manual transmission TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 167 of 2000

IN–22INTRODUCTION – REPAIR INSTRUCTION

IN

VEHICLE LIFT AND SUPPORT

LOCATIONS

1. NOTICE ABOUT VEHICLE CONDITION WHEN

JACKING UP VEHICLE

(a) The vehicle must be unloaded before jacking up /

lifting up the vehicle. Never jack up / lift up a heavily

loaded vehicle.

(b) When removing heavy parts such as the engine and

transmission, the center of gravity of the vehicle

may shift. To stabilize the vehicle, place a balance

weight in a location where it will not roll or shift, or

use a mission jack to hold the jacking support.

2. NOTICE FOR USING 4 POST LIFT

(a) Follow the safety procedures outlined in the lift

instruction manual.

(b) Use precautionary measures to prevent the free

wheel beam from damaging tires or wheels.

(c) Use wheel chocks to secure the vehicle.

3. NOTICE FOR USING JACK AND SAFETY STAND

(a) Work on a level surface. Use wheel chocks at all

times.

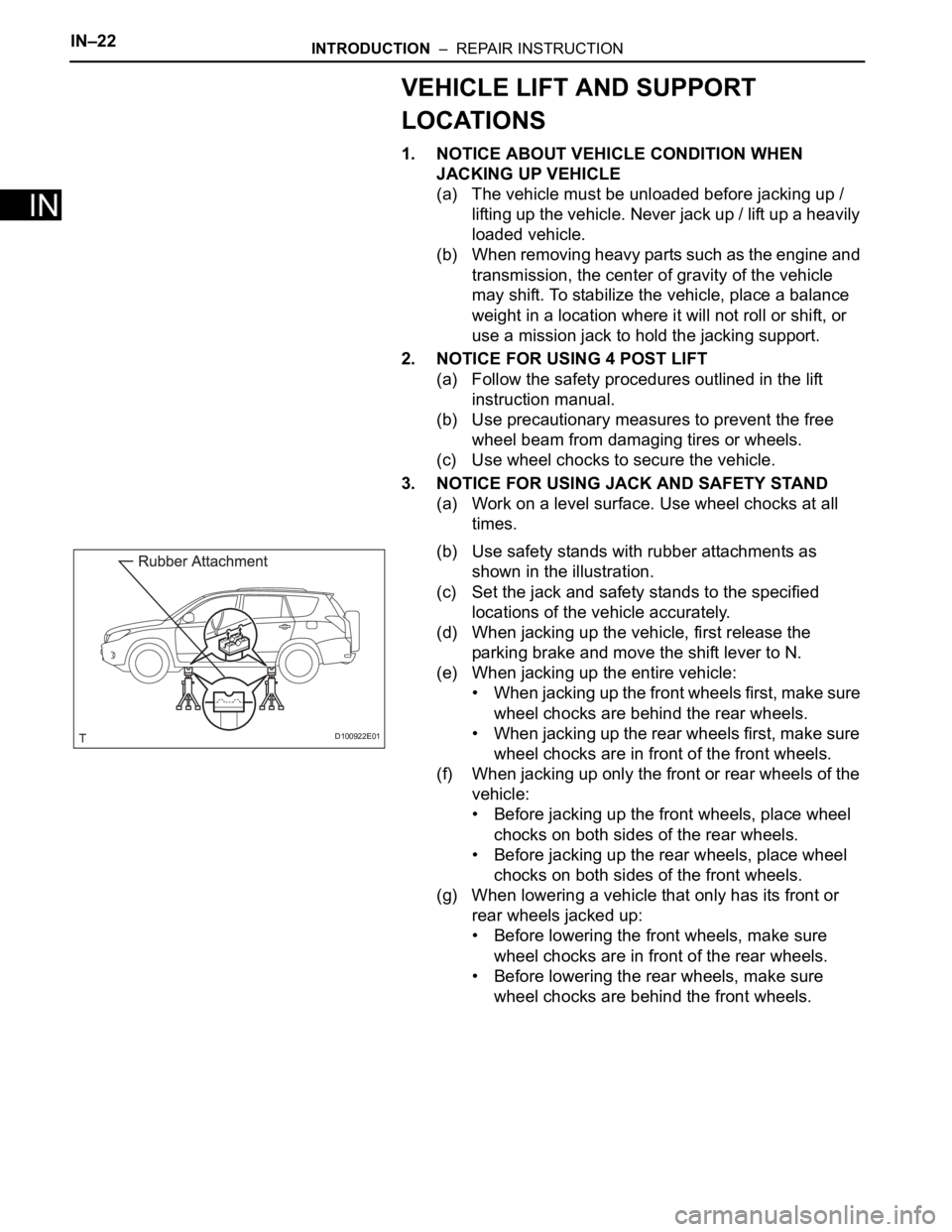

(b) Use safety stands with rubber attachments as

shown in the illustration.

(c) Set the jack and safety stands to the specified

locations of the vehicle accurately.

(d) When jacking up the vehicle, first release the

parking brake and move the shift lever to N.

(e) When jacking up the entire vehicle:

• When jacking up the front wheels first, make sure

wheel chocks are behind the rear wheels.

• When jacking up the rear wheels first, make sure

wheel chocks are in front of the front wheels.

