compression ratio TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 66 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG02Y

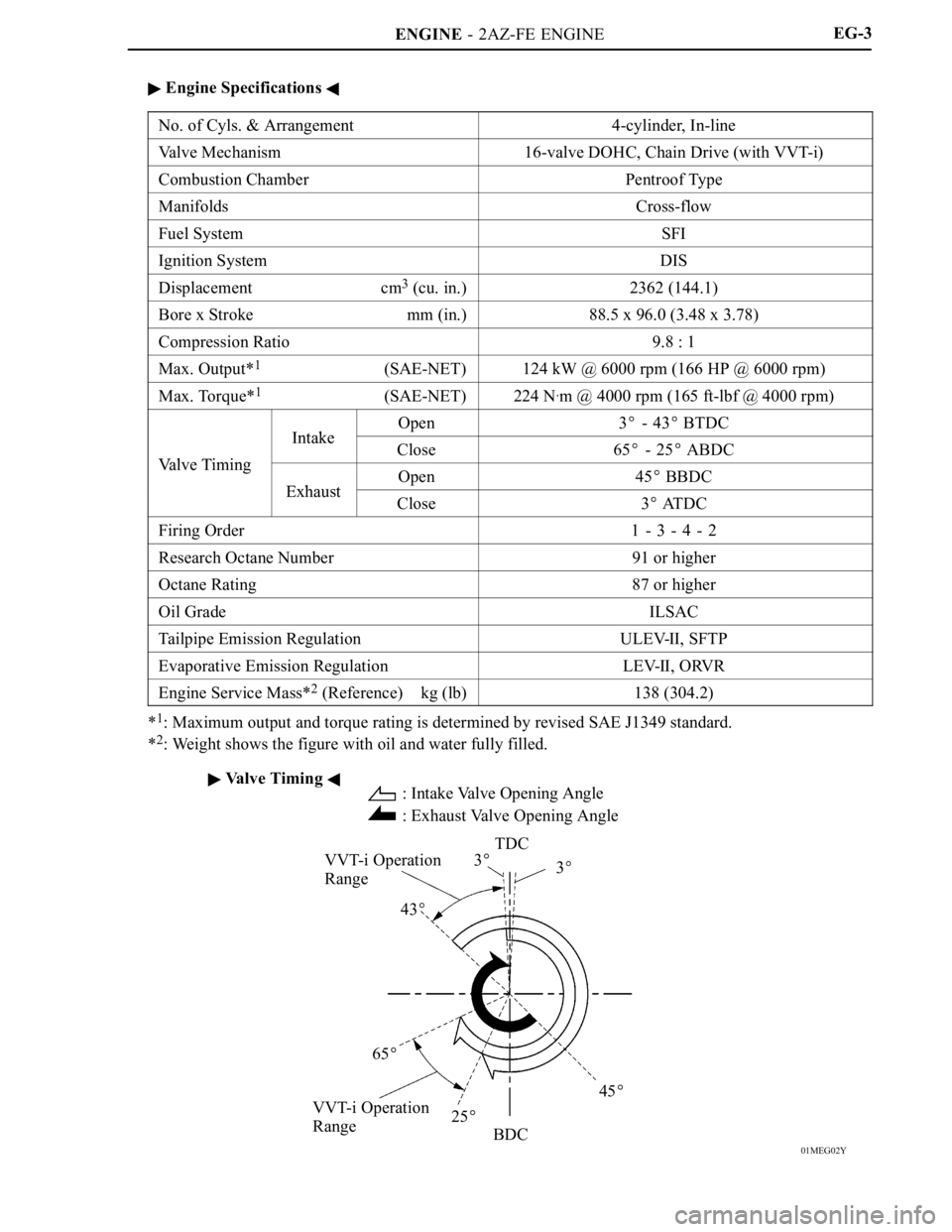

Valve Timing : Intake Valve Opening Angle

: Exhaust Valve Opening Angle

VVT-i Operation

Range

VVT-i Operation

RangeTDC

3

3

43

65

25

45

BDCEG-3

Engine Specifications

No. of Cyls. & Arrangement4-cylinder, In-line

Valve Mechanism16-valve DOHC, Chain Drive (with VVT-i)

Combustion ChamberPentroof Type

ManifoldsCross-flow

Fuel SystemSFI

Ignition SystemDIS

Displacement cm3 (cu. in.)2362 (144.1)

Bore x Stroke mm (in.)88.5 x 96.0 (3.48 x 3.78)

Compression Ratio9.8 : 1

Max. Output*1(SAE-NET)124 kW @ 6000 rpm (166 HP @ 6000 rpm)

Max. Torque*1(SAE-NET)224 N.m @ 4000 rpm (165 ft-lbf @ 4000 rpm)

IntakeOpen3 - 43 BTDC

Valve Timing

IntakeClose65 - 25 ABDCVa l v e T i m i n g

ExhaustOpen45 BBDCExhaustClose3 ATDC

Firing Order1 - 3 - 4 - 2

Research Octane Number91 or higher

Octane Rating87 or higher

Oil GradeILSAC

Tailpipe Emission RegulationULEV-II, SFTP

Evaporative Emission RegulationLEV-II, ORVR

Engine Service Mass*2 (Reference) kg (lb)138 (304.2)

*1: Maximum output and torque rating is determined by revised SAE J1349 standard.

*

2: Weight shows the figure with oil and water fully filled.

