oil TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 29 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG04Y

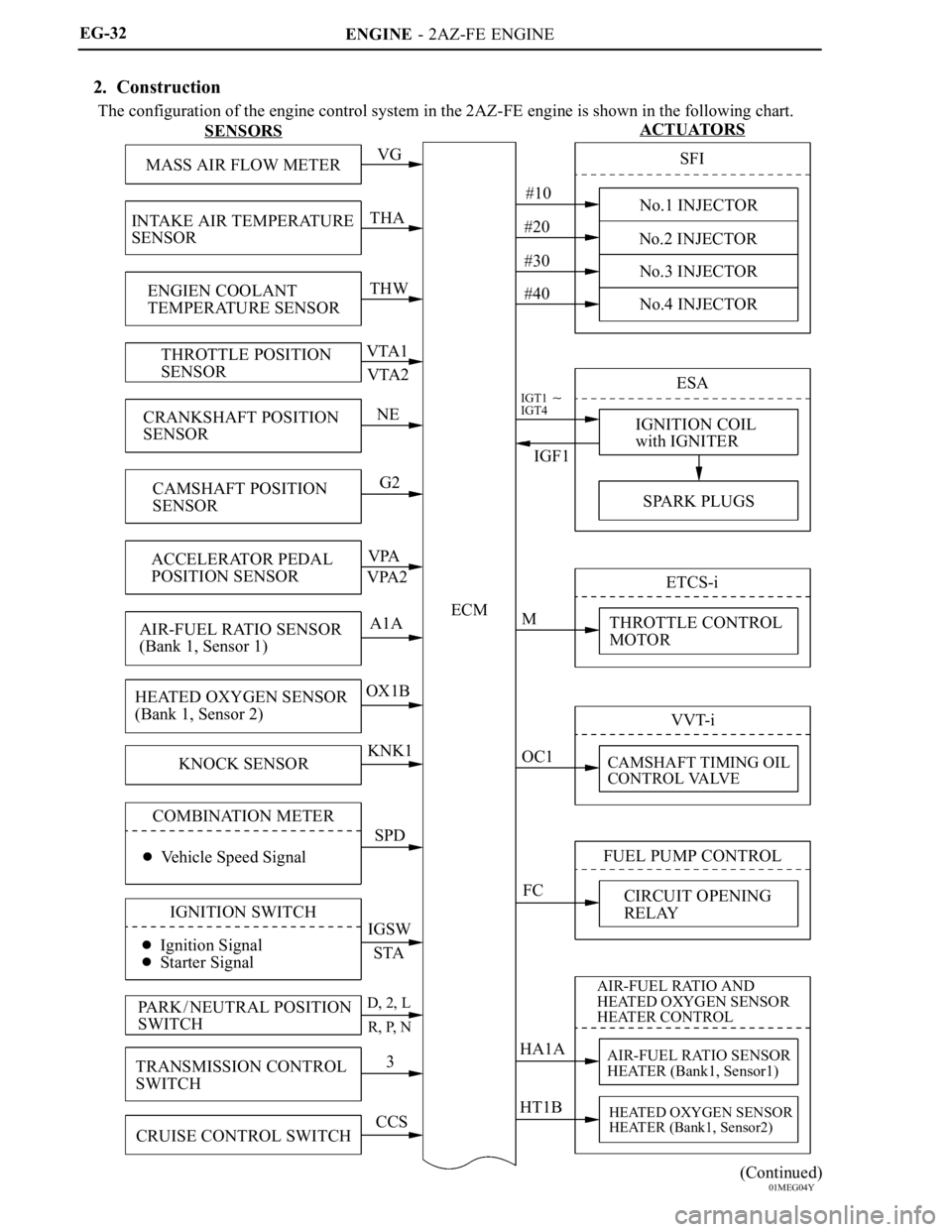

SENSORSACTUATORS

MASS AIR FLOW METER

INTAKE AIR TEMPERATURE

SENSOR

ENGIEN COOLANT

TEMPERATURE SENSOR

THROTTLE POSITION

SENSOR

CRANKSHAFT POSITION

SENSOR

CAMSHAFT POSITION

SENSOR

ACCELERATOR PEDAL

POSITION SENSOR

AIR-FUEL RATIO SENSOR

(Bank 1, Sensor 1)

HEATED OXYGEN SENSOR

(Bank 1, Sensor 2)

KNOCK SENSOR

COMBINATION METER

Vehicle Speed Signal

IGNITION SWITCH

Ignition Signal

Starter Signal

PA R K / N E U T R A L P O S I T I O N

SWITCH

TRANSMISSION CONTROL

SWITCH

CRUISE CONTROL SWITCHVG

THA

THW

VTA1

VTA2

NE

G2

VPA

VPA2

A1A

OX1B

KNK1

SPD

IGSW

STA

D, 2, L

R, P, N

3

CCSECM#10

#20

#30

#40

IGT1 IGT4

IGF1

M

OC1

FC

HA1A

HT1BSFI

No.1 INJECTOR

No.2 INJECTOR

No.3 INJECTOR

No.4 INJECTOR

ESA

IGNITION COIL

with IGNITER

SPARK PLUGS

ETCS-i

THROTTLE CONTROL

MOTOR

VVT-i

CAMSHAFT TIMING OIL

CONTROL VALVE

FUEL PUMP CONTROL

CIRCUIT OPENING

RELAY

AIR-FUEL RATIO AND

HEATED OXYGEN SENSOR

HEATER CONTROL

AIR-FUEL RATIO SENSOR

HEATER (Bank1, Sensor1)

HEATED OXYGEN SENSOR

HEATER (Bank1, Sensor2)

EG-32

2. Construction

The configuration of the engine control system in the 2AZ-FE engine is shown in the following chart.

