Abs TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 511 of 2000

EXTERIOR – FRONT BUMPERET–5

ET

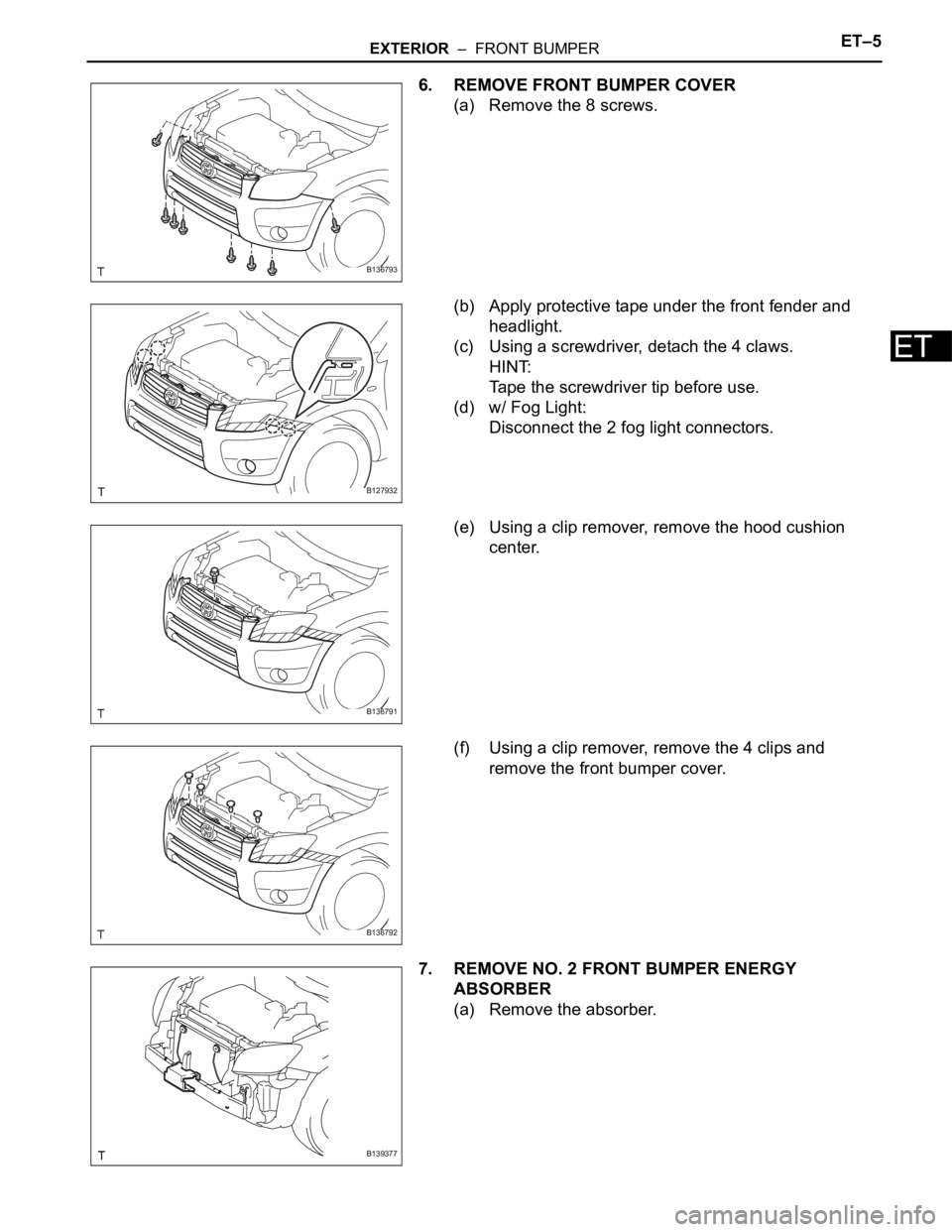

6. REMOVE FRONT BUMPER COVER

(a) Remove the 8 screws.

(b) Apply protective tape under the front fender and

headlight.

(c) Using a screwdriver, detach the 4 claws.

HINT:

Tape the screwdriver tip before use.

(d) w/ Fog Light:

Disconnect the 2 fog light connectors.

(e) Using a clip remover, remove the hood cushion

center.

(f) Using a clip remover, remove the 4 clips and

remove the front bumper cover.

7. REMOVE NO. 2 FRONT BUMPER ENERGY

ABSORBER

(a) Remove the absorber.

