spark plugs replace TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 50 of 346

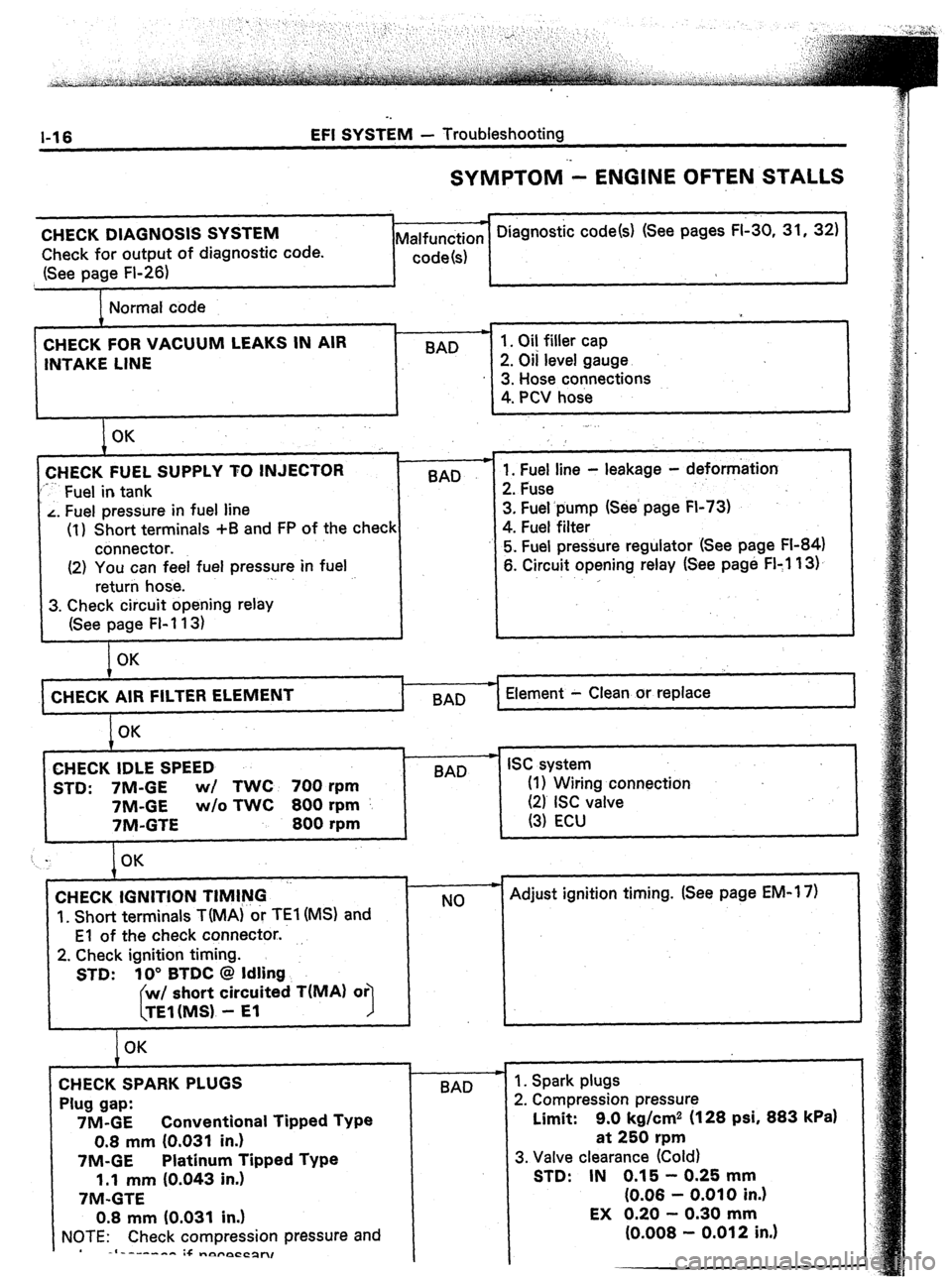

l-16 EFI SYSTEM - Troubleshooting

SYMPTOM - ENGINE OFTEN STALLS

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

(See page Fl-26) * Diagnostic code(s) (See pages FI-30, 31, 32)

Malfunction

code(s)

Normal code

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE BAD 1. Oil filler cap

2. Oil level gauge

3. Hose connections

4. PCV hose

I OK

CHECK FUEL SUPPLY TO INJECTOR

‘*-- Fuel in tank BAD

L. Fuel pressure in fuel line

(1) Short terminals +B and FP of the check

connector.

(2) You can feel fuel pressure in fuel

return hose. .

3. Check circuit opening relay

(See page FI-113) .

1. Fuel line - leakage - deformation

2. Fuse

3. Fuel.pump (See’ page FI-73)

4. Fuel filter

5. Fuel pressure regulator (See page FI-84)

6. Circuit opening relay (See page FI:1 13).

,

OK

CHECK AIR FILTER

I BAD Element - Clean or replace

OK

CHECK IDLE SPEED

STD: 7M-GE wl TWC 700 rpm

7M-GE w/o TWC 800 rpm

7M-GTE 800 rpm

t w

BAD ISC system

(I 1 Wiring connection

(21 ISC valve

(3) ECU

CHECK IGNITION TIMING ‘-

‘I. Short terminals TiMA) or TEl (MS) and

El of the check connector..

