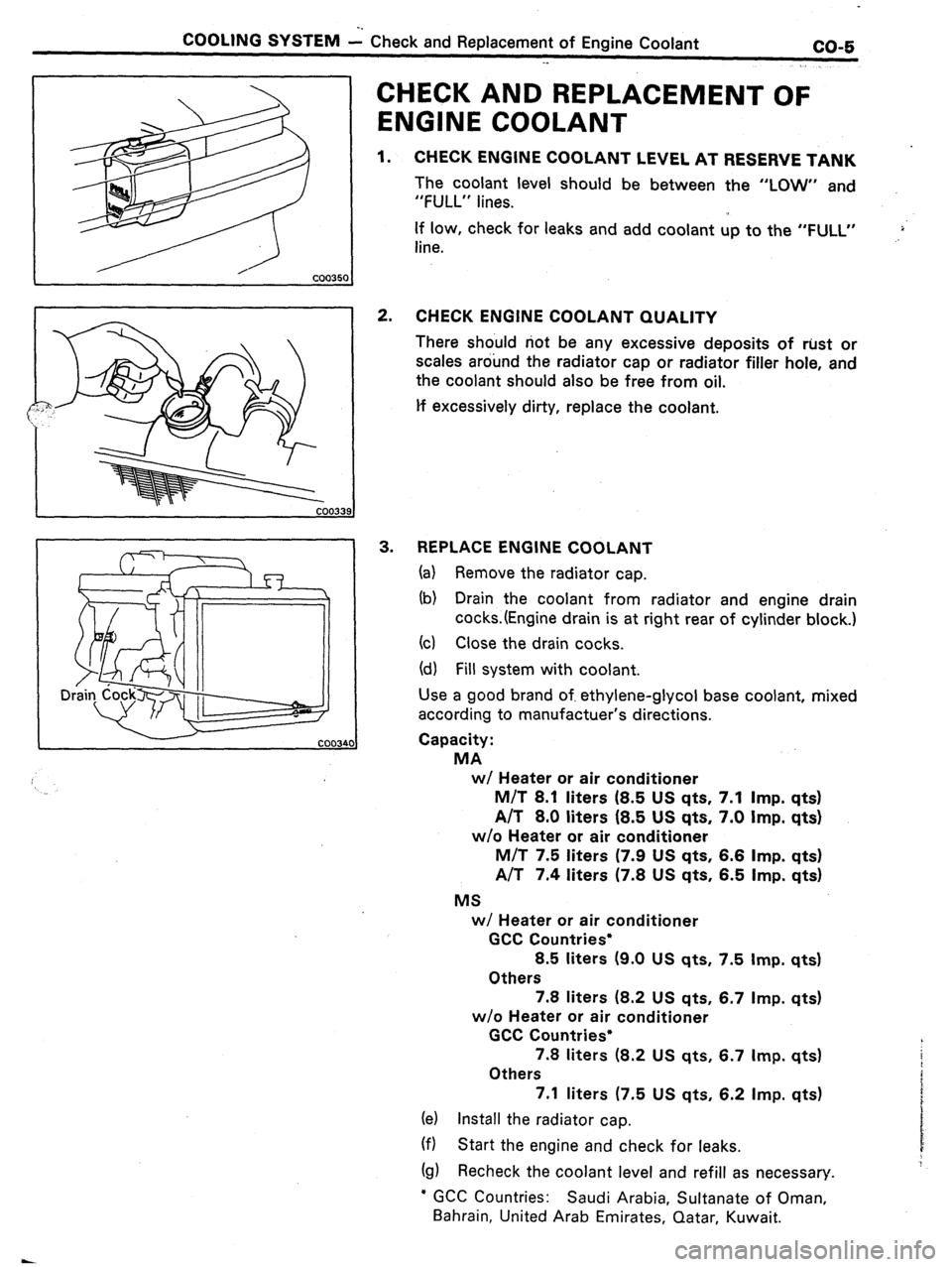

1. CHECK ENGINE COOLANT LEVEL AT RESERVE TANK

The coolant level should be between the “LOW” and

“FULL” lines.

