transmission TOYOTA HIGHLANDER 2001 Service Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2001, Model line: HIGHLANDER, Model: TOYOTA HIGHLANDER 2001Pages: 2572, PDF Size: 34.8 MB

Page 323 of 2572

2005 HIGHLANDER (EWD592U)

104

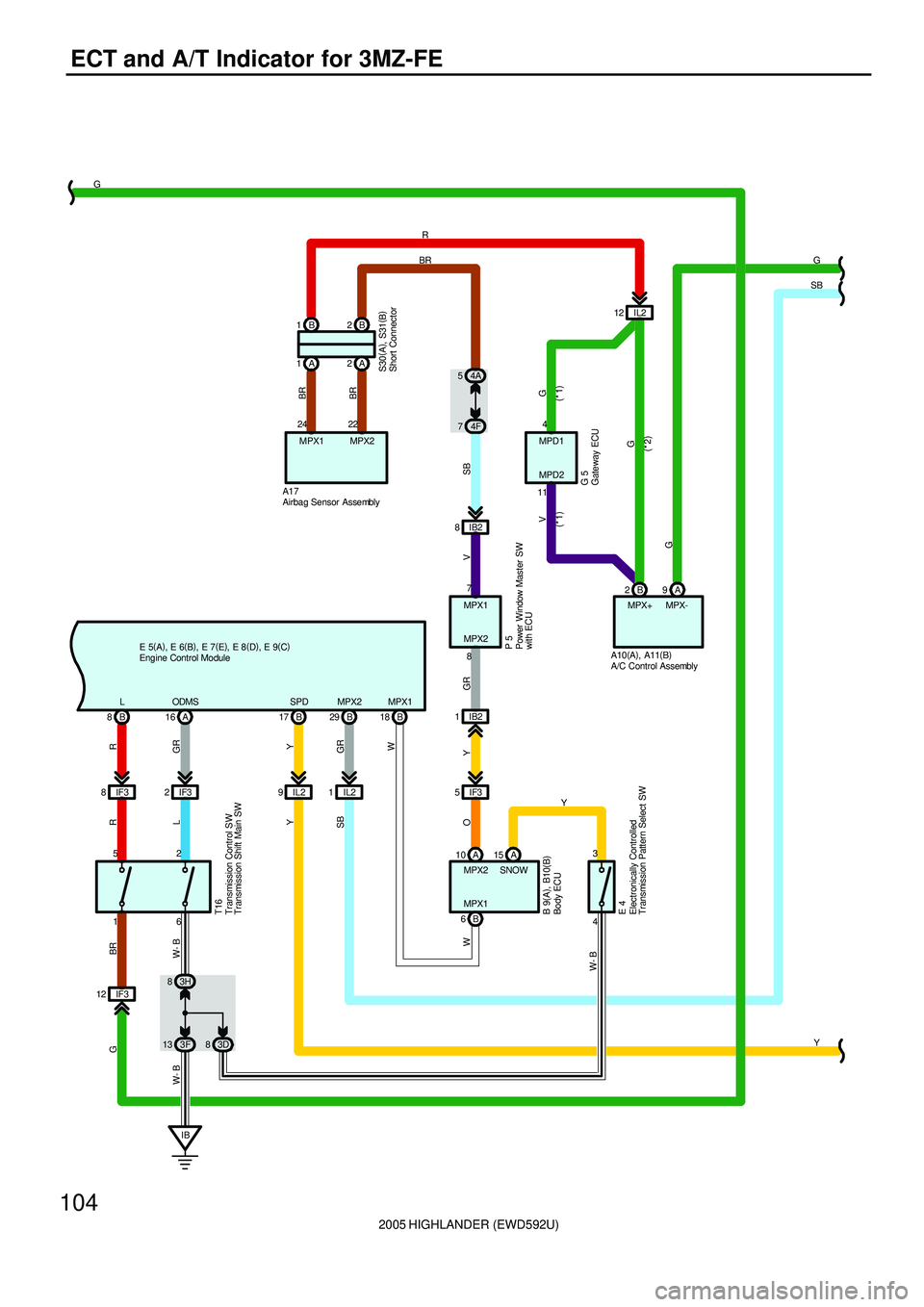

ECT and A/T Indicator for 3MZ-FE

BMPX-

A

1MPX1

W

2IF3R

SNOW MPX1

A 16

10

GR

ODMS9

MPX2

L

GR W- B

L

W- BW- BR

MPX2

V GR Y

E 4

29 BBR

R

8B

6

IB 13 3F6

83H3

4 A17

IF3 82B A IB2 8

IB2 1

IF3 5

15

O

7

8 MPX1

MPX2

A

P 5

MPX+

W

18 B

52

BR G

B

Y

SPD

17 B

IL2 9

Y

G

83D2 B 1

A 1A2

BR

24

MPX1

BR

22

MPX2

G V

4

11MPD1

MPD2

G 5

IL2 12

SB

74F 54AG

SB

Y IL2 1

SB

IF3 12

(

*1) (

*1)

G

(

*2)

G

Y

T16

S30(

A)

, S31(

B)

A10(

A)

, A11(

B)

B 9(

A)

, B10(

B)

E 5(

A)

, E 6(

B)

, E 7(

E)

, E 8(

D)

, E 9(

C)

A/C Control Assembly Airbag Sensor Assembly

Body ECU

Electronically Controlled

Transmission Pattern Select SW

Engine Control Module

Gateway ECU Power Window Master SW

with ECUShort Connector Transmission Control SW

Transmission Shift Main SW

Page 326 of 2572

2005 HIGHLANDER (EWD592U)

107

Previous automatic transaxle have selected each gear shift using mechanically controlled throttle hydraulic pressure,

governor hydraulic pressure and lock-up hydraulic pressure. The electronically controlled transmission, however, electrically

controls the line pressure, throttle pressure, lock-up pressure and accumulator pressure etc. through the solenoid valve. The

electronically controlled transmission is a system which precisely controls gear shift timing and lock-up timing in response to

the vehicle's driving conditions and the engine condition detected by various sensors. It makes smooth driving possible by

shift selection for each gear which is the most appropriate to the driving conditions at that time, and by preventing downing,

squat and gear shift shock when starting off.

1. Gear Shift Operation

During driving the engine warm up condition signal is input from engine coolant temp. sensor to TERMINAL THW of the

engine control module, and the vehicle speed signal is input from the ABS speed sensor to skid control ECU, and are sent to

the engine control module through communication control. At the same time, the throttle valve opening signal is sent from

the throttle position sensor to the TERMINALS VTA1 and VTA2 of the engine control module, as the throttle angle signal.

2. Lock-Up Operation

When the engine control module decides based on each signal that the lock-up condition has been met, the current flows

through TERMINAL DSL of the engine control module to TERMINAL 10 of the electronically controlled transmission solenoid

to GROUND.