B136793

B127932

B136791

B136792

B139377

Page 571 of 2000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–47

ES

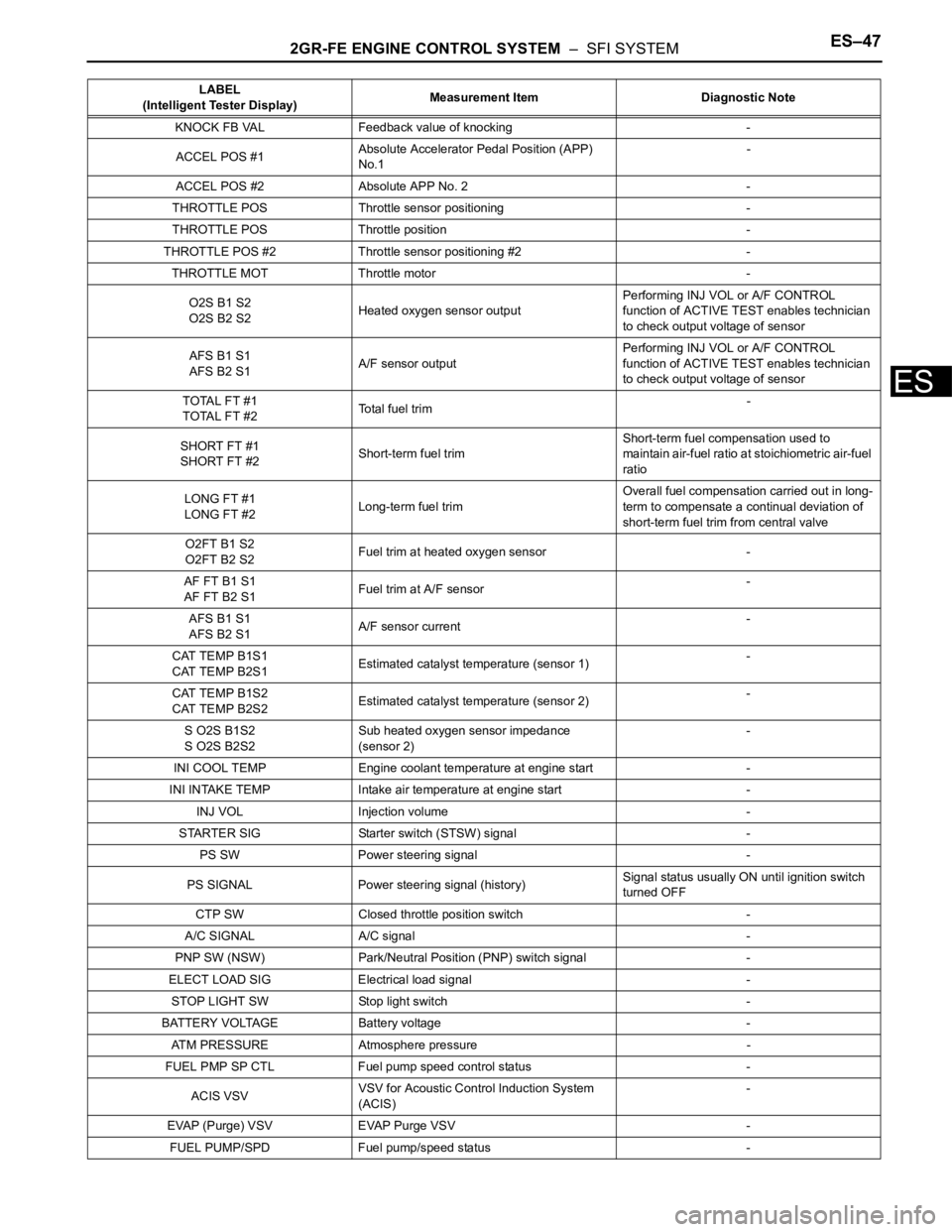

KNOCK FB VAL Feedback value of knocking -

ACCEL POS #1Absolute Accelerator Pedal Position (APP)

No.1-

ACCEL POS #2 Absolute APP No. 2 -

THROTTLE POS Throttle sensor positioning -

THROTTLE POS Throttle position -

THROTTLE POS #2 Throttle sensor positioning #2 -

THROTTLE MOT Throttle motor -

O2S B1 S2

O2S B2 S2Heated oxygen sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check output voltage of sensor

AFS B1 S1

AFS B2 S1A/F sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check output voltage of sensor

TOTAL FT #1

TOTAL FT #2Total fuel trim -

SHORT FT #1

SHORT FT #2Short-term fuel trimShort-term fuel compensation used to

maintain air-fuel ratio at stoichiometric air-fuel

ratio

LONG FT #1

LONG FT #2Long-term fuel trimOverall fuel compensation carried out in long-

term to compensate a continual deviation of

short-term fuel trim from central valve

O2FT B1 S2

O2FT B2 S2Fuel trim at heated oxygen sensor -

AF FT B1 S1

AF FT B2 S1Fuel trim at A/F sensor-

AFS B1 S1

AFS B2 S1A/F sensor current-

CAT TEMP B1S1

CAT TEMP B2S1Estimated catalyst temperature (sensor 1)-

CAT TEMP B1S2

CAT TEMP B2S2Estimated catalyst temperature (sensor 2)-

S O2S B1S2

S O2S B2S2Sub heated oxygen sensor impedance

(sensor 2)-

INI COOL TEMP Engine coolant temperature at engine start -

INI INTAKE TEMP Intake air temperature at engine start -

INJ VOL Injection volume -

STARTER SIG Starter switch (STSW) signal -

PS SW Power steering signal -

PS SIGNAL Power steering signal (history)Signal status usually ON until ignition switch

turned OFF

CTP SW Closed throttle position switch -

A/C SIGNAL A/C signal -

PNP SW (NSW) Park/Neutral Position (PNP) switch signal -

ELECT LOAD SIG Electrical load signal -

STOP LIGHT SW Stop light switch -

BATTERY VOLTAGE Battery voltage -

ATM PRESSURE Atmosphere pressure -

FUEL PMP SP CTL Fuel pump speed control status -

ACIS VSVVSV for Acoustic Control Induction System

(ACIS)-

EVAP (Purge) VSV EVAP Purge VSV -

FUEL PUMP/SPD Fuel pump/speed status -LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Page 1351 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–23