Page 131 of 2000

ENGINE - 2GR-FE ENGINEEG-69

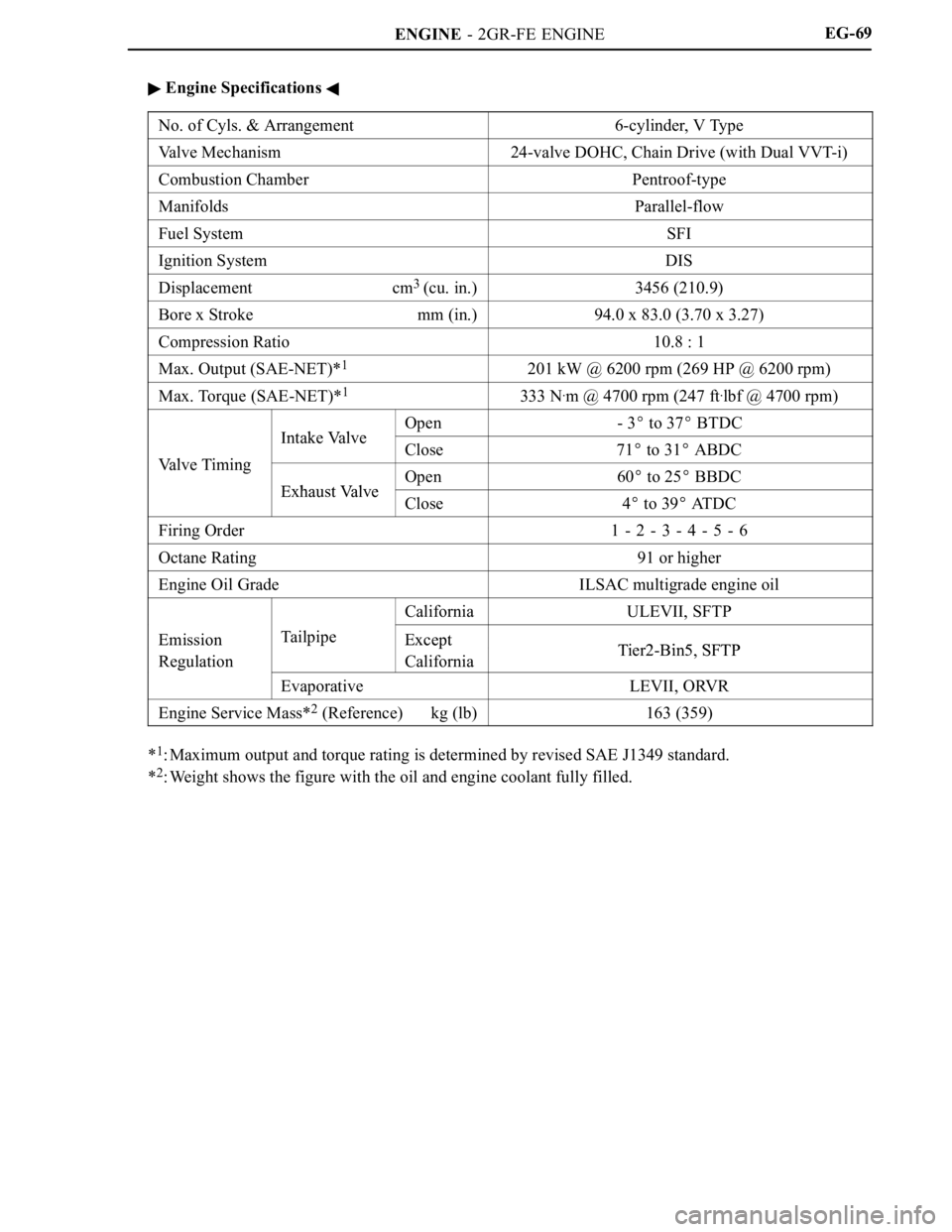

Engine Specifications

No. of Cyls. & Arrangement6-cylinder, V Type

Valve Mechanism24-valve DOHC, Chain Drive (with Dual VVT-i)

Combustion ChamberPentroof-type

ManifoldsParallel-flow

Fuel SystemSFI

Ignition SystemDIS

Displacement cm3

(cu. in.)3456 (210.9)

Bore x Stroke mm (in.)94.0 x 83.0 (3.70 x 3.27)

Compression Ratio10.8 : 1

Max. Output (SAE-NET)*1201 kW @ 6200 rpm (269 HP @ 6200 rpm)

Max. Torque (SAE-NET)*1333 N.m @ 4700 rpm (247 ft.lbf @ 4700 rpm)

Intake ValveOpen-3 to 37 BTDC

Valve Timing

Intake ValveClose71 to 31 ABDCVa l v e T i m i n g

Exhaust ValveOpen60 to 25 BBDCExhaust ValveClose4 to 39 ATDC

Firing Order1 - 2 - 3 - 4 - 5 - 6

Octane Rating91 or higher

Engine Oil GradeILSAC multigrade engine oil

CaliforniaULEVII, SFTP

EmissionTailpipeExceptTier2 Bin5 SFTPEmission

Regulation

ppExcept

CaliforniaTier2-Bin5, SFTPg

EvaporativeLEVII, ORVR

Engine Service Mass*2 (Reference) kg (lb)163 (359)

*1: Maximum output and torque rating is determined by revised SAE J1349 standard.

*

2: Weight shows the figure with the oil and engine coolant fully filled.

