alternator belt TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 9 of 346

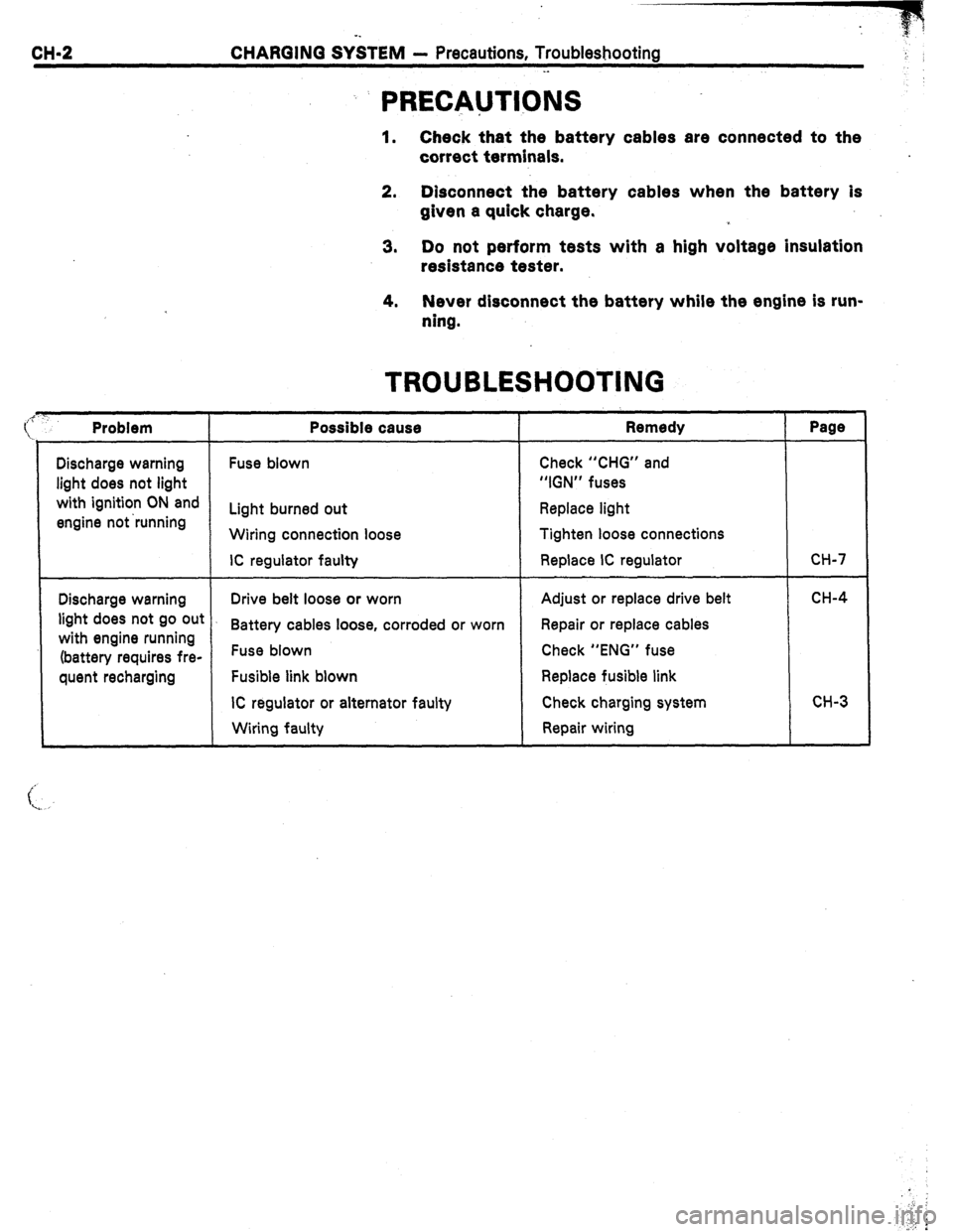

CH-2 CHARGING SY&EM - Precautions, Troubleshooting

._

: PRECAUTIONS

1. Check that the battery cables are connected to the

correct terminals.

2. Disconnect the battery cables when the battery is

given a quick charge.

3. Do not perform tests with a high voltage insulation

resistance tester.

4. Never disconnect the battery while the engine is run-

ning.

