Speed sensor TOYOTA RAV4 1996 Service Manual PDF

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1354, PDF Size: 30.43 MB

Page 799 of 1354

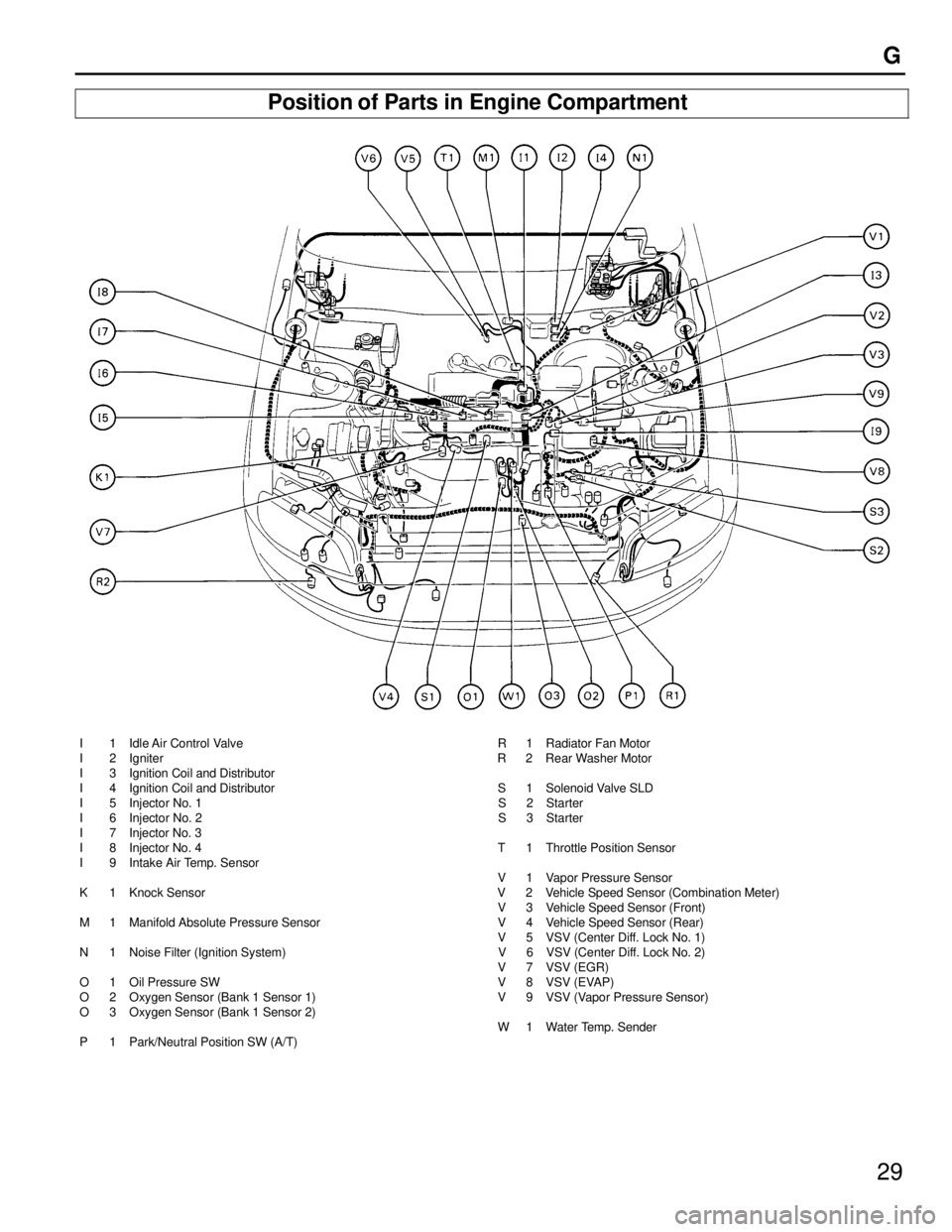

29

G

Position of Parts in Engine Compartment

I 1 Idle Air Control Valve R 1Radiator Fan Motor

I 2 Igniter R 2 Rear Washer Motor

I 3 Ignition Coil and Distributor

I 4 Ignition Coil and Distributor S 1 Solenoid Valve SLD

I 5 Injector No. 1 S 2 Starter

I 6 Injector No. 2 S 3 Starter

I 7 Injector No. 3

I 8 Injector No. 4 T 1 Throttle Position Sensor

I 9 Intake Air Temp. Sensor

V 1 Vapor Pressure Sensor

K 1 Knock Sensor V 2 Vehicle Speed Sensor (Combination Meter)

V 3 Vehicle Speed Sensor (Front)

M 1 Manifold Absolute Pressure Sensor V 4 Vehicle Speed Sensor (Rear)

V 5 VSV (Center Diff. Lock No. 1)

N 1 Noise Filter (Ignition System) V 6 VSV (Center Diff. Lock No. 2)

V 7 VSV (EGR)

O 1 Oil Pressure SW V 8 VSV (EVAP)

O 2 Oxygen Sensor (Bank 1 Sensor 1) V 9 VSV (Vapor Pressure Sensor)

O 3 Oxygen Sensor (Bank 1 Sensor 2)

W 1 Water Temp. Sender

P 1 Park/Neutral Position SW (A/T)

Page 802 of 1354

![TOYOTA RAV4 1996 Service Manual PDF 32

G ELECTRICAL WIRING ROUTING

Position of Parts in Body

[2-Door]

A 21 ABS Speed Sensor Rear LH L 1 License Plate Light

A 22 ABS Speed Sensor Rear RH

P 3 Personal Light

B 7 Back Door Open Detection TOYOTA RAV4 1996 Service Manual PDF 32

G ELECTRICAL WIRING ROUTING

Position of Parts in Body

[2-Door]

A 21 ABS Speed Sensor Rear LH L 1 License Plate Light

A 22 ABS Speed Sensor Rear RH

P 3 Personal Light

B 7 Back Door Open Detection](/img/14/57462/w960_57462-801.png)

32

G ELECTRICAL WIRING ROUTING

Position of Parts in Body

[2-Door]

A 21 ABS Speed Sensor Rear LH L 1 License Plate Light

A 22 ABS Speed Sensor Rear RH

P 3 Personal Light

B 7 Back Door Open Detection SW and Door Lock P 4 Power Window Master SW

Motor P 5 Power Window Motor (Driver's Side)

P 6 Power Window Motor (Front Passenger's Side)

D 6 Door Courtesy SW (Driver's Side) P 9 Power Window SW (Front Passenger's Side)

D 7 Door Courtesy SW (Front Passenger's Side)

