fuse TOYOTA RAV4 1996 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 88 of 1632

Fig. 15: Releasing Shorting Spring

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

DIAGNOSTIC TESTS

AIR BAG WARNING LIGHT DOES NOT ILLUMINATE

Description

AIR BAG warning light is located in instrument cluster. When air bag system is normal, AIR BAG warning

light illuminates for about 6 seconds after ignition switch is turned from LOCK to ACC or ON position, and

turns off automatically. If a malfunction is present in air bag system, AIR BAG warning light illuminates to

inform operator of malfunction. When Data Link Connector 1 (DLC1) terminals Tc and E1 are connected

together, a Diagnostic Trouble Code (DTC) is displayed by flashing AIR BAG warning light.

Diagnostic Procedure

1. Remove SRS-B fuse and check continuity across fuse blades. SRS-B fuse is located in instrument panel

fuse block under left side of instrument panel. If fuse is faulty, go to step 4). If fuse is okay, reinstall fuse

and go to next step.

2. Disable air bag system. See DISABLING SYSTEM

under DISABLING & ACTIVATING AIR BAG

SYSTEM. Reconnect negative battery cable. Turn ignition switch to ACC or ON position. Measure

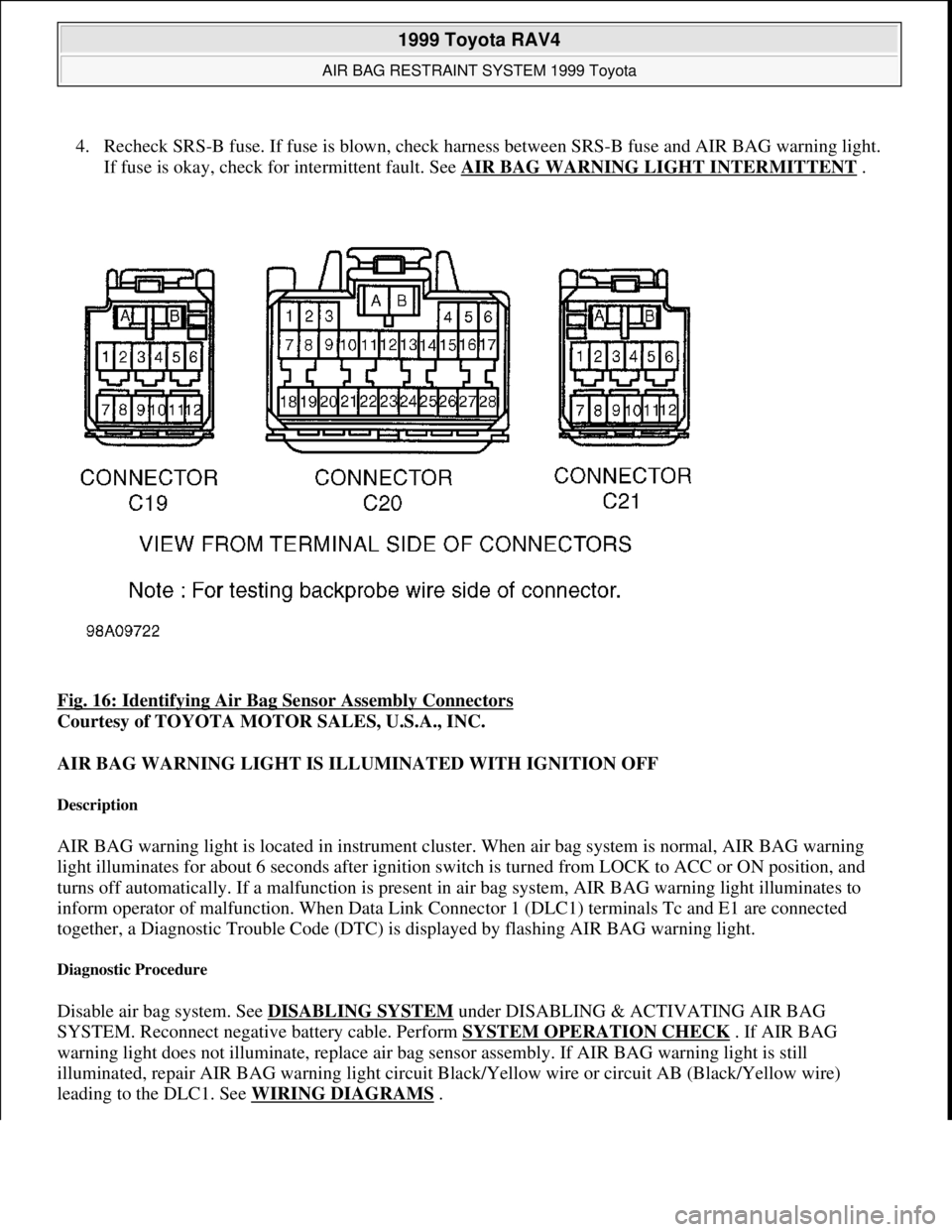

voltage between ground and harness side of air bag sensor assembly connector C20, terminal No. 3

(circuit LA, Black/Yellow wire). See Fig. 16

. If 10-14 volts is not present, repair AIR BAG warning

light bulb or circuit. If 10-14 volts is present, go to next step.

