air conditioning TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 4 of 2000

ENGINE - 2AZ-FE ENGINE

DR011EG22 01NEG26Y

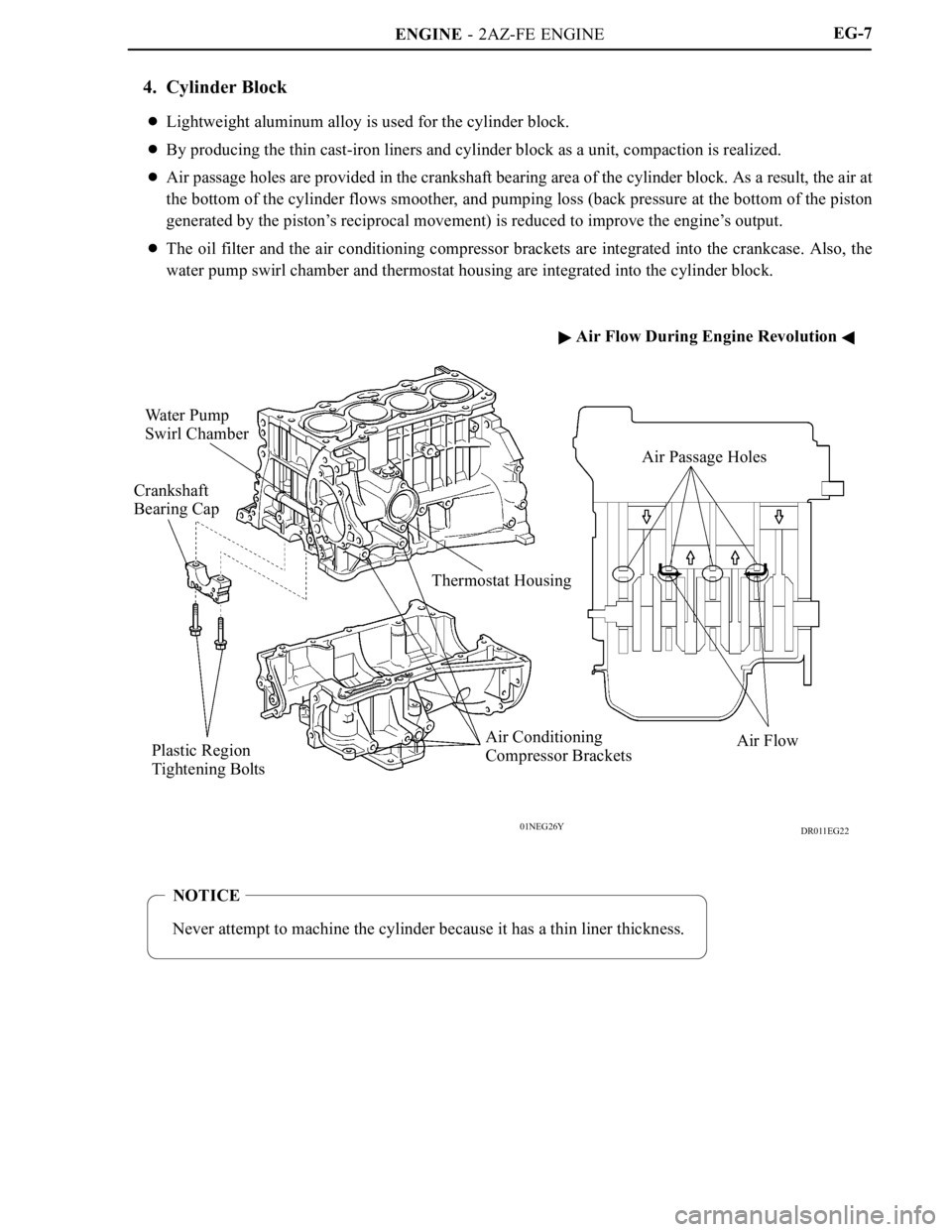

Air Flow During Engine Revolution

Wa t e r P u m p

Swirl Chamber

Crankshaft

Bearing Cap

Plastic Region

Tightening BoltsThermostat Housing

Air Conditioning

Compressor BracketsAir Passage Holes

Air Flow

NOTICE

Never attempt to machine the cylinder because it has a thin liner thickness.

EG-7

4. Cylinder Block

Lightweight aluminum alloy is used for the cylinder block.

By producing the thin cast-iron liners and cylinder block as a unit, compaction is realized.

Air passage holes are provided in the crankshaft bearing area of the cylinder block. As a result, the air at

the bottom of the cylinder flows smoother, and pumping loss (back pressure at the bottom of the piston

generated by the piston’s reciprocal movement) is reduced to improve the engine’s output.

The oil filter and the air conditioning compressor brackets are integrated into the crankcase. Also, the

water pump swirl chamber and thermostat housing are integrated into the cylinder block.