3. Stop Light SW Circuit

If the brake pedal is depressed (Stop light SW on) when driving in lock-up condition, a signal is input to TERMINAL STP of

the engine control module. The engine control module operates and cuts the current to the solenoid to release lock-up.

4. Overdrive Circuit

*O/D main SW on

When the O/D main SW is turned on, a signal is input to TERMINAL ODMS of the engine control module and engine

control module operation causes gear shift when the conditions for overdrive are met.

*O/D main SW off

When the O/D main SW is turned off, a signal is input into TERMINAL ODMS of the engine control module, and turns on

the O/D off indicator light. This activates the ECU, and the transmission system is controlled not to shift to overdrive.

E4 Electronically Controlled Transmission Pattern Select SW

3-4 : Closed with the select SW at SNOW position

E5 (A), E6 (B), E7 (E), E8 (D), E9 (C) Engine Control Module

BATT-E1 : Always approx. 12 volts

MREL-E1 : Approx. 12 volts with the ignition SW ON position

P1 A/T Indicator SW

2-6 : Closed with the shift lever in P position

2-1 : Closed with the shift lever in R position

2-9 : Closed with the shift lever in N position

2-7 : Closed with the shift lever in D position

2-3 : Closed with the shift lever in 2 position

2-8 : Closed with the shift lever in L position

: PARTS LOCATION

CodeSee PageCodeSee PageCodeSee Page

A10A42E5A42P544

A11B42E6B42S1543

A1742E7E42S2739 (3MZ-FE)

B9A42E8D42S28A43

B10B42E9C42S29B43

C638 (3MZ-FE)G543S30A43

C11A42J239 (3MZ-FE)S31B43

C12B42J643T339 (3MZ-FE)

E138 (3MZ-FE)J743T1339 (3MZ-FE)

E238 (3MZ-FE)J1743T1643

E442P139 (3MZ-FE)

System Outline

Service Hints

Page 392 of 2572

'05 HIGHLANDER_U (L/O 0409)

232

2005 HIGHLANDER from Nov. '04 Prod. (OM48570U)

CHANGING MENU PAGE OR TRACK

(video CD only)

Push the Prev. Pageº or Next Pageº

switch while the disc menu is displayed.

The next or previous page will appear on

the screen.

Push the Prev. Pageº or Next Pageº

switch while the player is playing video.

The next or previous track will be

searched and played.CHANGING A MULTIPLEX

TRANSMISSION (video CD only)

Push the Main/Subº switch to change a

multiplex transmission. The mode changes

from Main/Sub to Main to Sub and back

to Main/Sub by pushing the Main/Subº

switch.CHANGING THE INITIAL SETTING (video

CD only)

Push the Set Upº switch on the screen

and then the initial setting screen will ap-

pear. You can also display the screen by

pushing the SET UPº button on the con-

troller. You can change the initial setting.

(See CHANGING THE INITIAL SETTINGº

on page 222 in this Section for details.)

After the setting is done, the player plays

from the beginning of the chapter or the

track.