2. Check ignition timing.

STD: 10” BTDC @ Idling

short circuited T(MA) or

1

OK

CHECK SPARK PLUGS

Plug gap:

7M-GE Conventional Tipped Type

0.8 mm (0.031 in.)

7M-GE Platinum Tipped Type

1.1 mm (0.043 in.)

7M-GTE

0.8 mm (0.031 in.)

NOTE: Check compression pressure and

-I------- :+ -nyrpCCpn, c

NO

-I-

BAD - Adjust ignition timing. (See page EM-1 7)

1. Spark plugs

2. Compression pressure

Limit: 9.0 kg/cm2 (128 psi, 883

kPa)

at 250 rpm

3. Valve clearance (Cold)

STD: IN 0.15 - 0.25 mm

(0.06 - 0.010 in.)

Page 52 of 346

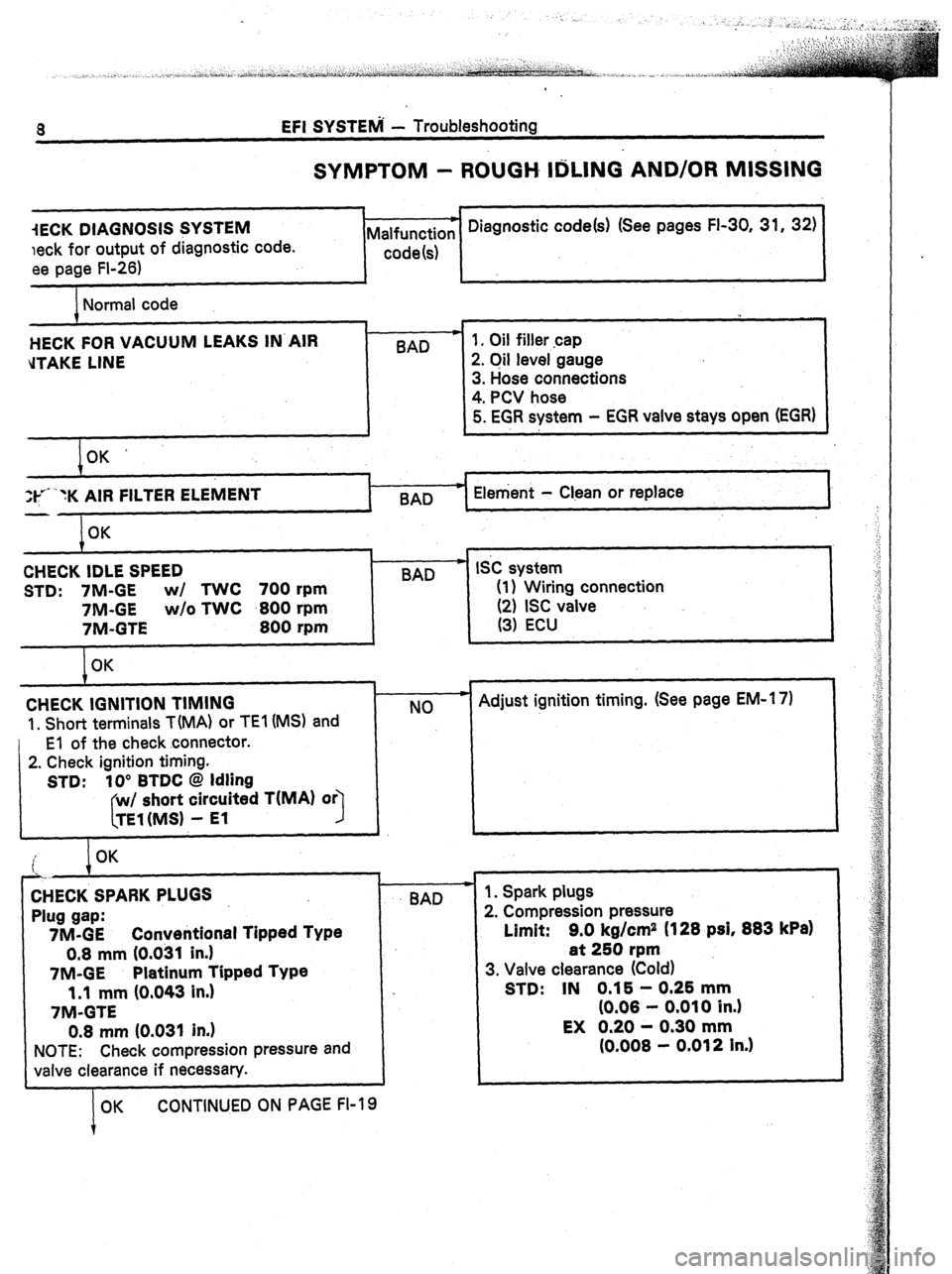

a EFI SYSTEM - Troubleshooting

SYMPTOM - ROUGH IrIiLlNG AND/OR MISSING

iECK DIAGNOSIS SYSTEM

leek for output of diagnostic code.

