TOYOTA PROACE 2019 Owners Manual (in English)

Manufacturer: TOYOTA, Model Year: 2019, Model line: PROACE, Model: TOYOTA PROACE 2019Pages: 516, PDF Size: 90.91 MB

Page 291 of 516

291

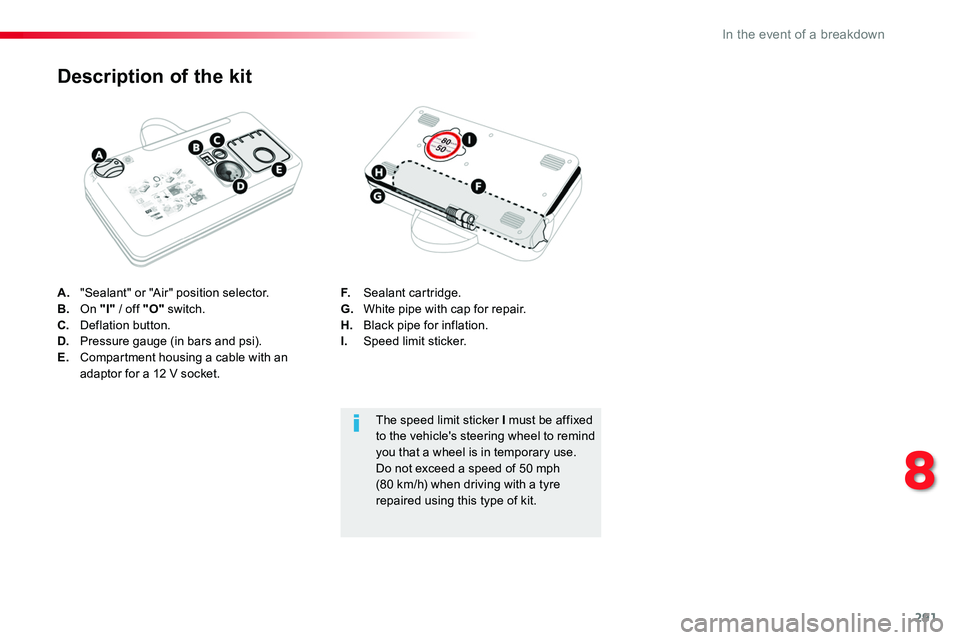

A. "Sealant" or "Air" position selector.B. On "I" / off "O" switch.C. Deflation button.D. Pressure gauge (in bars and psi).E. Compartment housing a cable with an adaptor for a 12 V socket.

Description of the kit

F. Sealant cartridge.G. White pipe with cap for repair.H. Black pipe for inflation.I. Speed limit sticker.

The speed limit sticker I must be affixed to the vehicle's steering wheel to remind you that a wheel is in temporary use.Do not exceed a speed of 50 mph (80 km/h) when driving with a tyre repaired using this type of kit.

