BAT TOYOTA LAND CRUISER 1996 J80 Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: LAND CRUISER, Model: TOYOTA LAND CRUISER 1996 J80Pages: 1399, PDF Size: 41.35 MB

Page 159 of 1399

−

BODY ELECTRICAL HEADLIGHT AND TAILLIGHT SYSTEM

BE−15

1996 LAND CRUISER (RM451U)

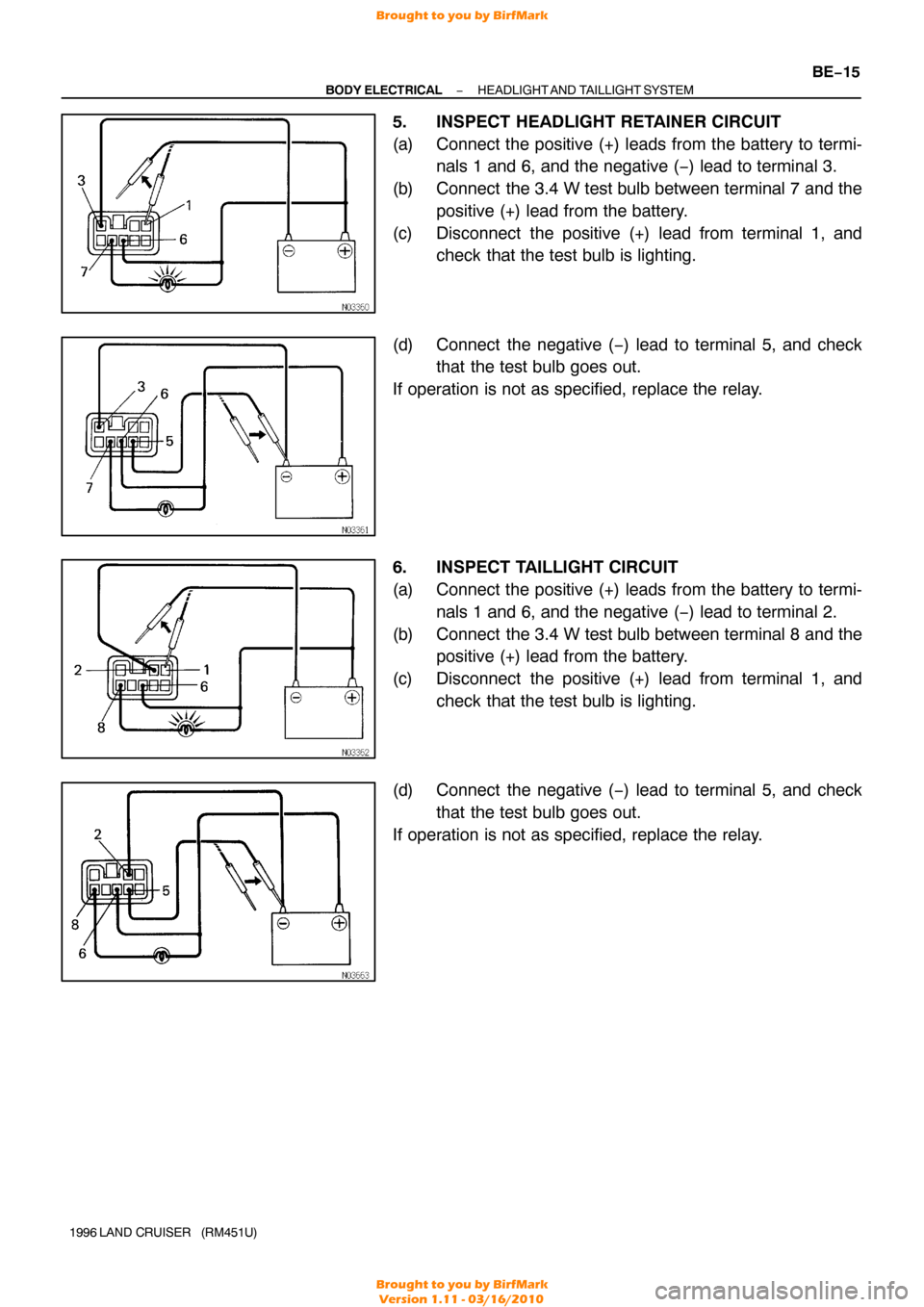

5. INSPECT HEADLIGHT RETAINER CIRCUIT

(a) Connect the positive (+) leads from the battery to termi-

nals 1 and 6, and the negative ( −) lead to terminal 3.

(b) Connect the 3.4 W test bulb between terminal 7 and the positive (+) lead from the battery.

(c) Disconnect the positive (+) lead from terminal 1, and check that the test bulb is lighting.

(d) Connect the negative ( −) lead to terminal 5, and check

that the test bulb goes out.

If operation is not as specified, replace the relay.

6. INSPECT TAILLIGHT CIRCUIT

(a) Connect the positive (+) leads from the battery to termi- nals 1 and 6, and the negative ( −) lead to terminal 2.

(b) Connect the 3.4 W test bulb between terminal 8 and the positive (+) lead from the battery.

(c) Disconnect the positive (+) lead from terminal 1, and check that the test bulb is lighting.

(d) Connect the negative ( −) lead to terminal 5, and check

that the test bulb goes out.

If operation is not as specified, replace the relay.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 163 of 1399

