radio TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 380 of 2000

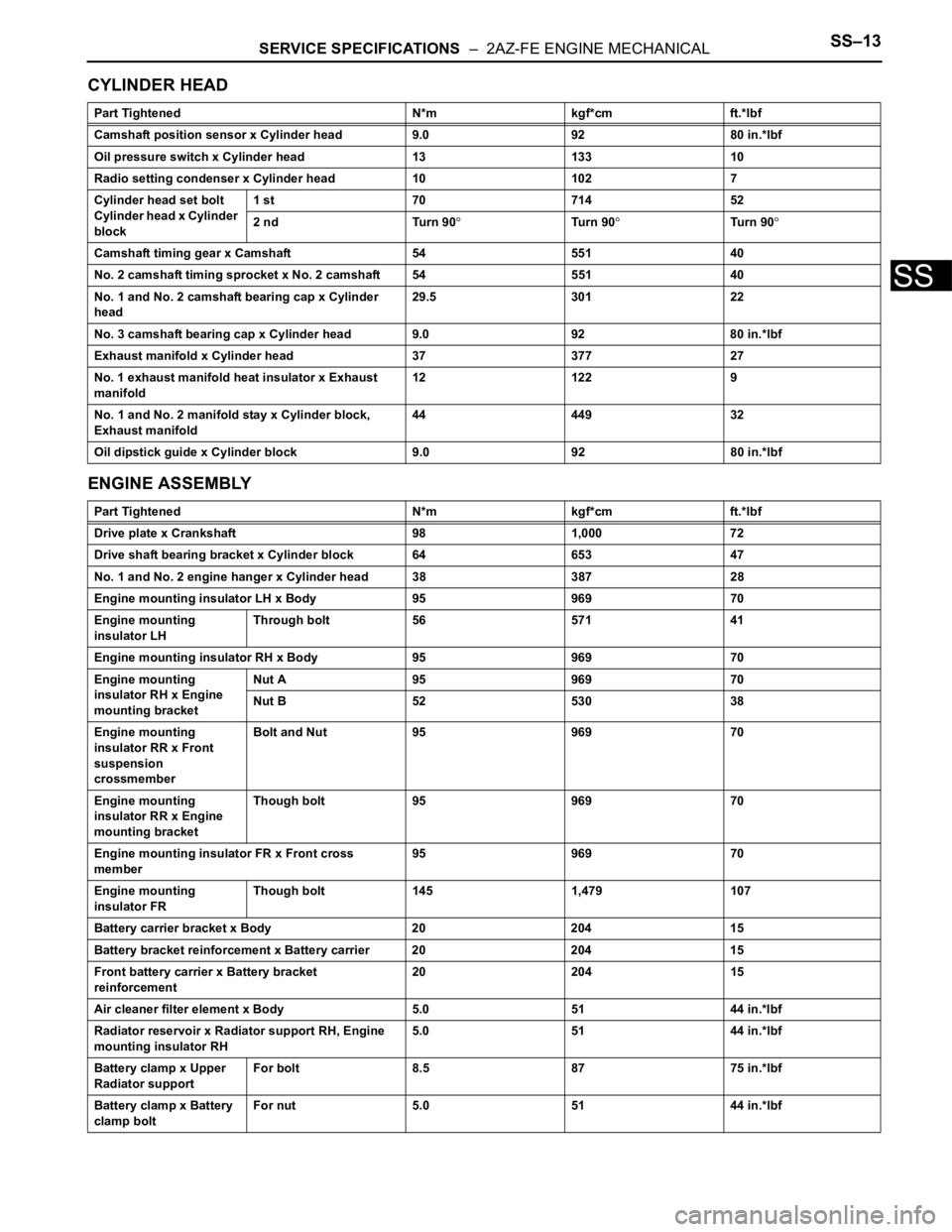

SERVICE SPECIFICATIONS – 2AZ-FE ENGINE MECHANICALSS–13

SS

CYLINDER HEAD

ENGINE ASSEMBLY

Part Tightened N*m kgf*cm ft.*lbf

Camshaft position sensor x Cylinder head 9.0 92 80 in.*lbf

Oil pressure switch x Cylinder head 13 133 10

Radio setting condenser x Cylinder head 10 102 7

Cylinder head set bolt

Cylinder head x Cylinder

block1 st 70 714 52

2 nd Turn 90

Tu r n 9 0Tu r n 9 0

Camshaft timing gear x Camshaft 54 551 40

No. 2 camshaft timing sprocket x No. 2 camshaft 54 551 40

No. 1 and No. 2 camshaft bearing cap x Cylinder

head29.5 301 22

No. 3 camshaft bearing cap x Cylinder head 9.0 92 80 in.*lbf

Exhaust manifold x Cylinder head 37 377 27

No. 1 exhaust manifold heat insulator x Exhaust

manifold12 122 9

No. 1 and No. 2 manifold stay x Cylinder block,

Exhaust manifold44 449 32

Oil dipstick guide x Cylinder block 9.0 92 80 in.*lbf

Part Tightened N*m kgf*cm ft.*lbf

Drive plate x Crankshaft 98 1,000 72

Drive shaft bearing bracket x Cylinder block 64 653 47

No. 1 and No. 2 engine hanger x Cylinder head 38 387 28

Engine mounting insulator LH x Body 95 969 70

Engine mounting

insulator LHThrough bolt 56 571 41

Engine mounting insulator RH x Body 95 969 70

Engine mounting

insulator RH x Engine

mounting bracketNut A 95 969 70

Nut B 52 530 38

Engine mounting

insulator RR x Front

suspension

crossmemberBolt and Nut 95 969 70

Engine mounting

insulator RR x Engine

mounting bracketThough bolt 95 969 70