TF

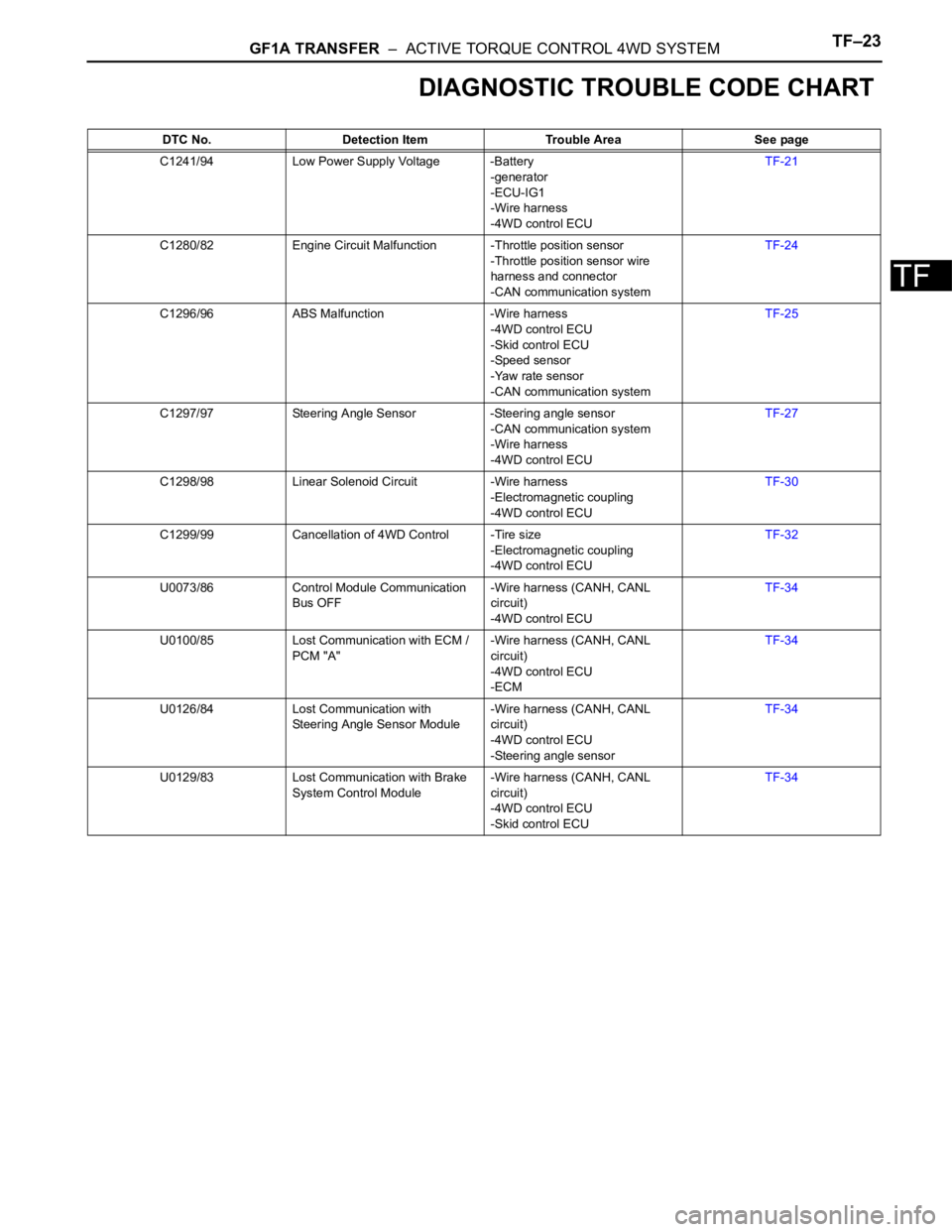

DIAGNOSTIC TROUBLE CODE CHART

DTC No. Detection Item Trouble Area See page

C1241/94 Low Power Supply Voltage -Battery

-generator

-ECU-IG1

-Wire harness

-4WD control ECUTF-21

C1280/82 Engine Circuit Malfunction -Throttle position sensor

-Throttle position sensor wire

harness and connector

-CAN communication systemTF-24

C1296/96 ABS Malfunction -Wire harness

-4WD control ECU

-Skid control ECU

-Speed sensor

-Yaw rate sensor

-CAN communication systemTF-25

C1297/97 Steering Angle Sensor -Steering angle sensor

-CAN communication system

-Wire harness

-4WD control ECUTF-27

C1298/98 Linear Solenoid Circuit -Wire harness

-Electromagnetic coupling

-4WD control ECUTF-30

C1299/99 Cancellation of 4WD Control -Tire size

-Electromagnetic coupling

-4WD control ECUTF-32

U0073/86 Control Module Communication

Bus OFF-Wire harness (CANH, CANL

circuit)

-4WD control ECUTF-34

U0100/85 Lost Communication with ECM /

PCM "A"-Wire harness (CANH, CANL

circuit)

-4WD control ECU

-ECMTF-34

U0126/84 Lost Communication with

Steering Angle Sensor Module-Wire harness (CANH, CANL

circuit)

-4WD control ECU

-Steering angle sensorTF-34

U0129/83 Lost Communication with Brake

System Control Module-Wire harness (CANH, CANL

circuit)