Page 407 of 2572

2005 HIGHLANDER (EWD592U)

11 0

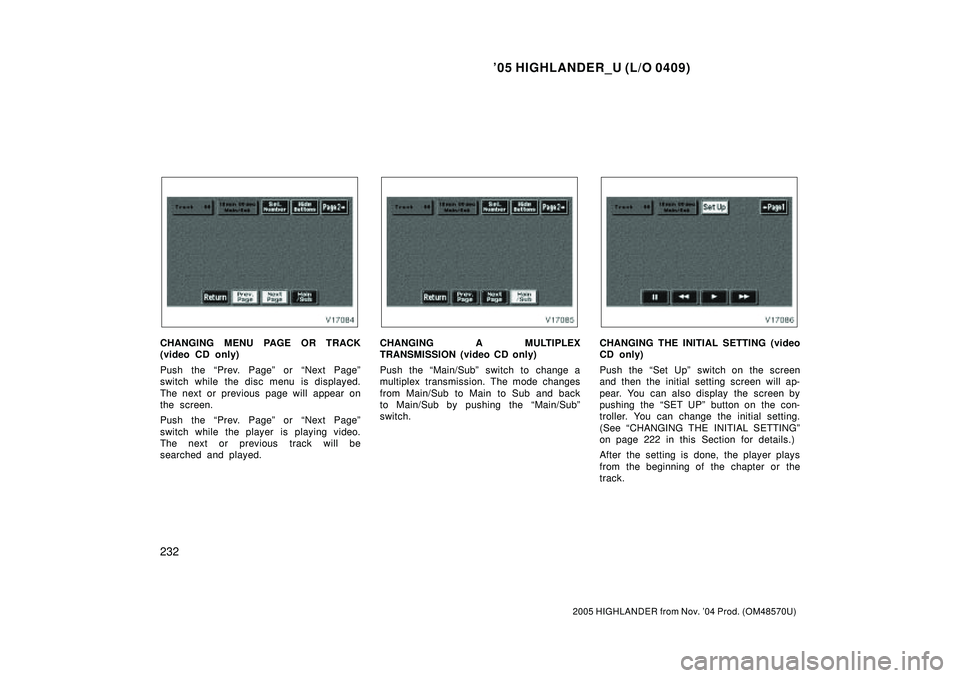

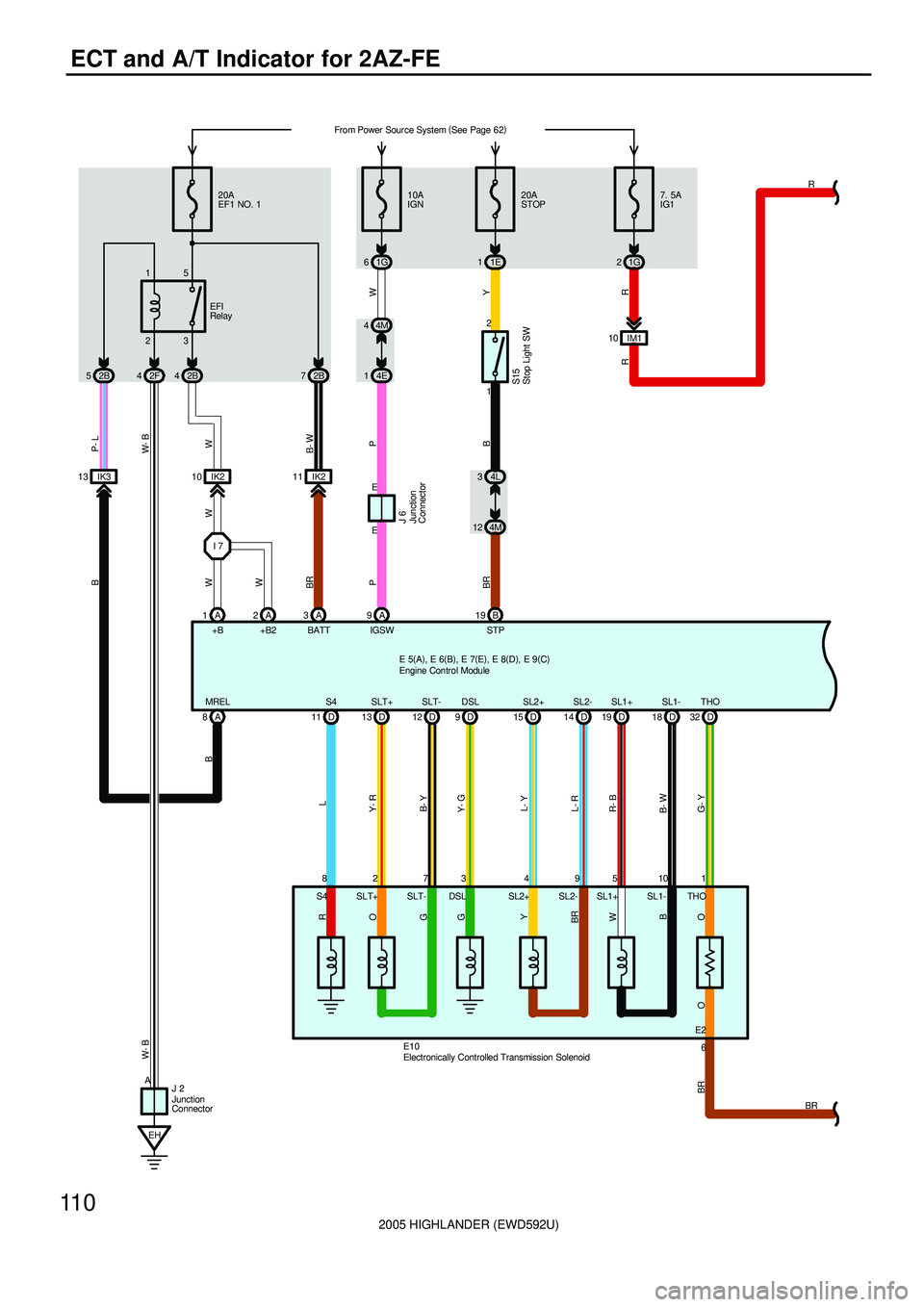

ECT and A/T Indicator for 2AZ-FE

1 9 4 3 7 2 8

G- YW P- L

+B BATT20A

EF1 NO. 1

B- W W- B

L

Y- R

B- Y

Y- G

L- Y

L- R

23 15

2B 4 2F 4 2B 52B7

Y

R W

IK2 10 IK21110A

IGN

1G 620A

STOP

1E 1

4E 1

B BRP

I 74M 4

EH1 2

4M 124L 3

1A A3A9B1921G7. 5A

IG1

A 8

BRW

D 11 D13 D9D15 D32 D 12 D14R

E10SL1- SL1+

18 D 19 D

B- WR- B

510 IGSW STP

A

J 2MREL S4 SLT+ SLT- DSL SL2+ SL2-

W- B

THO

S15

EFI

Relay

IK3 13

B

B

E2 IM1 10

R

E

E

R

O

G

G

Y

BR

O

+B2 2A

WW

P

W

B

O BR

BR 6 THO SL1- SL1+ SL2- SL2+ DSL SLT- SLT+ S4

J 6

From Power Source System (

See Page 62)

E 5(

A)

, E 6(

B)

, E 7(

E)

, E 8(

D)

, E 9(

C)

