ad blue TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 610 of 2000

EM–662AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

INSPECTION

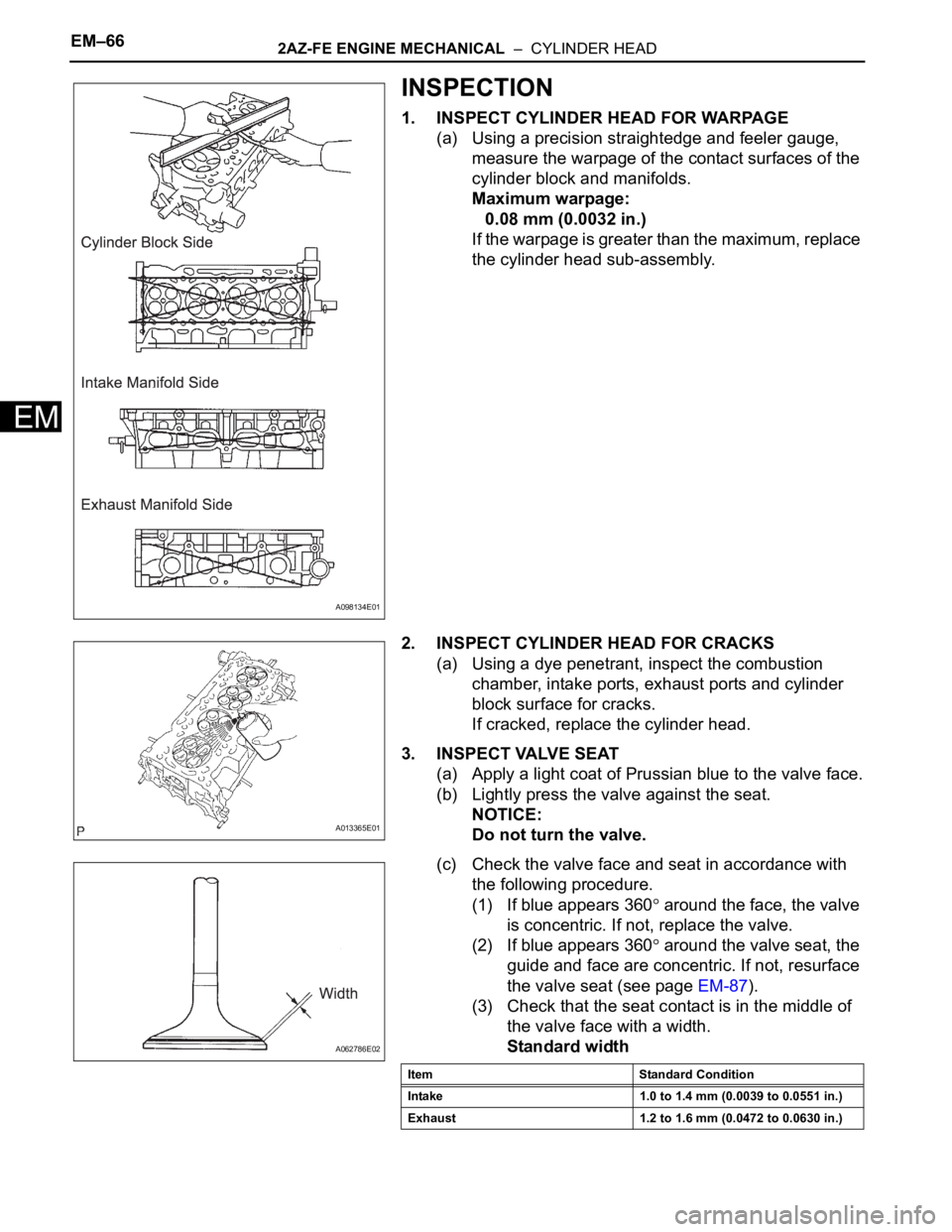

1. INSPECT CYLINDER HEAD FOR WARPAGE

(a) Using a precision straightedge and feeler gauge,

measure the warpage of the contact surfaces of the

cylinder block and manifolds.