BE27G−01

BE1843

−

BODY ELECTRICAL TURN SIGNAL AND HAZARD WARNING SYSTEM

BE−19

1996 LAND CRUISER (RM451U)

INSPECTION

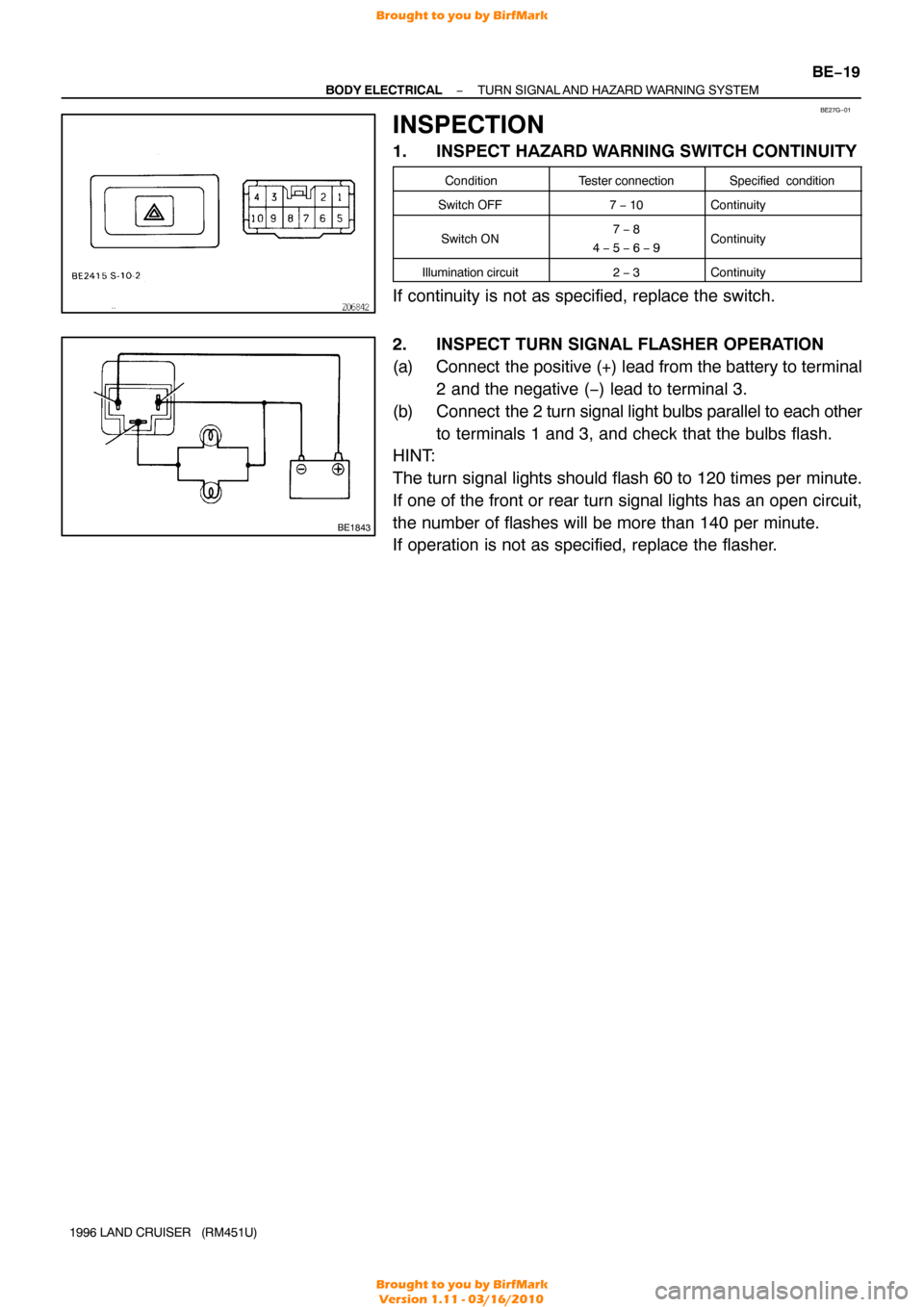

1. INSPECT HAZARD WARNING SWITCH CONTINUITY

ConditionTester connectionSpecified condition

Switch OFF7 − 10Continuity

Switch ON7 − 8

4 − 5 − 6 − 9Continuity

Illumination circuit2 − 3Continuity

If continuity is not as specified, replace the switch.

2. INSPECT TURN SIGNAL FLASHER OPERATION

(a) Connect the positive (+) lead from the battery to terminal

2 and the negative ( −) lead to terminal 3.

(b) Connect the 2 turn signal light bulbs parallel to each other

to terminals 1 and 3, and check that the bulbs flash.

HINT:

The turn signal lights should flash 60 to 120 times per minute.

If one of the front or rear turn signal lights has an open circuit,

the number of flashes will be more than 140 per minute.

If operation is not as specified, replace the flasher.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 171 of 1399