Engine Control Module

Electronically Controlled Transmission Solenoid

Junction

Connector

Junction

Connector

Stop Light SW

Page 409 of 2572

2005 HIGHLANDER (EWD592U)

11 2

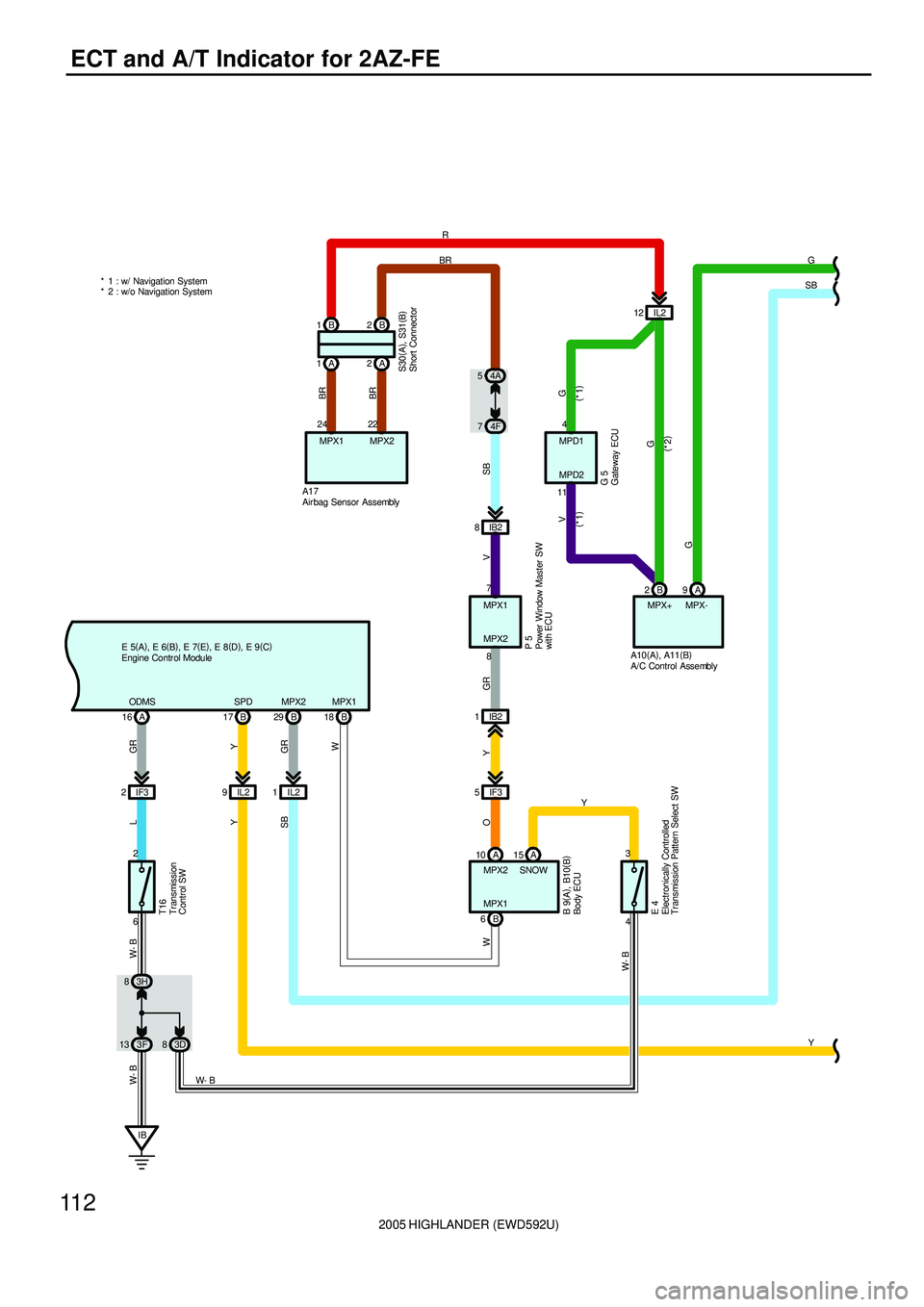

ECT and A/T Indicator for 2AZ-FE

BMPX-

A

MPX1

W

2IF3R

SNOW MPX1

A 16

10

GR

ODMS9

MPX2

L

GR W- B

W- BW- B

MPX2

V GR Y

E 4

29 BBR

6

IB 13 3F6

83H3

4 A17

2B A IB2 8

IB2 1

IF3 5

15

O

7

8 MPX1

MPX2

A

P 5

MPX+

W

18 B

2B

Y

SPD

17 B

IL2 9

Y

83D2 B 1

A 1A2

BR

24

MPX1

BR

22

MPX2

G V

4

11MPD1

MPD2

G 5

IL2 12

SB

74F 54AG

Y IL2 1

SB

(

*1) (

*1)

G

(

*2)

G

Y

T16

* 1 : w/ Navigation System

* 2 : w/o Navigation SystemSB

W- B

S30(

A)

, S31(

B)

B 9(

A)

, B10(

B)

E 5(

A)

, E 6(

B)

, E 7(

E)

, E 8(

D)

, E 9(

C)

A10(

A)

, A11(

B)

A/C Control Assembly Air bag Sensor Assembly

Body ECU

Electronically Controlled

Transmission Pattern Select SW

Engine Contr ol Module

Gateway ECU Power Window Master SW

with ECUShort Connector Transmission

Control SW

Page 412 of 2572

2005 HIGHLANDER (EWD592U)

11 5

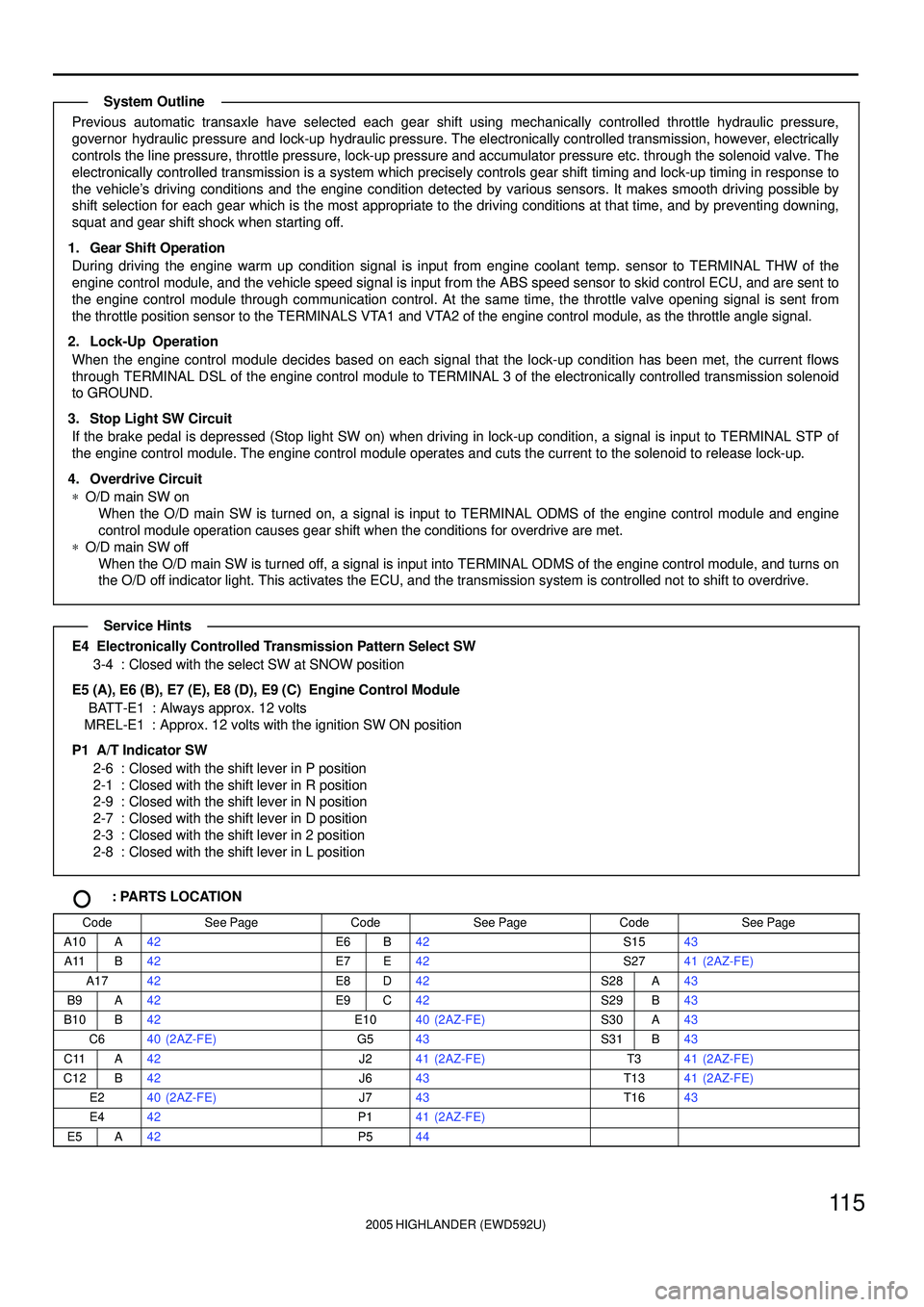

Previous automatic transaxle have selected each gear shift using mechanically controlled throttle hydraulic pressure,

governor hydraulic pressure and lock-up hydraulic pressure. The electronically controlled transmission, however, electrically

controls the line pressure, throttle pressure, lock-up pressure and accumulator pressure etc. through the solenoid valve. The

electronically controlled transmission is a system which precisely controls gear shift timing and lock-up timing in response to

the vehicle's driving conditions and the engine condition detected by various sensors. It makes smooth driving possible by

shift selection for each gear which is the most appropriate to the driving conditions at that time, and by preventing downing,

squat and gear shift shock when starting off.

