service TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1 of 2000

ENGINE - 2AZ-FE ENGINE EG-4

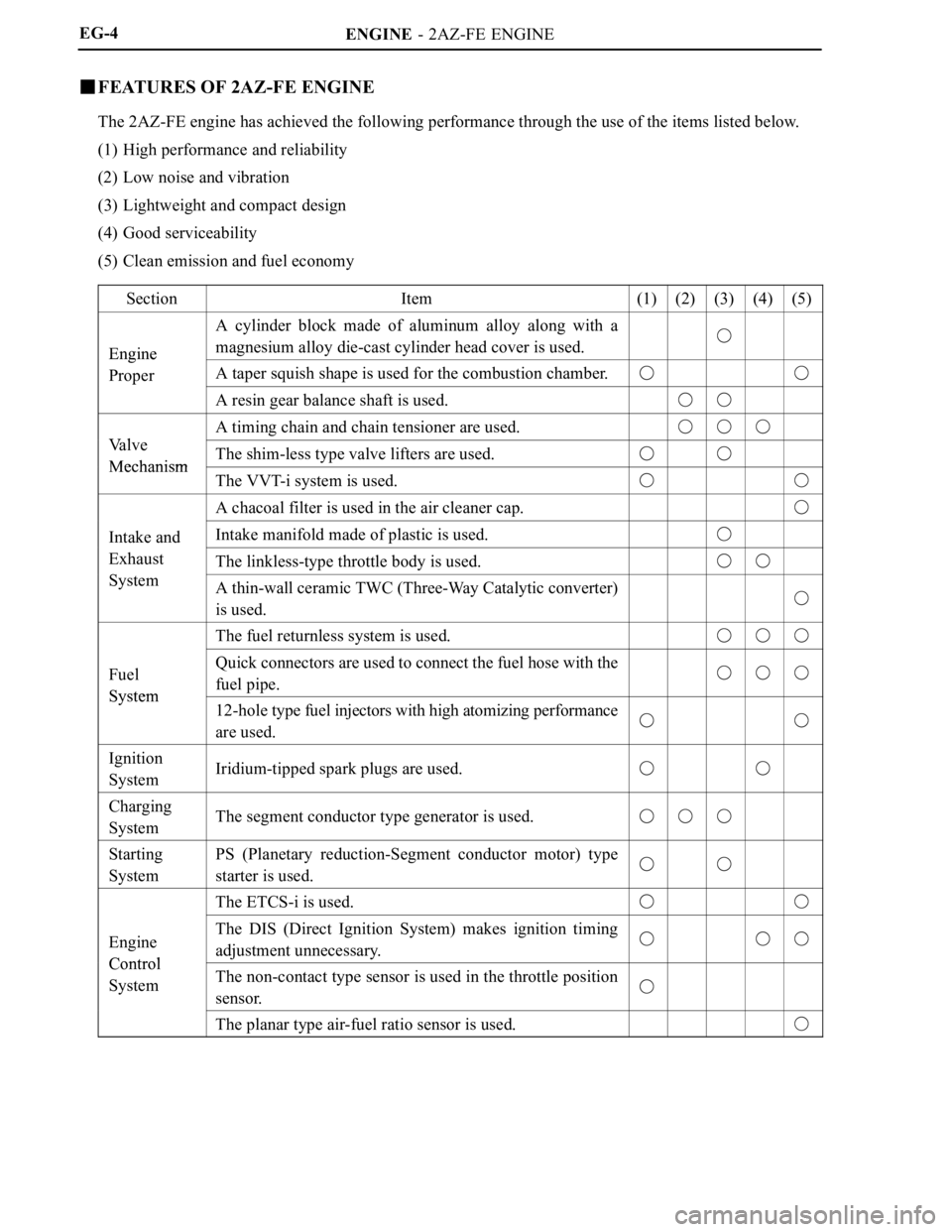

FEATURES OF 2AZ-FE ENGINE

The 2AZ-FE engine has achieved the following performance through the use of the items listed below.

(1) High performance and reliability

(2) Low noise and vibration

(3) Lightweight and compact design

(4) Good serviceability

(5) Clean emission and fuel economy

Section

Item(1)(2)(3)(4)(5)

Engine

A cylinder block made of aluminum alloy along with a

magnesium alloy die-cast cylinder head cover is used.

Engine

ProperA taper squish shape is used for the combustion chamber.p

A resin gear balance shaft is used.

Vl

A timing chain and chain tensioner are used.

Va l v e

MechanismThe shim-less type valve lifters are used.MechanismThe VVT-i system is used.

A chacoal filter is used in the air cleaner cap.

Intake andIntake manifold made of plastic is used.Intake and

ExhaustThe linkless-type throttle body is used.

SystemA thin-wall ceramic TWC (Three-Way Catalytic converter)

is used.

The fuel returnless system is used.

Fuel

System

Quick connectors are used to connect the fuel hose with the

fuel pipe.

System12-hole type fuel injectors with high atomizing performance

are used.

Ignition

SystemIridium-tipped spark plugs are used.

Charging

SystemThe segment conductor type generator is used.

Starting

SystemPS (Planetary reduction-Segment conductor motor) type

starter is used.

The ETCS-i is used.

Engine

Control

The DIS (Direct Ignition System) makes ignition timing

adjustment unnecessary.

Control

SystemThe non-contact type sensor is used in the throttle position

sensor.

The planar type air-fuel ratio sensor is used.

