height TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 419 of 2000

MA–12MAINTENANCE – CHASSIS

MA

GENERAL MAINTENANCE

(2006/01- )

1. INSPECT STEERING LINKAGE AND GEAR HOUSING

(a) Check the steering wheel free play.

(b) Check the steering linkage for looseness or

damage.

(1) Check that the tie rod ends do not have

excessive play.

(2) Check that the dust seals and boots are not

damaged.

(3) Check that the boot clamps are not loose.

(4) Check that the steering gear housing is not

damaged.

(5) Check that the connectors are properly

connected to the steering gear housing.

2. INSPECT BALL JOINTS AND DUST COVERS

(a) Inspect the ball joints for excessive looseness.

(1) Jack up the front of the vehicle and place

wooden blocks with a height of 180 to 200 mm

(7.09 to 7.87 in.) under the front tires.

(2) Lower the vehicle until the front coil spring has

about half its ordinary load. Place stands under

the vehicle for safety.

(3) Check that the front wheels are pointing

straight ahead. Use wheel chocks on all 4

wheels.

(4) Using a lever, pry up the end of the lower arm.

Check the amount of play.

Maximum ball joint vertical play:

0 mm (0 in.)

If there is any play, replace the ball joint.

(b) Check the dust cover for damage.

3. INSPECT DRIVE SHAFT BOOTS

(a) Check the drive shaft boots for loose clamps,

grease leakage, kinks or damage.

4. INSPECT AUTOMATIC TRANSAXLE FLUID LEVEL

(a) Visually check the transmission for fluid leakage. If

oil is leaking, find the cause and repair it.

5. INSPECT TRANSFER OIL (for 4WD)

(a) Visually check the transfer for oil leakage. If oil is

leaking, find the cause and repair it.

6. INSPECT REAR DIFFERENTIAL OIL (for 4WD)

(a) For the rear differential oil inspection, refer to the

following procedures (see page DF-3).

Type See procedures

U151E See page AX-126

U151F See page AX-126

Type See procedures

Front Oil See page TF-45

Rear Oil See page TF-45

Page 612 of 2000

EM–682AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

NOTICE:

Do not use an air gun to perform the

smooth operation check.

(d) Check the lock in the extreme retard position.

(1) Confirm that the camshaft timing gear is locked

at the extreme retard position.

5. INSPECT CAMSHAFT

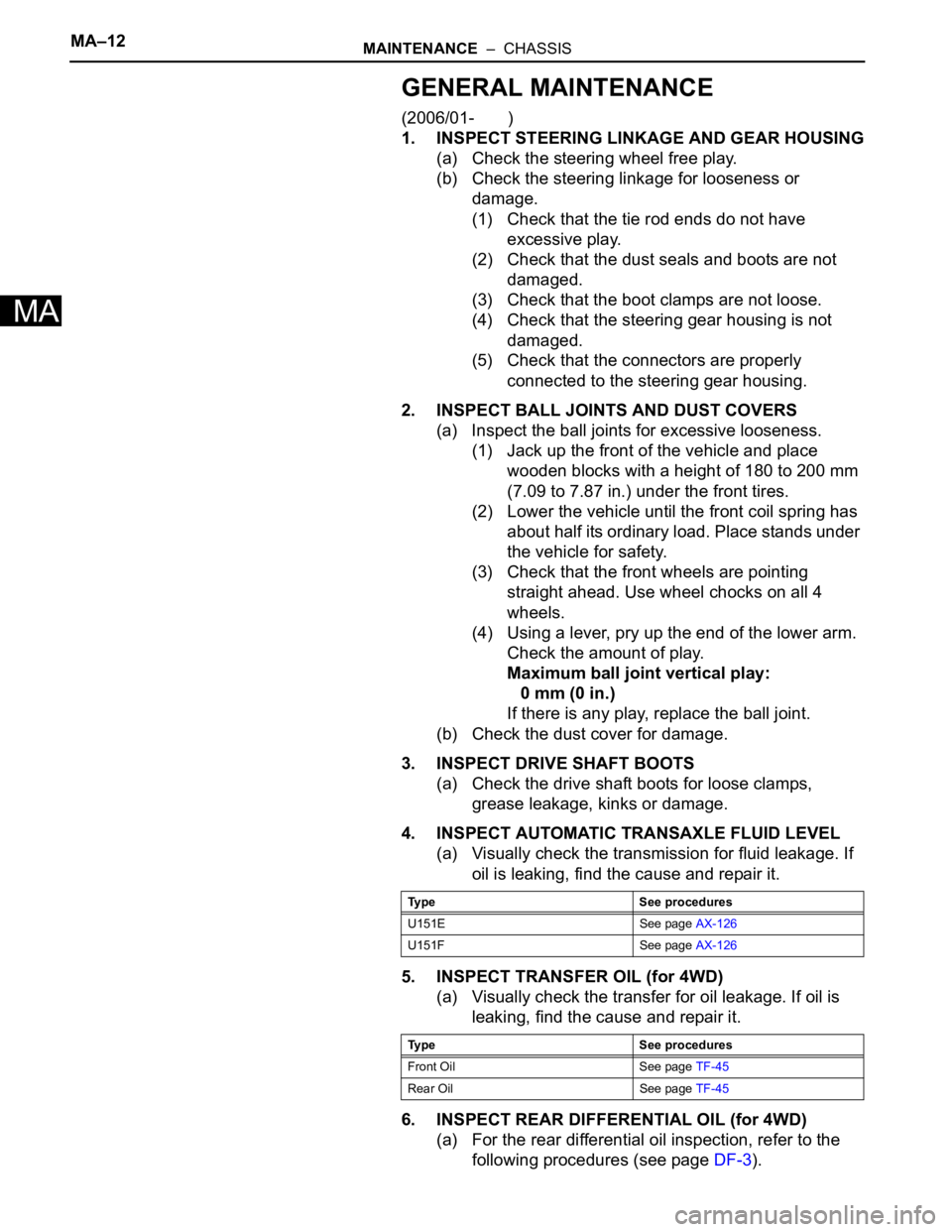

(a) Inspect the camshaft for runout.

(1) Place the camshaft on V-blocks.

(2) Using a dial indicator, measure the circle runout

at the center journal.

