TOYOTA RAV4 1996 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1354, PDF Size: 30.43 MB

Page 891 of 1354

122

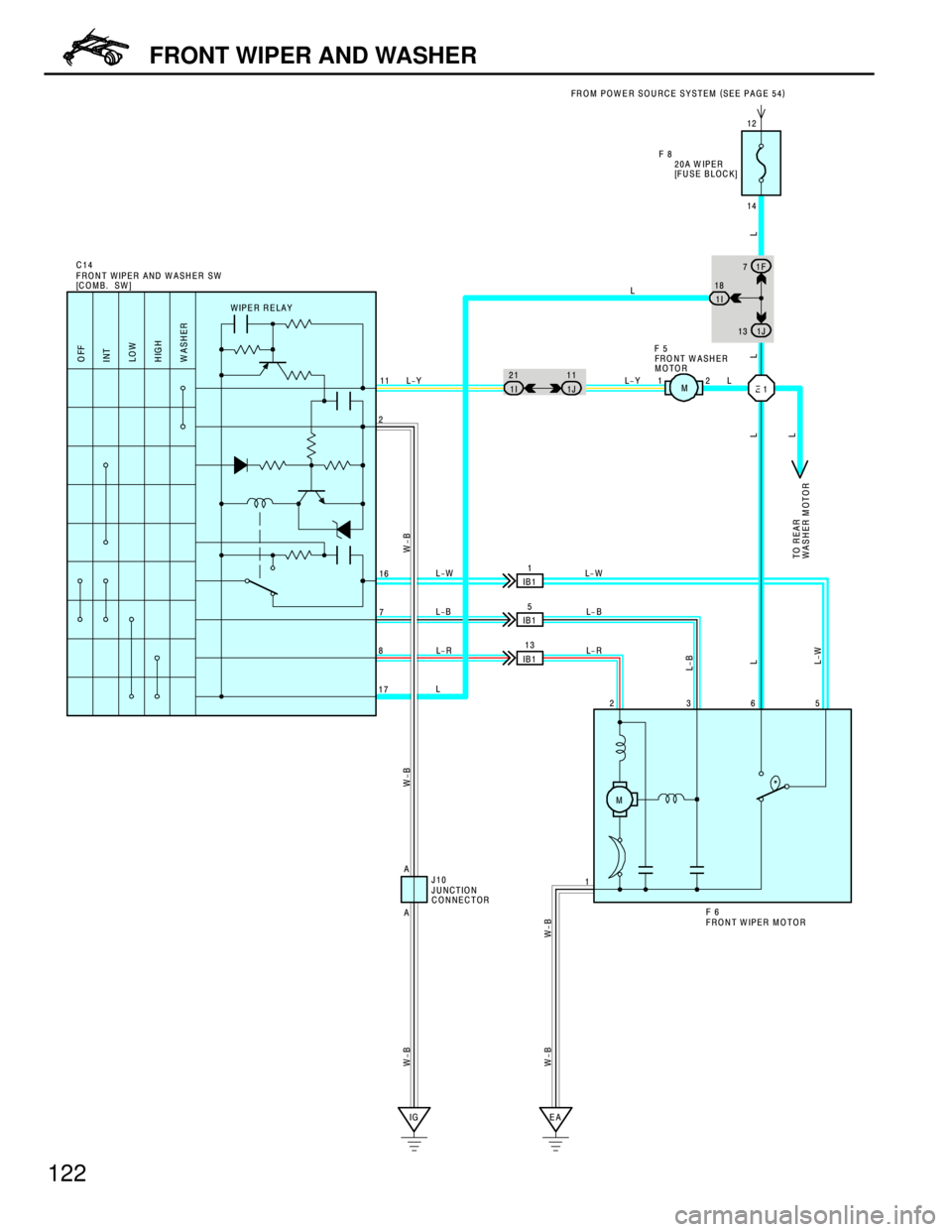

FRONT WIPER AND WASHER

L-W

L-B

L

L W-B

L-B

L

L-W

L- R

W-B

IG20A W IPER

[FUSE BLOCK

IB11

IB15

IB113L- W

L- B

L- RL YL FROM POW ER SOURCE SYSTEM (

SEE PAGE 54)

F 6

FRONT WIPER MOTOR

L

14 12

L

EA

W-B

F 8

L

TO REAR

WASHER M OTOR

AOR

W-B

E 1

1J 13 1I 181F 7

1I 21

1J 1112 -Y LFRO NT W ASHER

MOTOR F 5

W-B

L-

2365

M

1

A

JUNCTION

CONNECT J10

]

M

OFF

INT

HIGH

W ASHER

FRONT WIPER AND W ASHER SW

[COMB. SW ]

LOW

WIPER RELAY C14

16

7 2

8

1711

Page 892 of 1354

123

WITH THE IGNITION SW TURNED ON, THE CURRENT FLOWS TO TERMINAL 17 OF THE FRONT WIPER AND WASHER SW, TERMINAL

2 OF THE FRONT WASHER MOTOR AND TERMINAL 6 OF THE FRONT WIPER MOTOR THROUGH THE WIPER FUSE.

1. LOW SPEED POSITION

WITH WIPER SW TURNED TO LOW POSITION, THE CURRENT FLOWS FROM TERMINAL 17 OF THE FRONT WIPER AND WASHER SW

" TERMINAL 7 "TERMINAL 3 OF THE FRONT WIPER MOTOR "WIPER MOTOR "TERMINAL 1 "TO GROUND AND CAUSES THE

FRONT WIPER MOTOR TO RUN AT LOW SPEED.

2. HIGH SPEED POSITION

WITH WIPER SW TURNED TO HIGH POSITION, THE CURRENT FLOWS FROM TERMINAL 17 OF THE FRONT WIPER AND WASHER SW

"TERMINAL 8 "TERMINAL 2 OF THE FRONT WIPER MOTOR "WIPER MOTOR "TERMINAL 1 "TO GROUND AND CAUSES THE

FRONT WIPER MOTOR TO RUN AT HIGH SPEED.