3. Turn ignition switch to LOCK position. Disconnect negative battery cable. Reconnect 3 air bag sensor

assembly connectors. Leave air bag modules, pretensioners and front air bag sensors disconnected.

Reconnect negative battery cable and wait at least 2 seconds. Turn ignition switch to ACC or ON

position. If AIR BAG warning light illuminates, system operation is normal. If AIR BAG warning light

does not come on, check for poor connection at air bag sensor assembly connector C20, terminal No. 3

(Black/Yellow wire). If connection is oka

y, replace air bag sensor assembly. WARNING:Failure to follow service precautions may result in air bag deployment and

personal injury. See SERVICE PRECAUTIONS

. After component

replacement, check system operation. See SYSTEM OPERATION CHECK

.

CAUTION: Ensure ignition switch is in LOCK position before disconnecting or

connecting negative battery cable. If ignition switch is in ACC or ON

position when negative battery cable is disconnected or connected, air

bag sensor may be damaged. To prevent damage to connector terminals,

DO NOT probe terminal ends. Instead, backprobe terminals (probe

terminal where wire enters harness connector).

NOTE: In the following tests, the term squib connector and module connector may be

used interchangeably.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:23 AMPage 25 © 2005 Mitchell Repair Information Company, LLC.

Page 89 of 1632

4. Recheck SRS-B fuse. If fuse is blown, check harness between SRS-B fuse and AIR BAG warning light.

If fuse is okay, check for intermittent fault. See AIR BAG WARNING LIGHT INTERMITTENT

.

Fig. 16: Identifying Air Bag Sensor Assembly Connectors

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

AIR BAG WARNING LIGHT IS ILLUMINATED WITH IGNITION OFF

Description

AIR BAG warning light is located in instrument cluster. When air bag system is normal, AIR BAG warning

light illuminates for about 6 seconds after ignition switch is turned from LOCK to ACC or ON position, and

turns off automatically. If a malfunction is present in air bag system, AIR BAG warning light illuminates to

inform operator of malfunction. When Data Link Connector 1 (DLC1) terminals Tc and E1 are connected

together, a Diagnostic Trouble Code (DTC) is displayed by flashing AIR BAG warning light.

Diagnostic Procedure

Disable air bag system. See DISABLING SYSTEM under DISABLING & ACTIVATING AIR BAG

SYSTEM. Reconnect negative battery cable. Perform SYSTEM OPERATION CHECK

. If AIR BAG

warning light does not illuminate, replace air bag sensor assembly. If AIR BAG warning light is still

illuminated, repair AIR BAG warning light circuit Black/Yellow wire or circuit AB (Black/Yellow wire)

leadin

g to the DLC1. See WIRING DIAGRAMS.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:23 AMPage 26 © 2005 Mitchell Repair Information Company, LLC.

Page 405 of 1632

Check all fuses, fusible links, ignition switch and appropriate relays (if equipped). Check generator output. See

NO

-LOAD TEST under ON-VEHICLE TESTING.

ON-VEHICLE TESTING

NO-LOAD TEST

1. Disconnect battery-to-generator terminal "B" wire. See Fig. 2

. Using an ammeter and voltmeter, connect

negative ammeter lead to disconnected generator terminal "B" wire end, and connect positive ammeter

lead to generator terminal "B".

2. Connect voltmeter positive lead to generator terminal "B" and negative lead to ground. See Fig. 2

. Start

engine and increase engine speed to 2000 RPM. Both meters should read within specification. See

GENERATOR REGULATED OUTPUT SPECIFICATIONS

table. If voltage is more than specified,

replace IC regulator. If voltage is less than specified, go to next step.

3. Locate small hole in back of generator. See Fig. 3

. It may be necessary to remove generator end cover to

access hole. Using a probe, ground generator terminal "F" (full field) to generator case. See Fig. 3

. If

voltage is more than specified range, replace IC regulator. If voltage is less than specified range, repair or

replace generator.