(Continued)

Page 31 of 2000

ENGINE - 2AZ-FE ENGINE

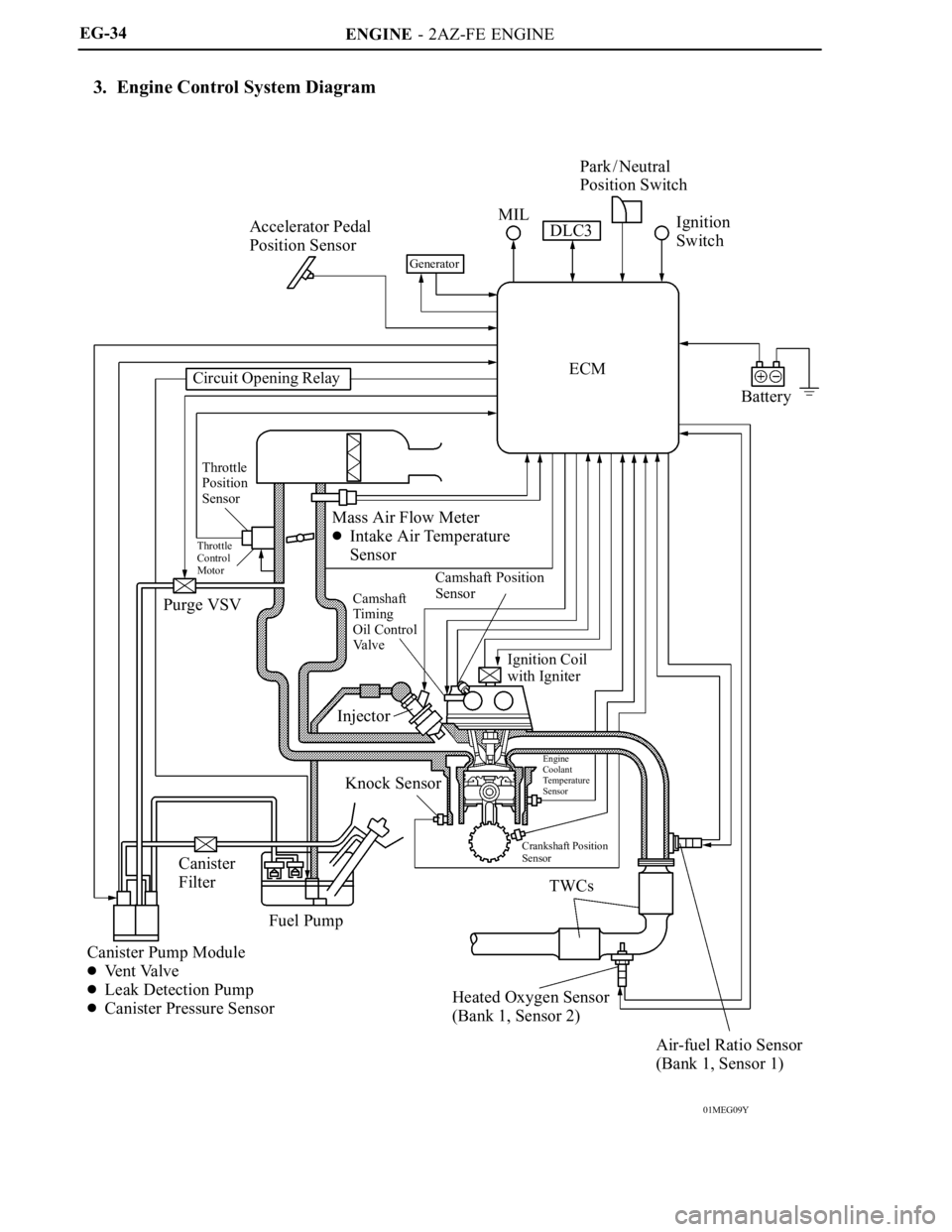

01MEG09Y

Accelerator Pedal

Position Sensor

Generator

MIL

DLC3Park / Neutral

Position Switch

Ignition

Switch

Circuit Opening RelayECM

Battery

Throttle

Position

Sensor

Throttle

Control

Motor

Purge VSVMass Air Flow Meter

Intake Air Temperature

Sensor

Camshaft Position

Sensor

Camshaft

Timing

Oil Control

Va l v e

Ignition Coil

with Igniter

Injector

Knock Sensor

Engine

Coolant

Temperature

Sensor

Crankshaft Position

Sensor

Canister

Filter

Fuel Pump

Canister Pump Module

Ve n t Va l v e

Leak Detection Pump

Canister Pressure SensorTWCs

Heated Oxygen Sensor

(Bank 1, Sensor 2)