(f) When jacking up only the front or rear wheels of the

vehicle:

• Before jacking up the front wheels, place wheel

chocks on both sides of the rear wheels.

• Before jacking up the rear wheels, place wheel

chocks on both sides of the front wheels.

(g) When lowering a vehicle that only has its front or

rear wheels jacked up:

• Before lowering the front wheels, make sure

wheel chocks are in front of the rear wheels.

• Before lowering the rear wheels, make sure

wheel chocks are behind the front wheels.

D100922E01

Page 180 of 2000

SS–48SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSMISSION

SS

Parking lock pawl bracket x Transaxle case 20 205 15

Manual detent spring x Transaxle case Bolt A 20 205 15

Bolt B 12 120 9

Automatic transaxle oil pan sub-assembly x Transaxle case 7.6 77 67 in.*lbf

Speed sensor x Transaxle case 11 112 8

Park/neutral start switch x Control shaft lever 13 130 9

Speedometer driven hole cover sub-assembly x Transaxle case 5.5 56 49 in.*lbf

Oil pump body x Stator shaft assembly 9.8 100 87 in.*lbf

Front differential case x Front differential ring gear 95 969 70Part Tightened N*m kgf*cm ft*lbf

Page 387 of 2000

SS–54SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSMISSION

SS

Automatic transmission case plug x Transaxle case 7.4 75 65 in.*lbf

Parking lock pawl bracket x Transaxle case 20 205 15

Manual detent spring x Transaxle case Bolt A 20 205 15

Bolt B 12 120 9

Automatic transaxle oil pan sub-assembly x Transaxle case 7.6 77 67 in.*lbf

Speed sensor x Transaxle case11 11 2 8

Park/neutral start switch x Control shaft lever 13 130 9

Speedometer driven hole cover sub-assembly x Transaxle case 5.5 56 49 in.*lbf

Oil pump body x Stator shaft assembly 9.8 100 87 in.*lbf

Front differential case x Front differential ring gear 95 969 70Part Tightened N*m kgf*cm ft*lbf

Page 955 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–21

AX

MANUAL SHIFTING TEST

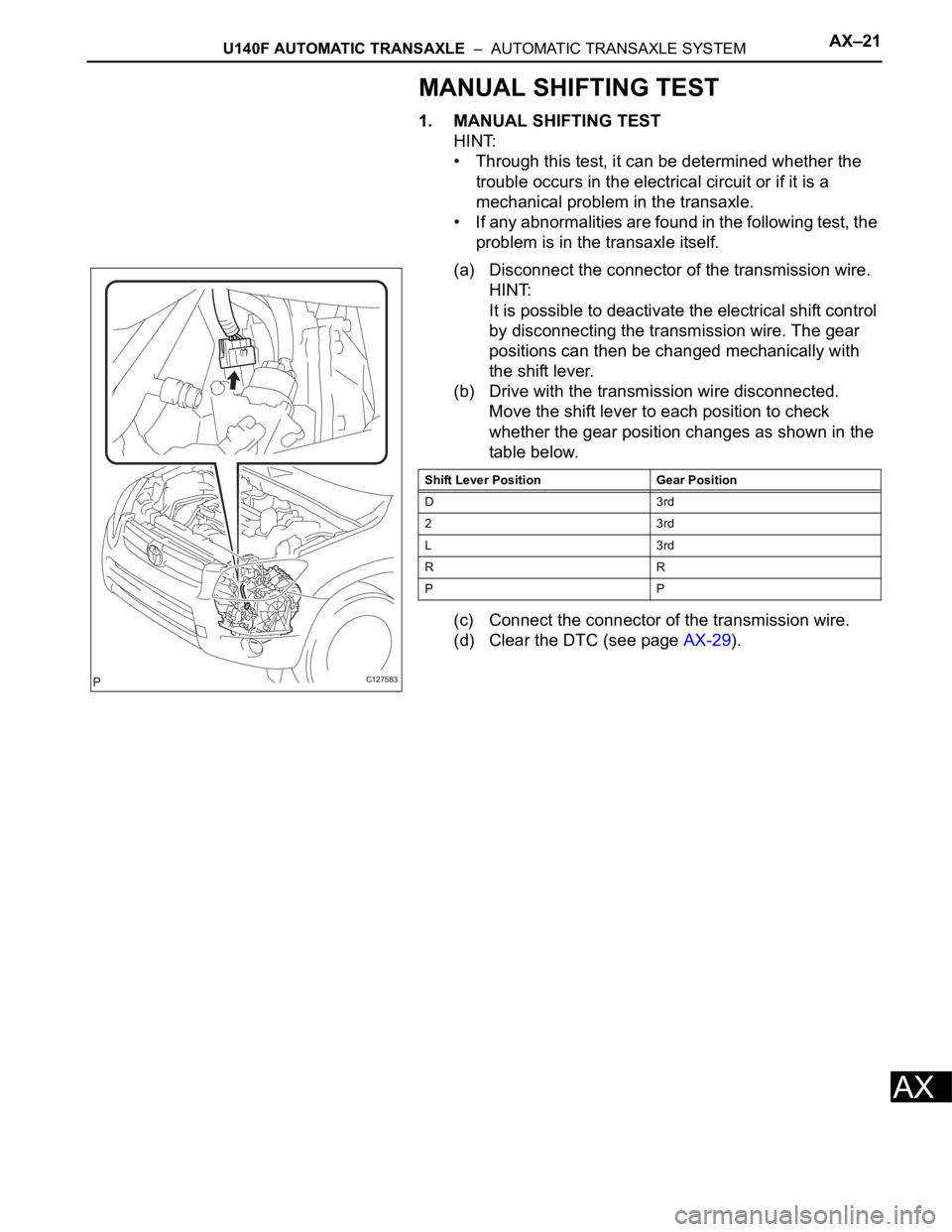

1. MANUAL SHIFTING TEST

HINT:

• Through this test, it can be determined whether the

trouble occurs in the electrical circuit or if it is a

mechanical problem in the transaxle.