Page 9 of 2000

ENGINE - 2AZ-FE ENGINE

240EG46 181EG10

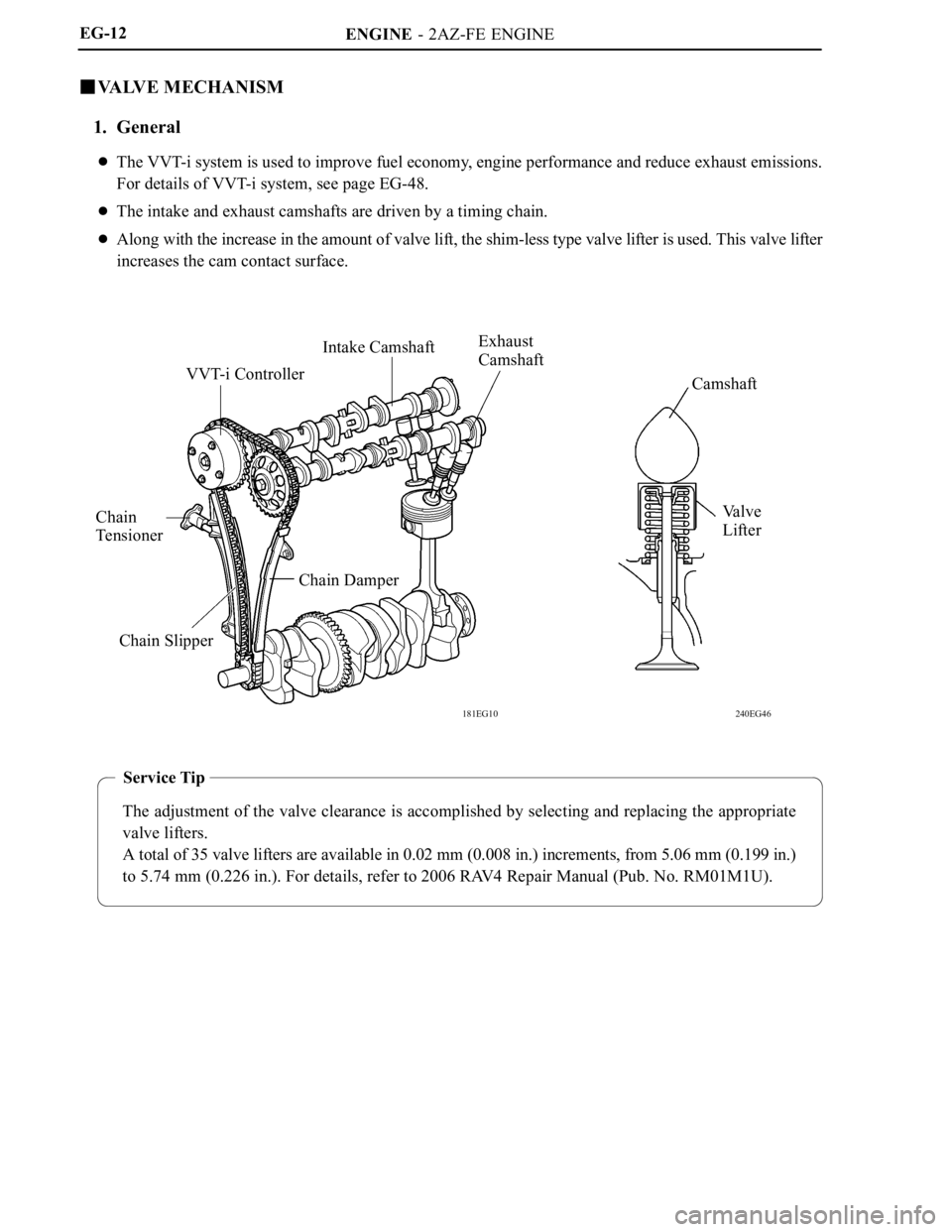

VVT-i ControllerIntake CamshaftExhaust

Camshaft

Chain

Te n s i o n e r

Chain Damper

Chain SlipperCamshaft

Va l v e

Lifter

Service Tip

The adjustment of the valve clearance is accomplished by selecting and replacing the appropriate

valve lifters.

A total of 35 valve lifters are available in 0.02 mm (0.008 in.) increments, from 5.06 mm (0.199 in.)

to 5.74 mm (0.226 in.). For details, refer to 2006 RAV4 Repair Manual (Pub. No. RM01M1U).

EG-12

VA LV E M E C H A N I S M

1. General

The VVT-i system is used to improve fuel economy, engine performance and reduce exhaust emissions.

For details of VVT-i system, see page EG-48.

The intake and exhaust camshafts are driven by a timing chain.

Along with the increase in the amount of valve lift, the shim-less type valve lifter is used. This valve lifter

increases the cam contact surface.