ee page FI-26)

1 -c Diagnostic code(s) (See pages FI-30, 31, 32)

Malfunction

code(s)

Normal code

HECK FOR VACUUM LEAKS IN’AIR

d-FAKE LINE

I OK’

If* “K AIR FILTER

ELEMENT Element - Clean or replace

I

I 1, Oil filler cap

2. Oil level gauge

3. Hose connections

4. PCV hose

5. EGR system - EGR vaive stays open (EGR)

OK

CHECK IDLE SPEED

STD: 7M-GE w/ TWC 700 rpm

7M-GE w/o TWC 800 rpm

7M-GTE

800 rpm

OK

,

BAD SC system

(1) Wiring connection

(2) ISC valve

(3) ECU

CHECK IGNITION TIMING

1, Short terminals T(MA) or TEI (MS) and

El of the check connector.

2. Check ignition timing.

STD: IO” BTDC @ Idling

w/ short circuited T(MA)

I TEl(MS1 - El NO F Adjust ignition timing. (See page EM-l 7)

i OK

‘.

7

I

CHECK SPARK PLUGS

Plug gap:

7M-GE Converitional Tipped Type

0.8 mm (0.031 in.)

7M-GE Platinum Tipped Type

1.1 mm (0,043 in.)

7M-GTE

0.8 mm (0.031 in.)

NOTE: Check compression pressure and

valve clearance if necessary.

OK CONTINUED ON PAGE FI-19 BAD 1. Spark plugs

2. Compression pressure

Limit: 9.0 kg/cm2 (128 psi, 883

kPa)

at 250 rpm

3. Valve clearance (Cold)

STD: IN 0.15 - 0.25 mm

(0.08 - 0.010 in.)

EX 0.20 - 0.30 mm

(0.008 - 0.012 in.)

Page 165 of 346

ENGINE MECHANICAL -, Description

EM-3

The 7M-GE, 7M-GTE engines are an in-line 6-

cylinder engine with the cylinders numbered l-2-

3-4-5-6 from the front. The crankshaft is sup-

ported by 7 bearings specified by the inside of the

crankcase. These bearings are made of kelmet.

.The crankshaft is integrated with 8 weights

which are cast along with it for balancing. Oil holes

‘are built into the crankshaft for supplying oil to the

connecting rods, pistons and other components.

These engine’s ignition order is l-5-3-6-2-4 .

The cylinder head is made of aluminum alloy, with

a cross flow type intake and exhaust layout and

with pent roof type combustion chambers. The

spark plugs are located in the center of the com-

bustion chambers.

Exhaust and intake valves are equipped with

irregular pitch springs with symmetrical ends

made of oil tempered silicon chrome steel wire

which are capable of following the valves even at

,high engine speeds.

Both the exhaust side cam shaft and the. intake

side cam shaft are driven by a single timing belt.

The cam journal is supported at 7 places between

the valve lifters of each cylinder and on the

cylinder head of front end. Lubrication of the cam

journal and cam is accomplished by oil being sup-

plied through the oiler port in the center of the

camshaft.

Adjustment of the valve clearance is done by

means of an outer shim type system, in which

valve adjusting shims are located above the valve

lifters. This permits replacement of the shims

without removal of the camshafts.

The resin timing belt cover is made in 2 pieces.

Pistons are made of highly temperature-resis-

tant aluminum alloy, and depressions are built into

the piston head to prevent interference with

valves.

Piston pins are the full-floating type, with the

pins fastened to neither the piston boss nor the

connecting rods. Instead, snap rings are fitted on

both ends of the pins, preventing the pins from

falling out.

The No. 1 compression ring is made of stainless

steel and the No. 2 compression ring is made of

cast iron. The oil ring is made of a combination of

stainless steel. The outer diameter of each piston

ring is slightly larger than the diameter of the

piston

and the flexibility of the rings allows them

to hug the cylinder walls when they are mounted

on the piston. Compression rings No. 1 and No. 2

work to prevent the leakage of gas from the

cylinder and the oil ring works to scrape oil off the

cylinder walls to prevent it from entering the com-

bustion chamber.

The cylinder block is made of cast iron. It has 6

cylinders which are approximately 1.6 times the

length of the piston stroke. The top of the cylin- ders is closed off by the cylinder head and the

lower end of the cylinders becomes the crankcase,

in which the crankshaft is installed. In addition,- the

cylinder block contains a water jacket, through

which coolant is pumped to cool the cylinders.

The .oil pan is bolted onto the botiom of the

cylinder block. The oil pan is an oil reservoir made .

of pressed steel sheet. A dividing plate’is included

-inside the oil pan to keep sufficient oil in the bot-

tom of the pan even when the vehicle is tilted. This

dividing plate also prevent5 the oil from making

waves when the vehicle is stopped suddenly and

thus shifting the oil away from the oil pump suc-

tion pipe.

