charging TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1 of 2000

ENGINE - 2AZ-FE ENGINE EG-4

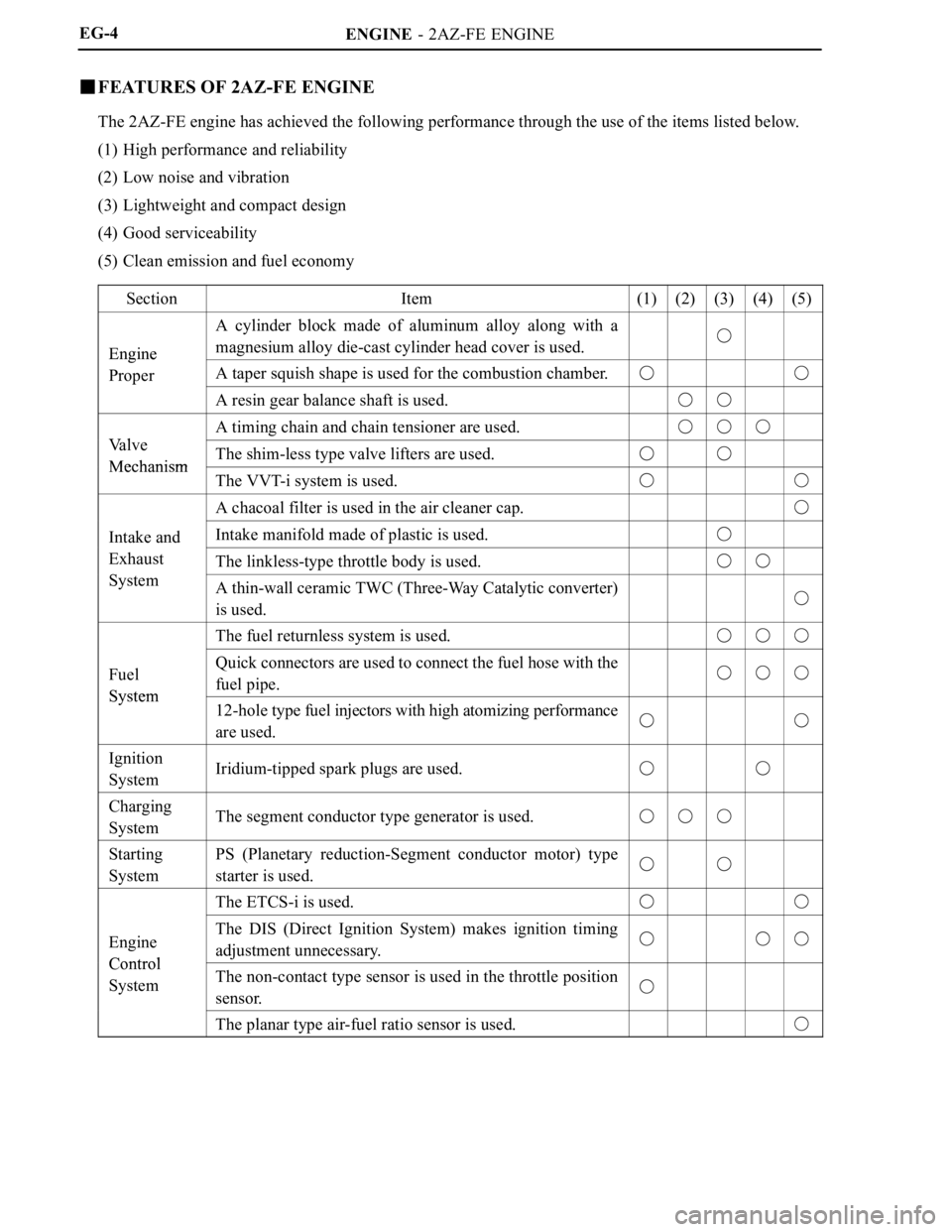

FEATURES OF 2AZ-FE ENGINE

The 2AZ-FE engine has achieved the following performance through the use of the items listed below.

(1) High performance and reliability

(2) Low noise and vibration

(3) Lightweight and compact design

(4) Good serviceability

(5) Clean emission and fuel economy

Section

Item(1)(2)(3)(4)(5)

Engine

A cylinder block made of aluminum alloy along with a

magnesium alloy die-cast cylinder head cover is used.

Engine

ProperA taper squish shape is used for the combustion chamber.p

A resin gear balance shaft is used.

Vl

A timing chain and chain tensioner are used.

Va l v e

MechanismThe shim-less type valve lifters are used.MechanismThe VVT-i system is used.

A chacoal filter is used in the air cleaner cap.

Intake andIntake manifold made of plastic is used.Intake and

ExhaustThe linkless-type throttle body is used.

SystemA thin-wall ceramic TWC (Three-Way Catalytic converter)

is used.

The fuel returnless system is used.

Fuel

System

Quick connectors are used to connect the fuel hose with the

fuel pipe.

System12-hole type fuel injectors with high atomizing performance

are used.

Ignition

SystemIridium-tipped spark plugs are used.

Charging

SystemThe segment conductor type generator is used.

Starting

SystemPS (Planetary reduction-Segment conductor motor) type

starter is used.

The ETCS-i is used.

Engine

Control

The DIS (Direct Ignition System) makes ignition timing

adjustment unnecessary.

Control

SystemThe non-contact type sensor is used in the throttle position

sensor.

The planar type air-fuel ratio sensor is used.