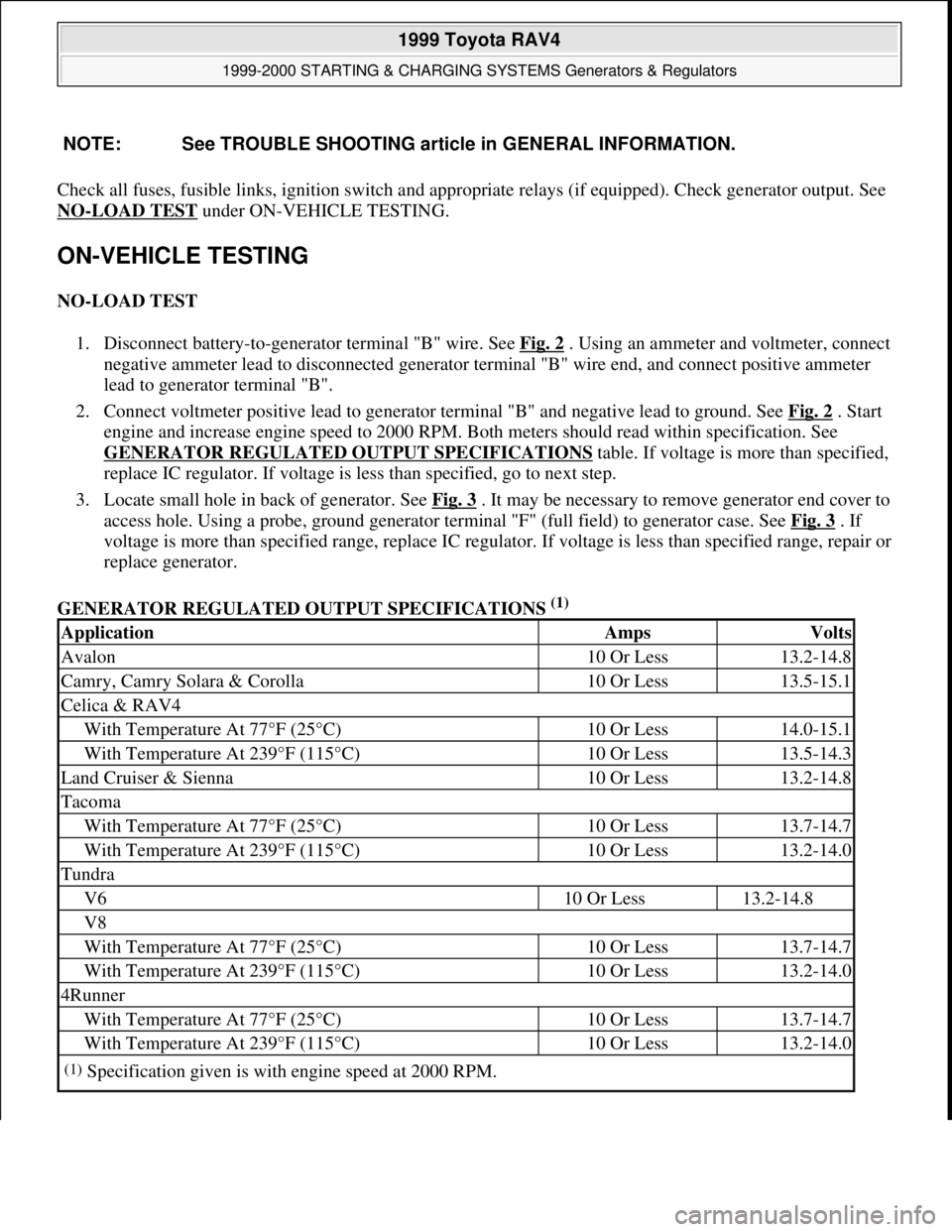

GENERATOR REGULATED OUTPUT SPECIFICATIONS

(1) NOTE: See TROUBLE SHOOTING article in GENERAL INFORMATION.

ApplicationAmpsVolts

Avalon10 Or Less13.2-14.8

Camry, Camry Solara & Corolla10 Or Less13.5-15.1

Celica & RAV4

With Temperature At 77°F (25°C)10 Or Less14.0-15.1

With Temperature At 239°F (115°C)10 Or Less13.5-14.3

Land Cruiser & Sienna10 Or Less13.2-14.8

Tacoma

With Temperature At 77°F (25°C)10 Or Less13.7-14.7

With Temperature At 239°F (115°C)10 Or Less13.2-14.0

Tundra

V610 Or Less13.2-14.8

V8

With Temperature At 77°F (25°C)10 Or Less13.7-14.7

With Temperature At 239°F (115°C)10 Or Less13.2-14.0

4Runner

With Temperature At 77°F (25°C)10 Or Less13.7-14.7

With Temperature At 239°F (115°C)10 Or Less13.2-14.0

(1)Specification given is with engine speed at 2000 RPM.

1999 Toyota RAV4

1999-2000 STARTING & CHARGING SYSTEMS Generators & Regulators

Microsoft

Sunday, November 22, 2009 10:13:07 AMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 461 of 1632