1. Gear Shift Operation

During driving the engine warm up condition signal is input from engine coolant temp. sensor to TERMINAL THW of the

engine control module, and the vehicle speed signal is input from the ABS speed sensor to skid control ECU, and are sent to

the engine control module through communication control. At the same time, the throttle valve opening signal is sent from

the throttle position sensor to the TERMINALS VTA1 and VTA2 of the engine control module, as the throttle angle signal.

2. Lock-Up Operation

When the engine control module decides based on each signal that the lock-up condition has been met, the current flows

through TERMINAL DSL of the engine control module to TERMINAL 3 of the electronically controlled transmission solenoid

to GROUND.

3. Stop Light SW Circuit

If the brake pedal is depressed (Stop light SW on) when driving in lock-up condition, a signal is input to TERMINAL STP of

the engine control module. The engine control module operates and cuts the current to the solenoid to release lock-up.

4. Overdrive Circuit

*O/D main SW on

When the O/D main SW is turned on, a signal is input to TERMINAL ODMS of the engine control module and engine

control module operation causes gear shift when the conditions for overdrive are met.

*O/D main SW off

When the O/D main SW is turned off, a signal is input into TERMINAL ODMS of the engine control module, and turns on

the O/D off indicator light. This activates the ECU, and the transmission system is controlled not to shift to overdrive.

E4 Electronically Controlled Transmission Pattern Select SW

3-4 : Closed with the select SW at SNOW position

E5 (A), E6 (B), E7 (E), E8 (D), E9 (C) Engine Control Module

BATT-E1 : Always approx. 12 volts

MREL-E1 : Approx. 12 volts with the ignition SW ON position

P1 A/T Indicator SW

2-6 : Closed with the shift lever in P position

2-1 : Closed with the shift lever in R position

2-9 : Closed with the shift lever in N position

2-7 : Closed with the shift lever in D position

2-3 : Closed with the shift lever in 2 position

2-8 : Closed with the shift lever in L position

: PARTS LOCATION

CodeSee PageCodeSee PageCodeSee Page

A10A42E6B42S1543

A11B42E7E42S2741 (2AZ-FE)

A1742E8D42S28A43

B9A42E9C42S29B43

B10B42E1040 (2AZ-FE)S30A43

C640 (2AZ-FE)G543S31B43

C11A42J241 (2AZ-FE)T341 (2AZ-FE)

C12B42J643T1341 (2AZ-FE)

E240 (2AZ-FE)J743T1643

E442P141 (2AZ-FE)