Page 22 of 2000

ENGINE - 2AZ-FE ENGINE

206EG40206EG41

206EG42

Stator Segment

ConductorStator

Joined

Joined Segment

Conductor SystemSegment

ConductorStator

StatorConductor

Wire

Conductor Wire

A

AA - A Cross

Section

Segment Conductor Type GeneratorB

BB - B Cross

Section

Conventional Type GeneratorWinding System

Stator

Segment

Conductor

Cross Section

Stator of Segment Conductor Type GeneratorEG-25

CHARGING SYSTEM

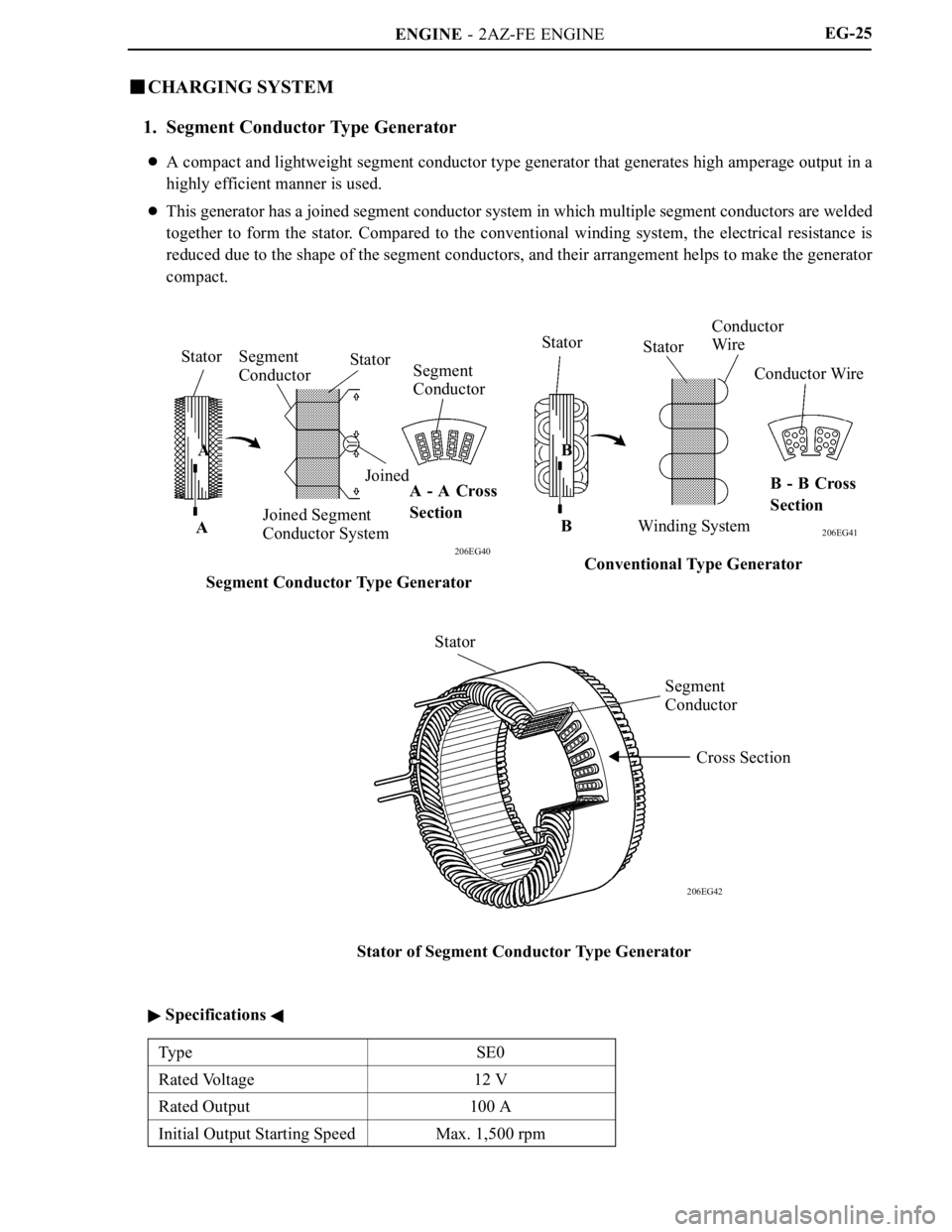

1. Segment Conductor Type Generator

A compact and lightweight segment conductor type generator that generates high amperage output in a

highly efficient manner is used.

This generator has a joined segment conductor system in which multiple segment conductors are welded

together to form the stator. Compared to the conventional winding system, the electrical resistance is

reduced due to the shape of the segment conductors, and their arrangement helps to make the generator

compact.