Page 10 of 2000

ENGINE - 2AZ-FE ENGINE

181EG11

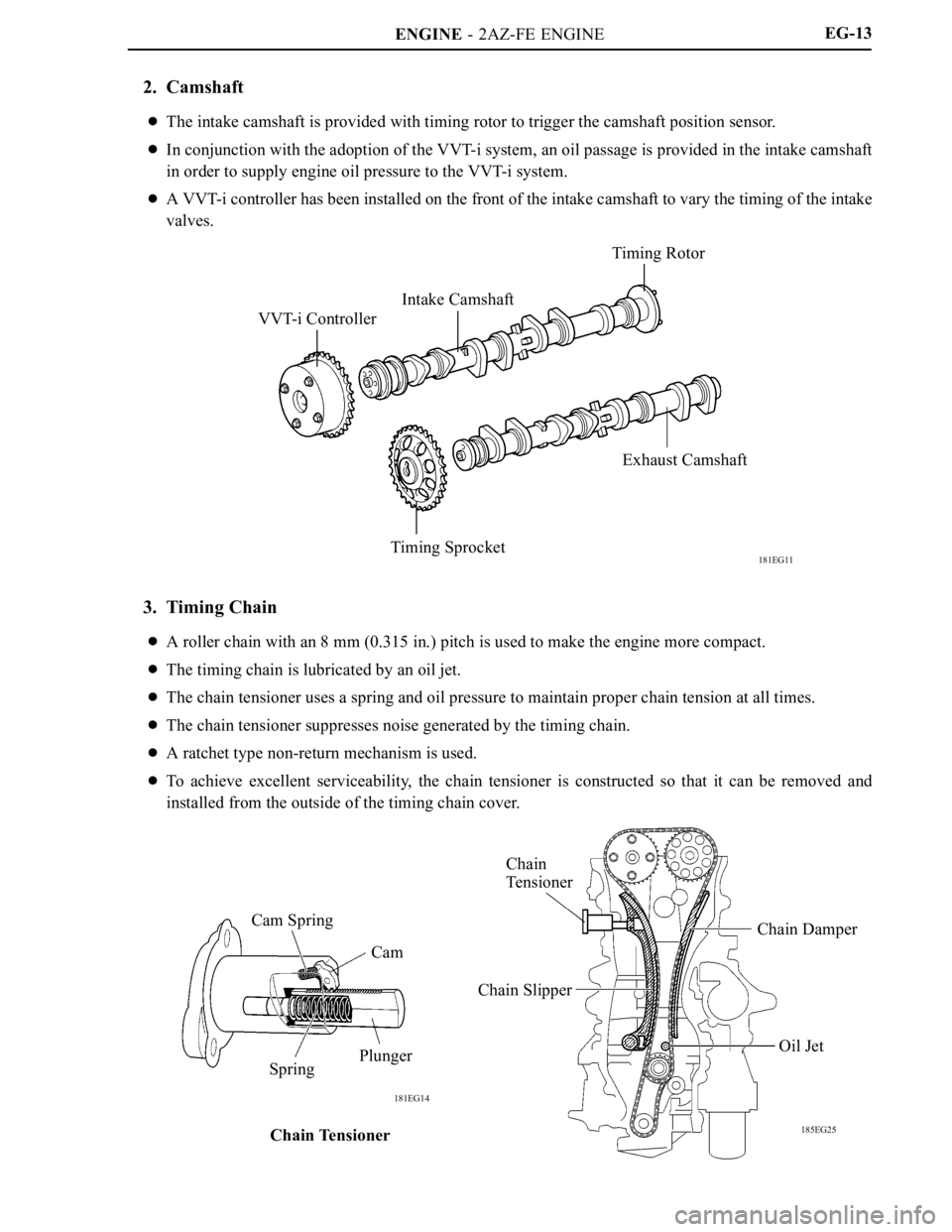

VVT-i ControllerIntake CamshaftTiming Rotor

Exhaust Camshaft

Timing Sprocket

185EG25 181EG14

Cam Spring

Cam

Plunger

SpringChain

Te n s i o n e r

Chain Damper

Oil Jet

Chain TensionerChain SlipperEG-13

2. Camshaft

The intake camshaft is provided with timing rotor to trigger the camshaft position sensor.

In conjunction with the adoption of the VVT-i system, an oil passage is provided in the intake camshaft

in order to supply engine oil pressure to the VVT-i system.

A VVT-i controller has been installed on the front of the intake camshaft to vary the timing of the intake

valves.

3. Timing Chain

A roller chain with an 8 mm (0.315 in.) pitch is used to make the engine more compact.

The timing chain is lubricated by an oil jet.

The chain tensioner uses a spring and oil pressure to maintain proper chain tension at all times.

The chain tensioner suppresses noise generated by the timing chain.

A ratchet type non-return mechanism is used.

To achieve excellent serviceability, the chain tensioner is constructed so that it can be removed and

installed from the outside of the timing chain cover.