If low, check for leaks and add coolant up to the “FULL”

line. .,>‘

2. CHECK ENGINE COOLANT QUALITY

There should not be any excessive deposits of rust or

scales around the radiator cap or radiator filler hole, and

the coolant should also be free from oil.

lf excessively dirty, replace the coolant.

3. REPLACE ENGINE COOLANT

(a) Remove the radiator cap.

(b) Drain the coolant from radiator and engine drain

cocks.(Engine drain is at right rear of cylinder block.)

(cl Close the drain cocks.

(d) Fill system with coolant.

Use a good brand of. ethylene-glycol base coolant, mixed

according to manufactuer’s directions.

Capacity:

MA

w/ Heater or air conditioner

M/T 8.1 liters (8.5 US qts. 7.1 Imp. qts)

A/T 8.0 liters (8.5 US qts, 7.0 Imp. qts)

w/o Heater or air conditioner

M/T 7.5 liters (7.9 US qts, 6.6

Imp. qts)

A/T 7.4 liters (7.8 US qts, 6.5 Imp. qts)

MS

w/ Heater or air conditioner

GCC Countries*

8.5 liters (9.0 US qts, 7.5 Imp. qts)

Others

7.8 liters (8.2 US qts, 6.7 Imp. qts)

w/o Heater or air conditioner

GCC Countries*

7.8 liters (8.2 US qts, 6.7 Imp. qts)

Others

7.1 liters (7.5 US qts, 6.2 Imp. qts)

(e) Install the radiator cap.

(f) Start the engine and check for leaks.

(g) Recheck the coolant level and refill as necessary.

l GCC Countries: Saudi Arabia, Sultanate of Oman,

Bahrain, United Arab Emirates, Qatar, Kuwait.

Page 29 of 346

COOLING SYSTEM - Radiator

-,... ~‘e:,.,,’ _,

CLEANING OF RADIATOR _ ---w..w- -...,.

Using water or steam cleaner, remove mud and dirt from

the radiator core.

CAUTION: If using’ high-pressure, type cleaner, be

careful not to deform the fins of the radiator core. Keep

a distance of more than 40 - 50 cm (15.75 - 19.69 in.)

between the radiator core and cleaner nozzle when

the cleaner nozzle pressure is 30 - 35 kg/cm2 (427 -

1

498 psi, 2,942 - 3,432 kPa1.