8

In the event of a breakdown

Page 292 of 516

292

Repair procedure

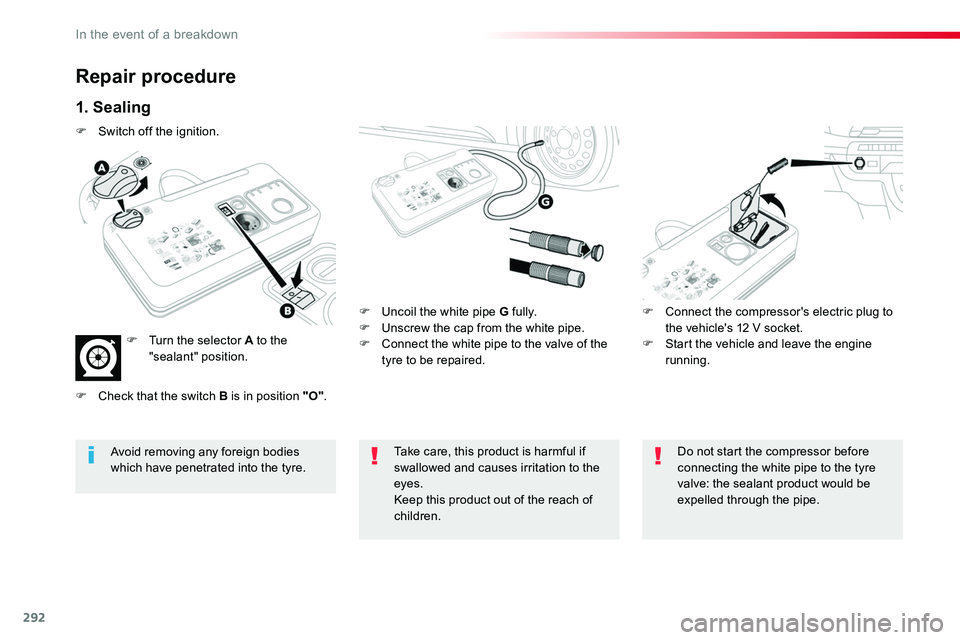

1. Sealing

F Uncoil the white pipe G fully.F Unscrew the cap from the white pipe.F Connect the white pipe to the valve of the tyre to be repaired.

F Connect the compressor's electric plug to the vehicle's 12 V socket.F Start the vehicle and leave the engine running.

Take care, this product is harmful if swallowed and causes irritation to the eyes.Keep this product out of the reach of children.

Avoid removing any foreign bodies which have penetrated into the tyre.

Do not start the compressor before connecting the white pipe to the tyre valve: the sealant product would be expelled through the pipe.

F Switch off the ignition.

F Turn the selector A to the "sealant" position.

F Check that the switch B is in position "O".

In the event of a breakdown

Page 293 of 516

293

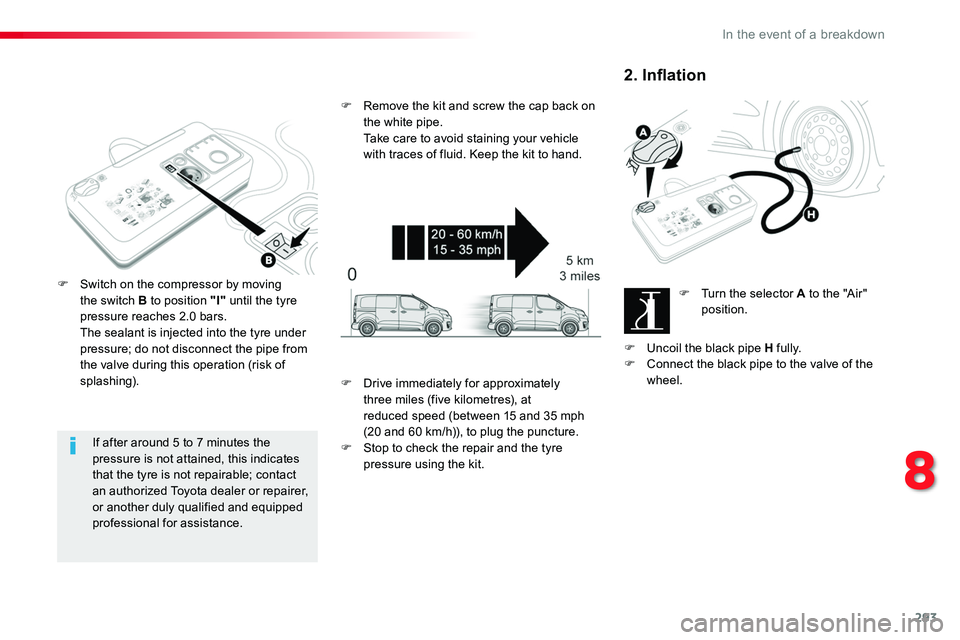

If after around 5 to 7 minutes the pressure is not attained, this indicates that the tyre is not repairable; contact an authorized Toyota dealer or repairer, or another duly qualified and equipped professional for assistance.

F Switch on the compressor by moving the switch B to position "I" until the tyre pressure reaches 2.0 bars. The sealant is injected into the tyre under pressure; do not disconnect the pipe from the valve during this operation (risk of splashing).

F Remove the kit and screw the cap back on the white pipe. Take care to avoid staining your vehicle with traces of fluid. Keep the kit to hand.

2. Inflation

F Turn the selector A to the "Air" position.