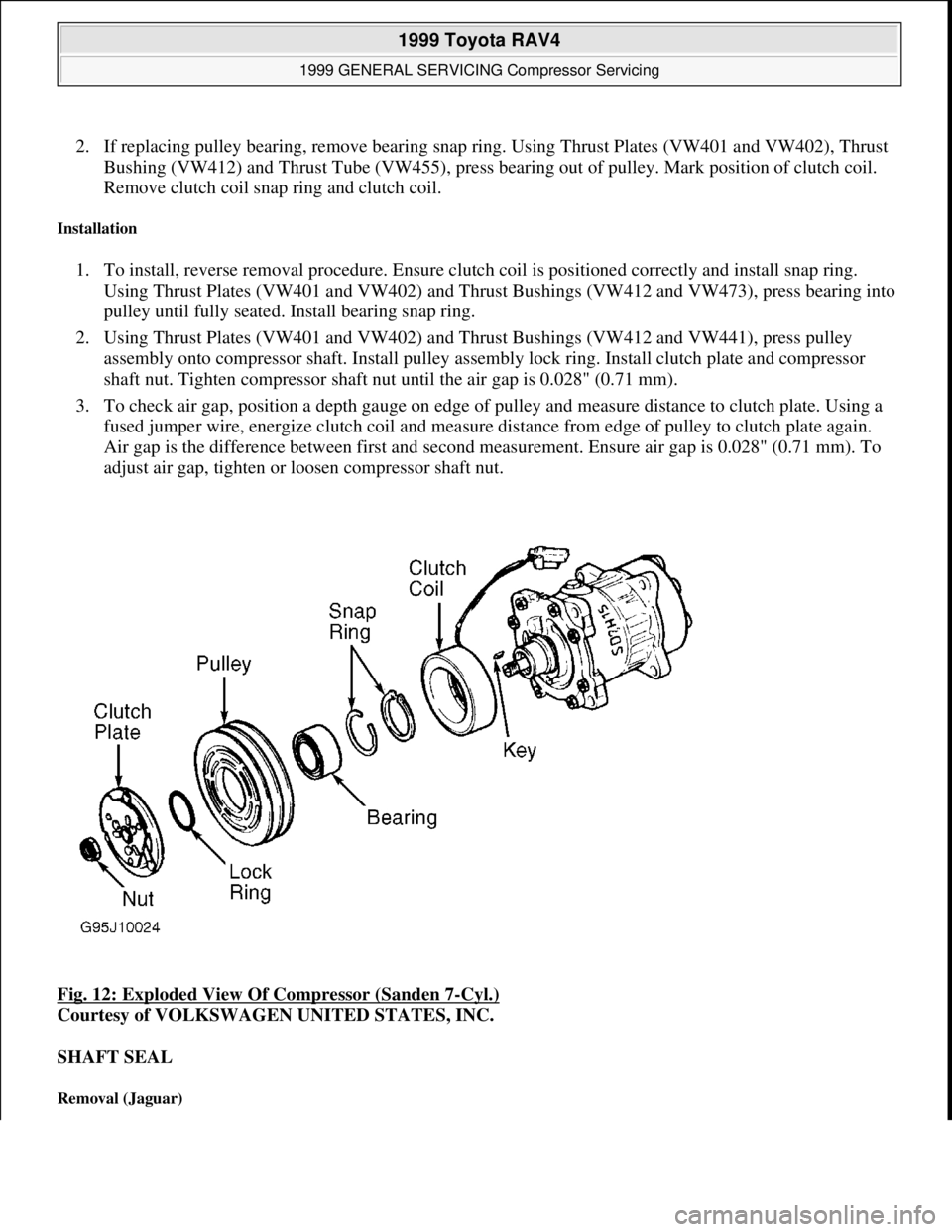

2. If replacing pulley bearing, remove bearing snap ring. Using Thrust Plates (VW401 and VW402), Thrust

Bushing (VW412) and Thrust Tube (VW455), press bearing out of pulley. Mark position of clutch coil.

Remove clutch coil snap ring and clutch coil.

Installation

1. To install, reverse removal procedure. Ensure clutch coil is positioned correctly and install snap ring.

Using Thrust Plates (VW401 and VW402) and Thrust Bushings (VW412 and VW473), press bearing into

pulley until fully seated. Install bearing snap ring.

2. Using Thrust Plates (VW401 and VW402) and Thrust Bushings (VW412 and VW441), press pulley

assembly onto compressor shaft. Install pulley assembly lock ring. Install clutch plate and compressor

shaft nut. Tighten compressor shaft nut until the air gap is 0.028" (0.71 mm).

3. To check air gap, position a depth gauge on edge of pulley and measure distance to clutch plate. Using a

fused jumper wire, energize clutch coil and measure distance from edge of pulley to clutch plate again.

Air gap is the difference between first and second measurement. Ensure air gap is 0.028" (0.71 mm). To

adjust air gap, tighten or loosen compressor shaft nut.

Fig. 12: Exploded View Of Compressor (Sanden 7

-Cyl.)

Courtesy of VOLKSWAGEN UNITED STATES, INC.

SHAFT SEAL

Removal (Jaguar)

1999 Toyota RAV4

1999 GENERAL SERVICING Compressor Servicing

Microsoft

Sunday, November 22, 2009 10:31:50 AMPage 24 © 2005 Mitchell Repair Information Company, LLC.

Page 471 of 1632

1999-2000 ENGINE COOLING

Electric Cooling Fans

IDENTIFICATION

ELECTRIC COOLING FAN IDENTIFICATION

DESCRIPTION & OPERATION

Land Cruiser, Tacoma, Tundra and 4Runner use a belt-driven cooling fan attached to the water pump. All other

models use 2 electric cooling fans located directly behind the radiator. Fans are controlled via Engine Coolant

Temperature (ECT) switches/sensors, and turn on when engine coolant temperature is above 208°F (98°C) on

Avalon, Camry with 3.0L, Camry Solara with 3.0L and Sienna. On Camry with 2.2L, Camry Solara with 2.2L,

Celica, Corolla, ECHO, MR2 and RAV4, ECT turns cooling fans on above 199°F (93°C). On Avalon, Camry

with 3.0L, Camry Solara with 3.0L and Sienna, fans will turn off when engine coolant temperature falls below

190°F (88°C). On Camry with 2.2L, Camry Solara with 2.2L, Celica, Corolla and RAV4, fans will turn off

below 181°F (83°C).