Maximum circle runout:

0.03 mm (0.0012 in.)

If the circle runout is greater than the

maximum, replace the camshaft.

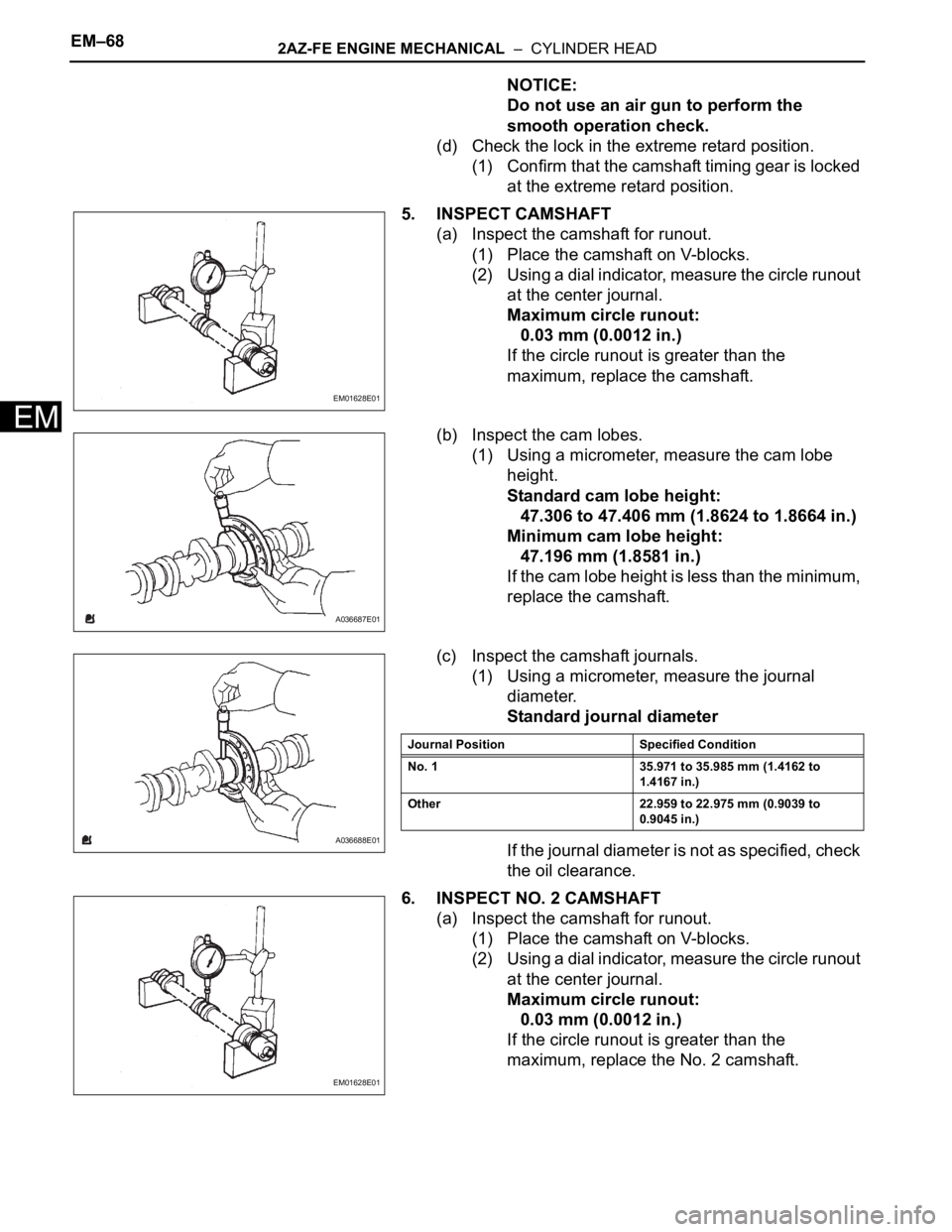

(b) Inspect the cam lobes.

(1) Using a micrometer, measure the cam lobe

height.

Standard cam lobe height:

47.306 to 47.406 mm (1.8624 to 1.8664 in.)

Minimum cam lobe height:

47.196 mm (1.8581 in.)

If the cam lobe height is less than the minimum,

replace the camshaft.

(c) Inspect the camshaft journals.

(1) Using a micrometer, measure the journal

diameter.

Standard journal diameter

If the journal diameter is not as specified, check

the oil clearance.

6. INSPECT NO. 2 CAMSHAFT

(a) Inspect the camshaft for runout.

(1) Place the camshaft on V-blocks.

(2) Using a dial indicator, measure the circle runout

at the center journal.

Maximum circle runout:

0.03 mm (0.0012 in.)

If the circle runout is greater than the

maximum, replace the No. 2 camshaft.

EM01628E01

A036687E01

A036688E01

Journal Position Specified Condition

No. 1 35.971 to 35.985 mm (1.4162 to

1.4167 in.)

Other 22.959 to 22.975 mm (0.9039 to

0.9045 in.)

EM01628E01

Page 613 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–69

EM

(b) Inspect the cam lobes.

(1) Using a micrometer, measure the cam lobe

height.

Standard cam lobe height:

45.983 to 46.083 mm (1.8104 to 1.8143 in.)

Minimum cam lobe height:

45.873 mm (1.8060 in.)

If the cam lobe height is less than the minimum,

replace the No. 2 camshaft.

(c) Inspect the camshaft journals.

(1) Using a micrometer, measure the journal

diameter.

Standard journal diameter

If the journal diameter is not as specified, check

the oil clearance.