D 10 Door Lock Control SW (Front Passenger's Side) R 8 Rear Combination Light LH

D 13 Door Lock Motor, Door Key Lock and Unlock SW R 9 Rear Combination Light RH

(Driver's Side) R 10Rear Side Marker Light LH

D 14 Door Lock Motor, Door Key Lock and Unlock SW R 11 Rear Side Marker Light RH

(Front Passenger's Side) R 12 Rear Speaker LH

R 13 Rear Speaker RH

F 9 Front Speaker LH R 14 Rear Window Defogger (+)

F 10 Front Speaker RH R 15 Rear Window Defogger (-)

F 11 Fuel Sender (Main) and Fuel Pump R 16 Rear Wiper Motor

F 12 Fuel Sender (Sub) R 17 Rear Wiper Relay

R 18 Remote Control Mirror LH

H 5 High Mounted Stop Light R 19 Remote Control Mirror RH

I 11 Interior Light

Page 803 of 1354

![TOYOTA RAV4 1996 Service Manual PDF 33

G

Position of Parts in Body

[4-Door]

A 21 ABS Speed Sensor Rear LH L 1 License Plate Light

A 22 ABS Speed Sensor Rear RH

P 3 Personal Light

B 7 Back Door Open Detection SW and Door Lock P 4 Power W TOYOTA RAV4 1996 Service Manual PDF 33

G

Position of Parts in Body

[4-Door]

A 21 ABS Speed Sensor Rear LH L 1 License Plate Light

A 22 ABS Speed Sensor Rear RH

P 3 Personal Light

B 7 Back Door Open Detection SW and Door Lock P 4 Power W](/img/14/57462/w960_57462-802.png)

33

G

Position of Parts in Body

[4-Door]

A 21 ABS Speed Sensor Rear LH L 1 License Plate Light

A 22 ABS Speed Sensor Rear RH

P 3 Personal Light

B 7 Back Door Open Detection SW and Door Lock P 4 Power Window Master SW

Motor P 5 Power Window Motor (Driver's Side)

P 6 Power Window Motor (Front Passengerºs Side)

D 6 Door Courtesy SW (Driver's Side) P 7 Power Window Motor (Rear LH)

D 7 Door Courtesy SW (Front Passenger's Side) P 8 Power Window Motor (Rear RH)

D 8 Door Courtesy SW (Rear LH) P 9 Power Window SW (Front Passenger's Side)

D 9 Door Courtesy SW (Rear RH) P 10 Power Window SW (Rear LH)

D 10 Door Lock Control SW (Front Passenger's Side) P 11 Power Window SW (Rear RH)

D 11 Door Lock Motor (Rear LH)

D 12 Door Lock Motor (Rear RH) R 8 Rear Combination Light LH

D 13 Door Lock Motor, Door Key Lock and Unlock SW R 9 Rear Combination Light RH

(Driver's Side) R 10Rear Side Marker Light LH

D 14 Door Lock Motor, Door Key Lock and Unlock SW R 11 Rear Side Marker Light RH

(Front Passenger's Side) R 12 Rear Speaker LH

R 13 Rear Speaker RH

F 9 Front Speaker LH R 14 Rear Window Defogger (+)

F 10 Front Speaker RH R 15 Rear Window Defogger (-)

F 11 Fuel Sender (Main) and Fuel Pump R 16 Rear Wiper Motor

F 12 Fuel Sender (Sub) R 17 Rear Wiper Relay

R 18 Remote Control Mirror LH

H 5 High Mounted Stop Light R 19 Remote Control Mirror RH

I 11 Interior Light

Page 833 of 1354

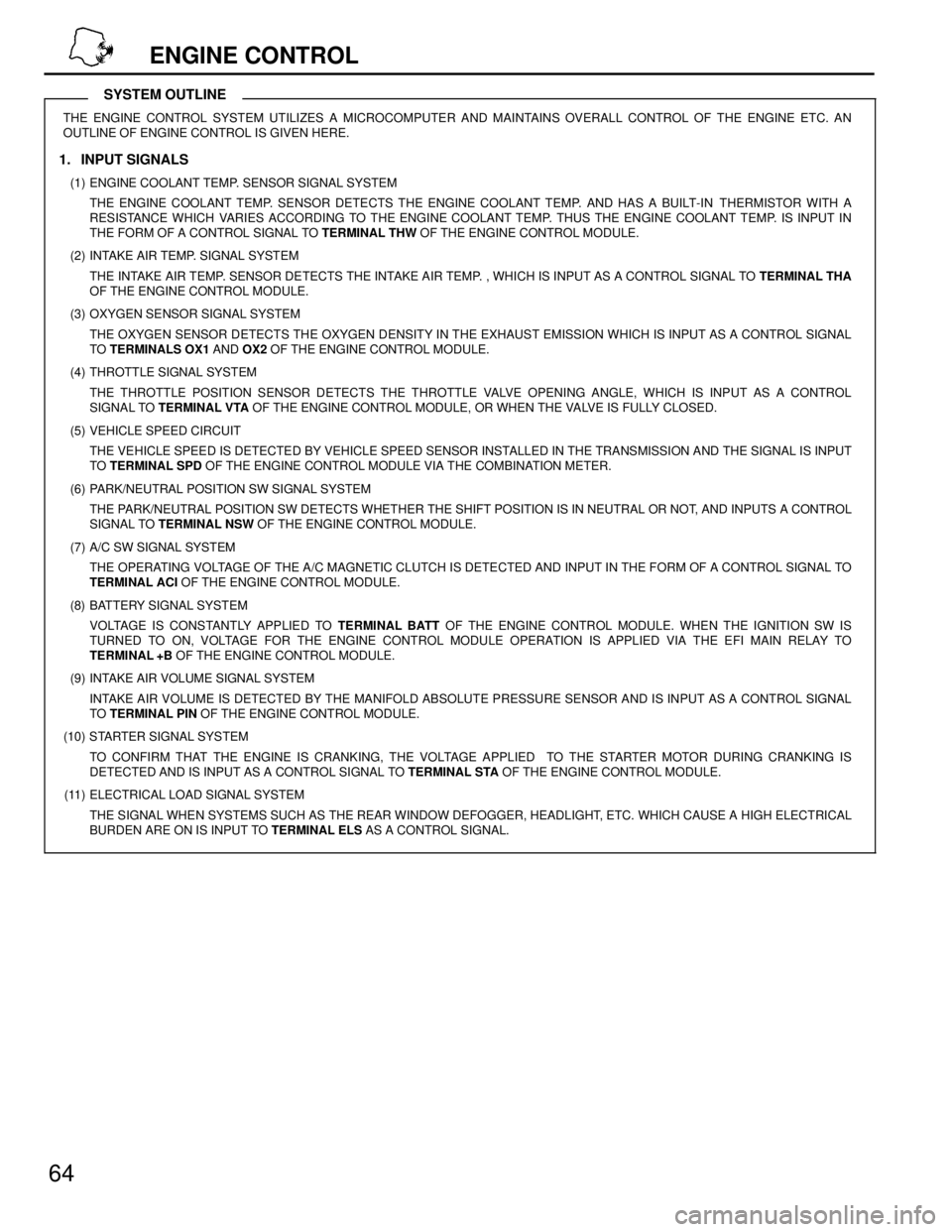

64

ENGINE CONTROL

THE ENGINE CONTROL SYSTEM UTILIZES A MICROCOMPUTER AND MAINTAINS OVERALL CONTROL OF THE ENGINE ETC. AN

OUTLINE OF ENGINE CONTROL IS GIVEN HERE.