I lNSPECTlON.OF RADIATOR

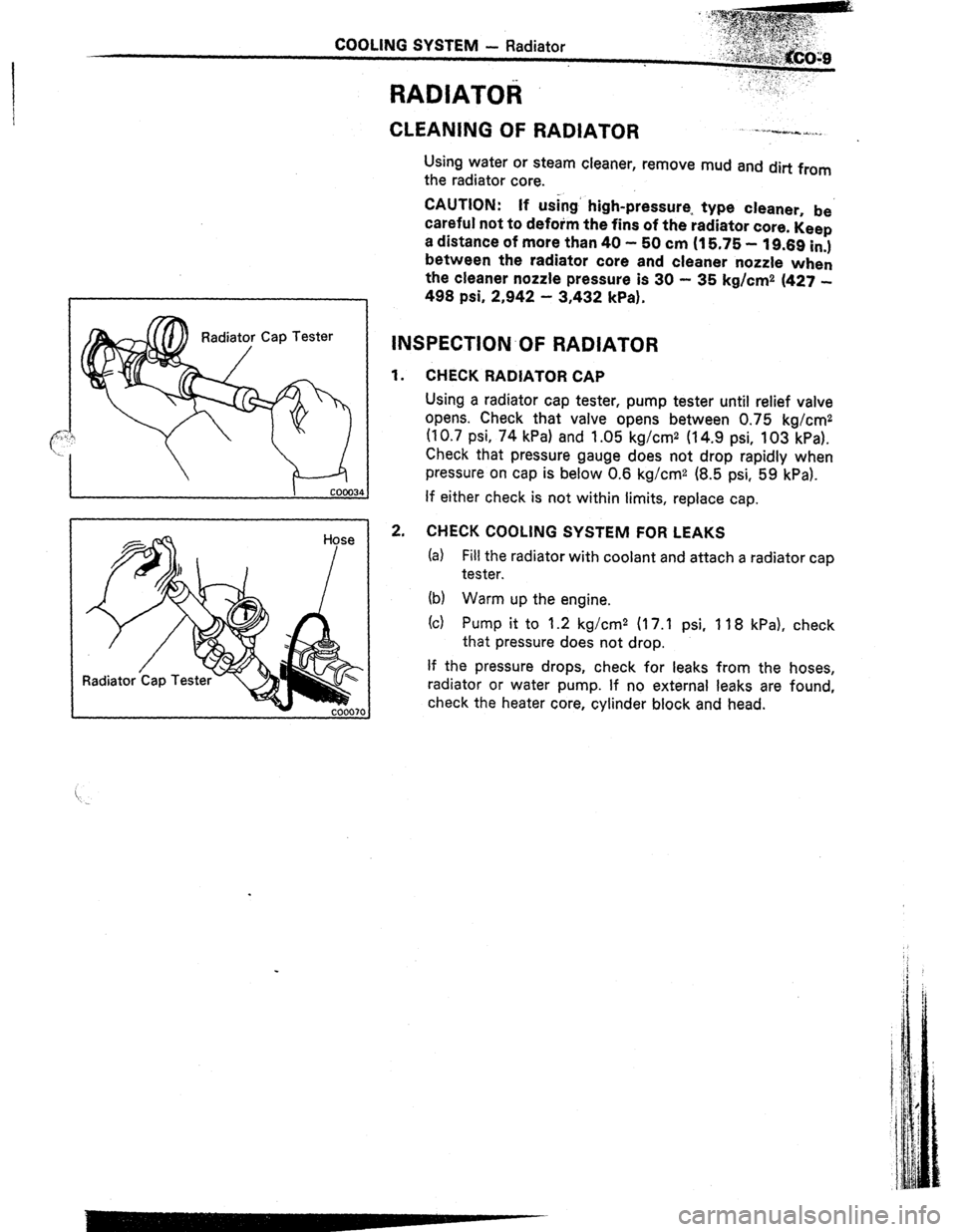

t 1. CHECK RADIATOR CAP

Using a radiator cap tester, pump tester until relief valve

opens. Check that valve opens between 0.75 kg/cm2

(10.7 psi, 74 kPa) and 1.05 kg/cm2 (14.9 psi, 103 kPa).

Check that pressure gauge does not drop rapidly when

pressure on cap is below 0.6 kg/cm2 (8.5 psi, 59 kPa).

!J If either check is not within limits, replace cap.

1 2. CHECK COOLING SYSTEM FOR LEAKS

(a) Fill the radiator with coolant and attach a radiator cap

tester.

(b) Warm up the engine.

(c) Pump it to 1.2 kg/cm2 117.1 psi, 118 kPa), check

that pressure does not drop.

If the pressure drops, check for leaks from the hoses,

radiator or water pump. If no external

leaks are found,

check the heater core, cylinder block

and head.

Page 33 of 346

COGLING SYSTEM - Radiator’ .