Page 260 of 346

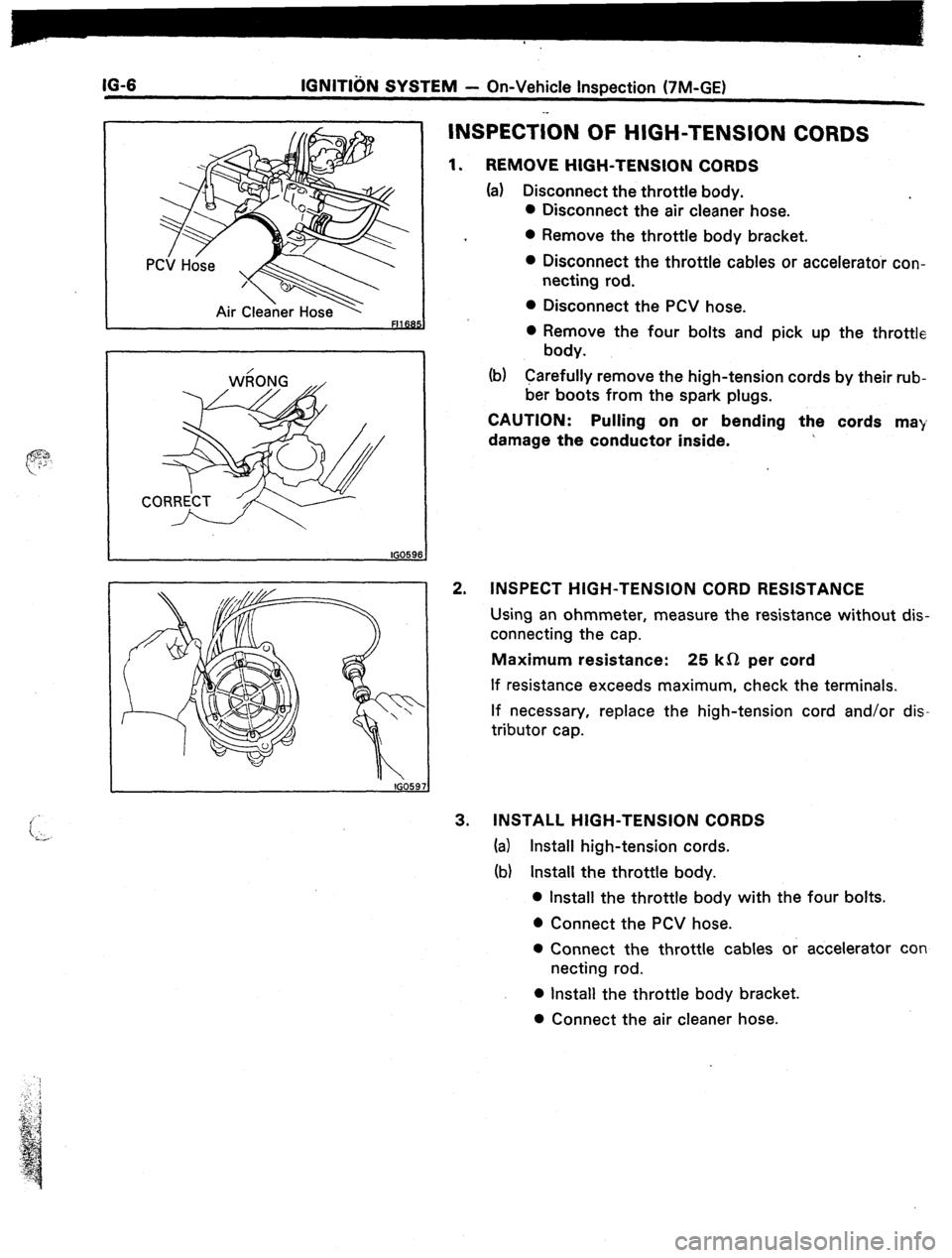

IGNlTliiN SYSTEM - On-Vehicle Inspection (7M-GE)

It059 ‘6

IG059

INSPECTiON OF HIGH-TENSION CORDS

1. REMOVE HIGH-TENSION CORDS

(a) Disconnect the throttle body.

l Disconnect the air cleaner hose.

l Remove the throttle body bracket.

0 Disconnect the throttle cables or accelerator con-

necting rod.

l Disconnect the PCV hose.

0 Remove the four bolts and pick up the throttle

body.

(b) Carefully remove the high-tension cords by their rub-

ber boots from the spark plugs.

CAUTION: Pulling on or bending the cords ma)

damage the conductor inside.

2. INSPECT HIGH-TENSION CORD RESISTANCE

Using an ohmmeter, measure the resistance without dis-

connecting the cap.

Maximum resistance: 25 kS2 per cord

If resistance exceeds maximum, check the terminals.

If necessary, replace the high-tension cord and/or dis-

tributor cap.

3. INSTALL HIGH-TENSION CORDS

(a) Install high-tension cords.

(b) Install the throttle body.

l Install the throttle body with the four bolts.

l Connect the PCV hose.

0 Connect the throttle cables or accelerator con

netting rod.

l Install the throttle body bracket.

0 Connect the air cleaner hose.

Page 261 of 346

IGNITION SYSTEM - On-Vehicle Inspection (‘/M-GE)

IG-lf.