• If any abnormalities are found in the following test, the

problem is in the transaxle itself.

(a) Disconnect the connector of the transmission wire.

HINT:

It is possible to deactivate the electrical shift control

by disconnecting the transmission wire. The gear

positions can then be changed mechanically with

the shift lever.

(b) Drive with the transmission wire disconnected.

Move the shift lever to each position to check

whether the gear position changes as shown in the

table below.

(c) Connect the connector of the transmission wire.

(d) Clear the DTC (see page AX-29).

C127583

Shift Lever Position Gear Position

D3rd

23rd

L3rd

RR

PP

Page 1006 of 2000

AX–212U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

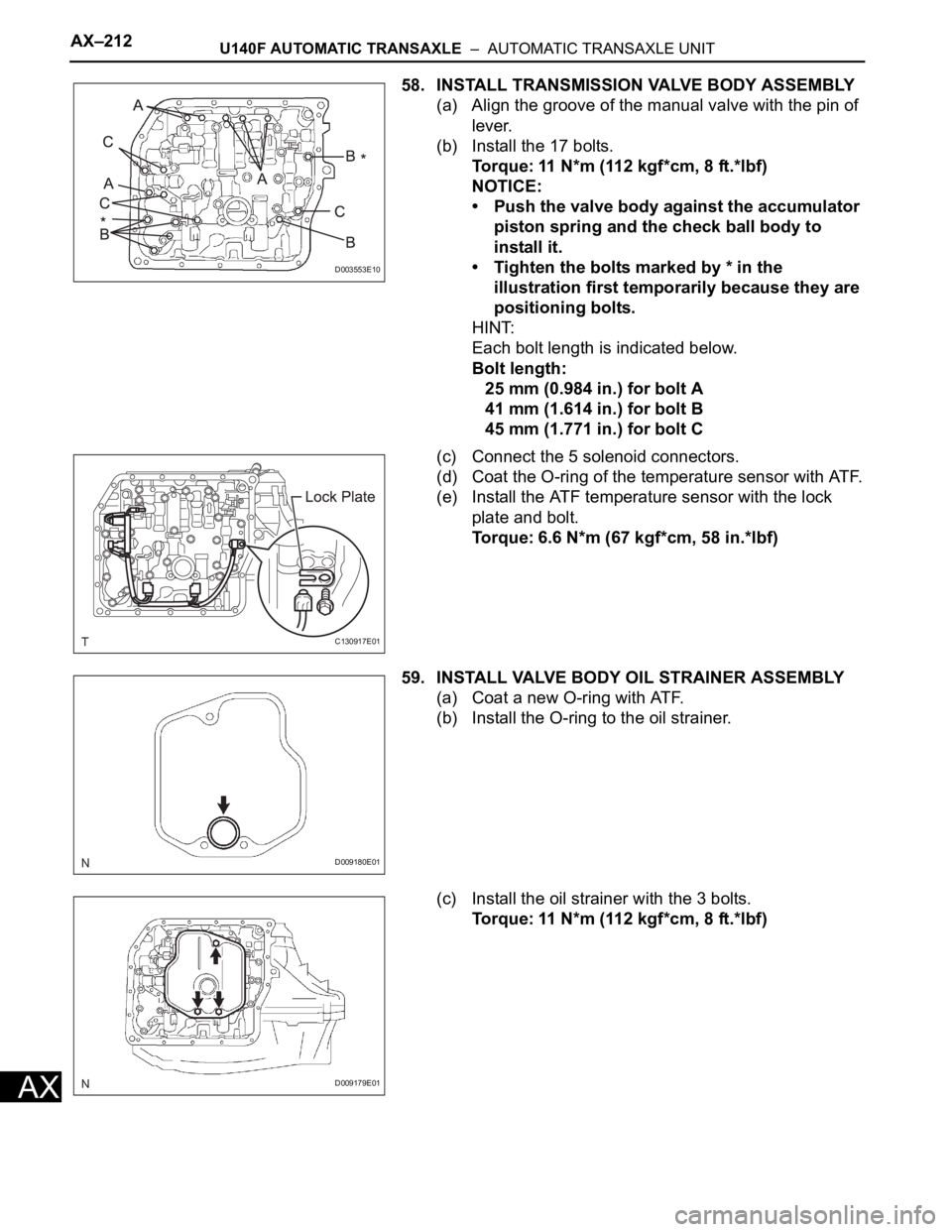

58. INSTALL TRANSMISSION VALVE BODY ASSEMBLY

(a) Align the groove of the manual valve with the pin of

lever.