1. INPUT SIGNALS

(1) ENGINE COOLANT TEMP. SENSOR SIGNAL SYSTEM

THE ENGINE COOLANT TEMP. SENSOR DETECTS THE ENGINE COOLANT TEMP. AND HAS A BUILT-IN THERMISTOR WITH A

RESISTANCE WHICH VARIES ACCORDING TO THE ENGINE COOLANT TEMP. THUS THE ENGINE COOLANT TEMP. IS INPUT IN

THE FORM OF A CONTROL SIGNAL TO TERMINAL THW OF THE ENGINE CONTROL MODULE.

(2) INTAKE AIR TEMP. SIGNAL SYSTEM

THE INTAKE AIR TEMP. SENSOR DETECTS THE INTAKE AIR TEMP. , WHICH IS INPUT AS A CONTROL SIGNAL TO TERMINAL THA

OF THE ENGINE CONTROL MODULE.

(3) OXYGEN SENSOR SIGNAL SYSTEM

THE OXYGEN SENSOR DETECTS THE OXYGEN DENSITY IN THE EXHAUST EMISSION WHICH IS INPUT AS A CONTROL SIGNAL

TO TERMINALS OX1 AND OX2 OF THE ENGINE CONTROL MODULE.

(4) THROTTLE SIGNAL SYSTEM

THE THROTTLE POSITION SENSOR DETECTS THE THROTTLE VALVE OPENING ANGLE, WHICH IS INPUT AS A CONTROL

SIGNAL TO TERMINAL VTA OF THE ENGINE CONTROL MODULE, OR WHEN THE VALVE IS FULLY CLOSED.

(5) VEHICLE SPEED CIRCUIT

THE VEHICLE SPEED IS DETECTED BY VEHICLE SPEED SENSOR INSTALLED IN THE TRANSMISSION AND THE SIGNAL IS INPUT

TO TERMINAL SPD OF THE ENGINE CONTROL MODULE VIA THE COMBINATION METER.

(6) PARK/NEUTRAL POSITION SW SIGNAL SYSTEM

THE PARK/NEUTRAL POSITION SW DETECTS WHETHER THE SHIFT POSITION IS IN NEUTRAL OR NOT, AND INPUTS A CONTROL

SIGNAL TO TERMINAL NSW OF THE ENGINE CONTROL MODULE.

(7) A/C SW SIGNAL SYSTEM

THE OPERATING VOLTAGE OF THE A/C MAGNETIC CLUTCH IS DETECTED AND INPUT IN THE FORM OF A CONTROL SIGNAL TO

TERMINAL ACI OF THE ENGINE CONTROL MODULE.

(8) BATTERY SIGNAL SYSTEM

VOLTAGE IS CONSTANTLY APPLIED TO TERMINAL BATT OF THE ENGINE CONTROL MODULE. WHEN THE IGNITION SW IS

TURNED TO ON, VOLTAGE FOR THE ENGINE CONTROL MODULE OPERATION IS APPLIED VIA THE EFI MAIN RELAY TO

TERMINAL +B OF THE ENGINE CONTROL MODULE.

(9) INTAKE AIR VOLUME SIGNAL SYSTEM

INTAKE AIR VOLUME IS DETECTED BY THE MANIFOLD ABSOLUTE PRESSURE SENSOR AND IS INPUT AS A CONTROL SIGNAL

TO TERMINAL PIN OF THE ENGINE CONTROL MODULE.

(10) STARTER SIGNAL SYSTEM

TO CONFIRM THAT THE ENGINE IS CRANKING, THE VOLTAGE APPLIED TO THE STARTER MOTOR DURING CRANKING IS

DETECTED AND IS INPUT AS A CONTROL SIGNAL TO TERMINAL STA OF THE ENGINE CONTROL MODULE.

(11) ELECTRICAL LOAD SIGNAL SYSTEM

THE SIGNAL WHEN SYSTEMS SUCH AS THE REAR WINDOW DEFOGGER, HEADLIGHT, ETC. WHICH CAUSE A HIGH ELECTRICAL

BURDEN ARE ON IS INPUT TO TERMINAL ELS AS A CONTROL SIGNAL.

SYSTEM OUTLINE

Page 834 of 1354

65

2. CONTROL SYSTEM

*SFI

THE SFI SYSTEM MONITORS THE ENGINE CONDITION THROUGH THE SIGNALS, WHICH ARE INPUT FROM EACH SENSOR (INPUT

SIGNALS (1) TO (11)). THE BEST FUEL INJECTION VOLUME IS DECIDED BASED ON THIS DATA AND THE PROGRAM MEMORIZED

BY THE ENGINE CONTROL MODULE, AND THE CONTROL SIGNAL IS OUTPUT TO TERMINALS #10, #20, #30, AND #40 OF THE

ENGINE CONTROL MODULE TO OPERATE THE INJECTOR (INJECT THE FUEL). THE SFI SYSTEM PRODUCES CONTROL OF FUEL

INJECTION OPERATION BY THE ENGINE CONTROL MODULE IN RESPONSE TO THE DRIVING CONDITIONS.

*IDLE SPEED CONTROL SYSTEM

THE IDLE SPEED CONTROL SYSTEM INCREASES THE RPM AND PROVIDES IDLING STABILITY FOR FAST IDLE-UP WHEN THE

ENGINE IS COLD AND WHEN THE IDLE SPEED HAS DROPPED DUE TO ELECTRICAL LOAD, ETC. THE ENGINE CONTROL MODULE

EVALUATES THE SIGNALS FROM EACH SENSOR (INPUT SIGNALS (1 TO 5, 11), OUTPUTS CURRENT TO TERMINAL ISCO AND ISCC,

AND CONTROLS THE IDLE AIR CONTROL VALVE.