__ co- 1.3::

.-

1 SST

r

i

Tank Plate

Punch I

I

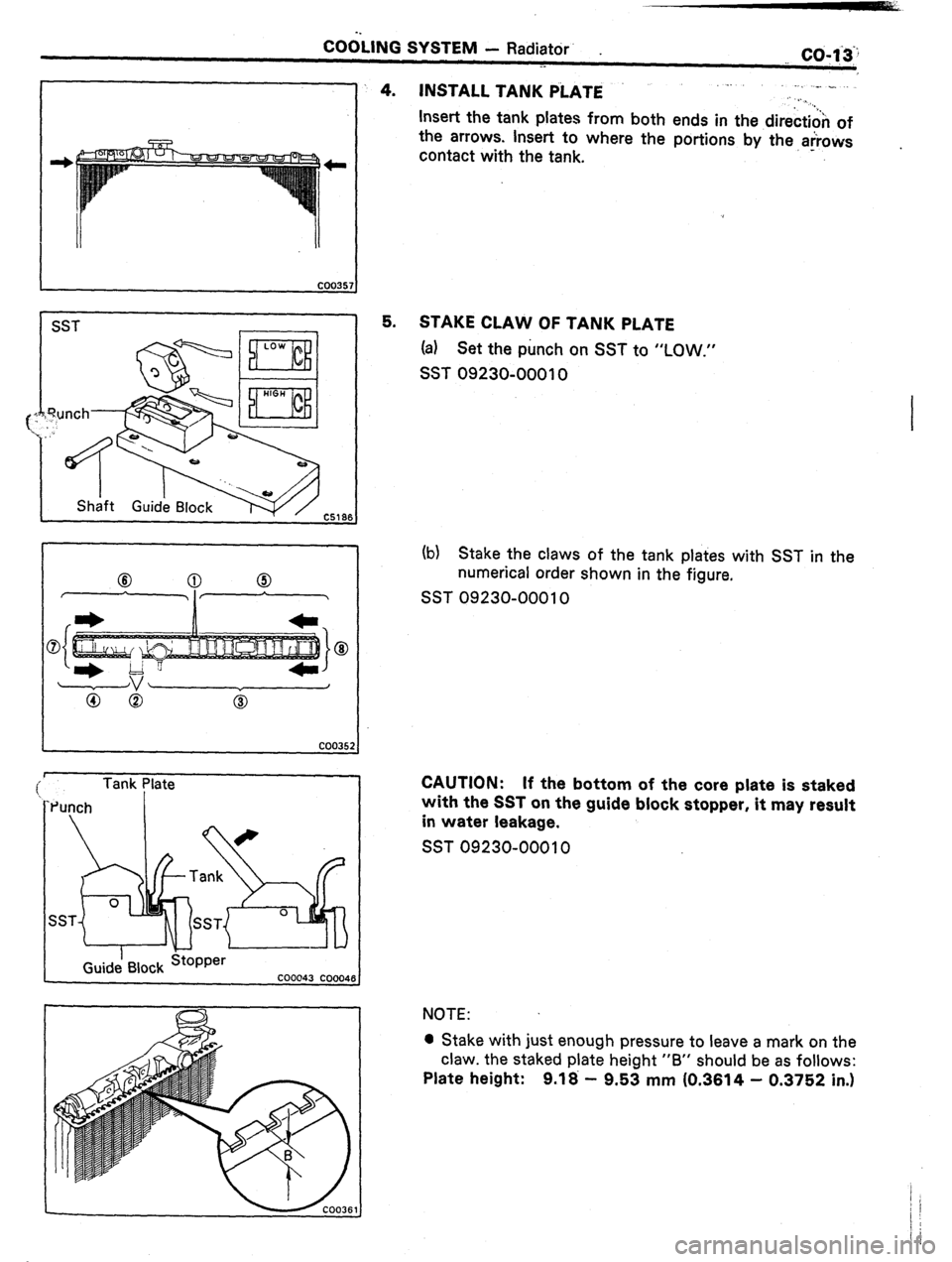

4. INSTALL TANK PiATE .

., _. .,

. ._

Insert the tank plates from both ends in the direction of

the arrows. Insert to where the portions by the arrows

contact with the tank. - .

5. STAKE CLAW OF TANK PLATE

(a) Set the punch on SST to “LOW.”

SST 09230-00010

(b) Stake the claws of the tank plates with SST in the

numerical order shown in the figure.

SST 09230-00010

CAUTION: If the bottom of the core plate is staked

with the SST on the guide block stopper, it may result

in water leakage.

SST 09230-00010

NOTE:

l Stake with just enough pressure to leave a mark on the

claw. the staked plate height “B” should be as follows:

Plate height: 9.18 - 9.53 mm (0.3614 - 0.3752 in.)