Specifications

Ty p eSE0

Rated Voltage12 V

Rated Output100 A

Initial Output Starting SpeedMax. 1,500 rpm

Page 27 of 2000

ENGINE - 2AZ-FE ENGINE EG-30

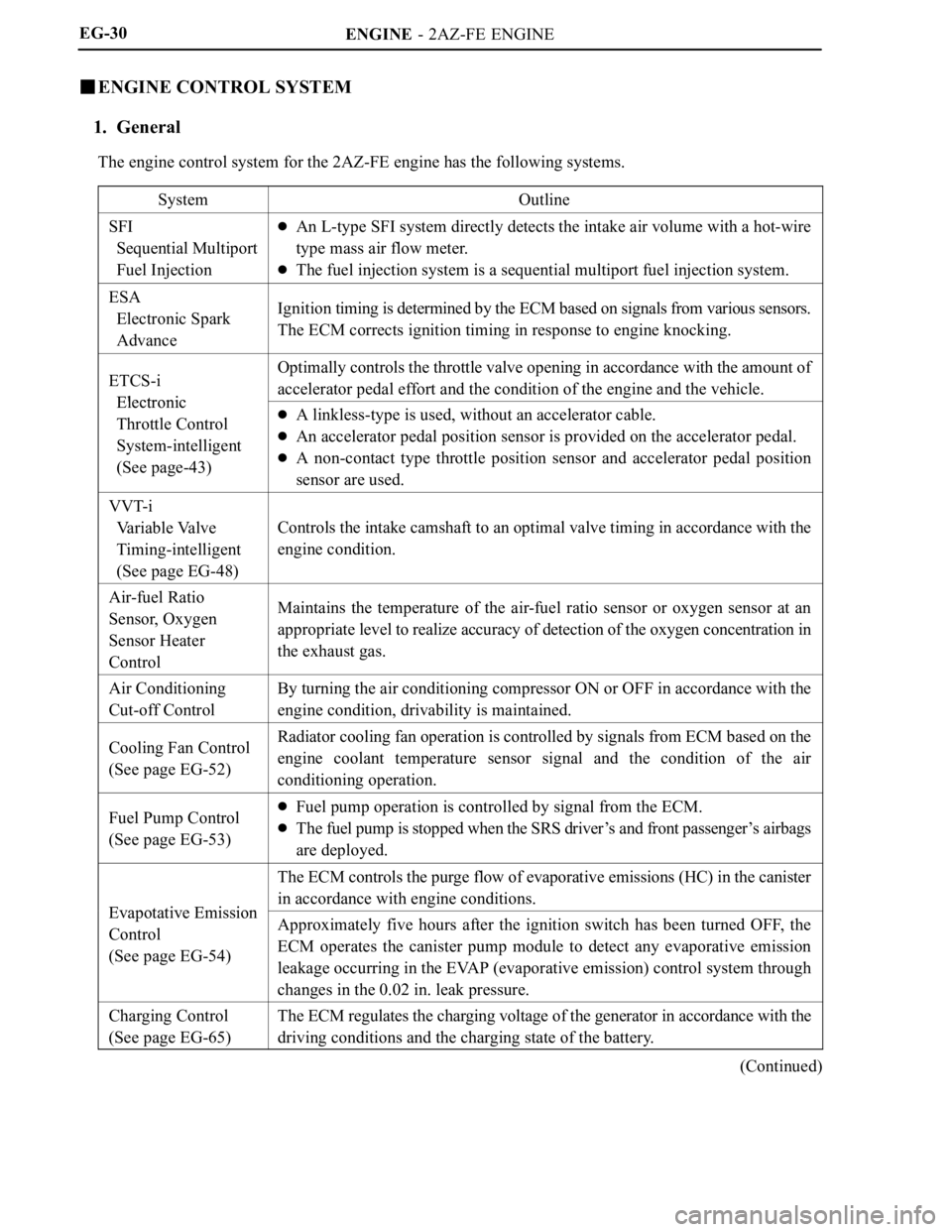

ENGINE CONTROL SYSTEM

1. General

The engine control system for the 2AZ-FE engine has the following systems.

System

Outline

SFI

Sequential Multiport

Fuel InjectionAn L-type SFI system directly detects the intake air volume with a hot-wire

type mass air flow meter.

The fuel injection system is a sequential multiport fuel injection system.

ESA

Electronic Spark

AdvanceIgnition timing is determined by the ECM based on signals from various sensors.

The ECM corrects ignition timing in response to engine knocking.

ETCS-i

Electronic

Optimally controls the throttle valve opening in accordance with the amount of

accelerator pedal effort and the condition of the engine and the vehicle.

Electronic

Throttle Control

System-intelligent

(See page-43)A linkless-type is used, without an accelerator cable.

An accelerator pedal position sensor is provided on the accelerator pedal.

A non-contact type throttle position sensor and accelerator pedal position

sensor are used.

VVT-i

Va r i a b l e Va l v e

Timing-intelligent

(See page EG-48)

Controls the intake camshaft to an optimal valve timing in accordance with the

engine condition.

Air-fuel Ratio

Sensor, Oxygen

Sensor Heater

ControlMaintains the temperature of the air-fuel ratio sensor or oxygen sensor at an

appropriate level to realize accuracy of detection of the oxygen concentration in

the exhaust gas.

Air Conditioning

Cut-off ControlBy turning the air conditioning compressor ON or OFF in accordance with the

engine condition, drivability is maintained.

Cooling Fan Control

(See page EG-52)Radiator cooling fan operation is controlled by signals from ECM based on the

engine coolant temperature sensor signal and the condition of the air

conditioning operation.

Fuel Pump Control

(See page EG-53)Fuel pump operation is controlled by signal from the ECM.

The fuel pump is stopped when the SRS driver’s and front passenger’s airbags

are deployed.

Evapotative Emission

The ECM controls the purge flow of evaporative emissions (HC) in the canister

in accordance with engine conditions.

Evapotative Emission

Control

(See page EG-54)Approximately five hours after the ignition switch has been turned OFF, the

ECM operates the canister pump module to detect any evaporative emission

leakage occurring in the EVAP (evaporative emission) control system through

changes in the 0.02 in. leak pressure.

Charging Control

(See page EG-65)The ECM regulates the charging voltage of the generator in accordance with the

driving conditions and the charging state of the battery.

(Continued)