Page 257 of 2000

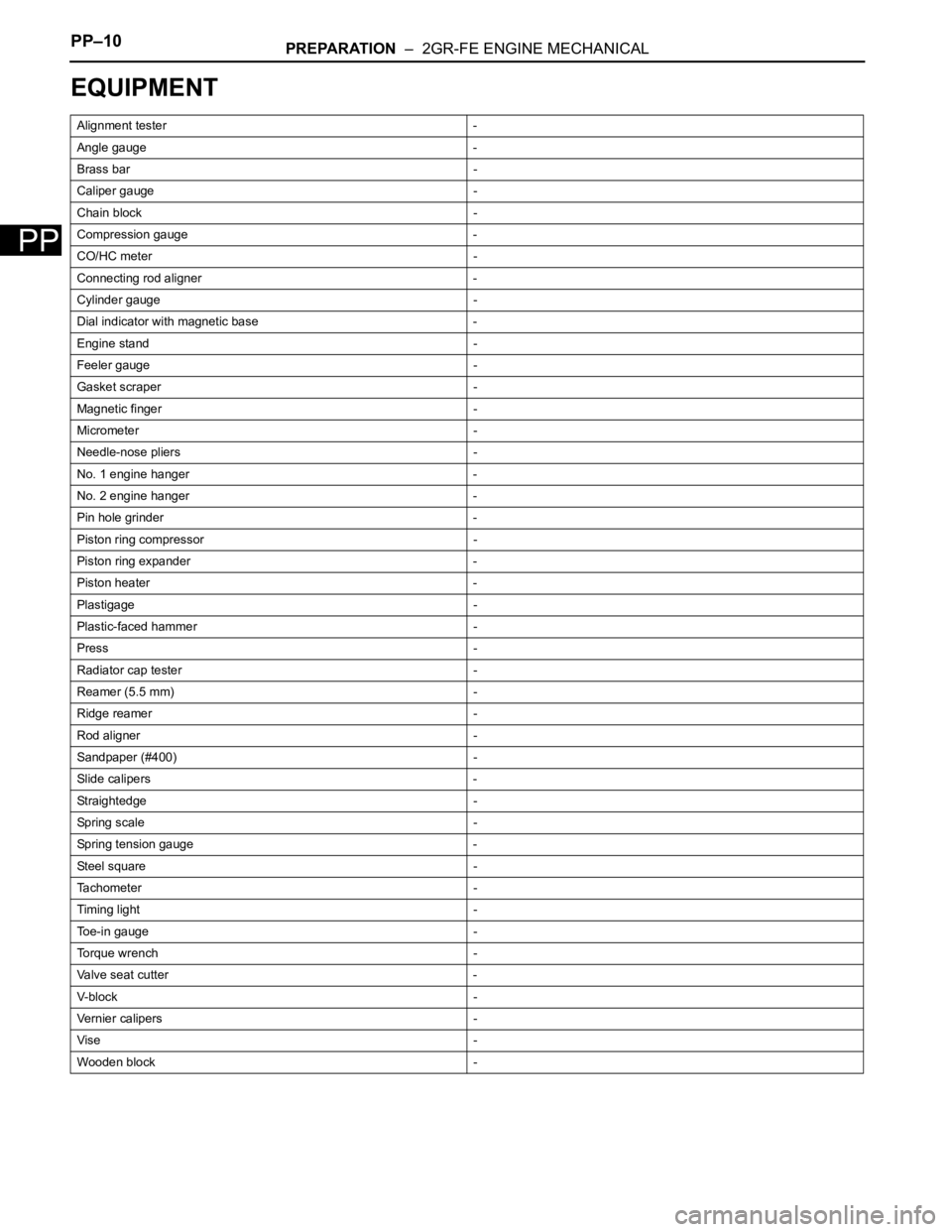

PP–10PREPARATION – 2GR-FE ENGINE MECHANICAL

PP

EQUIPMENT

Alignment tester -

Angle gauge -

Brass bar -

Caliper gauge -

Chain block -

Compression gauge -

CO/HC meter -

Connecting rod aligner -

Cylinder gauge -

Dial indicator with magnetic base -

Engine stand -

Feeler gauge -

Gasket scraper -

Magnetic finger -

Micrometer -

Needle-nose pliers -

No. 1 engine hanger -

No. 2 engine hanger -

Pin hole grinder -

Piston ring compressor -

Piston ring expander -

Piston heater -

Plastigage -

Plastic-faced hammer -

Press -

Radiator cap tester -

Reamer (5.5 mm) -

Ridge reamer -

Rod aligner -

Sandpaper (#400) -

Slide calipers -

Straightedge -

Spring scale -

Spring tension gauge -

Steel square -

Tachometer -

Timing light -

Toe-in gauge -

To r q u e w r e n c h -

Valve seat cutter -

V-block -

Vernier calipers -

Vise -

Wooden block -

Page 484 of 2000

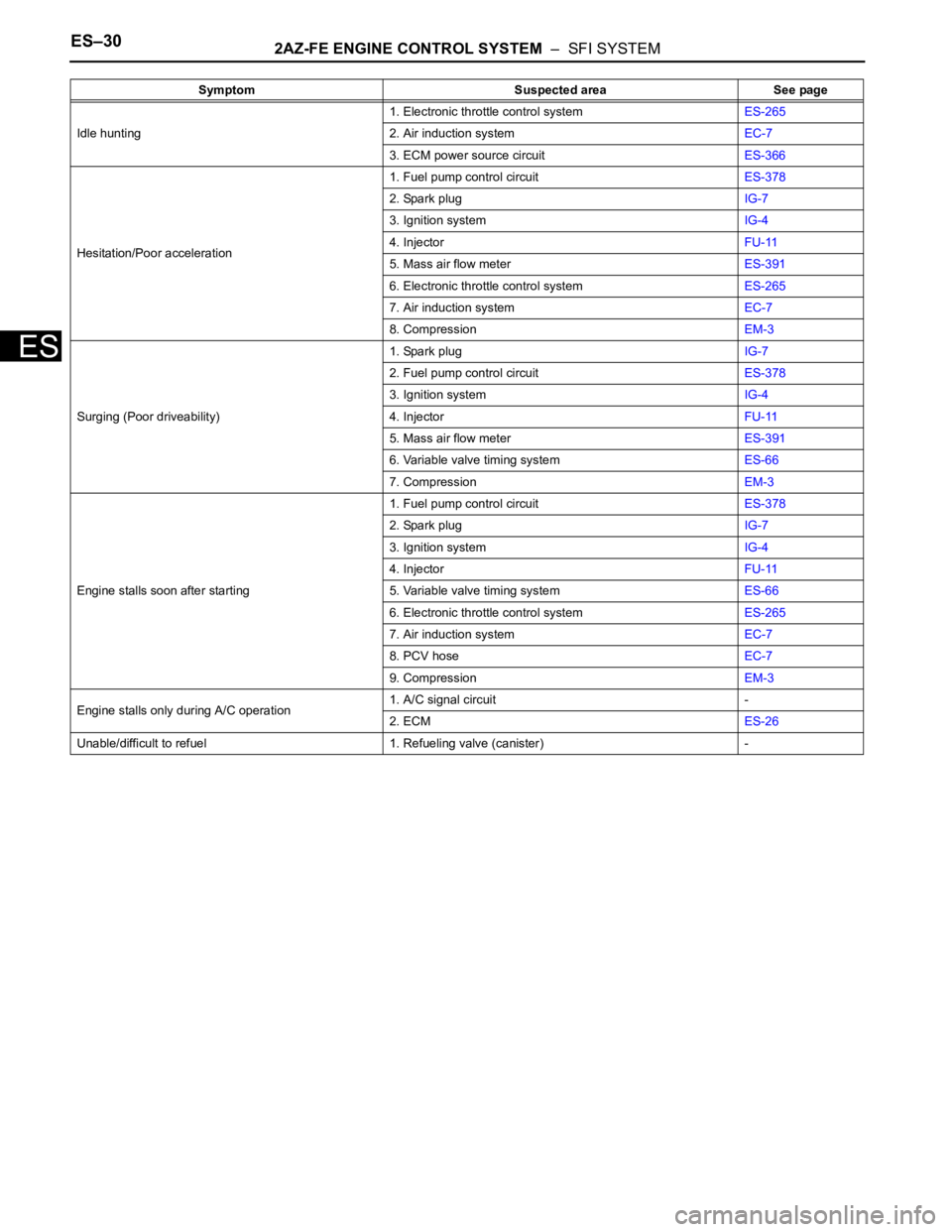

ES–302AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

Idle hunting1. Electronic throttle control systemES-265

2. Air induction systemEC-7

3. ECM power source circuitES-366

Hesitation/Poor acceleration1. Fuel pump control circuitES-378

2. Spark plugIG-7

3. Ignition systemIG-4

4. InjectorFU-11

5. Mass air flow meterES-391

6. Electronic throttle control systemES-265

7. Air induction systemEC-7

8. CompressionEM-3

Surging (Poor driveability)1. Spark plugIG-7

2. Fuel pump control circuitES-378

3. Ignition systemIG-4

4. InjectorFU-11

5. Mass air flow meterES-391

6. Variable valve timing systemES-66

7. CompressionEM-3

Engine stalls soon after starting1. Fuel pump control circuitES-378

2. Spark plugIG-7

3. Ignition systemIG-4

4. InjectorFU-11

5. Variable valve timing systemES-66

