timing belt TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 204 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–29

EM

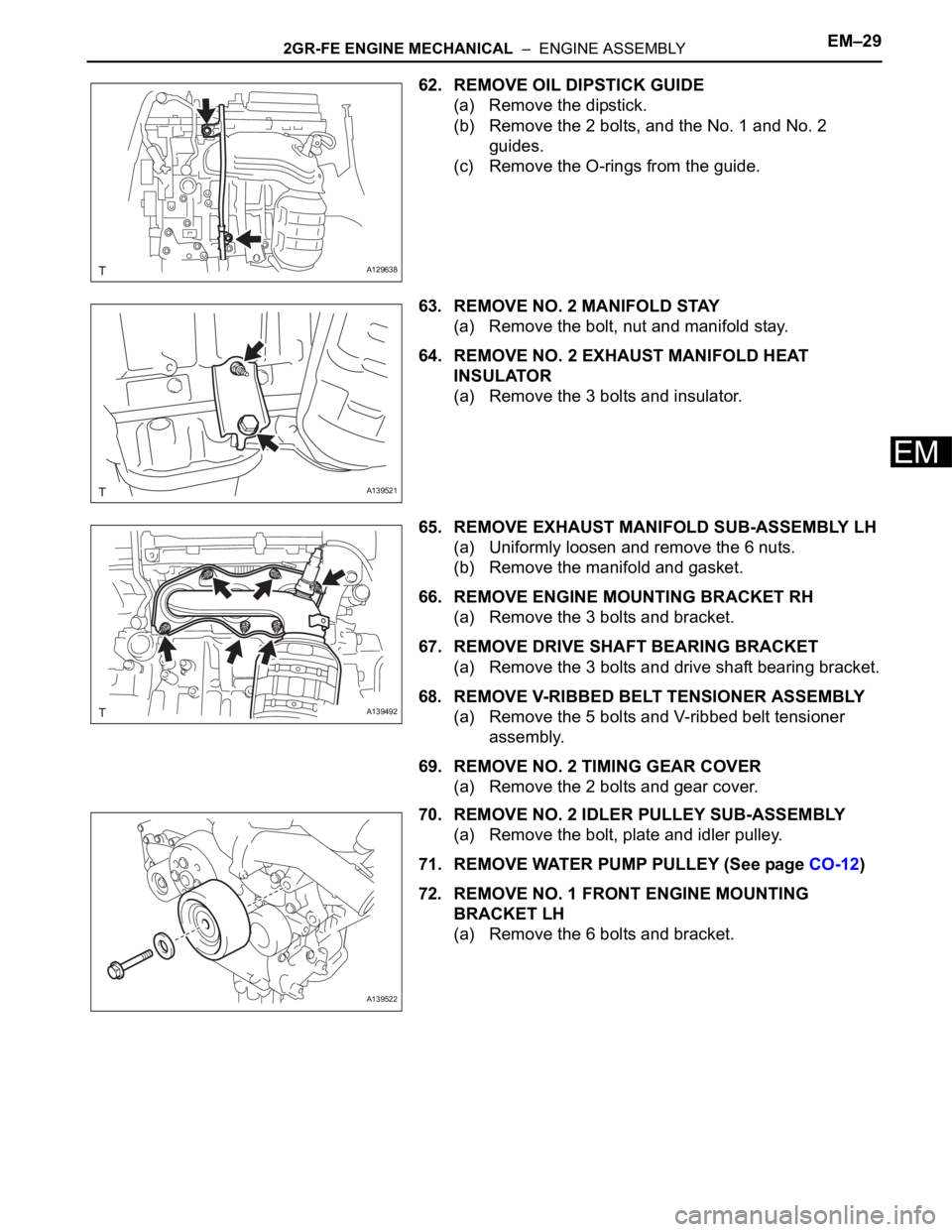

62. REMOVE OIL DIPSTICK GUIDE

(a) Remove the dipstick.

(b) Remove the 2 bolts, and the No. 1 and No. 2

guides.

(c) Remove the O-rings from the guide.