Maximum warpage:

0.08 mm (0.0032 in.)

If the warpage is greater than the maximum, replace

the cylinder head sub-assembly.

2. INSPECT CYLINDER HEAD FOR CRACKS

(a) Using a dye penetrant, inspect the combustion

chamber, intake ports, exhaust ports and cylinder

block surface for cracks.

If cracked, replace the cylinder head.

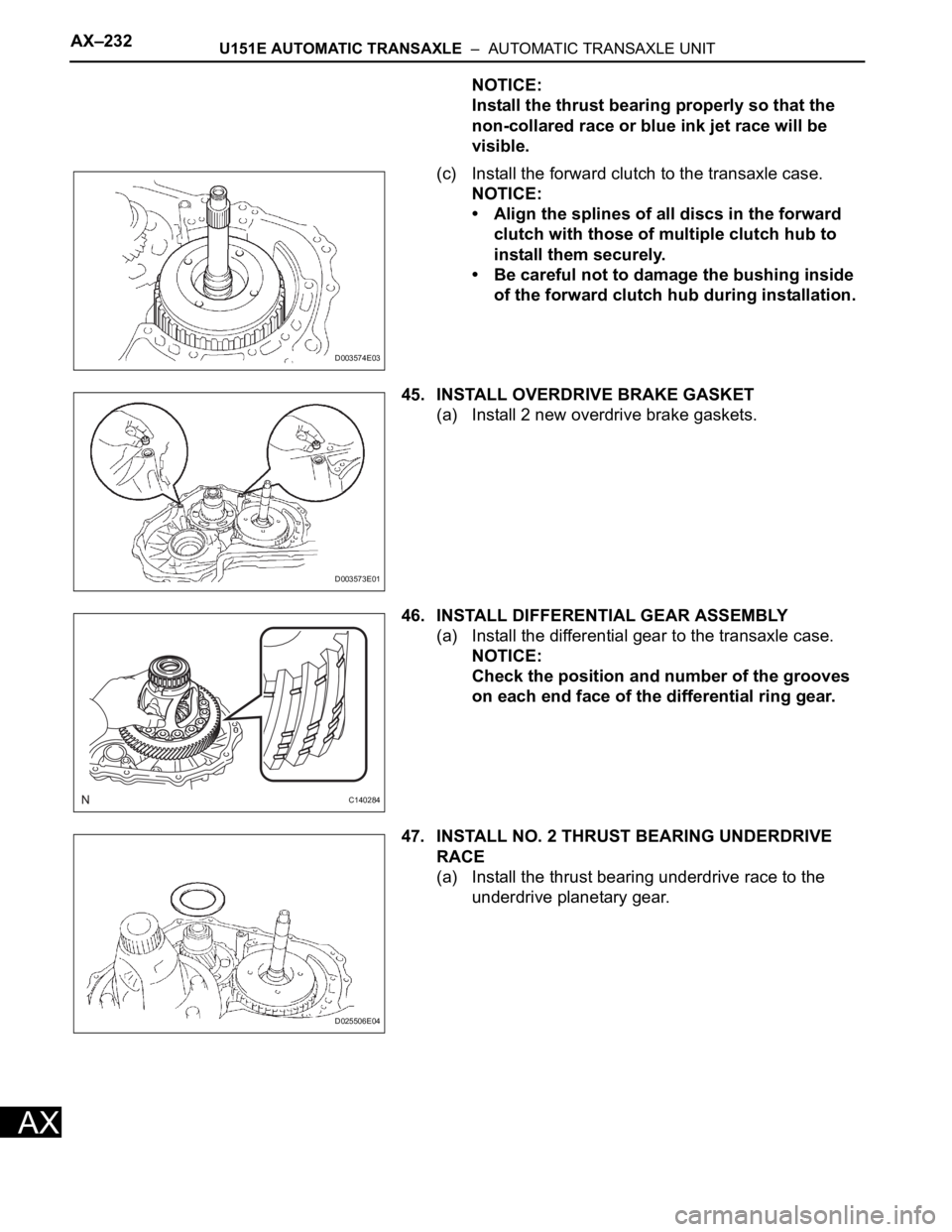

3. INSPECT VALVE SEAT

(a) Apply a light coat of Prussian blue to the valve face.