Discharge warning

light does not light

with ignition ON and

engine not ‘running

Problem

Discharge warning

light does not go out

with engine running

(battery requires fre-

quent recharging

Possible cause

Fuse blown

Light burned out

Wiring connection loose

IC regulator faulty

TROUBLESHOOTING

Remedy

Check “CHG” and

“IGN” fuses

Replace light

Tighten loose connections

Replace IC regulator

Drive belt loose or worn

Battery cables loose, corroded or worn

Fuse blown

Fusible link blown

IC regulator or alternator faulty

Wiring faulty Adjust or replace drive belt

Repair or replace cables

Check “ENG” fuse

Replace fusible link

Check charging system

Repair wiring

Page

CH-7

CH-4

CH-3

Page 24 of 346

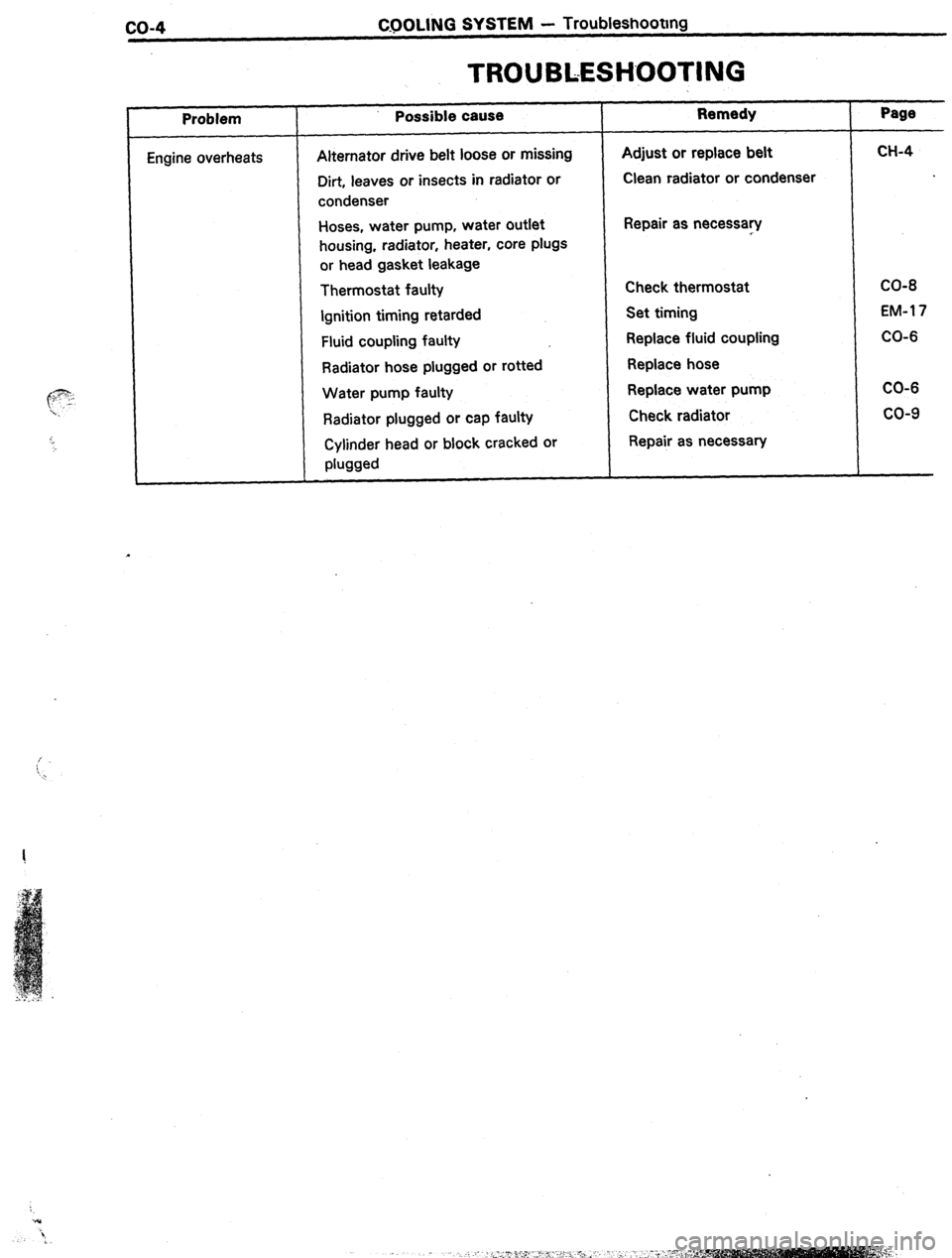

co-4 CQOLING SYSTEM - Troubleshootmg

TROUBLESHOOTING

, Problem

Engine overheats Possible cause

Alternator drive belt loose or missing

Dirt, leaves or insects in radiator or

condenser

Hoses, water pump, water outlet

housing, radiator, heater, core plugs

or head gasket leakage