-4WD control ECU

-Skid control ECUTF-34

Page 1356 of 2000

TF–28GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

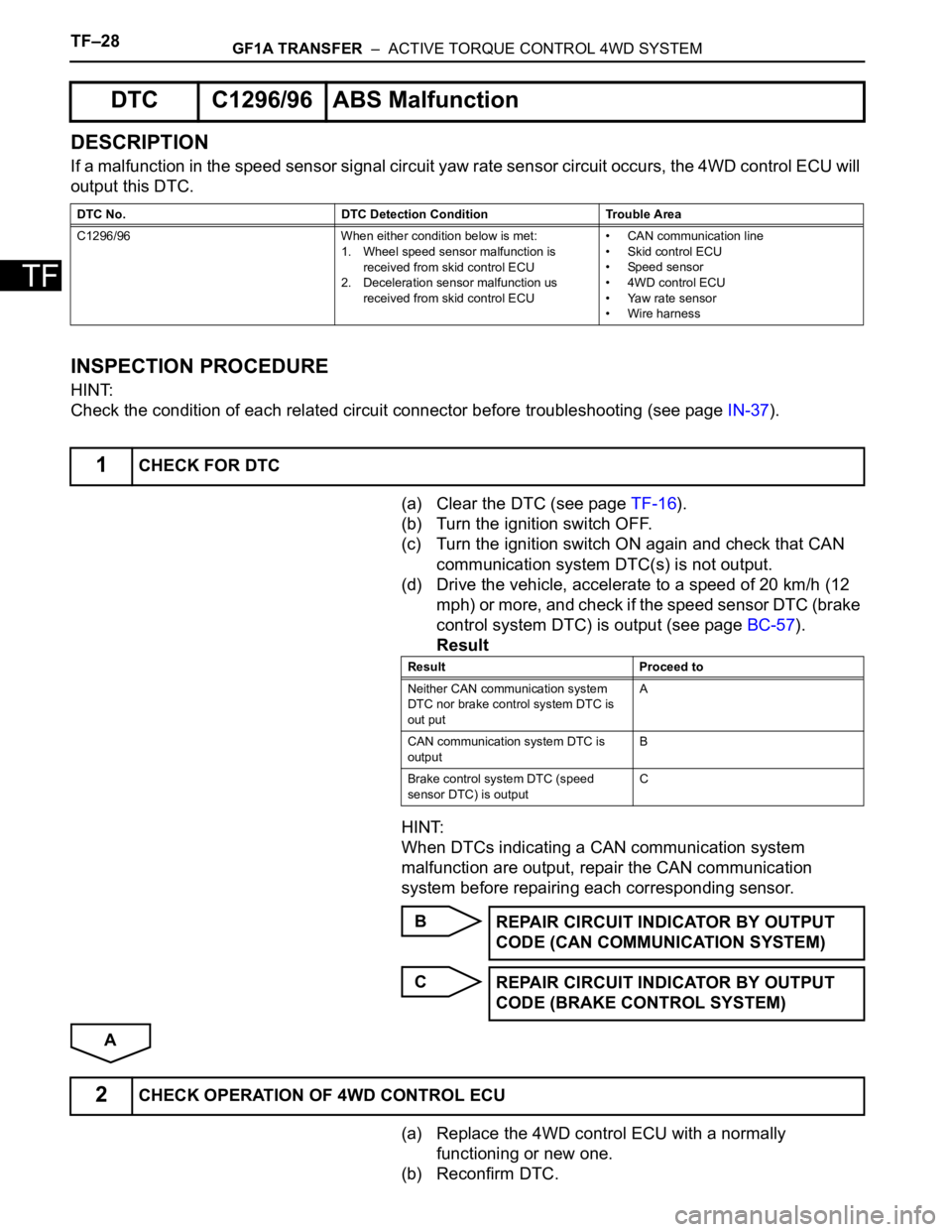

DESCRIPTION

If a malfunction in the speed sensor signal circuit yaw rate sensor circuit occurs, the 4WD control ECU will

output this DTC.

INSPECTION PROCEDURE

HINT:

Check the condition of each related circuit connector before troubleshooting (see page IN-37).

(a) Clear the DTC (see page TF-16).

(b) Turn the ignition switch OFF.

(c) Turn the ignition switch ON again and check that CAN

communication system DTC(s) is not output.

(d) Drive the vehicle, accelerate to a speed of 20 km/h (12

mph) or more, and check if the speed sensor DTC (brake

control system DTC) is output (see page BC-57).

Result

HINT:

When DTCs indicating a CAN communication system

malfunction are output, repair the CAN communication

system before repairing each corresponding sensor.

B

C

A

(a) Replace the 4WD control ECU with a normally

functioning or new one.

(b) Reconfirm DTC.

DTC C1296/96 ABS Malfunction

DTC No. DTC Detection Condition Trouble Area

C1296/96 When either condition below is met:

1. Wheel speed sensor malfunction is

received from skid control ECU

2. Deceleration sensor malfunction us

received from skid control ECU• CAN communication line

• Skid control ECU

• Speed sensor

• 4WD control ECU

• Yaw rate sensor

• Wire harness

1CHECK FOR DTC

Result Proceed to

Neither CAN communication system

DTC nor brake control system DTC is

out putA

CAN communication system DTC is

outputB

Brake control system DTC (speed

sensor DTC) is outputC

REPAIR CIRCUIT INDICATOR BY OUTPUT

CODE (CAN COMMUNICATION SYSTEM)

REPAIR CIRCUIT INDICATOR BY OUTPUT

CODE (BRAKE CONTROL SYSTEM)

2CHECK OPERATION OF 4WD CONTROL ECU

Page 1364 of 2000

DS–8DRIVE SHAFT – FRONT DRIVE SHAFT ASSEMBLY (for 2WD)

DS

14. DISCONNECT TIE ROD END SUB-ASSEMBLY LH

(See page PS-42)

