maintenance TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 41 of 346

EFI SYSTEM

- Precautions, Inspection Precautions

FI-7

PRECAUTIONS

._

1. Before working on the fuel system, disconnect the

negative terminal from the battery.

NOTE: Any diagnosis code retained by the computer will

be erased when the battery terminal is removed.

Therefore, if necessary, read the diagnosis before

removimg the battery terminal.

2. Do not smoke or work near an open flame when work-

ing on the fuel system.

3. Keep gasoline off rubber or leather parts.

INSPECTION PRECAUTl.ONS

MAINTENANCE PRECAUTIONS

1. INSURE CORRECT ENGINE TUNE-UP

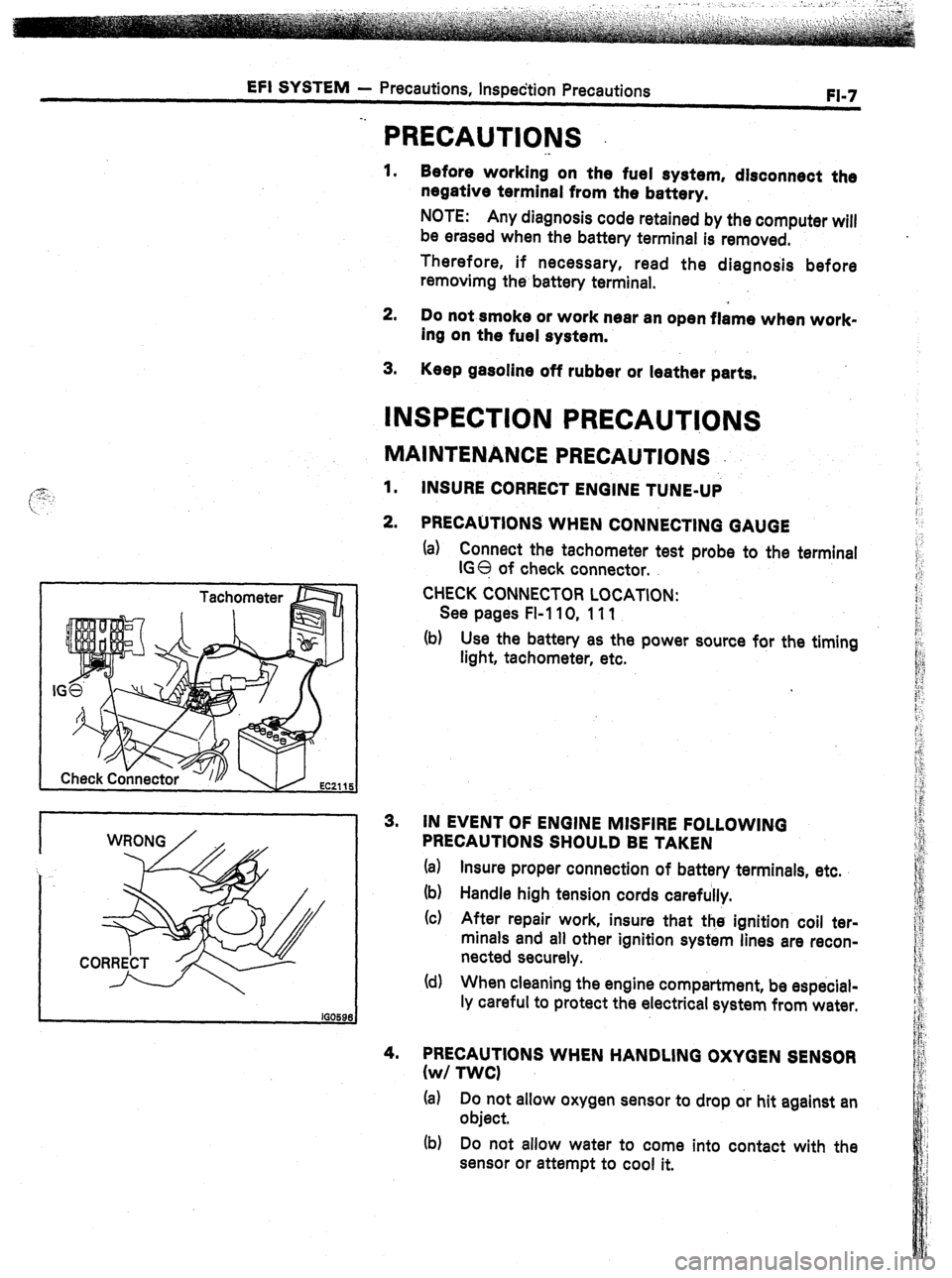

2. PRECAUTIONS WHEN CONNECTING GAUGE

(a) Connect the tachometer test probe to the terminal

IGO of check connector.

CHECK CONNECTOR LOCATION:

See pages FI-110, 111

(b) Use the battery as the power source for the timing

light, tachometer, etc.

3. IN EVENT OF ENGINE MISFIRE FOLLOWING

PRECAUTIONS SHOULD BE TAKEN

(a) Insure proper connection of battery terminals, etc.

(b) Handle high tension cords carefully.

(c) After repair work, insure that the ignition coil ter-

minals and all other ignition system lines are recon-

nected securely.

(d) When cleaning the engine compartment, be especial-

ly careful to protect the electrical system from water.