Thermostat faulty

Ignition timing

retarded

Fluid coupling faulty

Radiator hose plugged or rotted

Water pump faulty

Radiator plugged or cap faulty

Cylinder head or block cracked or

phwd Remedy

Adjust or replace belt

Clean radiator or condenser

Repair as necessary

Check thermostat

Set timing

Replace fluid coupling

Replace hose

Replace water pump

Check radiator

Repair as necessary Page

CH-4

CO-8

EM-l 7

CO-6

CO-6

co-9

Page 26 of 346

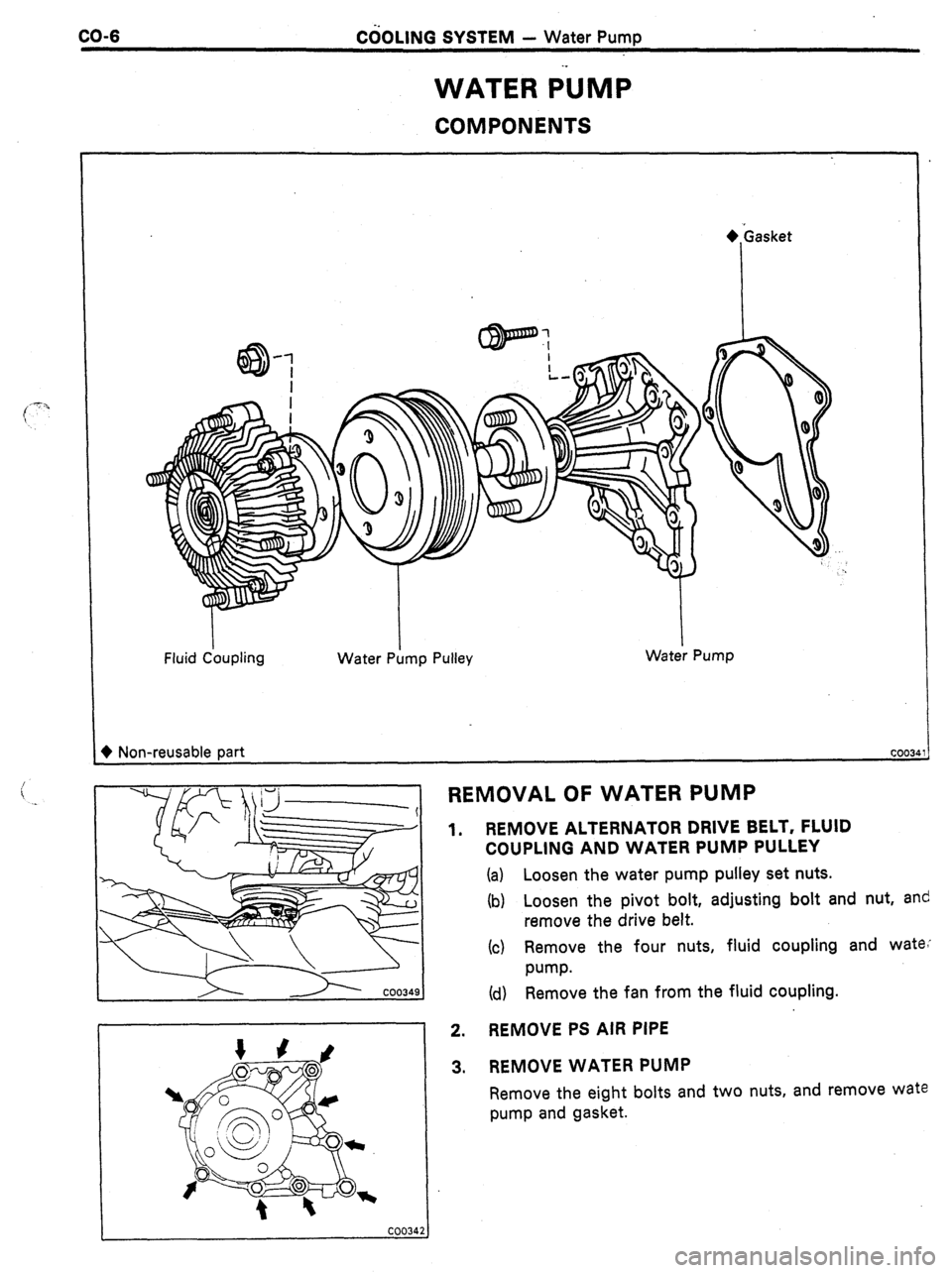

CO-6

C6OLlNG SYSTEM - Water Puma

WATER ilJMP

COMPONENTS

Fluid Ckqling Water P;lmp Pulley Water Pump

+ Non-reusable part COOL3

c REMOVAL OF WATER PUMP ._

1. REMOVE ALTERNATOR DRIVE BELT, FLUID

COUPLING AND WATER PUMP PULLEY

(a) Loosen the water pump pulley set nuts.

(b) Loosen the pivot bolt, adjusting bolt and nut, and

remove the drive belt.

(c) Remove the four nuts, fluid coupling and wate,

w-w.

(d) Remove the fan from the fluid coupling.

2. REMOVE PS AIR PIPE

3. REMOVE WATER PUMP

Remove the eight bolts and two nuts, and remove wate

pump and gasket.