Page 26 of 2000

ENGINE - 2AZ-FE ENGINE

240EG98

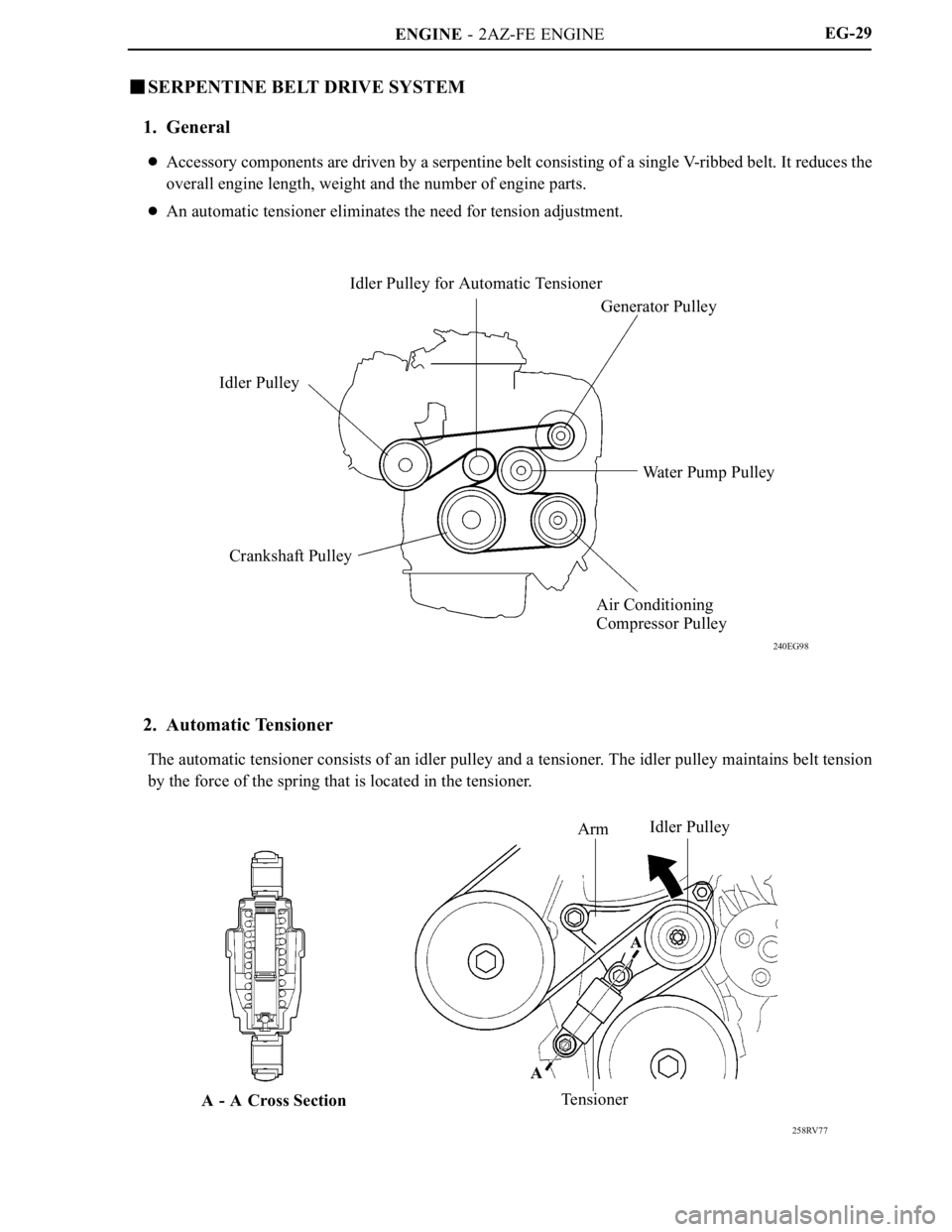

Idler Pulley for Automatic Tensioner

Generator Pulley

Water Pump Pulley

Air Conditioning

Compressor Pulley Crankshaft Pulley Idler Pulley

258RV77

ArmIdler Pulley

Te n s i o n e r

A - A Cross SectionAAEG-29

SERPENTINE BELT DRIVE SYSTEM

1. General

Accessory components are driven by a serpentine belt consisting of a single V-ribbed belt. It reduces the

overall engine length, weight and the number of engine parts.

An automatic tensioner eliminates the need for tension adjustment.

2. Automatic Tensioner

The automatic tensioner consists of an idler pulley and a tensioner. The idler pulley maintains belt tension

by the force of the spring that is located in the tensioner.

Page 27 of 2000

ENGINE - 2AZ-FE ENGINE EG-30

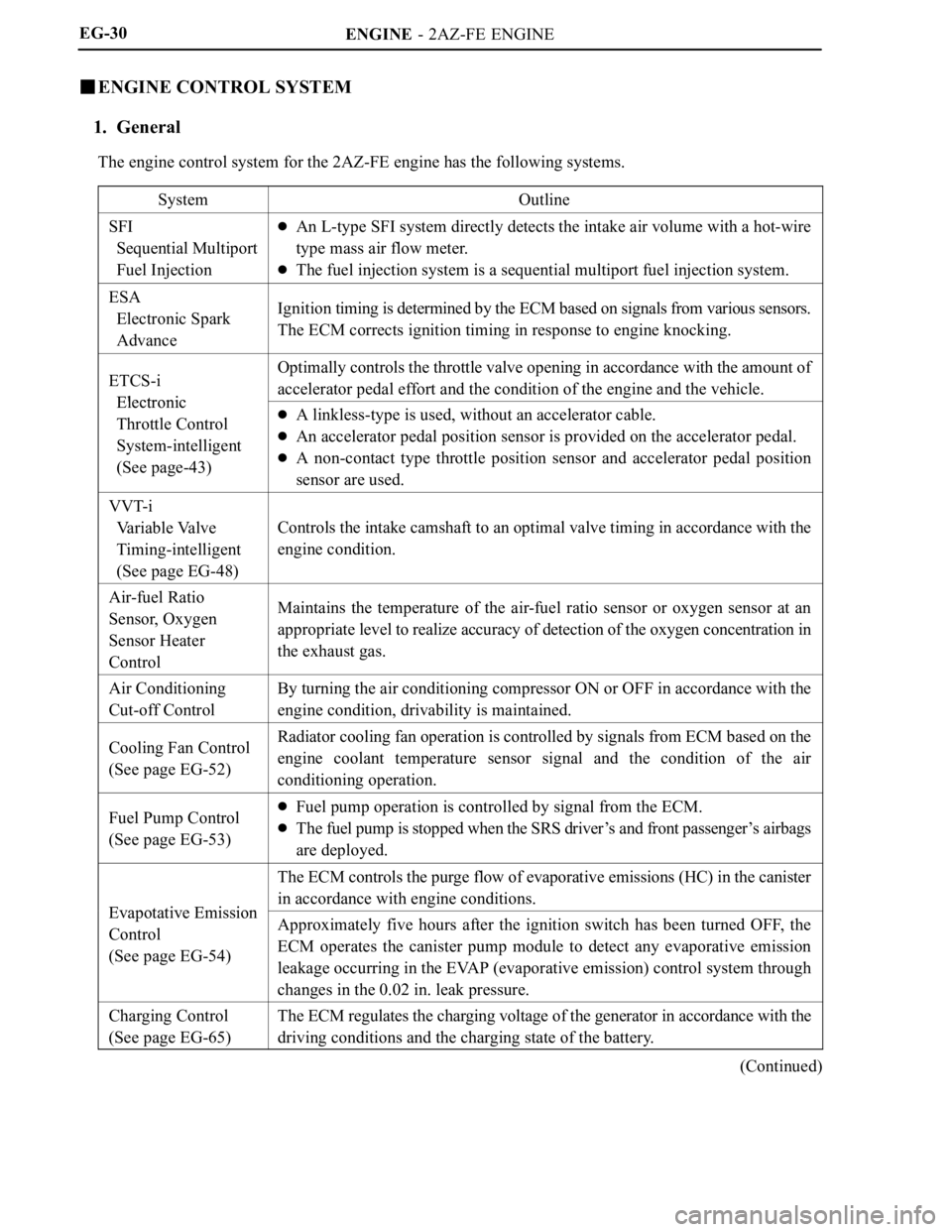

ENGINE CONTROL SYSTEM

1. General

The engine control system for the 2AZ-FE engine has the following systems.