F Uncoil the black pipe H fully.F Connect the black pipe to the valve of the wheel.F Drive immediately for approximately three miles (five kilometres), at reduced speed (between 15 and 35 mph (20 and 60 km/h)), to plug the puncture.F Stop to check the repair and the tyre pressure using the kit.

8

In the event of a breakdown

Page 294 of 516

294

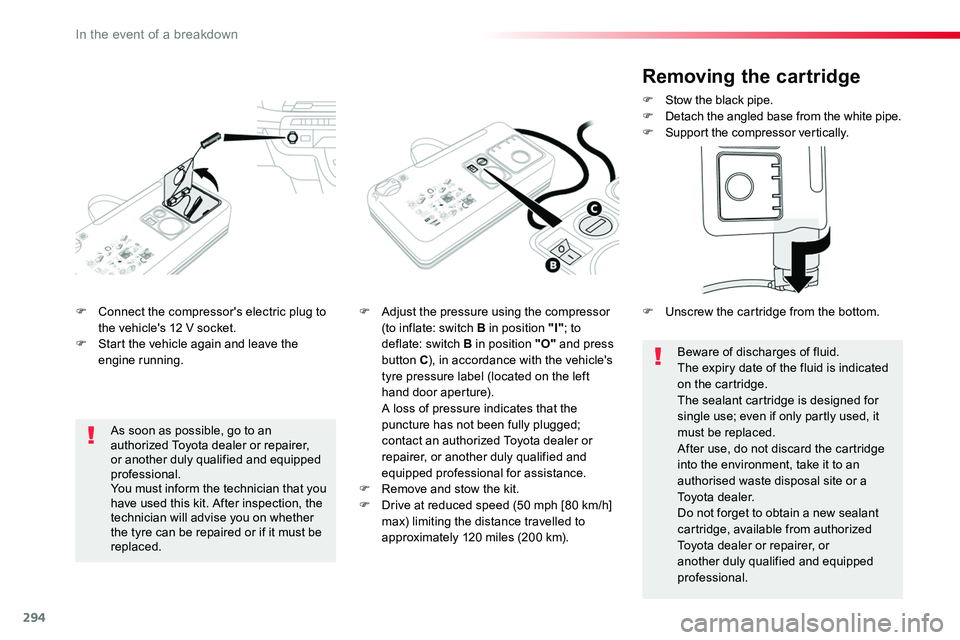

F Connect the compressor's electric plug to the vehicle's 12 V socket.F Start the vehicle again and leave the engine running.

F Adjust the pressure using the compressor (to inflate: switch B in position "I"; to deflate: switch B in position "O" and press button C), in accordance with the vehicle's tyre pressure label (located on the left hand door aperture). A loss of pressure indicates that the puncture has not been fully plugged;

contact an authorized Toyota dealer or repairer, or another duly qualified and equipped professional for assistance.F Remove and stow the kit.F Drive at reduced speed (50 mph [80 km/h] max) limiting the distance travelled to approximately 120 miles (200 km).

As soon as possible, go to an authorized Toyota dealer or repairer, or another duly qualified and equipped professional.You must inform the technician that you have used this kit. After inspection, the technician will advise you on whether the tyre can be repaired or if it must be replaced.

Removing the cartridge

F Stow the black pipe.F Detach the angled base from the white pipe.F Support the compressor vertically.

Beware of discharges of fluid.The expiry date of the fluid is indicated on the cartridge.The sealant cartridge is designed for single use; even if only partly used, it must be replaced.After use, do not discard the cartridge into the environment, take it to an authorised waste disposal site or a Toyota dealer.Do not forget to obtain a new sealant cartridge, available from authorized Toyota dealer or repairer, or another duly qualified and equipped professional.

F Unscrew the cartridge from the bottom.