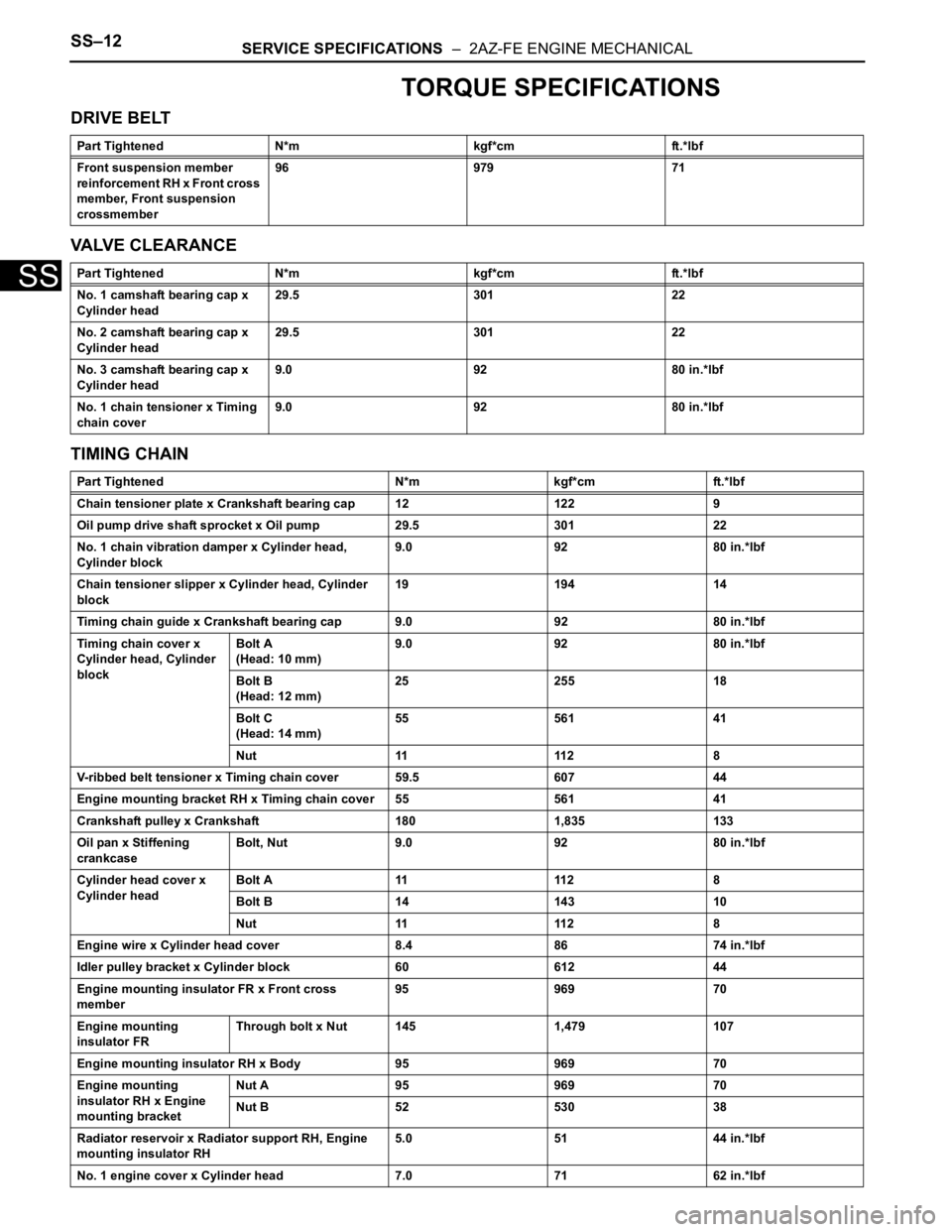

63. REMOVE NO. 2 MANIFOLD STAY

(a) Remove the bolt, nut and manifold stay.

64. REMOVE NO. 2 EXHAUST MANIFOLD HEAT

INSULATOR

(a) Remove the 3 bolts and insulator.

65. REMOVE EXHAUST MANIFOLD SUB-ASSEMBLY LH

(a) Uniformly loosen and remove the 6 nuts.

(b) Remove the manifold and gasket.