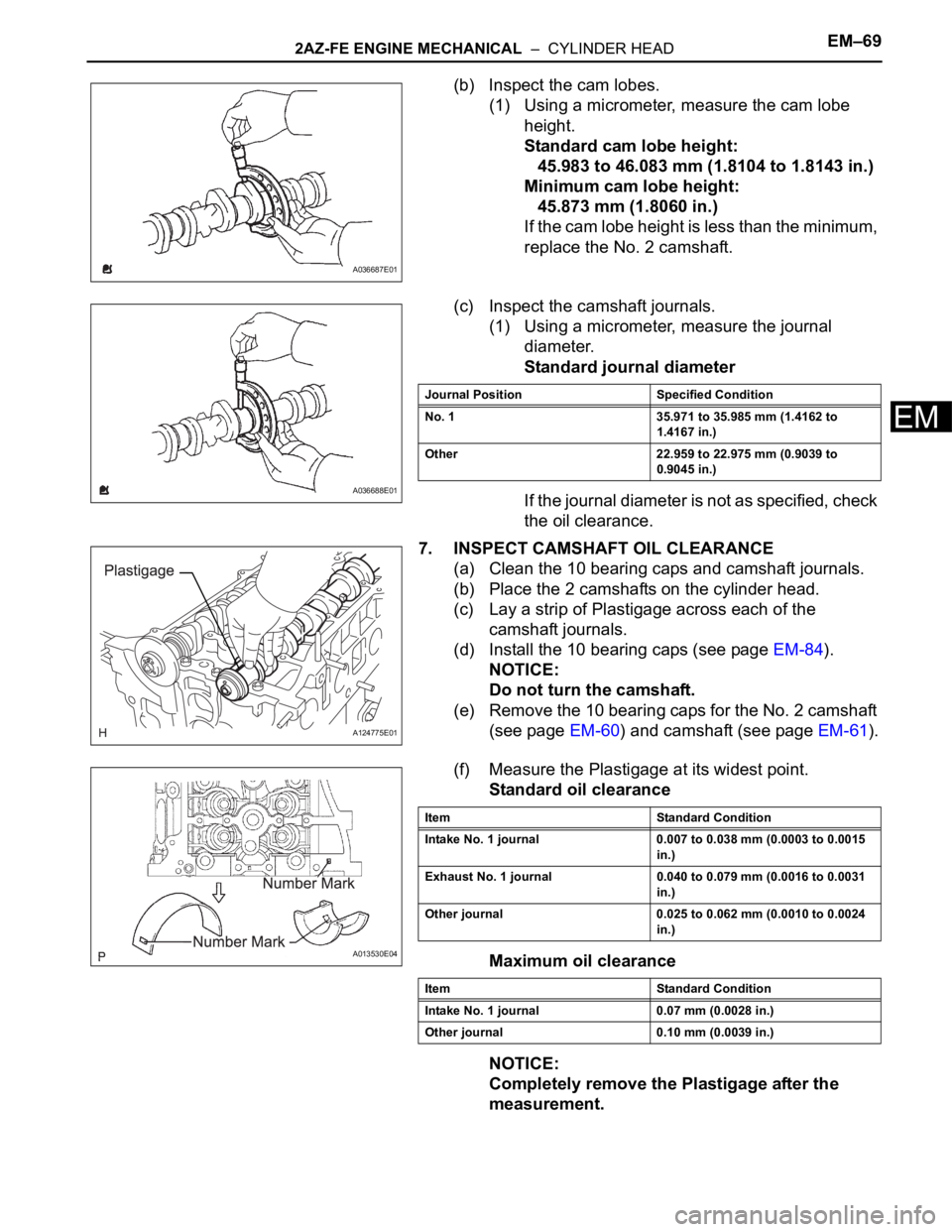

7. INSPECT CAMSHAFT OIL CLEARANCE

(a) Clean the 10 bearing caps and camshaft journals.

(b) Place the 2 camshafts on the cylinder head.

(c) Lay a strip of Plastigage across each of the

camshaft journals.

(d) Install the 10 bearing caps (see page EM-84).

NOTICE:

Do not turn the camshaft.

(e) Remove the 10 bearing caps for the No. 2 camshaft

(see page EM-60) and camshaft (see page EM-61).

(f) Measure the Plastigage at its widest point.

Standard oil clearance

Maximum oil clearance

NOTICE:

Completely remove the Plastigage after the

measurement.

A036687E01

A036688E01

Journal Position Specified Condition

No. 1 35.971 to 35.985 mm (1.4162 to

1.4167 in.)

Other 22.959 to 22.975 mm (0.9039 to

0.9045 in.)

A124775E01

A013530E04

Item Standard Condition

Intake No. 1 journal 0.007 to 0.038 mm (0.0003 to 0.0015

in.)

Exhaust No. 1 journal 0.040 to 0.079 mm (0.0016 to 0.0031

in.)

Other journal 0.025 to 0.062 mm (0.0010 to 0.0024

in.)

Item Standard Condition

Intake No. 1 journal 0.07 mm (0.0028 in.)

Other journal 0.10 mm (0.0039 in.)