BE1MA−01

B7B16

B18

B7 B4

B18 B16

−

BODY ELECTRICAL WIPER AND WASHER SYSTEM

BE−27

1996 LAND CRUISER (RM451U)

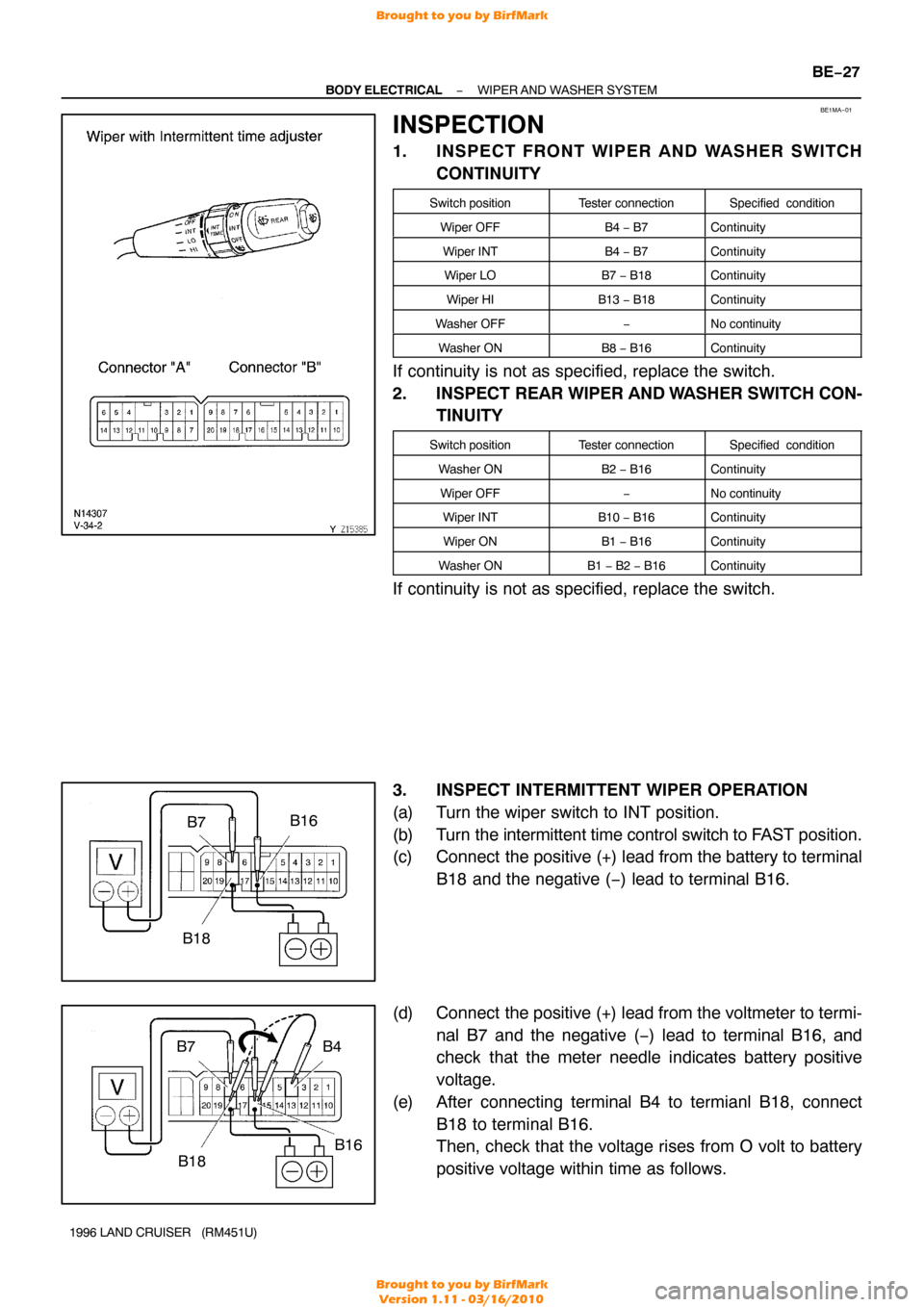

INSPECTION

1. INSPECT FRONT WIPER AND WASHER SWITCH

CONTINUITY

Switch positionTester connectionSpecified condition

Wiper OFFB4 − B7Continuity

Wiper INTB4 − B7Continuity

Wiper LOB7 − B18Continuity

Wiper HIB13 − B18Continuity

Washer OFF−No continuity

Washer ONB8 − B16Continuity

If continuity is not as specified, replace the switch.

2. INSPECT REAR WIPER AND WASHER SWITCH CON-

TINUITY

Switch positionTester connectionSpecified condition

Washer ONB2 − B16Continuity

Wiper OFF−No continuity

Wiper INTB10 − B16Continuity

Wiper ONB1 − B16Continuity

Washer ONB1 − B2 − B16Continuity

If continuity is not as specified, replace the switch.

3. INSPECT INTERMITTENT WIPER OPERATION

(a) Turn the wiper switch to INT position.

(b) Turn the intermitte nt time control switch to FAST position.

(c) Connect the positive (+) lead from the battery to terminal

B18 and the negative ( −) lead to terminal B16.

(d) Connect the positive (+) lead from the voltmeter to termi- nal B7 and the negative ( −) lead to terminal B16, and

check that the meter needle indicates battery positive

voltage.

(e) After connecting terminal B4 to termianl B18, connect B18 to terminal B16.

Then, check that the voltage rises from O volt to battery

positive voltage within time as follows.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 172 of 1399

V02744

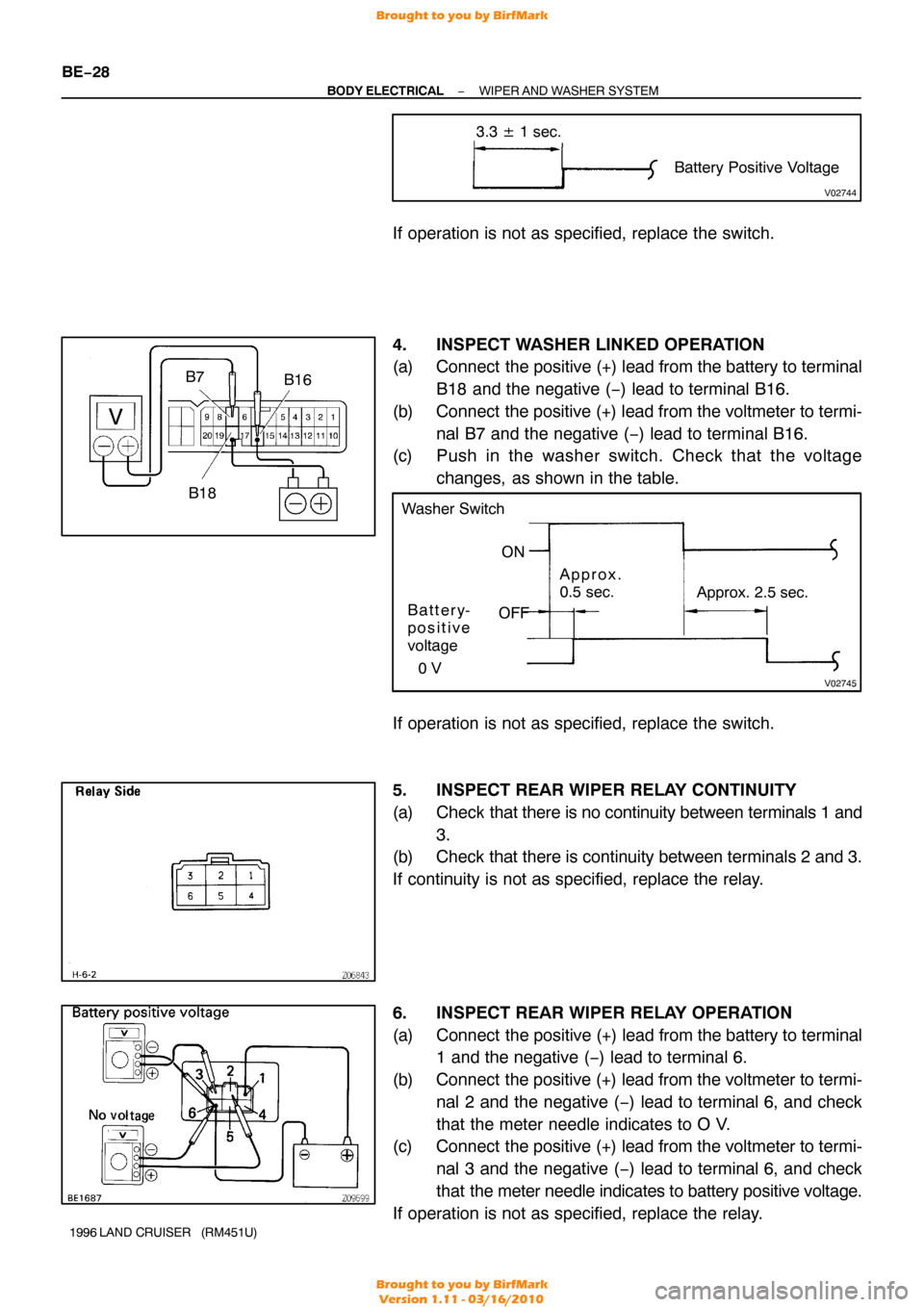

3.3 ± 1 sec.

Battery Positive Voltage

B7B16

B18

V02745

Washer Switch ON

OFF Approx.

0.5 sec.

Battery-

positive

voltage Approx. 2.5 sec.

0 V

BE−28

−

BODY ELECTRICAL WIPER AND WASHER SYSTEM

1996 LAND CRUISER (RM451U)

If operation is not as specified, replace the switch.

4. INSPECT WASHER LINKED OPERATION

(a) Connect the positive (+) lead from the battery to terminal

B18 and the negative ( −) lead to terminal B16.