Page 62 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG13Y

Generator

RegulatorB

DF

RLOECM

Various Electrical

Loads

Battery Current Sensor

Battery Temperature Sensor

Battery Voltage

Battery

Various Sensors and Switches

Throttle Position Sensor

Crankshaft Position Sensor

Accelerator Pedal Position

SensorEG-65

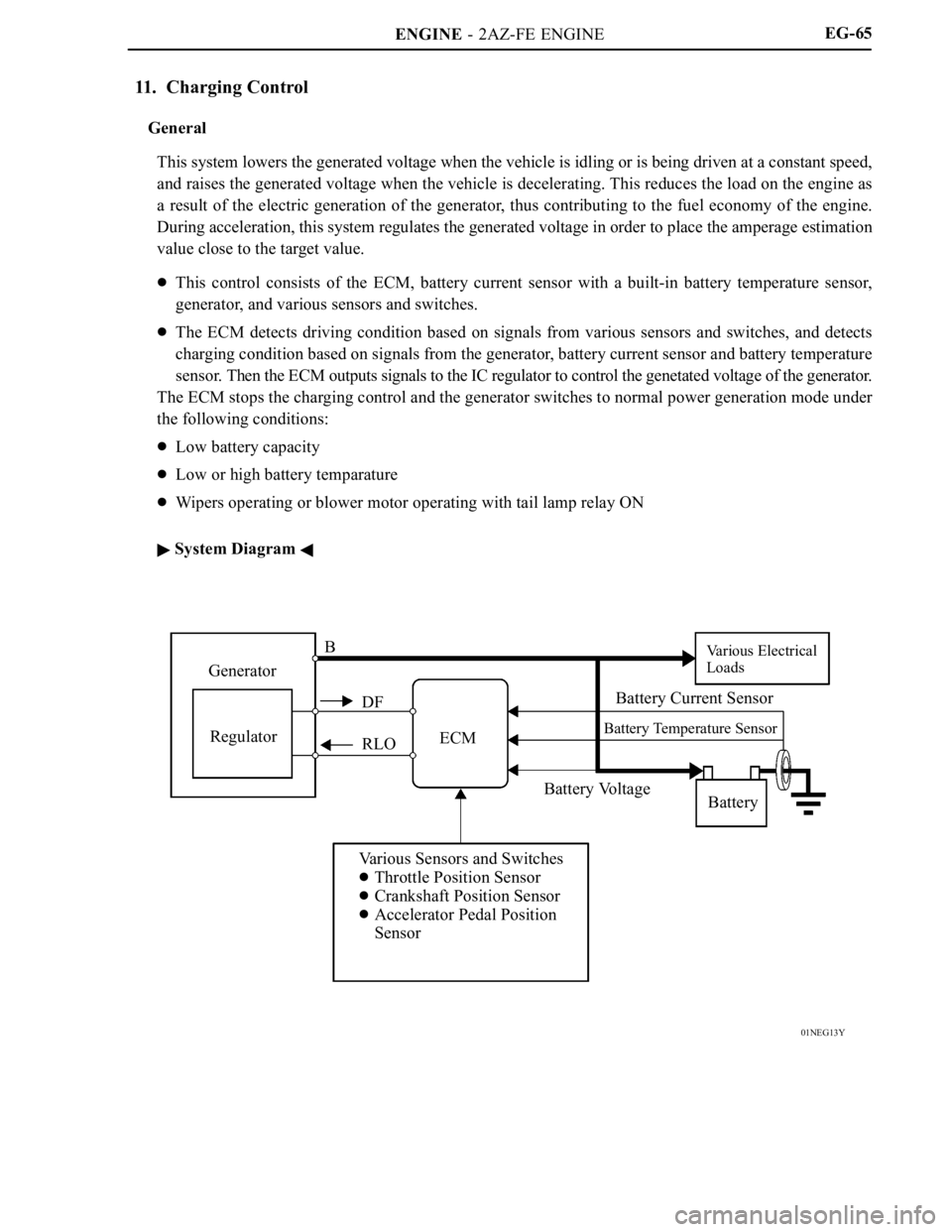

11. Charging Control

General

This system lowers the generated voltage when the vehicle is idling or is being driven at a constant speed,

and raises the generated voltage when the vehicle is decelerating. This reduces the load on the engine as

a result of the electric generation of the generator, thus contributing to the fuel economy of the engine.

During acceleration, this system regulates the generated voltage in order to place the amperage estimation

value close to the target value.

This control consists of the ECM, battery current sensor with a built-in battery temperature sensor,

generator, and various sensors and switches.

The ECM detects driving condition based on signals from various sensors and switches, and detects

charging condition based on signals from the generator, battery current sensor and battery temperature

sensor. Then the ECM outputs signals to the IC regulator to control the genetated voltage of the generator.

The ECM stops the charging control and the generator switches to normal power generation mode under

the following conditions:

Low battery capacity

Low or high battery temparature

Wipers operating or blower motor operating with tail lamp relay ON

System Diagram

Page 63 of 2000

ENGINE - 2AZ-FE ENGINE

258AS61 281EG86

Output

Voltage5 (V)

0

-100

Current+100 (A)

Characteristic of Current Sensor

288EG61C

(C) 60

Battery Temperature 0 Resistance(k

)

6 EG-66

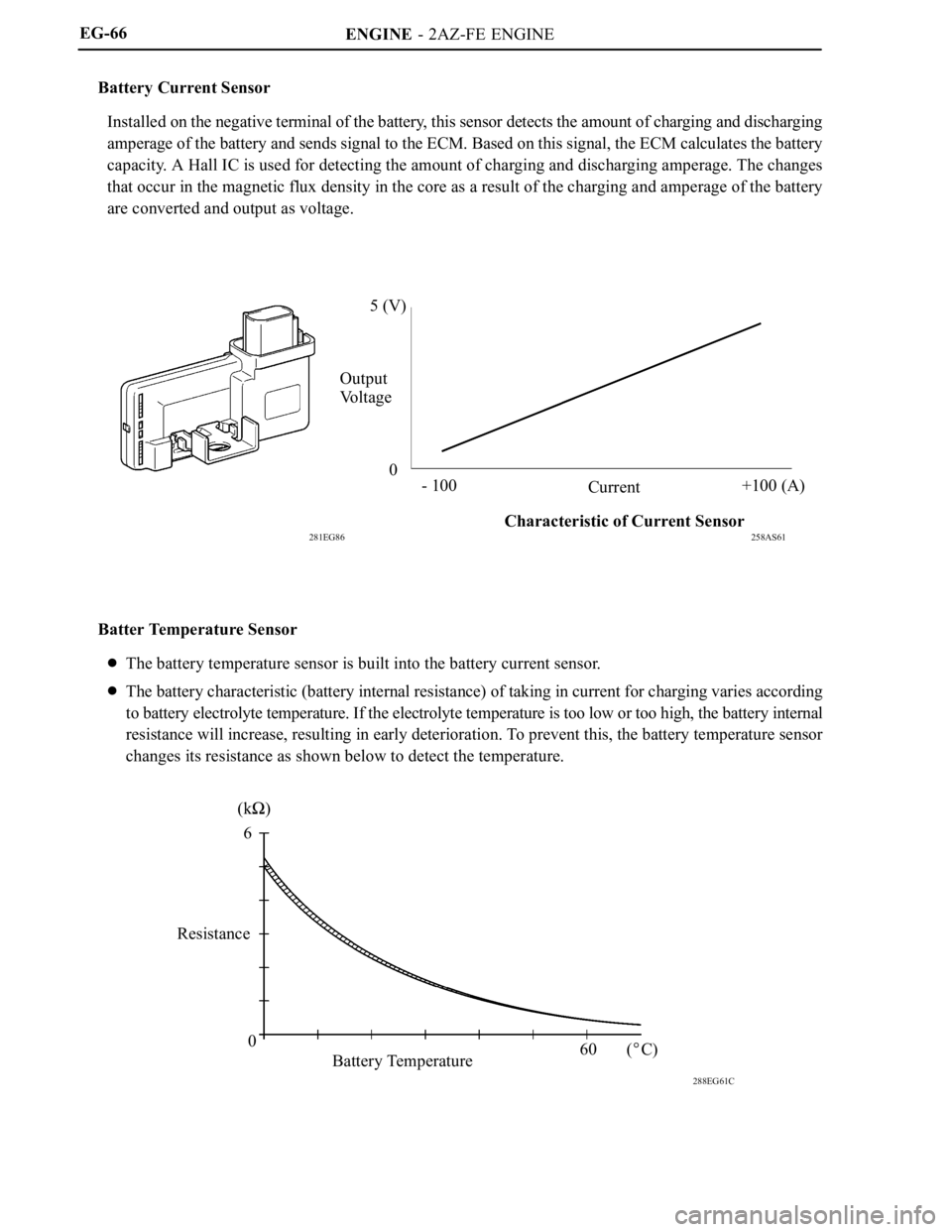

Battery Current Sensor

Installed on the negative terminal of the battery, this sensor detects the amount of charging and discharging

amperage of the battery and sends signal to the ECM. Based on this signal, the ECM calculates the battery

capacity. A Hall IC is used for detecting the amount of charging and discharging amperage. The changes

that occur in the magnetic flux density in the core as a result of the charging and amperage of the battery

are converted and output as voltage.

Batter Temperature Sensor

The battery temperature sensor is built into the battery current sensor.

The battery characteristic (battery internal resistance) of taking in current for charging varies according

to battery electrolyte temperature. If the electrolyte temperature is too low or too high, the battery internal

resistance will increase, resulting in early deterioration. To prevent this, the battery temperature sensor

changes its resistance as shown below to detect the temperature.