6. Electronic throttle control systemES-265

7. Air induction systemEC-7

8. PCV hoseEC-7

9. CompressionEM-3

Engine stalls only during A/C operation1. A/C signal circuit -

2. ECMES-26

Unable/difficult to refuel 1. Refueling valve (canister) - Symptom Suspected area See page

Page 557 of 2000

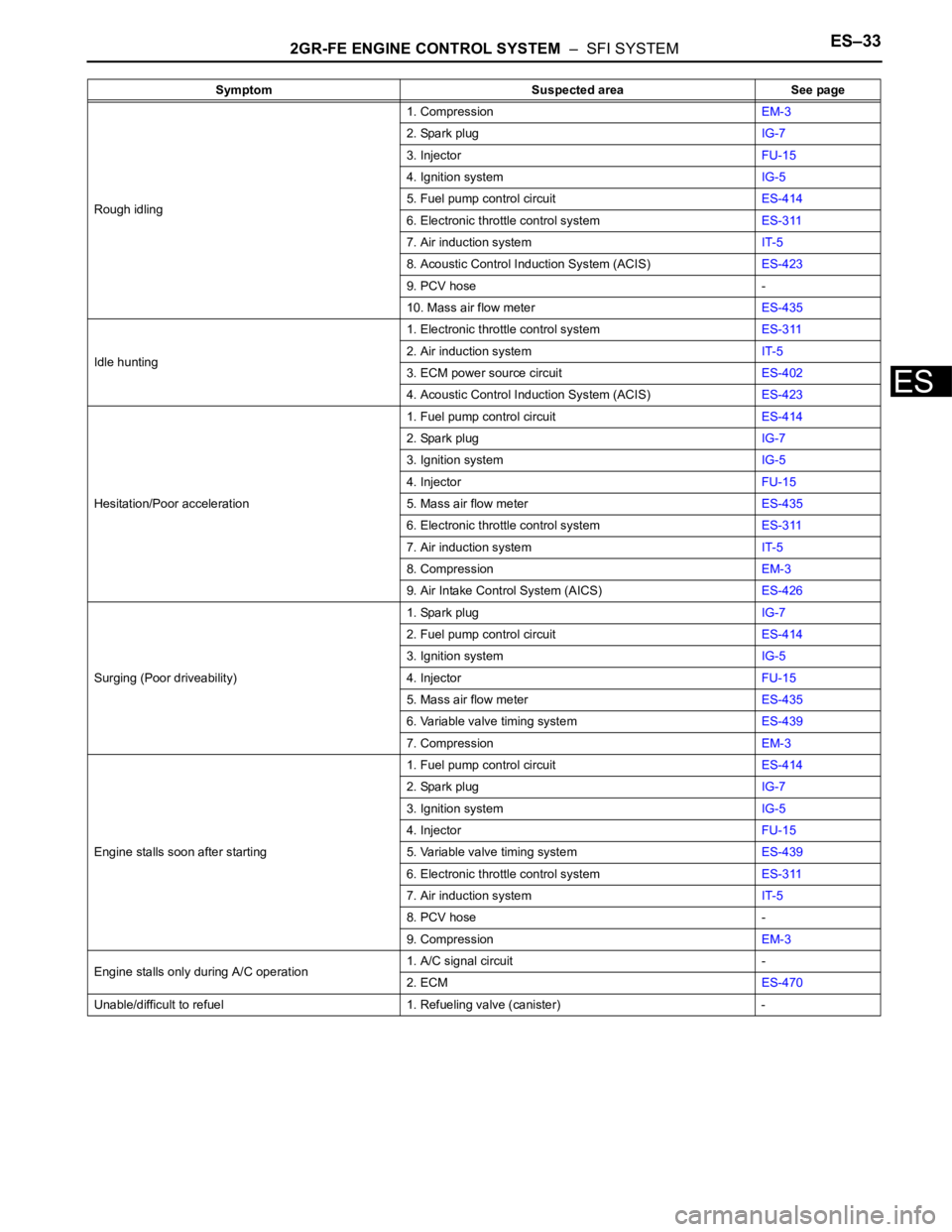

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–33

ES

Rough idling1. CompressionEM-3

2. Spark plugIG-7

3. InjectorFU-15

4. Ignition systemIG-5

5. Fuel pump control circuitES-414

6. Electronic throttle control systemES-311

7. Air induction systemIT-5

8. Acoustic Control Induction System (ACIS)ES-423

9. PCV hose -

10. Mass air flow meterES-435

Idle hunting1. Electronic throttle control systemES-311

2. Air induction systemIT-5

3. ECM power source circuitES-402

4. Acoustic Control Induction System (ACIS)ES-423

Hesitation/Poor acceleration1. Fuel pump control circuitES-414

2. Spark plugIG-7

3. Ignition systemIG-5

4. InjectorFU-15

5. Mass air flow meterES-435

6. Electronic throttle control systemES-311

7. Air induction systemIT-5

8. CompressionEM-3

9. Air Intake Control System (AICS)ES-426

Surging (Poor driveability)1. Spark plugIG-7

2. Fuel pump control circuitES-414

3. Ignition systemIG-5

4. InjectorFU-15

5. Mass air flow meterES-435

6. Variable valve timing systemES-439

7. CompressionEM-3

Engine stalls soon after starting1. Fuel pump control circuitES-414

2. Spark plugIG-7

3. Ignition systemIG-5

4. InjectorFU-15

5. Variable valve timing systemES-439

6. Electronic throttle control systemES-311

7. Air induction systemIT-5

8. PCV hose -

9. CompressionEM-3

Engine stalls only during A/C operation1. A/C signal circuit -

2. ECMES-470

Unable/difficult to refuel 1. Refueling valve (canister) -Symptom Suspected area See page