Air-fuel Ratio Sensor

(Bank 1, Sensor 1) EG-34

3. Engine Control System Diagram

Page 32 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG31Y

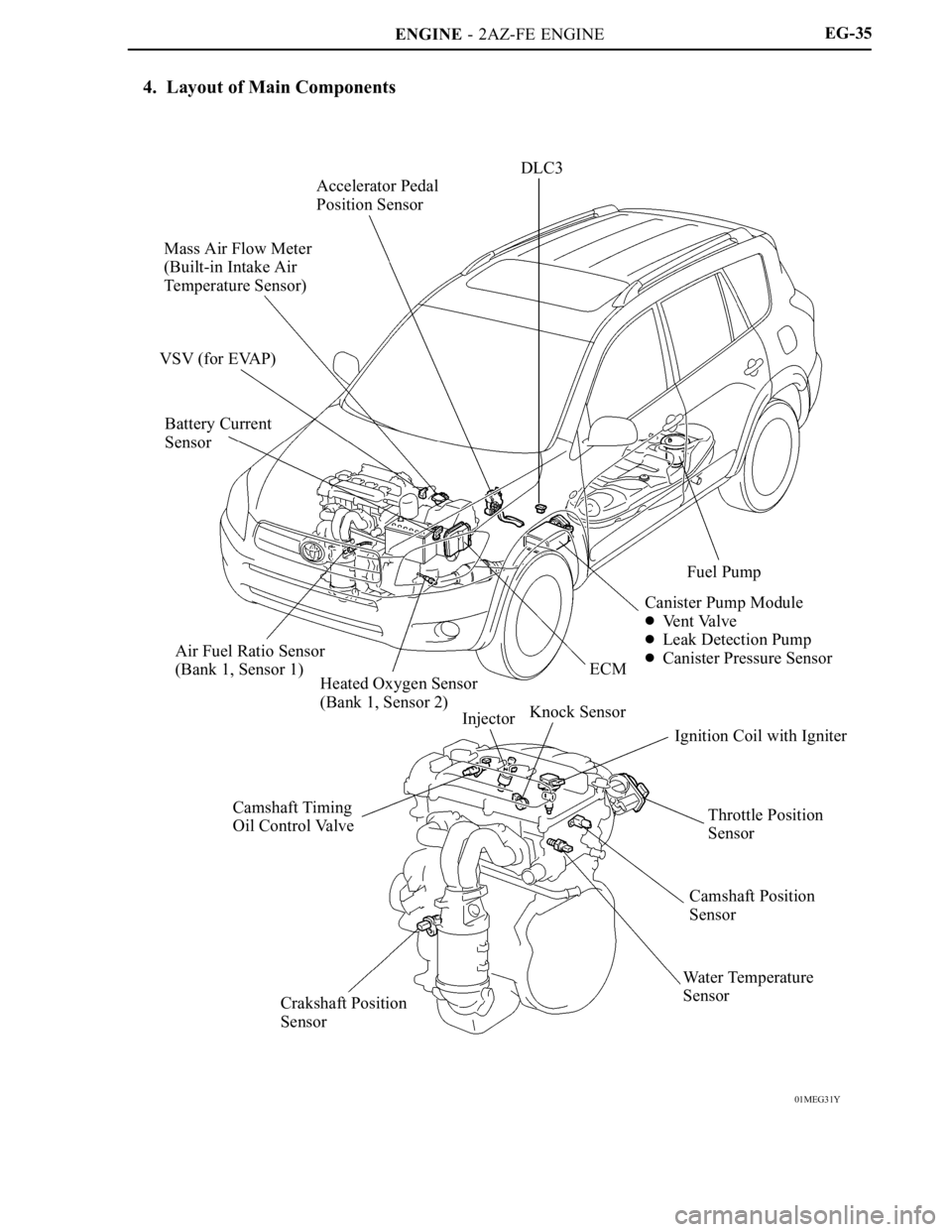

DLC3

Accelerator Pedal

Position Sensor

Mass Air Flow Meter

(Built-in Intake Air

Temperature Sensor)

VSV (for EVAP)

Battery Current

Sensor

Fuel Pump

Canister Pump Module

Ve n t Va l v e

Leak Detection Pump

Canister Pressure Sensor

ECM

Heated Oxygen Sensor

(Bank 1, Sensor 2) Air Fuel Ratio Sensor

(Bank 1, Sensor 1)

Camshaft Timing

Oil Control ValveInjectorKnock Sensor

Ignition Coil with Igniter

Throttle Position

Sensor

Camshaft Position

Sensor

Water Temperature

Sensor

Crakshaft Position

SensorEG-35

4. Layout of Main Components

Page 33 of 2000

ENGINE - 2AZ-FE ENGINE EG-36

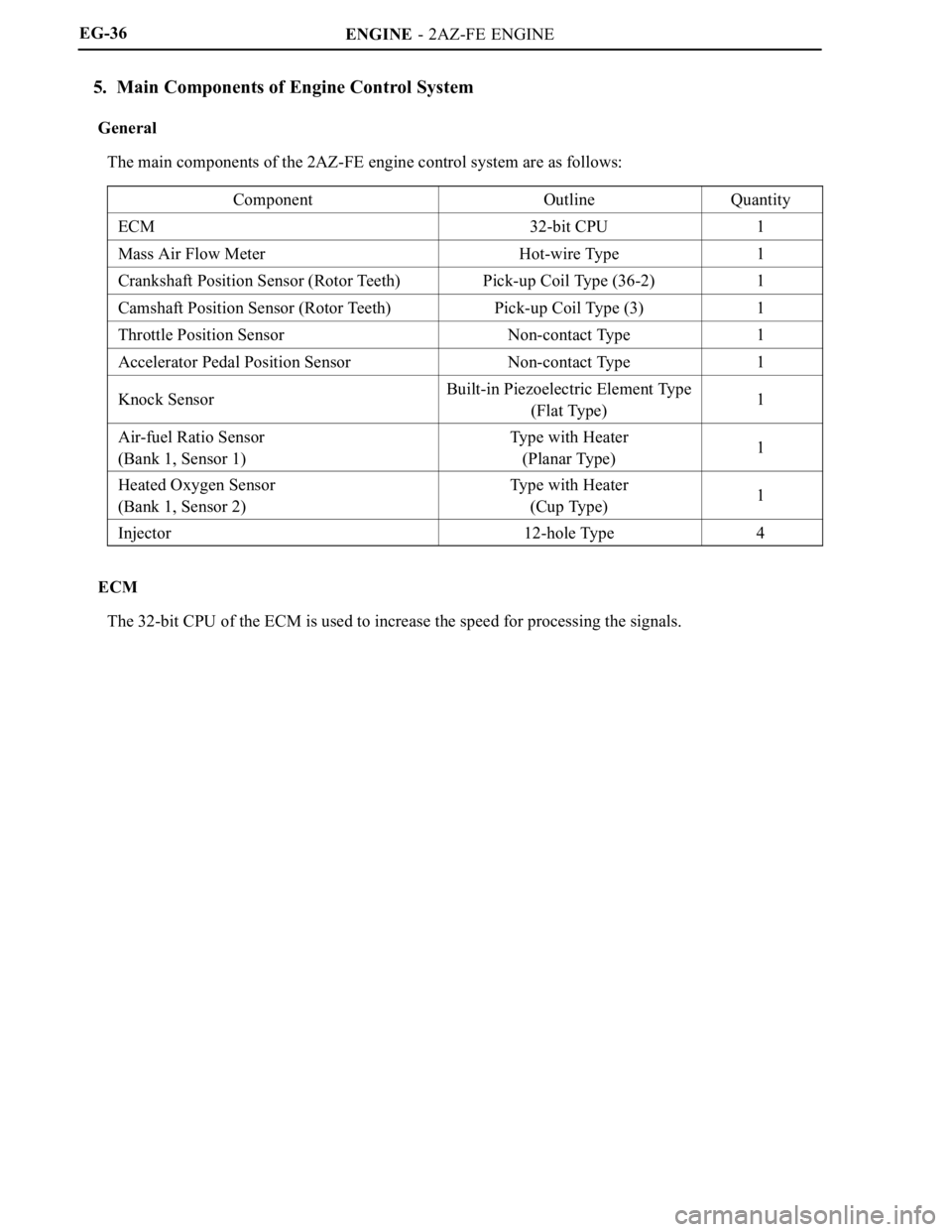

5. Main Components of Engine Control System

General

The main components of the 2AZ-FE engine control system are as follows:

