thermostat TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 22 of 346

. .

co-2 COOLING SYSTEM - Description

,- I . . .

DESCRlqTlON

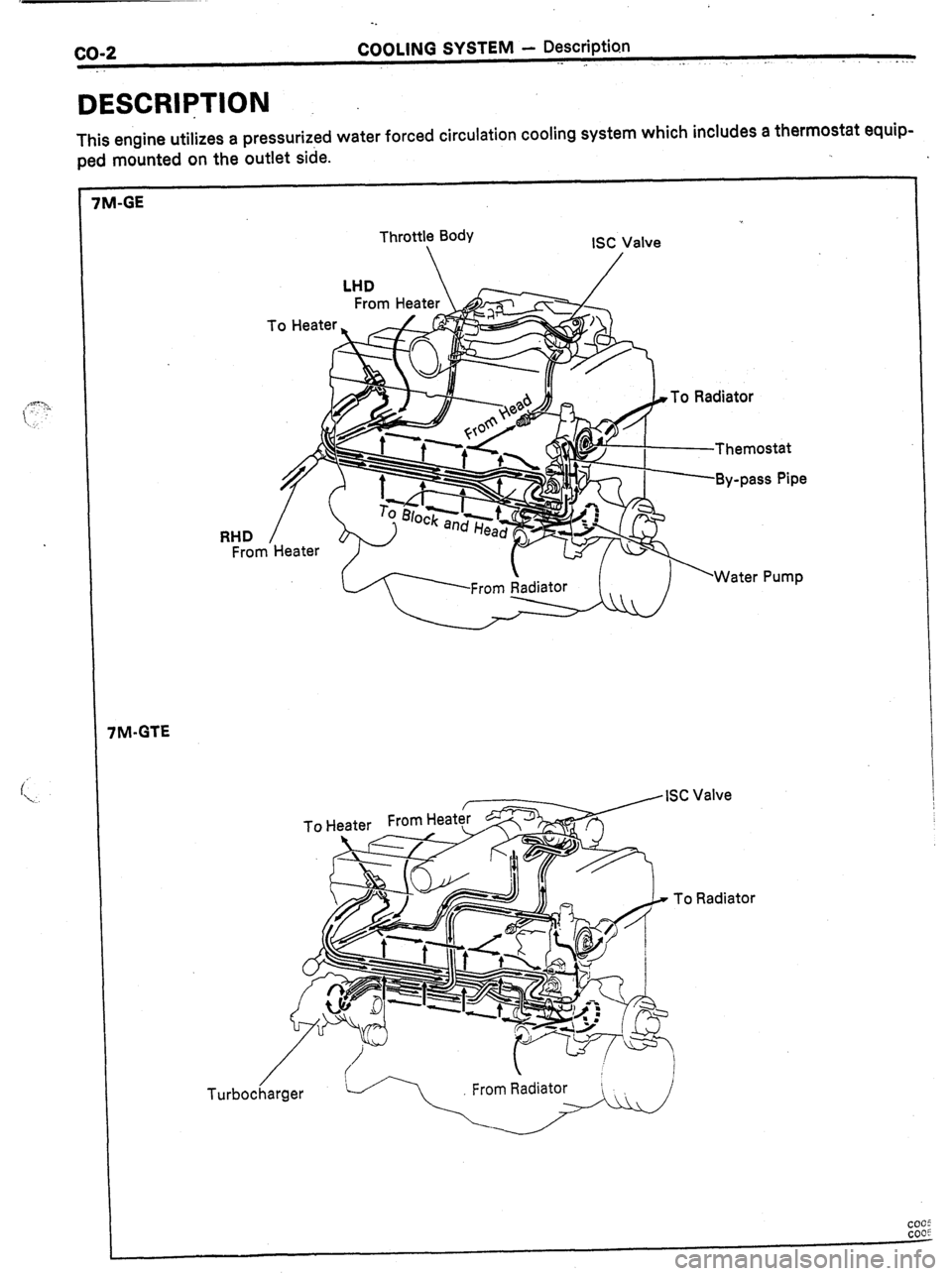

This engine utilizes a pressurized water forced circulation cooling system which includes a thermostat equip-

ped mounted on the outlet side.