(b) Connect the positive (+) lead from the voltmeter to termi- nal B7 and the negative ( −) lead to terminal B16.

(c) Push in the washer switch. Check that the voltage

changes, as shown in the table.

If operation is not as specified, replace the switch.

5. INSPECT REAR WIPER RELAY CONTINUITY

(a) Check that there is no continuity between terminals 1 and

3.

(b) Check that there is continuity between terminals 2 and 3.

If continuity is not as specified, replace the relay.

6. INSPECT REAR WIPER RELAY OPERATION

(a) Connect the positive (+) lead from the battery to terminal 1 and the negative ( −) lead to terminal 6.

(b) Connect the positive (+) lead from the voltmeter to termi- nal 2 and the negative ( −) lead to terminal 6, and check

that the meter needle indicates to O V.

(c) Connect the positive (+) lead from the voltmeter to termi-

nal 3 and the negative ( −) lead to terminal 6, and check

that the meter needle indicates to battery positive voltage.

If operation is not as specified, replace the relay.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 173 of 1399

−

BODY ELECTRICAL WIPER AND WASHER SYSTEM

BE−29

1996 LAND CRUISER (RM451U)

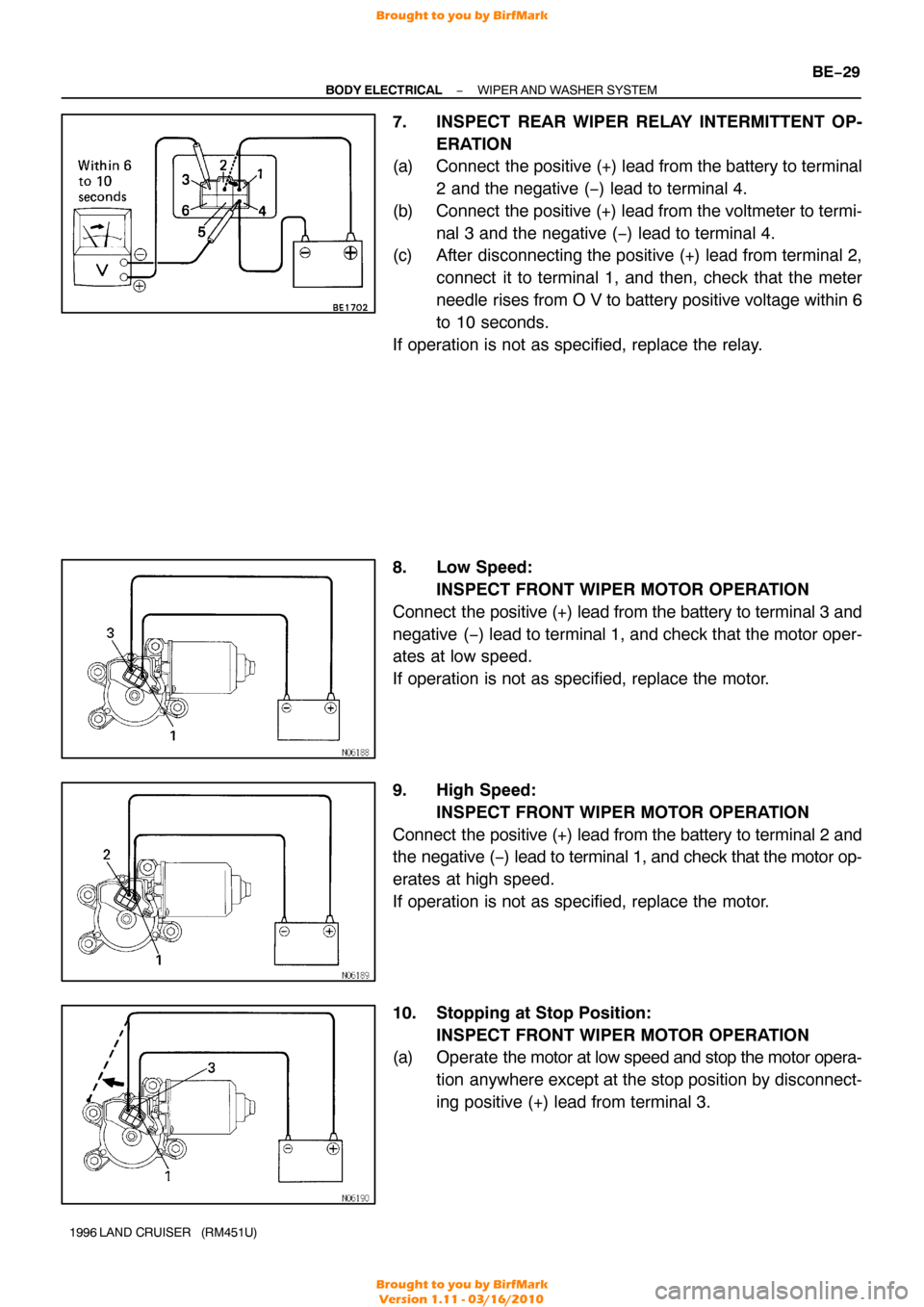

7. INSPECT REAR WIPER RELAY INTERMITTENT OP-

ERATION

(a) Connect the positive (+) lead from the battery to terminal

2 and the negative ( −) lead to terminal 4.

(b) Connect the positive (+) lead from the voltmeter to termi- nal 3 and the negative ( −) lead to terminal 4.

(c) After disconnecting the positive (+) lead from terminal 2,

connect it to terminal 1, and then, check that the meter

needle rises from O V to battery positive voltage within 6

to 10 seconds.

If operation is not as specified, replace the relay.