(b) Lightly press the valve against the seat.

NOTICE:

Do not turn the valve.

(c) Check the valve face and seat in accordance with

the following procedure.

(1) If blue appears 360

around the face, the valve

is concentric. If not, replace the valve.

(2) If blue appears 360

around the valve seat, the

guide and face are concentric. If not, resurface

the valve seat (see page EM-87).

(3) Check that the seat contact is in the middle of

the valve face with a width.

Standard width

A098134E01

A013365E01

A062786E02

Item Standard Condition

Intake 1.0 to 1.4 mm (0.0039 to 0.0551 in.)

Exhaust 1.2 to 1.6 mm (0.0472 to 0.0630 in.)

Page 724 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–87

EM

20. INSPECT INTAKE VALVE SEAT

(a) Apply a light coat of Prussian blue to the valve face.

(b) Lightly press the valve face against the valve seat.

(c) Check the valve face and valve seat by using the

following procedure.

(1) If Prussian blue appears around the entire

valve face, the valve face is concentric. If not,

replace the valve.

(2) If Prussian blue appears around the entire

valve seat, the guide and valve face are

concentric. If not, resurface the valve seat.

(3) Check that the valve seat contacts in the

middle of the valve face with the width between

1.1 and 1.5 mm (0.043 and 0.059 in.).

21. INSPECT EXHAUST VALVE SEAT

(a) Apply a light coat of Prussian blue to the valve face.

(b) Lightly press the valve face against the valve seat.

(c) Check the valve face and valve seat by using the

following procedure.

(1) If Prussian blue appears around the entire

valve face, the valve face is concentric. If not,

replace the valve.

(2) If Prussian blue appears around the entire

valve seat, the guide and valve face are

concentric. If not, resurface the valve seat.

(3) Check that the valve seat contacts in the

middle of the valve face with the width between

1.2 and 1.6 mm (0.047 and 0.063 in.).

22. INSPECT INNER COMPRESSION SPRING

(a) Using a vernier caliper, measure the free length of

the inner compression spring.

Standard free length:

45.46 mm (1.7898 in.)

If the free length is not as specified, replace the

spring.

(b) Using a steel square, measure the deviation of the

inner compression spring.

Maximum deviation:

1.0 mm (0.039 in.)

Maximum angle (reference):

2

If the deviation is greater than the maximum,

replace the spring.

A132152E01

A132152E01

A101392

A101393E02

Page 1003 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–209

AX

49. INSTALL MANUAL DETENT SPRING SUB-

ASSEMBLY

(a) Install the manual detent spring with the 2 bolts.

NOTICE:

Make sure to install the manual detent spring

and cover in this order.

Torque: 20 N*m (204 kgf*cm, 16 ft.*lbf) for bolt A

12 N*m (122 kgf*cm, 9 ft.*lbf) for bolt B

HINT:

Each bolt length is indicated below.

27 mm (1.063 in.) for bolt A

16 mm (0.630 in.) for bolt B

50. INSTALL B-3 ACCUMULATOR PISTON

(a) Coat a new O-ring with ATF, and install it to the B-3

accumulator piston.

(b) Coat the piston with ATF, install it to the transaxle.

Standard accumulator spring

51. INSTALL C-1 ACCUMULATOR PISTON

(a) Coat 2 new O-rings with ATF, and install them to the

C-1 accumulator piston.

D003560E01

D003904E05

D025512E02

Spring Free length

Outer diameterColor

B-3 Inner 60.24 mm (2.3716 in.)

15.9 (0.626 in.)Yellowish green

B-3 Outer 74.61 mm (2.9374 in.)