15. DISCONNECT TIE ROD END SUB-ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

16. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

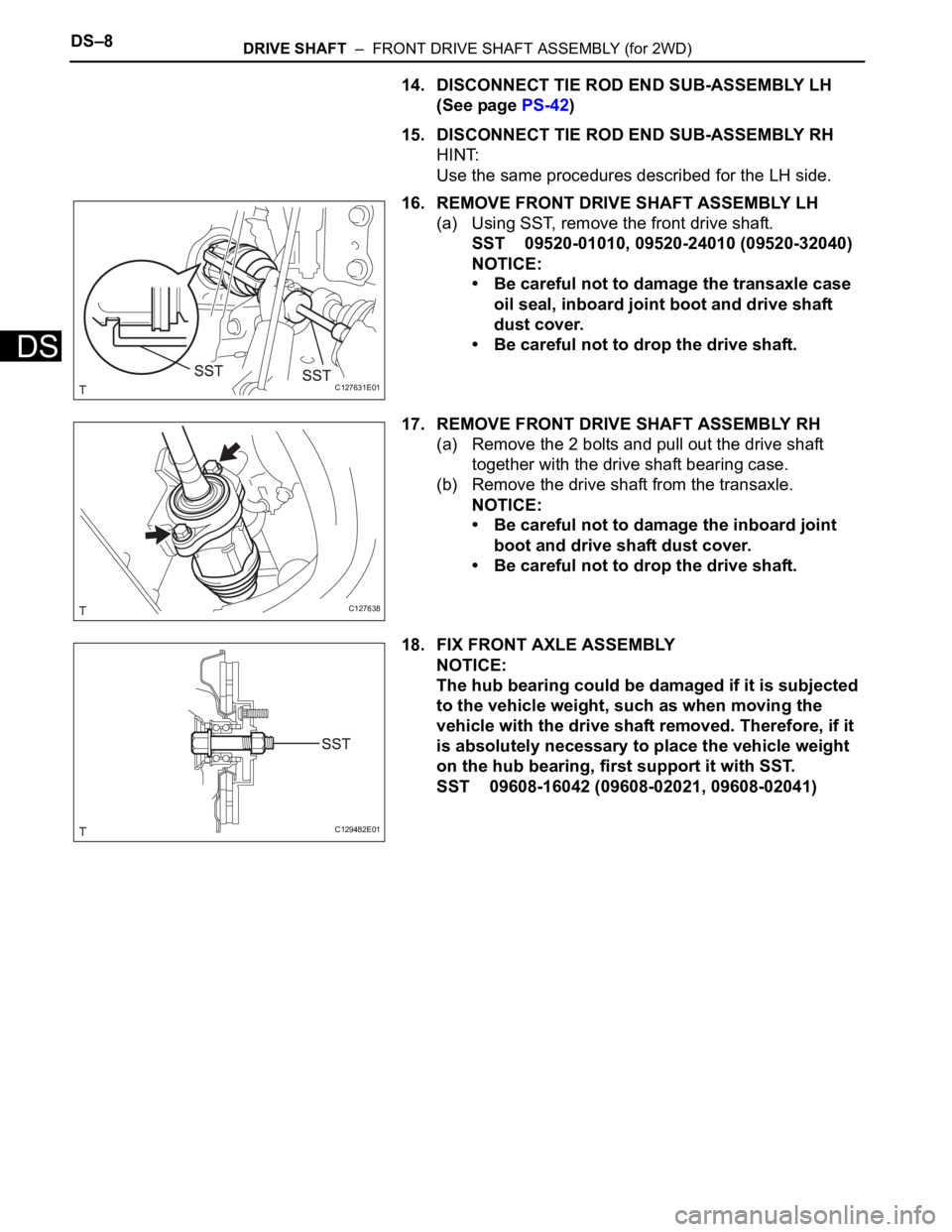

(a) Using SST, remove the front drive shaft.

SST 09520-01010, 09520-24010 (09520-32040)

NOTICE:

• Be careful not to damage the transaxle case

oil seal, inboard joint boot and drive shaft

dust cover.

• Be careful not to drop the drive shaft.

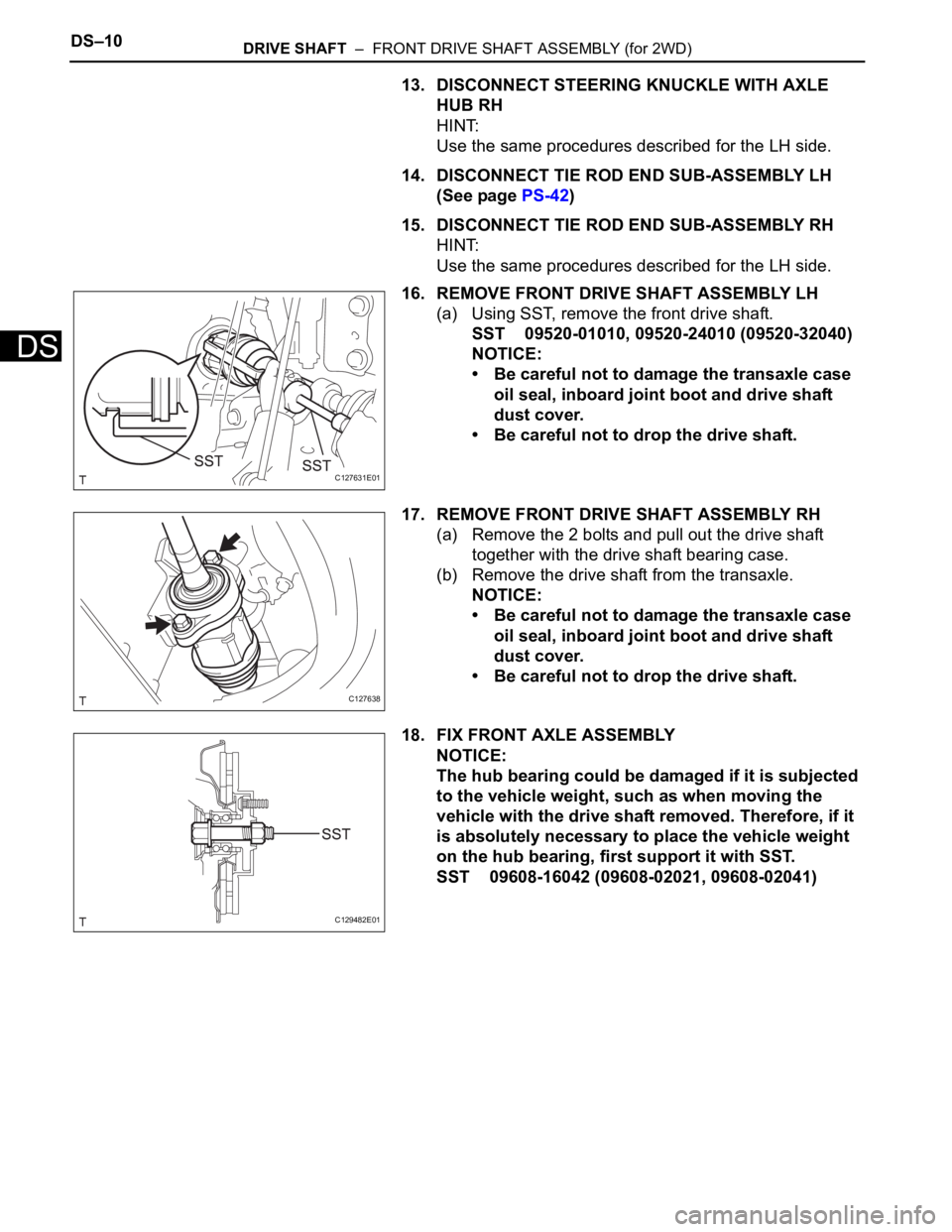

17. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH

(a) Remove the 2 bolts and pull out the drive shaft

together with the drive shaft bearing case.

(b) Remove the drive shaft from the transaxle.

NOTICE:

• Be careful not to damage the inboard joint

boot and drive shaft dust cover.

• Be careful not to drop the drive shaft.