(b) Install the 17 bolts.

Torque: 11 N*m (112 kgf*cm, 8 ft.*lbf)

NOTICE:

• Push the valve body against the accumulator

piston spring and the check ball body to

install it.

• Tighten the bolts marked by * in the

illustration first temporarily because they are

positioning bolts.

HINT:

Each bolt length is indicated below.

Bolt length:

25 mm (0.984 in.) for bolt A

41 mm (1.614 in.) for bolt B

45 mm (1.771 in.) for bolt C

(c) Connect the 5 solenoid connectors.

(d) Coat the O-ring of the temperature sensor with ATF.

(e) Install the ATF temperature sensor with the lock

plate and bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

59. INSTALL VALVE BODY OIL STRAINER ASSEMBLY

(a) Coat a new O-ring with ATF.

(b) Install the O-ring to the oil strainer.

(c) Install the oil strainer with the 3 bolts.

Torque: 11 N*m (112 kgf*cm, 8 ft.*lbf)

D003553E10

C130917E01

D009180E01

D009179E01

Page 1038 of 2000

AX–22U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

MANUAL SHIFTING TEST

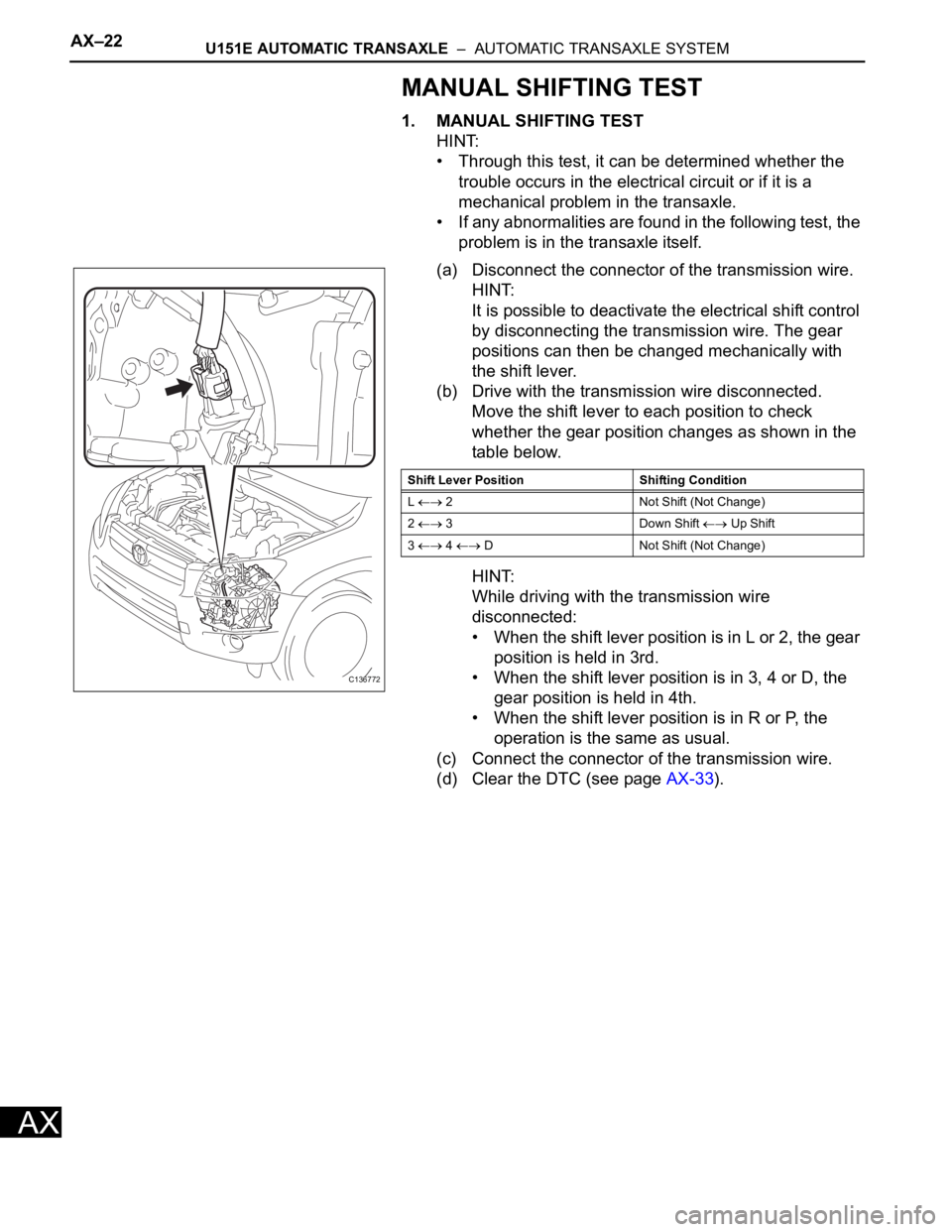

1. MANUAL SHIFTING TEST

HINT:

• Through this test, it can be determined whether the

trouble occurs in the electrical circuit or if it is a

mechanical problem in the transaxle.

• If any abnormalities are found in the following test, the

problem is in the transaxle itself.

(a) Disconnect the connector of the transmission wire.

HINT:

It is possible to deactivate the electrical shift control

by disconnecting the transmission wire. The gear

positions can then be changed mechanically with

the shift lever.