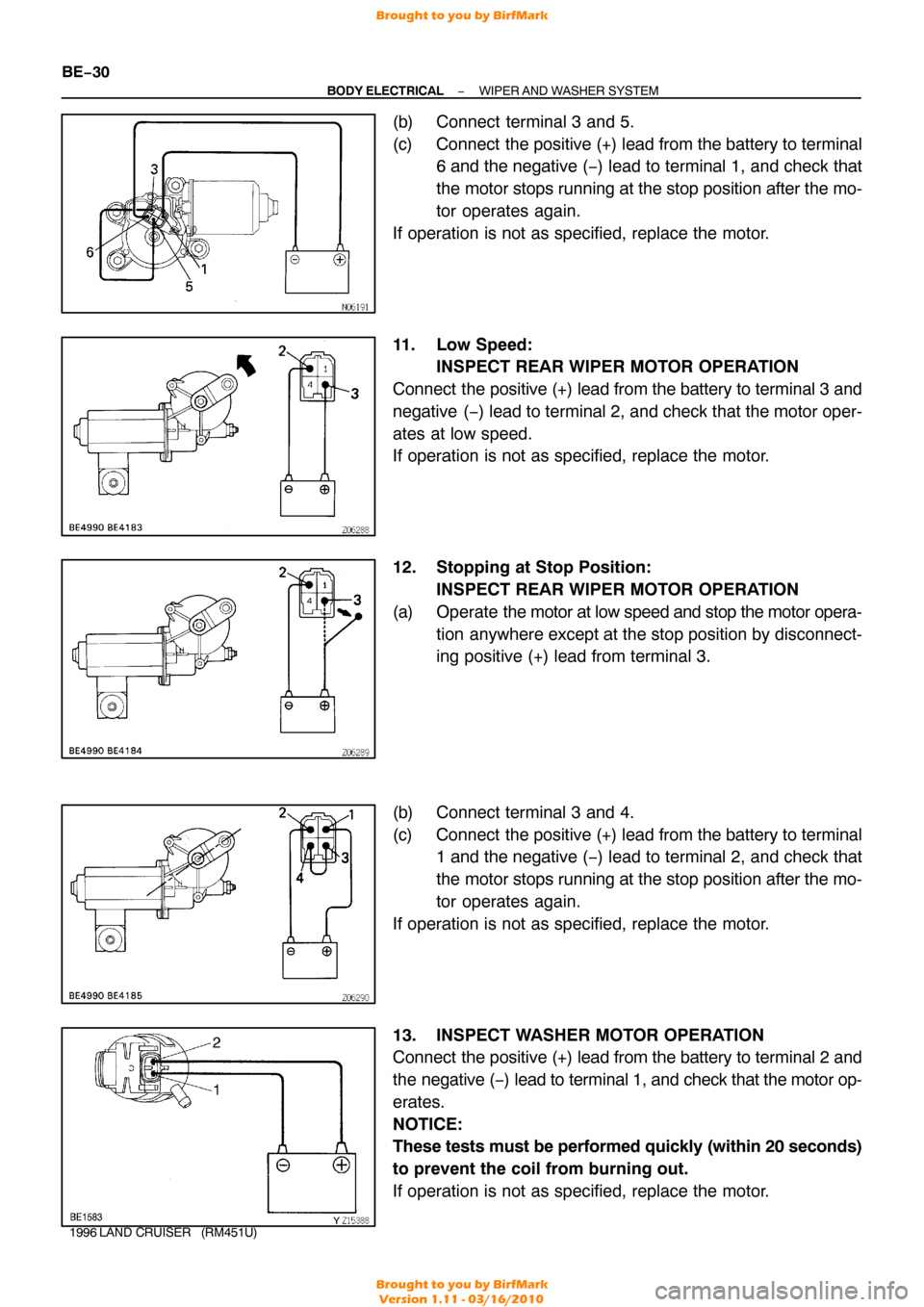

8. Low Speed: INSPECT FRONT WIPER MOTOR OPERATION

Connect the positive (+) lead from the battery to terminal 3 and

negative ( −) lead to terminal 1, and check that the motor oper-

ates at low speed.

If operation is not as specified, replace the motor.

9. High Speed:

INSPECT FRONT WIPER MOTOR OPERATION

Connect the positive (+) lead from the battery to terminal 2 and

the negative (− ) lead to terminal 1, and check that the motor op-

erates at high speed.

If operation is not as specified, replace the motor.

10. Stopping at Stop Position: INSPECT FRONT WIPER MOTOR OPERATION

(a) Operate the motor at low speed and stop the motor opera-

tion anywhere except at the stop position by disconnect-

ing positive (+) lead from terminal 3.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 174 of 1399

BE−30

−

BODY ELECTRICAL WIPER AND WASHER SYSTEM

1996 LAND CRUISER (RM451U)

(b) Connect terminal 3 and 5.

(c) Connect the positive (+) lead from the battery to terminal

6 and the negative ( −) lead to terminal 1, and check that

the motor stops running at the stop position after the mo-

tor operates again.

If operation is not as specified, replace the motor.

11. Low Speed: INSPECT REAR WIPER MOTOR OPERATION

Connect the positive (+) lead from the battery to terminal 3 and

negative ( −) lead to terminal 2, and check that the motor oper-

ates at low speed.

If operation is not as specified, replace the motor.

12. Stopping at Stop Position: INSPECT REAR WIPER MOTOR OPERATION

(a) Operate the motor at low speed and stop the motor opera-

tion anywhere except at the stop position by disconnect-

ing positive (+) lead from terminal 3.

(b) Connect terminal 3 and 4.

(c) Connect the positive (+) lead from the battery to terminal 1 and the negative ( −) lead to terminal 2, and check that

the motor stops running at the stop position after the mo-

tor operates again.

If operation is not as specified, replace the motor.

13. INSPECT WASHER MOTOR OPERATION

Connect the positive (+) lead from the battery to terminal 2 and

the negative (− ) lead to terminal 1, and check that the motor op-

erates.

NOTICE:

These tests must be performed quickly (within 20 seconds)

to prevent the coil from burning out.

If operation is not as specified, replace the motor.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 178 of 1399

BE1MD−01

BE−34

−

BODY ELECTRICAL COMBINATION METER

1996 LAND CRUISER (RM451U)

INSPECTION

1. INSPECT SPEEDOMETER ON−VEHICLE:

Using a speedometer tester, inspect the speedometer for allow-

able indication error and check the operation of the odometer.

HINT:

Tire wear and tire over or under inflation will increase the indica-

tion error.

If error is excessive, replace the speedometer.