*A/C CUT CONTROL SYSTEM

WHEN THE VEHICLE SUDDENLY ACCELERATES FROM LOW ENGINE SPEED, THIS SYSTEM CUTS OFF AIR CONDITIONING

OPERATION FOR A FIXED PERIOD OF TIME IN RESPONSE TO THE SPEED SENSOR, THROTTLE VALVE OPENING ANGLE AND

INTAKE MANIFOLD PRESSURE IN ORDER TO MAINTAIN ACCELERATION PERFORMANCE.

THE ENGINE CONTROL MODULE RECEIVES INPUT SIGNALS (4, 5 AND 9), AND INPUTS SIGNALS TO TERMINAL ACT.

3. DIAGNOSIS SYSTEM

WITH THE DIAGNOSIS SYSTEM, WHEN THERE IS A MALFUNCTION IN THE ENGINE CONTROL MODULE SIGNAL SYSTEM, THE

MALFUNCTIONING SYSTEM IS RECORDED IN THE MEMORY. THE MALFUNCTIONING SYSTEM CAN THEN BE FOUND BY READING

THE DISPLAY (CODE) OF THE MALFUNCTION INDICATOR LAMP.

4. FAIL-SAFE SYSTEM

WHEN A MALFUNCTION OCCURS ON ANY SYSTEM, IF THERE IS A POSSIBILITY OF ENGINE THROUBLE BEING CAUSED BY

CONTINUED CONTROL BASED IN THE SIGNALS FROM THAT SYSTEM, THE FAIL-SAFE SYSTEM EITHER CONTROLS THE SYSTEM BY

USING DATA (STANDARD VALUES) RECORDED IN THE ENGINE CONTROL MODULE MEMORY OR ELSE STOPS THE ENGINE.