Engine mounting insulator FR x Front cross

member95 969 70

Engine mounting

insulator FRThough bolt 145 1,479 107

Battery carrier bracket x Body 20 204 15

Battery bracket reinforcement x Battery carrier 20 204 15

Front battery carrier x Battery bracket

reinforcement20 204 15

Air cleaner filter element x Body 5.0 51 44 in.*lbf

Radiator reservoir x Radiator support RH, Engine

mounting insulator RH5.0 51 44 in.*lbf

Battery clamp x Upper

Radiator supportFor bolt 8.5 87 75 in.*lbf

Battery clamp x Battery

clamp boltFor nut 5.0 51 44 in.*lbf

Page 430 of 2000

AIR CONDITIONING – AIR CONDITIONING CONTROL ASSEMBLY (for Manual Air Condi-

tioning System)AC–245

AC

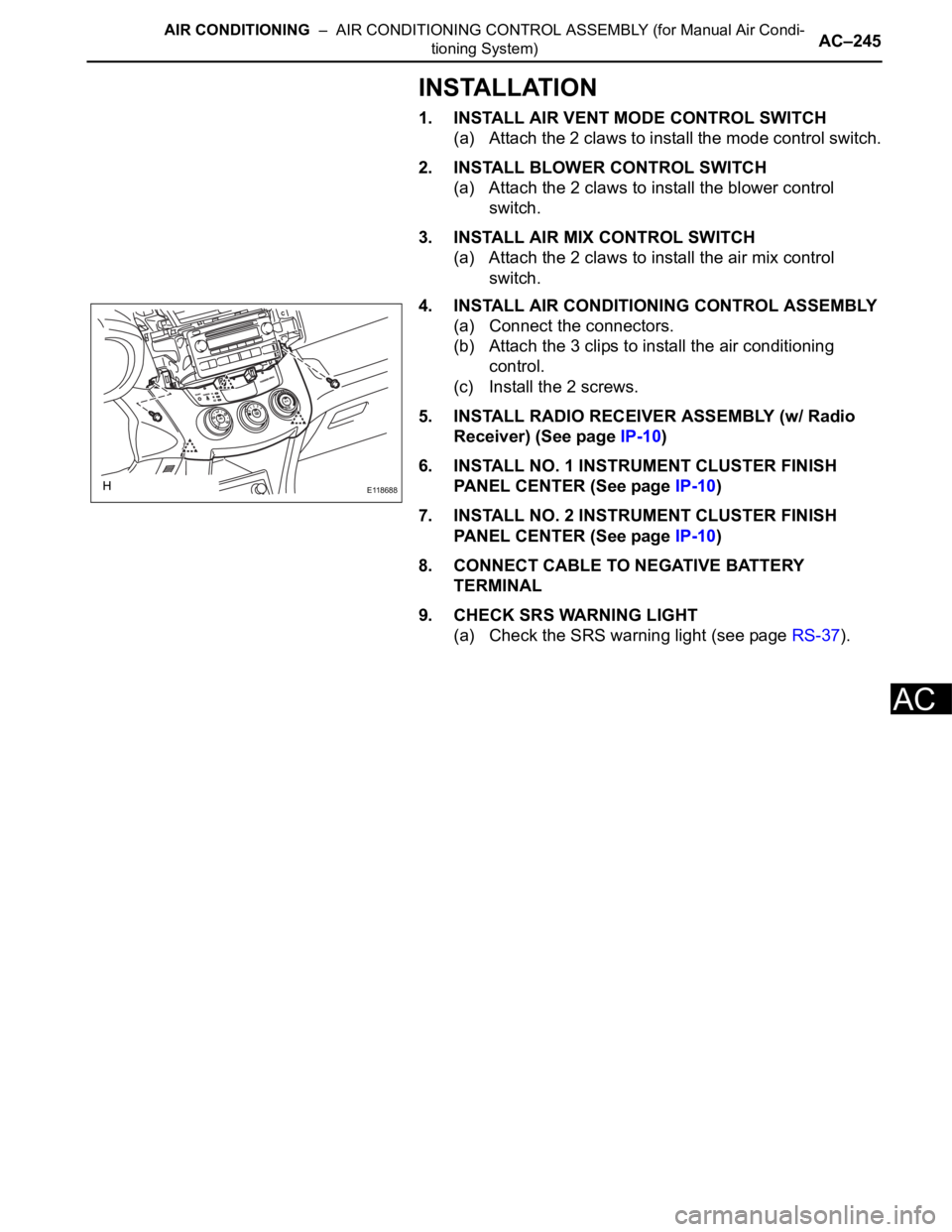

INSTALLATION

1. INSTALL AIR VENT MODE CONTROL SWITCH

(a) Attach the 2 claws to install the mode control switch.

2. INSTALL BLOWER CONTROL SWITCH

(a) Attach the 2 claws to install the blower control

switch.

3. INSTALL AIR MIX CONTROL SWITCH

(a) Attach the 2 claws to install the air mix control

switch.

4. INSTALL AIR CONDITIONING CONTROL ASSEMBLY

(a) Connect the connectors.

(b) Attach the 3 clips to install the air conditioning

control.

(c) Install the 2 screws.

5. INSTALL RADIO RECEIVER ASSEMBLY (w/ Radio

Receiver) (See page IP-10)

6. INSTALL NO. 1 INSTRUMENT CLUSTER FINISH

PANEL CENTER (See page IP-10)

7. INSTALL NO. 2 INSTRUMENT CLUSTER FINISH

PANEL CENTER (See page IP-10)

8. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

9. CHECK SRS WARNING LIGHT

(a) Check the SRS warning light (see page RS-37).