Component

OutlineQuantity

ECM32-bit CPU1

Mass Air Flow MeterHot-wire Type1

Crankshaft Position Sensor (Rotor Teeth)Pick-up Coil Type (36-2)1

Camshaft Position Sensor (Rotor Teeth)Pick-up Coil Type (3)1

Throttle Position SensorNon-contact Type1

Accelerator Pedal Position SensorNon-contact Type1

Knock SensorBuilt-in Piezoelectric Element Type

(Flat Type)1

Air-fuel Ratio Sensor

(Bank 1, Sensor 1)Type with Heater

(Planar Type)1

Heated Oxygen Sensor

(Bank 1, Sensor 2)Type with Heater

(Cup Type)1

Injector12-hole Type4

ECM

The 32-bit CPU of the ECM is used to increase the speed for processing the signals.

Page 40 of 2000

ENGINE - 2AZ-FE ENGINE

00REG17Y

Accelerator Pedal

Position SensorThrottle Valve

Throttle Position SensorThrottle

Control

Motor

Mass Air

Flow MeterECMSkid

Control

ECU

Ignition

CoilFuel

Injector

: CANEG-43

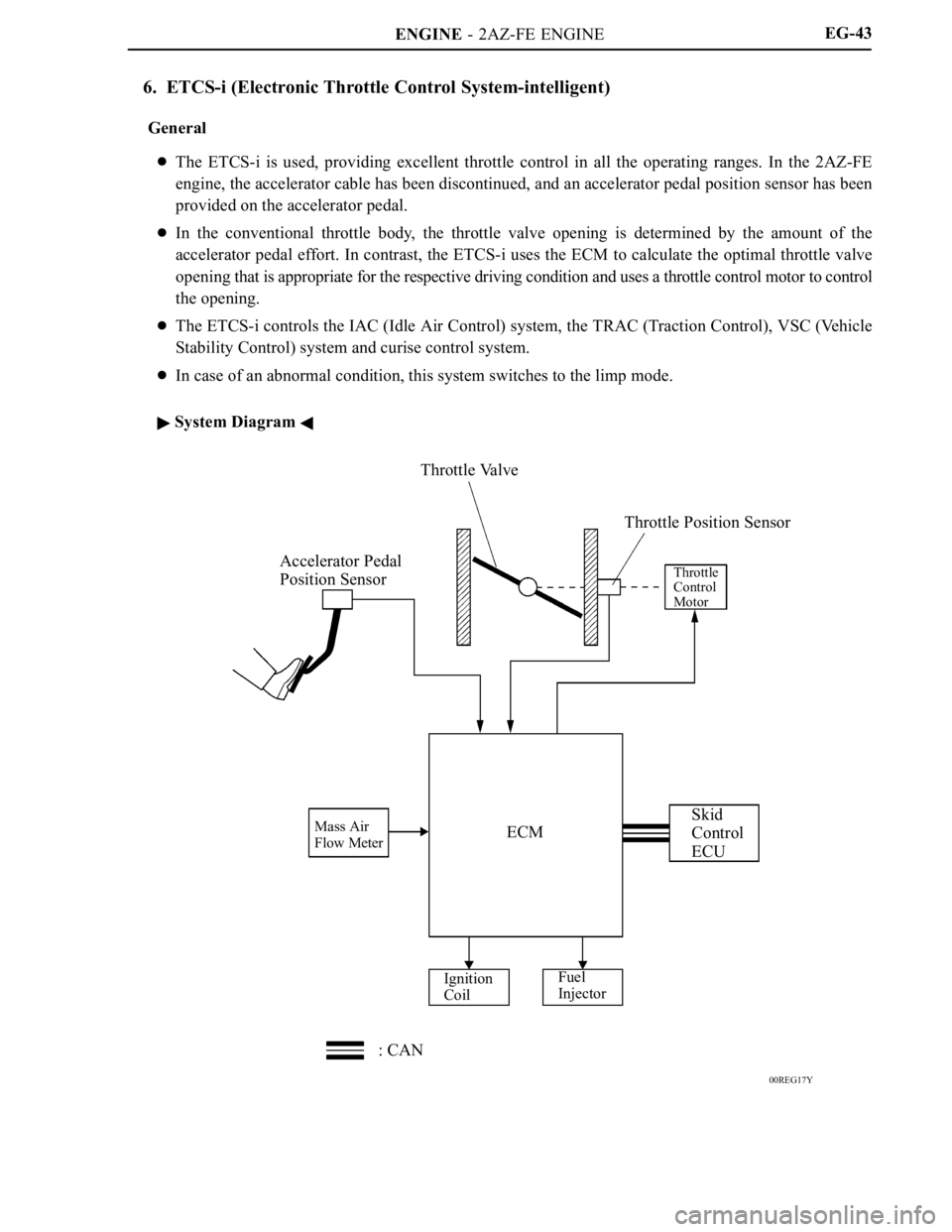

6. ETCS-i (Electronic Throttle Control System-intelligent)

General

The ETCS-i is used, providing excellent throttle control in all the operating ranges. In the 2AZ-FE

engine, the accelerator cable has been discontinued, and an accelerator pedal position sensor has been

provided on the accelerator pedal.

In the conventional throttle body, the throttle valve opening is determined by the amount of the

accelerator pedal effort. In contrast, the ETCS-i uses the ECM to calculate the optimal throttle valve

opening that is appropriate for the respective driving condition and uses a throttle control motor to control

the opening.

The ETCS-i controls the IAC (Idle Air Control) system, the TRAC (Traction Control), VSC (Vehicle

Stability Control) system and curise control system.

In case of an abnormal condition, this system switches to the limp mode.