SYSTEM TESTS

ELECTRIC COOLING FAN

Avalon (1999), Camry 3.0L, Camry Solara 3.0L & Sienna

1. With engine coolant temperature below 190°F (88°C), turn ignition switch to ON position (engine off).

Ensure fans stop.

2. If fan do not stop, test cooling fan relay and ECT switch. See COOLING FAN RELAYS

and ECT

SWITCH . Check for loose or broken connector or wiring between relay and ECT switch. Repair as

necessary.

3. Disconnect No. 1 ECT switch connector. See ECT SWITCH LOCATIONS

table. With ignition still in

ON position, ensure cooling fan turns on. If not, check fuses, engine main relay, cooling fan relay and

cooling fan motor. Check for short between cooling fan relay and ECT switch.

4. Start engine and raise temperature above 208°F (98°C). Ensure cooling fan turns. If not, replace No. 1

ECT switch.

5. Stop engine and disconnect cooling fan 2-pin connector. With battery connected to ammeter (positive

battery terminal to positive ammeter terminal and negative battery and negative ammeter terminals to

each connector pin), test amperage readings. See Fig. 1

. If readings are not as specified, replace cooling

fan. See COOLING FAN AMPERAGE READINGS

table. Reconnect fan connector.

Avalon (2000)

ApplicationCooling Fan Location

All Models

Condenser Cooling FanPassenger's Side, Rear Of Radiator

Radiator Cooling FanDriver's Side, Rear Of Radiator

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:21:45 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 474 of 1632

Fig. 1: Testing Amperage At Fan Connectors (Corolla Shown; Other Models Similar)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Camry 2.2L, Camry Solara 2.2L, Celica, Corolla, ECHO, MR2 & RAV4

1. With engine coolant temperature below 181°F (83°C), turn ignition switch to ON position (engine off).

Ensure fan stops.

2. If fan does not stop, test cooling fan relay and ECT switch/sensor. See COOLING FAN RELAYS

and

ECT SWITCH

or ECT SENSOR . Check for loose or broken connector or wiring between relay and

ECT switch. Repair as necessary.

3. Disconnect ECT switch/sensor connector. See ECT SWITCH LOCATIONS

table. With ignition still in

ON position, ensure cooling fan turns on. If not, check fuses, engine main relay (if equipped), cooling fan

relay, and cooling fan motor. On MR2, check ECM. On all models, check for short between cooling fan

relay and ECT switch.

4. Start engine and raise temperature above 199°F (93°C). Ensure cooling fan turns. If not, replace ECT

switch/sensor.

5. Stop engine and disconnect cooling fan 2-pin connector. With battery connected to ammeter (positive

battery terminal to positive ammeter terminal and negative battery and negative ammeter terminals to

each connector pin), test amperage readings. See Fig. 1

. If readings are not as specified, replace cooling

fan. See COOLING FAN AMPERAGE READINGS

table. Reconnect fan connector.

ECT SWITCH LOCATIONS

COOLING FAN AMPERAGE READINGS

ApplicationECT Switch Location

All Models

Condenser Cooling FanPassenger's Side, Rear Of Radiator

Radiator Cooling FanDriver's Side, Rear Of Radiator

ApplicationAmps @ 68°F (20°C)

Avalon

19999.2-11.0

20008.5-11.5

Camry & Camry Solara

5S-FE4.9-8.5

1MZ-FE8.3-11.3

Celica

19996.4-7.4

20005.2-8.2

Corolla5.2-8.2

ECHO (1) 7.8-11.8

MR25.7-7.7

RAV49.1-11.1

Sienna

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 475 of 1632

COMPONENT TESTS

COOLING FAN RELAYS

Cooling Fan Relay No. 1 (Avalon, Celica & RAV4 - 1999)

1. Disconnect negative battery cable. Remove cooling fan relay No. 1 from fuse/relay box. See Fig. 2 , Fig.

5 and Fig. 10 . Using an ohmmeter, check for continuity between relay terminals No. 1 and 2, and No. 3

and 4 on Denso type relays. See Fig. 13

. On Bosch type relays, check for continuity between relay

terminals No. 85 and 86, and No. 30 and 87a. If no continuity exists, replace relay.

2. To check relay operation, connect positive battery voltage to terminal No. 1 (Denso type), or No. 86

(Bosch type). Connect ground to terminal No. 2 (Denso type), or No. 85 (Bosch type). Check that no

continuity exists between relay terminals No. 3 and 4 on Denso type relays. On Bosch type relays, check

that no continuity exists between relay terminals No. 30 and 87a. If continuity exists, replace relay.