Page 43 of 346

EFI SYSTEM - inspection Precautions

FI-9

FM066

FlOO95 FlOO91

ELECTRONIC CONTROL SYSTEM

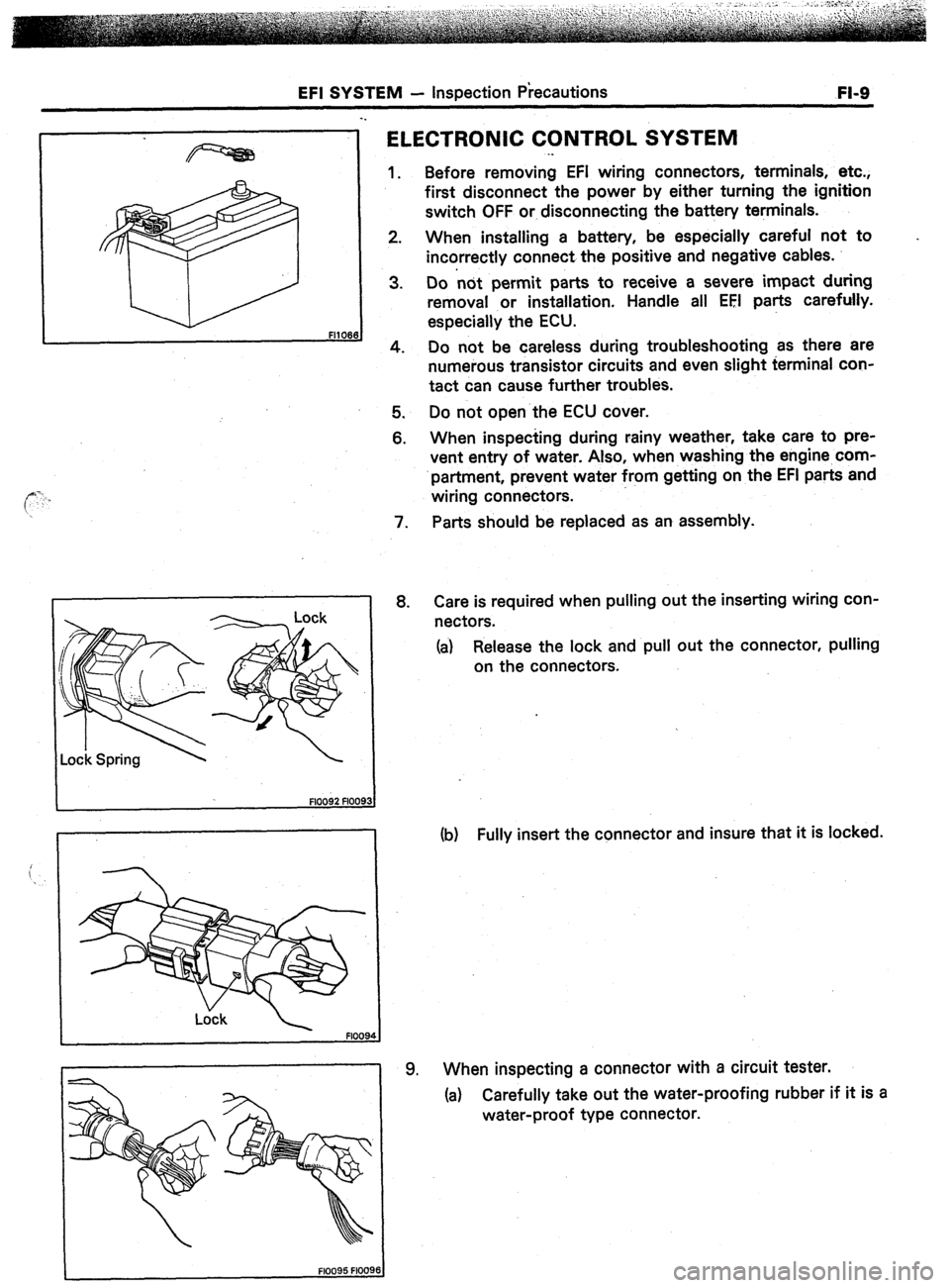

1.