Page 64 of 2000

ENGINE - 2AZ-FE ENGINE

Service Tip

To clear the DTC that is stored in the ECM, use a hand-held tester or disconnect the battery terminal

or remove the EFI fuse for 1 minute or longer.

EG-67

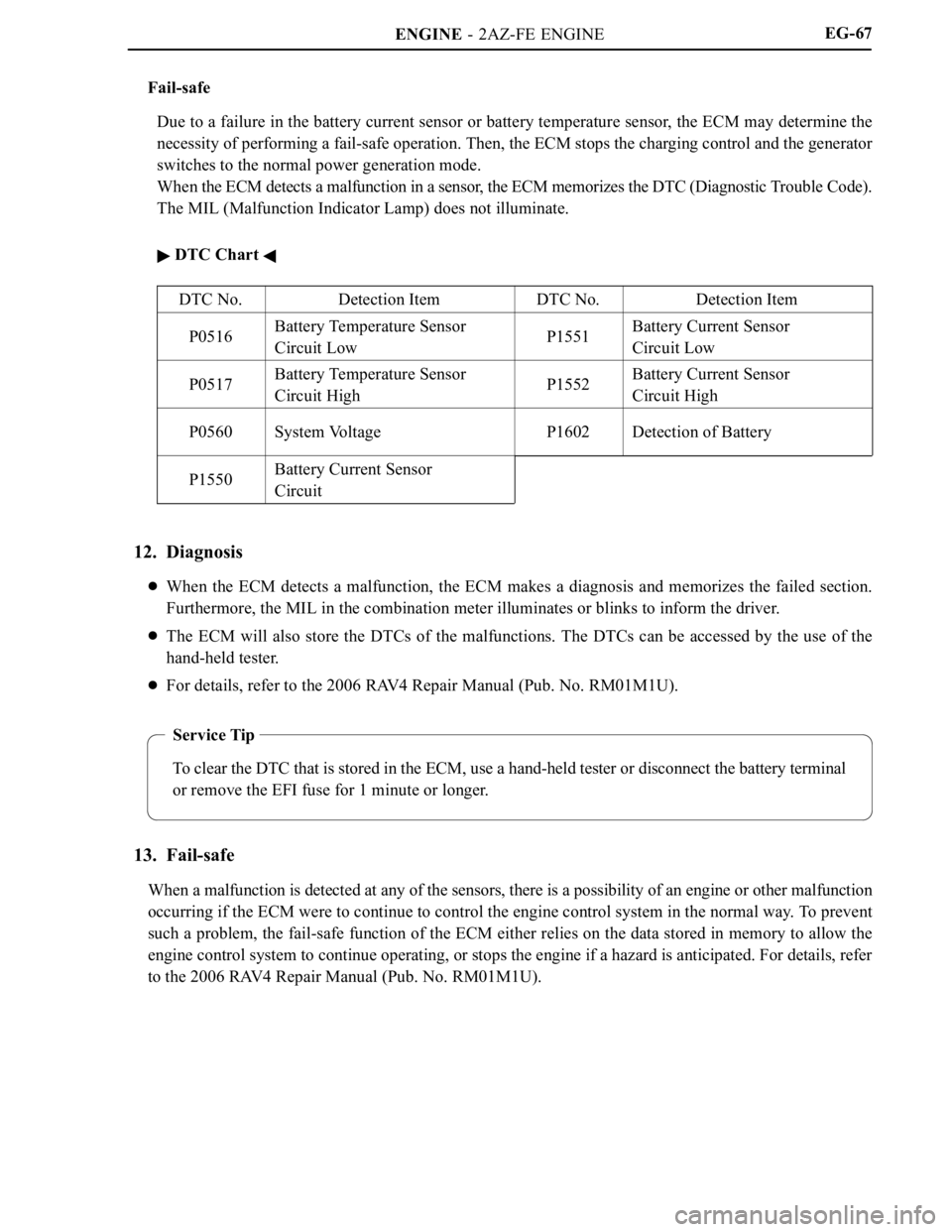

Fail-safe

Due to a failure in the battery current sensor or battery temperature sensor, the ECM may determine the

necessity of performing a fail-safe operation. Then, the ECM stops the charging control and the generator

switches to the normal power generation mode.

When the ECM detects a malfunction in a sensor, the ECM memorizes the DTC (Diagnostic Trouble Code).

The MIL (Malfunction Indicator Lamp) does not illuminate.

DTC Chart

DTC No.Detection ItemDTC No.Detection Item

P0516Battery Temperature Sensor

Circuit LowP1551Battery Current Sensor

Circuit Low

P0517Battery Temperature Sensor

Circuit HighP1552Battery Current Sensor

Circuit High

P0560System VoltageP1602Detection of Battery

P1550Battery Current Sensor

Circuit

12. Diagnosis

When the ECM detects a malfunction, the ECM makes a diagnosis and memorizes the failed section.

Furthermore, the MIL in the combination meter illuminates or blinks to inform the driver.

The ECM will also store the DTCs of the malfunctions. The DTCs can be accessed by the use of the

hand-held tester.

For details, refer to the 2006 RAV4 Repair Manual (Pub. No. RM01M1U).

13. Fail-safe

When a malfunction is detected at any of the sensors, there is a possibility of an engine or other malfunction

occurring if the ECM were to continue to control the engine control system in the normal way. To prevent

such a problem, the fail-safe function of the ECM either relies on the data stored in memory to allow the

engine control system to continue operating, or stops the engine if a hazard is anticipated. For details, refer

to the 2006 RAV4 Repair Manual (Pub. No. RM01M1U).