3. Reinstall cooling fan relay No. 1.

Cooling Fan Relay No. 1 (Avalon, Celica, ECHO & RAV4 - 2000)

1. Disconnect negative battery cable. Remove cooling fan relay No. 1 from fuse/relay box. See Fig. 3 , Fig.

6 , Fig. 8 and Fig. 11 . Using an ohmmeter, check for continuity between relay terminals No. 1 and 2. See

Fig. 14

. If there is no continuity, replace relay. Check that no continuity exists between relay terminals

No. 3 and 5. If continuity exists, replace relay.

2. To check relay operation, connect positive battery voltage to terminal No. 1 and ground to terminal No. 2.

Check for continuity between relay terminals No. 3 and 5. If no continuity exists, replace relay.

3. Reinstall cooling fan relay No. 1.

Cooling Fan Relay No. 1 (Camry, Camry Solara, Corolla & Sienna)

1. Disconnect negative battery cable. Remove cooling fan relay No. 1 from fuse/relay box. See Fig. 4 , Fig.

7 and Fig. 12 . Using an ohmmeter, check for continuity between relay terminals No. 1 and 2, and No. 3

and 4. See Fig. 15

. If no continuity exists, replace relay.

2. To check relay operation, connect positive battery voltage to terminal No. 1 and ground to terminal No. 2.

Check that no continuity exists between relay terminals No. 3 and 4. If continuity exists, replace relay.

3. Reinstall cooling fan relay No. 1.

With "S" Mark8.5-11.5

With "T" Mark14.0-20.0

(1)Amps @ 77°F (25°C)

CAUTION: When battery is disconnected, vehicle computer and memory systems

may lose memory data. Driveability problems may exist until computer

systems have completed a relearn cycle.

NOTE: Place match marks on all relays for proper reinstallation.

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 5 © 2005 Mitchell Repair Information Company, LLC.

Page 476 of 1632

Cooling Fan Relay No. 2 (Except Avalon)

1. Disconnect negative battery cable. Remove cooling fan relay No. 2 from fuse/relay box. See Fig. 4 -Fig.

12 . Using an ohmmeter, check for continuity between relay terminals No. 1 and 2, and No. 3 and 4. See

Fig. 13

-Fig. 15 . If no continuity exists, replace relay. Check that no continuity exists between relay

terminals No. 3 and 5. If continuity exists, replace relay.

2. To check relay operation, connect positive battery voltage to terminal No. 1 and ground to terminal No. 2.

Check that no continuity exists between relay terminals No. 3 and 4. If continuity exists, replace relay.

Check for continuity between relay terminals No. 3 and 5. If no continuity exists, replace relay.

3. Reinstall cooling fan relay No. 2.

Cooling Fan Relay No. 2 (Avalon)

1. Disconnect negative battery cable. Remove cooling fan relay No. 2 from fuse/relay box. See Fig. 2 and

Fig. 3

. Using an ohmmeter, check for continuity between relay terminals No. 1 and 2, and No. 3 and 4 on

Denso type relay. On Bosch type relay, check for continuity between relay terminals No. 85 and 86, and

No. 30 and 87a. See Fig. 13

and Fig. 14 . If there is no continuity, replace relay.

2. To check relay operation, connect positive battery voltage to terminal No. 1 (Denso type), or No. 85

(Bosch type). Connect ground to terminal No. 2 (Denso type), or No. 86 (Bosch type). Check that no

continuity exists between relay terminals No. 3 and 4 (Denso type), or No. 30 and 87a (Bosch type). If

continuity exists, replace relay. Check for continuity between relay terminals No. 3 and 5 (Denso), or No.

30 and 87 (Bosch). If no continuity exists, replace relay.

3. Reinstall cooling fan relay No. 2.

Cooling Fan Relay No. 3

1. Disconnect negative battery cable. Remove cooling fan relay No. 3 from fuse/relay box. See Fig. 2 - Fig.

12 . Using an ohmmeter, check for continuity between relay terminals No. 1 and 2 (Denso type), or No.

85 and 86 (Bosch type). See Fig. 13

- Fig. 15 . If no continuity exists, replace relay. Check that no

continuity exists between relay terminals No. 3 and 5 (Denso type), or No. 30 and 87 (Bosch type). If

continuity exists, replace relay.

2. To check relay operation, connect positive battery voltage to terminal No. 1 (Denso type), or No. 86

(Bosch type). Connect ground to terminal No. 2 (Denso type), or No. 85 (Bosch type). Check for

continuity between relay terminals No. 3 and 5 (Denso type), or No. 30 and 87 (Bosch type). If no

continuity exists, replace relay.

3. Reinstall cooling fan relay No. 3.

Engine Main Relay (Except 2000 Avalon, 2000 Celica, ECHO & MR2)

1. Disconnect negative battery cable. Remove engine main relay from fuse/relay box. See Fig. 2 -Fig. 12 .

Using an ohmmeter, check for continuity between relay terminals No. 3 and 5, and No. 2 and 4. See Fig.

16 . If no continuity exists, replace relay. Check that no continuity exists between relay terminals No. 1

and 2. If continuit

y exists, replace relay. NOTE: ECHO is not equipped with cooling fan relay No. 3.