Page 11 of 2000

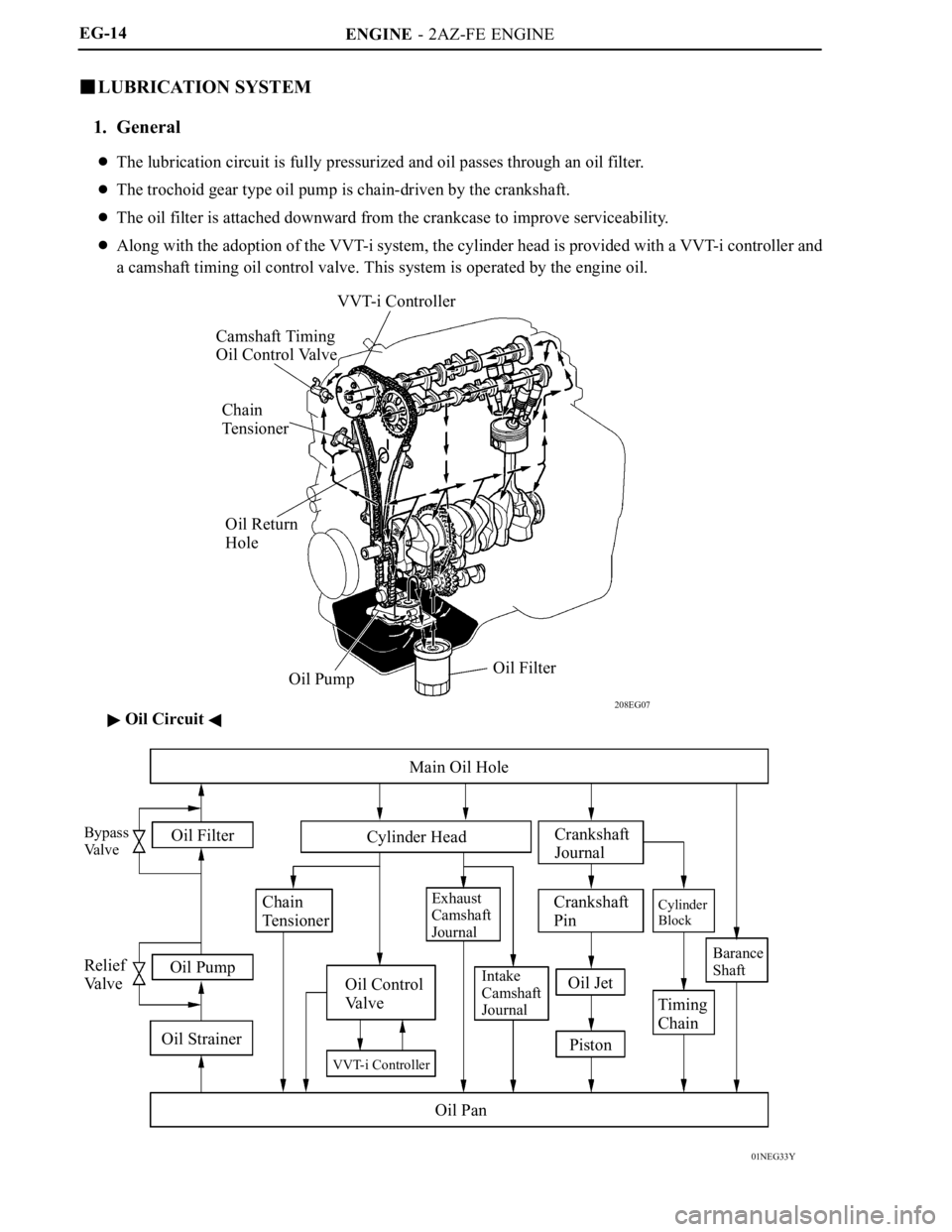

ENGINE - 2AZ-FE ENGINE

208EG07

VVT-i Controller

Camshaft Timing

Oil Control Valve

Oil Return

Hole

Oil PumpOil Filter Chain

Te n s i o n e r

01NEG33Y

Bypass

Va l v e

Relief

Va l v eMain Oil Hole

Oil Filter

Oil Pump

Oil StrainerChain

Te n s i o n e rCylinder Head

Exhaust

Camshaft

Journal

Oil Control

Va l v e

VVT-i Controller

Oil Pan

Intake

Camshaft

Journal

Crankshaft

Journal

Crankshaft

Pin

Oil Jet

Piston

Cylinder

Block

Barance

Shaft

Timing

Chain EG-14

LUBRICATION SYSTEM

1. General

The lubrication circuit is fully pressurized and oil passes through an oil filter.

The trochoid gear type oil pump is chain-driven by the crankshaft.

The oil filter is attached downward from the crankcase to improve serviceability.

Along with the adoption of the VVT-i system, the cylinder head is provided with a VVT-i controller and

a camshaft timing oil control valve. This system is operated by the engine oil.

Oil Circuit

Page 16 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG10Y

Charcoal FilterAir Cleaner Cap

Air Cleaner Element

(Nonwoven Fabric)