21.7 mm (0.854 in.)Blue

D003903E01

Page 1106 of 2000

AX–232U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

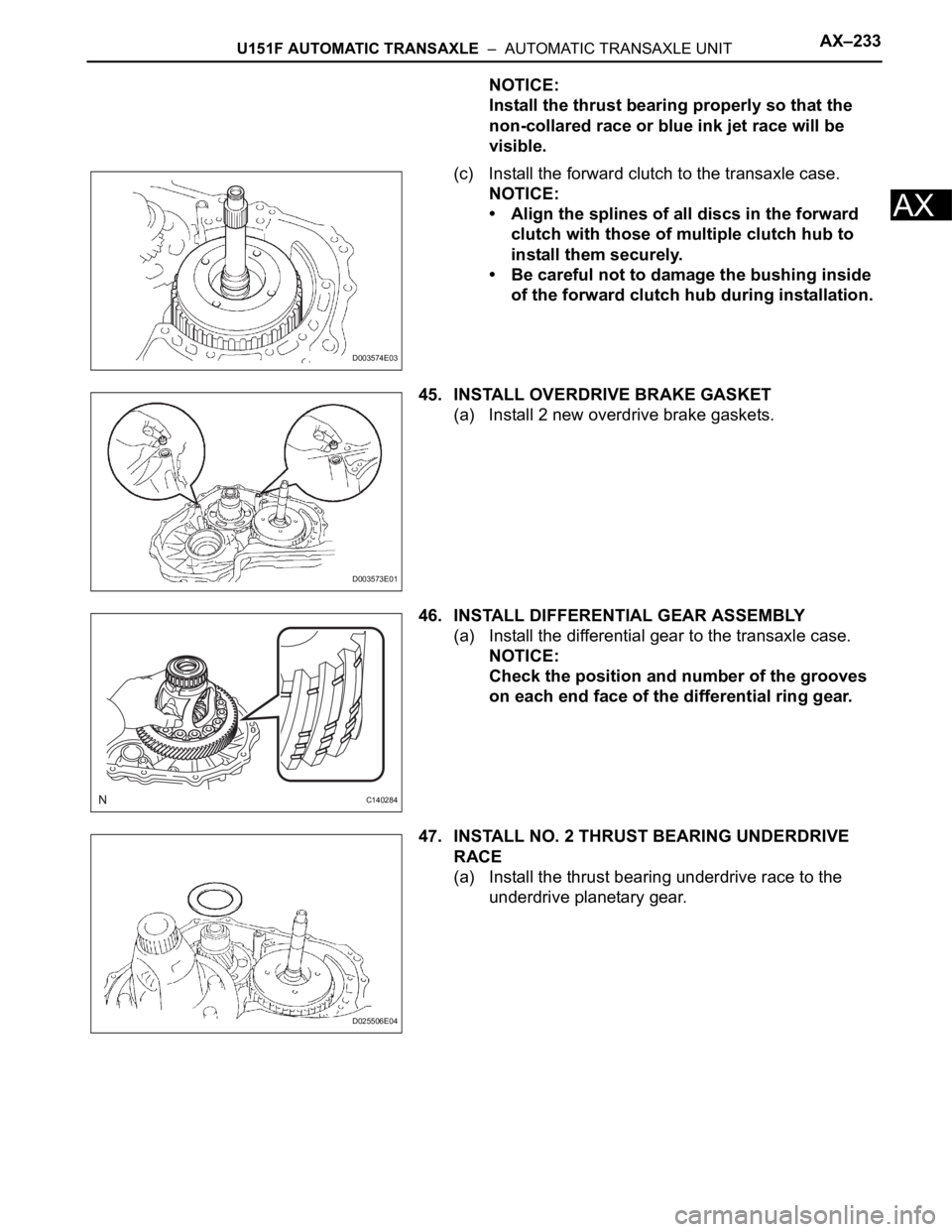

NOTICE:

Install the thrust bearing properly so that the

non-collared race or blue ink jet race will be

visible.

(c) Install the forward clutch to the transaxle case.