System

Outline

SFI

Sequential Multiport

Fuel InjectionAn L-type SFI system directly detects the intake air volume with a hot-wire

type mass air flow meter.

The fuel injection system is a sequential multiport fuel injection system.

ESA

Electronic Spark

AdvanceIgnition timing is determined by the ECM based on signals from various sensors.

The ECM corrects ignition timing in response to engine knocking.

ETCS-i

Electronic

Optimally controls the throttle valve opening in accordance with the amount of

accelerator pedal effort and the condition of the engine and the vehicle.

Electronic

Throttle Control

System-intelligent

(See page-43)A linkless-type is used, without an accelerator cable.

An accelerator pedal position sensor is provided on the accelerator pedal.

A non-contact type throttle position sensor and accelerator pedal position

sensor are used.

VVT-i

Va r i a b l e Va l v e

Timing-intelligent

(See page EG-48)

Controls the intake camshaft to an optimal valve timing in accordance with the

engine condition.

Air-fuel Ratio

Sensor, Oxygen

Sensor Heater

ControlMaintains the temperature of the air-fuel ratio sensor or oxygen sensor at an

appropriate level to realize accuracy of detection of the oxygen concentration in

the exhaust gas.

Air Conditioning

Cut-off ControlBy turning the air conditioning compressor ON or OFF in accordance with the

engine condition, drivability is maintained.

Cooling Fan Control

(See page EG-52)Radiator cooling fan operation is controlled by signals from ECM based on the

engine coolant temperature sensor signal and the condition of the air

conditioning operation.

Fuel Pump Control

(See page EG-53)Fuel pump operation is controlled by signal from the ECM.

The fuel pump is stopped when the SRS driver’s and front passenger’s airbags

are deployed.

Evapotative Emission

The ECM controls the purge flow of evaporative emissions (HC) in the canister

in accordance with engine conditions.

Evapotative Emission

Control

(See page EG-54)Approximately five hours after the ignition switch has been turned OFF, the

ECM operates the canister pump module to detect any evaporative emission

leakage occurring in the EVAP (evaporative emission) control system through

changes in the 0.02 in. leak pressure.

Charging Control

(See page EG-65)The ECM regulates the charging voltage of the generator in accordance with the

driving conditions and the charging state of the battery.

(Continued)

Page 30 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG05Y

DEFGGER SWITCH

TA I L L I G H T S W I T C H

STOP LIGHT SWITCH

CURRENT SENSOR

CANISTER PUMP MODULE

CANISTER PRESSURE

SENSOR

TRANSPONDER KEY ECU*

AIRBAG SENSOR ASSEMBLY

EPS ECU

AIR CONDITIONING ECU

SKID CONTROL ECU

DLC3

BATTERYELS1

ELS3

STP

ST1-

THB

VCIB

PPMP

IMI

IMO

CANH,

CANL

TC

TA C H

BATTECMFA N H

FA N L

MPMP

VPMP

PRG

RLO

DF

MREL

+B

WCOOLING FAN CONTROL

COOLING FAN RELAY No.1

COOLING FAN RELAY No.2

COOLING FAN RELAY No.3

EVAPORATIVE EMISSION

CONTROL

CANISTER PUMP MODULE

LEAK DETECTION PUMP

VENT VALVE

GENERATOR

MAIN RELAY

COMBINATION METER

MIL

PURGE VSV

: CANEG-33

*: Models with Engine Immobilizer System

Page 49 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG09Y

01NEG10Y

Air

Conditioning

ECU

Engine Coolant

Temperature SensorFANL

ECM

FA N HCooling Fan

Relay No.3

Cooling Fan

Motor No.2

Cooling Fan

Relay No.1

Cooling Fan

Motor No.1

Low Speed (Series Connection)