System Diagram

Page 44 of 2000

ENGINE - 2AZ-FE ENGINE

199EG47

Injectors

ECMIgnition Coils

Accelerator Pedal

Position Sensor

Main

Sub

Main

Sub

Return to

Prescribed Angle

Throttle ValveReturn

SpringThrottle

Control

Motor

Accelerator Pedal Throttle BodyEG-47

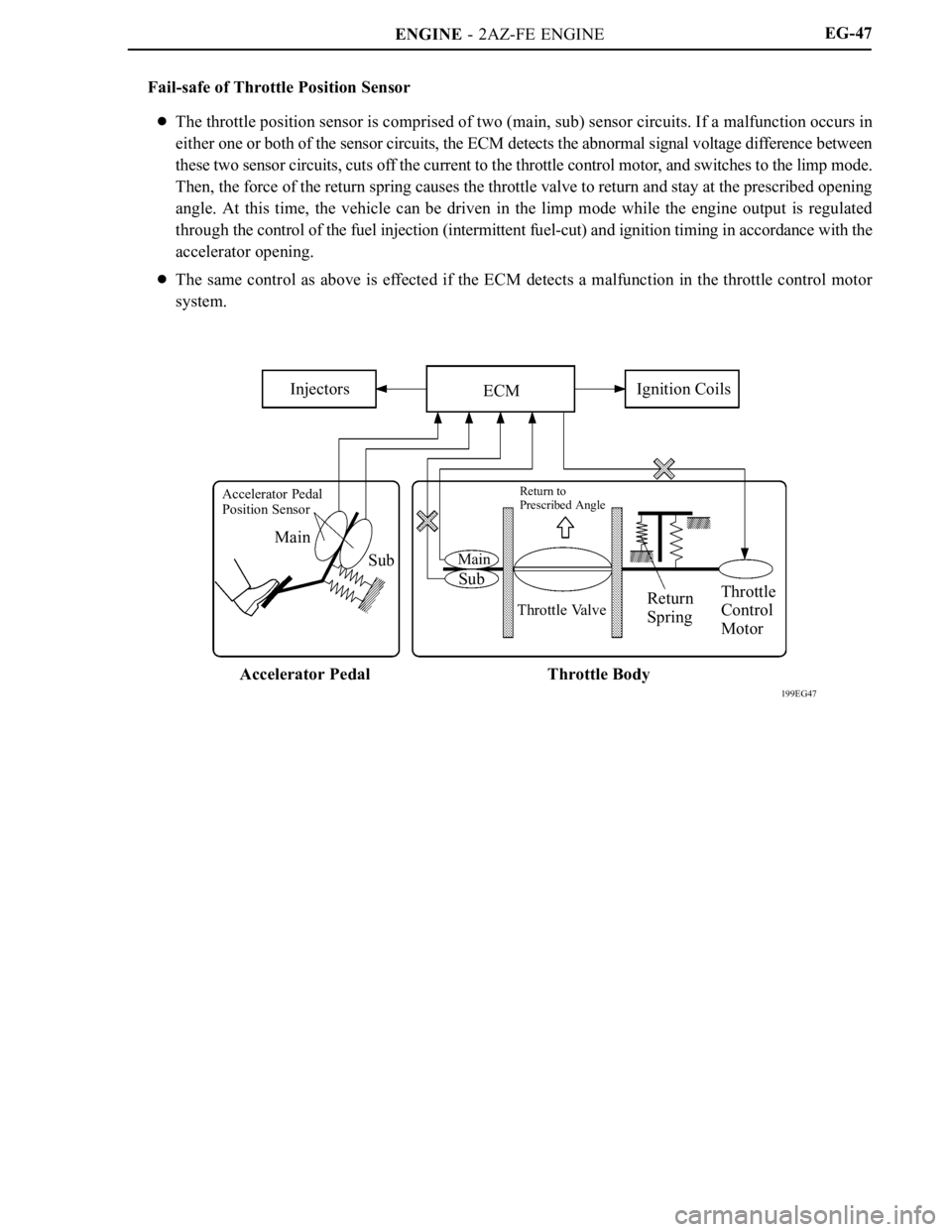

Fail-safe of Throttle Position Sensor

The throttle position sensor is comprised of two (main, sub) sensor circuits. If a malfunction occurs in

either one or both of the sensor circuits, the ECM detects the abnormal signal voltage difference between

these two sensor circuits, cuts off the current to the throttle control motor, and switches to the limp mode.

Then, the force of the return spring causes the throttle valve to return and stay at the prescribed opening

angle. At this time, the vehicle can be driven in the limp mode while the engine output is regulated

through the control of the fuel injection (intermittent fuel-cut) and ignition timing in accordance with the

accelerator opening.

The same control as above is effected if the ECM detects a malfunction in the throttle control motor

system.