E118688

Page 506 of 2000

INSTRUMENT PANEL – UPPER INSTRUMENT PANELIP–5

IP

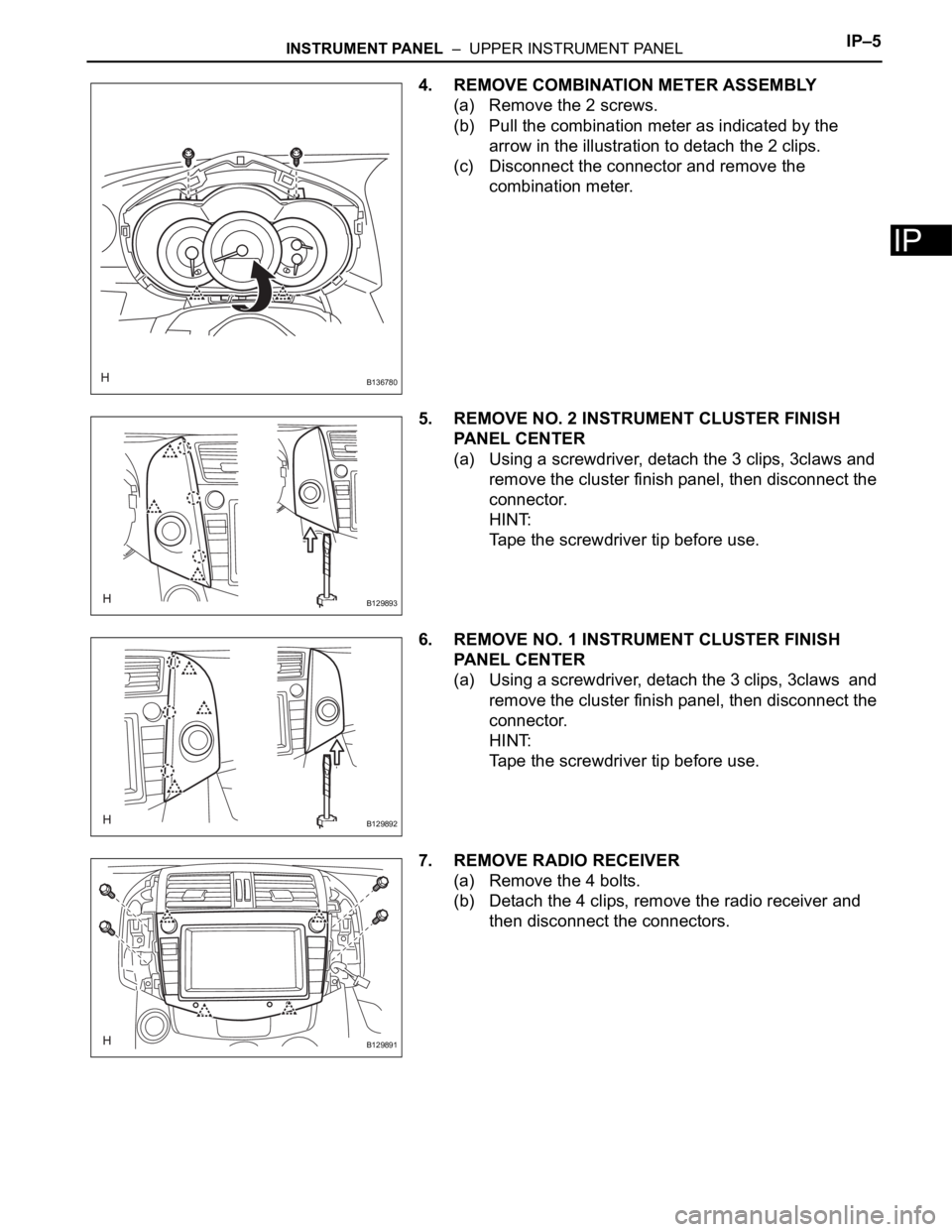

4. REMOVE COMBINATION METER ASSEMBLY

(a) Remove the 2 screws.

(b) Pull the combination meter as indicated by the

arrow in the illustration to detach the 2 clips.

(c) Disconnect the connector and remove the

combination meter.

5. REMOVE NO. 2 INSTRUMENT CLUSTER FINISH

PANEL CENTER

(a) Using a screwdriver, detach the 3 clips, 3claws and

remove the cluster finish panel, then disconnect the

connector.

HINT:

Tape the screwdriver tip before use.

6. REMOVE NO. 1 INSTRUMENT CLUSTER FINISH

PANEL CENTER

(a) Using a screwdriver, detach the 3 clips, 3claws and

remove the cluster finish panel, then disconnect the

connector.

HINT:

Tape the screwdriver tip before use.

7. REMOVE RADIO RECEIVER

(a) Remove the 4 bolts.

(b) Detach the 4 clips, remove the radio receiver and

then disconnect the connectors.