Page 68 of 2000

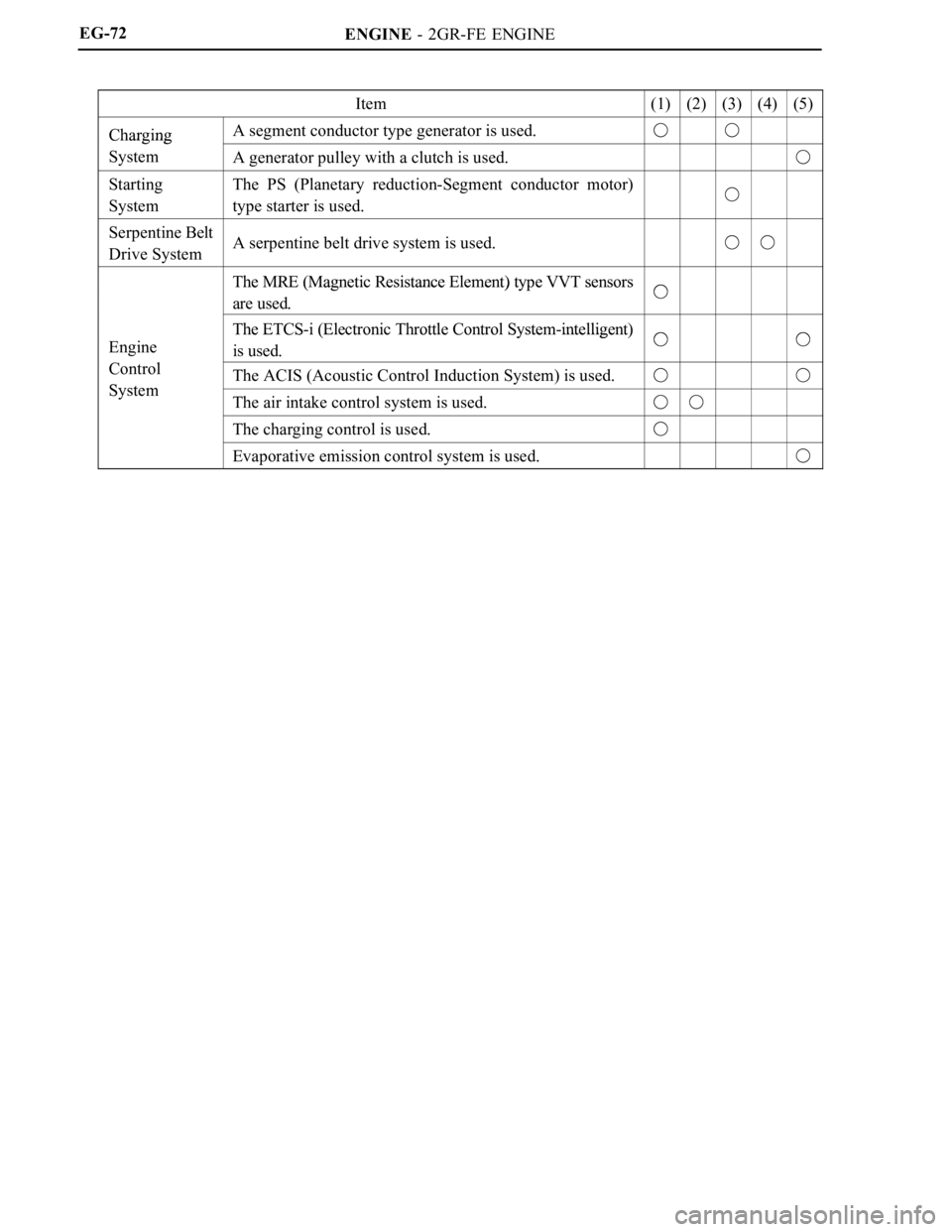

ENGINE - 2GR-FE ENGINE EG-72

Item

(1)(2)(3)(4)(5)

ChargingA segment conductor type generator is used.Charging

SystemA generator pulley with a clutch is used.

Starting

SystemThe PS (Planetary reduction-Segment conductor motor)

type starter is used.

Serpentine Belt

Drive SystemA serpentine belt drive system is used.

The MRE (Magnetic Resistance Element) type VVT sensorsThe MRE (Magnetic Resistance Element) type VVT sensors

are used.

The ETCS-i (Electronic Throttle Control System-intelligent)

Engine

The ETCS i (Electronic Throttle Control System intelligent)

is used.

Control

SystemThe ACIS (Acoustic Control Induction System) is used.SystemThe air intake control system is used.

The charging control is used.

Evaporative emission control system is used.