NOTICE:

• Align the splines of all discs in the forward

clutch with those of multiple clutch hub to

install them securely.

• Be careful not to damage the bushing inside

of the forward clutch hub during installation.

45. INSTALL OVERDRIVE BRAKE GASKET

(a) Install 2 new overdrive brake gaskets.

46. INSTALL DIFFERENTIAL GEAR ASSEMBLY

(a) Install the differential gear to the transaxle case.

NOTICE:

Check the position and number of the grooves

on each end face of the differential ring gear.

47. INSTALL NO. 2 THRUST BEARING UNDERDRIVE

RACE

(a) Install the thrust bearing underdrive race to the

underdrive planetary gear.

D003574E03

D003573E01

C140284

D025506E04

Page 1211 of 2000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–233

AX

NOTICE:

Install the thrust bearing properly so that the

non-collared race or blue ink jet race will be

visible.

(c) Install the forward clutch to the transaxle case.

NOTICE:

• Align the splines of all discs in the forward

clutch with those of multiple clutch hub to

install them securely.

• Be careful not to damage the bushing inside

of the forward clutch hub during installation.

45. INSTALL OVERDRIVE BRAKE GASKET

(a) Install 2 new overdrive brake gaskets.

46. INSTALL DIFFERENTIAL GEAR ASSEMBLY

(a) Install the differential gear to the transaxle case.

NOTICE:

Check the position and number of the grooves

on each end face of the differential ring gear.

47. INSTALL NO. 2 THRUST BEARING UNDERDRIVE

RACE

(a) Install the thrust bearing underdrive race to the

underdrive planetary gear.