Page 839 of 1354

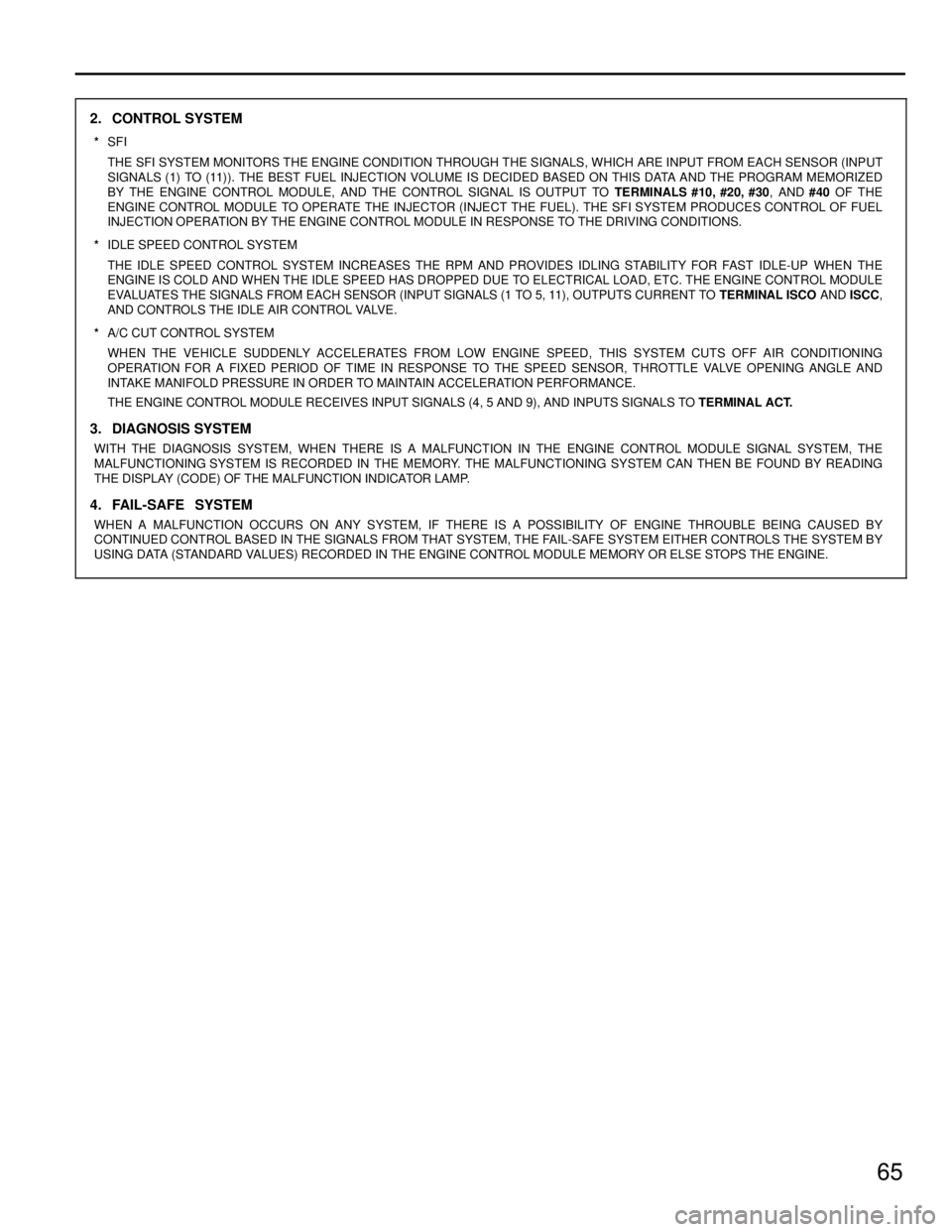

70

ENGINE CONTROL

IG 2 10 IG 2 9 IG 1 28 R-L

R-L

R-L

L-B

R-YL-B

R-

V- W

G-R

VEHICLE SPE ED SENSOR

(

CO MBINATION M ETER) COMBINATION

METER C 9

G-R V-WR-B J10 , J11

A

A C

B B

B B LJUNCTION CONNECTOR

R-L

11 1 0 2 9

Y

3 2 1

V 2

MALFANCTION

INDICATOR LAMP

SPEED

1B8

1E8

Page 899 of 1354

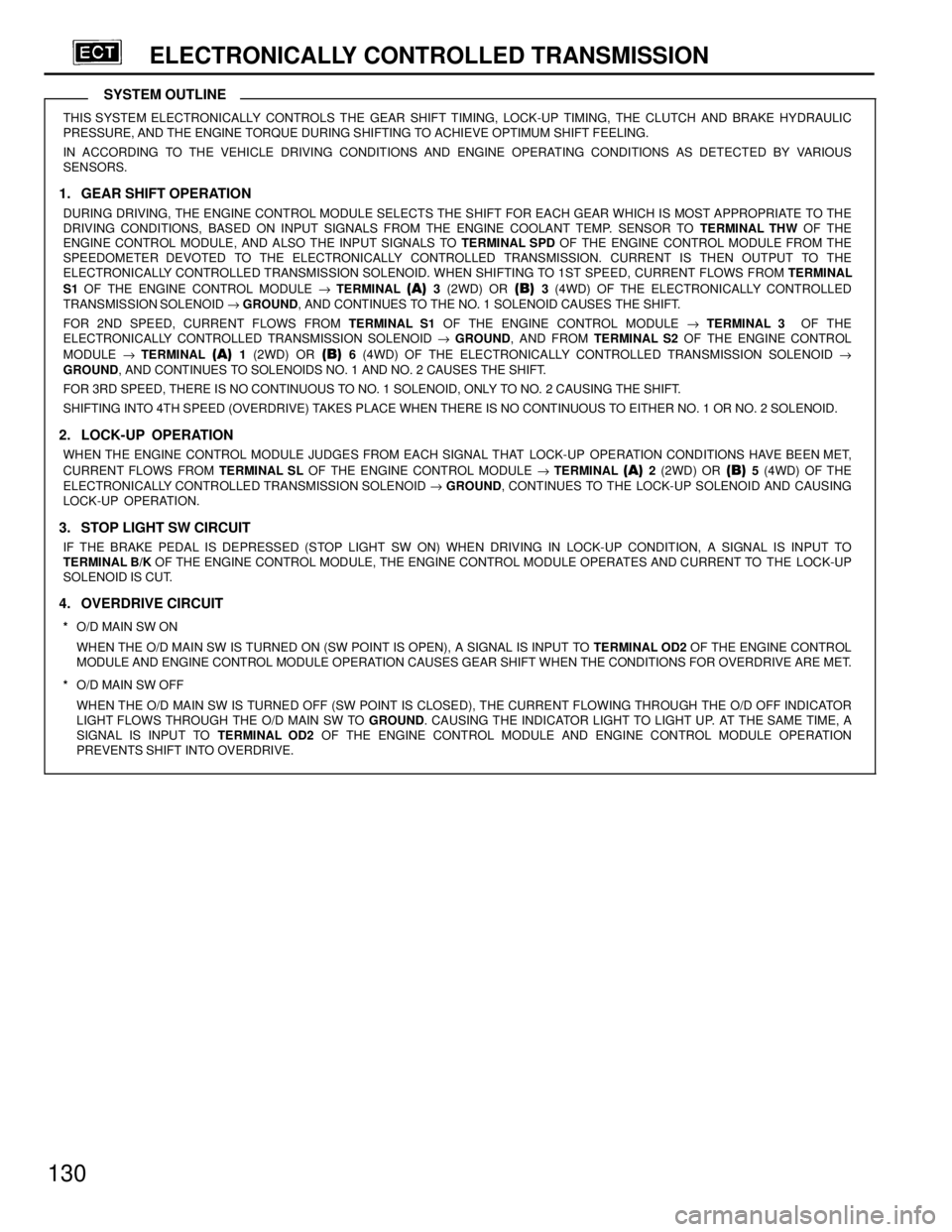

130

ELECTRONICALLY CONTROLLED TRANSMISSION

THIS SYSTEM ELECTRONICALLY CONTROLS THE GEAR SHIFT TIMING, LOCK-UP TIMING, THE CLUTCH AND BRAKE HYDRAULIC

PRESSURE, AND THE ENGINE TORQUE DURING SHIFTING TO ACHIEVE OPTIMUM SHIFT FEELING.

IN ACCORDING TO THE VEHICLE DRIVING CONDITIONS AND ENGINE OPERATING CONDITIONS AS DETECTED BY VARIOUS

SENSORS.

1. GEAR SHIFT OPERATION

DURING DRIVING, THE ENGINE CONTROL MODULE SELECTS THE SHIFT FOR EACH GEAR WHICH IS MOST APPROPRIATE TO THE

DRIVING CONDITIONS, BASED ON INPUT SIGNALS FROM THE ENGINE COOLANT TEMP. SENSOR TO TERMINAL THW OF THE

ENGINE CONTROL MODULE, AND ALSO THE INPUT SIGNALS TO TERMINAL SPD OF THE ENGINE CONTROL MODULE FROM THE

SPEEDOMETER DEVOTED TO THE ELECTRONICALLY CONTROLLED TRANSMISSION. CURRENT IS THEN OUTPUT TO THE

ELECTRONICALLY CONTROLLED TRANSMISSION SOLENOID. WHEN SHIFTING TO 1ST SPEED, CURRENT FLOWS FROM TERMINAL

S1 OF THE ENGINE CONTROL MODULE "TERMINAL

(A) 3 (2WD) OR (B) 3 (4WD) OF THE ELECTRONICALLY CONTROLLED

TRANSMISSION SOLENOID "GROUND, AND CONTINUES TO THE NO. 1 SOLENOID CAUSES THE SHIFT.

FOR 2ND SPEED, CURRENT FLOWS FROM TERMINAL S1 OF THE ENGINE CONTROL MODULE "TERMINAL 3 OF THE

ELECTRONICALLY CONTROLLED TRANSMISSION SOLENOID "GROUND, AND FROM TERMINAL S2 OF THE ENGINE CONTROL

MODULE "TERMINAL

(A) 1 (2WD) OR (B) 6 (4WD) OF THE ELECTRONICALLY CONTROLLED TRANSMISSION SOLENOID "

GROUND, AND CONTINUES TO SOLENOIDS NO. 1 AND NO. 2 CAUSES THE SHIFT.

FOR 3RD SPEED, THERE IS NO CONTINUOUS TO NO. 1 SOLENOID, ONLY TO NO. 2 CAUSING THE SHIFT.

SHIFTING INTO 4TH SPEED (OVERDRIVE) TAKES PLACE WHEN THERE IS NO CONTINUOUS TO EITHER NO. 1 OR NO. 2 SOLENOID.

2. LOCK-UP OPERATION

WHEN THE ENGINE CONTROL MODULE JUDGES FROM EACH SIGNAL THAT LOCK-UP OPERATION CONDITIONS HAVE BEEN MET,

CURRENT FLOWS FROM TERMINAL SL OF THE ENGINE CONTROL MODULE "TERMINAL

(A) 2 (2WD) OR (B) 5 (4WD) OF THE

ELECTRONICALLY CONTROLLED TRANSMISSION SOLENOID "GROUND, CONTINUES TO THE LOCK-UP SOLENOID AND CAUSING

LOCK-UP OPERATION.