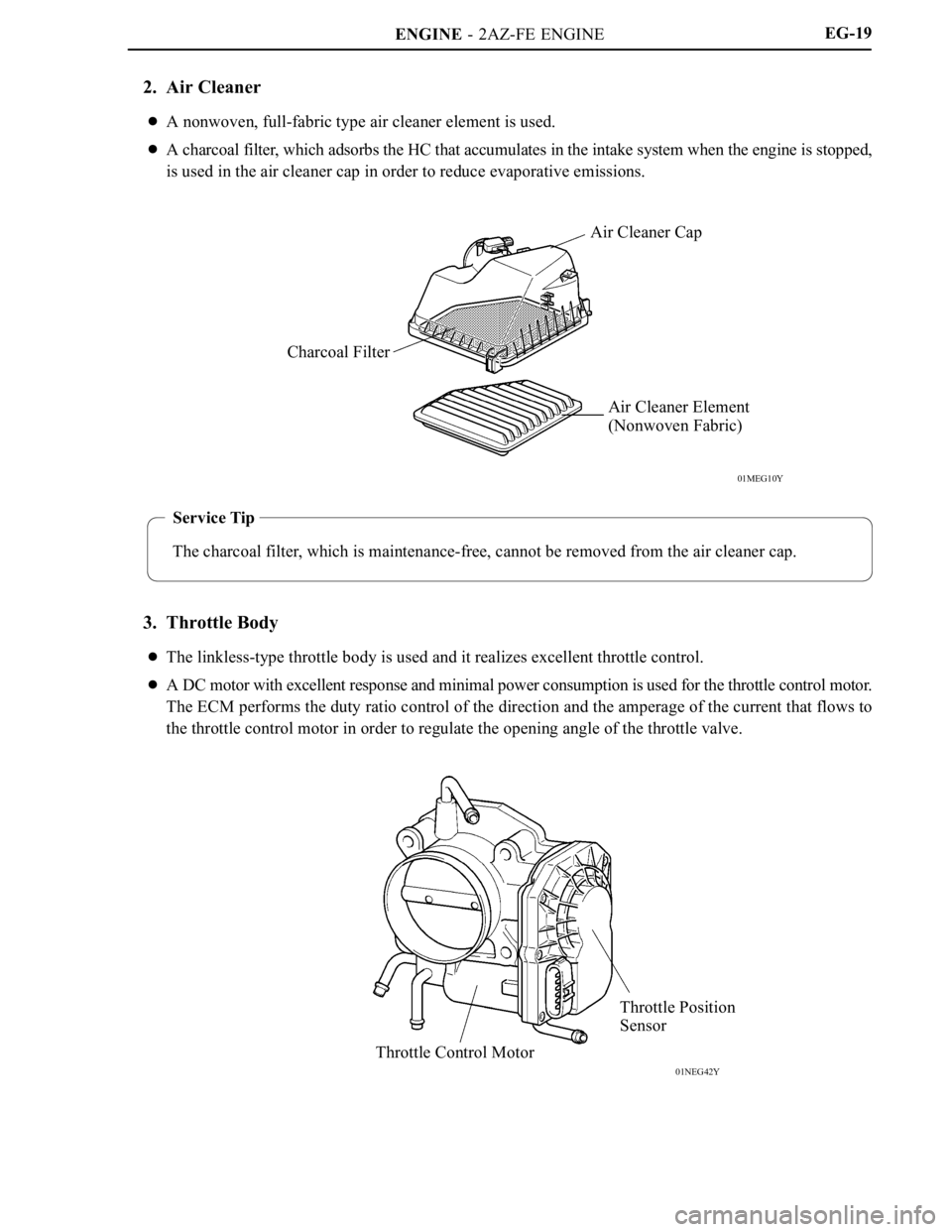

Service Tip

The charcoal filter, which is maintenance-free, cannot be removed from the air cleaner cap.

01NEG42Y

Throttle Position

Sensor

Throttle Control MotorEG-19

2. Air Cleaner

A nonwoven, full-fabric type air cleaner element is used.

A charcoal filter, which adsorbs the HC that accumulates in the intake system when the engine is stopped,

is used in the air cleaner cap in order to reduce evaporative emissions.

3. Throttle Body

The linkless-type throttle body is used and it realizes excellent throttle control.

A DC motor with excellent response and minimal power consumption is used for the throttle control motor.

The ECM performs the duty ratio control of the direction and the amperage of the current that flows to

the throttle control motor in order to regulate the opening angle of the throttle valve.

Page 19 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG30Y

Fuel Pump Assembly

Fuel Filter

Pressure Regulator

Quick Connector

Injector

Fuel Tank

Canister EG-22

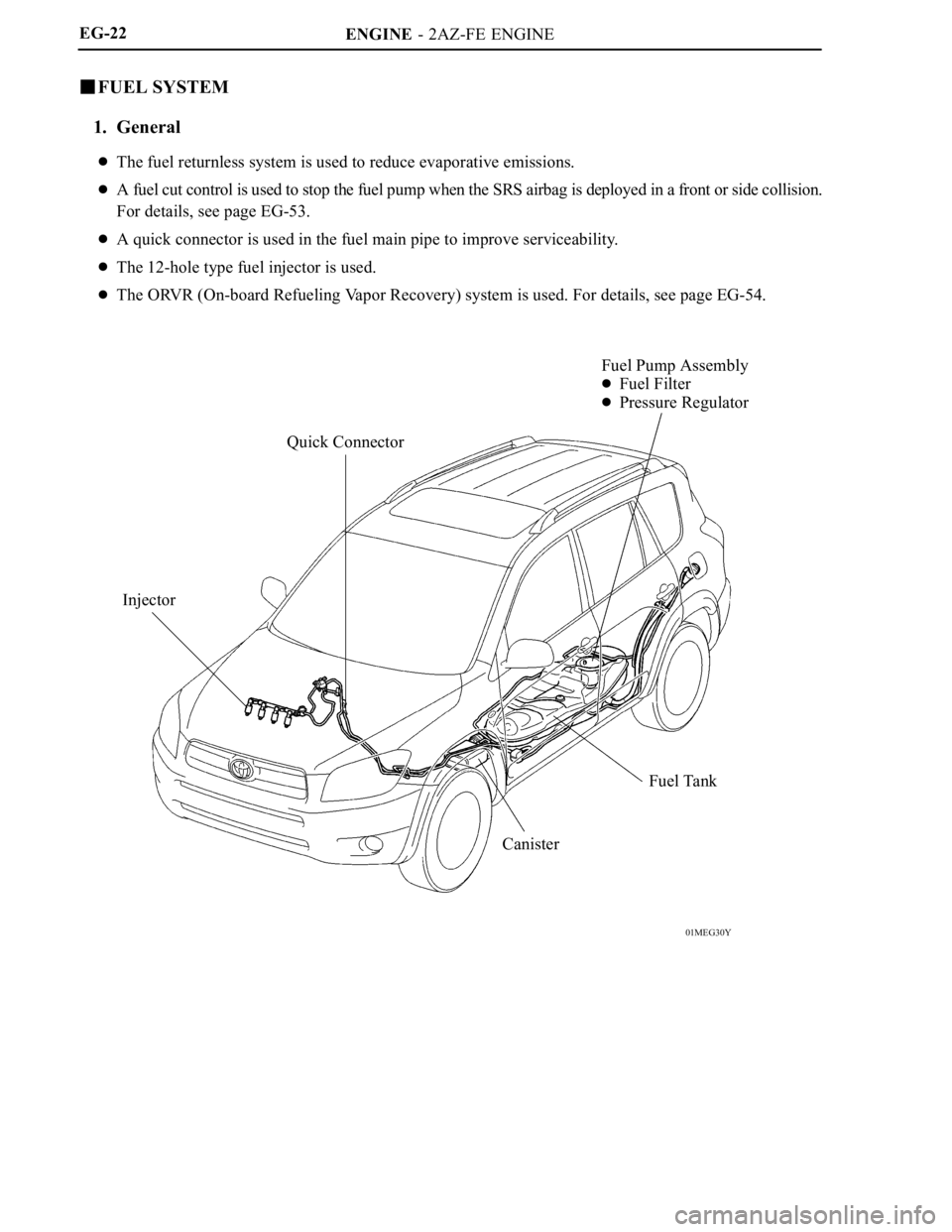

FUEL SYSTEM

1. General

The fuel returnless system is used to reduce evaporative emissions.