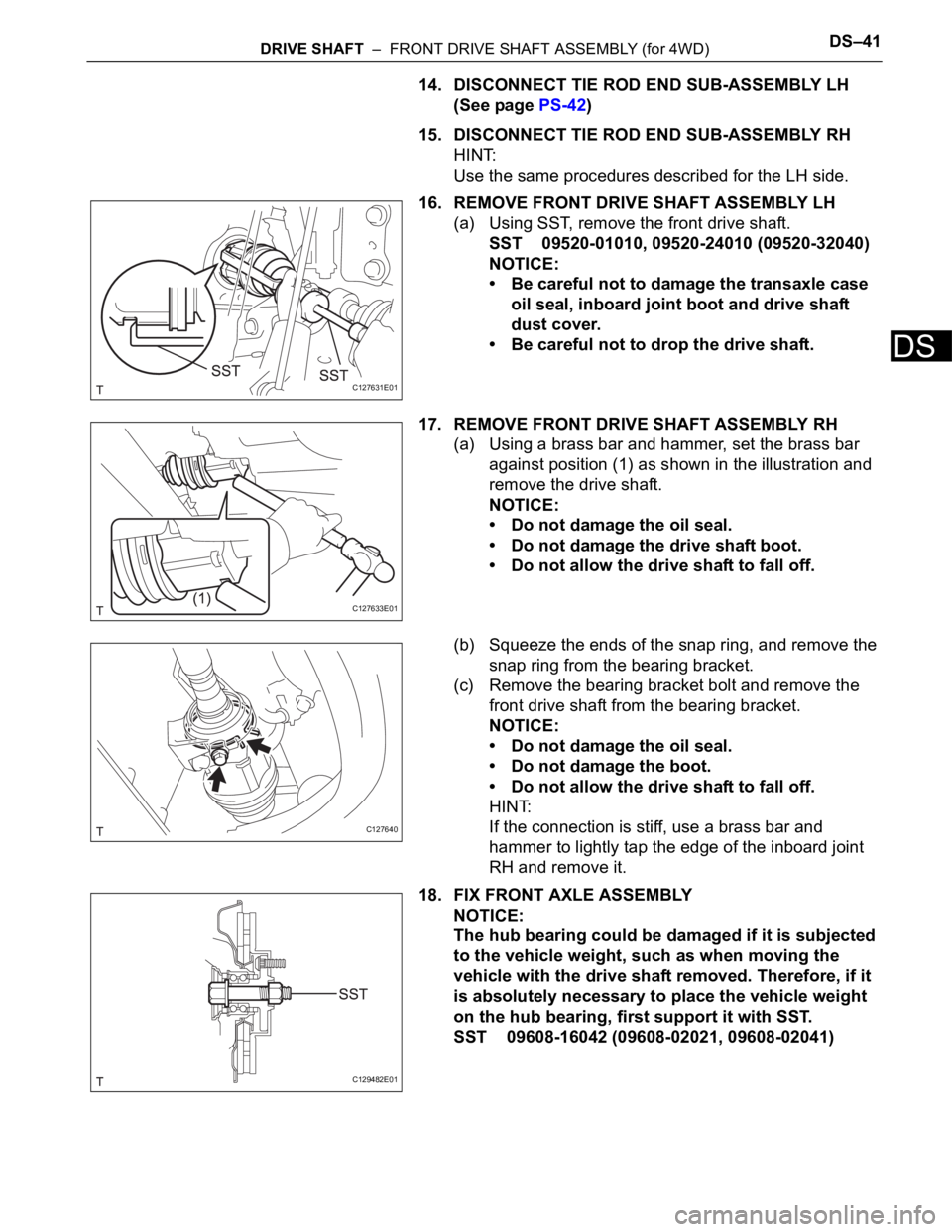

18. FIX FRONT AXLE ASSEMBLY

NOTICE:

The hub bearing could be damaged if it is subjected

to the vehicle weight, such as when moving the

vehicle with the drive shaft removed. Therefore, if it

is absolutely necessary to place the vehicle weight

on the hub bearing, first support it with SST.

SST 09608-16042 (09608-02021, 09608-02041)

C127631E01

C127638

C129482E01

Page 1366 of 2000

DS–10DRIVE SHAFT – FRONT DRIVE SHAFT ASSEMBLY (for 2WD)

DS

13. DISCONNECT STEERING KNUCKLE WITH AXLE

HUB RH

HINT:

Use the same procedures described for the LH side.

14. DISCONNECT TIE ROD END SUB-ASSEMBLY LH

(See page PS-42)

15. DISCONNECT TIE ROD END SUB-ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

16. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

(a) Using SST, remove the front drive shaft.

SST 09520-01010, 09520-24010 (09520-32040)

NOTICE:

• Be careful not to damage the transaxle case

oil seal, inboard joint boot and drive shaft

dust cover.

• Be careful not to drop the drive shaft.

17. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH

(a) Remove the 2 bolts and pull out the drive shaft

together with the drive shaft bearing case.

(b) Remove the drive shaft from the transaxle.

NOTICE:

• Be careful not to damage the transaxle case

oil seal, inboard joint boot and drive shaft

dust cover.

• Be careful not to drop the drive shaft.

18. FIX FRONT AXLE ASSEMBLY

NOTICE:

The hub bearing could be damaged if it is subjected

to the vehicle weight, such as when moving the

vehicle with the drive shaft removed. Therefore, if it

is absolutely necessary to place the vehicle weight

on the hub bearing, first support it with SST.

SST 09608-16042 (09608-02021, 09608-02041)

C127631E01

C127638

C129482E01

Page 1395 of 2000

DRIVE SHAFT – FRONT DRIVE SHAFT ASSEMBLY (for 4WD)DS–41

DS

14. DISCONNECT TIE ROD END SUB-ASSEMBLY LH

(See page PS-42)

15. DISCONNECT TIE ROD END SUB-ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

16. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

(a) Using SST, remove the front drive shaft.

SST 09520-01010, 09520-24010 (09520-32040)

NOTICE:

• Be careful not to damage the transaxle case

oil seal, inboard joint boot and drive shaft

dust cover.

• Be careful not to drop the drive shaft.

17. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH

(a) Using a brass bar and hammer, set the brass bar

against position (1) as shown in the illustration and

remove the drive shaft.

NOTICE:

• Do not damage the oil seal.

• Do not damage the drive shaft boot.

• Do not allow the drive shaft to fall off.

(b) Squeeze the ends of the snap ring, and remove the

snap ring from the bearing bracket.

(c) Remove the bearing bracket bolt and remove the

front drive shaft from the bearing bracket.

NOTICE:

• Do not damage the oil seal.