3. STOP LIGHT SW CIRCUIT

IF THE BRAKE PEDAL IS DEPRESSED (STOP LIGHT SW ON) WHEN DRIVING IN LOCK-UP CONDITION, A SIGNAL IS INPUT TO

TERMINAL B/K OF THE ENGINE CONTROL MODULE, THE ENGINE CONTROL MODULE OPERATES AND CURRENT TO THE LOCK-UP

SOLENOID IS CUT.

4. OVERDRIVE CIRCUIT

*O/D MAIN SW ON

WHEN THE O/D MAIN SW IS TURNED ON (SW POINT IS OPEN), A SIGNAL IS INPUT TO TERMINAL OD2 OF THE ENGINE CONTROL

MODULE AND ENGINE CONTROL MODULE OPERATION CAUSES GEAR SHIFT WHEN THE CONDITIONS FOR OVERDRIVE ARE MET.

*O/D MAIN SW OFF

WHEN THE O/D MAIN SW IS TURNED OFF (SW POINT IS CLOSED), THE CURRENT FLOWING THROUGH THE O/D OFF INDICATOR

LIGHT FLOWS THROUGH THE O/D MAIN SW TO GROUND. CAUSING THE INDICATOR LIGHT TO LIGHT UP. AT THE SAME TIME, A

SIGNAL IS INPUT TO TERMINAL OD2 OF THE ENGINE CONTROL MODULE AND ENGINE CONTROL MODULE OPERATION

PREVENTS SHIFT INTO OVERDRIVE.

SYSTEM OUTLINE

Page 902 of 1354

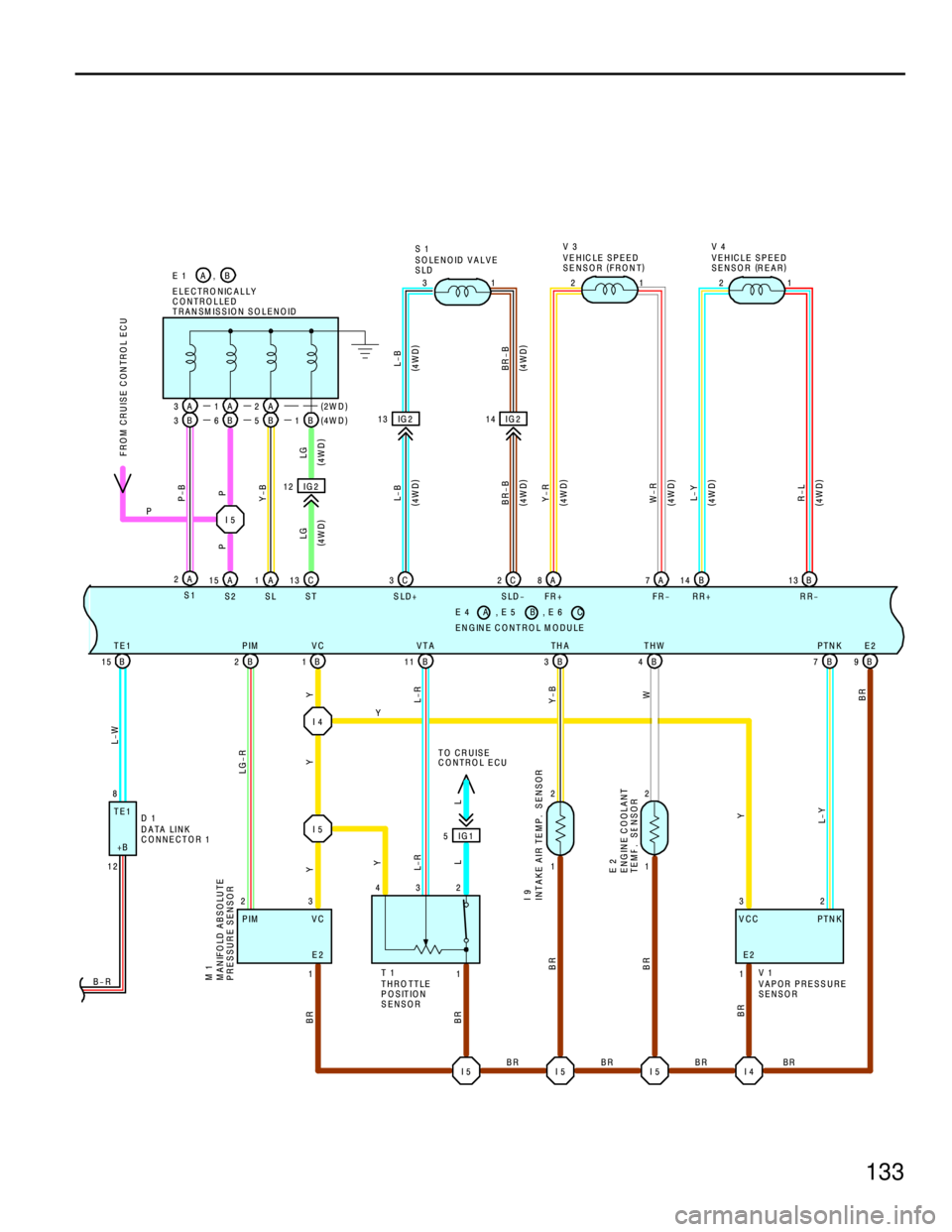

133

I 4 I 4 B 2PIM

B 1VC

B 11VTA

B 3TH A

B 4THW

B 7PTN K

B 9E2

Y

BR BR BR

LG-R

YY

L-R

Y-B

W

BR BR

BR

BR

BR SENSOR

OR

ENGINE CONTROL M ODULEB E 4 , E 5AC, E 6

B 15

L-W

A 2

A 15 A1C13 C3C2A8A7B14 B13

TE1S1

S2 SL ST SLD+ SLD- FR+ FR- RR+ RR-

P-B

P

Y-B

LG

L- B

BR-B

Y-R

W-R

L- Y

R-L

I 5 I 5 I 5 TO CRUISE

CONTROL ECUIG 2 14 IG 2 13

IG 2 12 A 3

B 3A 1A2(

2W D)

B 1(

4W D)

B 5 B 6

(

4W D)

(

4W D)(

4WD)

(

4WD)

(

4W D)

(

4W D)

(

4W D)

(

4W D)L-B

BR - B LG

B E 1 , A

ELECTRO NICALLY

CONTROLLED

TRANSM ISSION SOLENOID

(

4W D)(

4W D)