D003574E03

D003573E01

C140284

D025506E04

Page 1315 of 2000

U241E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–211

AX

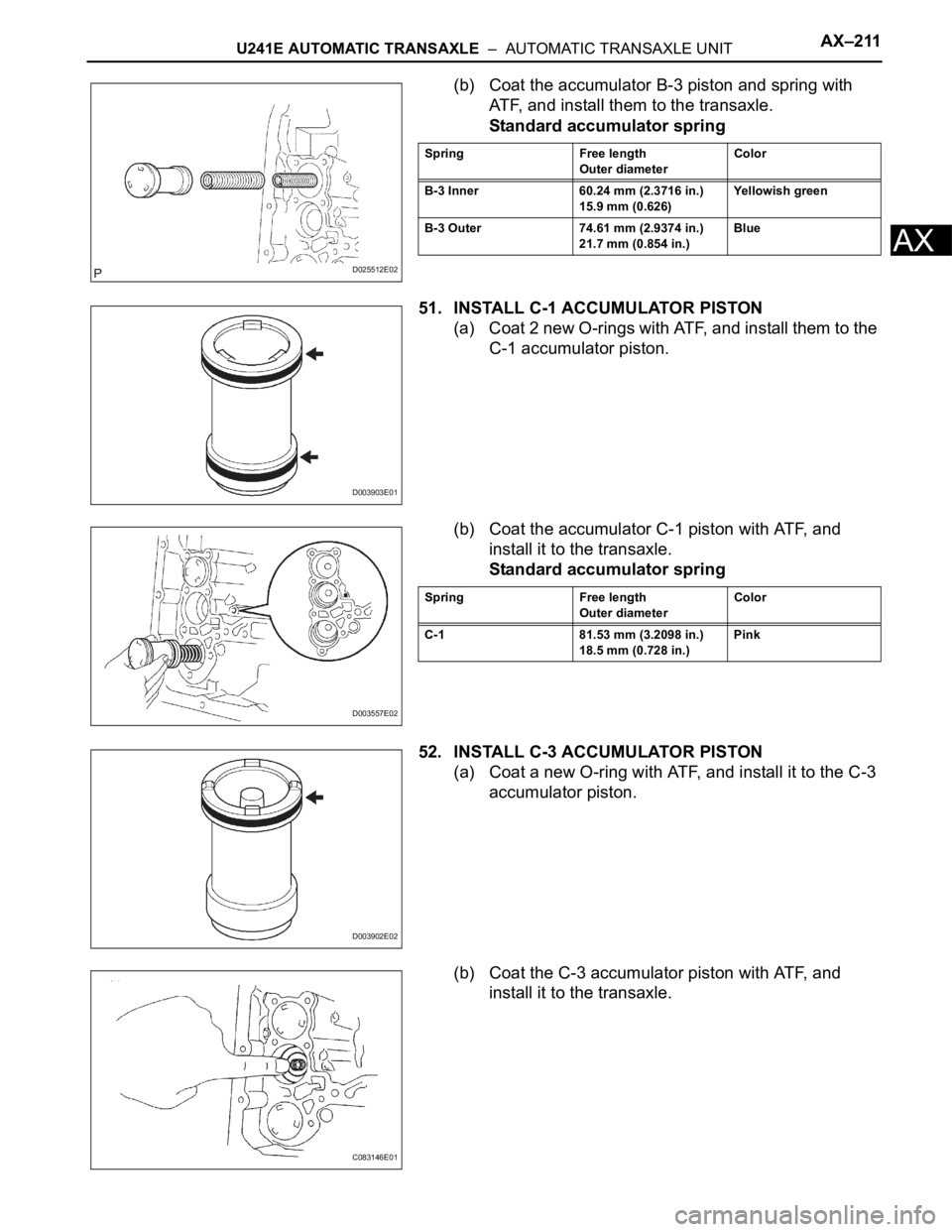

(b) Coat the accumulator B-3 piston and spring with

ATF, and install them to the transaxle.

Standard accumulator spring

51. INSTALL C-1 ACCUMULATOR PISTON

(a) Coat 2 new O-rings with ATF, and install them to the

C-1 accumulator piston.

(b) Coat the accumulator C-1 piston with ATF, and

install it to the transaxle.

Standard accumulator spring

52. INSTALL C-3 ACCUMULATOR PISTON

(a) Coat a new O-ring with ATF, and install it to the C-3

accumulator piston.

(b) Coat the C-3 accumulator piston with ATF, and

install it to the transaxle.

D025512E02

Spring Free length

Outer diameterColor

B-3 Inner 60.24 mm (2.3716 in.)

15.9 mm (0.626)Yellowish green

B-3 Outer 74.61 mm (2.9374 in.)

21.7 mm (0.854 in.)Blue

D003903E01

D003557E02

Spring Free length

Outer diameterColor

C-1 81.53 mm (3.2098 in.)