Page 582 of 2000

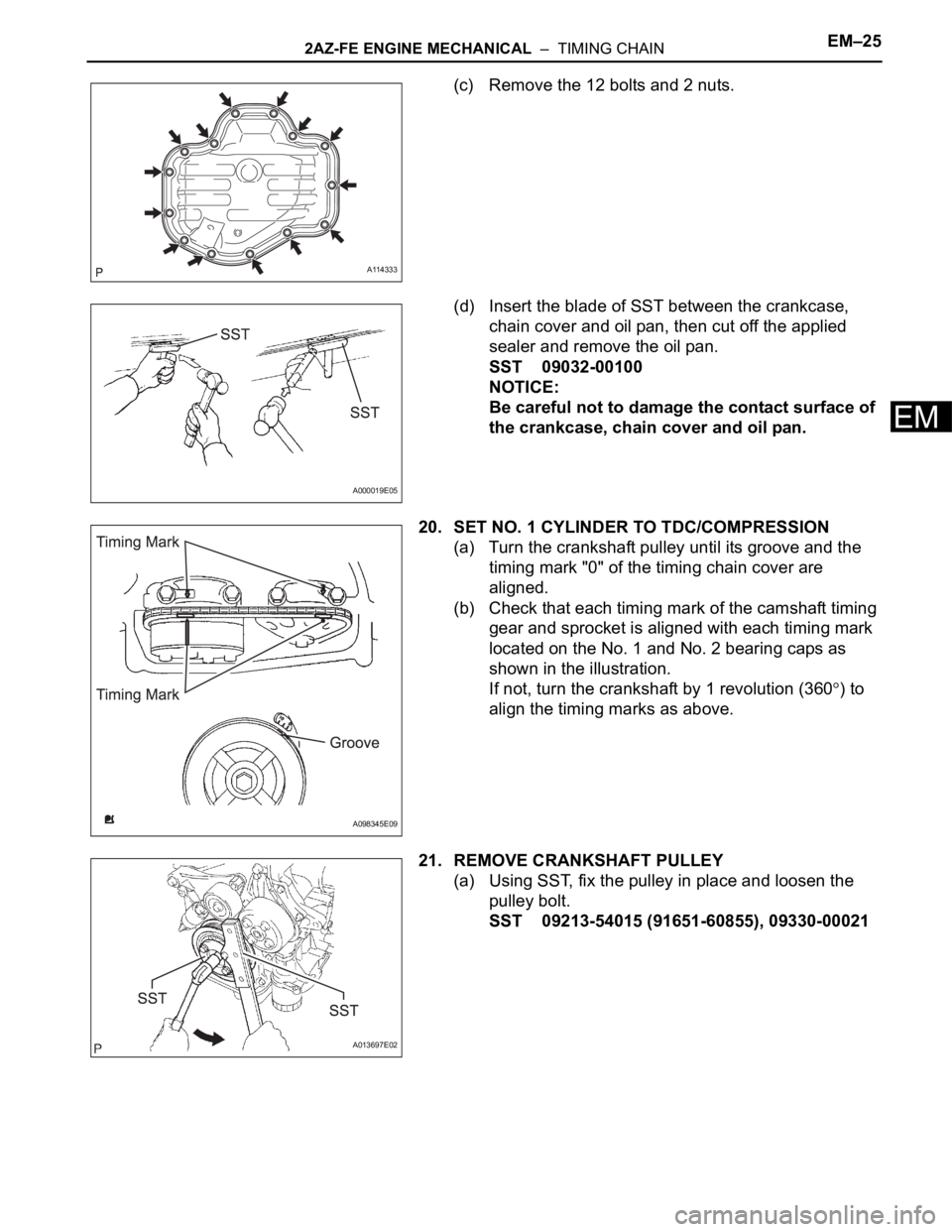

2AZ-FE ENGINE MECHANICAL – TIMING CHAINEM–25

EM

(c) Remove the 12 bolts and 2 nuts.

(d) Insert the blade of SST between the crankcase,

chain cover and oil pan, then cut off the applied

sealer and remove the oil pan.

SST 09032-00100

NOTICE:

Be careful not to damage the contact surface of

the crankcase, chain cover and oil pan.

20. SET NO. 1 CYLINDER TO TDC/COMPRESSION

(a) Turn the crankshaft pulley until its groove and the

timing mark "0" of the timing chain cover are

aligned.

(b) Check that each timing mark of the camshaft timing

gear and sprocket is aligned with each timing mark

located on the No. 1 and No. 2 bearing caps as

shown in the illustration.

If not, turn the crankshaft by 1 revolution (360

) to

align the timing marks as above.

21. REMOVE CRANKSHAFT PULLEY

(a) Using SST, fix the pulley in place and loosen the

pulley bolt.