Page 27 of 346

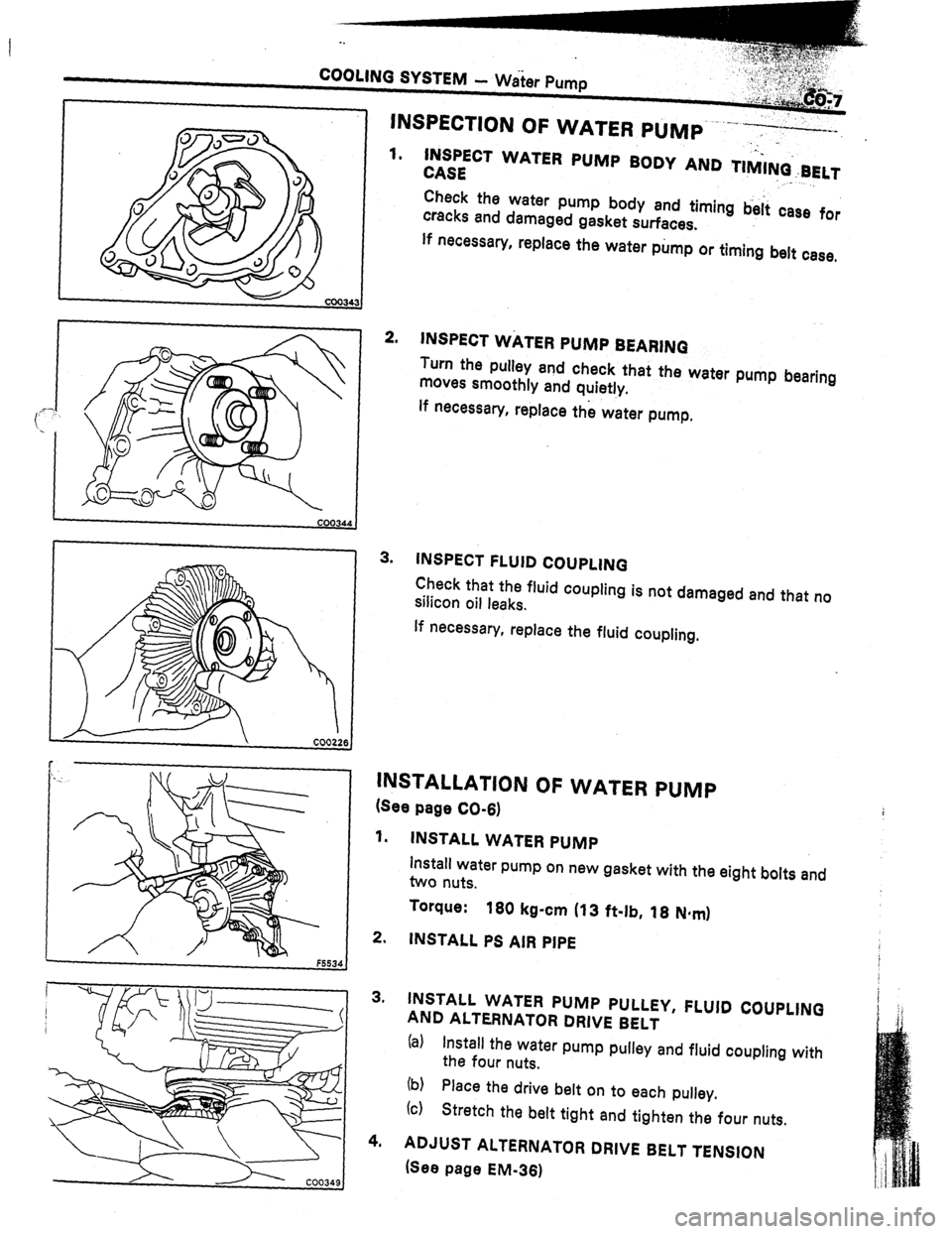

1.

2.

3.

.._ INSPECT WATER PUMP BODY AND TIMI+BELT

CASE ” ._

Check the water pump body and timing b&i case for

cracks and damaged gasket surfaces.

If necessary, replace the water pump or timing belt case,

INSPECT WATER PUMP BEARINQ

Turn the pulley and check that the water pump bearing

moves smoothly and quietly.

lf necessary, replace the water pump,

INSPECT FLUID COUPLING

Check that the fluid coupling is not damaged and that no

silicon oil leaks.

If necessary, replace the fluid coupling.

INSTALLATION OF WATER PUMP

(See page CO-6)

1. INSTALL WATER PUMP

install water pump on new gasket with the eight bolts and

two nuts.

Torque:

160 kg-cm (13 ft-lb, 18 N*mI

2. INSTALL PS AIR PIPE

3. INSTALL WATER PUMP PULLEY, FLUID COUPLING

AND ALTERNATOR DRIVE BELT

(al Install the water pump pulley and fluid coupling with

the four nuts.

(b)

(c) Place the drive belt on to each pulley.

Stretch the belt tight and tighten the four nuts.

4. ADJUST ALTERNATOR DRIVE BELT TENSION

(See page EM-361

Page 190 of 346

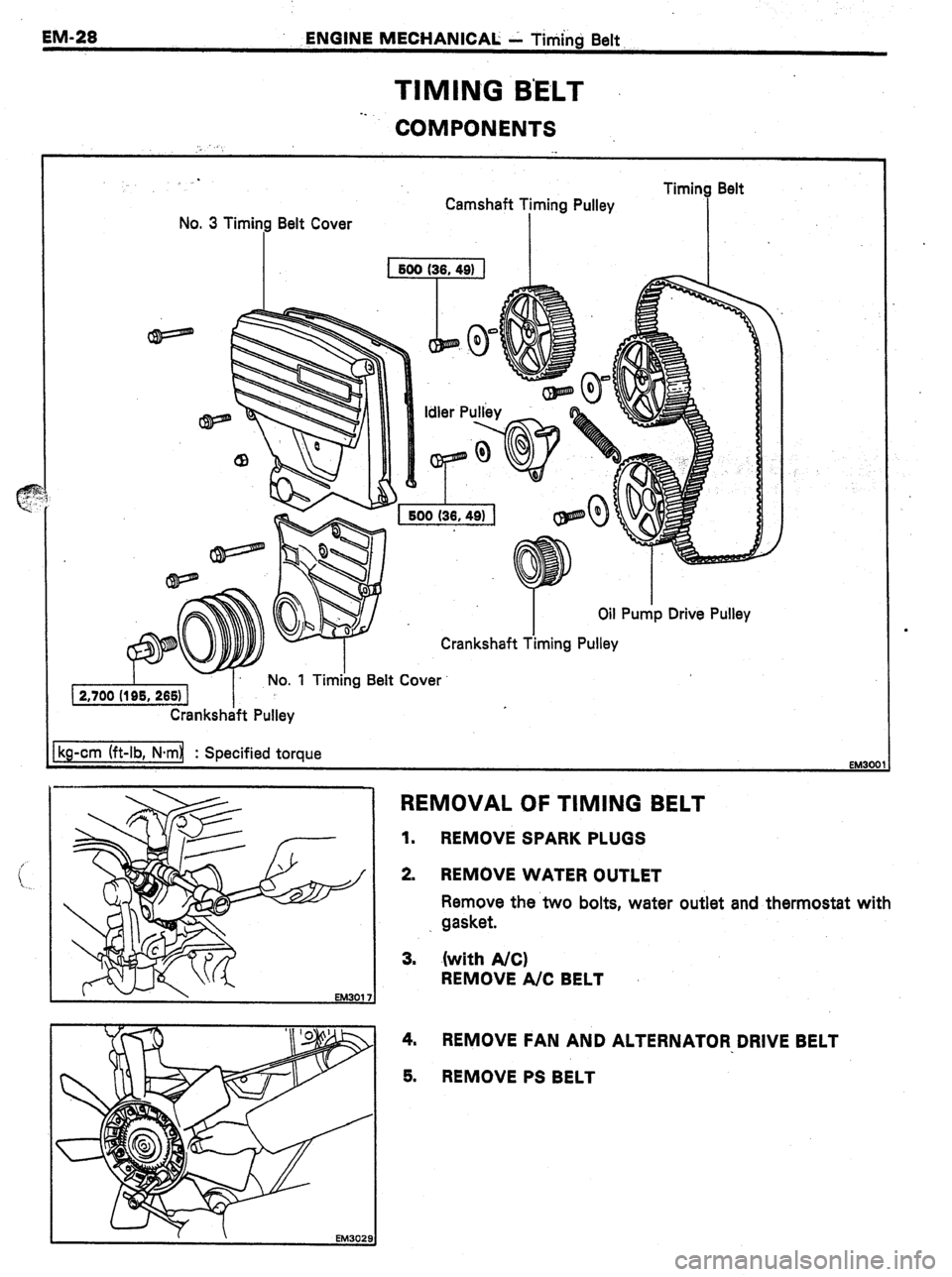

EM-28

ENGINE MECliANICAL - Titiingj Belt.