(b) Drive with the transmission wire disconnected.

Move the shift lever to each position to check

whether the gear position changes as shown in the

table below.

HINT:

While driving with the transmission wire

disconnected:

• When the shift lever position is in L or 2, the gear

position is held in 3rd.

• When the shift lever position is in 3, 4 or D, the

gear position is held in 4th.

• When the shift lever position is in R or P, the

operation is the same as usual.

(c) Connect the connector of the transmission wire.

(d) Clear the DTC (see page AX-33).

C136772

Shift Lever Position Shifting Condition

L

2 Not Shift (Not Change)

2

3 Down Shift Up Shift

3

4 D Not Shift (Not Change)

Page 1113 of 2000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–239

AX

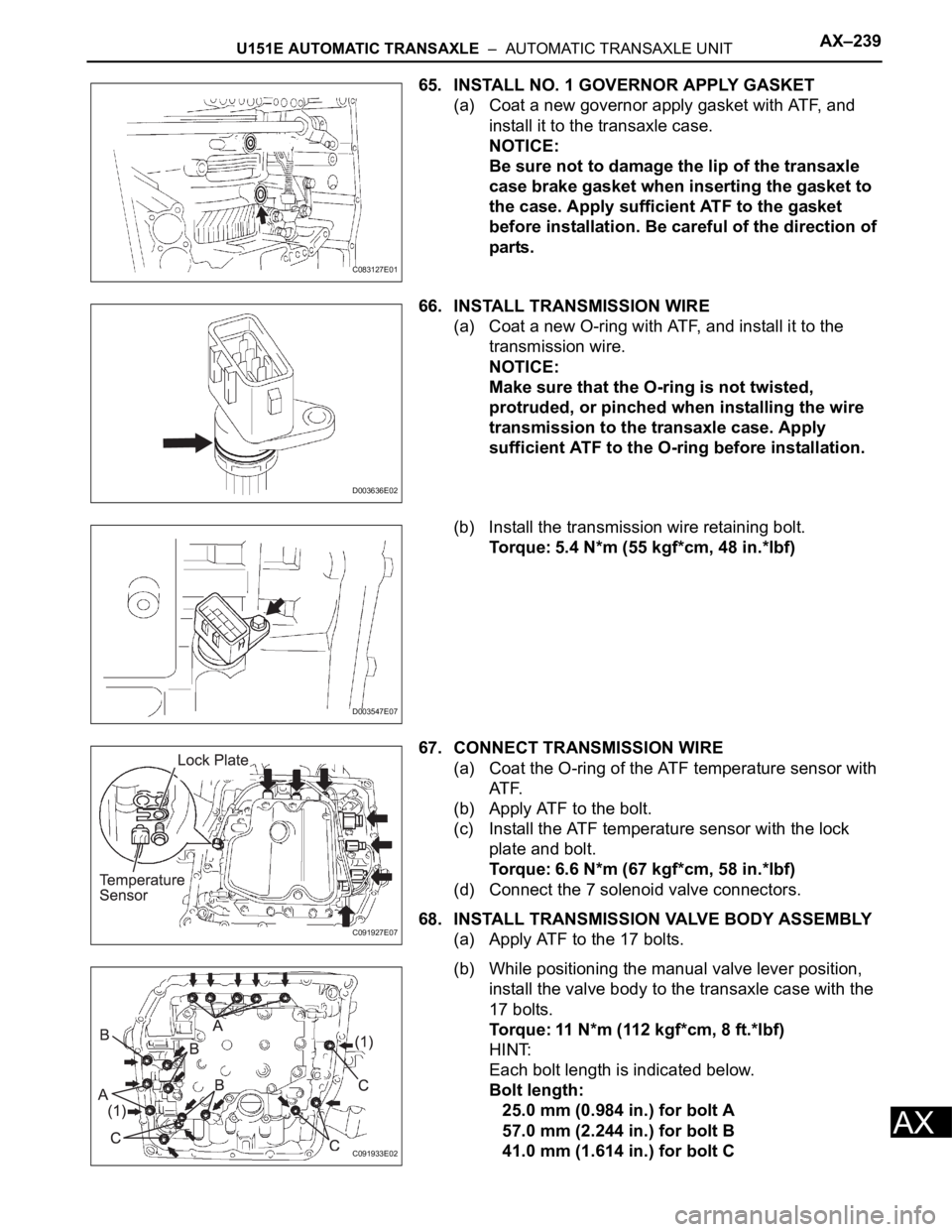

65. INSTALL NO. 1 GOVERNOR APPLY GASKET

(a) Coat a new governor apply gasket with ATF, and

install it to the transaxle case.

NOTICE:

Be sure not to damage the lip of the transaxle

case brake gasket when inserting the gasket to

the case. Apply sufficient ATF to the gasket

before installation. Be careful of the direction of

parts.

66. INSTALL TRANSMISSION WIRE

(a) Coat a new O-ring with ATF, and install it to the

transmission wire.

NOTICE:

Make sure that the O-ring is not twisted,

protruded, or pinched when installing the wire

transmission to the transaxle case. Apply

sufficient ATF to the O-ring before installation.