High Speed (Parallel Connection) Air

Conditioning

ECU

Engine Coolant

Temperature SensorFA N L

ECM

FA N HCooling Fan

Relay No.3

Cooling Fan

Motor No.2

Cooling Fan

Relay No.1

Cooling Fan

Relay No.2

Cooling Fan

Motor No.1 : CAN

Cooling Fan

Relay No.2

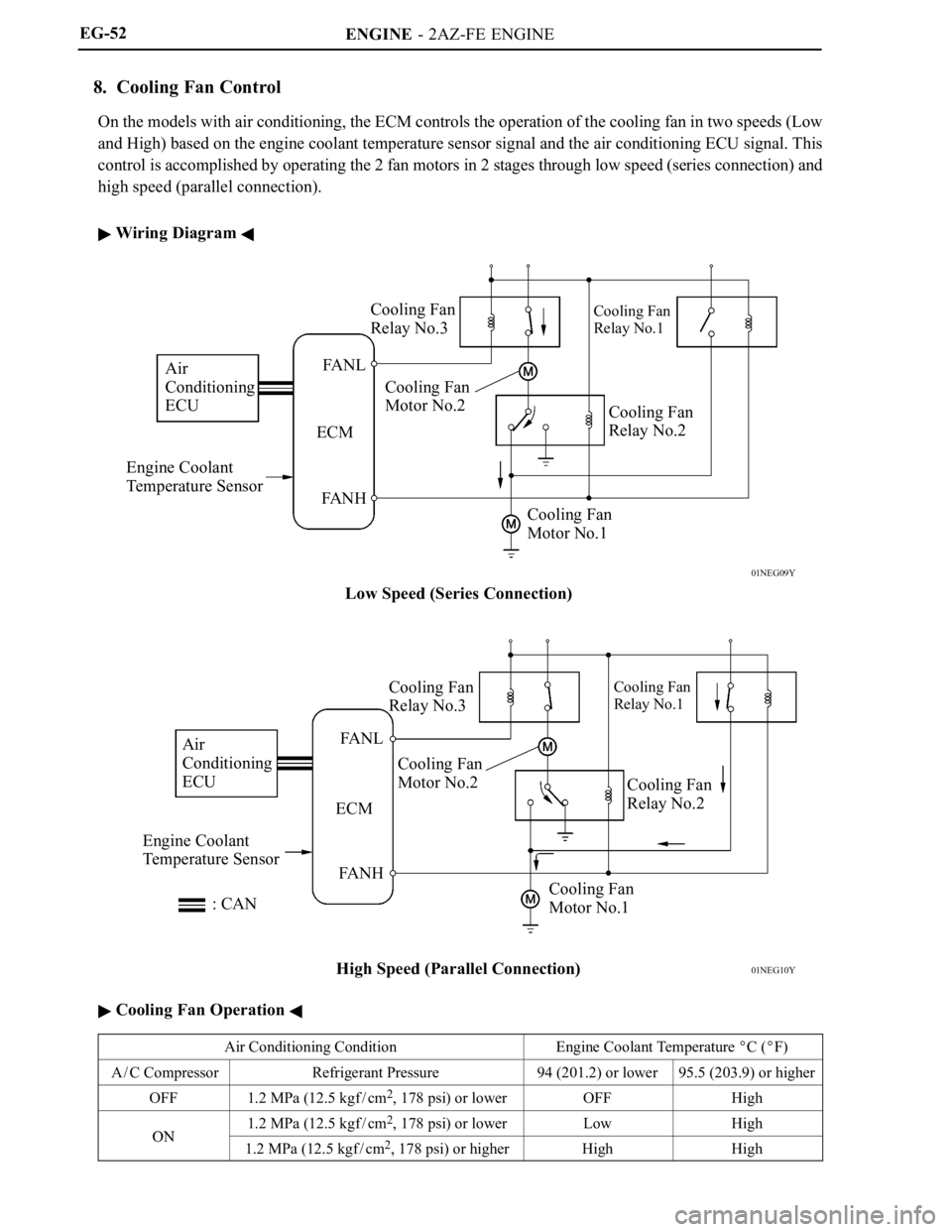

EG-52

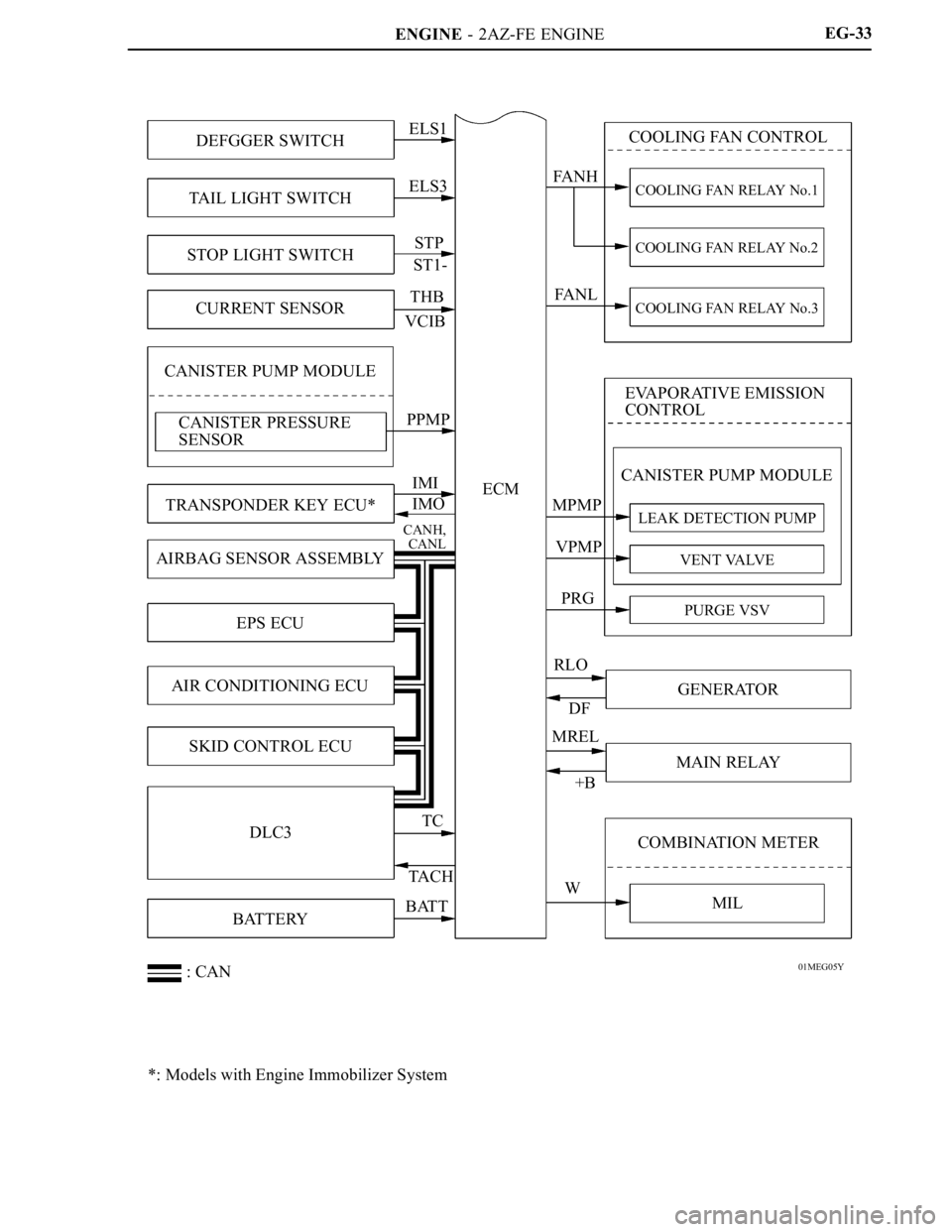

8. Cooling Fan Control

On the models with air conditioning, the ECM controls the operation of the cooling fan in two speeds (Low

and High) based on the engine coolant temperature sensor signal and the air conditioning ECU signal. This

control is accomplished by operating the 2 fan motors in 2 stages through low speed (series connection) and

high speed (parallel connection).

Wiring Diagram

Cooling Fan Operation

Air Conditioning ConditionEngine Coolant Temperature C (F)

A / C CompressorRefrigerant Pressure94 (201.2) or lower95.5 (203.9) or higher

OFF1.2 MPa (12.5 kgf / cm2, 178 psi) or lowerOFFHigh

ON1.2 MPa (12.5 kgf / cm2, 178 psi) or lowerLowHighON1.2 MPa (12.5 kgf / cm2, 178 psi) or higherHighHigh

Page 96 of 2000

ENGINE - 2GR-FE ENGINE

01MEG38Y

Water Pump Pulley

Crankshaft Pulley

Air Conditioning

Compressor PulleyIdler Pulley for

Automatic

Te n s i o n e rGenerator Pulley Belt Idler

285EG78

Idler

PulleySpring

Arm

BracketBelt Pulling

Direction

Belt Tension

Direction

Fulcrum

Cross Section EG-98

STARTING SYSTEM

The 2GR-FE engine uses the same starter as the 2AZ-FE engine. For details, see page EG-27.