Standard indicationAllowable range

2018 − 24

4038 − 44

6058 − 66

8078 − 88

10098 − 11 0

120118 − 132

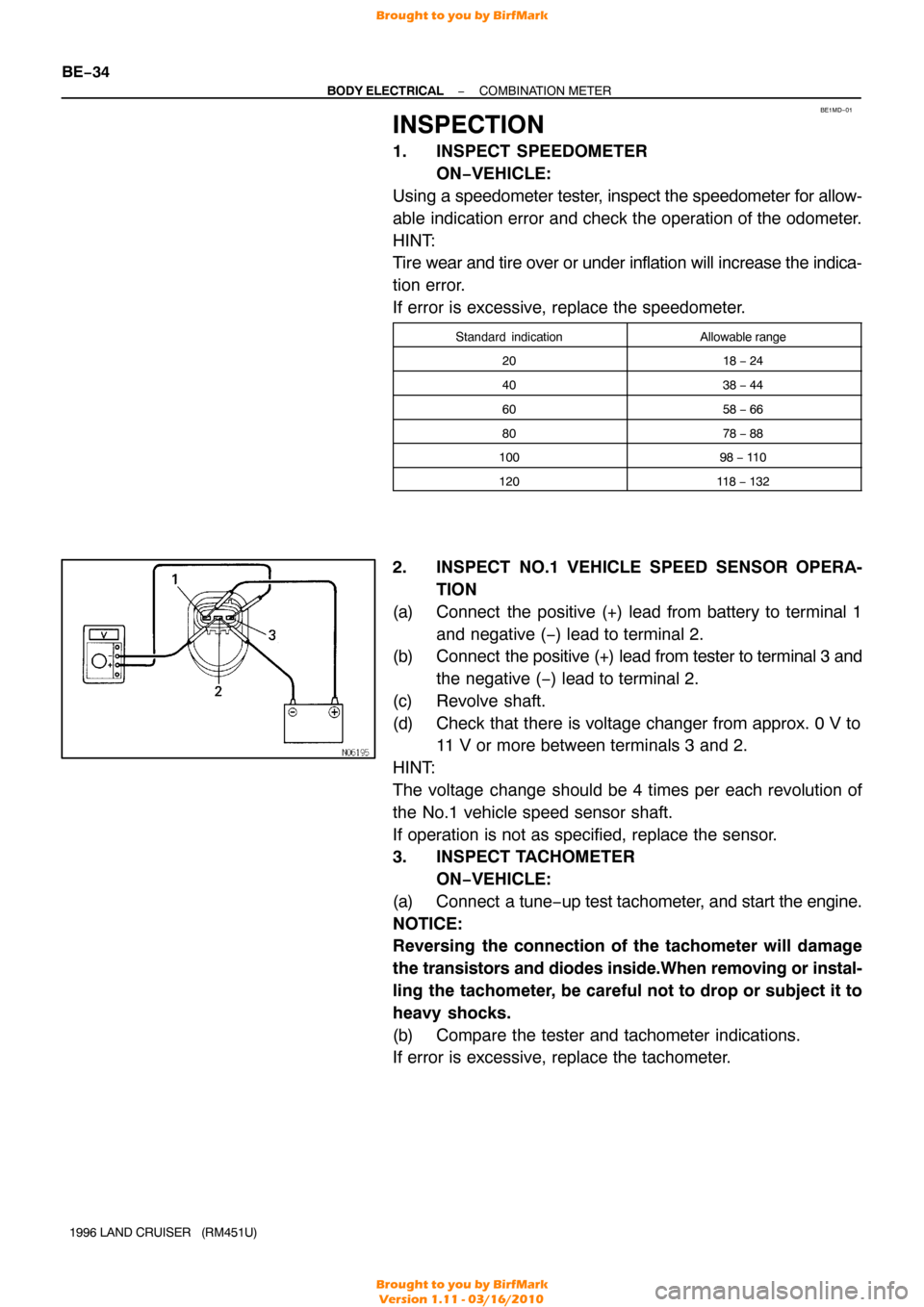

2. INSPECT NO.1 VEHICLE SPEED SENSOR OPERA-

TION

(a) Connect the positive (+) lead from battery to terminal 1 and negative ( −) lead to terminal 2.

(b) Connect the positive (+) lead from tester to terminal 3 and

the negative ( −) lead to terminal 2.

(c) Revolve shaft.

(d) Check that there is voltage changer from approx. 0 V to 11 V or more between terminals 3 and 2.

HINT:

The voltage change should be 4 times per each revolution of

the No.1 vehicle speed sensor shaft.

If operation is not as specified, replace the sensor.

3. INSPECT TACHOMETER ON−VEHICLE:

(a) Connect a tune− up test tachometer, and start the engine.

NOTICE:

Reversing the connection of the tachometer will damage

the transistors and diodes inside.When removing or instal-

ling the tachometer, be careful not to drop or subject it to

heavy shocks.

(b) Compare the tester and tachometer indications.

If error is excessive, replace the tachometer.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 180 of 1399

BE−36

−

BODY ELECTRICAL COMBINATION METER

1996 LAND CRUISER (RM451U)

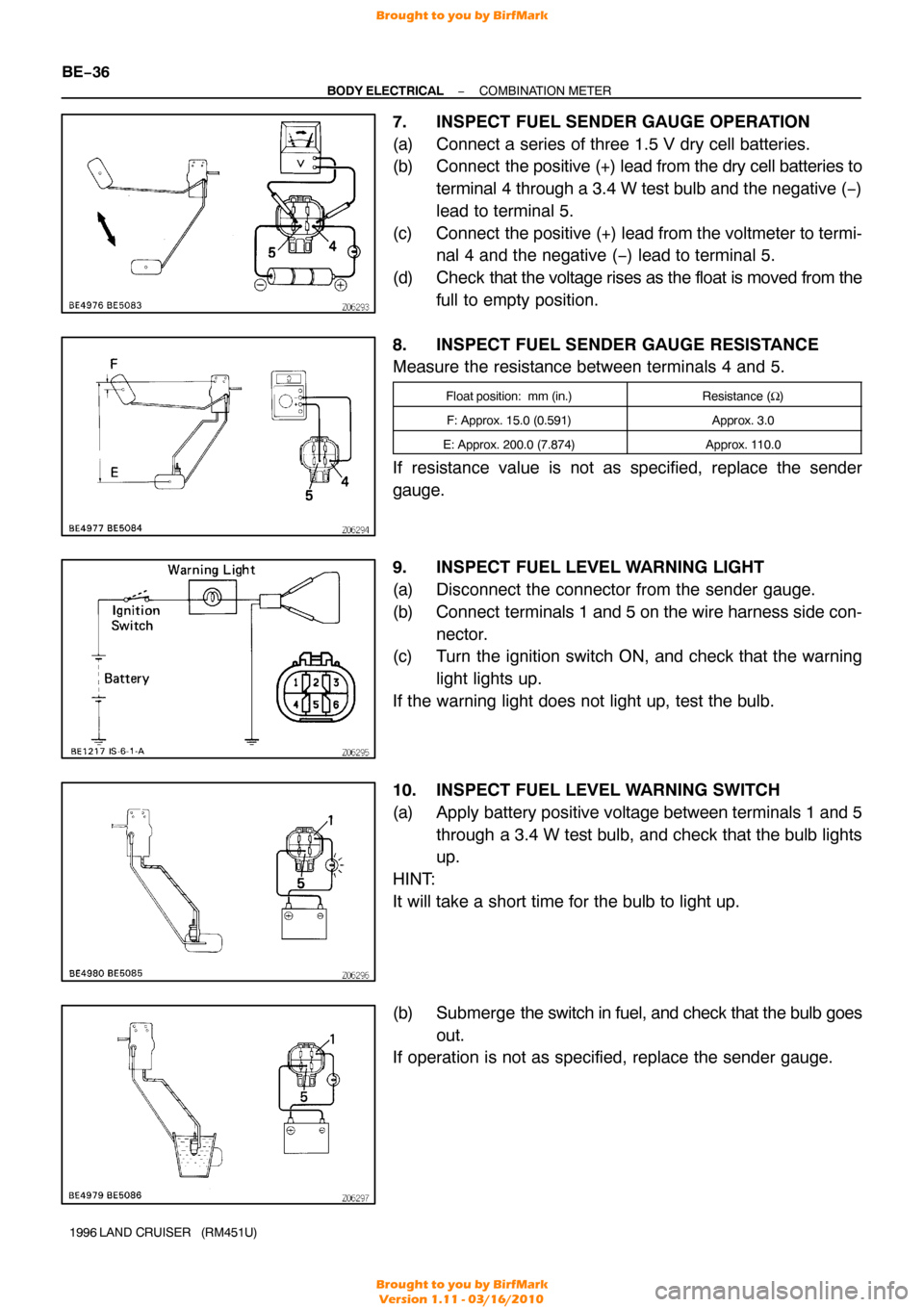

7. INSPECT FUEL SENDER GAUGE OPERATION

(a) Connect a series of three 1.5 V dry cell batteries.