Page 45 of 2000

ENGINE - 2AZ-FE ENGINE

DR011EG25

Camshaft Position Sensor

Engine Coolant

Temperature Sensor

Crankshaft

Position Sensor

Camshaft Timing

Oil Control Valve

Throttle Position

Sensor

ECM

Mass Air Flow Meter Vehicle Speed Signal

221EG16

Crankshaft Position Sensor

Mass Air Flow Meter

Throttle Position Sensor

Engine Coolant Temp. Sensor

Camshaft Position Sensor

Vehicle Speed SignalECM

Target Valve Timing

Feedback

Correction

Actual Valve Timing

Duty-cycle

Control

Camshaft Timing

Oil Control Valve

EG-48

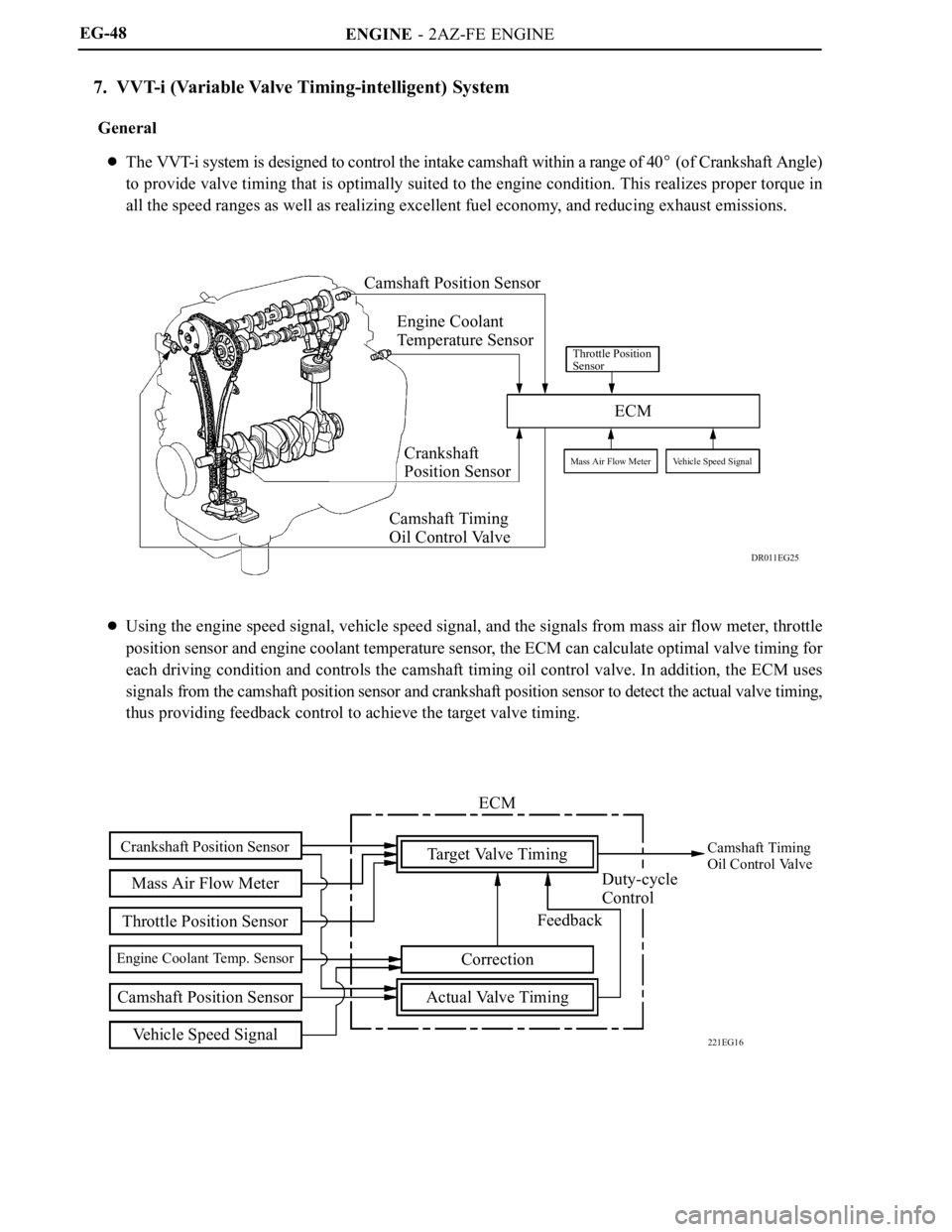

7. VVT-i (Variable Valve Timing-intelligent) System

General

The VVT-i system is designed to control the intake camshaft within a range of 40 (of Crankshaft Angle)

to provide valve timing that is optimally suited to the engine condition. This realizes proper torque in

all the speed ranges as well as realizing excellent fuel economy, and reducing exhaust emissions.

Using the engine speed signal, vehicle speed signal, and the signals from mass air flow meter, throttle

position sensor and engine coolant temperature sensor, the ECM can calculate optimal valve timing for

each driving condition and controls the camshaft timing oil control valve. In addition, the ECM uses

signals from the camshaft position sensor and crankshaft position sensor to detect the actual valve timing,

thus providing feedback control to achieve the target valve timing.

Page 47 of 2000

ENGINE - 2AZ-FE ENGINE

169EG36

HousingLock Pin

Intake Camshaft

Vane (Fixed on Intake Camshaft)

Oil Pressure

At a Stop In Operation

Lock Pin

221EG17

To VVT-i Controller

(Advance Side)To V V T- i C o n t r o l l e r

(Retard Side)