5 7M-GE

Throttle Body

ISC Valve

/

To Radiator

RHD

/

From Heater

rM-GTE

/

To Heater From Heat: ISC Valve

To Radiator

COGS

COOF

Page 23 of 346

. COOLING SYSTEM - Description

co;3

RESERVOIR TANK

The reservoir tank is used to catch coolant

which overflows the cooling systein as a result of

volumetric expansion when the coolant is heated.

The coolant in the reservoir tank returns to the

radiator when the coolant temperature drops, thus

keeping the radiator full at all times and avoiding

needless coolant loss. Check the reservoir tank

level to learn if the coolant needs to be rep-

lenished.

WATER PUMP

The water pump is used for forced circulation of

coolant through the cooling system. It is mounted

on the front of the cylinder block and driven by a

V-ribbed belt,

THERMOSTAT I The cooling system is composed of the water

jacket (inside the cylinder block and cylinder head),

radiator, water pump, thermostat, cooling fan,

hoses and other components.

Coolant which is heated in the water

jacket is

pumped to the radiator, through which a cooling

fan blows air to cool the coolant as it passes

through. Coolant which has been cooled is then

sent back to the engine by the water pump, where

it cools the engine.

The water jacket is a network of channels in the

shell of the cylinder block and cylinder head

through which coolant passes. It is designed to

provide adequate cooling of the cylinders are com-

bustion chambers which become the hottest dur-

ing engine operation.

F(/ “ IATOR

The radiator performs the function of cooling

the coolant which has passed through the water

jacket and become hot, and is mounted in the front

of the vehicle. The radiator consists of an upper

tank and ‘lower tank, and a core which connects

the two tanks. The upper tank contains the inlet for

coolant from the water jacket and the filter inlet. It

also has a hose attached through which excess

coolant or steam can flow. The lower tank contains

the outlet for coolant and the drain cock. The core

contains many tubes through which coolant flows

from the upper tank to the lower tank as well as

cooling fins which radiate heat away from the coo-

lant in the tubes. The air sucked through the radia-

tor by cooling fan, as well as the wind generated

by the vehicle’s travel, passes through the radia-

tor, cooling it. Models with automatic transmission

incrl*-le an automatic transmission fluid cooler built

in:.

.le lower tank of the radiator.

RADIATOR CAP

The radiator cap is a pressure type can which

seals the radiator, resulting in pressurization of the

radiator as the coolant expands. The pressuriza-

tion prevents the coolant from boiling even when

the coolant temperature exceeds 100°C. A relief

valve (pressurization valve) and a vacuum valve

(negative pressure valve) are built into the radiator

zap. The relief valve opens and lets steam escape

:hrough the overflow pipe when the pressure

3enerated inside the cooling system exceeds the

imit (coolant temperature:

110 - 1 20°C, (230

- 248”F), pressure; 0.3 - 1 .O kg/cmz, (4.3 - 14.2

)si, 29.4 - 98.1 kPa). The vacuum valve opens to

3ljeviate the vacuum which develops in the coolant

system after the engine is stopped and the coolant

emperature drops. The valve’s opening allows the

)ressure in the cooling system to return to the

Qclant in the reservoir tank. The thermostat has a wax type and is mounted

in the. water outlet housing. The thermostat

includes a type of automatic valve operated by

fluctuations in the coolant temperature. This valve

closes when the coolant temperature drops, pre-

venting the circulation of coolant through the

engine and thus permitting the engine to warm up

rapidly. The valve opens when the coolant tem-

perature has risen, allowing the circulation of coo-

lant. Wax inside the thermostat expands when

heated and contracts when cooled. Heating the

wax thus generates pressure which overpowers

the force of the spring which keeps the valve

closed, thus opening the valve. When the wax

cools, its contraction causes the force of the

spring to take effect once more, closing the valve.

The thermostat in this engine operates at a tem-

perature of 88”C(19O”F).