1999 Toyota RAV4

1999-2000 ENGINE COOLING Electric Cooling Fans

Microsoft

Sunday, November 22, 2009 10:21:41 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 537 of 1632

FUNCTION TEST under TROUBLE SHOOTING. If clutch switch input signal is not as specified, go to

next step. If clutch switch input signal is as specified, no problem is indicated at this time. Fault may be

intermittent. If sent here from SYMPTOM DIAGNOSIS, perform next test listed.

3. Remove cruise control ECU with connector attached. See Fig. 1

. Turn ignition switch to ON position.

Using voltmeter positive lead, backprobe cruise control ECU connector terminal No. 3 (Blue/Black wire)

with negative lead to ground. With clutch pedal depressed, battery voltage should exist. With clutch pedal

released, voltage should be less than one volt. If voltage is not as specified, go to next step. If voltage is

as specified, no problem is indicated at this time. Fault may be intermittent. If sent here from SYMPTOM

DIAGNOSIS, perform next test listed.

4. Check wiring harness and connectors between cruise control ECU and TURN & GAUGE fuses in

instrument panel junction block. Repair as necessary. If wiring harness and connectors are okay, replace

cruise control ECU and retest system.

CRUISE CONTROL ECU POWER SOURCE CIRCUIT

1. Locate ECU-IG (10-amp) fuse in instrument panel junction block. See Fig. 1

. Remove ECU-IG fuse and

ensure fuse continuity. If fuse is okay, go to next step. If fuse is not okay, check for short between cruise

control ECU connector terminal No. 9 (Black/Yellow wire) and ECU-IG fuse.

2. Remove cruise control ECU with connector attached. See Fig. 1

. Turn ignition switch to ON position.

Using voltmeter, backprobe between cruise control ECU connector terminals No. 9 (Black/Yellow wire)

and No. 16 (White/Black wire). If battery voltage is not present, go to next step. If battery voltage is

present, no problem is indicated at this time. Fault may be intermittent. If sent here from SYMPTOM

DIAGNOSIS, perform next test listed.

3. Turn ignition switch to OFF position. Backprobing connector, measure resistance between ground and

terminal No. 16 (White/Black wire) at cruise control ECU connector. If resistance is less than one ohm,

check wiring harness or connector between cruise control ECU connector and battery. Repair as

necessary and retest system. If resistance is one ohm or more, repair wiring harness or connector between

cruise control ECU connector terminal No. 16 (White/Black wire) and ground. Retest system.

CRUISE CONTROL INDICATOR LIGHT CIRCUIT

1. Turn ignition switch to ON position. Backprobing connector, measure voltage between ground and

terminal No. 4 (Green/Red wire) at cruise control ECU connector. With cruise control switch in OFF

position, battery voltage should be present. With cruise control switch in ON position, voltage should be

less than 1.2 volts.

2. If voltage is as specified, no problem is indicated at this time. Fault may be intermittent. If sent here from

SYMPTOM DIAGNOSIS, perform next test listed. If voltage is not as specified, check instrument

cluster. See appropriate INSTRUMENT PANELS article. Repair as necessary. If instrument cluster is

okay, replace cruise control ECU and retest system.

DIAGNOSTIC CIRCUIT

1. Locate Data Link Connector (DLC) No. 1 in right side of engine compartment, near shock tower.

Connect voltmeter positive lead to terminal Tc and negative lead to terminal E1. See Fig. 2

. Turn

ignition switch to ON position. If battery voltage is not present, go to next step. If battery voltage is

present, no problem is indicated at this time. Fault ma

y be intermittent. If sent here from SYMPTOM

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Cruise Control Systems - RAV4

Microsoft

Sunday, November 22, 2009 10:52:01 AMPage 13 © 2005 Mitchell Repair Information Company, LLC.

Page 541 of 1632

2. Turn cruise control main switch off. Connect a jumper wire between terminals E1 and Tc at DLC No. 1.

See Fig. 2

. If any DTCs are present, perform appropriate DTC test under DIAGNOSTIC TESTS . See

DIAGNOSTIC TROUBLE CODE DEFINITIONS

table.

3. If no codes are present and CRUISE indicator light begins flashing on and off every .25 second, system is

operating normally at this time. If no codes are present and cruise control system fault still exists, perform

CRUISE CONTROL FUNCTION TEST

under TROUBLE SHOOTING.