Sleeve

Spring

Drain

Oil PressureDrain

Spool ValveCoil

Plunger EG-50

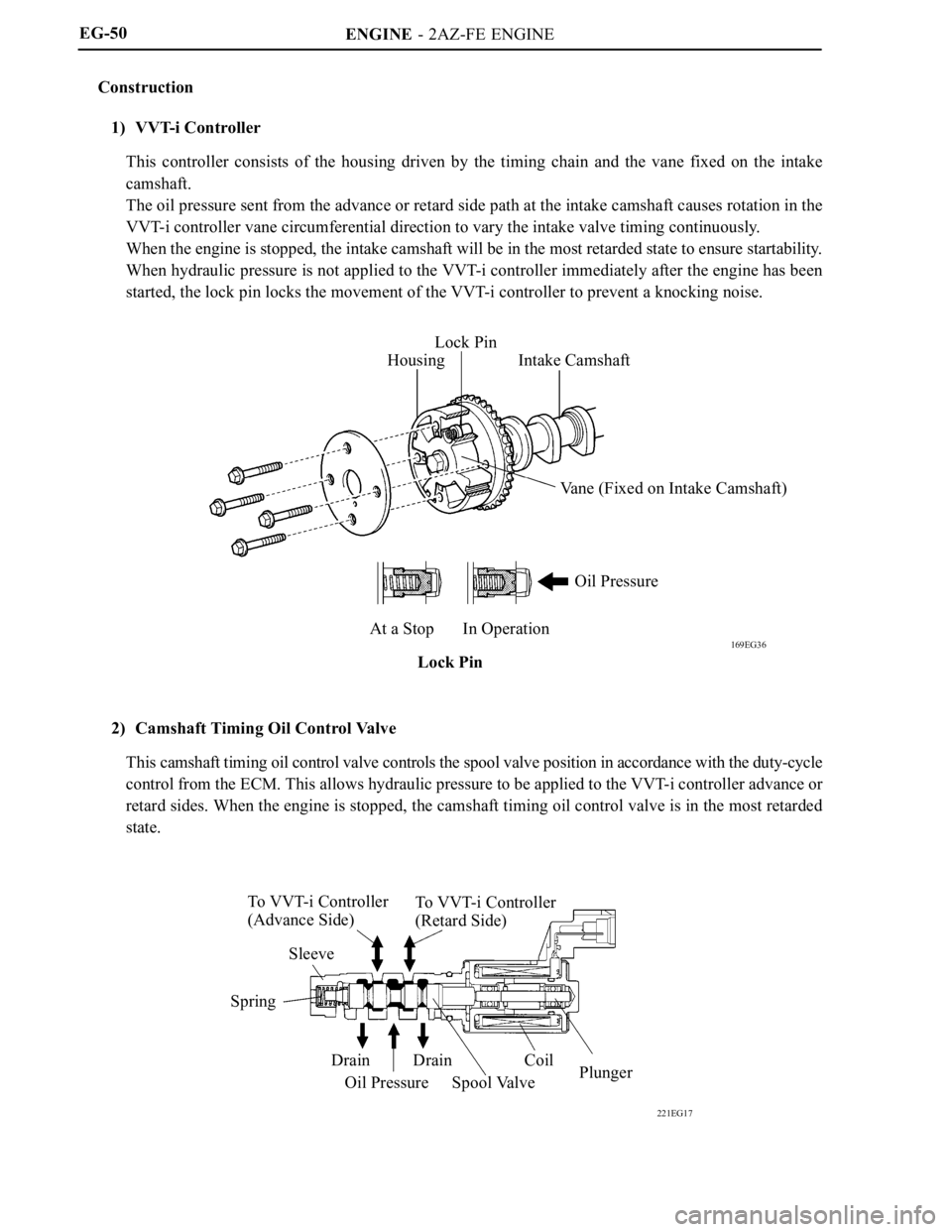

Construction

1) VVT-i Controller

This controller consists of the housing driven by the timing chain and the vane fixed on the intake

camshaft.

The oil pressure sent from the advance or retard side path at the intake camshaft causes rotation in the

VVT-i controller vane circumferential direction to vary the intake valve timing continuously.

When the engine is stopped, the intake camshaft will be in the most retarded state to ensure startability.

When hydraulic pressure is not applied to the VVT-i controller immediately after the engine has been

started, the lock pin locks the movement of the VVT-i controller to prevent a knocking noise.

2) Camshaft Timing Oil Control Valve

This camshaft timing oil control valve controls the spool valve position in accordance with the duty-cycle

control from the ECM. This allows hydraulic pressure to be applied to the VVT-i controller advance or

retard sides. When the engine is stopped, the camshaft timing oil control valve is in the most retarded

state.

Page 48 of 2000

ENGINE - 2AZ-FE ENGINE

198EG35

Va n e

Rotation DirectionOil PressureECM

IN Drain

198EG36

Va n e

Rotation DirectionOil Pressure

Drain INECMEG-51

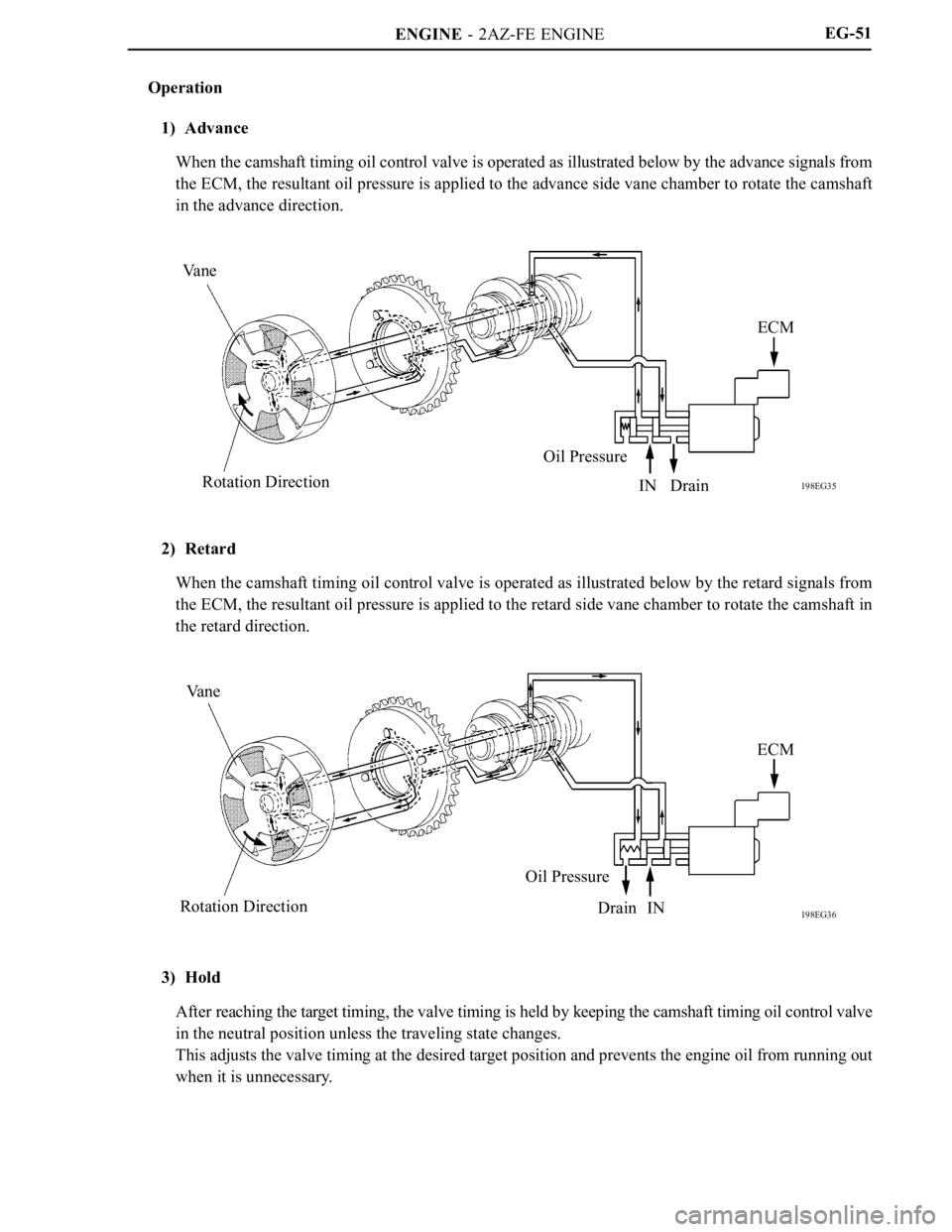

Operation

1) Advance

When the camshaft timing oil control valve is operated as illustrated below by the advance signals from

the ECM, the resultant oil pressure is applied to the advance side vane chamber to rotate the camshaft

in the advance direction.