TIMING B’ELT

-.

COMPONENTS

No. 3 Timing Belt Cover Camshaft Timing Pulley

I I ImIng oen

I

Crankshaft Pulley

kg-cm (ft-lb, N-ml : Specified torque

EM30f 31

REMOVAL OF TIMING BELT

1.

REMOVE SPARK PLUGS

2. REMOVE WATER OUTLET

Remove the two bolts, water outlet and thermostat with

. gasket.

3. .(with A/C)

REMOVE A/C BELT

4. REMOVE FAN AND ALTERNATOR DRIVE BELT

5.

REMOVE PS BELT

Page 198 of 346

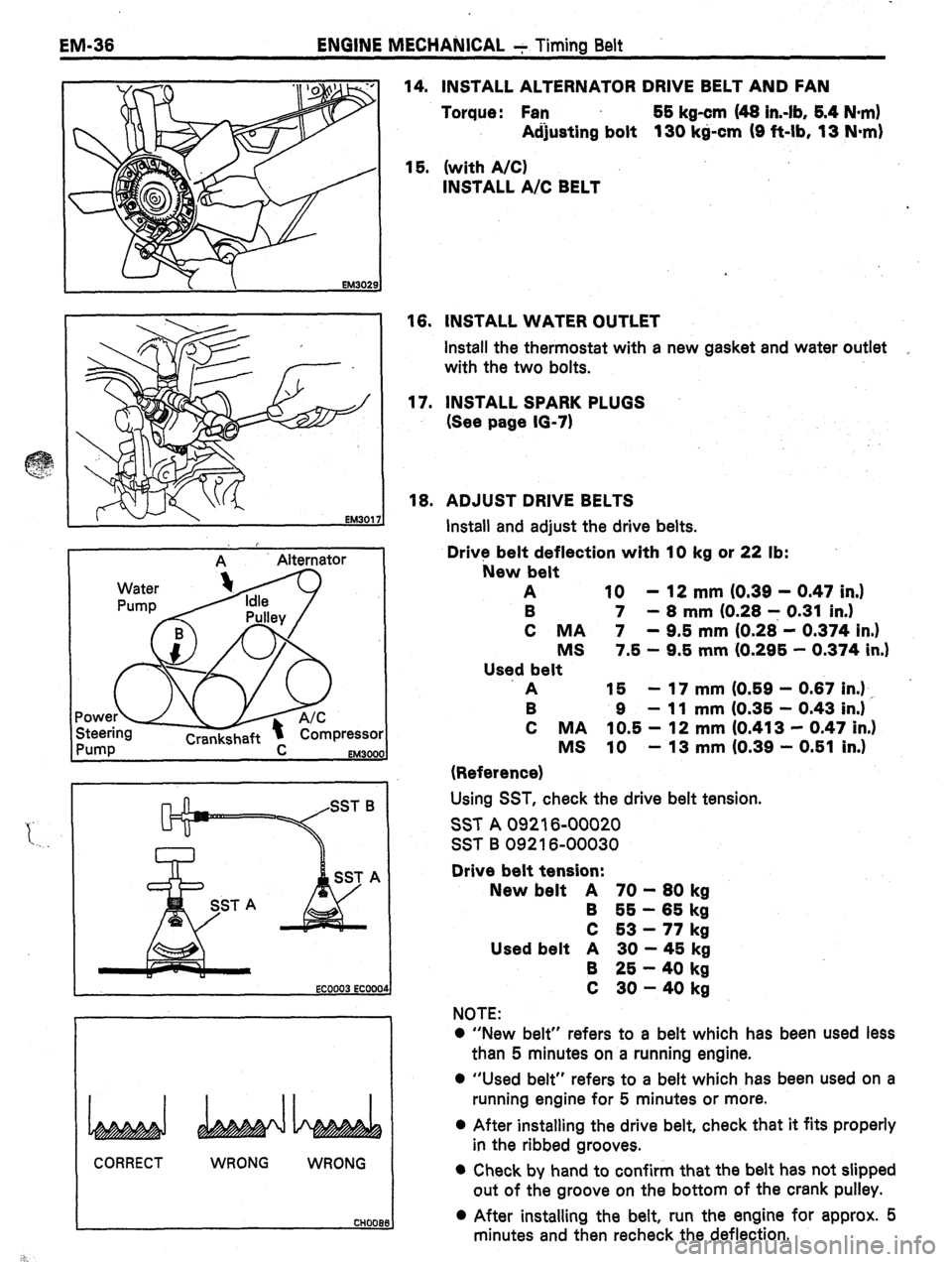

EM-36 ENGINE MECHANICAL - Timinn Belt

EM302

EM301

,

A

Alternator

1

EM3000

CORRECT WRONG

WRONG 14. INSTALL ALTERNATOR DRIVE BELT AND FAN

Torque: Fan 55 kg-cm (48 in.-lb, 6.4 N-m)

Adjusting bolt 130 kg-cm (9 ft-lb, 13 N*m)

15. (with A/C)

INSTALL A/C BELT

16. INSTALL WATER OUTLET

install the thermostat with a new gasket and water outlet

with the two bolts.

17. INSTALL SPARK PLUGS

(See page 10-7)

16. ADJUST DRIVE BELTS

Install and adjust the drive belts.

Drive belt deflection with 10 kg or 22 lb:

New belt

A 10 - 12 mm IO.39 - 0.47 in.)

B 7 - 8 mm (0.28 7 0.31 in.)

C MA 7 - 9.5 mm (0.28 - 0.374 in.)