B136780

B129893

B129892

B129891

Page 603 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–59

EM

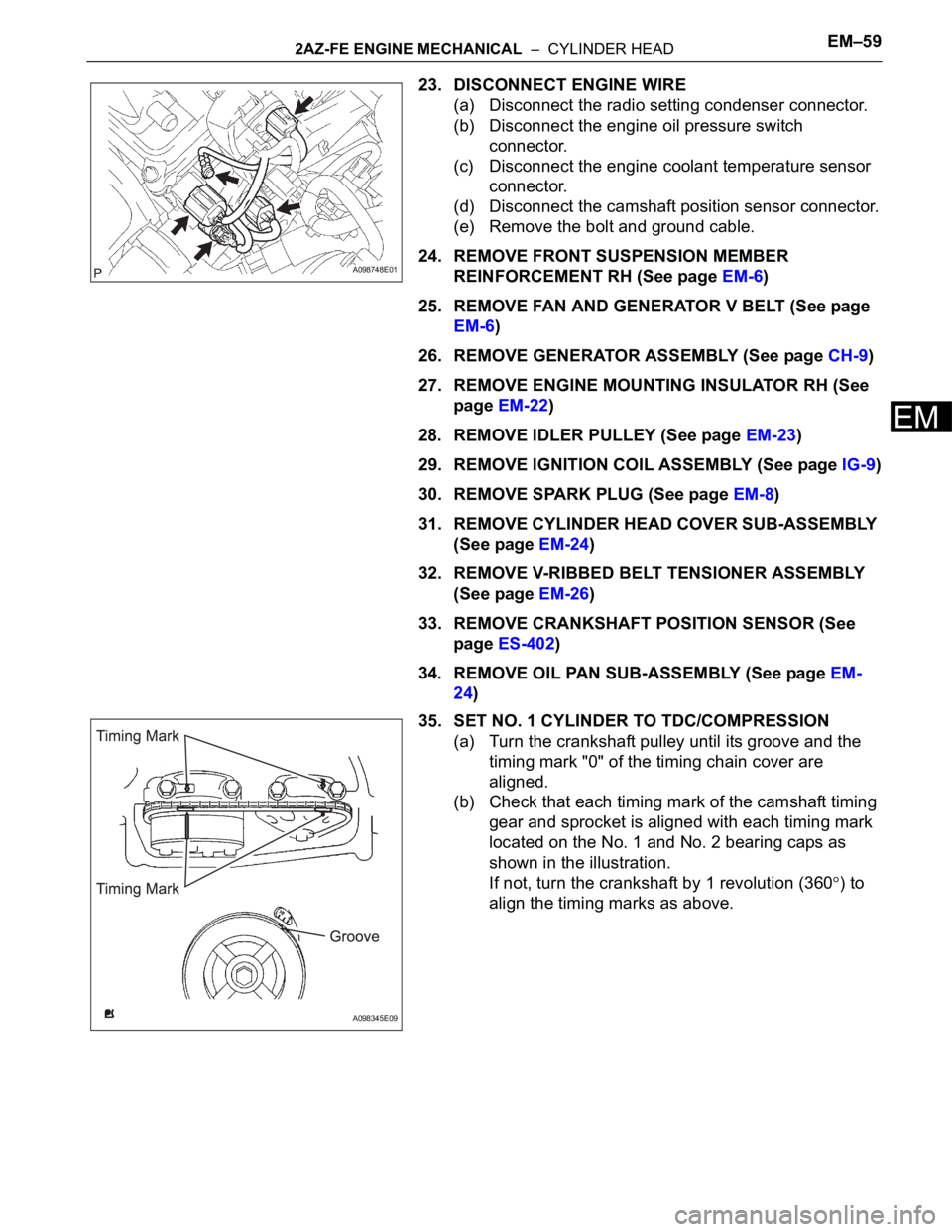

23. DISCONNECT ENGINE WIRE

(a) Disconnect the radio setting condenser connector.

(b) Disconnect the engine oil pressure switch

connector.

(c) Disconnect the engine coolant temperature sensor

connector.

(d) Disconnect the camshaft position sensor connector.

(e) Remove the bolt and ground cable.

24. REMOVE FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-6)

25. REMOVE FAN AND GENERATOR V BELT (See page

EM-6)

26. REMOVE GENERATOR ASSEMBLY (See page CH-9)

27. REMOVE ENGINE MOUNTING INSULATOR RH (See

page EM-22)

28. REMOVE IDLER PULLEY (See page EM-23)

29. REMOVE IGNITION COIL ASSEMBLY (See page IG-9)

30. REMOVE SPARK PLUG (See page EM-8)

31. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(See page EM-24)

32. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(See page EM-26)

33. REMOVE CRANKSHAFT POSITION SENSOR (See

page ES-402)

34. REMOVE OIL PAN SUB-ASSEMBLY (See page EM-

24)

35. SET NO. 1 CYLINDER TO TDC/COMPRESSION

(a) Turn the crankshaft pulley until its groove and the

timing mark "0" of the timing chain cover are

aligned.

(b) Check that each timing mark of the camshaft timing

gear and sprocket is aligned with each timing mark

located on the No. 1 and No. 2 bearing caps as

shown in the illustration.

If not, turn the crankshaft by 1 revolution (360

) to

align the timing marks as above.