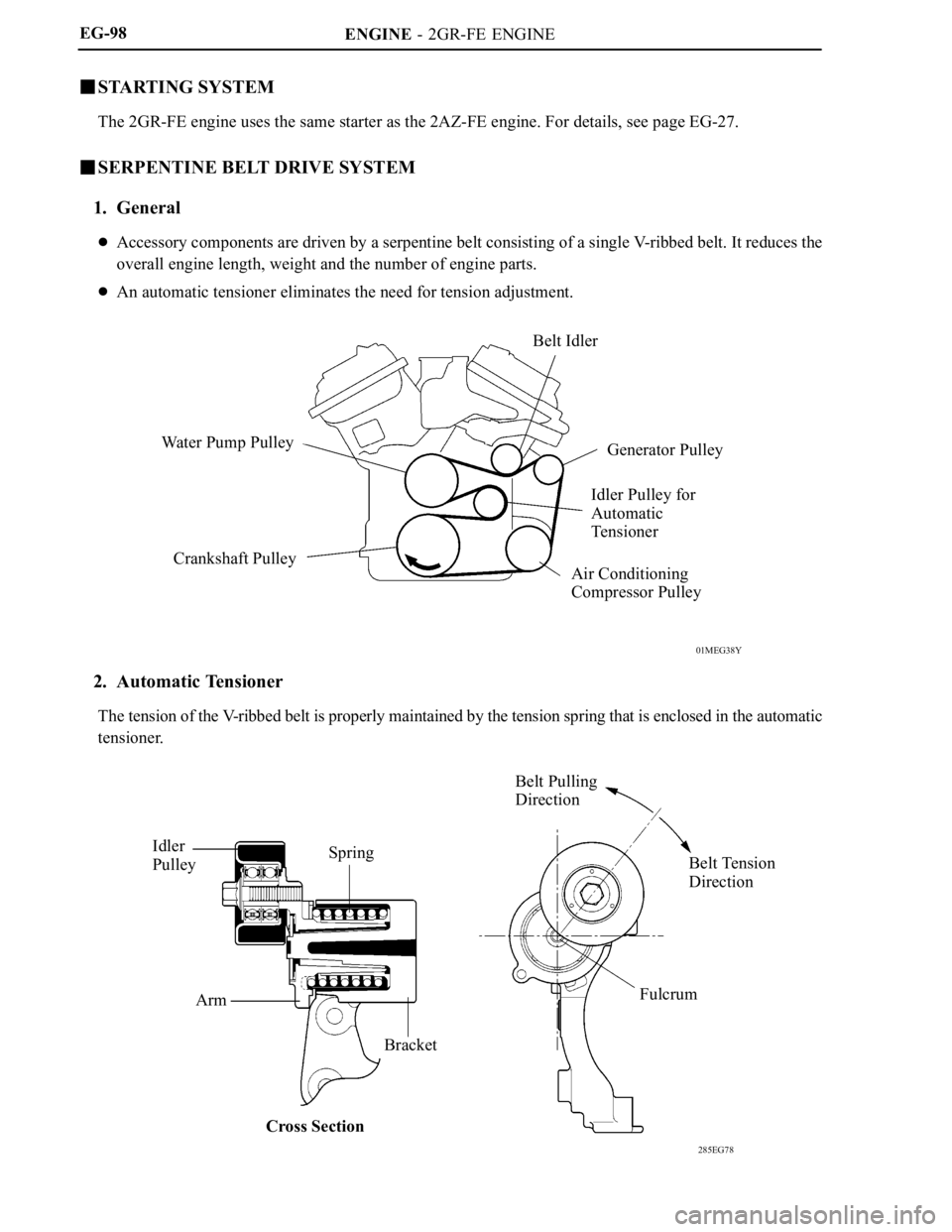

SERPENTINE BELT DRIVE SYSTEM

1. General

Accessory components are driven by a serpentine belt consisting of a single V-ribbed belt. It reduces the

overall engine length, weight and the number of engine parts.

An automatic tensioner eliminates the need for tension adjustment.

2. Automatic Tensioner

The tension of the V-ribbed belt is properly maintained by the tension spring that is enclosed in the automatic

tensioner.