• Do not damage the boot.

• Do not allow the drive shaft to fall off.

HINT:

If the connection is stiff, use a brass bar and

hammer to lightly tap the edge of the inboard joint

RH and remove it.

18. FIX FRONT AXLE ASSEMBLY

NOTICE:

The hub bearing could be damaged if it is subjected

to the vehicle weight, such as when moving the

vehicle with the drive shaft removed. Therefore, if it

is absolutely necessary to place the vehicle weight

on the hub bearing, first support it with SST.

SST 09608-16042 (09608-02021, 09608-02041)

C127631E01

C127633E01

C127640

C129482E01

Page 1397 of 2000

DRIVE SHAFT – FRONT DRIVE SHAFT ASSEMBLY (for 4WD)DS–43

DS

14. DISCONNECT TIE ROD END SUB-ASSEMBLY LH

(See page PS-42)

15. DISCONNECT TIE ROD END SUB-ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

16. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

(a) Using SST, remove the front drive shaft.

SST 09520-01010, 09520-24010 (09520-32040)

NOTICE:

• Be careful not to damage the transaxle case

oil seal, inboard joint boot and drive shaft

dust cover.

• Be careful not to drop the drive shaft.

17. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH

(a) Squeeze the ends of the snap ring, and remove the

snap ring from the bearing bracket.

(b) Remove the bearing bracket bolt and remove the

front drive shaft from the bearing bracket.

NOTICE:

• Do not damage the oil seal.

• Do not damage the boot.

• Do not allow the drive shaft to fall off.

HINT:

If the connection is stiff, use a brass bar and

hammer to lightly tap the edge of the inboard joint

RH and remove it.

18. FIX FRONT AXLE ASSEMBLY

NOTICE:

The hub bearing could be damaged if it is subjected

to the vehicle weight, such as when moving the

vehicle with the drive shaft removed. Therefore, if it

is absolutely necessary to place the vehicle weight

on the hub bearing, first support it with SST.

SST 09608-16042 (09608-02021, 09608-02041)

C127631E01

C127640

C129482E01

Page 1451 of 2000

AH–10AXLE – FRONT AXLE HUB

AH

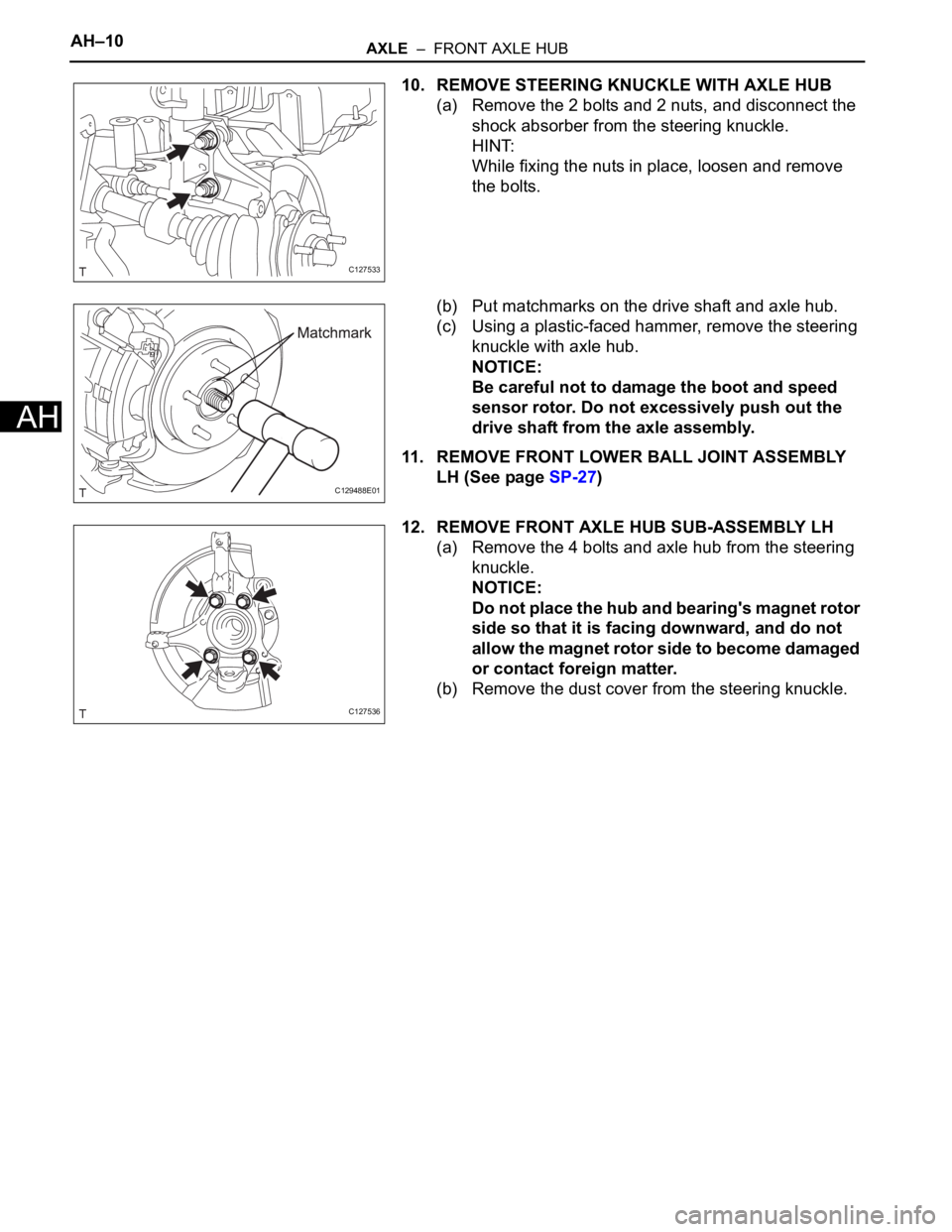

10. REMOVE STEERING KNUCKLE WITH AXLE HUB

(a) Remove the 2 bolts and 2 nuts, and disconnect the

shock absorber from the steering knuckle.

HINT:

While fixing the nuts in place, loosen and remove

the bolts.