I 5 P

PFROM CRUISE CONTROL ECU

1 31212 SOLENOID VALVE

SLD S 1

VEHICLE SPEED

SENSOR (

FRO N T) V 3

VEHICLE SPEED

SENSOR (

REAR) V 4

1 2

1 2

11 1 3 2432

32

E2

L Y

BR

BR

Y

L- Y

VCC PTNK

L-R

L Y M 1

MANIFOLD ABSOLUTE

PRESSURE SENSOR

THRO TTLE

POSITION T 1

INTAKE AIR TEMP. SENS I 9

ENGINE COOLANT

TEM P

. SE

NSOR E 2

VAPOR PRESSURE

SENSOR V 1 8

B-RDATA LINK

CONNECTOR 1 D 1

12I 5

IG 1 5

E2 VC PIM

+B TE1

Page 903 of 1354

![TOYOTA RAV4 1996 Service Manual PDF 134

ELECTRONICALLY CONTROLLED TRANSMISSION

GAUGE

SE BLOCK] FROM POW ER SOURCE SYSTEM (

SEE PAGE 54)

IG 1 2 IG 2 9 IG 2 10

EC IGA 8

A 5A4A2 A 10 A11 B2

ECT PW RO/D OFF

4

R-G

LG

R-L

R- B LG-LG BR BR BR

TOYOTA RAV4 1996 Service Manual PDF 134

ELECTRONICALLY CONTROLLED TRANSMISSION

GAUGE

SE BLOCK] FROM POW ER SOURCE SYSTEM (

SEE PAGE 54)

IG 1 2 IG 2 9 IG 2 10

EC IGA 8

A 5A4A2 A 10 A11 B2

ECT PW RO/D OFF

4

R-G

LG

R-L

R- B LG-LG BR BR BR](/img/14/57462/w960_57462-902.png)

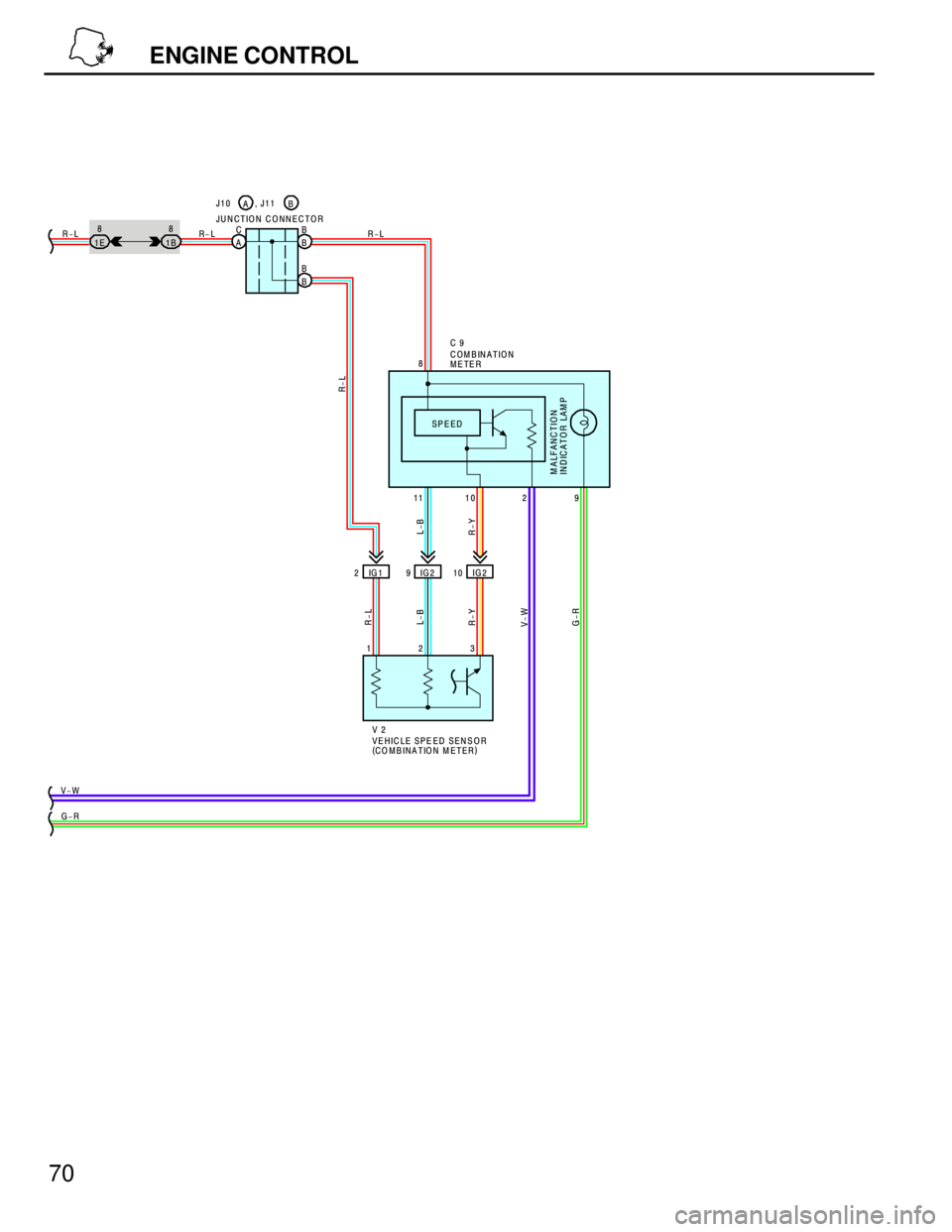

134

ELECTRONICALLY CONTROLLED TRANSMISSION

GAUGE

SE BLOCK] FROM POW ER SOURCE SYSTEM (

SEE PAGE 54)

IG 1 2 IG 2 9 IG 2 10

EC IGA 8

A 5A4A2 A 10 A11 B2

ECT PW RO/D OFF

4

R-G

LG

R-L

R- B LG-LG BR BR BR

R-L R-LR-L

R-LR-L-L

-L

LG

R-G LG

R-G

-W

V-WR- Y

L- B R- Y

L-B

W-B LG W-B

CO MBINATION M ETERB C 9 , C10A

EL ECTRONICALLY

CONTROLLED TRANSM ISSION

PATTERN SELECT SW E 3

(

COM BINATION METER) SPEED

JUNC

CONN J 32

CTION

NECTORB , J1 1 A

W-B JUNCTION CONNECTORB J10 , J11A

B BBBA C A C

I 5

1E 81B8

R

R

10A

[FU 3

F 8

POW ER NORMAL

3

BB B

B

TION

ECTORB

B JUN CTIO N

CONNECTOR J 5

C 7

OD2C 15

PC 9

SPD

C 8R

C 182

C 19L

A 14E1

A 26E02

A 13E01321

R

V

W-B

ENGINE CONTRO L M ODULEB E 4 , E 5AC, E 6

VEHICLE SPEED SENSOR V 2

IG 2 15 IG 216 IG17

4 2

A A

R-B LG - RLG BR BR BR

R-L

W-B

JUN CTION

CONNECTOR J 2O/D MAIN SW O 4

B A B 8(

4WD) A 5(

2WD)