Page 97 of 2000

ENGINE - 2GR-FE ENGINEEG-101

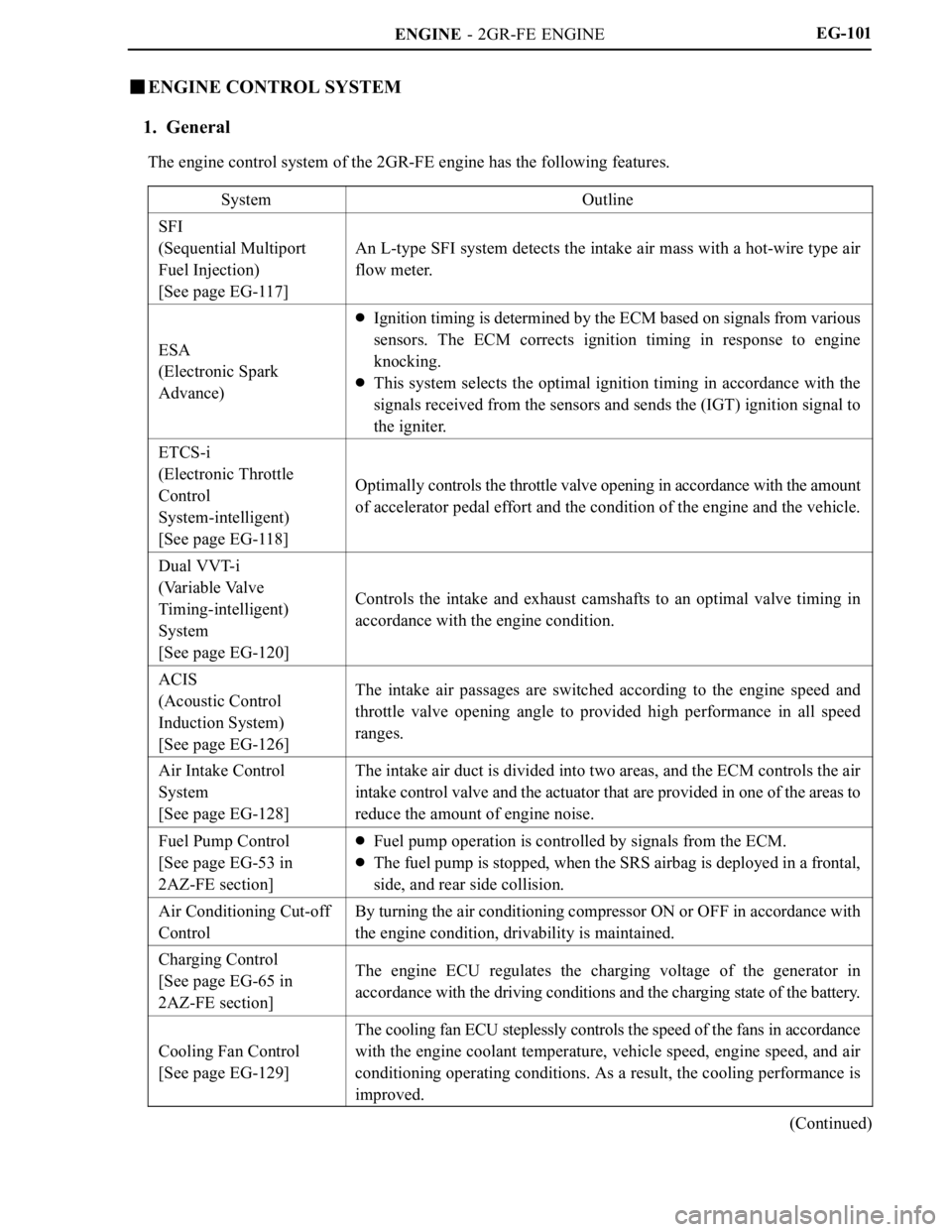

ENGINE CONTROL SYSTEM

1. General

The engine control system of the 2GR-FE engine has the following features.

System

Outline

SFI

(Sequential Multiport

Fuel Injection)

[See page EG-117]

An L-type SFI system detects the intake air mass with a hot-wire type air

flow meter.

ESA

(Electronic Spark

Advance)

Ignition timing is determined by the ECM based on signals from various

sensors. The ECM corrects ignition timing in response to engine

knocking.

This system selects the optimal ignition timing in accordance with the

signals received from the sensors and sends the (IGT) ignition signal to

the igniter.

ETCS-i

(Electronic Throttle

Control

System-intelligent)

[See page EG-118]

Optimally controls the throttle valve opening in accordance with the amount

of accelerator pedal effort and the condition of the engine and the vehicle.

Dual VVT-i

(Variable Valve

Timing-intelligent)

System

[See page EG-120]

Controls the intake and exhaust camshafts to an optimal valve timing in

accordance with the engine condition.

ACIS

(Acoustic Control

Induction System)

[See page EG-126]The intake air passages are switched according to the engine speed and

throttle valve opening angle to provided high performance in all speed

ranges.

Air Intake Control

System

[See page EG-128]The intake air duct is divided into two areas, and the ECM controls the air

intake control valve and the actuator that are provided in one of the areas to

reduce the amount of engine noise.

Fuel Pump Control

[See page EG-53 in

2AZ-FE section]Fuel pump operation is controlled by signals from the ECM.

The fuel pump is stopped, when the SRS airbag is deployed in a frontal,

side, and rear side collision.

Air Conditioning Cut-off

ControlBy turning the air conditioning compressor ON or OFF in accordance with

the engine condition, drivability is maintained.

Charging Control

[See page EG-65 in

2AZ-FE section]The engine ECU regulates the charging voltage of the generator in

accordance with the driving conditions and the charging state of the battery.

Cooling Fan Control

[See page EG-129]

The cooling fan ECU steplessly controls the speed of the fans in accordance

with the engine coolant temperature, vehicle speed, engine speed, and air

conditioning operating conditions. As a result, the cooling performance is

improved.

(Continued)