Page 94 of 2000

ENGINE - 2GR-FE ENGINE

01NEG63Y

01MEG36Y

Generator

Stator

RotorRegulator

EB

IG

M

RLOL

Ignition Switch

ECM

Towing Package Models and Models with RSES

Other Models Generator

Rectifier

Stator

Rotor

ERegulatorB

IG

M

RLOL

Ignition Switch

ECM

Discharge

Warning Light

Discharge

Warning Light

EG-98

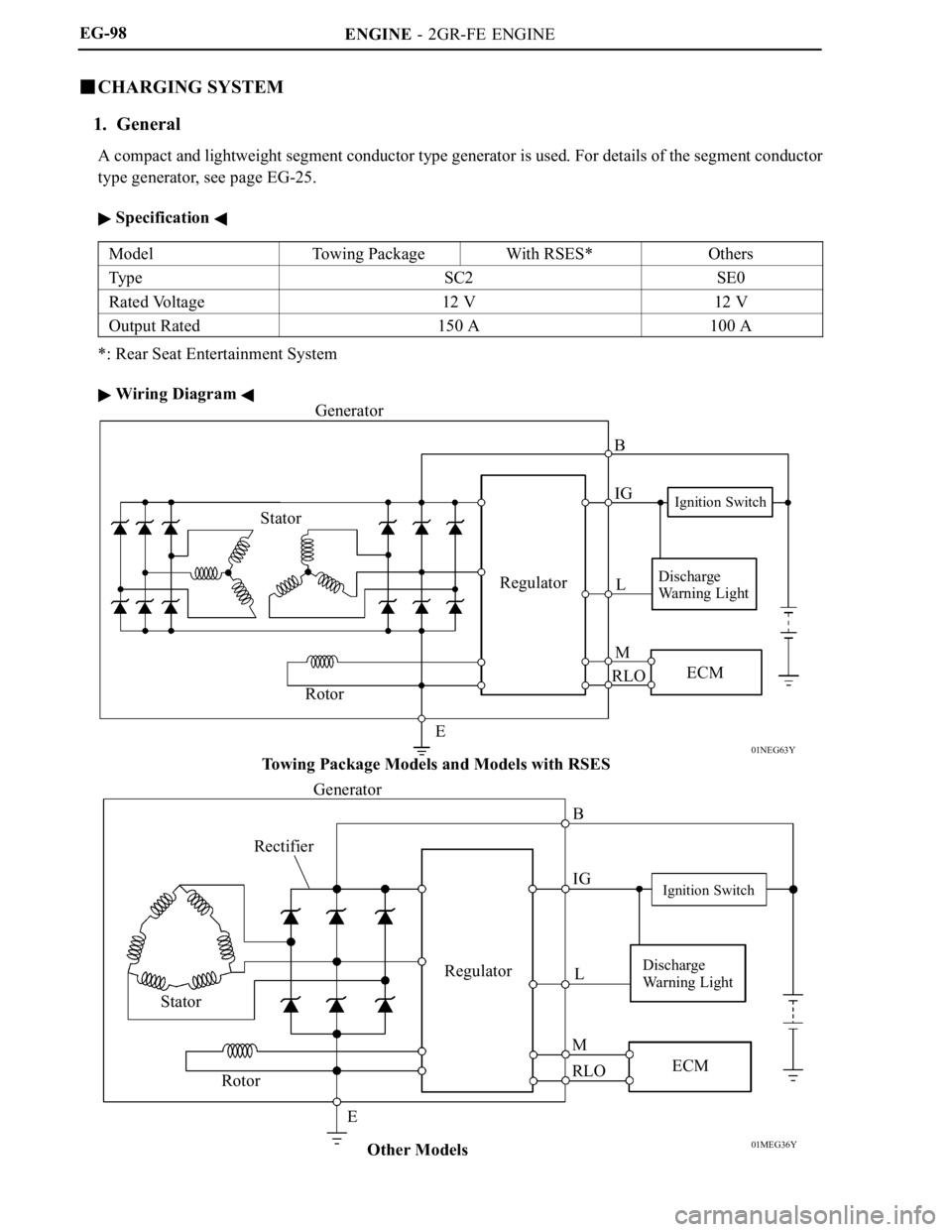

CHARGING SYSTEM

1. General

A compact and lightweight segment conductor type generator is used. For details of the segment conductor

type generator, see page EG-25.

Specification

ModelTowing PackageWith RSES*Others

Ty p eSC2SE0

Rated Voltage12 V12 V

Output Rated150 A100 A

*: Rear Seat Entertainment System

Wiring Diagram

Page 97 of 2000

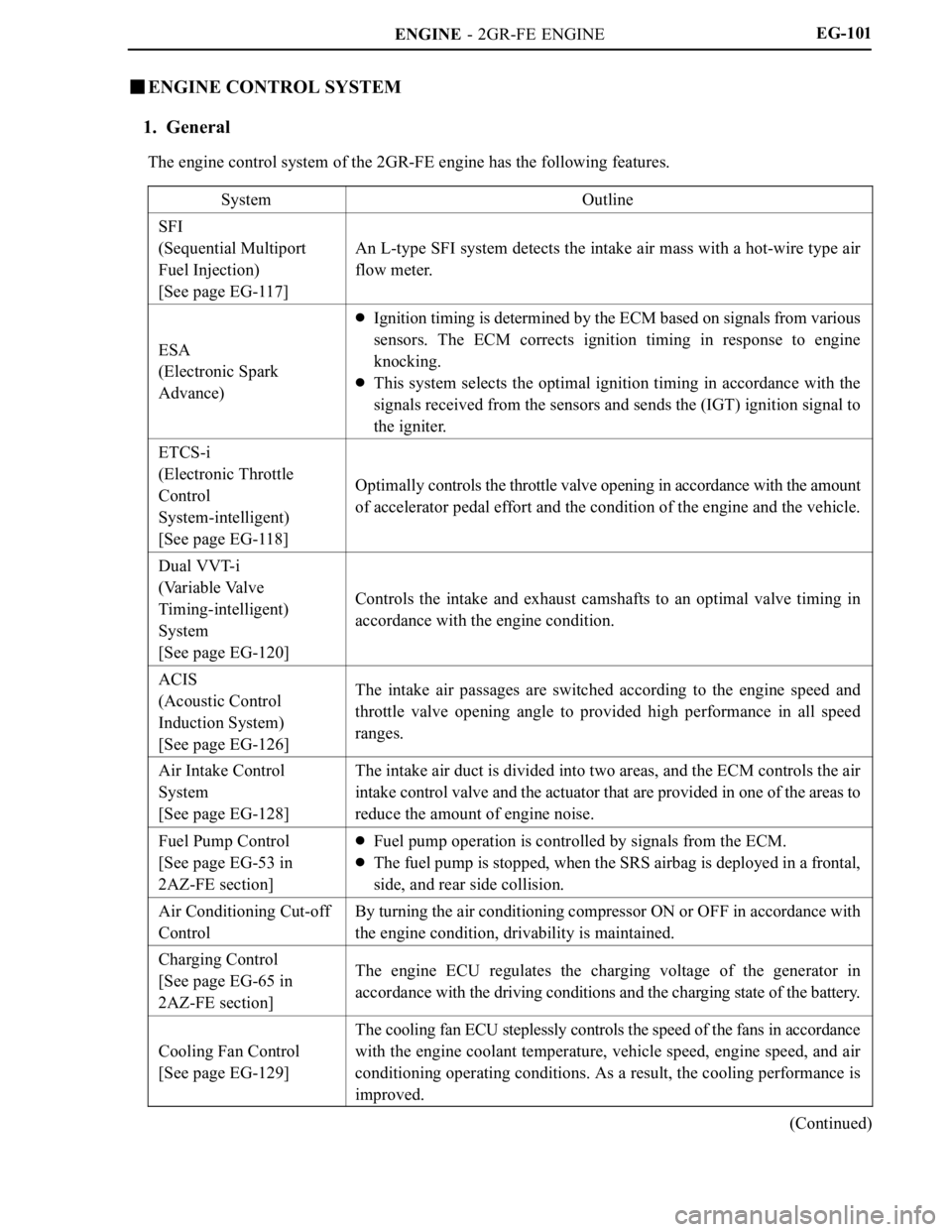

ENGINE - 2GR-FE ENGINEEG-101

ENGINE CONTROL SYSTEM

1. General

The engine control system of the 2GR-FE engine has the following features.

System

Outline

SFI

(Sequential Multiport

Fuel Injection)

[See page EG-117]

An L-type SFI system detects the intake air mass with a hot-wire type air

flow meter.

ESA

(Electronic Spark

Advance)

Ignition timing is determined by the ECM based on signals from various

sensors. The ECM corrects ignition timing in response to engine

knocking.

This system selects the optimal ignition timing in accordance with the

signals received from the sensors and sends the (IGT) ignition signal to

the igniter.

ETCS-i

(Electronic Throttle

Control

System-intelligent)

[See page EG-118]

Optimally controls the throttle valve opening in accordance with the amount

of accelerator pedal effort and the condition of the engine and the vehicle.

Dual VVT-i

(Variable Valve

Timing-intelligent)

System

[See page EG-120]

Controls the intake and exhaust camshafts to an optimal valve timing in

accordance with the engine condition.