B 3A 9

B 4A 4

A AAA A 6(

2WD)

B 2(

4WD)JU N

CON J10W-B

B P 1 , A

PARK/NEUTRAL

POSITION

SW

Page 909 of 1354

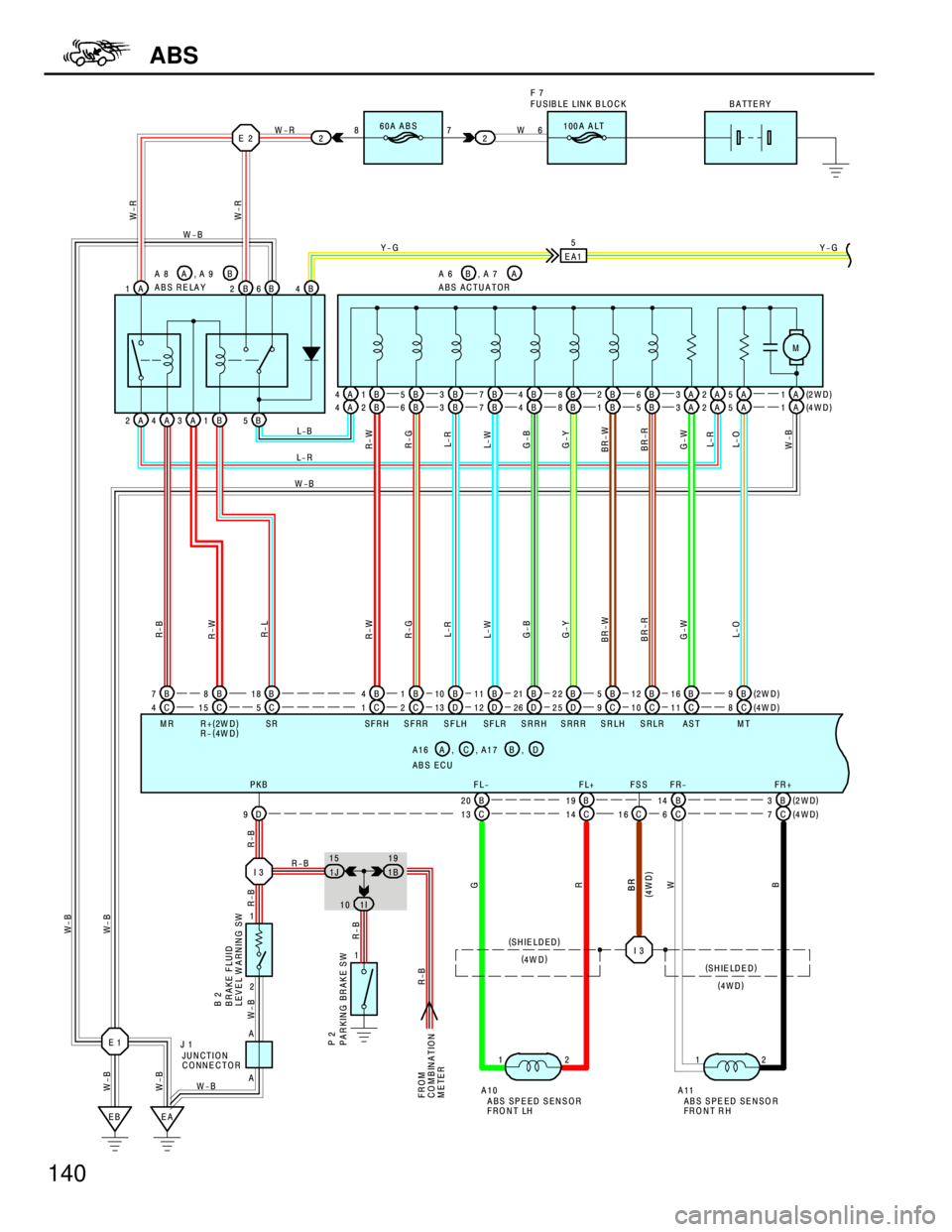

140

ABS

M A 1B2B4

C 8 C 11 C 10 C 9 D 25 D 26 D 12 D 13 C 2 C 1 C 5 C 15 C 4 A 2A4B1B5 A 3A 4B1B5B3B7B4B8B2B6A3A2A5A1

B 3 B 14 B 19 B 20

EA EBY-GY-G

L-B

L-R

W-B

W-R W-R

R-W

R- L R-B

W-BL- OL- R G-W BR-R BR-WG-Y

G-B

L- WL- R R-G R- W R-W

R-G

L-R

L-W

G-B

G-Y

BR-W

BR-R

G-W

L-O BR

BATTERY

ABS ACTUATOR ABS RELAYB A 8 , A 9AA A 6 , A 7B

ABS ECU A16 A MR R+(

2W D)

R-(

4W D)SR SFRH SFRR SFLH SFLR SRRH SRRR SRLH SRLR AST MT

FR+ FR- FSS FL+ FL-

B W BRG

R

FR O N T R H FRO NT LHEA15 2 W-RFU

B 6 W-BF 7

PKB

R-

R-B R-B

E 2

E 1I 3

W-B W-B W-BW- B

A 4B2B6B3B7B4B8B1B5A3A2A5A1(

2WD)

(

4WD)

B 4 B 18 B 8 B 7B 9 B 16 B 12 B 5 B 22 B 21 B 11 B 10 B 1(

2W D)

(

4W D)

B , A1 7

C 16 C 14 C 13 D 9

JU

CO J 1C 7 C 6(

2WD)

(

4WD) C , D,

(

4WD)

87

2 60A ABS

6 W

1J 15

1B19

1I 10 B

2 1 2 1

ABS SPEED SENSOR ABS SPEED SENSOR A10 A11 2 1

1

R-B

R-B FROM

CO M BINATION

METER(

SHIELDED)

PARKING BRAKE SW P 2BRAKE FLUID

LEVEL W ARNING SW B 2

A A

W-B

W-B

I 3

NCTION

NNECTOR(

4W D)

(

SHIELDED)

(

4WD)

SIBLE LINK BLOCK

100A ALT