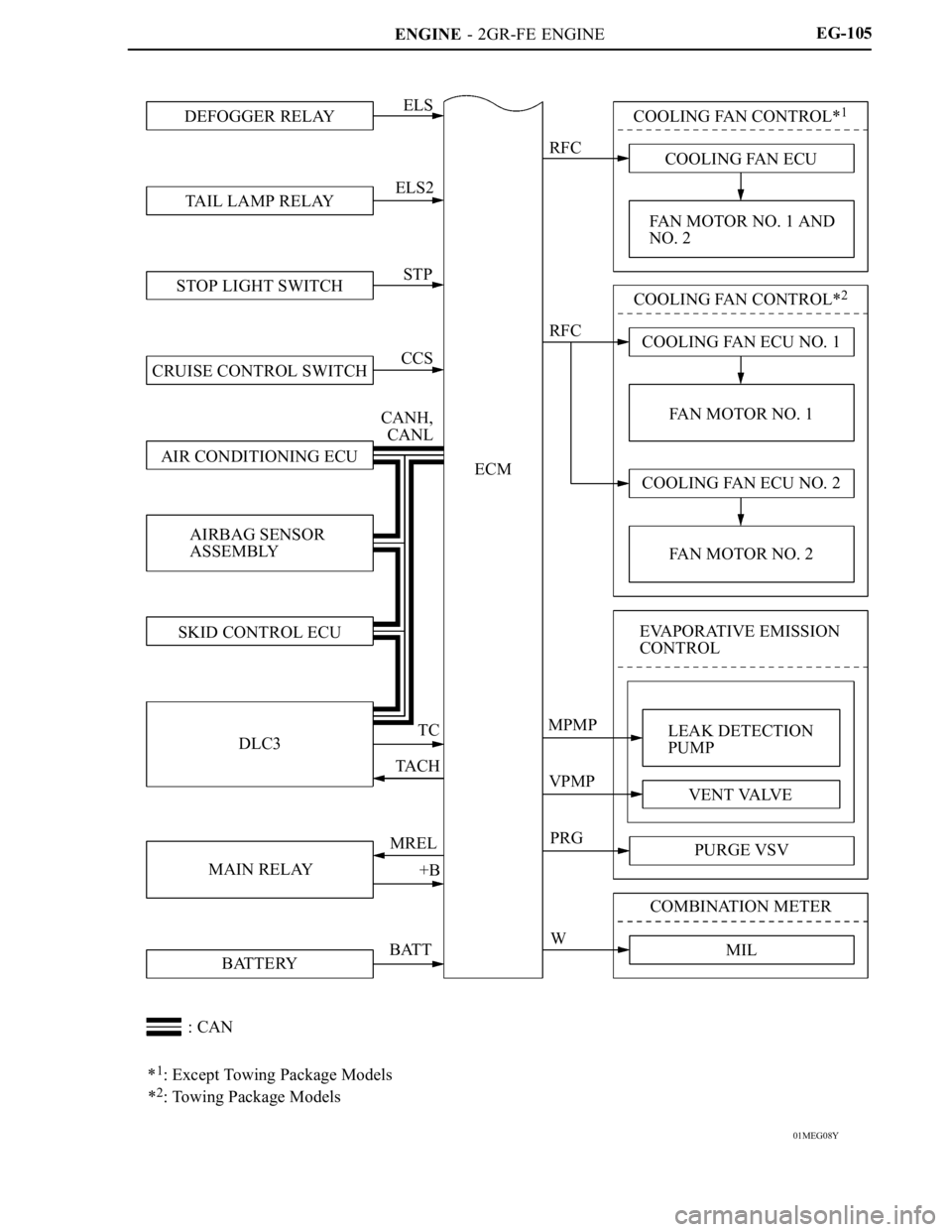

Page 101 of 2000

ENGINE - 2GR-FE ENGINE

01MEG08Y

DEFOGGER RELAY

TA I L L A M P R E L AY

STOP LIGHT SWITCH

CRUISE CONTROL SWITCH

AIR CONDITIONING ECU

AIRBAG SENSOR

ASSEMBLY

SKID CONTROL ECU

DLC3

MAIN RELAY

BATTERYELS

ELS2

STP

CCS

CANH,

CANL

TC

TA C H

MREL

+B

BATTECMRFC

RFC

MPMP

VPMP

PRG

WCOOLING FAN CONTROL*1

COOLING FAN ECU

FAN MOTOR NO. 1 AND

NO. 2

COOLING FAN CONTROL*

2

COOLING FAN ECU NO. 1

FAN MOTOR NO. 1

COOLING FAN ECU NO. 2

FAN MOTOR NO. 2

EVAPORATIVE EMISSION

CONTROL

LEAK DETECTION

PUMP

VENT VALVE

PURGE VSV

COMBINATION METER

MIL

: CANEG-105

*

1: Except Towing Package Models

*

2: Towing Package Models

Page 102 of 2000

ENGINE - 2GR-FE ENGINE

01MEG29Y

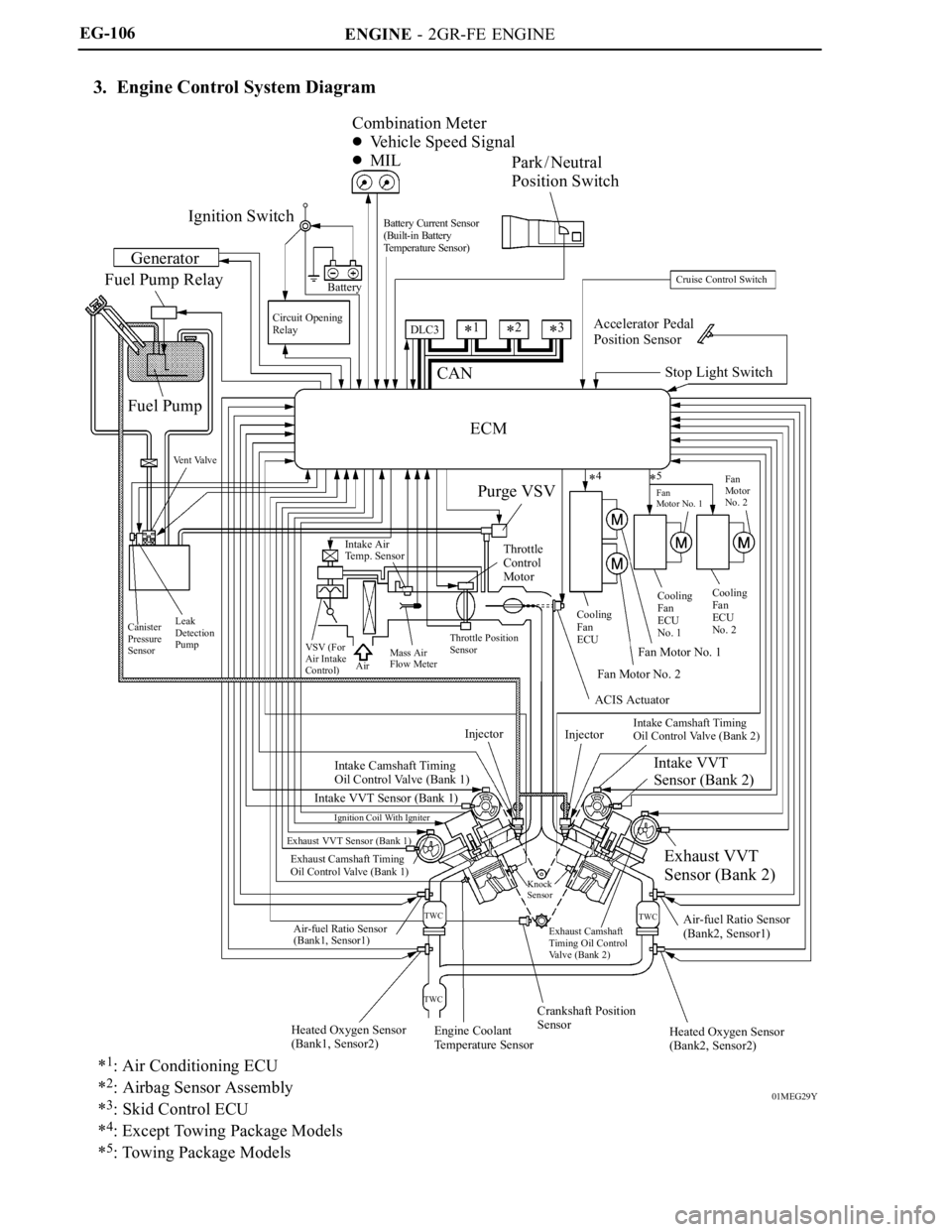

Ignition SwitchCombination Meter

Vehicle Speed Signal

MIL

Battery Current Sensor

(Built-in Battery

Temperature Sensor)