3. INT POSITION

WITH WIPER SW TURNED TO INT POSITION, THE RELAY OPERATES AND THE CURRENT WHICH IS CONNECTED BY RELAY

FUNCTION FLOWS FROM TERMINAL 17 OF THE FRONT WIPER AND WASHER SW "TERMINAL 2 "TO GROUND. THIS FLOW OF

CURRENT OPERATES THE INTERMITTENT CIRCUIT AND THE CURRENT FLOWS FROM TERMINAL 17 OF THE WIPER AND FRONT

WASHER SW "TERMINAL 7 "TERMINAL 3 OF THE FRONT WIPER MOTOR "WIPER MOTOR "TERMINAL 1 "TO GROUND AND

OPERATES THE WIPER.

THE INTERMITTENT OPERATION IS CONTROLLED BY A CONDENSER'S CHARGED AND DISCHARGED FUNCTION INSTALLED IN THE

RELAY AND THE INTERMITTENT TIME IS CONTROLLED BY A TIME CONTROL SW TO CHANGE THE CHARGING TIME OF THE

CONDENSER.

4. WASHER CONTINUOUS OPERATION (W/ INT CONTROL)

WITH WASHER SW TURNED TO ON, THE CURRENT FLOWS FROM TERMINAL 2 OF THE FRONT WASHER MOTOR "TERMINAL 1 "

TERMINAL 11 OF THE FRONT WIPER AND WASHER SW "TERMINAL 2 "TO GROUND AND CAUSES TO THE FRONT WASHER

MOTOR TO RUN. AND THE WINDOW WASHER EMITS A WATER SPRAY. THIS CAUSES THE CURRENT TO FLOW TO WASHER

CONTINUOUS OPERATION CIRCUIT IN TERMINAL 17 OF THE WIPER AND WASHER SW "TERMINAL 7 "TERMINAL 3 OF THE

FRONT WIPER MOTOR "WIPER MOTOR "TERMINAL 1 "TO GROUND AND OPERATES THE WIPER.

C14 FRONT WIPER AND WASHER SW [COMB. SW]