Page 619 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–75

EM

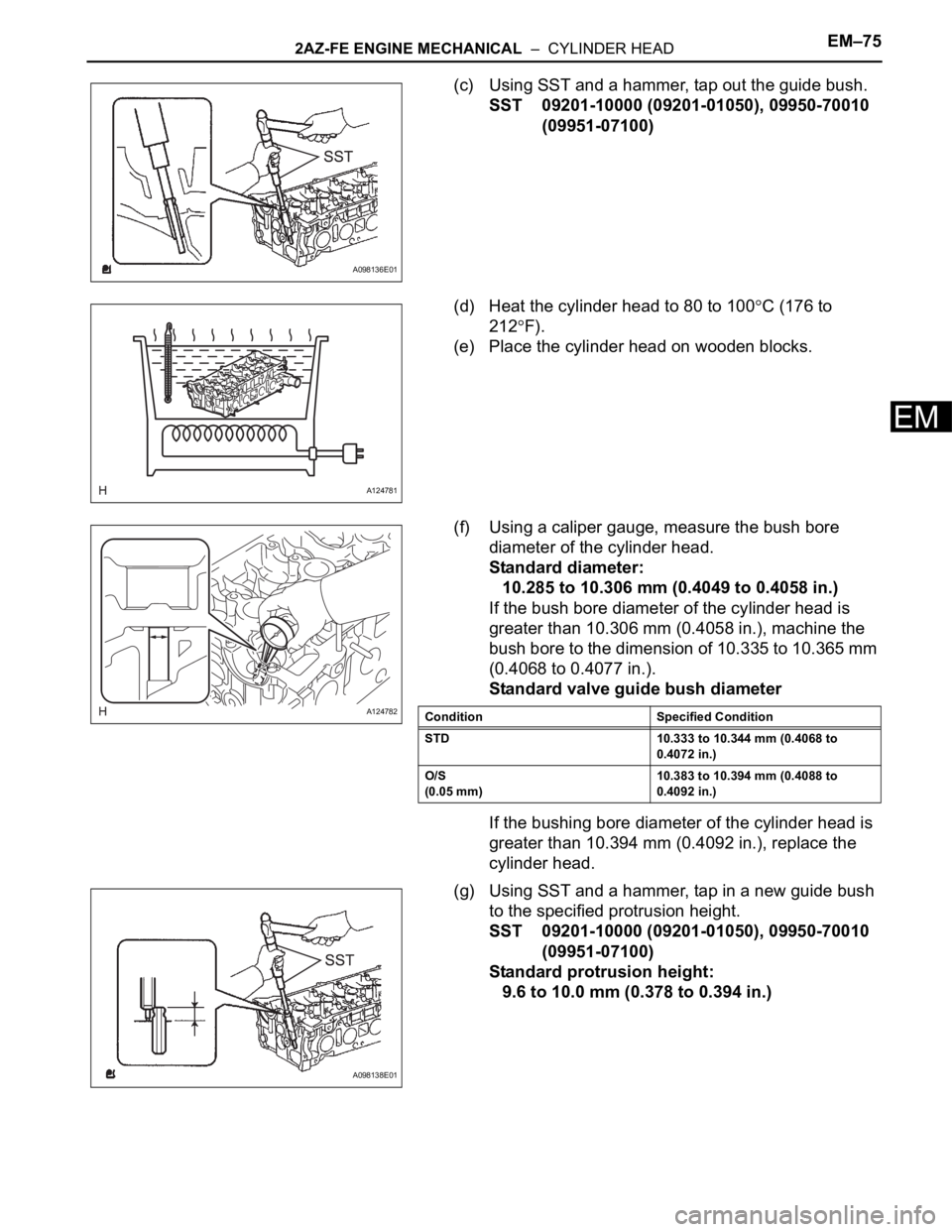

(c) Using SST and a hammer, tap out the guide bush.

SST 09201-10000 (09201-01050), 09950-70010

(09951-07100)

(d) Heat the cylinder head to 80 to 100

C (176 to

212

F).

(e) Place the cylinder head on wooden blocks.

(f) Using a caliper gauge, measure the bush bore

diameter of the cylinder head.

Standard diameter:

10.285 to 10.306 mm (0.4049 to 0.4058 in.)

If the bush bore diameter of the cylinder head is

greater than 10.306 mm (0.4058 in.), machine the

bush bore to the dimension of 10.335 to 10.365 mm

(0.4068 to 0.4077 in.).

Standard valve guide bush diameter

If the bushing bore diameter of the cylinder head is

greater than 10.394 mm (0.4092 in.), replace the

cylinder head.

(g) Using SST and a hammer, tap in a new guide bush

to the specified protrusion height.

SST 09201-10000 (09201-01050), 09950-70010

(09951-07100)

Standard protrusion height:

9.6 to 10.0 mm (0.378 to 0.394 in.)

A098136E01

A124781

A124782Condition Specified Condition

STD 10.333 to 10.344 mm (0.4068 to

0.4072 in.)

O/S

(0.05 mm)10.383 to 10.394 mm (0.4088 to

0.4092 in.)

A098138E01

Page 621 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–77

EM

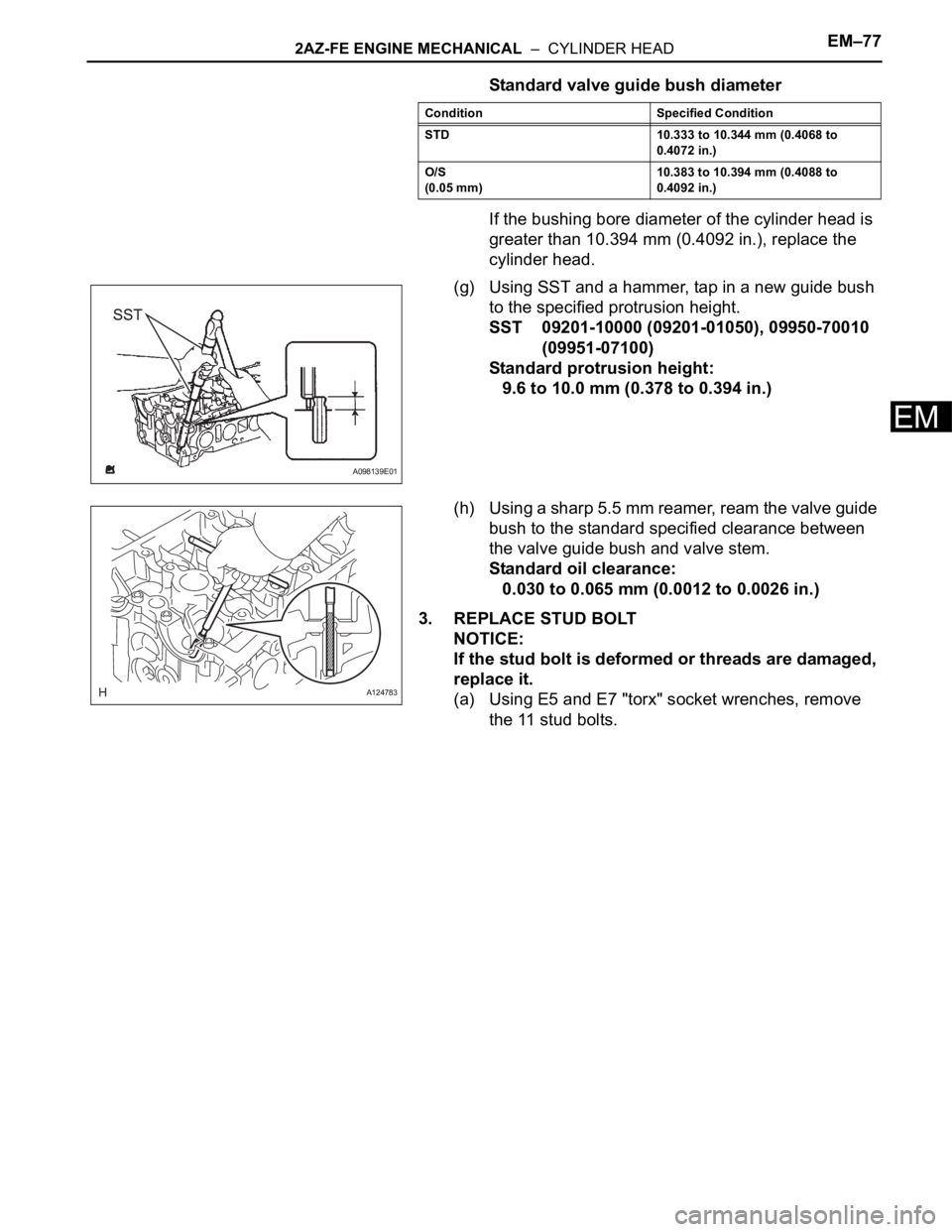

Standard valve guide bush diameter

If the bushing bore diameter of the cylinder head is

greater than 10.394 mm (0.4092 in.), replace the

cylinder head.