In the event of a breakdown

Page 295 of 516

295

Checking / adjusting tyre

pressures

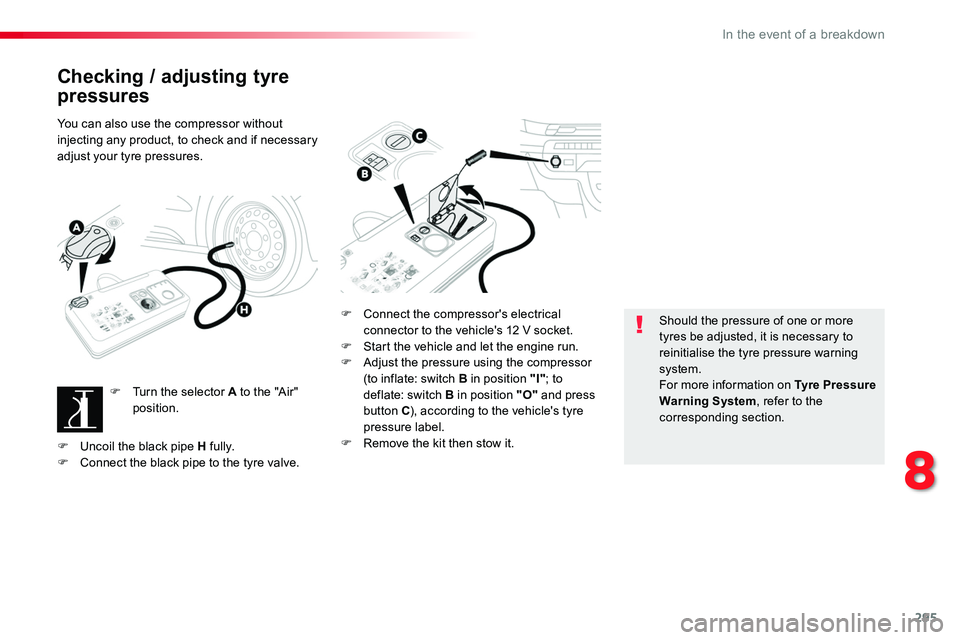

You can also use the compressor without injecting any product, to check and if necessary adjust your tyre pressures.

F Turn the selector A to the "Air" position.

F Connect the compressor's electrical connector to the vehicle's 12 V socket.F Start the vehicle and let the engine run.F Adjust the pressure using the compressor (to inflate: switch B in position "I"; to deflate: switch B in position "O" and press button C), according to the vehicle's tyre pressure label.F Remove the kit then stow it.

Should the pressure of one or more tyres be adjusted, it is necessary to reinitialise the tyre pressure warning system.For more information on Tyre Pressure Warning System, refer to the corresponding section.

F Uncoil the black pipe H fully.F Connect the black pipe to the tyre valve.

8

In the event of a breakdown

Page 296 of 516

296

Changing a wheel

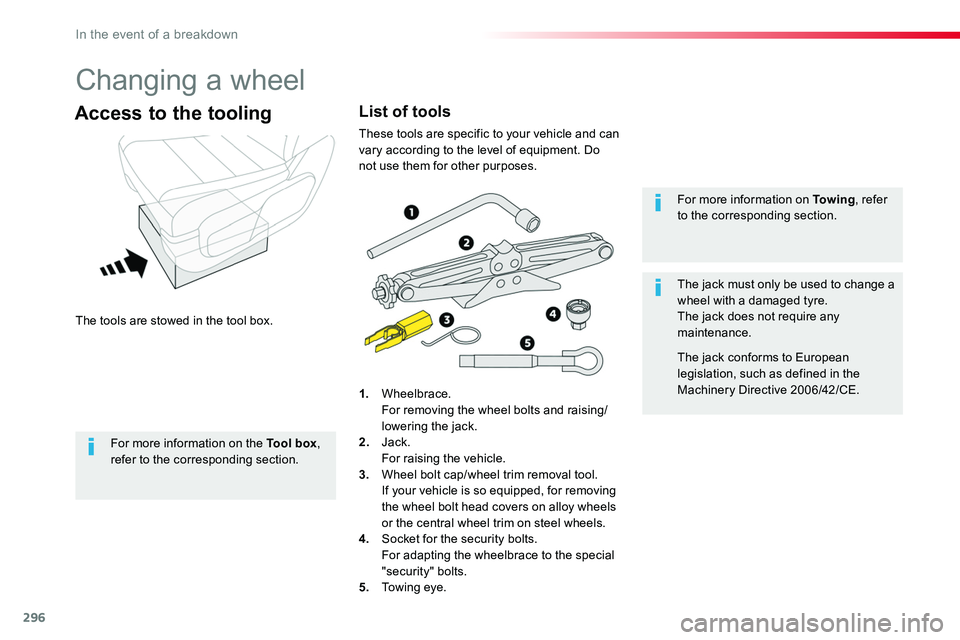

The tools are stowed in the tool box.