(b) Install the transmission wire retaining bolt.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

67. CONNECT TRANSMISSION WIRE

(a) Coat the O-ring of the ATF temperature sensor with

AT F.

(b) Apply ATF to the bolt.

(c) Install the ATF temperature sensor with the lock

plate and bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(d) Connect the 7 solenoid valve connectors.

68. INSTALL TRANSMISSION VALVE BODY ASSEMBLY

(a) Apply ATF to the 17 bolts.

(b) While positioning the manual valve lever position,

install the valve body to the transaxle case with the

17 bolts.

Torque: 11 N*m (112 kgf*cm, 8 ft.*lbf)

HINT:

Each bolt length is indicated below.

Bolt length:

25.0 mm (0.984 in.) for bolt A

57.0 mm (2.244 in.) for bolt B

41.0 mm (1.614 in.) for bolt C

C083127E01

D003636E02

D003547E07

C091927E07

C091933E02

Page 1141 of 2000

AX–22U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

MANUAL SHIFTING TEST

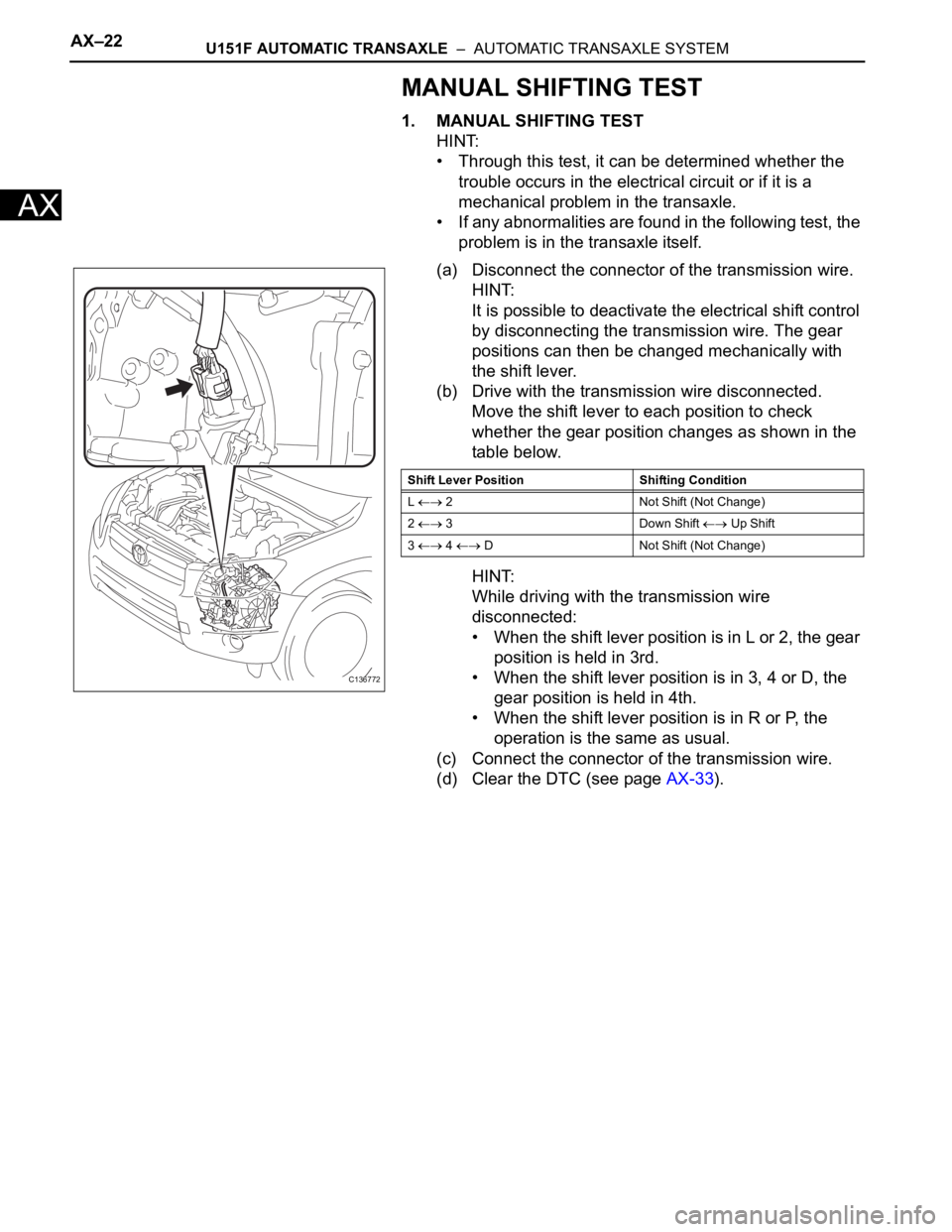

1. MANUAL SHIFTING TEST

HINT:

• Through this test, it can be determined whether the

trouble occurs in the electrical circuit or if it is a

mechanical problem in the transaxle.

• If any abnormalities are found in the following test, the

problem is in the transaxle itself.

(a) Disconnect the connector of the transmission wire.

HINT:

It is possible to deactivate the electrical shift control

by disconnecting the transmission wire. The gear

positions can then be changed mechanically with

the shift lever.

(b) Drive with the transmission wire disconnected.

Move the shift lever to each position to check

whether the gear position changes as shown in the

table below.