E5A42P544

System Outline

Service Hints

Page 479 of 2572

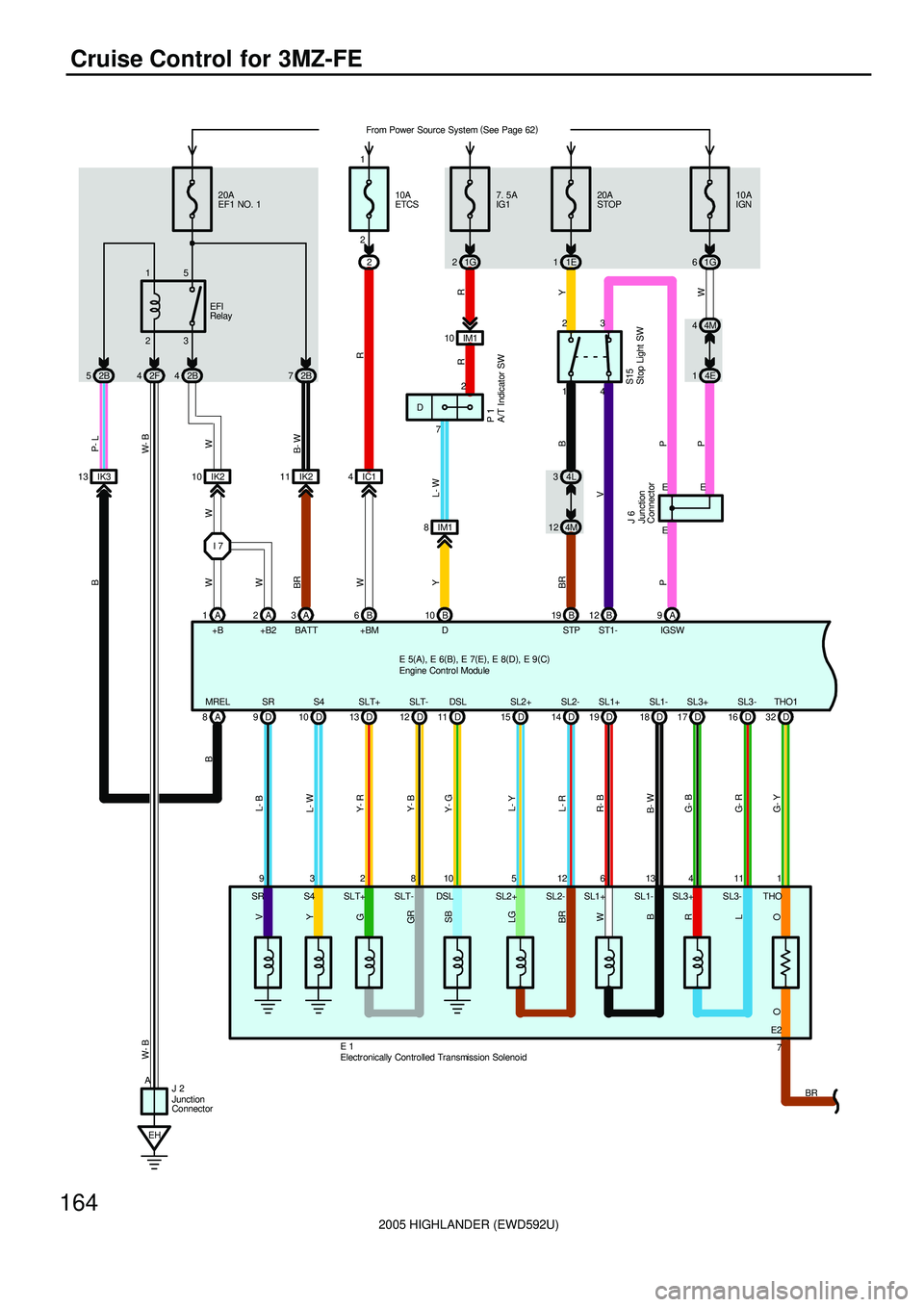

2005 HIGHLANDER (EWD592U)

164

Cruise Control for 3MZ-FE

1 11 4 12 5 10 8 2 3

G- YW P- L

+B BATT20A

EF1 NO. 1

B- W W- B

L- W

Y- R

Y- B

Y- G

L- Y

L- R

G- B

G- R

23 15

2B 4 2F 4 2B 52B7

Y

W

IK2 10 IK21110A

IGN

1G 6 20A

STOP

1E 1

4E 1

B BR

P

I 74M 4

EH1 2

4M 124L 3

1A A3A 9 B 19

A 8

BRW

D 10 D13 D11 D15 D17 D32 D 16 D 12 D14 9

L- B

E 1SL1- SL1+

18 D 19 D

B- WR- B

613IGSW STP

A

J 2MREL S4 SLT+ SLT- DSL SL2+ SL2-

W- B

SL3+ SL3- THO1

D

S15

EFI

Relay

IK3 13

B

B

9E

E

Y

G

GR

SB

LG

BR

R

OL

+B2 2A

WW

P W

B

SR

O

E

P V

B 12

ST1-4 3

R

10A

ETCS

2

W

B 6

+BMIC1 42 1

L- W

R

721G7. 5A

IG1

B 10

D 8IM1IM1 10

R Y

2

J 6P 1 V

THO SL3- SL3+ SL1- SL1+ SL2- SL2+ DSL SLT- SLT+ S4 SR

E2

7

BR D From Power Source System (

See Page 62)

E 5(

A)

, E 6(

B)

, E 7(

E)

, E 8(

D)

, E 9(

C)

Electr onically Controlled Transmission SolenoidEngine Control Module

Junction

Connector

Junction

ConnectorA/T Indicator SW

Stop Light SW

Page 487 of 2572

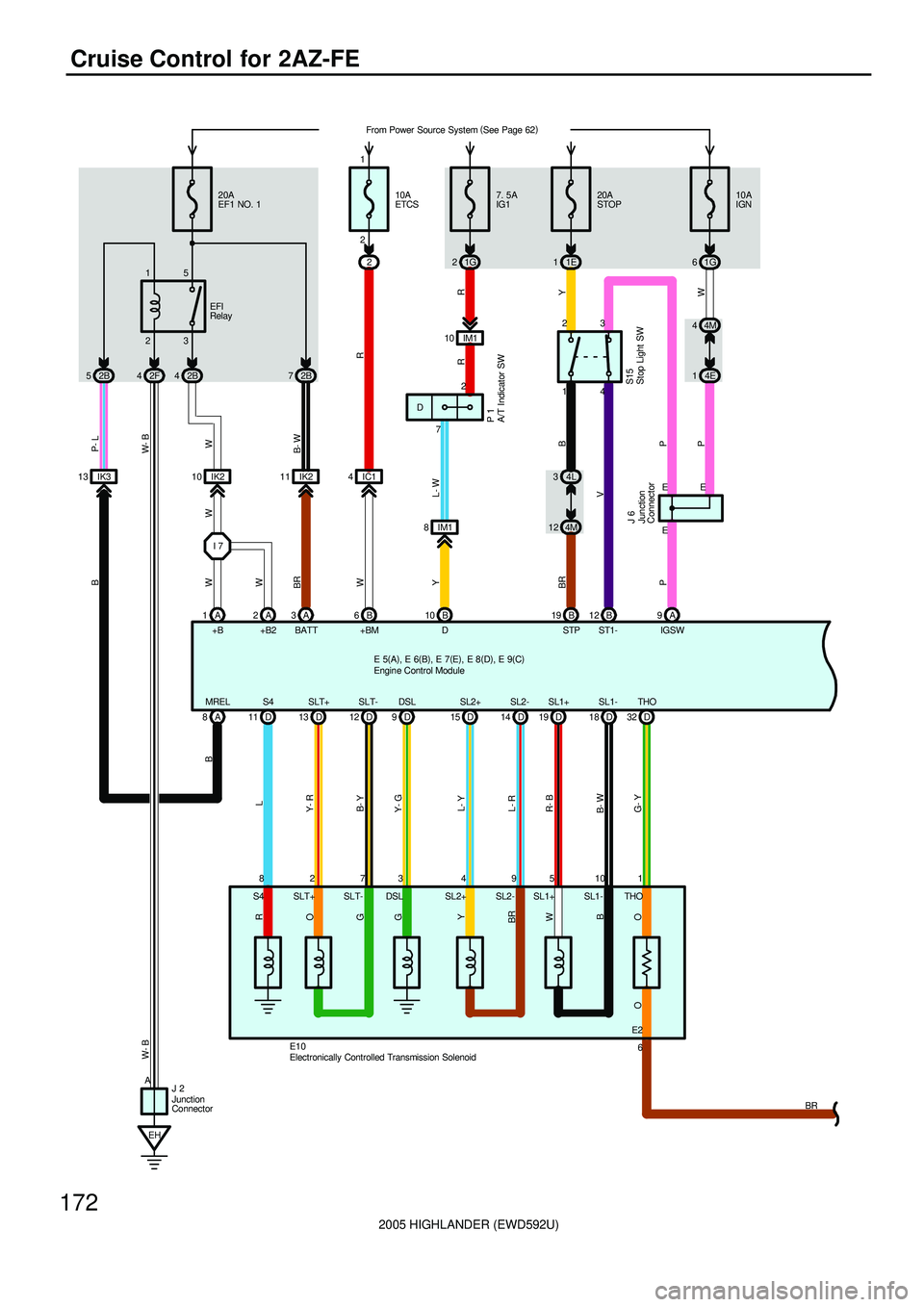

2005 HIGHLANDER (EWD592U)

172

Cruise Control for 2AZ-FE

1 9 4 3 7 2 8

G- YW P- L

+B BATT20A

EF1 NO. 1

B- W W- B

L

Y- R

B- Y

Y- G

L- Y

L- R

23 15

2B 4 2F 4 2B 52B7

Y

W

IK2 10 IK21110A

IGN

1G 6 20A

STOP

1E 1

4E 1

B BR

P

I 74M 4

EH1 2

4M 124L 3

1A A3A 9 B 19

A 8

BRW

D 11 D13 D9D15 D32 D 12 D14

E10SL1- SL1+

18 D 19 D

B- WR- B

510IGSW STP

A

J 2MREL S4 SLT+ SLT- DSL SL2+ SL2-

W- B

THO

S15

EFI

Relay

IK3 13

B

B

E

E

R

O

G

G

Y

BR

O

+B2 2A

WW

P W

B

O

E

P V

B 12

ST1-4 3

R

10A

ETCS

2

W

B 6

+BMIC1 42 1

L- W

R

21G7. 5A

IG1

B 10

D 8IM1IM1 10

R Y

2

J 6P 1

BR THO SL1- SL1+ SL2- SL2+ DSL SLT- SLT+ S4

6 E2 7 D From Power Source System (

See Page 62)