(b) Put matchmarks on the drive shaft and axle hub.

(c) Using a plastic-faced hammer, remove the steering

knuckle with axle hub.

NOTICE:

Be careful not to damage the boot and speed

sensor rotor. Do not excessively push out the

drive shaft from the axle assembly.

11. REMOVE FRONT LOWER BALL JOINT ASSEMBLY

LH (See page SP-27)

12. REMOVE FRONT AXLE HUB SUB-ASSEMBLY LH

(a) Remove the 4 bolts and axle hub from the steering

knuckle.

NOTICE:

Do not place the hub and bearing's magnet rotor

side so that it is facing downward, and do not

allow the magnet rotor side to become damaged

or contact foreign matter.

(b) Remove the dust cover from the steering knuckle.

C127533

C129488E01

C127536

Page 1457 of 2000

AXLE – REAR AXLE HUB AND BEARINGAH–17

AH

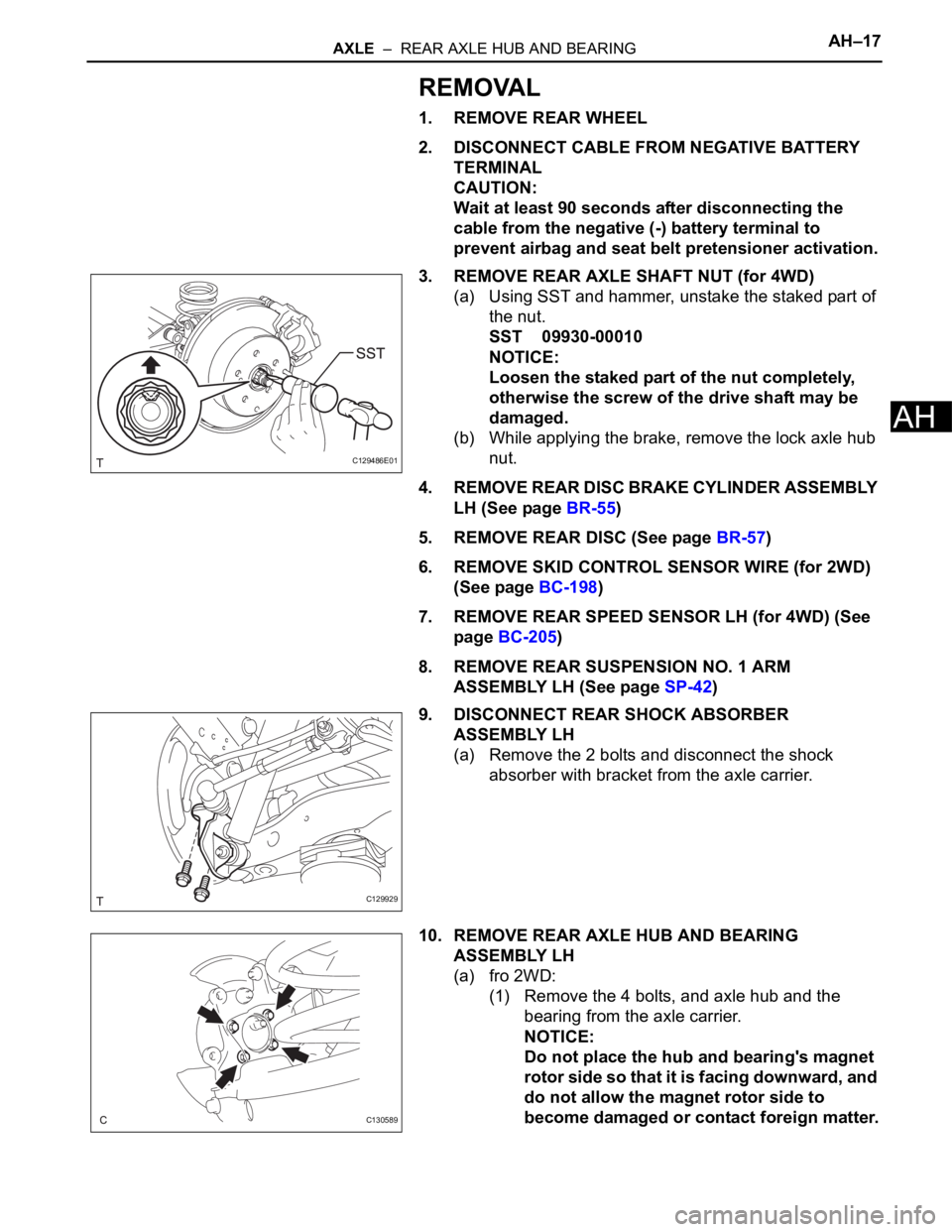

REMOVAL

1. REMOVE REAR WHEEL

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

3. REMOVE REAR AXLE SHAFT NUT (for 4WD)

(a) Using SST and hammer, unstake the staked part of

the nut.

SST 09930-00010

NOTICE:

Loosen the staked part of the nut completely,

otherwise the screw of the drive shaft may be

damaged.

(b) While applying the brake, remove the lock axle hub

nut.

4. REMOVE REAR DISC BRAKE CYLINDER ASSEMBLY

LH (See page BR-55)

5. REMOVE REAR DISC (See page BR-57)

6. REMOVE SKID CONTROL SENSOR WIRE (for 2WD)

(See page BC-198)

7. REMOVE REAR SPEED SENSOR LH (for 4WD) (See

page BC-205)

8. REMOVE REAR SUSPENSION NO. 1 ARM

ASSEMBLY LH (See page SP-42)

9. DISCONNECT REAR SHOCK ABSORBER

ASSEMBLY LH

(a) Remove the 2 bolts and disconnect the shock

absorber with bracket from the axle carrier.

10. REMOVE REAR AXLE HUB AND BEARING

ASSEMBLY LH

(a) fro 2WD:

(1) Remove the 4 bolts, and axle hub and the

bearing from the axle carrier.

NOTICE:

Do not place the hub and bearing's magnet

rotor side so that it is facing downward, and

do not allow the magnet rotor side to

become damaged or contact foreign matter.

C129486E01

C129929

C130589