HINT:

While driving with the transmission wire

disconnected:

• When the shift lever position is in L or 2, the gear

position is held in 3rd.

• When the shift lever position is in 3, 4 or D, the

gear position is held in 4th.

• When the shift lever position is in R or P, the

operation is the same as usual.

(c) Connect the connector of the transmission wire.

(d) Clear the DTC (see page AX-33).

C136772

Shift Lever Position Shifting Condition

L

2 Not Shift (Not Change)

2

3 Down Shift Up Shift

3

4 D Not Shift (Not Change)

Page 1218 of 2000

AX–240U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

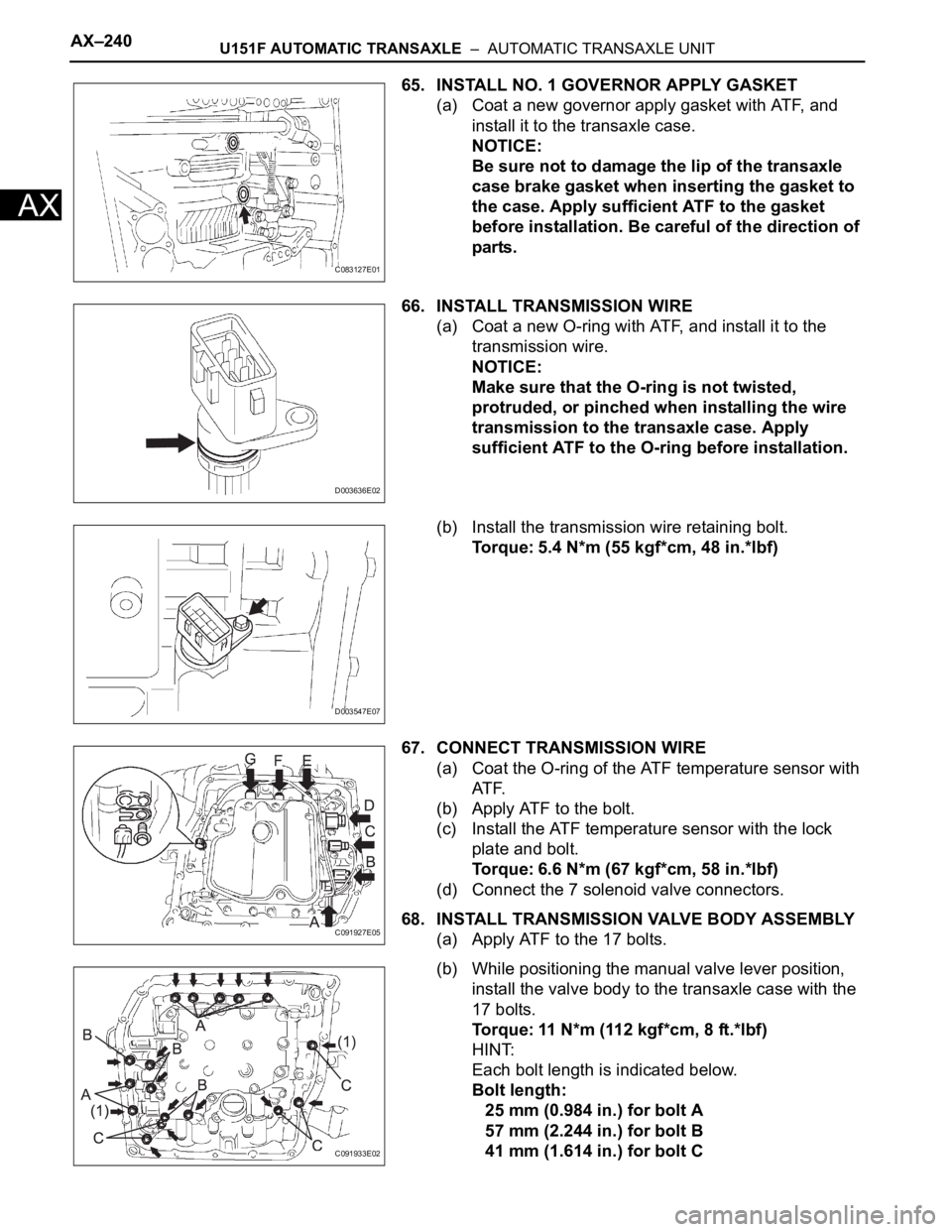

65. INSTALL NO. 1 GOVERNOR APPLY GASKET

(a) Coat a new governor apply gasket with ATF, and

install it to the transaxle case.

NOTICE:

Be sure not to damage the lip of the transaxle

case brake gasket when inserting the gasket to

the case. Apply sufficient ATF to the gasket

before installation. Be careful of the direction of

parts.

66. INSTALL TRANSMISSION WIRE

(a) Coat a new O-ring with ATF, and install it to the

transmission wire.

NOTICE:

Make sure that the O-ring is not twisted,

protruded, or pinched when installing the wire

transmission to the transaxle case. Apply

sufficient ATF to the O-ring before installation.

(b) Install the transmission wire retaining bolt.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

67. CONNECT TRANSMISSION WIRE

(a) Coat the O-ring of the ATF temperature sensor with

AT F.

(b) Apply ATF to the bolt.