A098748E01

A098345E09

Page 607 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–63

EM

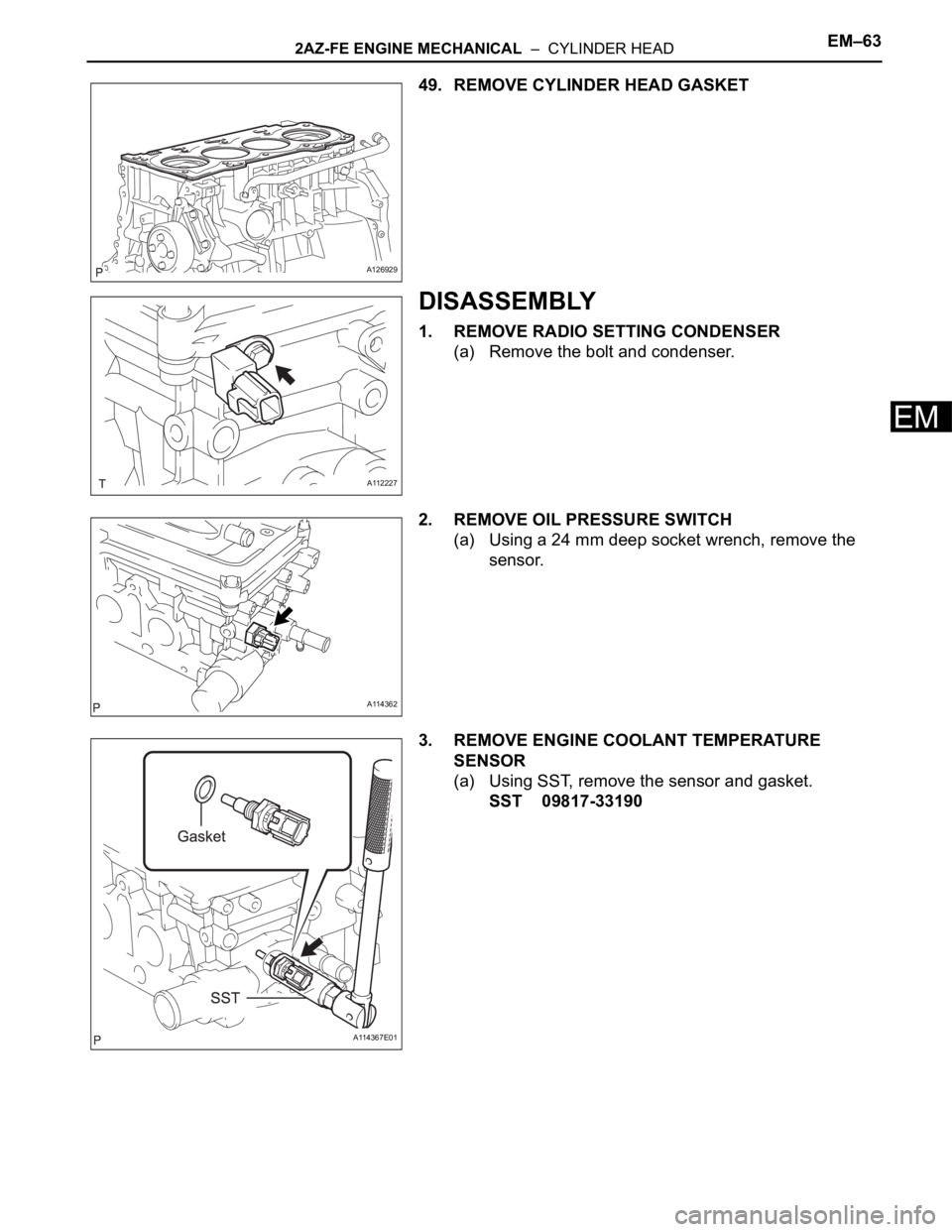

49. REMOVE CYLINDER HEAD GASKET

DISASSEMBLY

1. REMOVE RADIO SETTING CONDENSER

(a) Remove the bolt and condenser.

2. REMOVE OIL PRESSURE SWITCH

(a) Using a 24 mm deep socket wrench, remove the

sensor.

3. REMOVE ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using SST, remove the sensor and gasket.

SST 09817-33190

A126929

A112227

A114362

A114367E01

Page 627 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–83

EM

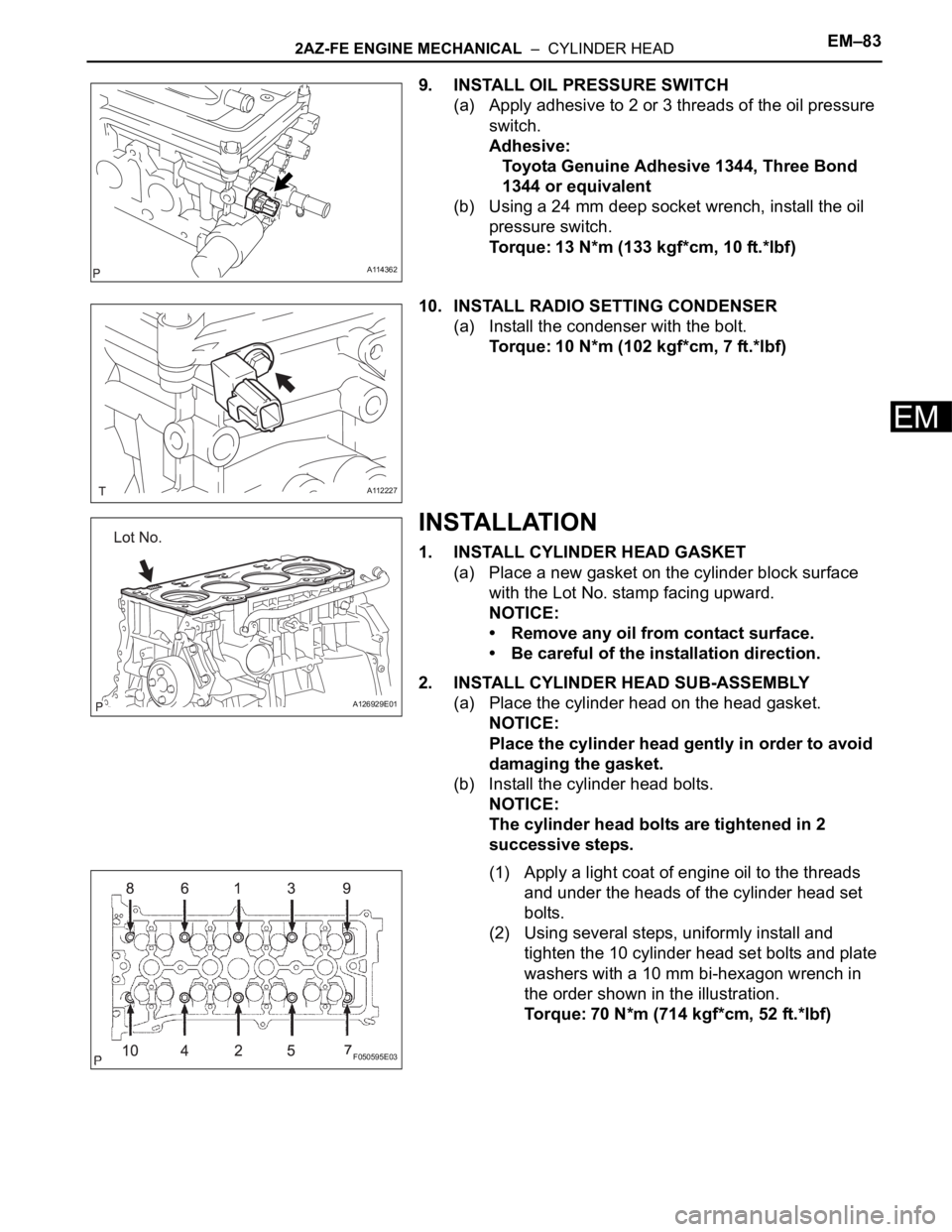

9. INSTALL OIL PRESSURE SWITCH

(a) Apply adhesive to 2 or 3 threads of the oil pressure

switch.

Adhesive:

Toyota Genuine Adhesive 1344, Three Bond

1344 or equivalent

(b) Using a 24 mm deep socket wrench, install the oil

pressure switch.

Torque: 13 N*m (133 kgf*cm, 10 ft.*lbf)

10. INSTALL RADIO SETTING CONDENSER

(a) Install the condenser with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

INSTALLATION

1. INSTALL CYLINDER HEAD GASKET

(a) Place a new gasket on the cylinder block surface

with the Lot No. stamp facing upward.