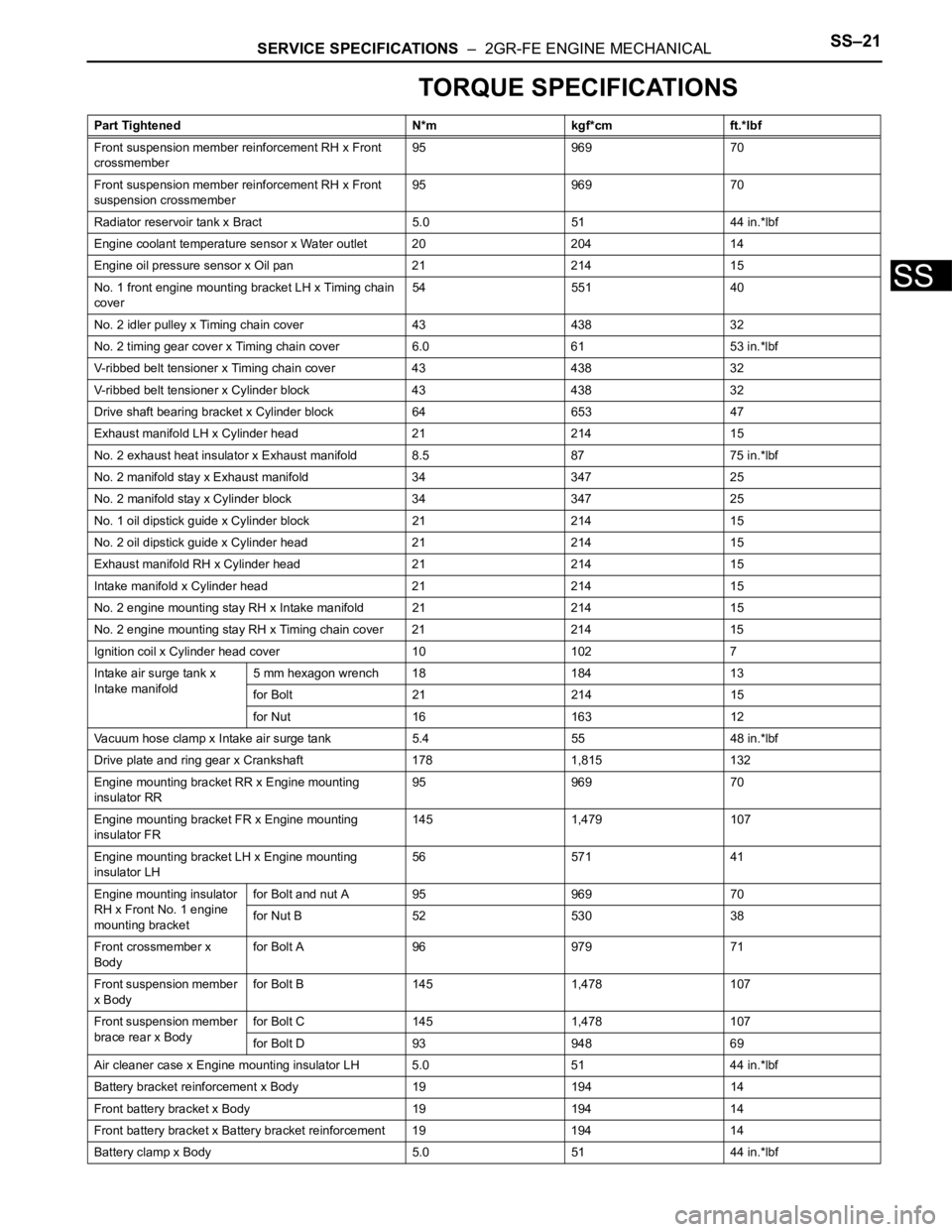

66. REMOVE ENGINE MOUNTING BRACKET RH

(a) Remove the 3 bolts and bracket.

67. REMOVE DRIVE SHAFT BEARING BRACKET

(a) Remove the 3 bolts and drive shaft bearing bracket.

68. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(a) Remove the 5 bolts and V-ribbed belt tensioner

assembly.

69. REMOVE NO. 2 TIMING GEAR COVER

(a) Remove the 2 bolts and gear cover.

70. REMOVE NO. 2 IDLER PULLEY SUB-ASSEMBLY

(a) Remove the bolt, plate and idler pulley.