A fuel cut control is used to stop the fuel pump when the SRS airbag is deployed in a front or side collision.

For details, see page EG-53.

A quick connector is used in the fuel main pipe to improve serviceability.

The 12-hole type fuel injector is used.

The ORVR (On-board Refueling Vapor Recovery) system is used. For details, see page EG-54.

Page 37 of 2000

ENGINE - 2AZ-FE ENGINE

214CE08

Steel Weight

Inertia

Piezoelectric

Element

214CE06

Knock Sensor

200 k

Piezoelectric

ElementOpen / Short Circuit

Detection ResistorKNK1

EKNKECM

5 V

200 k

IC

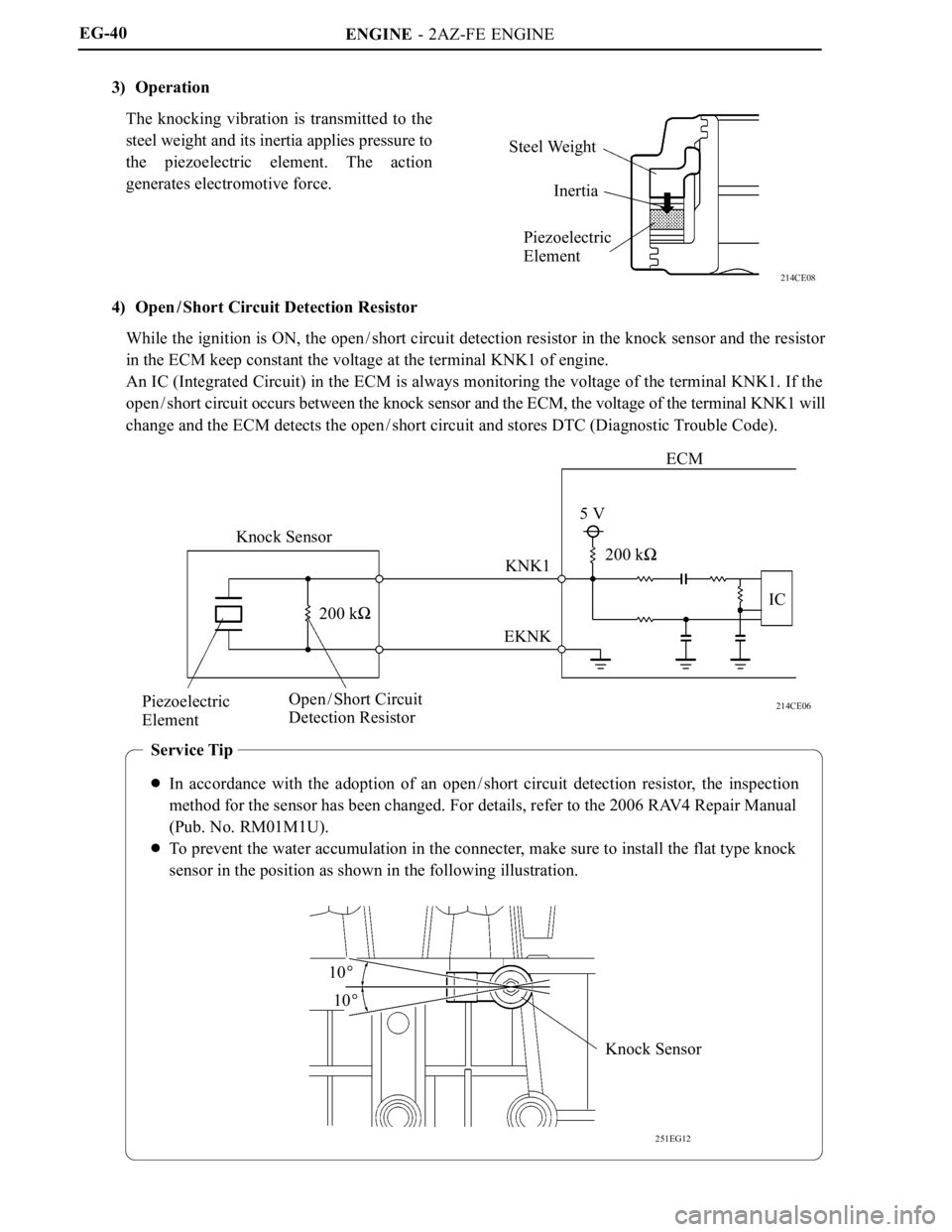

Service Tip

In accordance with the adoption of an open / short circuit detection resistor, the inspection

method for the sensor has been changed. For details, refer to the 2006 RAV4 Repair Manual

(Pub. No. RM01M1U).

To prevent the water accumulation in the connecter, make sure to install the flat type knock

sensor in the position as shown in the following illustration.

251EG12

10

10

Knock Sensor EG-40

3) Operation

The knocking vibration is transmitted to the

steel weight and its inertia applies pressure to

the piezoelectric element. The action

generates electromotive force.

4) Open / Short Circuit Detection Resistor

While the ignition is ON, the open / short circuit detection resistor in the knock sensor and the resistor

in the ECM keep constant the voltage at the terminal KNK1 of engine.

An IC (Integrated Circuit) in the ECM is always monitoring the voltage of the terminal KNK1. If the

open / short circuit occurs between the knock sensor and the ECM, the voltage of the terminal KNK1 will

change and the ECM detects the open / short circuit and stores DTC (Diagnostic Trouble Code).