NOTICE:

• Remove any oil from contact surface.

• Be careful of the installation direction.

2. INSTALL CYLINDER HEAD SUB-ASSEMBLY

(a) Place the cylinder head on the head gasket.

NOTICE:

Place the cylinder head gently in order to avoid

damaging the gasket.

(b) Install the cylinder head bolts.

NOTICE:

The cylinder head bolts are tightened in 2

successive steps.

(1) Apply a light coat of engine oil to the threads

and under the heads of the cylinder head set

bolts.

(2) Using several steps, uniformly install and

tighten the 10 cylinder head set bolts and plate

washers with a 10 mm bi-hexagon wrench in

the order shown in the illustration.

Torque: 70 N*m (714 kgf*cm, 52 ft.*lbf)

A114362

A112227

A126929E01

F050595E03

Page 630 of 2000

EM–862AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

22. INSTALL ENGINE MOUNTING INSULATOR RH (See

page EM-41)

23. INSTALL RADIATOR RESERVOIR (See page EM-112)

24. INSTALL GENERATOR ASSEMBLY (See page CH-15)

25. INSTALL FAN AND GENERATOR V BELT (See page

EM-7)

26. INSTALL FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-7)

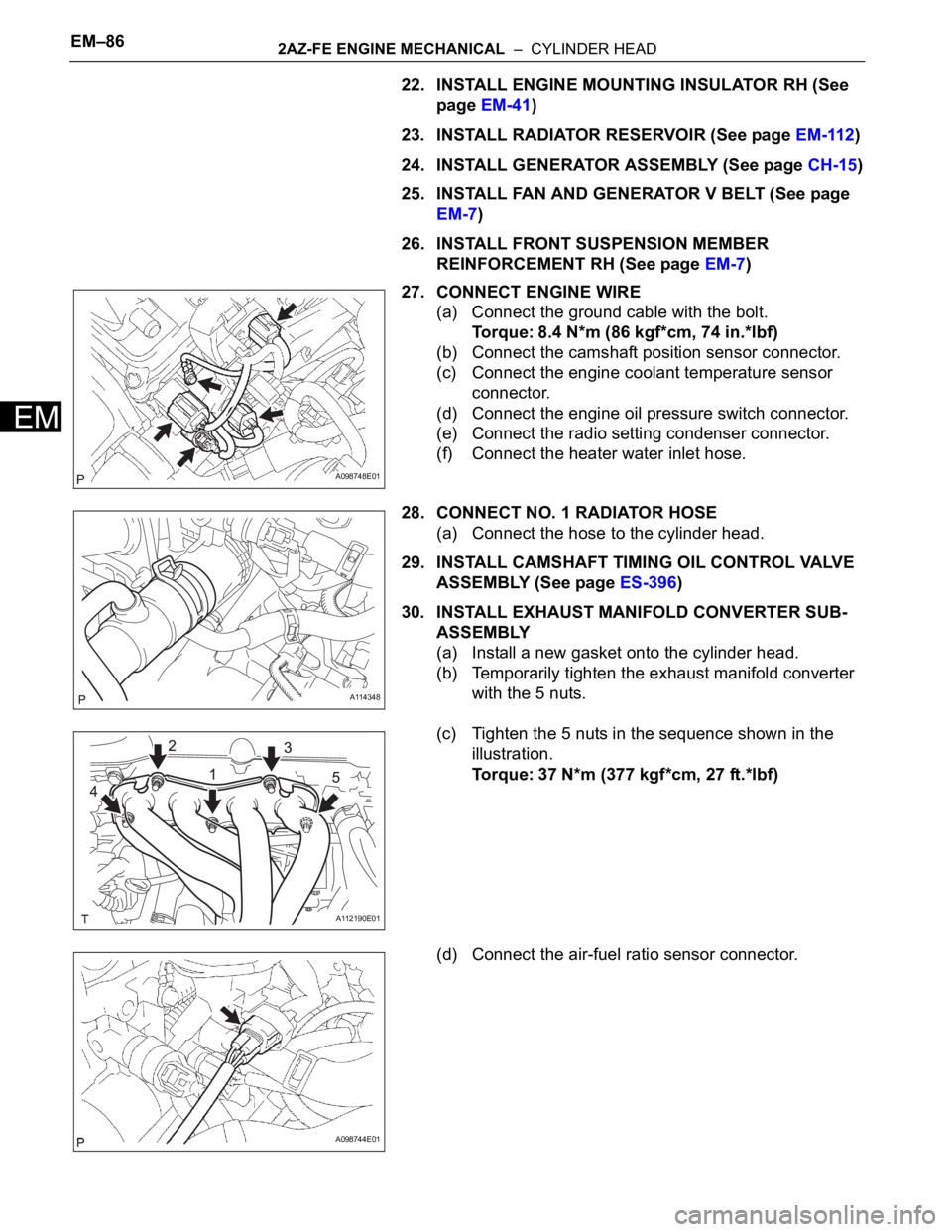

27. CONNECT ENGINE WIRE

(a) Connect the ground cable with the bolt.

Torque: 8.4 N*m (86 kgf*cm, 74 in.*lbf)

(b) Connect the camshaft position sensor connector.

(c) Connect the engine coolant temperature sensor

connector.

(d) Connect the engine oil pressure switch connector.

(e) Connect the radio setting condenser connector.

(f) Connect the heater water inlet hose.

28. CONNECT NO. 1 RADIATOR HOSE

(a) Connect the hose to the cylinder head.

29. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY (See page ES-396)

30. INSTALL EXHAUST MANIFOLD CONVERTER SUB-

ASSEMBLY

(a) Install a new gasket onto the cylinder head.

(b) Temporarily tighten the exhaust manifold converter

with the 5 nuts.

(c) Tighten the 5 nuts in the sequence shown in the

illustration.

Torque: 37 N*m (377 kgf*cm, 27 ft.*lbf)

(d) Connect the air-fuel ratio sensor connector.