~. .

__

1

8 SST I ffio59

IGOt! i2

INSPECTION OF SPARK PLUGS

(Conventional Tipped Type Spark Plug)

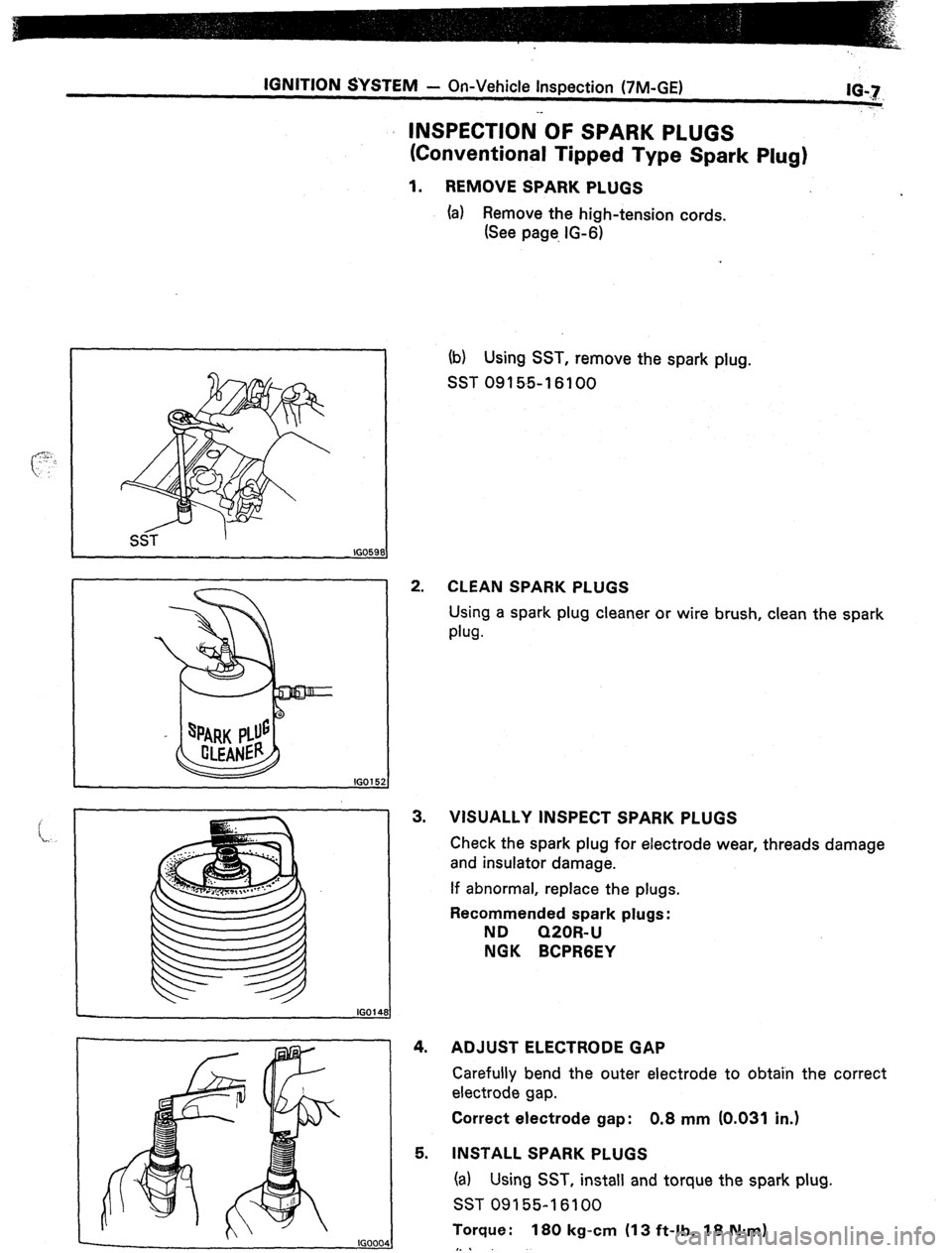

1. REMOVE SPARK PLUGS

(a) Remove the high-tension cords.

(See page. IG-6)

2.

3.

I

lGOl48

4.

5. (b) Using SST, remove the spark plug.

SST 0915~5-16100

CLEAN SPARK PLUGS

Using a spark plug cleaner or wire brush, clean the spark

plug.

VISUALLY INSPECT SPARK PLUGS

Check the spark plug for electrode wear, threads damage

and insulator damage.

If abnormal, replace the plugs.

Recommended spark plugs:

ND Q20R- U

NGK BCPRGEY

ADJUST ELECTRODE GAP

Carefully bend the outer electrode to obtain the correct

electrode gap.

Correct electrode gap: 0.8 mm (0.031 in.)

INSTALL SPARK PLUGS

(a) Using SST, install and torque the spark plug.

SST 09155-l 6100

Torque : 180 kg-cm (13 ft-lb, 18 Nmrn)

I..