SST 09213-54015 (91651-60855), 09330-00021

A114333

A000019E05

A098345E09

A013697E02

Page 590 of 2000

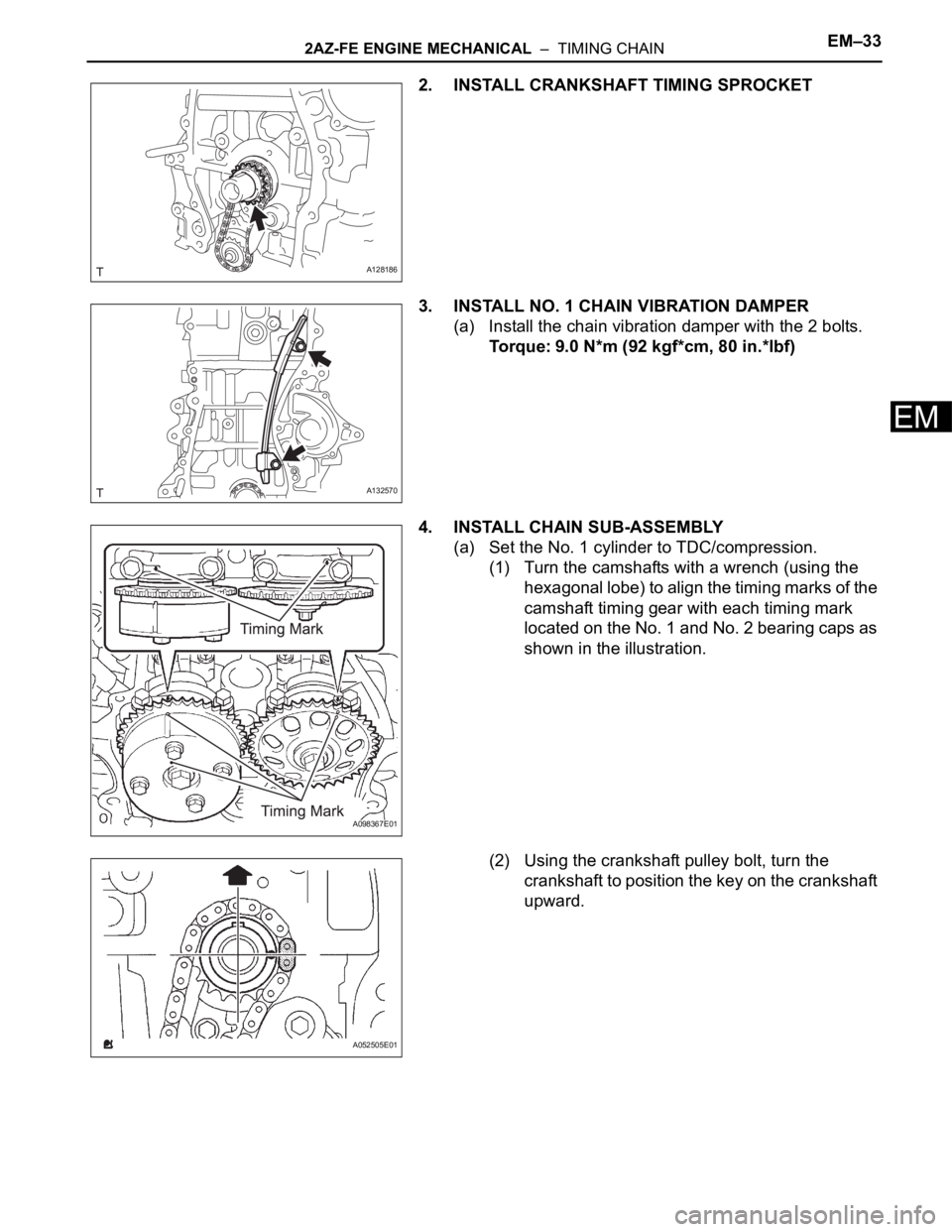

2AZ-FE ENGINE MECHANICAL – TIMING CHAINEM–33

EM

2. INSTALL CRANKSHAFT TIMING SPROCKET

3. INSTALL NO. 1 CHAIN VIBRATION DAMPER

(a) Install the chain vibration damper with the 2 bolts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

4. INSTALL CHAIN SUB-ASSEMBLY

(a) Set the No. 1 cylinder to TDC/compression.

(1) Turn the camshafts with a wrench (using the

hexagonal lobe) to align the timing marks of the

camshaft timing gear with each timing mark

located on the No. 1 and No. 2 bearing caps as

shown in the illustration.

(2) Using the crankshaft pulley bolt, turn the

crankshaft to position the key on the crankshaft

upward.