2-GROUND : ALWAYS CONTINUITY

17-GROUND : APPROX. 12 VOLTS WITH THE IGNITION SW AT ON POSITION

7-GROUND : APPROX. 12 VOLTS WITH THE WIPER AND WASHER SW AT LOW OR MIST POSITION

: APPROX. 12 VOLTS 2 TO 12 SECONDS INTERMITTENTLY WITH THE WIPER AND WASHER SW AT INT POSITION

16-GROUND : APPROX. 12 VOLTS WITH THE IGNITION SW ON UNLESS THE WIPER MOTOR AT STOP POSITION

8-GROUND : APPROX. 12 VOLTS WITH THE WIPER AND WASHER SW AT HIGH POSITION

F6 FRONT WIPER MOTOR

6-5 : CLOSED UNLESS THE WIPER MOTOR AT STOP POSITION

SYSTEM OUTLINE

SERVICE HINTS

Page 893 of 1354

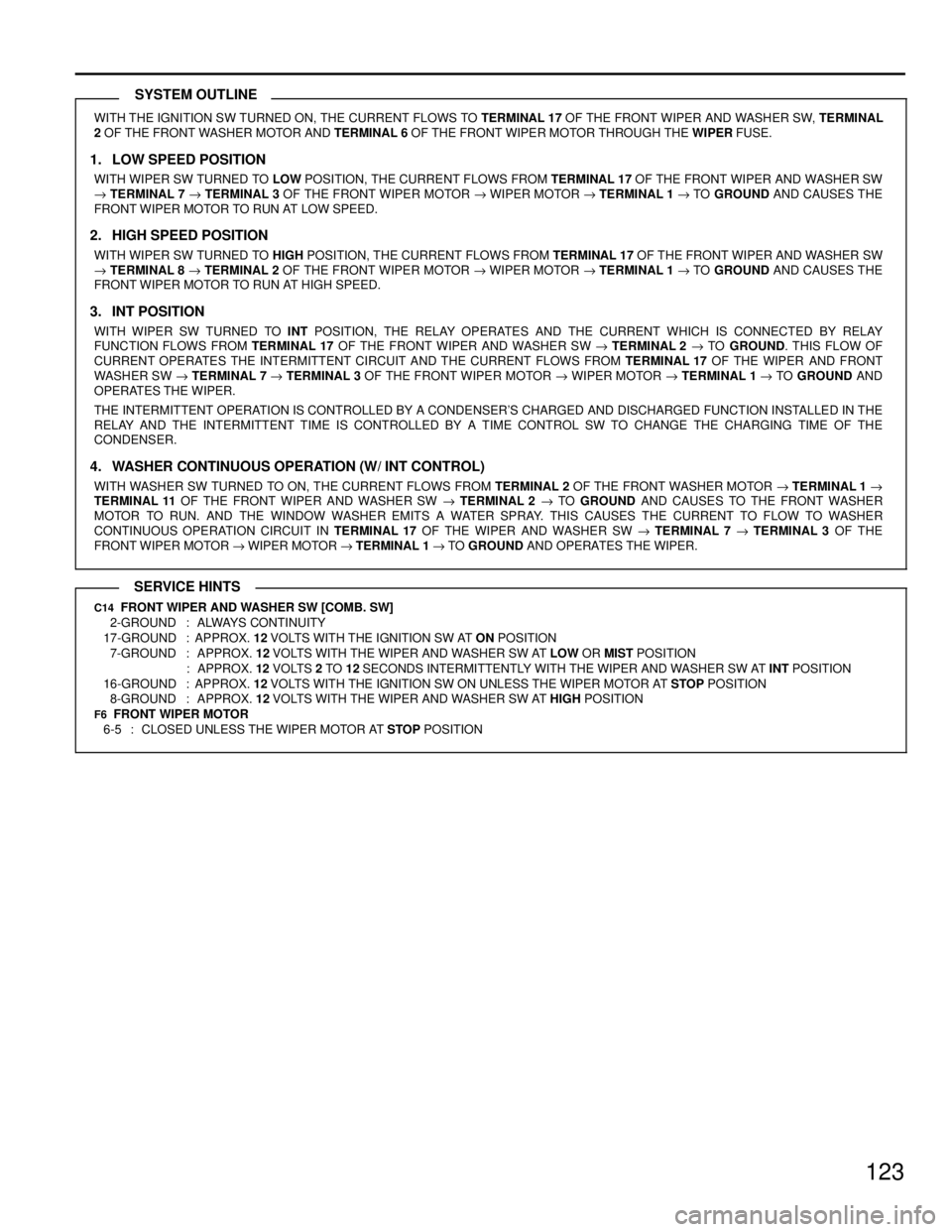

124

FRONT WIPER AND WASHER

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

C1430F 628J1031

F 528F 831

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1F20FUSE BLOCK ASSY WIRE AND J/B NO. 1 (LOWER FINISH PANEL)

1I20INSTRUMENT PANEL WIRE AND J/B NO 1 (LOWER FINISH PANEL)1J20INSTRUMENT PANEL WIRE AND J/B NO. 1 (LOWER FINISH PANEL)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

IB136ENGINE ROOM MAIN WIRE AND INSTRUMENT PANEL WIRE (LEFT KICK PANEL)

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

EA34RADIATOR RIGHT

IG36RIGHT KICK PANEL

: SPLICE POINTS

CODESEE PAGEWIRE HARNESS WITH SPLICE POINTSCODESEE PAGEWIRE HARNESS WITH SPLICE POINTS

E 134ENGINE ROOM MAIN WIRE

Page 894 of 1354

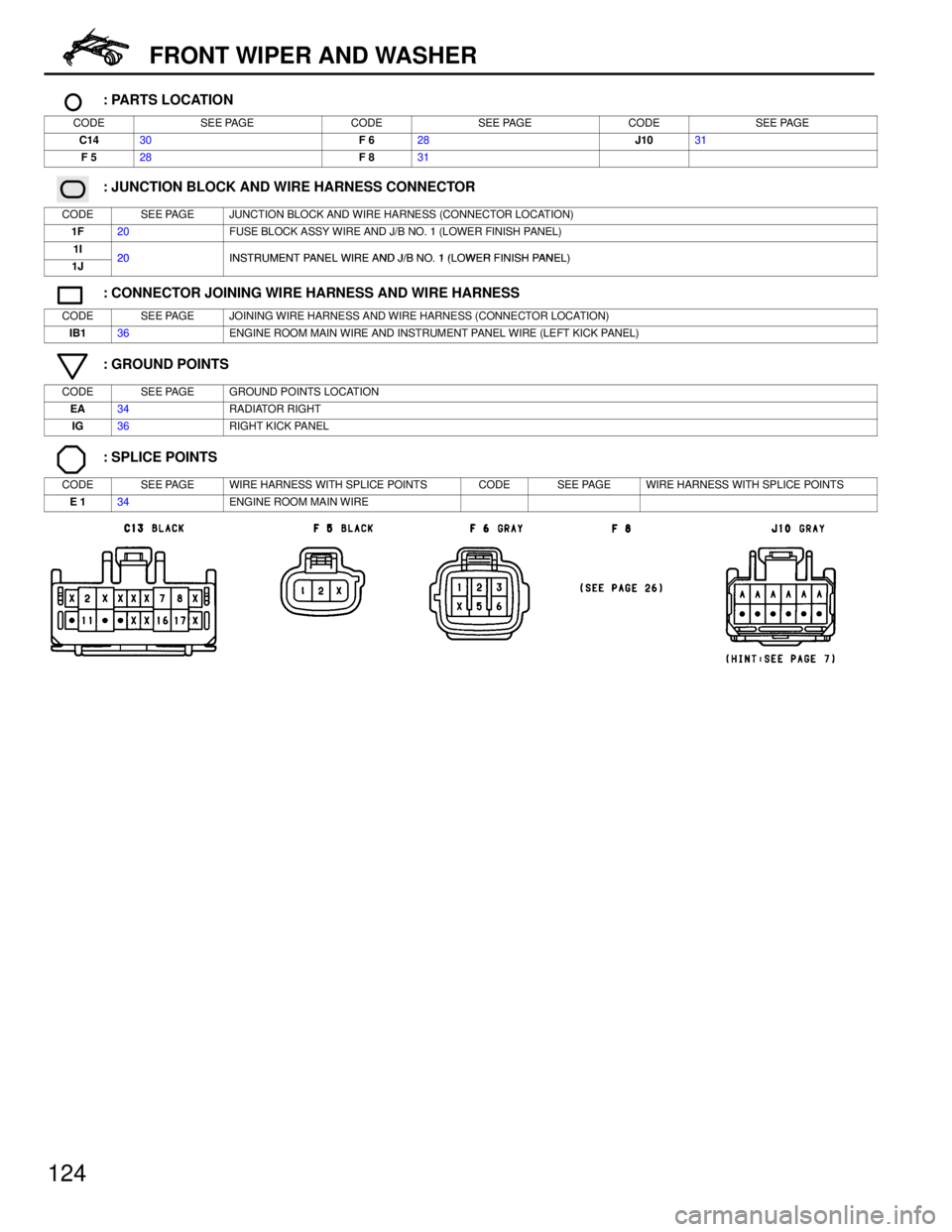

125

REAR WIPER AND WASHER

Page 895 of 1354

![TOYOTA RAV4 1996 Service Repair Manual 126

REAR WIPER AND WASHER

IG

L

L-Y

L-R

W-B W-BW-BG-BP

LPG

L FROM POWER SOURCE SYSTEM (

SEE PAGE 54)