Page 38 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG43Y

238EG79

230LX12

Throttle Body

Throttle Position

Sensor Portion

Throttle Control

MotorMagnetic

Yo k e

Hall IC

Cross Section

Throttle Position

Sensor

Magnetic Yoke

Hall

IC

Hall

IC

VTA1

ETA

VCTA

VTA2ECMOutput

Voltage(V)

5

0

Fully Close10 90 (

)

Fully Open VTA2

VTA1

Throttle Valve Opening Angle

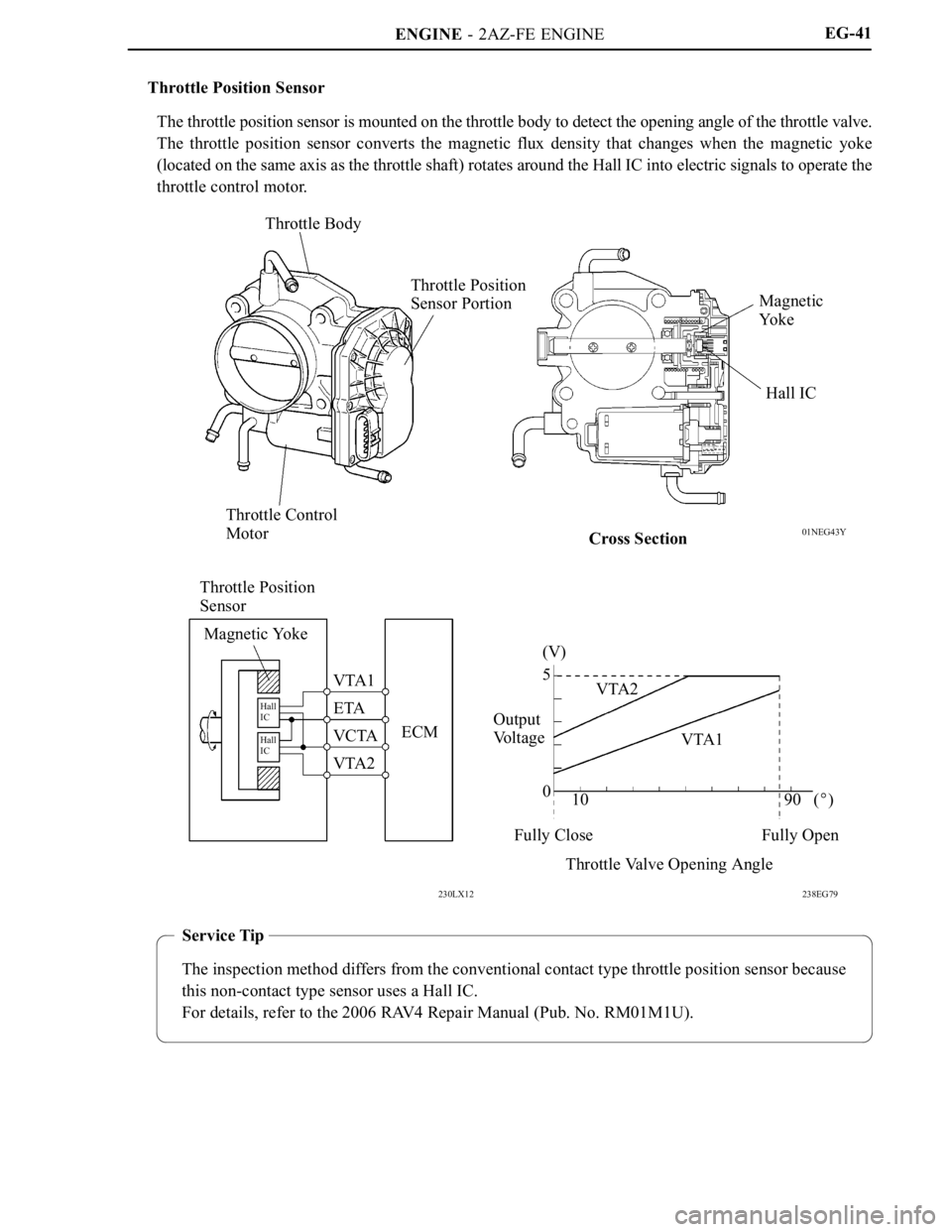

Service Tip

The inspection method differs from the conventional contact type throttle position sensor because

this non-contact type sensor uses a Hall IC.

For details, refer to the 2006 RAV4 Repair Manual (Pub. No. RM01M1U).

EG-41

Throttle Position Sensor

The throttle position sensor is mounted on the throttle body to detect the opening angle of the throttle valve.

The throttle position sensor converts the magnetic flux density that changes when the magnetic yoke

(located on the same axis as the throttle shaft) rotates around the Hall IC into electric signals to operate the

throttle control motor.