Access to the tooling

1. Wheelbrace. For removing the wheel bolts and raising/lowering the jack.2. Jack. For raising the vehicle.3. Wheel bolt cap/wheel trim removal tool. If your vehicle is so equipped, for removing the wheel bolt head covers on alloy wheels or the central wheel trim on steel wheels.

4. Socket for the security bolts. For adapting the wheelbrace to the special "security" bolts.5. Towing eye.

For more information on To w i n g, refer to the corresponding section.

The jack must only be used to change a wheel with a damaged tyre.The jack does not require any maintenance.

The jack conforms to European legislation, such as defined in the Machinery Directive 2006/42/CE.

List of tools

These tools are specific to your vehicle and can vary according to the level of equipment. Do not use them for other purposes.

For more information on the Tool box, refer to the corresponding section.

In the event of a breakdown

Page 297 of 516

297

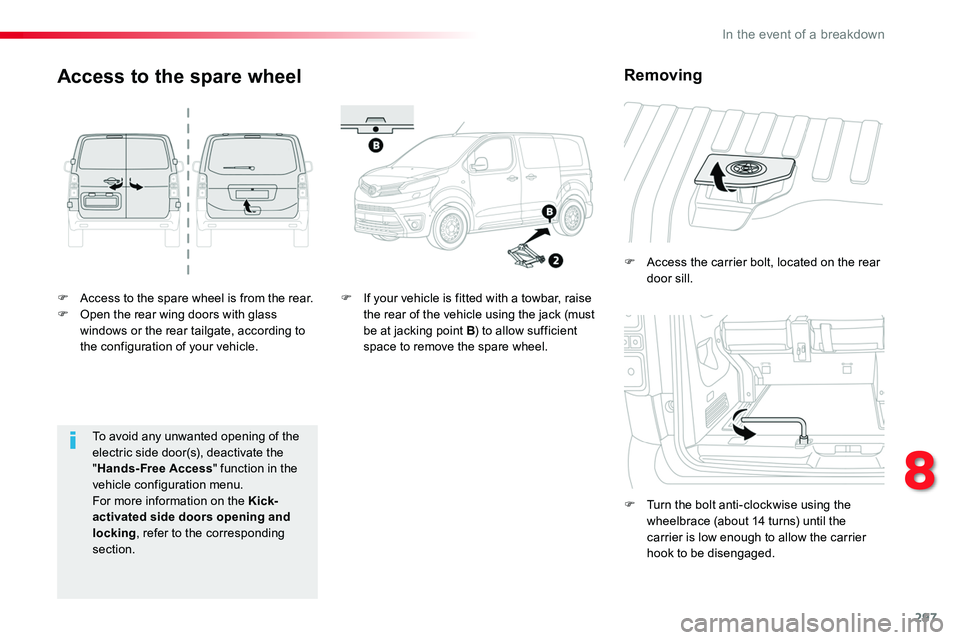

F Access to the spare wheel is from the rear.F Open the rear wing doors with glass windows or the rear tailgate, according to the configuration of your vehicle.

F Access the carrier bolt, located on the rear door sill.

F Turn the bolt anti-clockwise using the wheelbrace (about 14 turns) until the carrier is low enough to allow the carrier hook to be disengaged.

Access to the spare wheel

F If your vehicle is fitted with a towbar, raise the rear of the vehicle using the jack (must be at jacking point B) to allow sufficient space to remove the spare wheel.

Removing

To avoid any unwanted opening of the electric side door(s), deactivate the "Hands-Free Access" function in the vehicle configuration menu.For more information on the Kick-activated side doors opening and

locking, refer to the corresponding section.