18.5 mm (0.728 in.)Pink

D003902E02

C083146E01

Page 1438 of 2000

DF–34DIFFERENTIAL – REAR DIFFERENTIAL CARRIER ASSEMBLY

DF

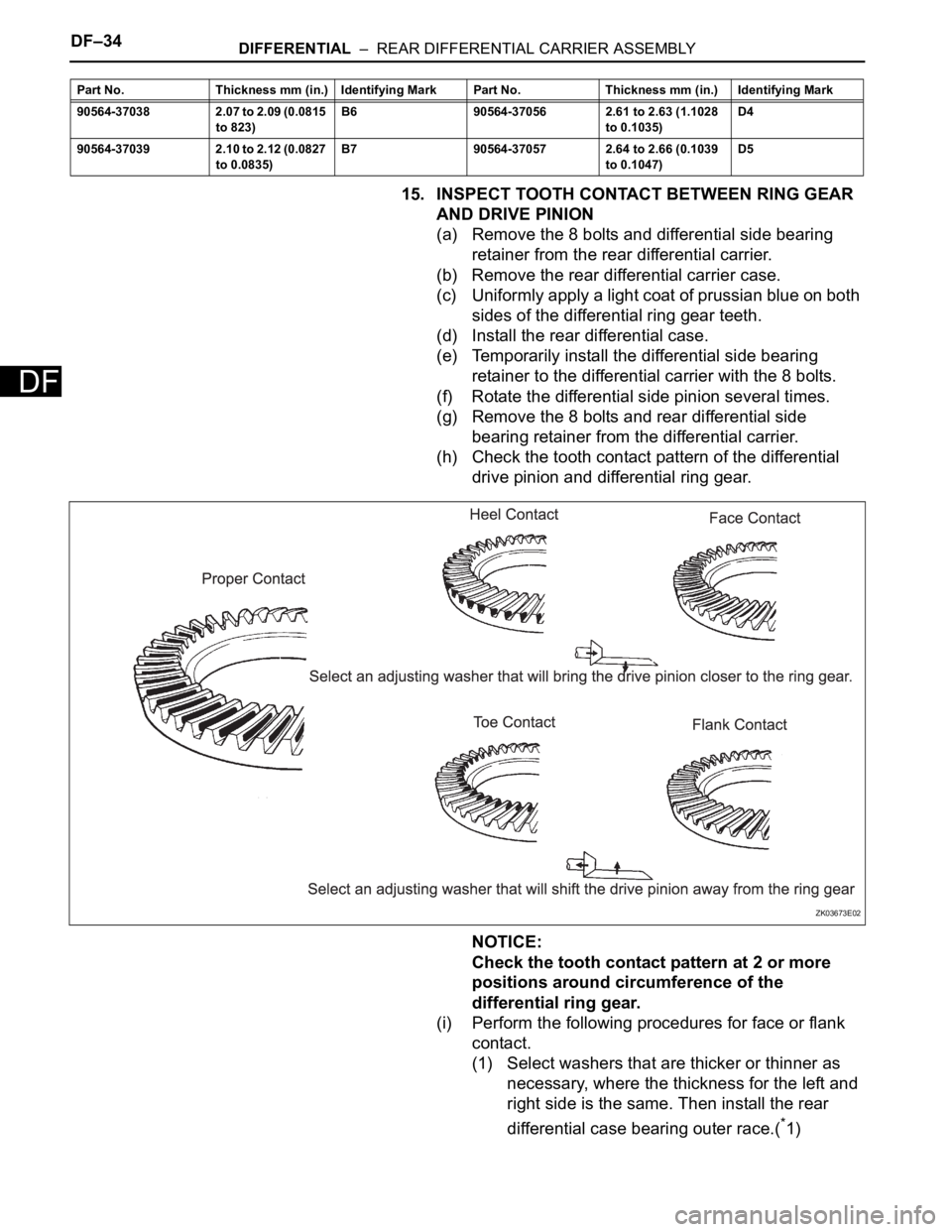

15. INSPECT TOOTH CONTACT BETWEEN RING GEAR

AND DRIVE PINION

(a) Remove the 8 bolts and differential side bearing

retainer from the rear differential carrier.

(b) Remove the rear differential carrier case.

(c) Uniformly apply a light coat of prussian blue on both

sides of the differential ring gear teeth.

(d) Install the rear differential case.

(e) Temporarily install the differential side bearing

retainer to the differential carrier with the 8 bolts.

(f) Rotate the differential side pinion several times.

(g) Remove the 8 bolts and rear differential side

bearing retainer from the differential carrier.

(h) Check the tooth contact pattern of the differential

drive pinion and differential ring gear.

NOTICE:

Check the tooth contact pattern at 2 or more

positions around circumference of the

differential ring gear.

(i) Perform the following procedures for face or flank

contact.

(1) Select washers that are thicker or thinner as

necessary, where the thickness for the left and

right side is the same. Then install the rear

differential case bearing outer race.(

*1)

90564-37038 2.07 to 2.09 (0.0815

to 823)B6 90564-37056 2.61 to 2.63 (1.1028

to 0.1035)D4

90564-37039 2.10 to 2.12 (0.0827

to 0.0835)B7 90564-37057 2.64 to 2.66 (0.1039

to 0.1047)D5 Part No. Thickness mm (in.) Identifying Mark Part No. Thickness mm (in.) Identifying Mark

ZK03673E02