I

I

Page 24 of 346

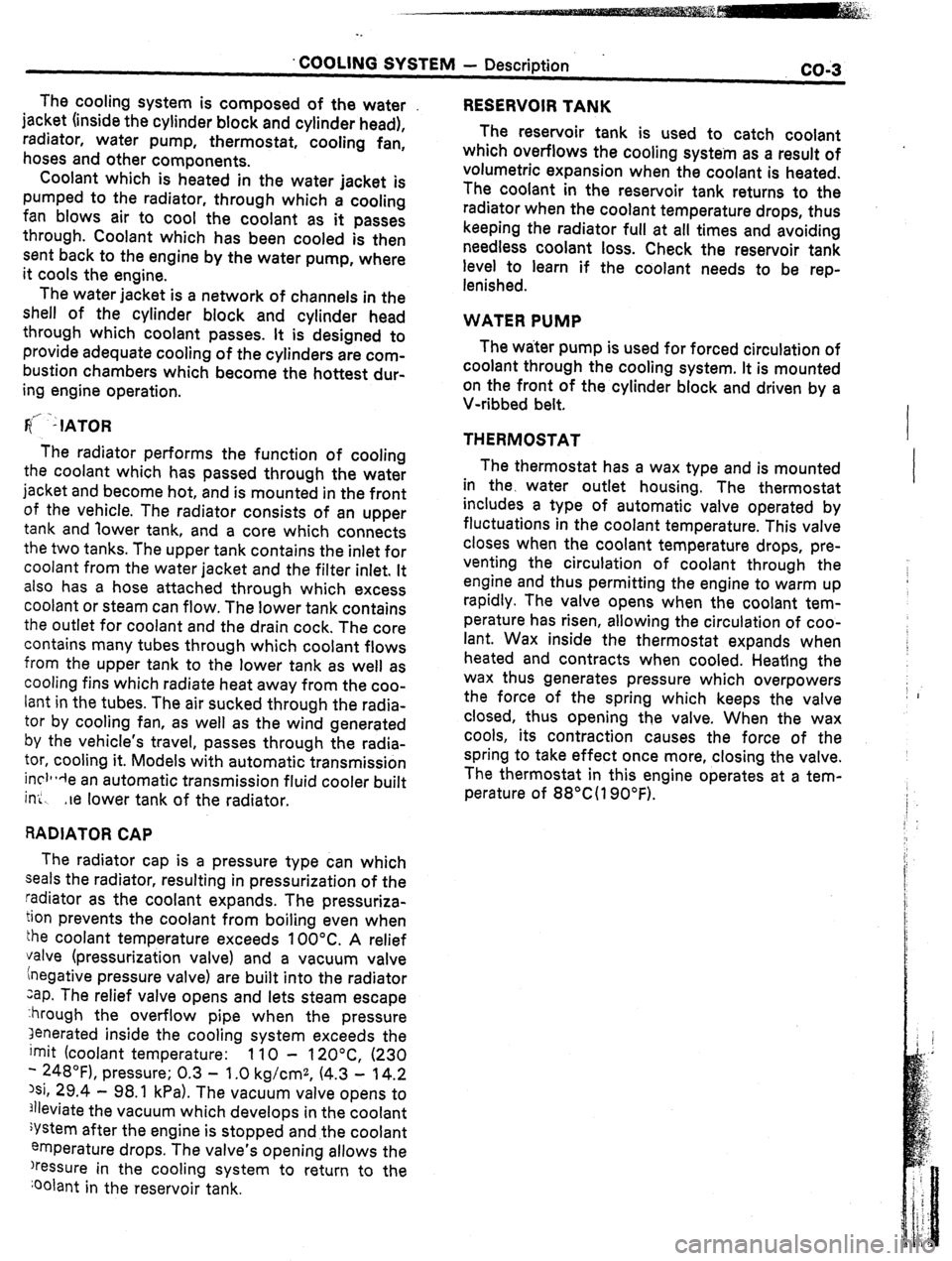

co-4 CQOLING SYSTEM - Troubleshootmg

TROUBLESHOOTING

, Problem

Engine overheats Possible cause

Alternator drive belt loose or missing

Dirt, leaves or insects in radiator or

condenser

Hoses, water pump, water outlet

housing, radiator, heater, core plugs

or head gasket leakage

Thermostat faulty

Ignition timing

retarded

Fluid coupling faulty

Radiator hose plugged or rotted

Water pump faulty

Radiator plugged or cap faulty

Cylinder head or block cracked or

phwd Remedy

Adjust or replace belt

Clean radiator or condenser

Repair as necessary

Check thermostat

Set timing

Replace fluid coupling

Replace hose

Replace water pump

Check radiator

Repair as necessary Page

CH-4

CO-8

EM-l 7

CO-6

CO-6

co-9

Page 28 of 346

CO-8 -. COOLING SYSTEM L Thermostat

._

Valve Lift

i

t-

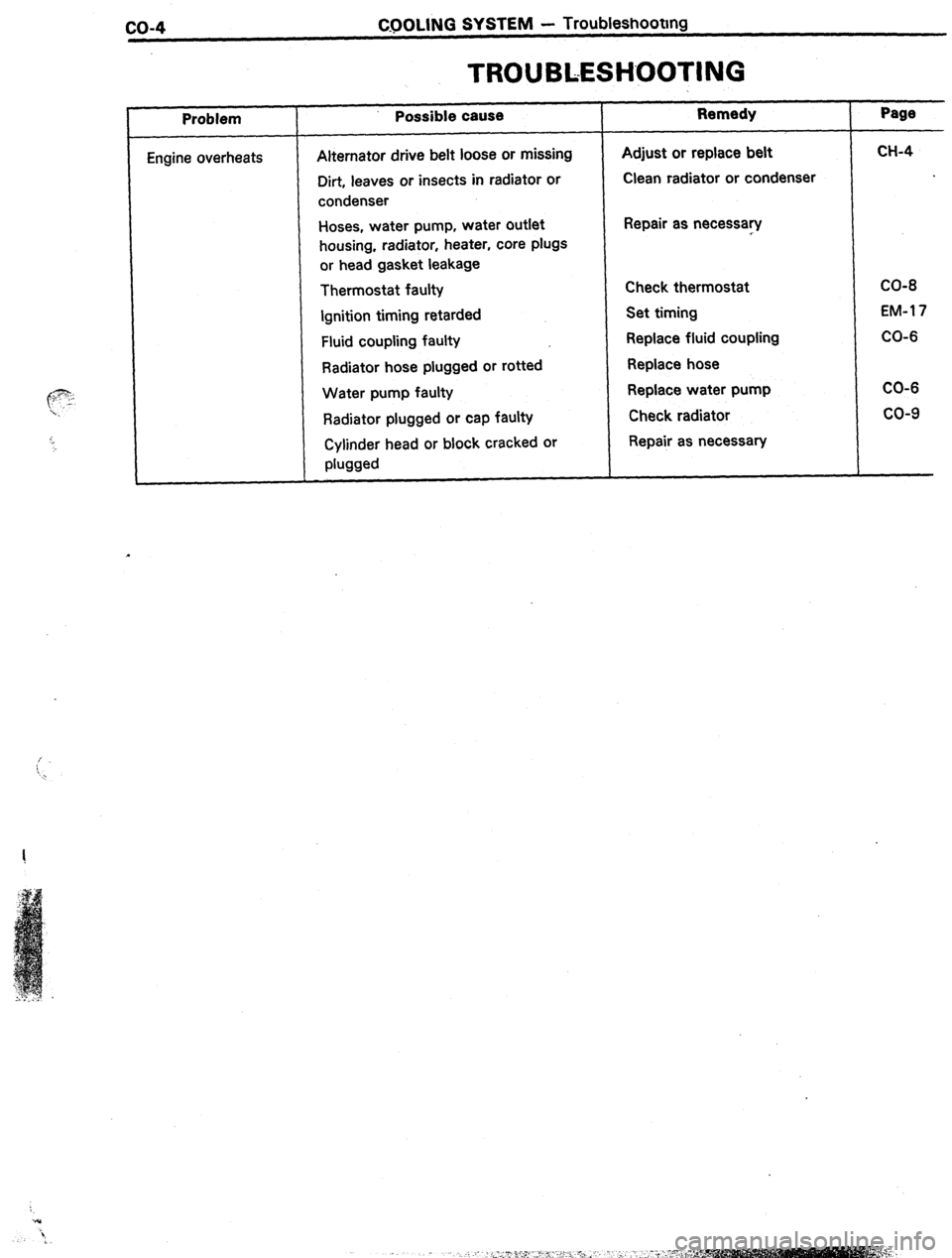

THERMOSTAT

REMOVAL OF THERMOSTAT

REMOVE WATER OUTLET AND THERMOSTAT

(a) Remove two bolts, water outlet and thermostat with

gasket from the water outlet, housing.

(b) Remove the gasket from the thermostat.

INSPECTION OF THERMOSTAT

NOTE: Thermostat is numbered according to the valve

opening temperature.

(a)

Immerse the thermostat in water and heat the water

gradually.

(b)

Check the valve opening temperature.

Valve opening temperature:

86 - 90°C (187

- 194°F)

If the valve opening temperature is not within specifica-

tion, replace the thermostat.

(c) Check the vatve lift.

Valve lift:

8 mm (0.31 in.) or more at

100°C (212°F)

If the valve lift is less than specification, replace the ther-

mostat.

(d) Check that the valve spring is tight when the ther-

mostat is fully closed.

If necessary, replace the thermostat.

INSTALLATION OF THERMOSTAT

INSTALL THERMOSTAT AND WATER OUTLET

(a) Place a new gasket to the thermostat.

(b) Install the thermostat with the jiggle valve facin

upward as shown in the illustration, and water outlc

with the two bolts.