2.

3. Before removing EFI wiring connectors, terminals, etc.,

first disconnect-the power-by either turning the ignition

switch OFF or disconnecting the battery terminals.

When installing a battery, be especially careful not to

incorrectly connect the positive and negative cables.

Do not permit parts to receive a severe impact during

removal or installation. Handle all EEI parts carefully.

especially the ECU.

4. Do not be careless during troubleshooting as there are

numerous transistor circuits and even slight terminal con-

tact can cause further troubles.

5.

6. Do not open the ECU cover.

When inspecting during rainy weather, take care to pre-

vent entry of water. Also, when washing the engine com-

.partment, prevent water from getting on the EFI parts and

wiring connectors.

7. Parts should be replaced as an assembly.

8. Care is required when pulling out the inserting wiring con-

nectors.

(a) Release the lock and pull out the connector, pulling

on the connectors. .

(b) Fully insert the connector and insure that it is locked.

9. When inspecting a connector with a circuit tester.

(a) Carefully take out the water-proofing rubber if it is a

water-proof type connector.

Page 46 of 346

1-12 EFI SYSTEM - Troubleshooting’

FlO48

TROUBLESH~~TI~~G

. .

TROUBLESHOOTING HlhJTS

1. Engine troubles are usually not caused by the EFI system.

When troubleshooting, always first check the condition of

the other systems.

(a) Electronic source

0 Battery

0 Fusible links

0 Fuses

(b) Body ground

(cl Fuel supply

0 Fuel leakage

0 Fuel filter

0 Fuel pump

(d) Ignition system

0 Spark plug

0 High-tension cord

l Distributor (7M-GE) or cam position sensor (7M-

GTE)

0 Igniter and ignition coil

(e) Air induction system

0 Vacuum leaks

(f) Emission control system

0 PCV system

0 EGR system (w/ EGR)

(g) Others

l Ignition timing (ESA system)