A098748E01

A114348

A112190E01

A098744E01

Page 650 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–123

EM

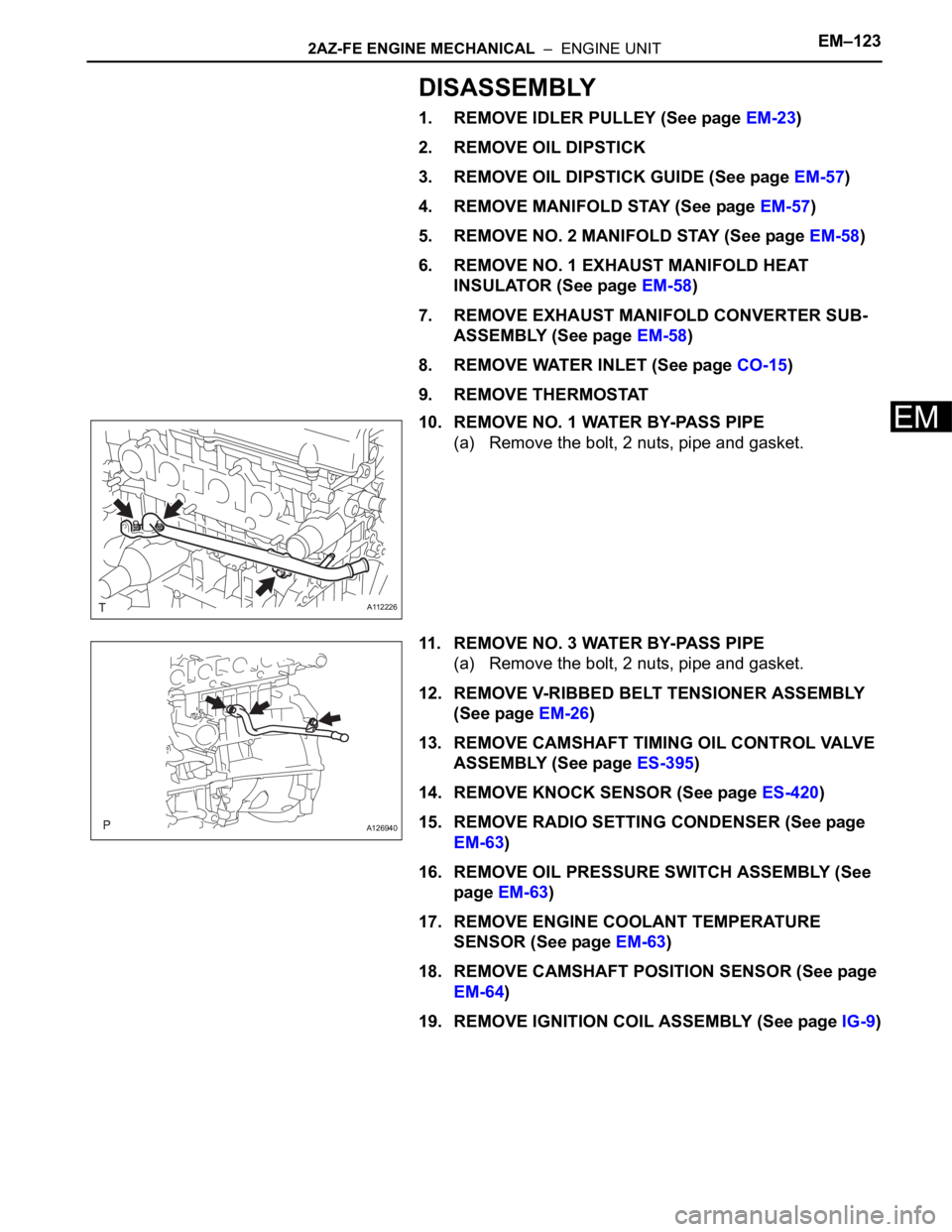

DISASSEMBLY

1. REMOVE IDLER PULLEY (See page EM-23)

2. REMOVE OIL DIPSTICK

3. REMOVE OIL DIPSTICK GUIDE (See page EM-57)

4. REMOVE MANIFOLD STAY (See page EM-57)

5. REMOVE NO. 2 MANIFOLD STAY (See page EM-58)

6. REMOVE NO. 1 EXHAUST MANIFOLD HEAT

INSULATOR (See page EM-58)

7. REMOVE EXHAUST MANIFOLD CONVERTER SUB-

ASSEMBLY (See page EM-58)

8. REMOVE WATER INLET (See page CO-15)

9. REMOVE THERMOSTAT

10. REMOVE NO. 1 WATER BY-PASS PIPE

(a) Remove the bolt, 2 nuts, pipe and gasket.

11. REMOVE NO. 3 WATER BY-PASS PIPE

(a) Remove the bolt, 2 nuts, pipe and gasket.

12. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(See page EM-26)

13. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY (See page ES-395)

14. REMOVE KNOCK SENSOR (See page ES-420)

15. REMOVE RADIO SETTING CONDENSER (See page

EM-63)

16. REMOVE OIL PRESSURE SWITCH ASSEMBLY (See

page EM-63)

17. REMOVE ENGINE COOLANT TEMPERATURE

SENSOR (See page EM-63)

18. REMOVE CAMSHAFT POSITION SENSOR (See page

EM-64)