MS 7.5 - 9.5 mm (0.296 - 0.374 in.1

Used belt

A 15 - 17 mm (0.59 - 0.67 in.1 ,

B 9 - 11 mm (0.35 - 0.43 in.)

C MA 10.5 - 12 mm (0.413 - 0.47 in.)

MS 10 - 13 mm (0.39 - 0.51 in.)

(Reference)

Using SST, check the drive belt tension.

SST A 09216-00020

SST B 09216-00030

Drive belt tension:

New belt A 70 - 80 kg

B 65 - 65 kg

C 53 - 77 kg

Used belt A 30 - 45 kg

B 25 - 40 kg

C 30 - 40 kg

NOTE:

0 “New belt” refers to a belt which has been used less

than 5 minutes on a running engine.

0 “Used belt” refers to a belt which has been used on a

running engine for 5 minutes or more.

0 After installing the drive belt, check that it fits properly

in the ribbed grooves. l Check by hand to confirm that the belt has not slipped

out of the groove on the bottom of the crank pulley.

l After installing the belt, run the engine for approx. 5

minutes and then recheck the deflection.

Page 199 of 346

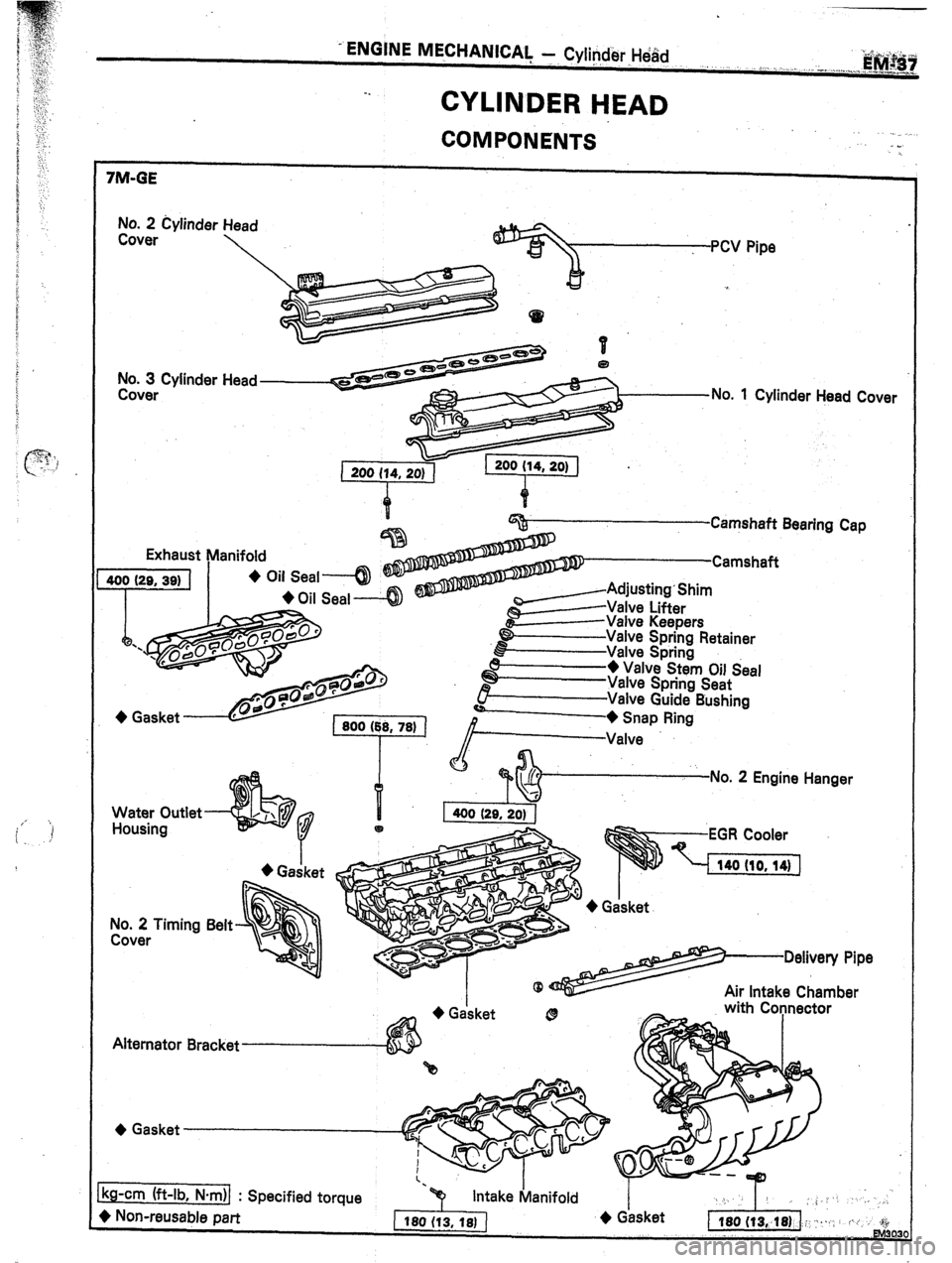

- ENGINE MECHANICAI, - Cylinder H&d

1

-.