8

In the event of a breakdown

Page 298 of 516

298

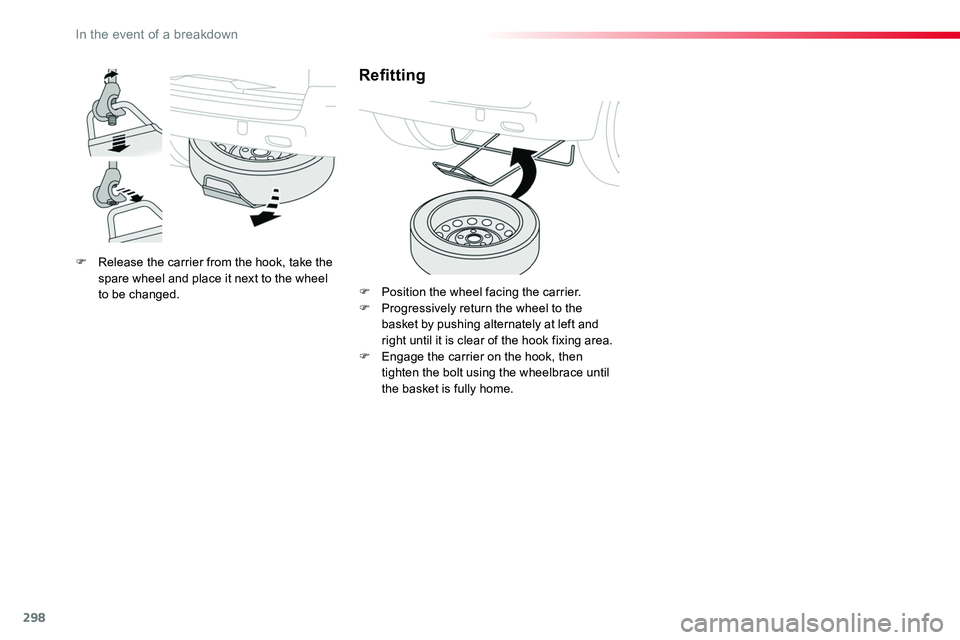

F Release the carrier from the hook, take the spare wheel and place it next to the wheel to be changed.

Refitting

F Position the wheel facing the carrier.F Progressively return the wheel to the basket by pushing alternately at left and right until it is clear of the hook fixing area.F Engage the carrier on the hook, then tighten the bolt using the wheelbrace until the basket is fully home.

In the event of a breakdown

Page 299 of 516

299

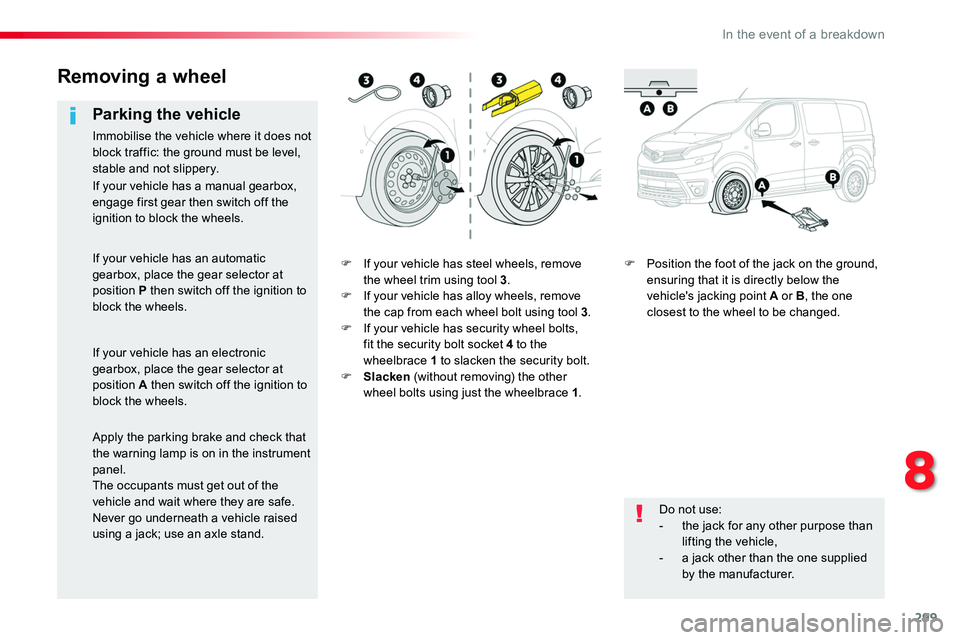

F If your vehicle has steel wheels, remove the wheel trim using tool 3.F If your vehicle has alloy wheels, remove the cap from each wheel bolt using tool 3.F If your vehicle has security wheel bolts, fit the security bolt socket 4 to the wheelbrace 1 to slacken the security bolt.F Slacken (without removing) the other wheel bolts using just the wheelbrace 1.