(b) Connect the positive (+) lead from the dry cell batteries to

terminal 4 through a 3.4 W test bulb and the negative ( −)

lead to terminal 5.

(c) Connect the positive (+) lead from the voltmeter to termi- nal 4 and the negative ( −) lead to terminal 5.

(d) Check that the voltage rises as the float is moved from the

full to empty position.

8. INSPECT FUEL SENDER GAUGE RESISTANCE

Measure the resistance between terminals 4 and 5.

Float position: mm (in.)Resistance (Ω )

F: Approx. 15.0 (0.591)Approx. 3.0

E: Approx. 200.0 (7.874)Approx. 110.0

If resistance value is not as specified, replace the sender

gauge.

9. INSPECT FUEL LEVEL WARNING LIGHT

(a) Disconnect the connector from the sender gauge.

(b) Connect terminals 1 and 5 on the wire harness side con-

nector.

(c) Turn the ignition switch ON, and check that the warning

light lights up.

If the warning light does not light up, test the bulb.

10. INSPECT FUEL LEVEL WARNING SWITCH

(a) Apply battery positive voltage between terminals 1 and 5

through a 3.4 W test bulb, and check that the bulb lights

up.

HINT:

It will take a short time for the bulb to light up.

(b) Submerge the switch in fuel, and check that the bulb goes

out.

If operation is not as specified, replace the sender gauge.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 181 of 1399

Engine Coolant

Temperature

Gauge

Ignition Switch

Battery Sender

Gauge

Z06815

Engine

Coolant T emperature Gauge

Ignition

Switch Tester Bulb

(3.4 W)

Battery

BE1222

Oil Pressure Gauge

Ignition

Switch Sender

Gauge

Battery

−

BODY ELECTRICAL COMBINATION METER

BE−37

1996 LAND CRUISER (RM451U)

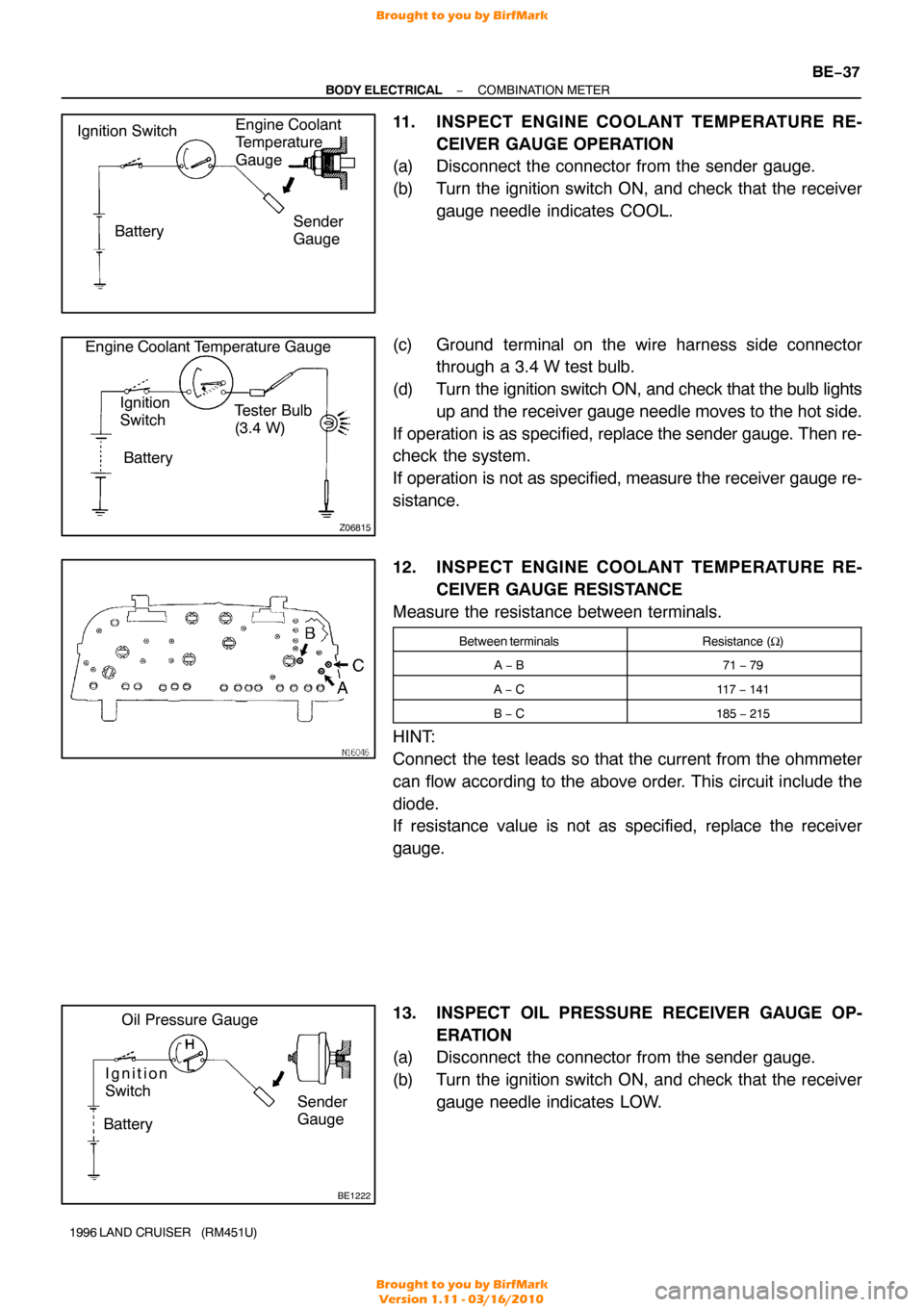

11. INSPECT ENGINE COOLANT TEMPERATURE RE-

CEIVER GAUGE OPERATION

(a) Disconnect the connector from the sender gauge.