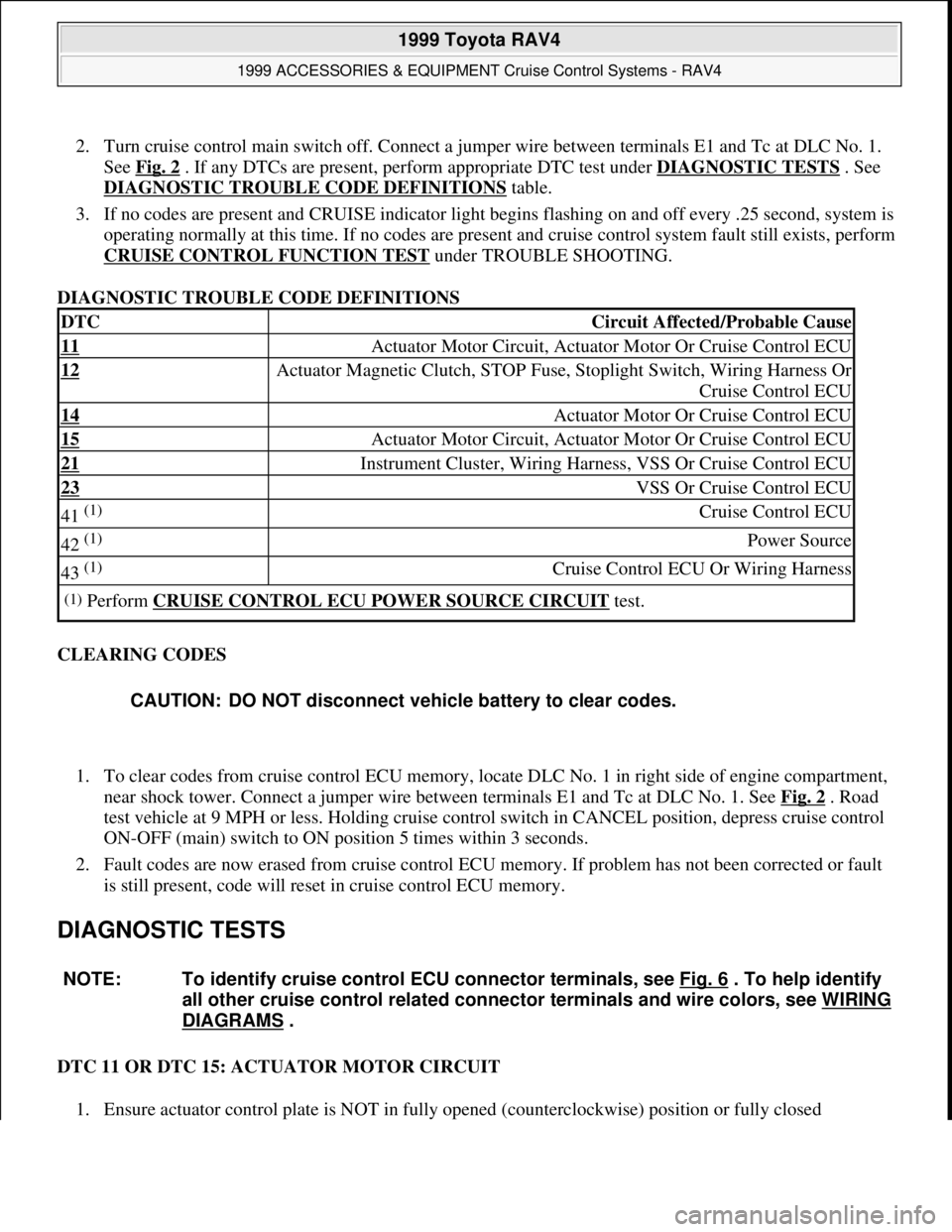

DIAGNOSTIC TROUBLE CODE DEFINITIONS

CLEARING CODES

1. To clear codes from cruise control ECU memory, locate DLC No. 1 in right side of engine compartment,

near shock tower. Connect a jumper wire between terminals E1 and Tc at DLC No. 1. See Fig. 2

. Road

test vehicle at 9 MPH or less. Holding cruise control switch in CANCEL position, depress cruise control

ON-OFF (main) switch to ON position 5 times within 3 seconds.

2. Fault codes are now erased from cruise control ECU memory. If problem has not been corrected or fault

is still present, code will reset in cruise control ECU memory.

DIAGNOSTIC TESTS

DTC 11 OR DTC 15: ACTUATOR MOTOR CIRCUIT

1. Ensure actuator control plate is NOT in full

y opened (counterclockwise) position or fully closed

DTCCircuit Affected/Probable Cause

11 Actuator Motor Circuit, Actuator Motor Or Cruise Control ECU

12 Actuator Magnetic Clutch, STOP Fuse, Stoplight Switch, Wiring Harness Or

Cruise Control ECU

14 Actuator Motor Or Cruise Control ECU

15 Actuator Motor Circuit, Actuator Motor Or Cruise Control ECU

21 Instrument Cluster, Wiring Harness, VSS Or Cruise Control ECU

23 VSS Or Cruise Control ECU

41 (1) Cruise Control ECU

42 (1) Power Source

43 (1) Cruise Control ECU Or Wiring Harness

(1)Perform CRUISE CONTROL ECU POWER SOURCE CIRCUIT test.

CAUTION: DO NOT disconnect vehicle battery to clear codes.

NOTE: To identify cruise control ECU connector terminals, see Fig. 6

. To help identify

all other cruise control related connector terminals and wire colors, see WIRING

DIAGRAMS .

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Cruise Control Systems - RAV4

Microsoft

Sunday, November 22, 2009 10:52:01 AMPage 17 © 2005 Mitchell Repair Information Company, LLC.