Page 262 of 346

IO-8 IGNITION’SYSTEM - On-Vehicle Inspection (7M-GE)

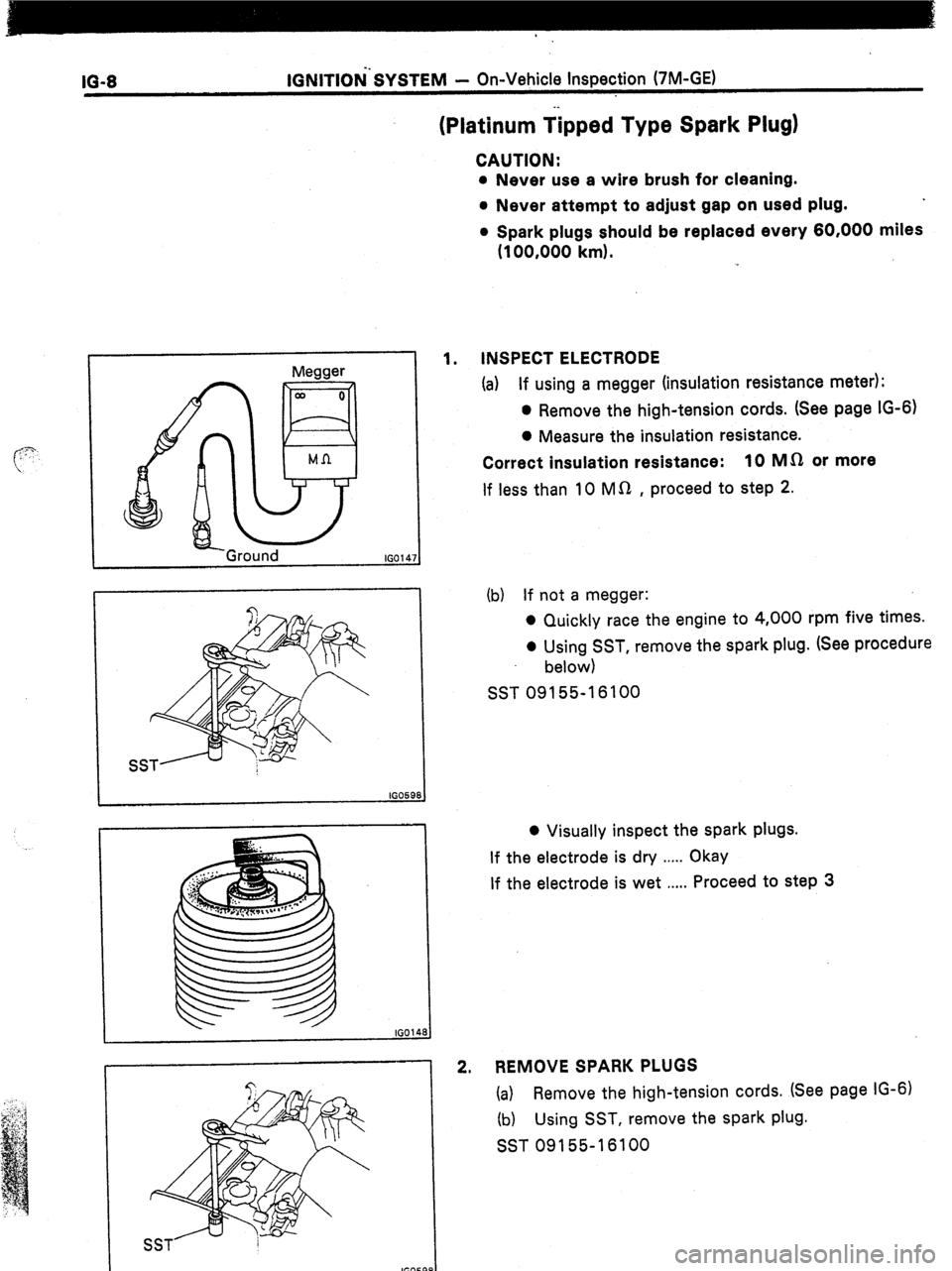

(Platinum tipped Type Spark Plug)

CAUTION:

l Never use a wire brush for cleaning.

l Never attempt to adjust gap on used plug.

l Spark plugs should be replaced every 80,000 miles

(100,000 km).

Megger

IGOlr 17

1. INSPECT ELECTRODE

(a) If using a megger (insulation resistance meter):

0 Remove the high-tension cords. (See page G-6)

0 Measure the insulation resistance.

Correct insulation resistance: 10 MQ or more

If less than 10 MAI , proceed to step 2.

I . IG01481

IG059

0 Visually inspect the spark plugs.

If the electrode is dry ,.... Okay

If the electrode is wet ..,.. Proceed to step 3

2, REMOVE SPARK PLUGS

(a) Remove the high-tension cords. (See page IS-61

Ib) Using SST, remove the spark plug.