0A W IPER

FUSE BLOCK]REAR W IPER AND W ASHER SW [COMB. SW ] C14

ID1 8

P-B

R MOTOR

REAR W IPER

MOTO TOYOTA RAV4 1996 Service Repair Manual 126

REAR WIPER AND WASHER

IG

L

L-Y

L-R

W-B W-BW-BG-BP

LPG

L FROM POWER SOURCE SYSTEM (

SEE PAGE 54)

0A W IPER

FUSE BLOCK]REAR W IPER AND W ASHER SW [COMB. SW ] C14

ID1 8

P-B

R MOTOR

REAR W IPER

MOTO](/img/14/57462/w960_57462-894.png)

126

REAR WIPER AND WASHER

IG

L

L-Y

L-R

W-B W-BW-BG-BP

LPG

L FROM POWER SOURCE SYSTEM (

SEE PAGE 54)

0A W IPER

FUSE BLOCK]REAR W IPER AND W ASHER SW [COMB. SW ] C14

ID1 8

P-B

R MOTOR

REAR W IPER

MOTOR6ID 1 3

P

G-B

12

BK1 6

L L L

BK1 5BK14

P

8

L

L

TO FRONT

WASHER MOTOR

B10E 1 14

1L 9L 1F 7

1J 13

1J8

1I6

21 REAR W ASHE R 2

3

54REAR W IPER RELAY R1 7

26

A

J10

JUNCTION

CONNECTOR

A

MR1

214

2

[ FWASHER 1

OFF

IN T

ON

12 13 10 2 WASHER 2

M

Page 896 of 1354

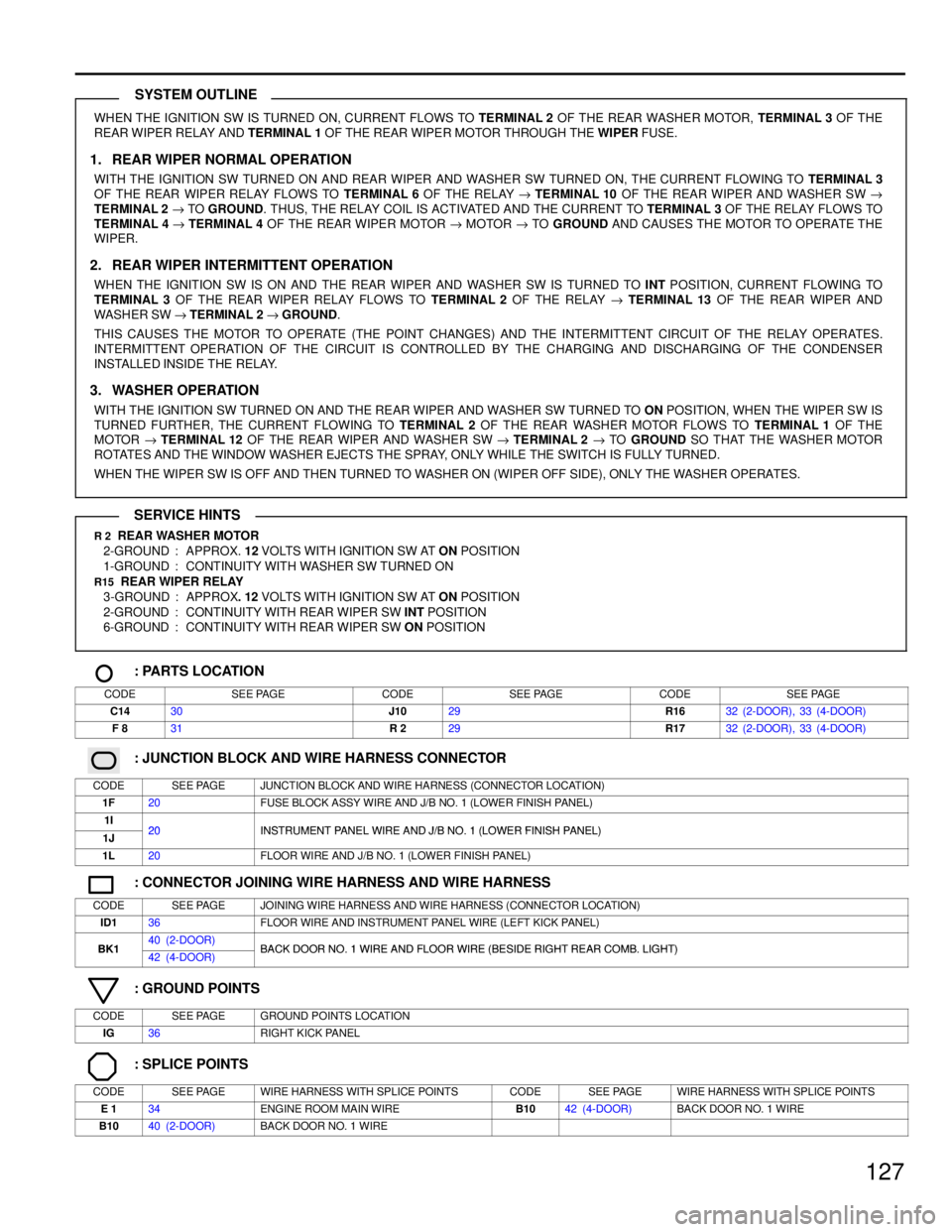

127

WHEN THE IGNITION SW IS TURNED ON, CURRENT FLOWS TO TERMINAL 2 OF THE REAR WASHER MOTOR, TERMINAL 3 OF THE

REAR WIPER RELAY AND TERMINAL 1 OF THE REAR WIPER MOTOR THROUGH THE WIPER FUSE.