19. REMOVE IGNITION COIL ASSEMBLY (See page IG-9)

A112226

A126940

Page 1478 of 2000

TW–6TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TW

SYSTEM DESCRIPTION

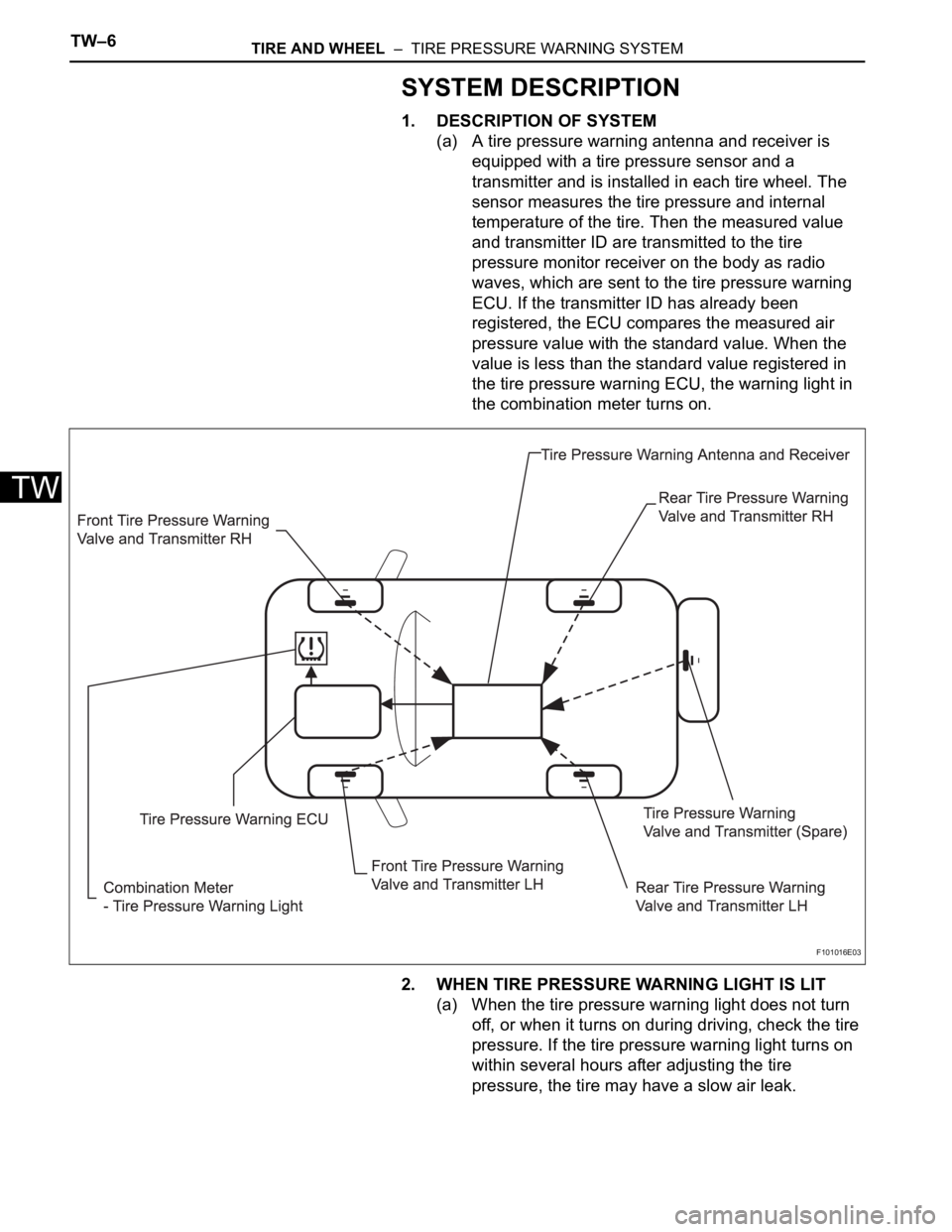

1. DESCRIPTION OF SYSTEM

(a) A tire pressure warning antenna and receiver is

equipped with a tire pressure sensor and a

transmitter and is installed in each tire wheel. The

sensor measures the tire pressure and internal

temperature of the tire. Then the measured value

and transmitter ID are transmitted to the tire

pressure monitor receiver on the body as radio

waves, which are sent to the tire pressure warning

ECU. If the transmitter ID has already been

registered, the ECU compares the measured air

pressure value with the standard value. When the

value is less than the standard value registered in

the tire pressure warning ECU, the warning light in

the combination meter turns on.

2. WHEN TIRE PRESSURE WARNING LIGHT IS LIT

(a) When the tire pressure warning light does not turn

off, or when it turns on during driving, check the tire

pressure. If the tire pressure warning light turns on

within several hours after adjusting the tire

pressure, the tire may have a slow air leak.

F101016E03

Page 1479 of 2000

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–7

TW

(b) Under the following conditions, the system may not

function properly;

• Areas, facilities or devices that use similar radio

frequencies are located in the vicinity of the

vehicle.

• Devices using similar radio frequencies are used

in the vehicle.

• Large amounts of snow or ice are stuck to the

vehicle, especially on the wheels and around the

wheel houses.

• The battery of the transmitter is depleted.

• Tires and wheels without tire pressure warning

valves and transmitters are used.

• Snow tires and tire chains are used.

• If wheels other than the specified ones are used,

the system may not function properly because

different radio waves are transmitted from the tire

pressure warning valve and transmitter.

• Depending on the tire type, the tire pressure

warning valve and transmitter may not function

properly even though the specified wheels are

used.

• The system may not function properly if it is

initialized with tire pressures which are not the

specified values.

(c) The average life of the grommet of the tire pressure

warning antenna and receiver is approximately 5

years, at which time it must be replaced. Retighten

the valve nut if the valve is leaking air, if it is less

than 5 years old, and there is no problem with the

grommets.

(d) After removing and installing the ECU or a sensor,

output a diagnosis code and check that it is a

normal code.

3. FUNCTION OF COMPONENTS

Components Function

Tire pressure warning antenna and receiver • Combined as a single unit with a disc wheel air valve, it measures

tire pressure and temperature, and transmits an ID number for

measurement value and identification

• Battery is built into valve

Tire pressure warning antenna and receiver Receives necessary signals from tire pressure warning antenna and

receiver and transmits them to tire pressure warning ECU

Tire pressure warning ECU • Receives signal from receiver and identifies it as vehicle's own

signal.

• If measurement value is equal to or lower than specified value, it

transmits a signal so that the air pressure warning light on

combination meter turns on.

Tire pressure warning light Located in the combination meter, it informs driver of lowered tire air

pressure and system failure