(g) Using SST and a hammer, tap in a new guide bush

to the specified protrusion height.

SST 09201-10000 (09201-01050), 09950-70010

(09951-07100)

Standard protrusion height:

9.6 to 10.0 mm (0.378 to 0.394 in.)

(h) Using a sharp 5.5 mm reamer, ream the valve guide

bush to the standard specified clearance between

the valve guide bush and valve stem.

Standard oil clearance:

0.030 to 0.065 mm (0.0012 to 0.0026 in.)

3. REPLACE STUD BOLT

NOTICE:

If the stud bolt is deformed or threads are damaged,

replace it.

(a) Using E5 and E7 "torx" socket wrenches, remove

the 11 stud bolts.

Condition Specified Condition

STD 10.333 to 10.344 mm (0.4068 to

0.4072 in.)

O/S

(0.05 mm)10.383 to 10.394 mm (0.4088 to

0.4092 in.)

A098139E01

A124783

Page 623 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–79

EM

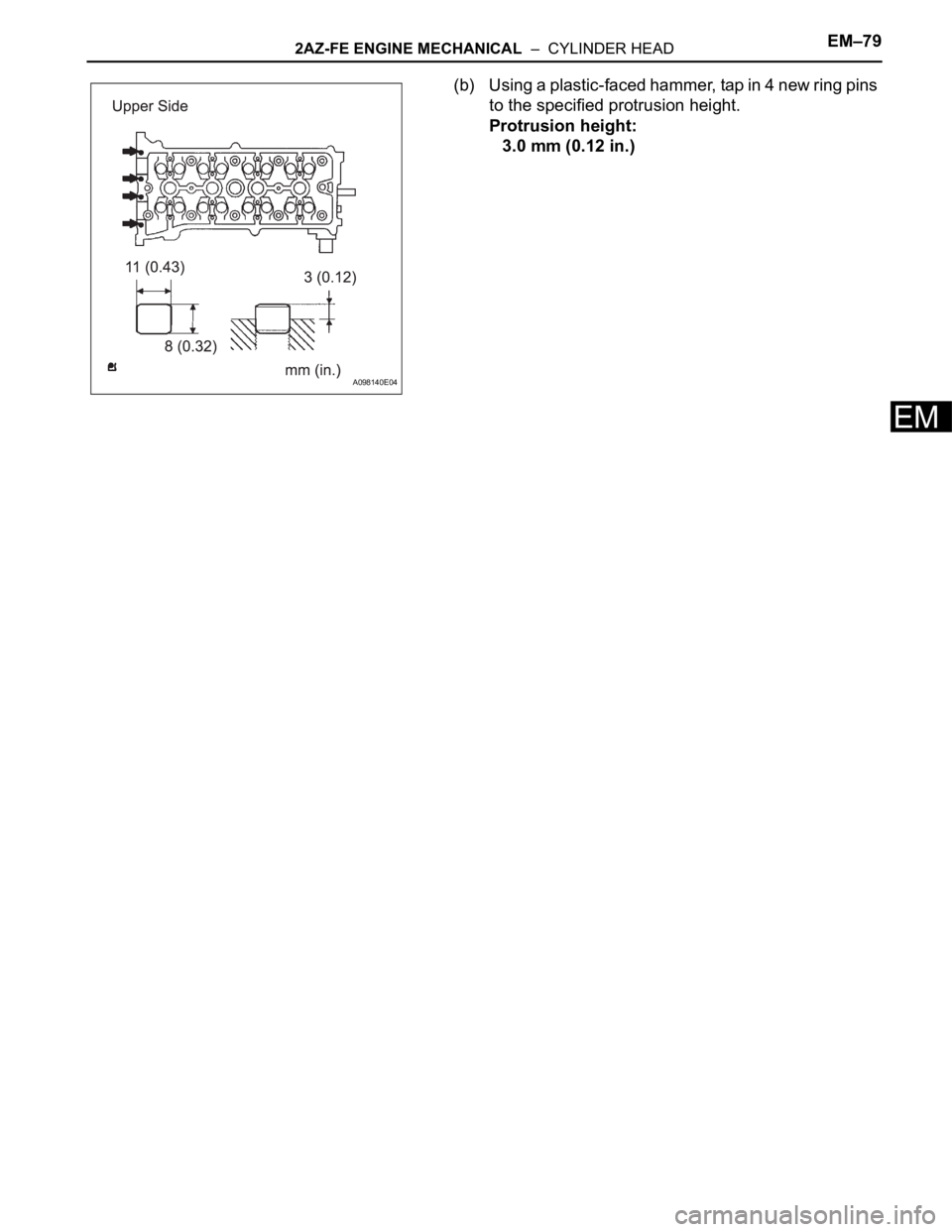

(b) Using a plastic-faced hammer, tap in 4 new ring pins

to the specified protrusion height.

Protrusion height:

3.0 mm (0.12 in.)