1. REAR WIPER NORMAL OPERATION

WITH THE IGNITION SW TURNED ON AND REAR WIPER AND WASHER SW TURNED ON, THE CURRENT FLOWING TO TERMINAL 3

OF THE REAR WIPER RELAY FLOWS TO TERMINAL 6 OF THE RELAY "TERMINAL 10 OF THE REAR WIPER AND WASHER SW "

TERMINAL 2 "TOGROUND. THUS, THE RELAY COIL IS ACTIVATED AND THE CURRENT TO TERMINAL 3 OF THE RELAY FLOWS TO

TERMINAL 4 " TERMINAL 4 OF THE REAR WIPER MOTOR " MOTOR "TO GROUND AND CAUSES THE MOTOR TO OPERATE THE

WIPER.

2. REAR WIPER INTERMITTENT OPERATION

WHEN THE IGNITION SW IS ON AND THE REAR WIPER AND WASHER SW IS TURNED TO INT POSITION, CURRENT FLOWING TO

TERMINAL 3 OF THE REAR WIPER RELAY FLOWS TO TERMINAL 2 OF THE RELAY "TERMINAL 13 OF THE REAR WIPER AND

WASHER SW "TERMINAL 2 "GROUND.

THIS CAUSES THE MOTOR TO OPERATE (THE POINT CHANGES) AND THE INTERMITTENT CIRCUIT OF THE RELAY OPERATES.

INTERMITTENT OPERATION OF THE CIRCUIT IS CONTROLLED BY THE CHARGING AND DISCHARGING OF THE CONDENSER

INSTALLED INSIDE THE RELAY.

3. WASHER OPERATION

WITH THE IGNITION SW TURNED ON AND THE REAR WIPER AND WASHER SW TURNED TO ON POSITION, WHEN THE WIPER SW IS

TURNED FURTHER, THE CURRENT FLOWING TO TERMINAL 2 OF THE REAR WASHER MOTOR FLOWS TO TERMINAL 1 OF THE

MOTOR "TERMINAL 12 OF THE REAR WIPER AND WASHER SW "TERMINAL 2 "TO GROUND SO THAT THE WASHER MOTOR

ROTATES AND THE WINDOW WASHER EJECTS THE SPRAY, ONLY WHILE THE SWITCH IS FULLY TURNED.

WHEN THE WIPER SW IS OFF AND THEN TURNED TO WASHER ON (WIPER OFF SIDE), ONLY THE WASHER OPERATES.

R 2 REAR WASHER MOTOR

2-GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

1-GROUND : CONTINUITY WITH WASHER SW TURNED ON

R15 REAR WIPER RELAY

3-GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

2-GROUND : CONTINUITY WITH REAR WIPER SW INT POSITION

6-GROUND : CONTINUITY WITH REAR WIPER SW ON POSITION

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

C1430J1029R1632 (2-DOOR), 33 (4-DOOR)

F 831R 229R1732 (2-DOOR), 33 (4-DOOR)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1F20FUSE BLOCK ASSY WIRE AND J/B NO. 1 (LOWER FINISH PANEL)

1I20INSTRUMENT PANEL WIRE AND J/B NO 1 (LOWER FINISH PANEL)1J20INSTRUMENT PANEL WIRE AND J/B NO. 1 (LOWER FINISH PANEL)

1L20FLOOR WIRE AND J/B NO. 1 (LOWER FINISH PANEL)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

ID136FLOOR WIRE AND INSTRUMENT PANEL WIRE (LEFT KICK PANEL)

BK140 (2-DOOR)BACK DOOR NO 1 WIRE AND FLOOR WIRE (BESIDE RIGHT REAR COMB LIGHT)BK142 (4-DOOR)BACK DOOR NO. 1 WIRE AND FLOOR WIRE (BESIDE RIGHT REAR COMB. LIGHT)