Park / Neutral

Position Switch

Battery

Generator

Fuel Pump Relay

Fuel Pump

Vent Valve

Circuit Opening

RelayDLC3*1*2*3

CAN

ECM

Cruise Control Switch

Accelerator Pedal

Position Sensor

Stop Light Switch

Canister

Pressure

SensorLeak

Detection

Pump

Intake Air

Temp. Sensor

VSV (For

Air Intake

Control)Mass Air

Flow Meter

AirThrottle Position

Sensor

Purge VSV

Throttle

Control

Motor

*4*5

Fan

Motor No. 1Fan

Motor

No. 2

Cooling

Fan

ECUCooling

Fan

ECU

No. 1Cooling

Fan

ECU

No. 2

Fan Motor No. 1

Fan Motor No. 2

ACIS Actuator

Intake Camshaft Timing

Oil Control Valve (Bank 2)Injector Injector

Intake Camshaft Timing

Oil Control Valve (Bank 1)

Intake VVT Sensor (Bank 1)

Ignition Coil With Igniter

Exhaust VVT Sensor (Bank 1)

Exhaust Camshaft Timing

Oil Control Valve (Bank 1)

Air-fuel Ratio Sensor

(Bank1, Sensor1)

TWC

Knock

Sensor

Intake VVT

Sensor (Bank 2)

Exhaust VVT

Sensor (Bank 2)

Air-fuel Ratio Sensor

(Bank2, Sensor1)Exhaust Camshaft

Timing Oil Control

Valve (Bank 2)

Crankshaft Position

Sensor

Engine Coolant

Temperature Sensor Heated Oxygen Sensor

(Bank1, Sensor2)Heated Oxygen Sensor

(Bank2, Sensor2)TWCTWC

EG-106

3. Engine Control System Diagram

*1: Air Conditioning ECU

*

2: Airbag Sensor Assembly

*

3: Skid Control ECU

*

4: Except Towing Package Models

*

5: Towing Package Models

Page 125 of 2000

ENGINE - 2GR-FE ENGINE

01MEG21Y

01MEG22Y

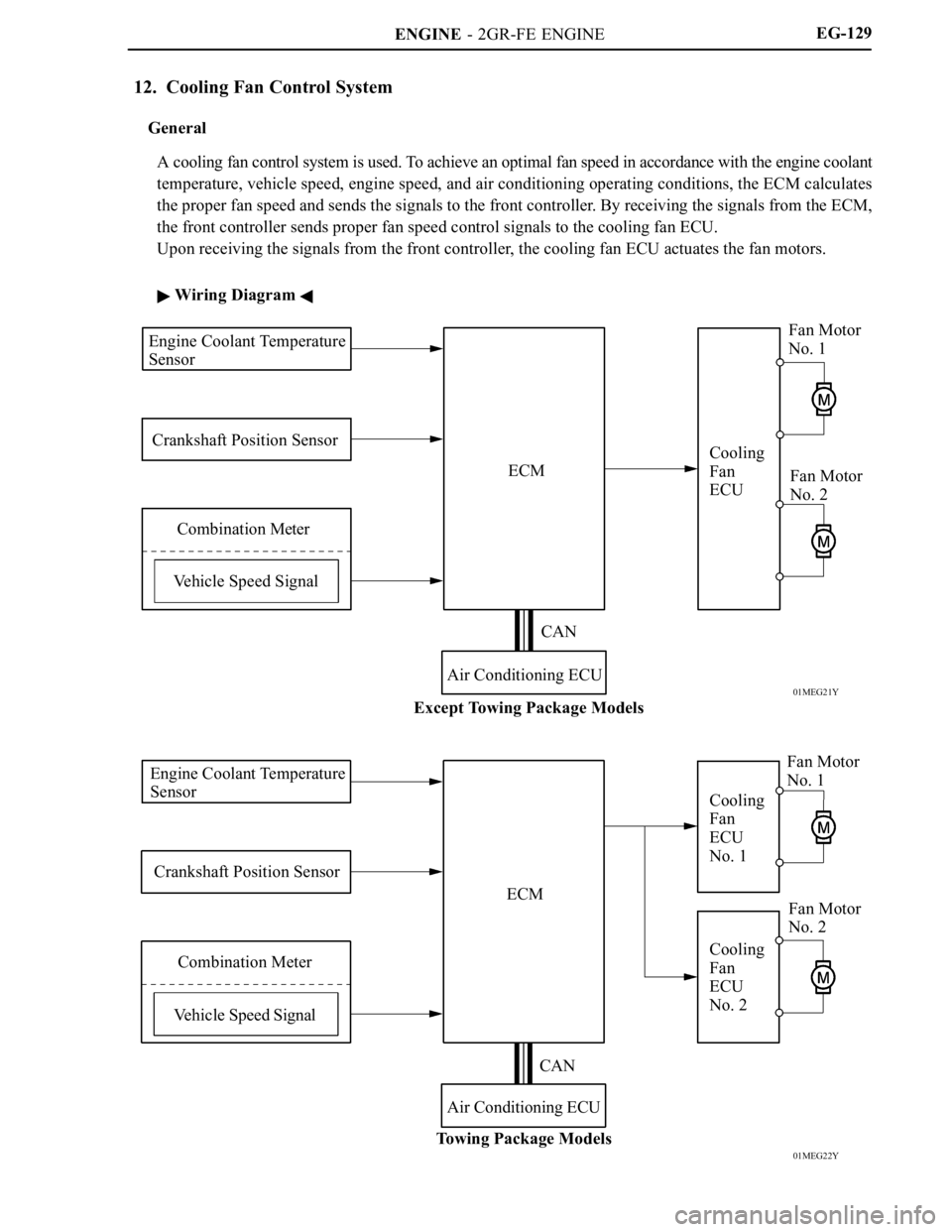

Engine Coolant Temperature

Sensor

Crankshaft Position Sensor

Combination Meter

Vehicle Speed SignalECM

CAN

Air Conditioning ECUCooling

Fan

ECUFan Motor

No. 1

Fan Motor

No. 2

Except Towing Package Models

Towing Package Models Engine Coolant Temperature

Sensor

Crankshaft Position Sensor

Combination Meter

Vehicle Speed SignalECM

CAN

Air Conditioning ECUCooling

Fan

ECU

No. 1

Cooling

Fan

ECU

No. 2Fan Motor

No. 1

Fan Motor

No. 2EG-129

12. Cooling Fan Control System

General

A cooling fan control system is used. To achieve an optimal fan speed in accordance with the engine coolant

temperature, vehicle speed, engine speed, and air conditioning operating conditions, the ECM calculates

the proper fan speed and sends the signals to the front controller. By receiving the signals from the ECM,

the front controller sends proper fan speed control signals to the cooling fan ECU.

Upon receiving the signals from the front controller, the cooling fan ECU actuates the fan motors.

Wiring Diagram