CYLINDER HEAD

COMPONENTS _

7M-GE

No. 2 Cylinder

Cover

No. 3 Cylinder

Cover Head

PCV Pipe

-No. 1 Cylinder Head

Cover

q--Camshaft Bearing

Water Outlet

Housing

No. 2 Timing Belt

Cover , ’ @&-No. 2 Engine Hanger

II 1

400 (29. 20) 1

Air Intake Chamber

Alternator Bracket

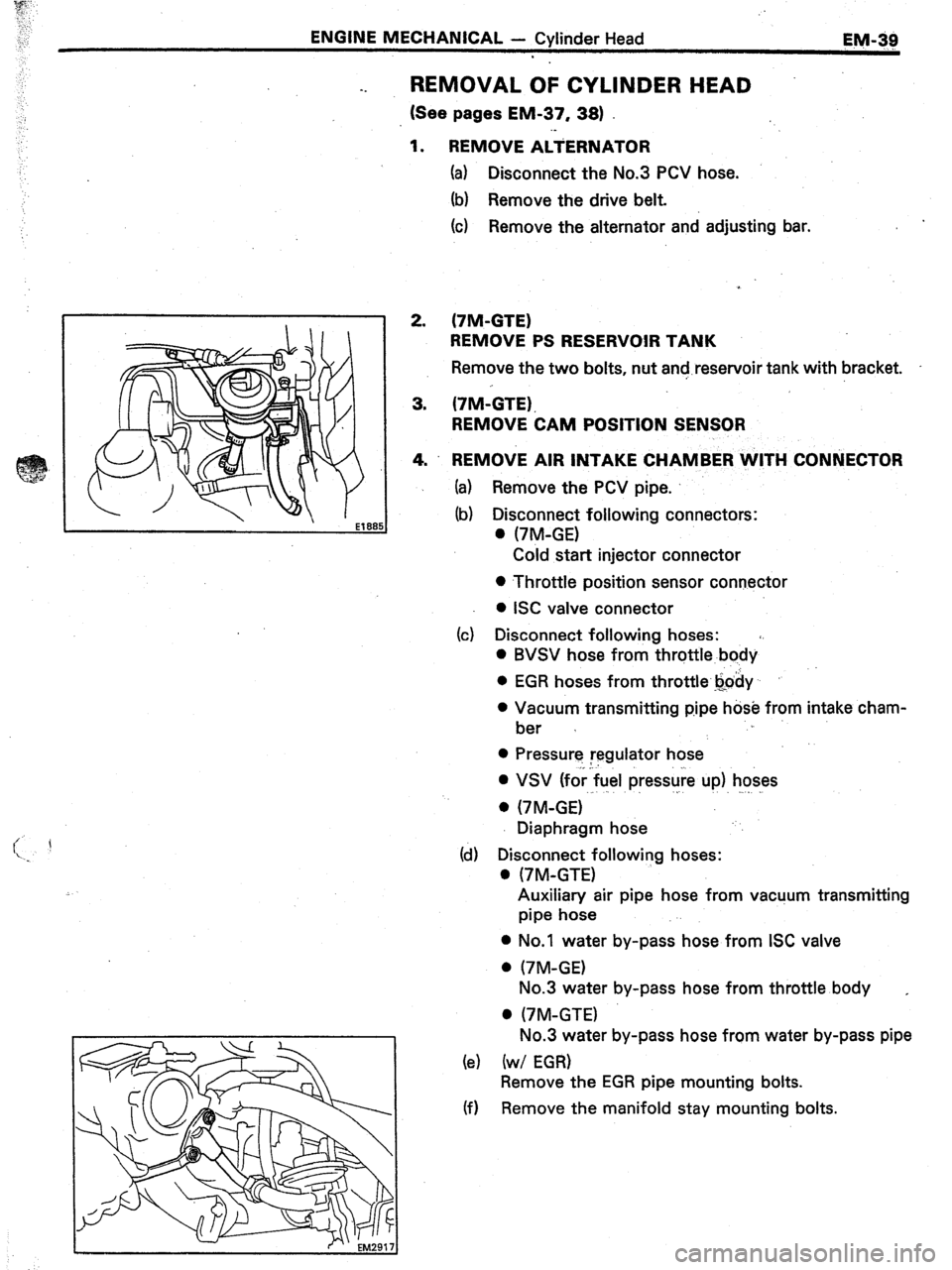

Page 201 of 346

ENGINE MECHANICAL - Cylinder Head

EM-&j

REMOVAL OF CYLINDER HEAD

1. (See pages EM-37, 38)

REMOVE AiiERNATOR

(a) Disconnect the No.3 PCV hose.

(b) Remove the drive belt.

(c) Remove the alternator and adjusting bar.

2.

3.

4. (7M-GTE)

REMOVE PS RESERVOIR TANK

Remove the two bolts, nut and, reservoir tank with bracket.

(‘IM-GTE),

REMOVE CAM POSITION SENSOR

REMOVE AIR INTAKE CHAMBER WITH CONNECTOR

(a) Remove the PCV pipe.

(b) Disconnect following connectors:

. (7M-GE)

Cold start injector connector

l Throttle position sensor connector

l ISC valve connector

(c) Disconnect following hoses: aI

l BVSV hose from throttle body

l EGR hoses from throttle.boby

l Vacuum transmitting p.ipe hose from intake cham-

ber

0 Pressure regulator hose

;, I

l VSV (for fuel pressure up) &es

. (7 M-GE)

Diaphragm hose

(d) Disconnect following hoses:

-

0 (7M-GTE)

Auxiliary air pipe hose from vacuum transmitting

pipe hose

l No.1 water by-pass hose from ISC valve

. (7M-GE)

No.3 water by-pass hose from throttle body ,

0 (-/M-GTE)

No.3 water by-pass hose from water by-pass pipe

(e) (w/ EGR)

Remove the EGR pipe mounting bolts.

(f) Remove the manifold stay mounting bolts.

Page 220 of 346

EM-58

ENGINE MECHANICAL - Cylinder Head

-.

(w/o EGR)

0 install.-the intake manifold four nuts and seven

bolts.

l Torque the bolts and nuts.