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

IG36RIGHT KICK PANEL

: SPLICE POINTS

CODESEE PAGEWIRE HARNESS WITH SPLICE POINTSCODESEE PAGEWIRE HARNESS WITH SPLICE POINTS

E 134ENGINE ROOM MAIN WIREB1042 (4-DOOR)BACK DOOR NO. 1 WIRE

B1040 (2-DOOR)BACK DOOR NO. 1 WIRE

SYSTEM OUTLINE

SERVICE HINTS

Page 897 of 1354

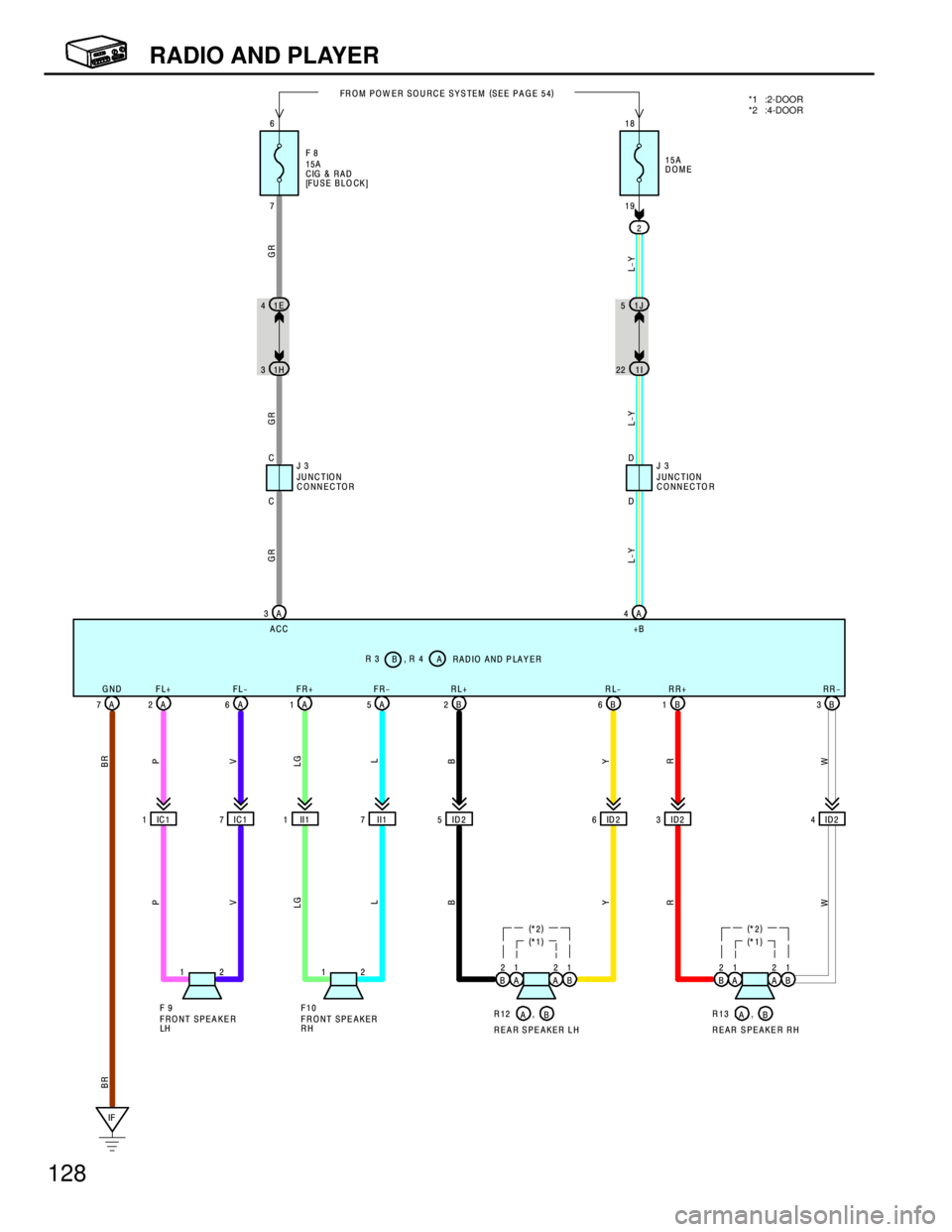

128

RADIO AND PLAYER

15A

CIG & RADFROM POW ER SOURCE SYSTEM (

SEE PAGE 54)

6

GR

TION

NECTOR

A 3A 415A

DOME 18

L-Y L-YGR

ACC+B

R 3 , R 4

B A RADIO AND PLAYER

A 7A2A6A1A5B2B6B1B3 GND FL+ FL- FR+ FR- RL+ RR+ RR-RL-

IFIC 1 1IC17II11 II17ID25ID26ID23ID24

(

*

2) (

*

2)

P

V

LG

L

B

Y

R

W BR BR

P

V

LG

L

B

Y

R

W

F 8

[FUSE BLOCK]

7

GR

19

2

L-Y

C

J 3

JU NC TIO N

CONNECTOR

CD

J 3

JUNC

CON

D

12 12

A1

B2

A2

B1 (

*1)

A1

B2

A2

B 1 (

*1)