(c) Install the ATF temperature sensor with the lock

plate and bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(d) Connect the 7 solenoid valve connectors.

68. INSTALL TRANSMISSION VALVE BODY ASSEMBLY

(a) Apply ATF to the 17 bolts.

(b) While positioning the manual valve lever position,

install the valve body to the transaxle case with the

17 bolts.

Torque: 11 N*m (112 kgf*cm, 8 ft.*lbf)

HINT:

Each bolt length is indicated below.

Bolt length:

25 mm (0.984 in.) for bolt A

57 mm (2.244 in.) for bolt B

41 mm (1.614 in.) for bolt C

C083127E01

D003636E02

D003547E07

C091927E05

C091933E02

Page 1245 of 2000

U241E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–21

AX

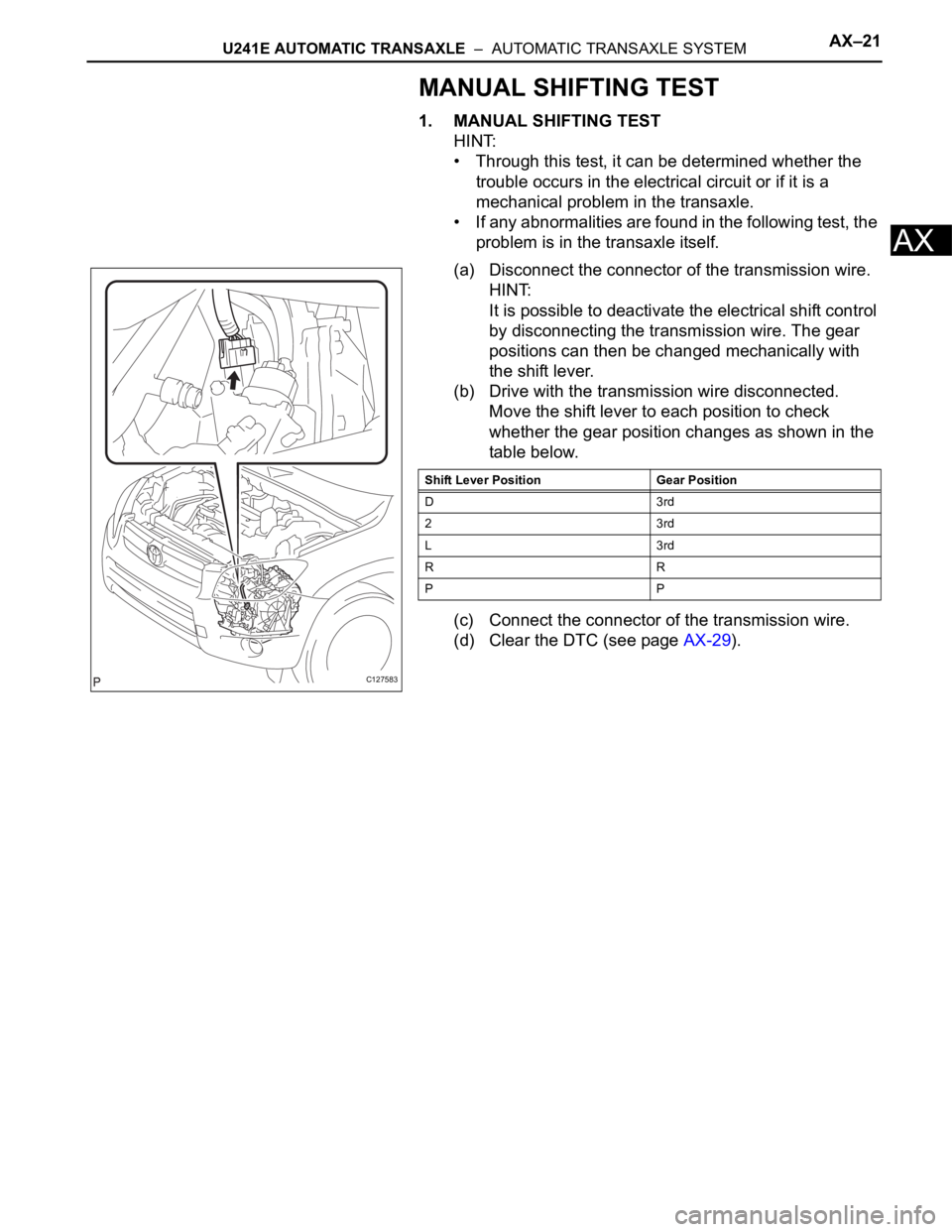

MANUAL SHIFTING TEST

1. MANUAL SHIFTING TEST

HINT:

• Through this test, it can be determined whether the

trouble occurs in the electrical circuit or if it is a

mechanical problem in the transaxle.

• If any abnormalities are found in the following test, the

problem is in the transaxle itself.

(a) Disconnect the connector of the transmission wire.

HINT:

It is possible to deactivate the electrical shift control

by disconnecting the transmission wire. The gear

positions can then be changed mechanically with

the shift lever.

(b) Drive with the transmission wire disconnected.

Move the shift lever to each position to check

whether the gear position changes as shown in the

table below.

(c) Connect the connector of the transmission wire.

(d) Clear the DTC (see page AX-29).

C127583

Shift Lever Position Gear Position

D3rd

23rd

L3rd

RR

PP