F Position the foot of the jack on the ground, ensuring that it is directly below the vehicle's jacking point A or B, the one closest to the wheel to be changed.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does not block traffic: the ground must be level, stable and not slippery.

Do not use:- the jack for any other purpose than lifting the vehicle,- a jack other than the one supplied by the manufacturer.

If your vehicle has a manual gearbox, engage first gear then switch off the ignition to block the wheels.

If your vehicle has an automatic gearbox, place the gear selector at position P then switch off the ignition to block the wheels.

If your vehicle has an electronic gearbox, place the gear selector at position A then switch off the ignition to block the wheels.

Apply the parking brake and check that the warning lamp is on in the instrument panel.The occupants must get out of the vehicle and wait where they are safe.Never go underneath a vehicle raised using a jack; use an axle stand.

8

In the event of a breakdown

Page 300 of 516

300

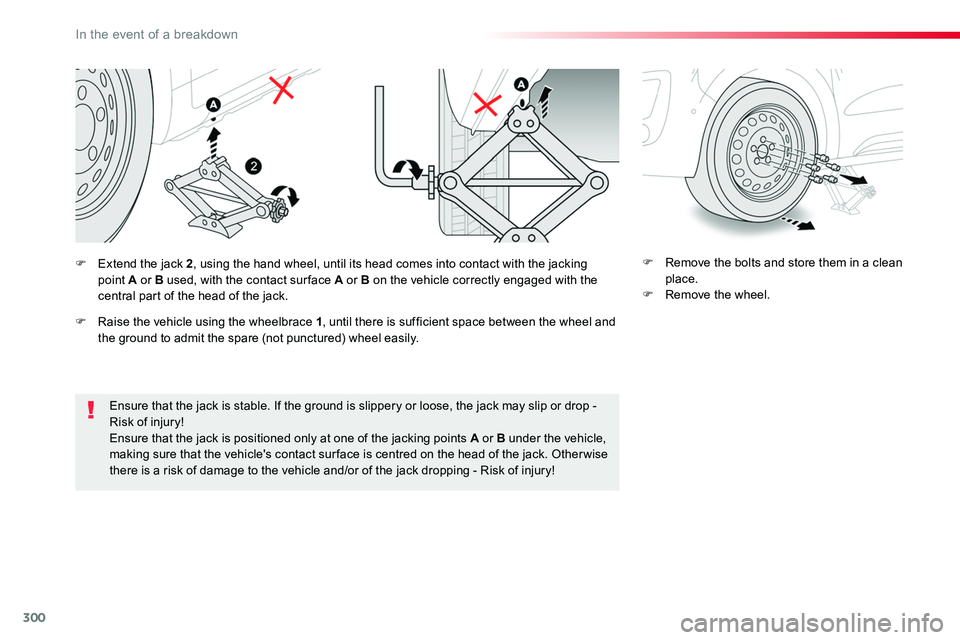

Ensure that the jack is stable. If the ground is slippery or loose, the jack may slip or drop - Risk of injury!

Ensure that the jack is positioned only at one of the jacking points A or B under the vehicle, making sure that the vehicle's contact sur face is centred on the head of the jack. Other wise there is a risk of damage to the vehicle and/or of the jack dropping - Risk of injury!

F Remove the bolts and store them in a clean place.F Remove the wheel.

F Extend the jack 2, using the hand wheel, until its head comes into contact with the jacking point A or B used, with the contact sur face A or B on the vehicle correctly engaged with the central part of the head of the jack.

F Raise the vehicle using the wheelbrace 1, until there is sufficient space between the wheel and the ground to admit the spare (not punctured) wheel easily.

In the event of a breakdown