E 5(

A)

, E 6(

B)

, E 7(

E)

, E 8(

D)

, E 9(

C)

Engine Control Module

Electronically Controlled Transmission Solenoid

Junction

Connector

Junction

ConnectorA/T Indicator SW

Stop Light SW

Page 499 of 2572

2005 HIGHLANDER (EWD592U)

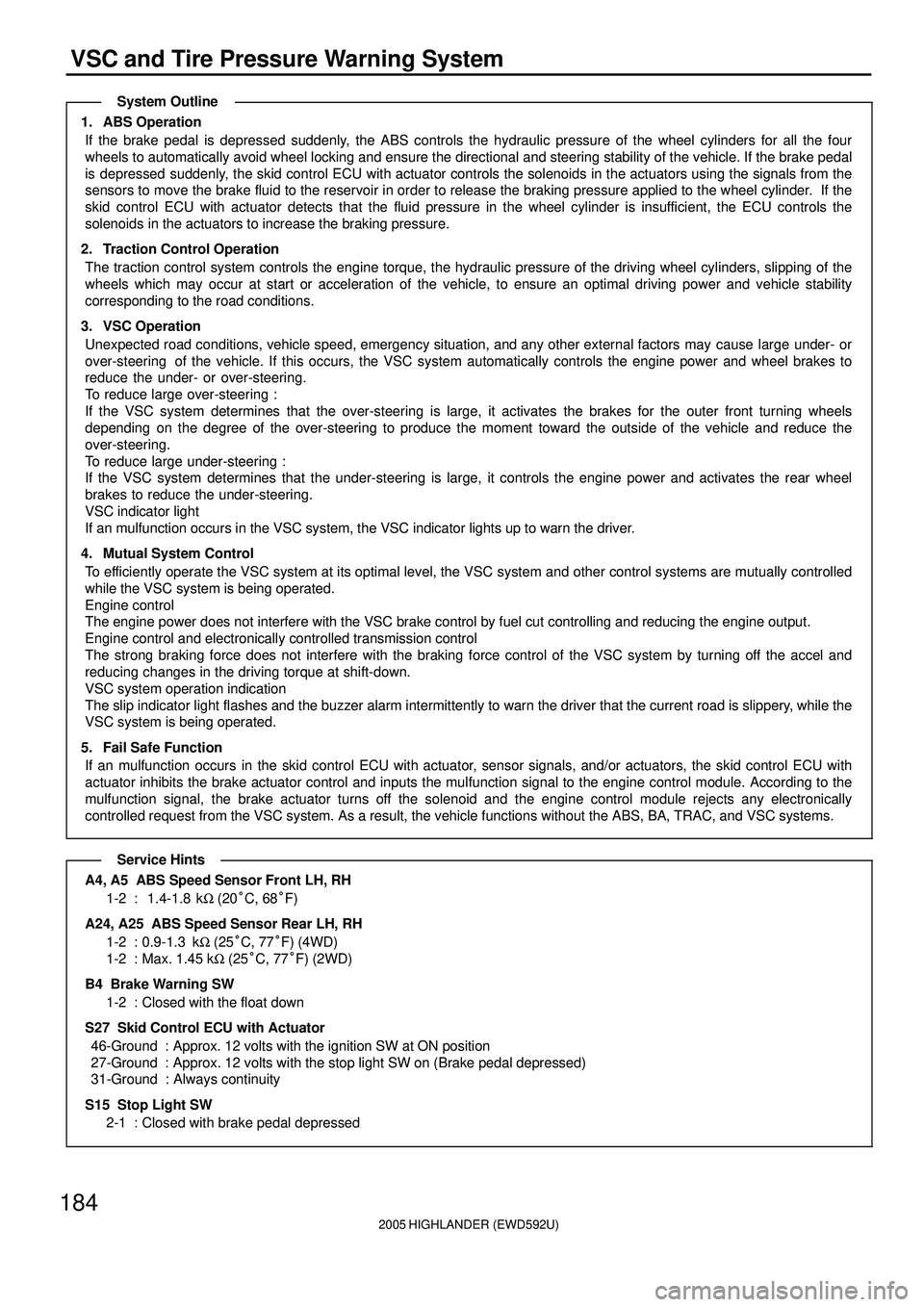

184

VSC and Tire Pressure Warning System

1. ABS Operation

If the brake pedal is depressed suddenly, the ABS controls the hydraulic pressure of the wheel cylinders for all the four

wheels to automatically avoid wheel locking and ensure the directional and steering stability of the vehicle. If the brake pedal

is depressed suddenly, the skid control ECU with actuator controls the solenoids in the actuators using the signals from the

sensors to move the brake fluid to the reservoir in order to release the braking pressure applied to the wheel cylinder. If the

skid control ECU with actuator detects that the fluid pressure in the wheel cylinder is insufficient, the ECU controls the

solenoids in the actuators to increase the braking pressure.

2. Traction Control Operation

The traction control system controls the engine torque, the hydraulic pressure of the driving wheel cylinders, slipping of the

wheels which may occur at start or acceleration of the vehicle, to ensure an optimal driving power and vehicle stability

corresponding to the road conditions.

3. VSC Operation

Unexpected road conditions, vehicle speed, emergency situation, and any other external factors may cause large under- or

over-steering of the vehicle. If this occurs, the VSC system automatically controls the engine power and wheel brakes to

reduce the under- or over-steering.

To reduce large over-steering :

If the VSC system determines that the over-steering is large, it activates the brakes for the outer front turning wheels

depending on the degree of the over-steering to produce the moment toward the outside of the vehicle and reduce the

over-steering.

To reduce large under-steering :

If the VSC system determines that the under-steering is large, it controls the engine power and activates the rear wheel

brakes to reduce the under-steering.

VSC indicator light

If an mulfunction occurs in the VSC system, the VSC indicator lights up to warn the driver.

4. Mutual System Control

To efficiently operate the VSC system at its optimal level, the VSC system and other control systems are mutually controlled

while the VSC system is being operated.

Engine control

The engine power does not interfere with the VSC brake control by fuel cut controlling and reducing the engine output.

Engine control and electronically controlled transmission control

The strong braking force does not interfere with the braking force control of the VSC system by turning off the accel and

reducing changes in the driving torque at shift-down.

VSC system operation indication

The slip indicator light flashes and the buzzer alarm intermittently to warn the driver that the current road is slippery, while the

VSC system is being operated.

5. Fail Safe Function

If an mulfunction occurs in the skid control ECU with actuator, sensor signals, and/or actuators, the skid control ECU with

actuator inhibits the brake actuator control and inputs the mulfunction signal to the engine control module. According to the

mulfunction signal, the brake actuator turns off the solenoid and the engine control module rejects any electronically

controlled request from the VSC system. As a result, the vehicle functions without the ABS, BA, TRAC, and VSC systems.