A098140E04

Page 675 of 2000

EM–1482AZ-FE ENGINE MECHANICAL – ENGINE UNIT

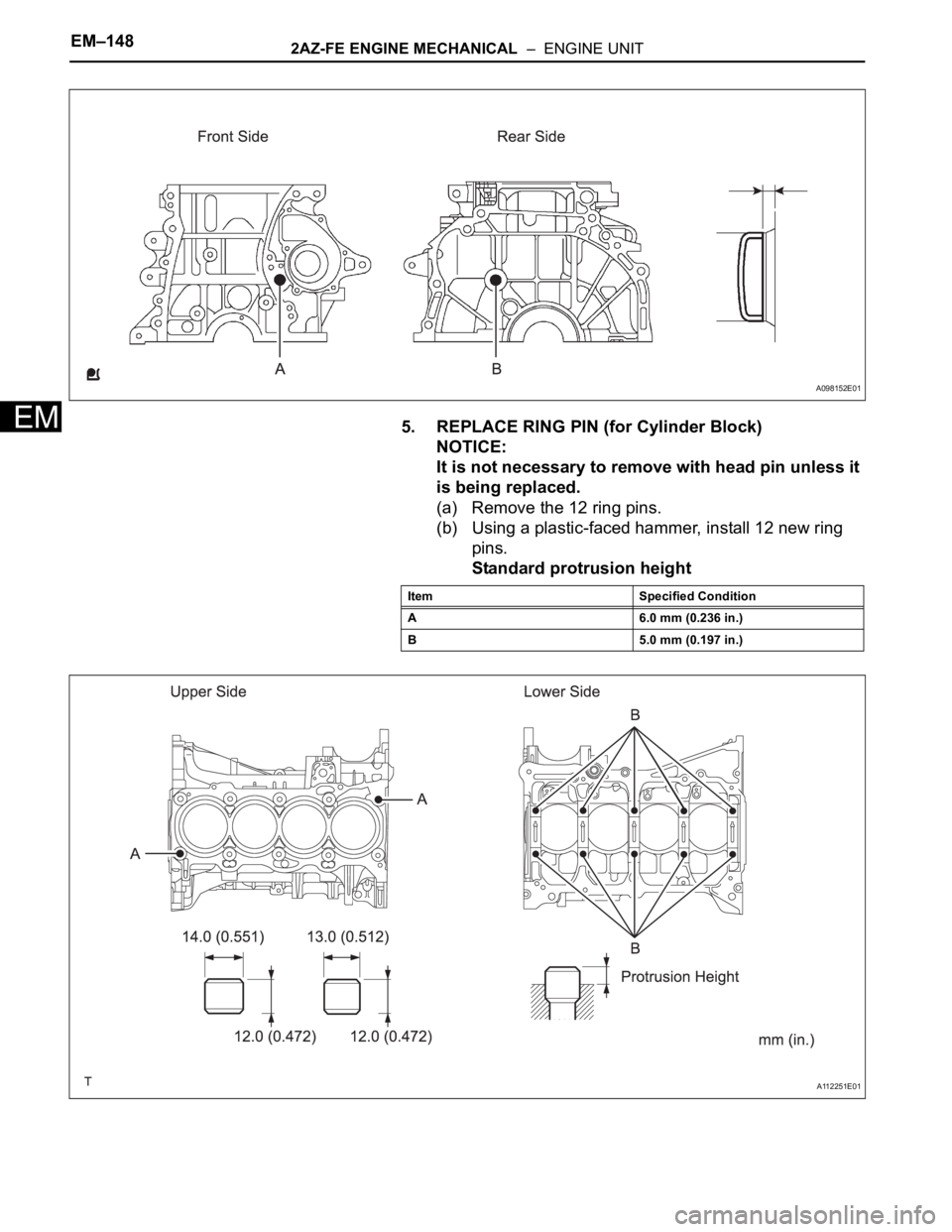

EM5. REPLACE RING PIN (for Cylinder Block)

NOTICE:

It is not necessary to remove with head pin unless it

is being replaced.

(a) Remove the 12 ring pins.

(b) Using a plastic-faced hammer, install 12 new ring

pins.

Standard protrusion height

A098152E01

Item Specified Condition

A 6.0 mm (0.236 in.)

B 5.0 mm (0.197 in.)