A128186

A132570

A098367E01

A052505E01

Page 603 of 2000

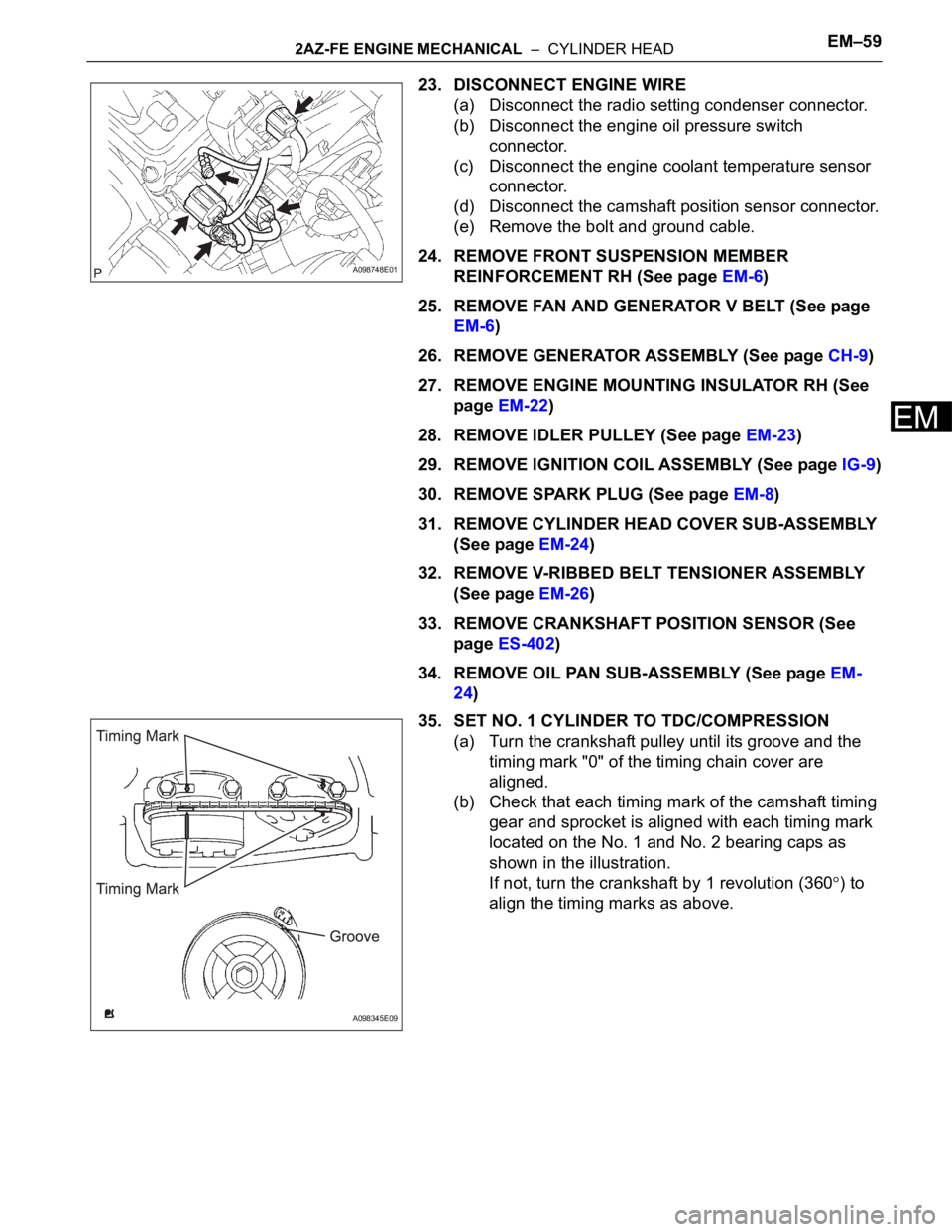

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–59

EM

23. DISCONNECT ENGINE WIRE

(a) Disconnect the radio setting condenser connector.

(b) Disconnect the engine oil pressure switch

connector.

(c) Disconnect the engine coolant temperature sensor

connector.

(d) Disconnect the camshaft position sensor connector.

(e) Remove the bolt and ground cable.

24. REMOVE FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-6)

25. REMOVE FAN AND GENERATOR V BELT (See page

EM-6)

26. REMOVE GENERATOR ASSEMBLY (See page CH-9)

27. REMOVE ENGINE MOUNTING INSULATOR RH (See

page EM-22)

28. REMOVE IDLER PULLEY (See page EM-23)

29. REMOVE IGNITION COIL ASSEMBLY (See page IG-9)

30. REMOVE SPARK PLUG (See page EM-8)

31. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(See page EM-24)

32. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(See page EM-26)

33. REMOVE CRANKSHAFT POSITION SENSOR (See

page ES-402)

34. REMOVE OIL PAN SUB-ASSEMBLY (See page EM-

24)

35. SET NO. 1 CYLINDER TO TDC/COMPRESSION

(a) Turn the crankshaft pulley until its groove and the

timing mark "0" of the timing chain cover are

aligned.

(b) Check that each timing mark of the camshaft timing

gear and sprocket is aligned with each timing mark

located on the No. 1 and No. 2 bearing caps as

shown in the illustration.

If not, turn the crankshaft by 1 revolution (360

) to

align the timing marks as above.

A098748E01

A098345E09

Page 692 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–55

EM

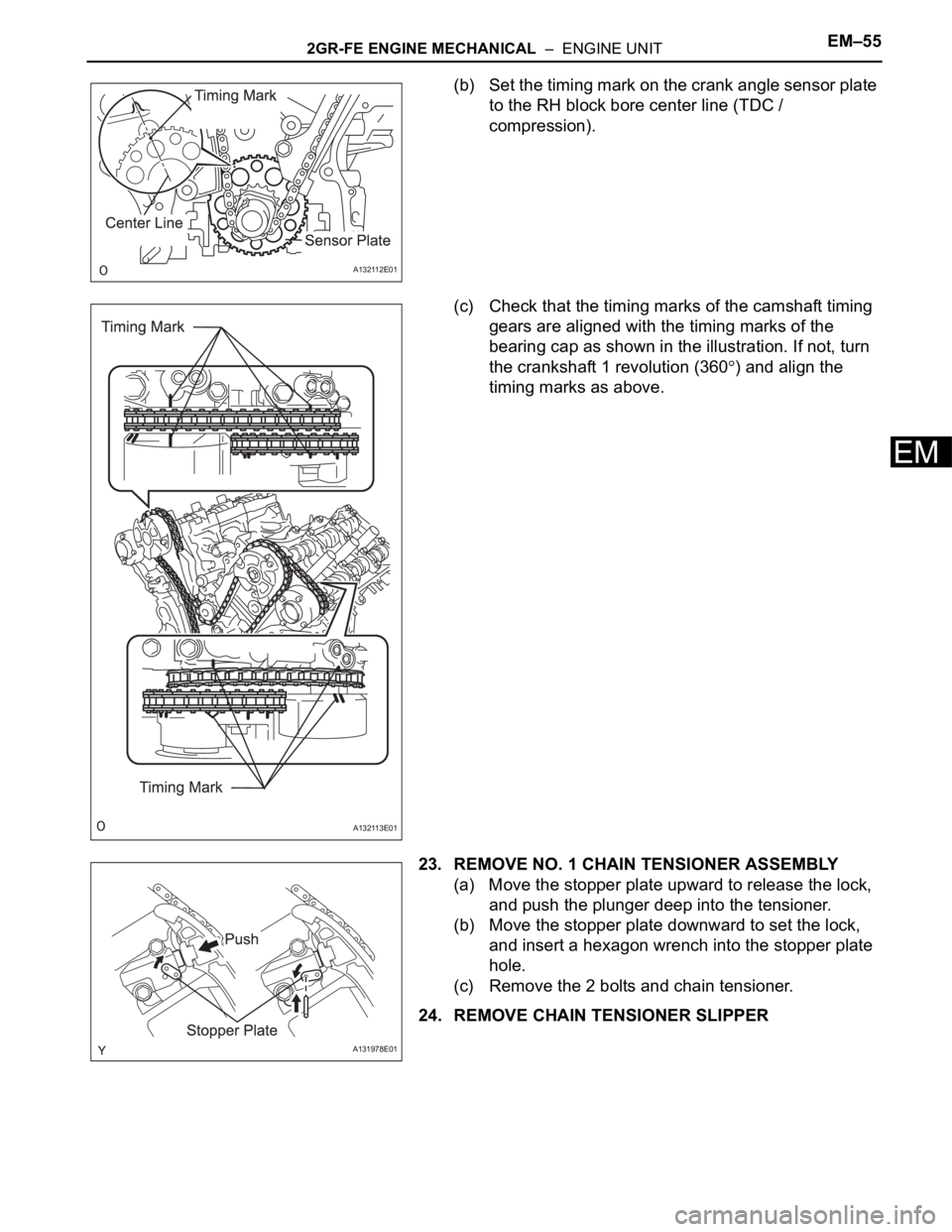

(b) Set the timing mark on the crank angle sensor plate

to the RH block bore center line (TDC /

compression).