A4, A5 ABS Speed Sensor Front LH, RH

1-2 : 1.4-1.8 kW (20°C, 68°F)

A24, A25 ABS Speed Sensor Rear LH, RH

1-2 : 0.9-1.3 kW (25°C, 77°F) (4WD)

1-2 : Max. 1.45 kW (25°C, 77°F) (2WD)

B4 Brake Warning SW

1-2 : Closed with the float down

S27 Skid Control ECU with Actuator

46-Ground : Approx. 12 volts with the ignition SW at ON position

27-Ground : Approx. 12 volts with the stop light SW on (Brake pedal depressed)

31-Ground : Always continuity

S15 Stop Light SW

2-1 : Closed with brake pedal depressed

System Outline

Service Hints

Page 575 of 2572

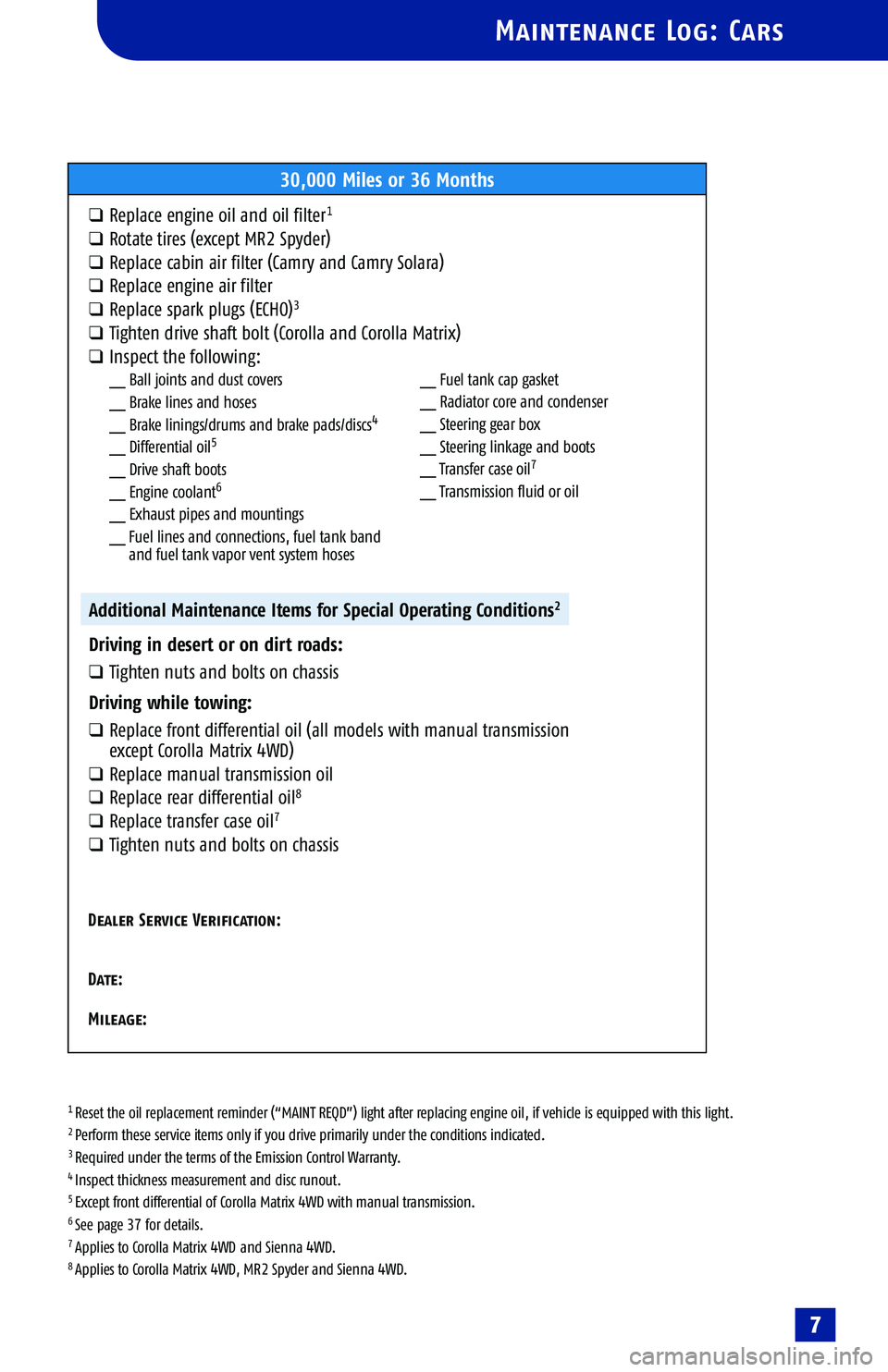

1 Reset the oil replacement reminder (“MAINT REQD”) light after replacing engine oil, if vehicle is equipped with this light.2 Perform these service items only if you drive primarily under the conditions indicated.3 Required under the terms of the Emission Control Warranty.4 Inspec tthickness measurement and disc runout.5 Ex cept front differential of Corolla Matrix 4WD with manual transmission.6 See page 37 for details.7 Applies t o Coroll a M atrix 4WD and Sienna 4WD.8 Applies to Corolla Matrix 4WD, MR2 Spyder and Sienna 4WD.

Maintenance Log: Cars

30,000 Miles or 36 Months

qReplace engine oil and oil filter1

qRotate tires (except MR2 Spyder)

qReplace cabin air filter (Camry and Camry Solara)

qReplace engine air filter

qReplace spark plugs (ECHO)3

qTighten drive shaft bolt (Corolla and Corolla Matrix)

qInspect the following:__ Ball joints and dust covers

__ Brake lines and hoses

__ Brake linings/drums and brake pads/discs

4

__ Differential oil5

__ Drive shaft boots

__ Engine coolant6

__ Exhaust pipes and mountings

__ Fuel lines and connections, fuel tank band

and fuel tank vapor vent system hoses

Additional Maintenance Items for Special Operating Conditions2

Driving in desert or on dirt roads:

qTighten nuts and bolts on chassis

Driving while towing:

qR epl ac e f ront diff erential oil (all models with manual transmission

e x ce pt Cor oll a M atrix 4WD)

qReplace manual transmission oil

qRepl ac e r ear differential oil8

qRepl ac e t ran sfer case oil7

qTighten nuts and bolts on chassis

Dealer Service Verification:

Date:

M ileage:

7

__ Fuel tank cap gasket

__ Radiator core and condenser

__ Steering gear box

__ Steering linkage and boots

__ Transfer case oil

7

__ Transmission fluid or oil