A112251E01

Page 676 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–149

EM

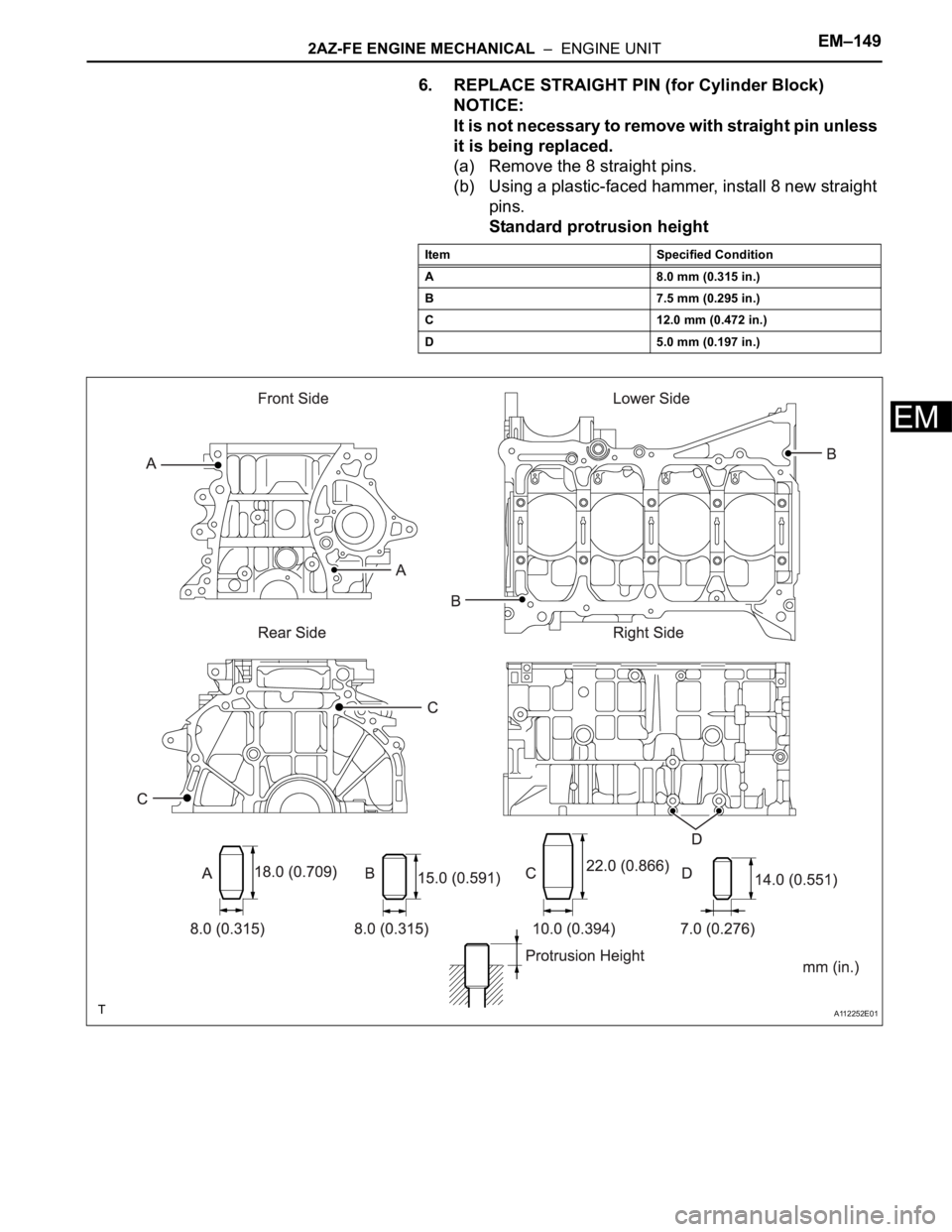

6. REPLACE STRAIGHT PIN (for Cylinder Block)

NOTICE:

It is not necessary to remove with straight pin unless

it is being replaced.

(a) Remove the 8 straight pins.

(b) Using a plastic-faced hammer, install 8 new straight

pins.

Standard protrusion height

Item Specified Condition

A 8.0 mm (0.315 in.)

B 7.5 mm (0.295 in.)

C 12.0 mm (0.472 in.)

D 5.0 mm (0.197 in.)

A112252E01

Page 714 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–77

EM

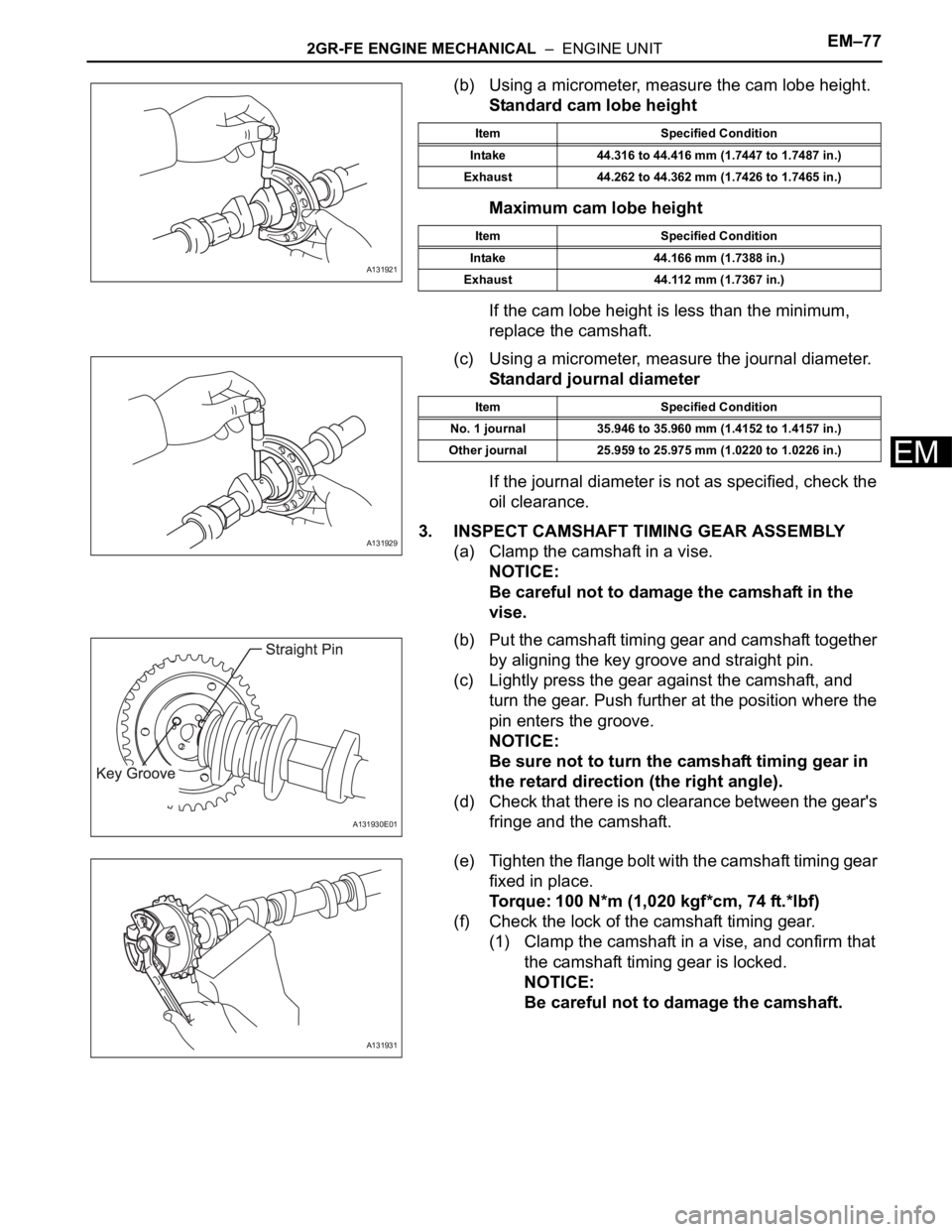

(b) Using a micrometer, measure the cam lobe height.

Standard cam lobe height

Maximum cam lobe height

If the cam lobe height is less than the minimum,

replace the camshaft.

(c) Using a micrometer, measure the journal diameter.

Standard journal diameter

If the journal diameter is not as specified, check the

oil clearance.

3. INSPECT CAMSHAFT TIMING GEAR ASSEMBLY

(a) Clamp the camshaft in a vise.

NOTICE:

Be careful not to damage the camshaft in the

vise.

(b) Put the camshaft timing gear and camshaft together

by aligning the key groove and straight pin.

(c) Lightly press the gear against the camshaft, and

turn the gear. Push further at the position where the

pin enters the groove.