,

Page 190 of 346

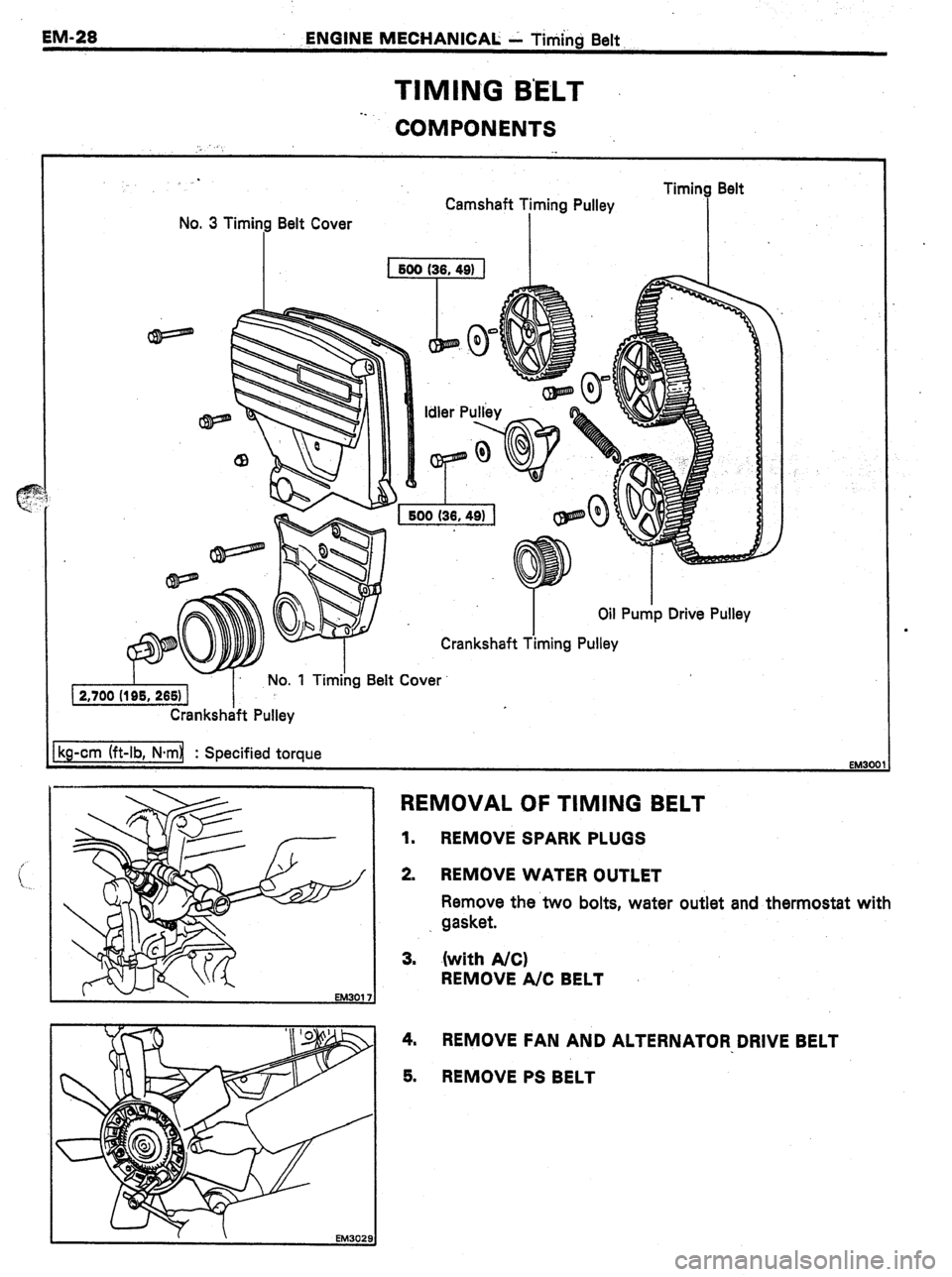

EM-28

ENGINE MECliANICAL - Titiingj Belt.

TIMING B’ELT

-.

COMPONENTS

No. 3 Timing Belt Cover Camshaft Timing Pulley

I I ImIng oen

I

Crankshaft Pulley

kg-cm (ft-lb, N-ml : Specified torque

EM30f 31

REMOVAL OF TIMING BELT

1.

REMOVE SPARK PLUGS

2. REMOVE WATER OUTLET

Remove the two bolts, water outlet and thermostat with

. gasket.

3. .(with A/C)

REMOVE A/C BELT

4. REMOVE FAN AND ALTERNATOR DRIVE BELT

5.