Torque :

180 kg-cm (13 ft-lb, 18 N.mI

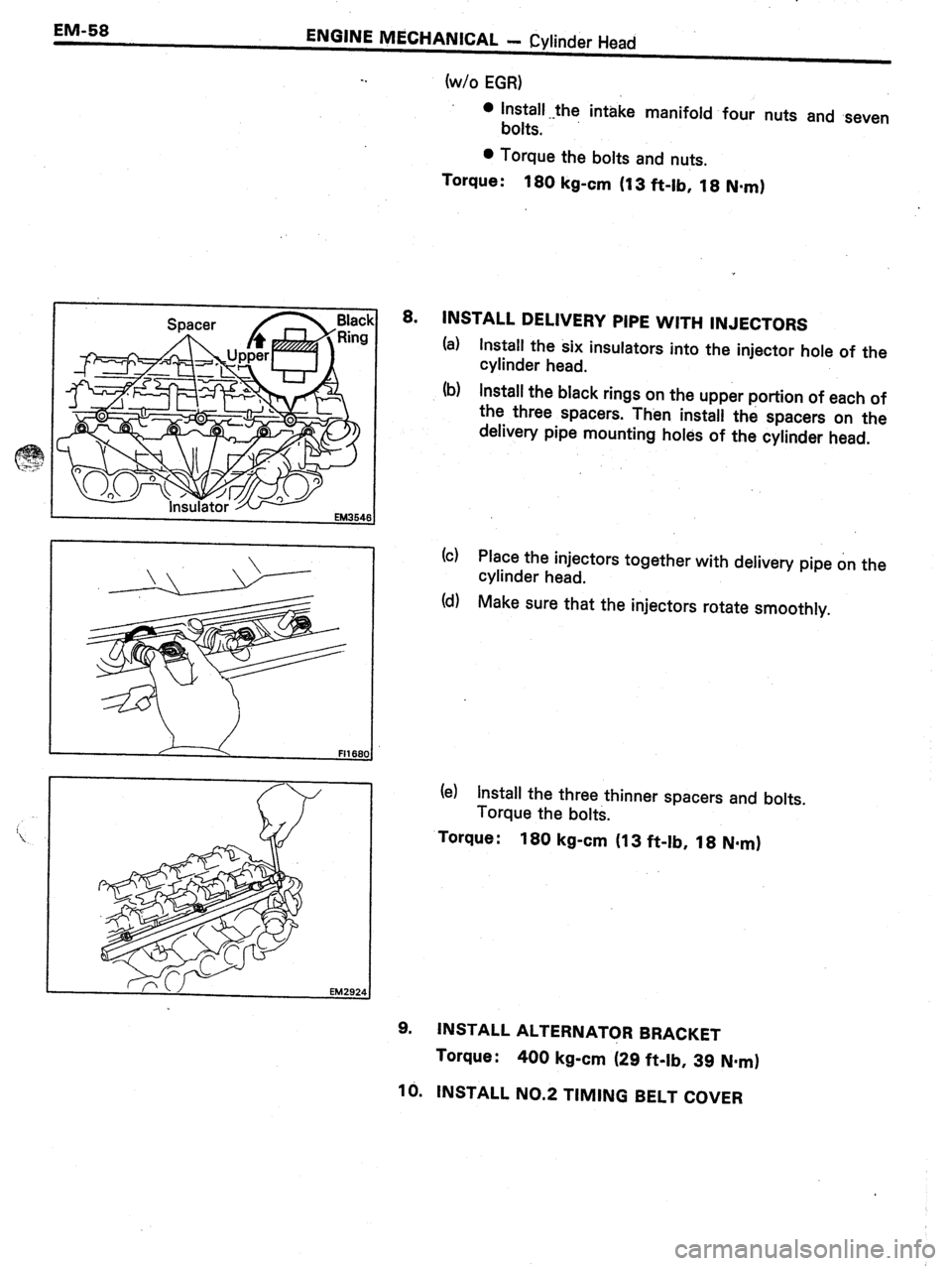

8.

INSTALL DELIVERY PIPE WITH INJECTORS

(a)

Install the six insulators into the injector hole of the

cylinder head.

(b) Install the black rings on the upper portion of each of

the three spacers. Then install the spacers on the

delivery pipe mounting holes of the cylinder head.

(c) Place the injectors together with delivery pipe on the

cylinder head.

(d) Make sure that the injectors rotate smoothly.

(e) Install the three thinner spacers and bolts.

Torque the bolts.

Torque :

180 kg-cm (13 ft-lb, 18 N*m)

9.

INSTALL ALTERNATOR BRACKET

Torque :

400 kg-cm (29 ft-lb, 39 N.rnI

16. INSTALL NO.2 TIMING BELT COVER

Page 226 of 346

-.

,y. ,. P > .: (i) install the EGR

pipe mounting bolts.

:i

(k) Install the manifold ‘stay mounting bolt.

(I) Connect following hoses:

. 47M-GE)

No.3 water by-pass hose to throttle body

(‘IM-GTE)

0 Auxiliary air pipe hose to vacuum transmitting pipe ’

l No.1 water by-pass hose to ISC valve .

(m) Connect following hoses: .,

. (7M-GE)

Diaphragm hose

0 VSWfor fuel. pressure up)hoses

l Pressure regulator hose

0 EGR hoses to throttle body and vacuum transmit-

ting pipe.

0 Vacuum transmitting pipe hose to intake chamber

-I

0 BVSV hose to throttle body

(r-r) Connect following wires:

0 ISC valve connector

0 Throttle position sensor connector

0 (‘/M-GE)

Cold start injector connector.

(01 Install the PCV pipe.

16. (‘IM-GTE)

INSTALL CAM POSITION SENSOR

(See steps 1, 2 on page 10-26)

17. (7M-GTE)

INSTALL PS RESERVOIR TANK

Install the PS reservoir tank with bracket.

18. INSTALL ALTERNATOR AND ADJUSTING BAR

(a) Install the alternator and adjusting bar.

(b) Install the drive belt.

(See page EM-361

(c) Connect the No.3 PCV pipe.