NOTICE:

Be sure not to turn the camshaft timing gear in

the retard direction (the right angle).

(d) Check that there is no clearance between the gear's

fringe and the camshaft.

(e) Tighten the flange bolt with the camshaft timing gear

fixed in place.

Torque: 100 N*m (1,020 kgf*cm, 74 ft.*lbf)

(f) Check the lock of the camshaft timing gear.

(1) Clamp the camshaft in a vise, and confirm that

the camshaft timing gear is locked.

NOTICE:

Be careful not to damage the camshaft.

A131921

Item Specified Condition

Intake 44.316 to 44.416 mm (1.7447 to 1.7487 in.)

Exhaust 44.262 to 44.362 mm (1.7426 to 1.7465 in.)

Item Specified Condition

Intake 44.166 mm (1.7388 in.)

Exhaust 44.112 mm (1.7367 in.)

A131929

Item Specified Condition

No. 1 journal 35.946 to 35.960 mm (1.4152 to 1.4157 in.)

Other journal 25.959 to 25.975 mm (1.0220 to 1.0226 in.)

A131930E01

A131931

Page 735 of 2000

EM–982GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

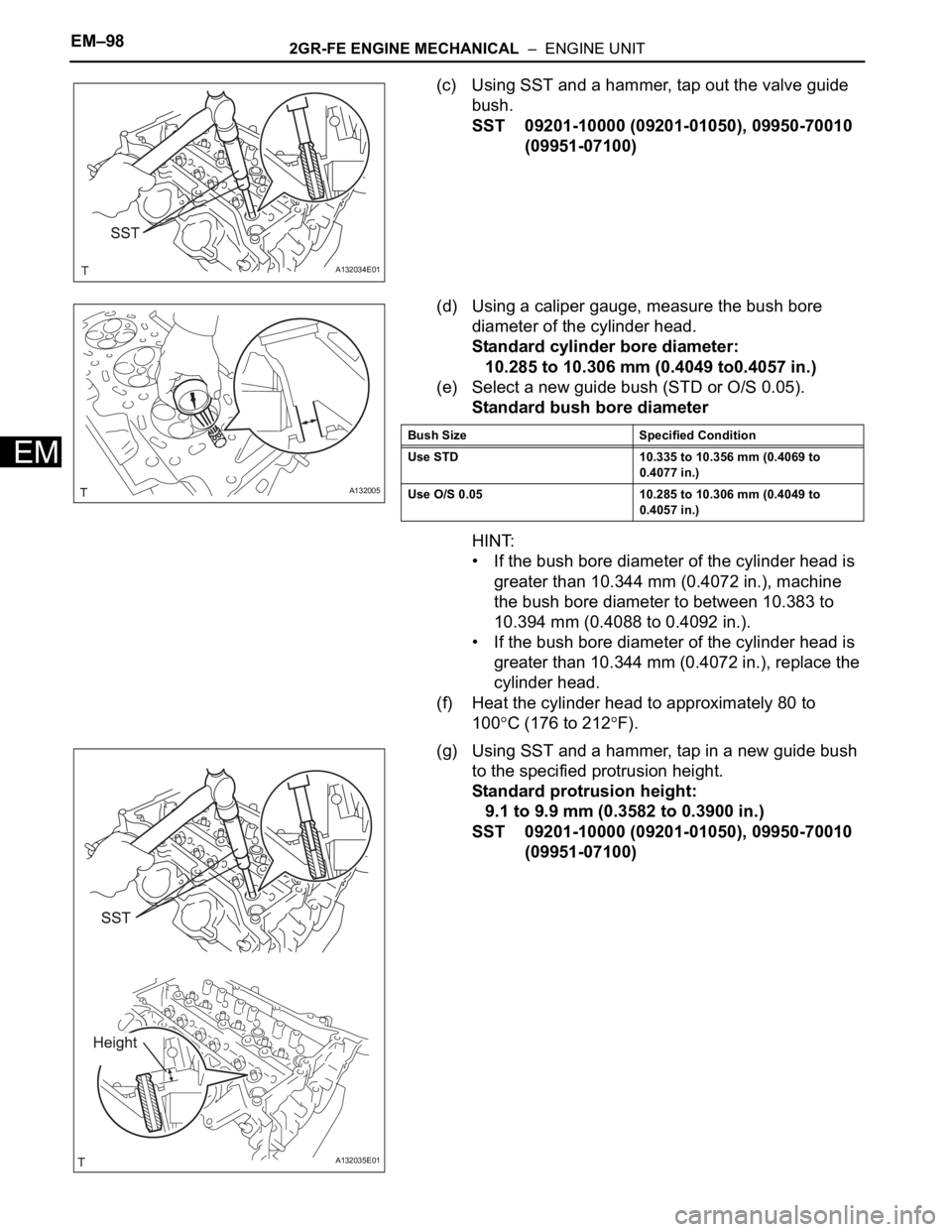

(c) Using SST and a hammer, tap out the valve guide

bush.

SST 09201-10000 (09201-01050), 09950-70010

(09951-07100)

(d) Using a caliper gauge, measure the bush bore

diameter of the cylinder head.

Standard cylinder bore diameter:

10.285 to 10.306 mm (0.4049 to0.4057 in.)

(e) Select a new guide bush (STD or O/S 0.05).

Standard bush bore diameter

HINT:

• If the bush bore diameter of the cylinder head is

greater than 10.344 mm (0.4072 in.), machine

the bush bore diameter to between 10.383 to

10.394 mm (0.4088 to 0.4092 in.).

• If the bush bore diameter of the cylinder head is

greater than 10.344 mm (0.4072 in.), replace the

cylinder head.

(f) Heat the cylinder head to approximately 80 to

100

C (176 to 212F).

(g) Using SST and a hammer, tap in a new guide bush

to the specified protrusion height.

Standard protrusion height:

9.1 to 9.9 mm (0.3582 to 0.3900 in.)

SST 09201-10000 (09201-01050), 09950-70010

(09951-07100)

A132034E01

A132005

Bush Size Specified Condition

Use STD 10.335 to 10.356 mm (0.4069 to

0.4077 in.)

Use O/S 0.05 10.285 to 10.306 mm (0.4049 to

0.4057 in.)

A132035E01