0 Idle speed (ISC system)

-r

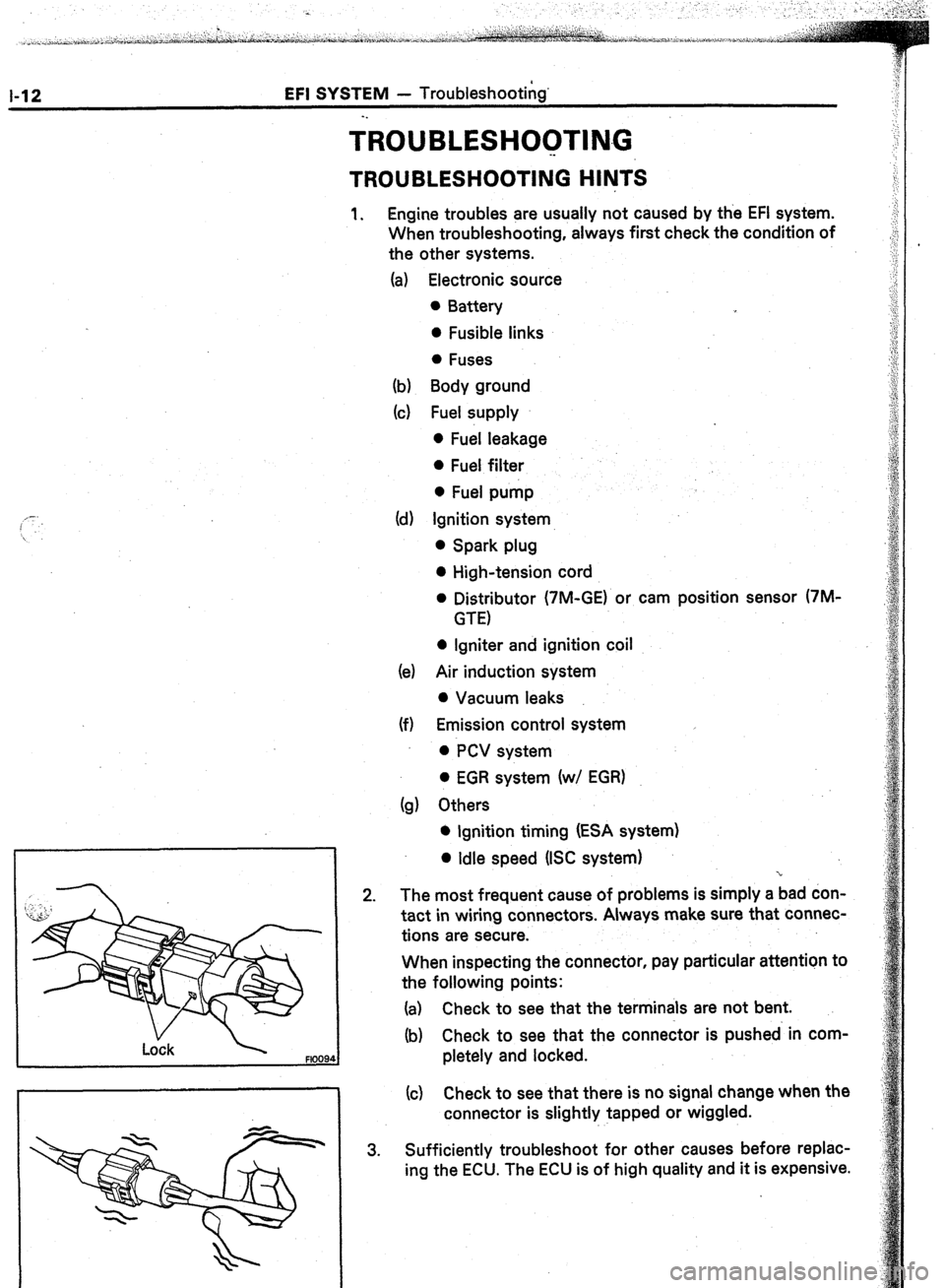

2. The most frequent cause of problems is simply a bad don-

tact in wiring connectors. Always make sure that connec-

tions are secure.

When inspecting the connector, pay particular attention to

the following points:

(a) Check to see that the terminals are not bent.

(b) Check to see that the connector is pushed in com-

pletely and locked.

(c) Check to see that there is no signal change when the

connector is slightly tapped or wiggled.

3. Sufficiently troubleshoot for other causes before replac-

ing the ECU. The ECU is of high quality and it is expensive.

Page 63 of 346

EFI SYSTEM - Diagnosis System FI-29

MS EFI 15iA

LHD

EFI 15A

EFI 15A

R16C

FI26:

CANCELLING OUT DIAGNOSTIC CODE

1.