(c) Check that the timing marks of the camshaft timing

gears are aligned with the timing marks of the

bearing cap as shown in the illustration. If not, turn

the crankshaft 1 revolution (360

) and align the

timing marks as above.

23. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

(a) Move the stopper plate upward to release the lock,

and push the plunger deep into the tensioner.

(b) Move the stopper plate downward to set the lock,

and insert a hexagon wrench into the stopper plate

hole.

(c) Remove the 2 bolts and chain tensioner.

24. REMOVE CHAIN TENSIONER SLIPPER

A132112E01

A132113E01

A131978E01

Page 713 of 2000

EM–762GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

INSPECTION

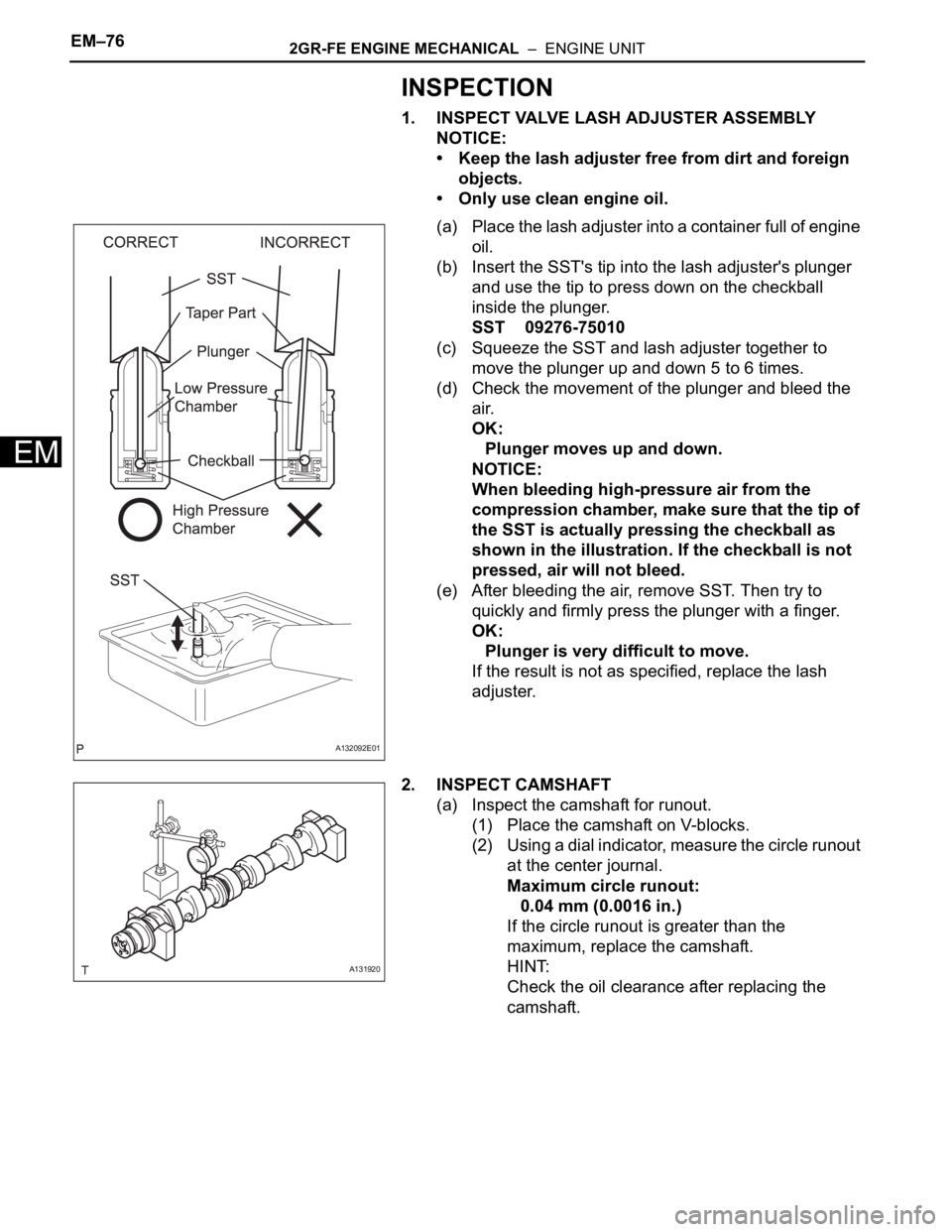

1. INSPECT VALVE LASH ADJUSTER ASSEMBLY

NOTICE:

• Keep the lash adjuster free from dirt and foreign

objects.

• Only use clean engine oil.

(a) Place the lash adjuster into a container full of engine

oil.

(b) Insert the SST's tip into the lash adjuster's plunger

and use the tip to press down on the checkball

inside the plunger.

SST 09276-75010

(c) Squeeze the SST and lash adjuster together to

move the plunger up and down 5 to 6 times.

(d) Check the movement of the plunger and bleed the

air.

OK:

Plunger moves up and down.

NOTICE:

When bleeding high-pressure air from the

compression chamber, make sure that the tip of

the SST is actually pressing the checkball as

shown in the illustration. If the checkball is not

pressed, air will not bleed.

(e) After bleeding the air, remove SST. Then try to

quickly and firmly press the plunger with a finger.

OK:

Plunger is very difficult to move.

If the result is not as specified, replace the lash

adjuster.

2. INSPECT CAMSHAFT

(a) Inspect the camshaft for runout.

(1) Place the camshaft on V-blocks.

(2) Using a dial indicator, measure the circle runout

at the center journal.

Maximum circle runout:

0.04 mm (0.0016 in.)

If the circle runout is greater than the

maximum, replace the camshaft.

HINT:

Check the oil clearance after replacing the

camshaft.

A132092E01

A131920