2) Retard

When the camshaft timing oil control valve is operated as illustrated below by the retard signals from

the ECM, the resultant oil pressure is applied to the retard side vane chamber to rotate the camshaft in

the retard direction.

3) Hold

After reaching the target timing, the valve timing is held by keeping the camshaft timing oil control valve

in the neutral position unless the traveling state changes.

This adjusts the valve timing at the desired target position and prevents the engine oil from running out

when it is unnecessary.

Page 66 of 2000

ENGINE - 2AZ-FE ENGINE

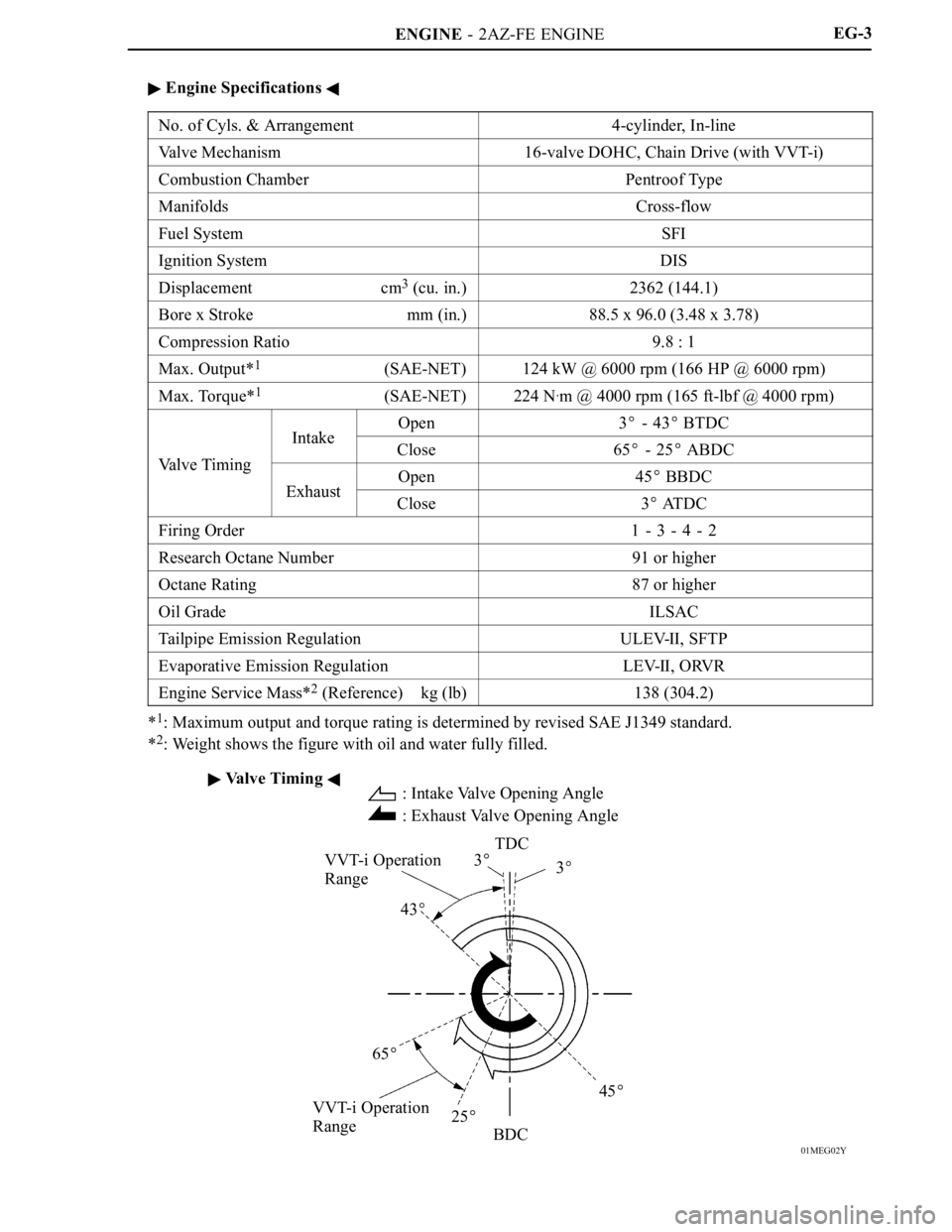

01MEG02Y

Valve Timing : Intake Valve Opening Angle

: Exhaust Valve Opening Angle

VVT-i Operation

Range

VVT-i Operation

RangeTDC

3

3

43

65

25

45

BDCEG-3

Engine Specifications

No. of Cyls. & Arrangement4-cylinder, In-line

Valve Mechanism16-valve DOHC, Chain Drive (with VVT-i)

Combustion ChamberPentroof Type

ManifoldsCross-flow

Fuel SystemSFI

Ignition SystemDIS

Displacement cm3 (cu. in.)2362 (144.1)

Bore x Stroke mm (in.)88.5 x 96.0 (3.48 x 3.78)

Compression Ratio9.8 : 1

Max. Output*1(SAE-NET)124 kW @ 6000 rpm (166 HP @ 6000 rpm)

Max. Torque*1(SAE-NET)224 N.m @ 4000 rpm (165 ft-lbf @ 4000 rpm)

IntakeOpen3 - 43 BTDC

Valve Timing

IntakeClose65 - 25 ABDCVa l v e T i m i n g

ExhaustOpen45 BBDCExhaustClose3 ATDC

Firing Order1 - 3 - 4 - 2

Research Octane Number91 or higher

Octane Rating87 or higher

Oil GradeILSAC

Tailpipe Emission RegulationULEV-II, SFTP

Evaporative Emission RegulationLEV-II, ORVR

Engine Service Mass*2 (Reference) kg (lb)138 (304.2)

*1: Maximum output and torque rating is determined by revised SAE J1349 standard.

*

2: Weight shows the figure with oil and water fully filled.