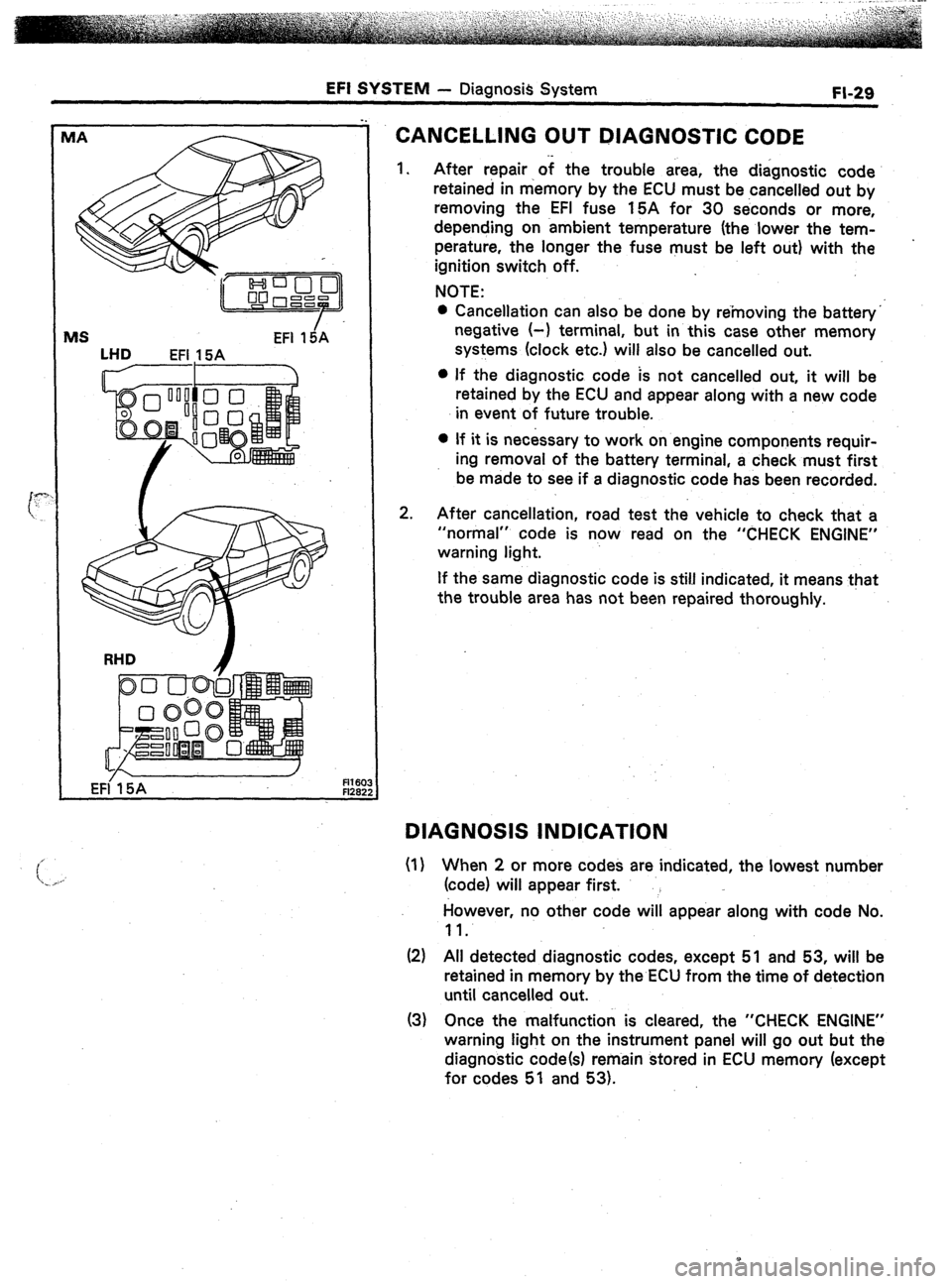

2. After repair of the trouble area, the diagnostic code

retained in memory by the ECU must be cancelled out by

removing the EFI fuse 15A for 30 seconds or more,

depending on ambient temperature (the lower the tem-

perature, the longer the fuse must be left out) with the

ignition switch off.

NOTE:

l Cancellation can also be done by removing the battery”

negative (-1 terminal, but in this case other memory

systems (clock etc.) will also be cancelled out.

l If the diagnostic code is not cancelled out, it will be

retained by the ECU and appear along with a new code

in event of future trouble.

l If it is necessary to work on engine components requir-

ing removal of the battery terminal, a check must first

be made to see if a diagnostic code has been recorded.

After cancellation, road test the vehicle to check that a

“normal” code is now read on the “CHECK ENGINE”

warning light.

If the same diagnostic code is still indicated, it means that

the trouble area has not been repaired thoroughly.

DIAGNOSIS INDICATION

(I) When 2 or more codes are indicated, the lowest number

(code) will appear first.

However, no other code will appear along with code No.

11.

(2) All detected diagnostic codes, except 51 and 53, will be

retained in memory by the ECU from the time of detection

until cancelled out.

(3) Once the malfunction is cleared, the “CHECK ENGINE”

warning light on the instrument panel will go out but the

diagnostic code(s) remain stored in ECU memory (except

for codes 51 and 53).