FRONT SPEAKER

LH F 9

FRONT SPEAKER

RH F10

B R12 ,

A

REAR SPEAKER L HB R13 ,

A

REAR SPEAKER RH

1E 4

1H 31J 5

1I 22

*1 :2-DOOR

*2 :4-DOOR

Page 898 of 1354

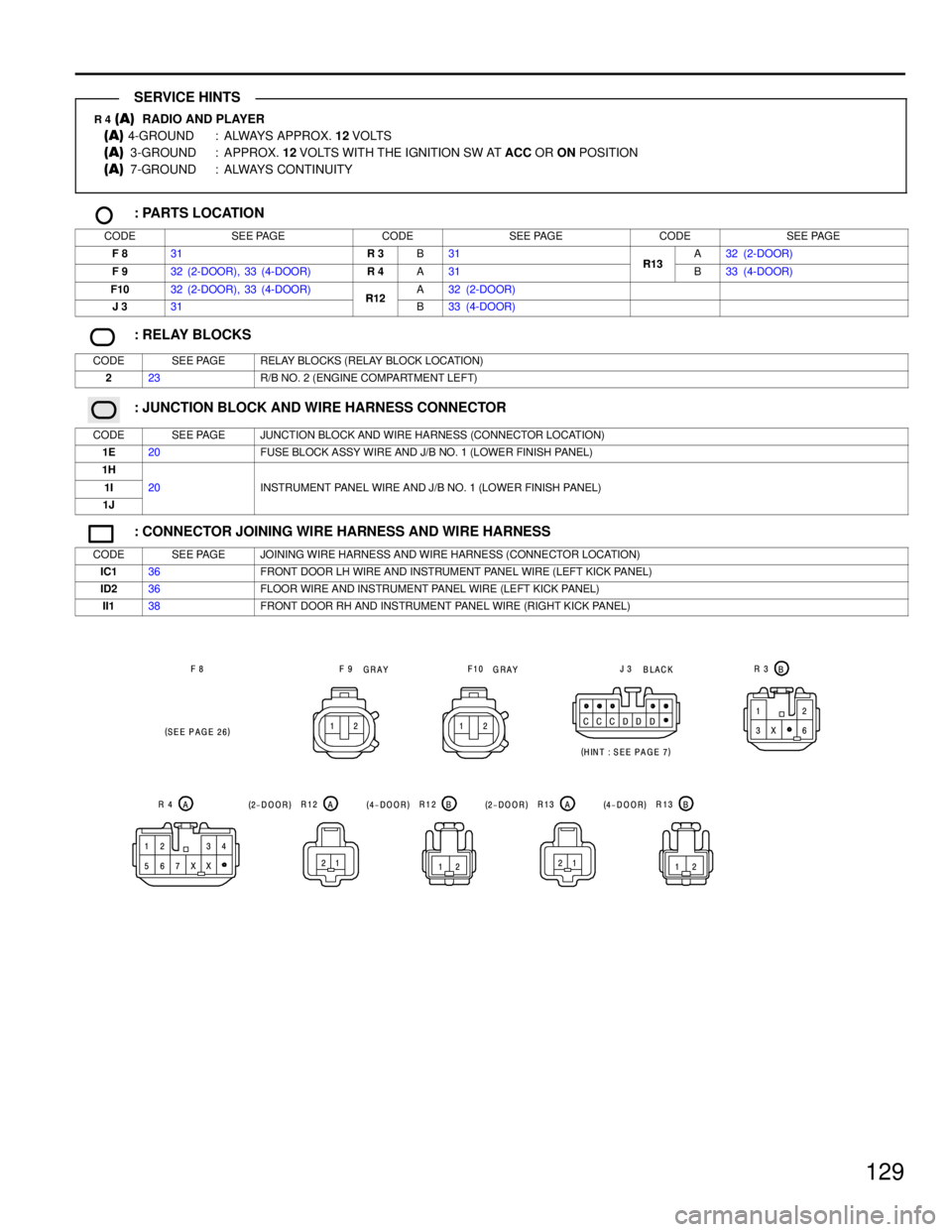

129

R 4 (A) RADIO AND PLAYER

(A) 4-GROUND : ALWAYS APPROX. 12 VOLTS

(A) 3-GROUND : APPROX. 12 VOLTS WITH THE IGNITION SW AT ACC OR ON POSITION

(A) 7-GROUND : ALWAYS CONTINUITY

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

F 831R 3B31R13A32 (2-DOOR)

F 932 (2-DOOR), 33 (4-DOOR)R 4A31R13B33 (4-DOOR)

F1032 (2-DOOR), 33 (4-DOOR)R12A32 (2-DOOR)

J 331R12B33 (4-DOOR)

: RELAY BLOCKS

CODESEE PAGERELAY BLOCKS (RELAY BLOCK LOCATION)

223R/B NO. 2 (ENGINE COMPARTMENT LEFT)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1E20FUSE BLOCK ASSY WIRE AND J/B NO. 1 (LOWER FINISH PANEL)

1H

1I20INSTRUMENT PANEL WIRE AND J/B NO. 1 (LOWER FINISH PANEL)

1J

()

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

IC136FRONT DOOR LH WIRE AND INSTRUMENT PANEL WIRE (LEFT KICK PANEL)

ID236FLOOR WIRE AND INSTRUMENT PANEL WIRE (LEFT KICK PANEL)

II138FRONT DOOR RH AND INSTRUMENT PANEL WIRE (RIGHT KICK PANEL)

(

SEE PAGE 26)12 1212

3X 6 CCCDD D

12 34

567XX

12 1 2

12 1 2(

HINT : SEE PAGE 7) F 8 F 9

GRAYF10

GRAYJ 3

BLACK BR 3

A R13 (

2-DOOR)

B R13 (

4-DOOR)

A R12 (

2-DOOR)

B R12 (

4-DOOR)

A R 4

SERVICE HINTS

Page 899 of 1354

130

ELECTRONICALLY CONTROLLED TRANSMISSION

THIS SYSTEM ELECTRONICALLY CONTROLS THE GEAR SHIFT TIMING, LOCK-UP TIMING, THE CLUTCH AND BRAKE HYDRAULIC

PRESSURE, AND THE ENGINE TORQUE DURING SHIFTING TO ACHIEVE OPTIMUM SHIFT FEELING.

IN ACCORDING TO THE VEHICLE DRIVING CONDITIONS AND ENGINE OPERATING CONDITIONS AS DETECTED BY VARIOUS

SENSORS.

1. GEAR SHIFT OPERATION

DURING DRIVING, THE ENGINE CONTROL MODULE SELECTS THE SHIFT FOR EACH GEAR WHICH IS MOST APPROPRIATE TO THE

DRIVING CONDITIONS, BASED ON INPUT SIGNALS FROM THE ENGINE COOLANT TEMP. SENSOR TO TERMINAL THW OF THE

ENGINE CONTROL MODULE, AND ALSO THE INPUT SIGNALS TO TERMINAL SPD OF THE ENGINE CONTROL MODULE FROM THE

SPEEDOMETER DEVOTED TO THE ELECTRONICALLY CONTROLLED TRANSMISSION. CURRENT IS THEN OUTPUT TO THE

ELECTRONICALLY CONTROLLED TRANSMISSION SOLENOID. WHEN SHIFTING TO 1ST SPEED, CURRENT FLOWS FROM TERMINAL

S1 OF THE ENGINE CONTROL MODULE "TERMINAL

(A) 3 (2WD) OR (B) 3 (4WD) OF THE ELECTRONICALLY CONTROLLED

TRANSMISSION SOLENOID "GROUND, AND CONTINUES TO THE NO. 1 SOLENOID CAUSES THE SHIFT.

FOR 2ND SPEED, CURRENT FLOWS FROM TERMINAL S1 OF THE ENGINE CONTROL MODULE "TERMINAL 3 OF THE

ELECTRONICALLY CONTROLLED TRANSMISSION SOLENOID "GROUND, AND FROM TERMINAL S2 OF THE ENGINE CONTROL

MODULE "TERMINAL

(A) 1 (2WD) OR (B) 6 (4WD) OF THE ELECTRONICALLY CONTROLLED TRANSMISSION SOLENOID "

GROUND, AND CONTINUES TO SOLENOIDS NO. 1 AND NO. 2 CAUSES THE SHIFT.

FOR 3RD SPEED, THERE IS NO CONTINUOUS TO NO. 1 SOLENOID, ONLY TO NO. 2 CAUSING THE SHIFT.