SST 09155-l 6100

Page 263 of 346

IGNITION SYSTEM

- On-Vehicle Inspection (7M-GE)

,“lG-9

16031

0.8 mm (7M-GTE)

1 .I

mm (7M-GE)

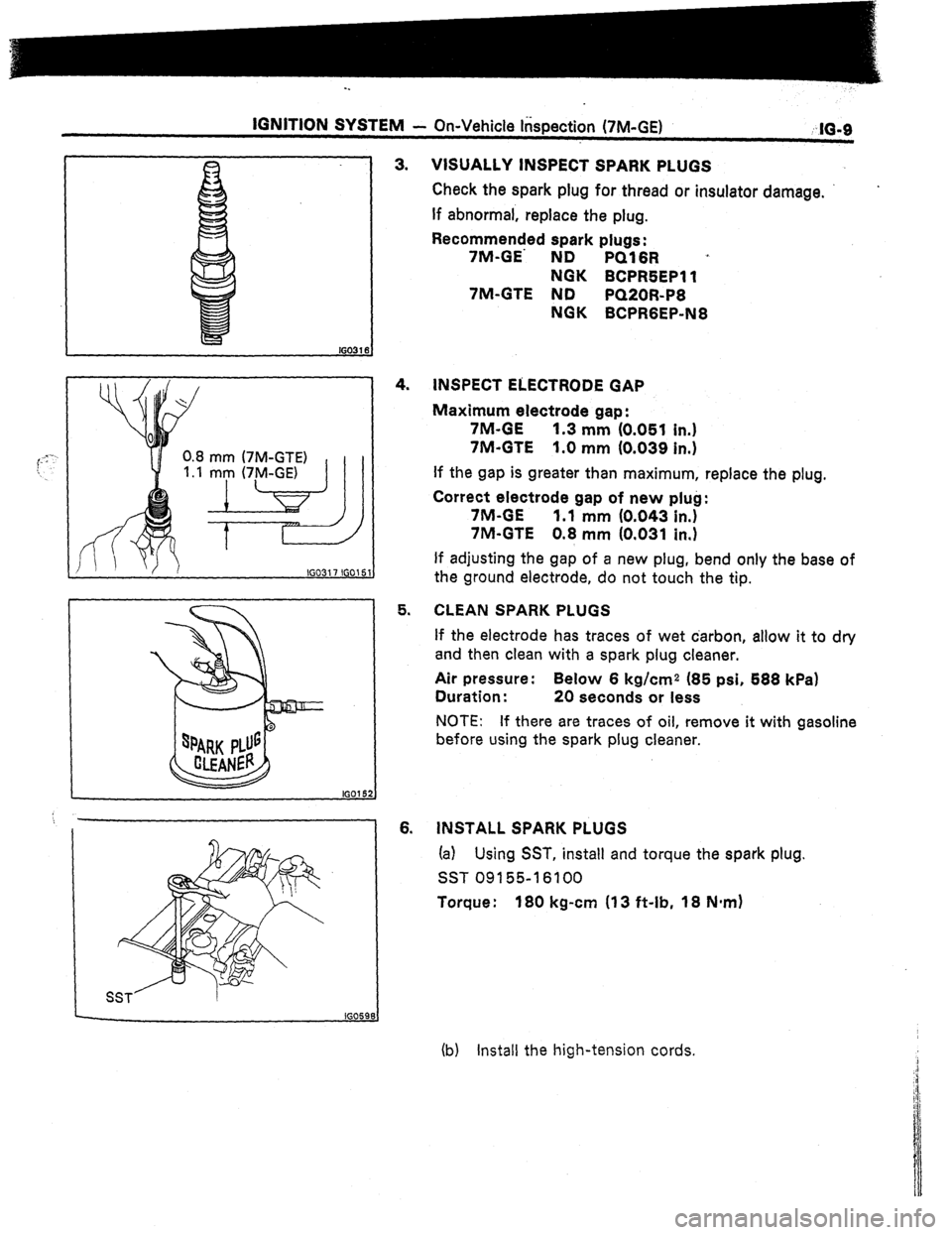

VISUALLY INSPECT SPARK PLUGS

Check the spark plug for thread or insulator damage.

If abnormal, replace the plug.

Recommended spark plugs:

7M-GE’ ND

PQ16R ’

NGK BCPR5EPll

7M-GTE ND

PQ20R-P6

NGK BCPRGEP-N8

INSPECT ELECTRODE GAP

Maximum electrode gap:

7M-GE

1.3 mm (0.051 in.)

7M-GTE 1.0 mm (0.039 in.)

If the gap is greater than maximum, replace the plug.

Correct electrode gap of new plug:

7M-GE

1.1 mm (0.043 in.)

7M-GTE 0.8 mm (0.031 in.)

If adjusting the gap of a new plug, bend only the base of

5. CLEAN SPARK PLUGS

6. the ground electrode, do not touch the tip.

If the electrode has traces of wet carbon, allow it to dry

and then clean with a spark plug cleaner.

Air pressure: Below 6 kg/cm2 (85 psi, 588 kPa)

Duration : 20 seconds or less

NOTE: If there are traces of oil, remove it with gasoline

before using the spark plug cleaner.

INSTALL SPARK PLUGS

(a) Using SST, install and torque the spark plug.

SST 09155-l 6100

Torque : 180 kg-cm (13 ft-lb, 18 N*m)

(b) Install the high-tension cords.