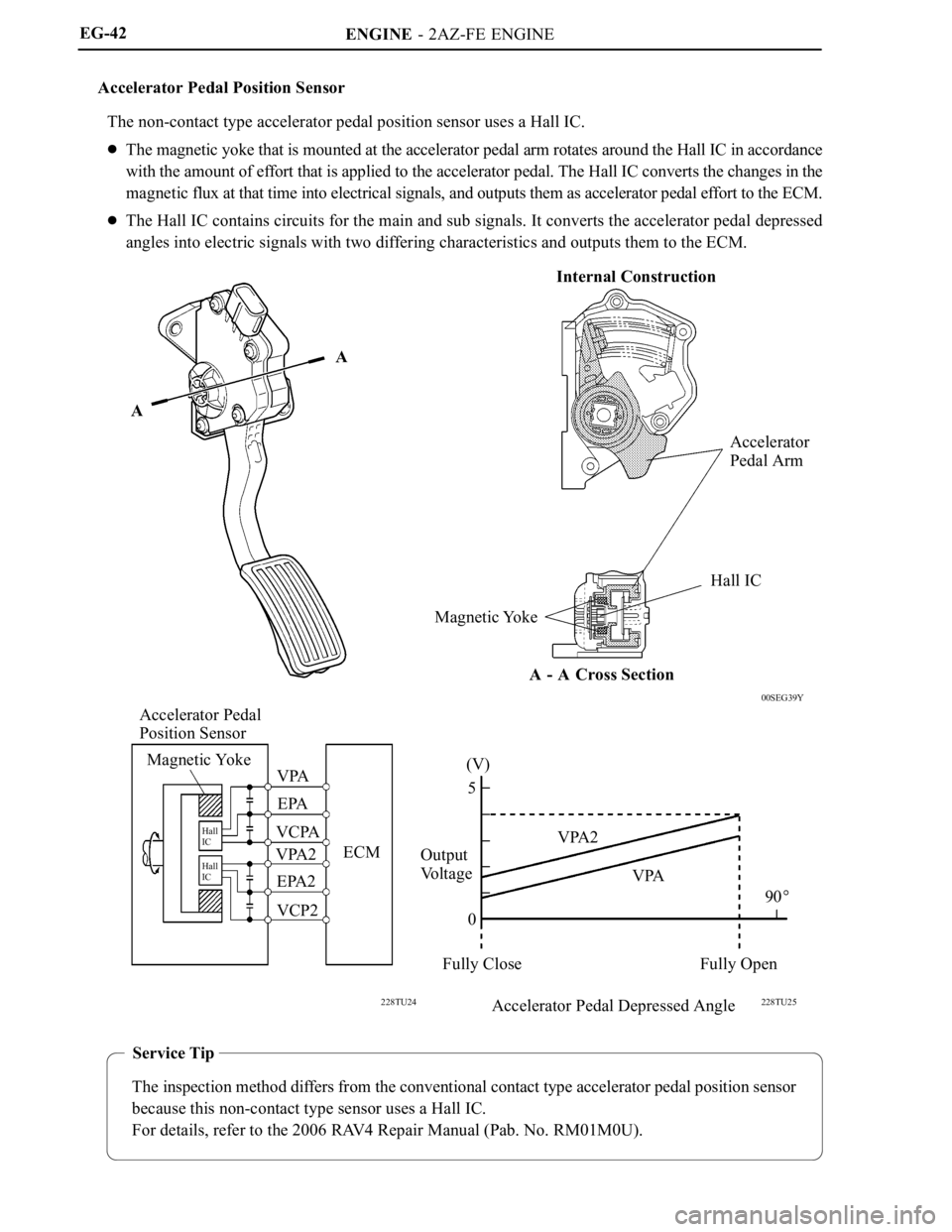

Page 39 of 2000

ENGINE - 2AZ-FE ENGINE

00SEG39Y

228TU25 228TU24

A

AInternal Construction

A - A Cross SectionAccelerator

Pedal Arm

Hall IC

Magnetic Yoke

Accelerator Pedal

Position Sensor

Magnetic Yoke

Hall

IC

Hall

IC

VPA

EPA

VCPA

VPA2

EPA2ECM

Output

Voltage(V)

5

0VPA2

VPA

Fully Close Fully Open90

Accelerator Pedal Depressed Angle VCP2

Service Tip

The inspection method differs from the conventional contact type accelerator pedal position sensor

because this non-contact type sensor uses a Hall IC.

For details, refer to the 2006 RAV4 Repair Manual (Pab. No. RM01M0U).

EG-42

Accelerator Pedal Position Sensor

The non-contact type accelerator pedal position sensor uses a Hall IC.

The magnetic yoke that is mounted at the accelerator pedal arm rotates around the Hall IC in accordance

with the amount of effort that is applied to the accelerator pedal. The Hall IC converts the changes in the

magnetic flux at that time into electrical signals, and outputs them as accelerator pedal effort to the ECM.

The Hall IC contains circuits for the main and sub signals. It converts the accelerator pedal depressed

angles into electric signals with two differing characteristics and outputs them to the ECM.

Page 51 of 2000

ENGINE - 2AZ-FE ENGINE

Service Tip

The canister pump module performs the EVAP leak check. This check is done approximately five

hours after the engine is turned off. So you may hear sound coming from underneath the luggage

compartment for several minutes. It does not indicate a malfunction.

The pinpoint pressure test procedure is carried out by pressurizing the fresh air line that runs from

the pump module to the air filler neck. For details, refer to the 2006 RAV4 Repair Manual (Pub.

No. RM01M1U).

EG-54

10. EVAP (evaporative Emission) Control System

General

The EVAP (evaporative emission) control system prevents the vapor gas that is created in the fuel tank from

being released directly into the atmosphere.

The canister stores the vapor gas that has been created in the fuel tank.

The ECM controls the purge VSV in accordance with the driving conditions in order to direct the vapor

gas into the engine, where it is burned.

In this system, the ECM checks the evaporative emission leak and outputs DTC (Diagnostic Trouble

Code) in the event of a malfunction. An EVAP (evaporative emission) leak check consists of an

application of a vacuum pressure to the system and monitoring the changes in the system pressure in order

to detect a leakage.

This system consists of the purge VSV, canister, refueling valve, canister pump module, and ECM.

The ORVR (Onboard Refueling Vapor Recovery) function is provided in the refueling valve.

The canister pressure sensor has been included to the canister pump module.

The canister filter has been provided on the fresh air line. This canister filter is maintenance-free.

The followings are the typical conditions for enabling an EVAP leak check:

Typical Enabling

Condition

Five hours have elapsed after the engine has been turned OFF*.

Altitude: Below 2400 m (8000 feet)

Battery voltage: 10.5 V or more

Ignition switch: OFF

Engine coolant temperature: 4.4 to 35C (40 to 95F)

Intake air temperature: 4.4 to 35C (40 to 95F)

*: If engine coolant temperature does not drop below 35C (95F), this time should be extended to 7hours.

Even after that, if the temperature is not less than 35

C (95F), the time should be extended to 9.5 hours.