SHIFTING INTO 4TH SPEED (OVERDRIVE) TAKES PLACE WHEN THERE IS NO CONTINUOUS TO EITHER NO. 1 OR NO. 2 SOLENOID.

2. LOCK-UP OPERATION

WHEN THE ENGINE CONTROL MODULE JUDGES FROM EACH SIGNAL THAT LOCK-UP OPERATION CONDITIONS HAVE BEEN MET,

CURRENT FLOWS FROM TERMINAL SL OF THE ENGINE CONTROL MODULE "TERMINAL

(A) 2 (2WD) OR (B) 5 (4WD) OF THE

ELECTRONICALLY CONTROLLED TRANSMISSION SOLENOID "GROUND, CONTINUES TO THE LOCK-UP SOLENOID AND CAUSING

LOCK-UP OPERATION.

3. STOP LIGHT SW CIRCUIT

IF THE BRAKE PEDAL IS DEPRESSED (STOP LIGHT SW ON) WHEN DRIVING IN LOCK-UP CONDITION, A SIGNAL IS INPUT TO

TERMINAL B/K OF THE ENGINE CONTROL MODULE, THE ENGINE CONTROL MODULE OPERATES AND CURRENT TO THE LOCK-UP

SOLENOID IS CUT.

4. OVERDRIVE CIRCUIT

*O/D MAIN SW ON

WHEN THE O/D MAIN SW IS TURNED ON (SW POINT IS OPEN), A SIGNAL IS INPUT TO TERMINAL OD2 OF THE ENGINE CONTROL

MODULE AND ENGINE CONTROL MODULE OPERATION CAUSES GEAR SHIFT WHEN THE CONDITIONS FOR OVERDRIVE ARE MET.

*O/D MAIN SW OFF

WHEN THE O/D MAIN SW IS TURNED OFF (SW POINT IS CLOSED), THE CURRENT FLOWING THROUGH THE O/D OFF INDICATOR

LIGHT FLOWS THROUGH THE O/D MAIN SW TO GROUND. CAUSING THE INDICATOR LIGHT TO LIGHT UP. AT THE SAME TIME, A

SIGNAL IS INPUT TO TERMINAL OD2 OF THE ENGINE CONTROL MODULE AND ENGINE CONTROL MODULE OPERATION

PREVENTS SHIFT INTO OVERDRIVE.

SYSTEM OUTLINE

Page 900 of 1354

131

5. CENTER DIFFERENTIAL CLUTCH CONTROL (4WD)

THE CENTER DIFFERENTIAL CLUTCH CONTROL USES A LINEAR SOLENOID TYPE VALVE (SOLENOID VALVE SLD) TO CONTROL THE

CENTER DIFFERENTIAL CLUTCH. BY CONTROLLING THE FLUID PRESSURE, THE LIMITED SLIP DIFFERENTIAL EFFECT OF THE

CENTER DIFFERENTIAL CAN ALWAYS BE MAINTAINED AT THE OPTIMUM FOR THE CURRENT DRIVING CONDITIONS TO INCREASE

ROAD-HOLDING ABILITY.

SOLENOID VALVE SLD OPENS AND CLOSES IN RESPONSE TO SIGNALS FROM THE ENGINE CONTROL MODULE. THUS THE

SOLENOID MODULATOR VALVE MAINTAINS A CONSTANT FLUID PRESSURE FOR OPERATION OF THE CENTER DIFFERENTIAL

CLUTCH CONTROL VALVE AND CENTER DIFFERENTIAL CLUTCH.

*NORMAL DRIVING

SOLENOID VALVE SLD OPENS AND CLOSES IN RESPONSE TO THE THROTTLE OPENING ANGLE TO CONTROL THE FLUID

PRESSURE OPERATING ON THE CENTER DIFFERENTIAL CLUTCH. WHEN THE VEHICLE TAKES OFF IN FIRST GEAR WITH A

LARGE THROTTLE OPENING ANGLE, THE FLUID PRESSURE IS KEPT HIGH. SO EVEN IF THE VEHICLE TAKES OFF SUDDENLY OR

THE ROAD SURFACE IS SLIPPERY, SMOOTH, RELIABLE ACCELERATION IS POSSIBLE.

*SLIPPING

WHEN A LARGE DIFFERENCE OCCURS BETWEEN THE FRONT WHEEL SPEED AND REAR WHEEL SPEED AT LOW SPEEDS,

SOLENOID VALVE SLD IS FULLY CLOSED TO APPLY HIGH FLUID PRESSURE TO THE CENTER DIFFERENTIAL CLUTCH AND

PROVIDE A LARGE LIMITED SLIP DIFFERENTIAL EFFECT.

*WIDE CORNERING

WHEN DIFFERENCES ARISE BETWEEN THE FRONT WHEEL SPEED AND REAR WHEEL SPEED DUE TO DIFFERENCES IN THE

TURNING RADIUS DURING CORNERING AT LOW SPEEDS, SOLENOID VALVE SLD IS FULLY OPEN TO APPLY A WEAK LIMITED SLIP

DIFFERENTIAL EFFECT AND PERMIT SMOOTH CORNERING.

6. ELECTRONICALLY CONTROLLED TRANSMISSION PATTERN SELECT SW

IF THE ELECTRONICALLY CONTROLLED TRANSMISSION PATTERN SELECT SW IS CHANGED FROM NORMAL TO POWER, THE

CURRENT THROUGH THE POWER INDICATOR FLOWS TO GROUND, CURRENT FLOWS TO TERMINAL P OF THE ENGINE CONTROL

MODULE, THE ENGINE CONTROL MODULE OPERATES, AND SHIFT UP AND SHIFT DOWN OCCURS AT HIGHER VEHICLE SPEEDS

THAN WHEN THE SW IS IN NORMAL POSITION.