ACIS

(Acoustic Control

Induction System)

[See page EG-126]The intake air passages are switched according to the engine speed and

throttle valve opening angle to provided high performance in all speed

ranges.

Air Intake Control

System

[See page EG-128]The intake air duct is divided into two areas, and the ECM controls the air

intake control valve and the actuator that are provided in one of the areas to

reduce the amount of engine noise.

Fuel Pump Control

[See page EG-53 in

2AZ-FE section]Fuel pump operation is controlled by signals from the ECM.

The fuel pump is stopped, when the SRS airbag is deployed in a frontal,

side, and rear side collision.

Air Conditioning Cut-off

ControlBy turning the air conditioning compressor ON or OFF in accordance with

the engine condition, drivability is maintained.

Charging Control

[See page EG-65 in

2AZ-FE section]The engine ECU regulates the charging voltage of the generator in

accordance with the driving conditions and the charging state of the battery.

Cooling Fan Control

[See page EG-129]

The cooling fan ECU steplessly controls the speed of the fans in accordance

with the engine coolant temperature, vehicle speed, engine speed, and air

conditioning operating conditions. As a result, the cooling performance is

improved.

(Continued)

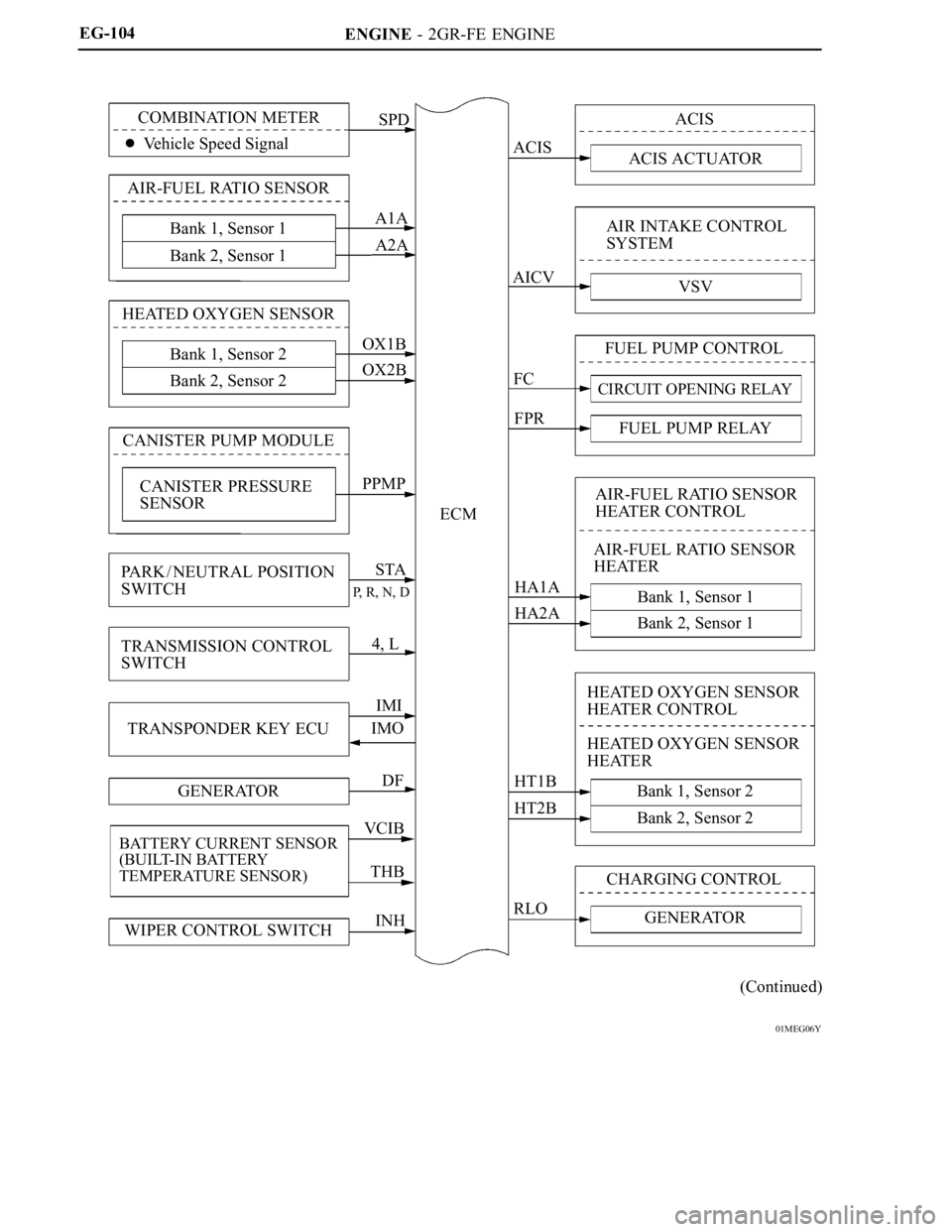

Page 100 of 2000

ENGINE - 2GR-FE ENGINE

01MEG06Y

COMBINATION METER

Vehicle Speed Signal

AIR-FUEL RATIO SENSOR

Bank 1, Sensor 1

Bank 2, Sensor 1

HEATED OXYGEN SENSOR

Bank 1, Sensor 2

Bank 2, Sensor 2

CANISTER PUMP MODULE

CANISTER PRESSURE

SENSOR

PARK / NEUTRAL POSITION

SWITCH

TRANSMISSION CONTROL

SWITCH

TRANSPONDER KEY ECU

GENERATOR

BATTERY CURRENT SENSOR

(BUILT-IN BATTERY

TEMPERATURE SENSOR)

WIPER CONTROL SWITCHSPD

A1A

A2A

OX1B

OX2B

PPMP

STA

P, R, N, D

4, L

IMI

IMO

DF

THB VCIB

INHECMACIS

AICV

FC

FPR

HA1A

HA2A

HT1B

HT2B

RLOACIS

ACIS ACTUATOR

AIR INTAKE CONTROL

SYSTEM

VSV

FUEL PUMP CONTROL

CIRCUIT OPENING RELAY

FUEL PUMP RELAY

AIR-FUEL RATIO SENSOR

HEATER CONTROL

AIR-FUEL RATIO SENSOR

HEATER

Bank 1, Sensor 1

Bank 2, Sensor 1

HEATED OXYGEN SENSOR

HEATER CONTROL

HEATED OXYGEN SENSOR

HEATER

Bank 1, Sensor 2

Bank 2, Sensor 2

CHARGING CONTROL

GENERATOR EG-104

(Continued)