Page 267 of 346

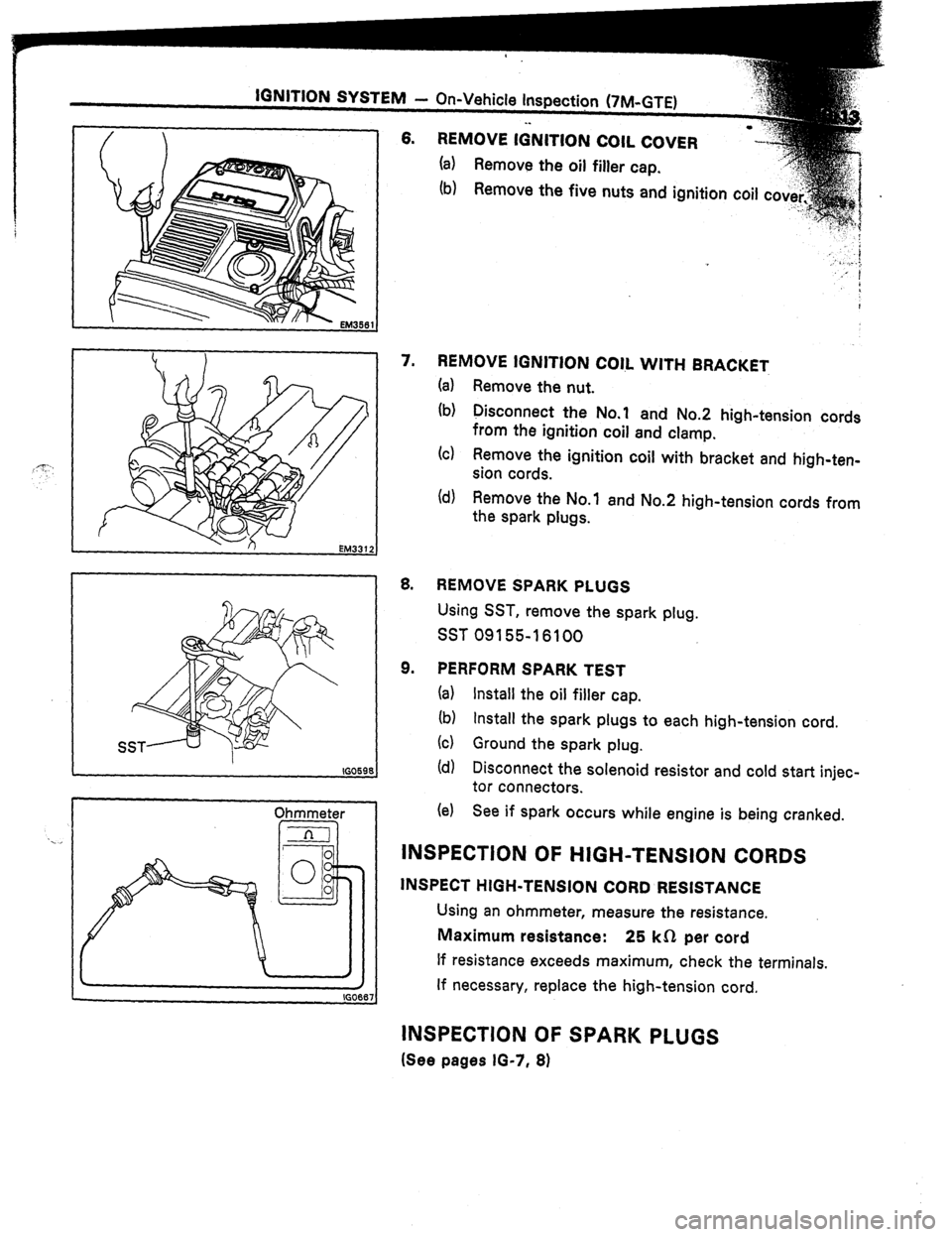

6. REMOVE IGNITION COIL COVER

(a) Remove the oil filler cap.

‘...”

I I

I(30598

Ohmmeter

/

IGO

7. REMOVE IGNITION C0l.L WITH BRACKET

(a) Remove the nut.

(b) Disconnect the No.1 and No.2 high-tension cords

from the ignition coil and clamp.

(cl Remove the ignition coil with bracket and high-ten-

sion cords.

id) Remove the No.1 and No.2 high-tension cords from

the spark plugs.

8.

9. REMOVE SPARK PLUGS

Using SST, remove the spark plug.

SST 09155-16100

PERFORM SPARK TEST

Ia) Install the oil filler cap.

(b) Install the spark plugs to each high-tension cord.

(4 Ground the spark plug.

(d) Disconnect the solenoid resistor and cold start injec-

tor connectors.

(e) See if spark occurs while engine is being cranked.

INSPECTION OF HIGH-TENSION CORDS

INSPECT HIGH-TENSION CORD RESISTANCE

Using an ohmmeter, measure the resistance.

Maximum resistance: 25 kfl per cord

If resistance exceeds maximum, check the terminals.

If necessary, replace the high-tension cord.

INSPECTION OF SPARK PLUGS

(See pages IG-7, 8)