REMOVE PS BELT

Page 198 of 346

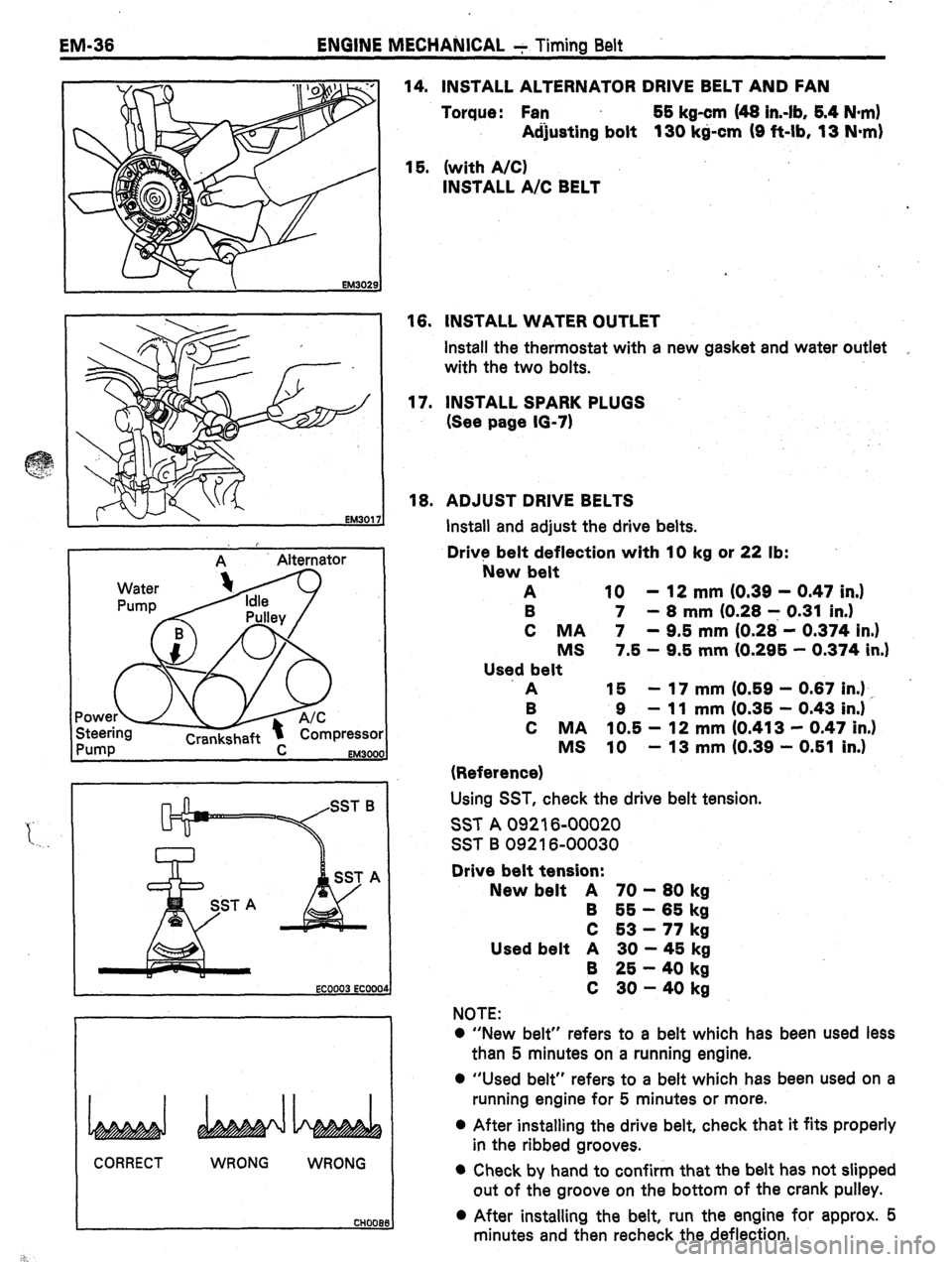

EM-36 ENGINE MECHANICAL - Timinn Belt

EM302

EM301

,

A

Alternator

1

EM3000

CORRECT WRONG

WRONG 14. INSTALL ALTERNATOR DRIVE BELT AND FAN

Torque: Fan 55 kg-cm (48 in.-lb, 6.4 N-m)

Adjusting bolt 130 kg-cm (9 ft-lb, 13 N*m)

15. (with A/C)

INSTALL A/C BELT

16. INSTALL WATER OUTLET

install the thermostat with a new gasket and water outlet

with the two bolts.

17. INSTALL SPARK PLUGS

(See page 10-7)

16. ADJUST DRIVE BELTS

Install and adjust the drive belts.

Drive belt deflection with 10 kg or 22 lb:

New belt

A 10 - 12 mm IO.39 - 0.47 in.)

B 7 - 8 mm (0.28 7 0.31 in.)

C MA 7 - 9.5 mm (0.28 - 0.374 in.)

MS 7.5 - 9.5 mm (0.296 - 0.374 in.1

Used belt

A 15 - 17 mm (0.59 - 0.67 in.1 ,

B 9 - 11 mm (0.35 - 0.43 in.)

C MA 10.5 - 12 mm (0.413 - 0.47 in.)

MS 10 - 13 mm (0.39 - 0.51 in.)

(Reference)

Using SST, check the drive belt tension.

SST A 09216-00020

SST B 09216-00030

Drive belt tension:

New belt A 70 - 80 kg

B 65 - 65 kg

C 53 - 77 kg

Used belt A 30 - 45 kg

B 25 - 40 kg

C 30 - 40 kg

NOTE:

0 “New belt” refers to a belt which has been used less

than 5 minutes on a running engine.

0 “Used belt” refers to a belt which has been used on a

running engine for 5 minutes or more.

0 After installing the drive belt, check that it fits properly

in the ribbed grooves. l Check by hand to confirm that the belt has not slipped

out of the groove on the bottom of the crank pulley.

l After installing the belt, run the engine for approx. 5

minutes and then recheck the deflection.