(b) Turn the ignition switch ON, and check that the receiver

gauge needle indicates COOL.

(c) Ground terminal on the wire harness side connector through a 3.4 W test bulb.

(d) Turn the ignition switch ON, and check that the bulb lights up and the receiver gauge needle moves to the hot side.

If operation is as specified, replace the sender gauge. Then re-

check the system.

If operation is not as specified, measure the receiver gauge re-

sistance.

12. INSPECT ENGINE COOLANT TEMPERATURE RE-

CEIVER GAUGE RESISTANCE

Measure the resistance between terminals.

Between terminalsResistance (Ω )

A − B71 − 79

A − C117 − 141

B − C185 − 215

HINT:

Connect the test leads so that the current from the ohmmeter

can flow according to the above order. This circuit include the

diode.

If resistance value is not as specified, replace the receiver

gauge.

13. INSPECT OIL PRESSURE RECEIVER GAUGE OP-

ERATION

(a) Disconnect the connector from the sender gauge.

(b) Turn the ignition switch ON, and check that the receiver

gauge needle indicates LOW.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 182 of 1399

BE4917

Test LED

Battery

BE1217

Warning Light

Ignition

Switch Battery

N01212

BE−38

−

BODY ELECTRICAL COMBINATION METER

1996 LAND CRUISER (RM451U)

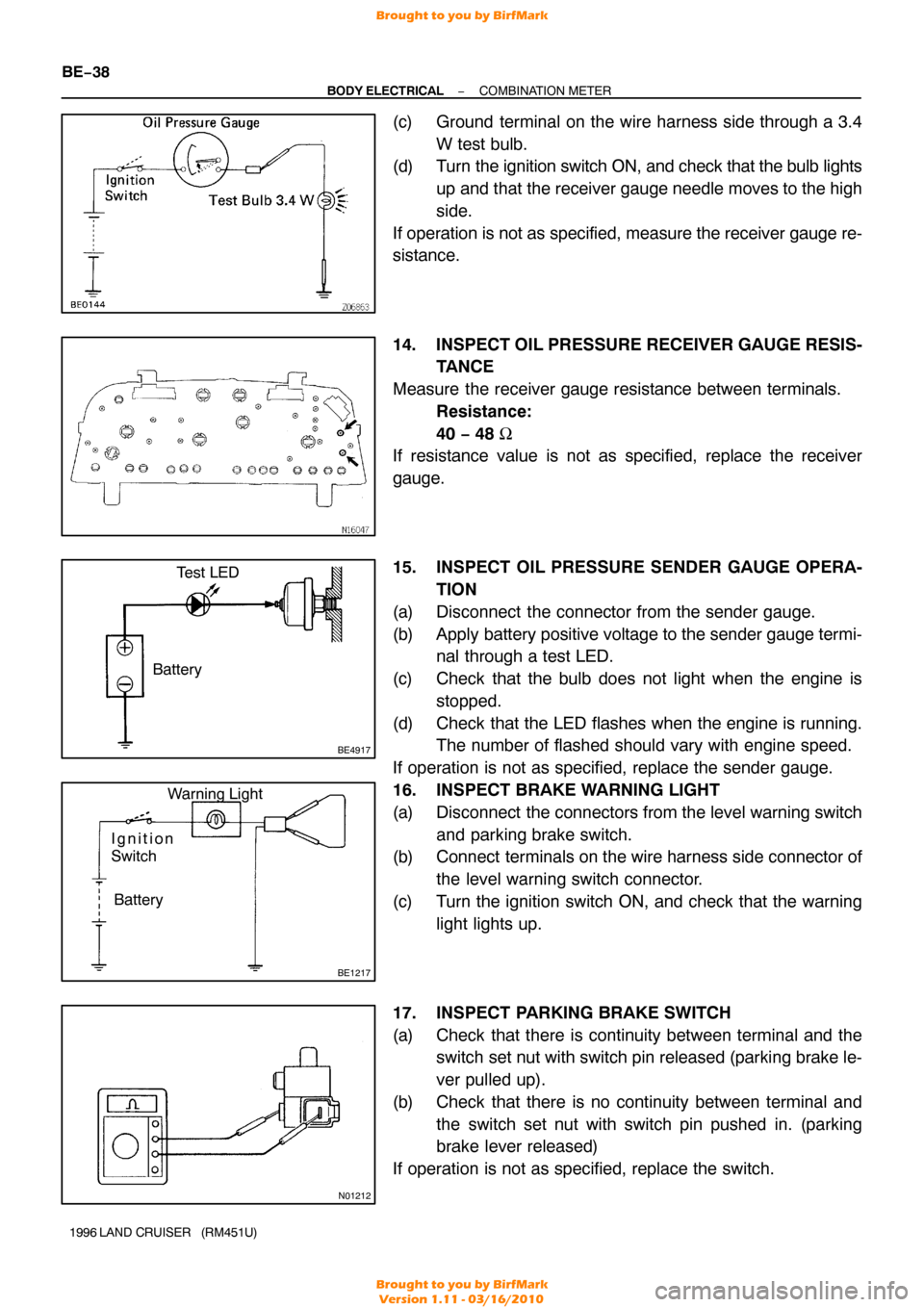

(c) Ground terminal on the wire harness side through a 3.4

W test bulb.

(d) Turn the ignition switch ON, and check that the bulb lights

up and that the receiver gauge needle moves to the high

side.

If operation is not as specified, measure the receiver gauge re-

sistance.

14. INSPECT OIL PRESSURE RECEIVER GAUGE RESIS- TANCE

Measure the receiver gauge resistance between terminals. Resistance:

40 − 48 Ω

If resistance value is not as specified, replace the receiver

gauge.

15. INSPECT OIL PRESSURE SENDER GAUGE OPERA-

TION

(a) Disconnect the connector from the sender gauge.

(b) Apply battery positive voltage to the sender gauge termi- nal through a test LED.

(c) Check that the bulb does not light when the engine is stopped.

(d) Check that the LED flashes when the engine is running. The number of flashed should vary with engine speed.

If operation is not as specified, replace the sender gauge.

16. INSPECT BRAKE WARNING LIGHT

(a) Disconnect the connectors from the level warning switch and parking brake switch.

(b) Connect terminals on the wire harness side connector of

the level warning switch connector.

(c) Turn the ignition switch ON, and check that the warning light lights up.

17. INSPECT PARKING BRAKE SWITCH

(a) Check that there is continuity between terminal and the switch set nut with switch pin released (parking brake le-

ver pulled up).

(b) Check that there is no continuity between terminal and the switch set nut with switch pin pushed in. (parking

brake lever released)

If operation is not as specified, replace the switch.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010