4. PRECAUTIONS WHEN HANDLING OXYGEN SENSOR

(w/ TWCI

(a) Do not allow oxygen sensor to drop or hit against an

object.

(b) Do not allow water to come into contact with the

sensor or attempt to cool it.

Page 45 of 346

EFI SYSTEM

- inspection Precautions

FI-11

I CORRECT i

Gro

Q * Delivery

Ring pipe

*

Black Ring

Delivew

Pipe -

O-Ring

-Grommet

3.

4.

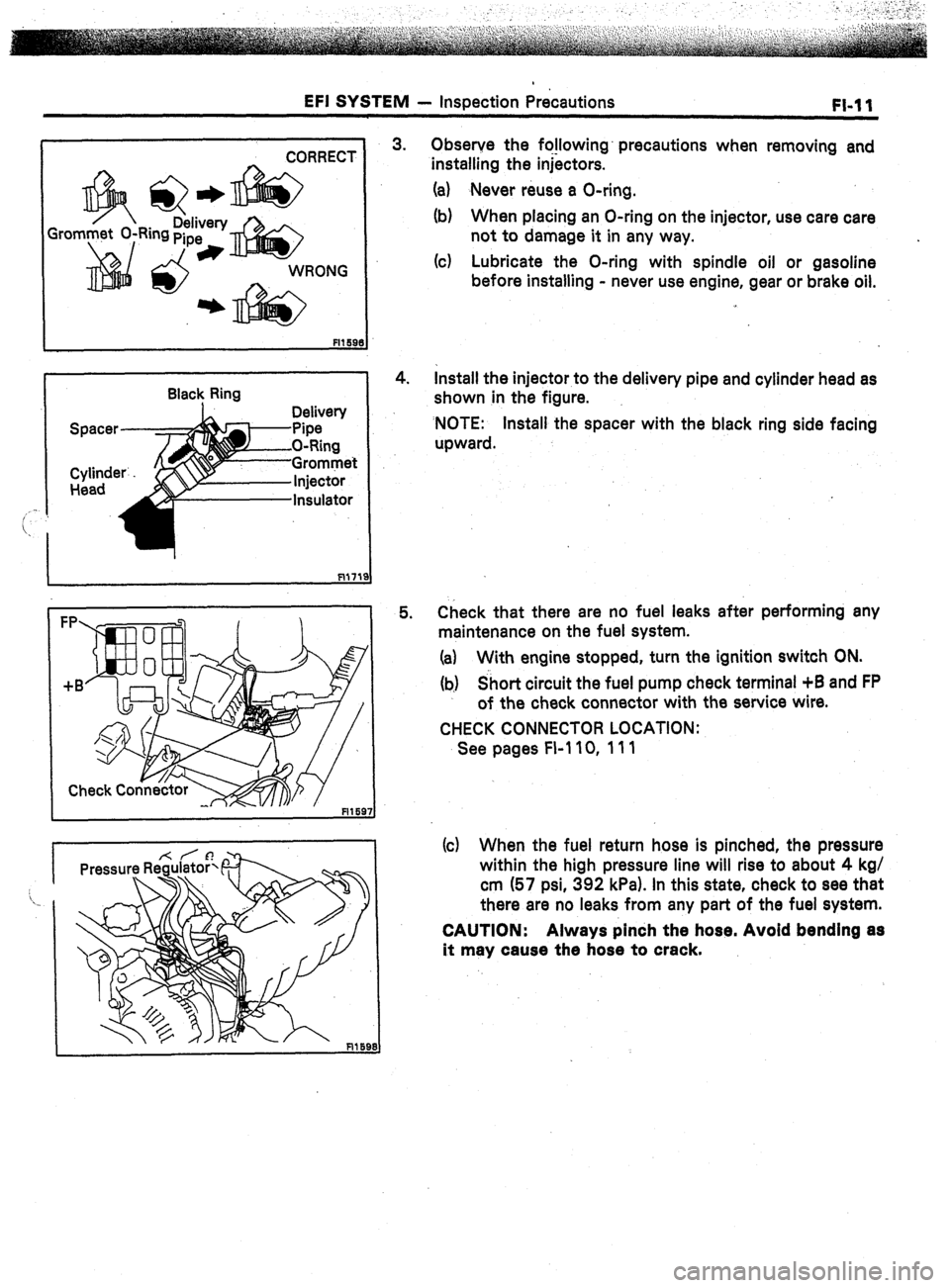

5. Observe the fo!lowing’ precautions when removing and

installing the injectors.

(a) Never reuse a O-ring.

(b) When placing an O-ring on the injector, use care care

not to damage it in any way.

(c) Lubricate the O-ring with spindle oil or gasoline

before installing - never use engine, gear or brake oil.

Install the injector to the delivery pipe and cylinder head as

shown in the figure.

‘NOTE: Install the spacer with the black ring side facing

upward.

Check that there are no fuel leaks after performing any

maintenance on the fuel system.

(a) With engine stopped, turn the ignition switch ON.

(b) Short circuit the fuel pump check terminal +B and FP

of the check connector with the service wire.

CHECK CONNECTOR LOCATION:

See pages FI-110, 111

(c) When the fuel return hose is pinched, the pressure

within the high pressure line will rise to about 4 kg/

cm (57 psi, 392 kPa). In this state, check to see that

there are no leaks from any part of the fuel system.

CAUTION: Always pinch the hose. Avoid bending as

it may cause the hose to crack.