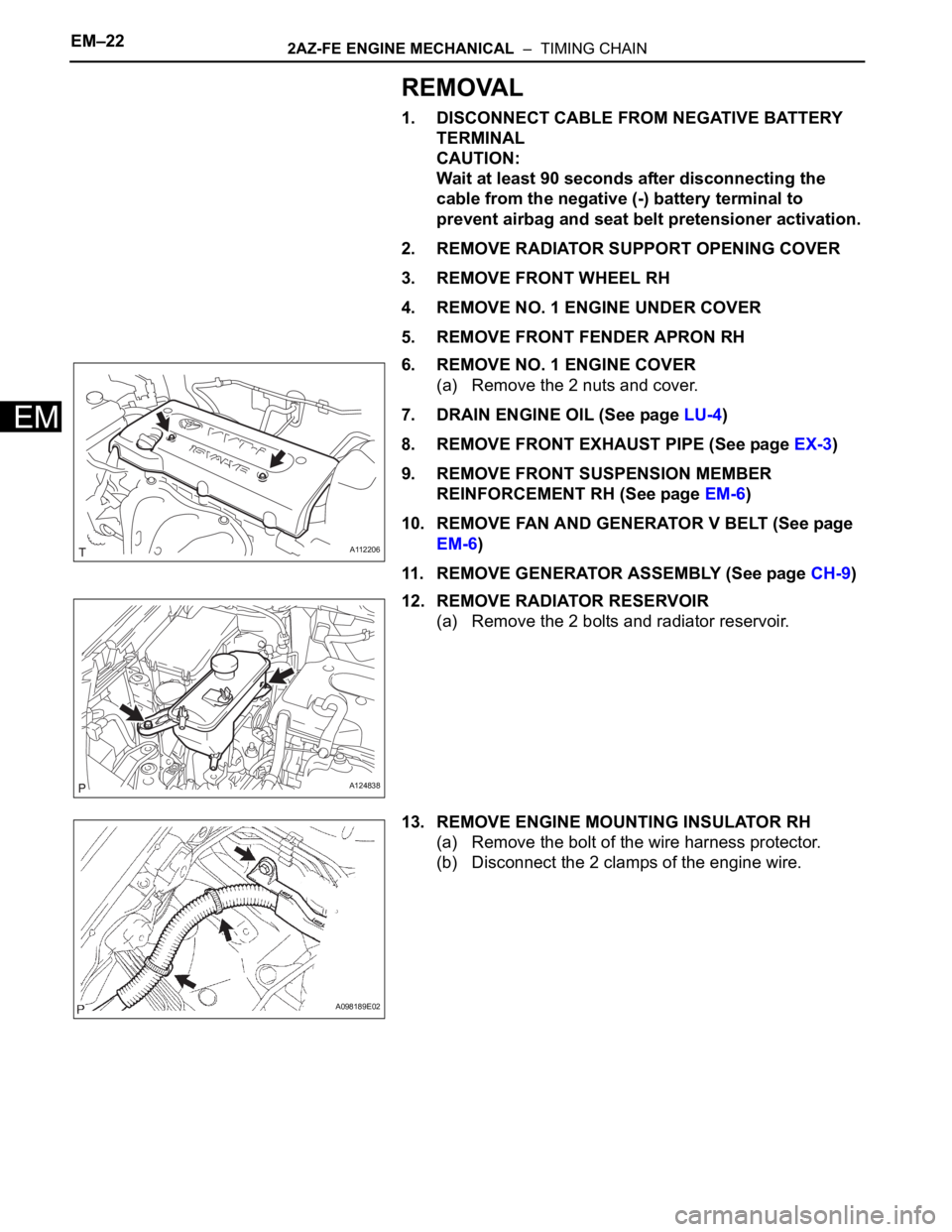

71. REMOVE WATER PUMP PULLEY (See page CO-12)

72. REMOVE NO. 1 FRONT ENGINE MOUNTING

BRACKET LH

(a) Remove the 6 bolts and bracket.

A129638

A139521

A139492

A139522

Page 379 of 2000

SS–12SERVICE SPECIFICATIONS – 2AZ-FE ENGINE MECHANICAL

SS

TORQUE SPECIFICATIONS

DRIVE BELT

VALVE CLEARANCE

TIMING CHAIN

Part Tightened N*m kgf*cm ft.*lbf

Front suspension member

reinforcement RH x Front cross

member, Front suspension

crossmember96 979 71

Part Tightened N*m kgf*cm ft.*lbf

No. 1 camshaft bearing cap x

Cylinder head29.5 301 22

No. 2 camshaft bearing cap x

Cylinder head29.5 301 22

No. 3 camshaft bearing cap x

Cylinder head9.0 92 80 in.*lbf

No. 1 chain tensioner x Timing

chain cover9.0 92 80 in.*lbf

Part Tightened N*m kgf*cm ft.*lbf

Chain tensioner plate x Crankshaft bearing cap 12 122 9

Oil pump drive shaft sprocket x Oil pump 29.5 301 22

No. 1 chain vibration damper x Cylinder head,

Cylinder block9.0 92 80 in.*lbf

Chain tensioner slipper x Cylinder head, Cylinder

block19 194 14

Timing chain guide x Crankshaft bearing cap 9.0 92 80 in.*lbf

Timing chain cover x

Cylinder head, Cylinder

blockBolt A

(Head: 10 mm)9.0 92 80 in.*lbf

Bolt B

(Head: 12 mm)25 255 18

Bolt C

(Head: 14 mm)55 561 41

Nut 11 112 8

V-ribbed belt tensioner x Timing chain cover 59.5 607 44

Engine mounting bracket RH x Timing chain cover 55 561 41

Crankshaft pulley x Crankshaft 180 1,835 133

Oil pan x Stiffening

crankcaseBolt, Nut 9.0 92 80 in.*lbf

Cylinder head cover x

Cylinder headBolt A 11 112 8

Bolt B 14 143 10

Nut 11 112 8

Engine wire x Cylinder head cover 8.4 86 74 in.*lbf

Idler pulley bracket x Cylinder block 60 612 44

Engine mounting insulator FR x Front cross

member95 969 70

Engine mounting

insulator FRThrough bolt x Nut 145 1,479 107

Engine mounting insulator RH x Body 95 969 70

Engine mounting

insulator RH x Engine

mounting bracketNut A 95 969 70

Nut B 52 530 38

Radiator reservoir x Radiator support RH, Engine

mounting insulator RH5.0 51 44 in.*lbf

No. 1 engine cover x Cylinder head 7.0 71 62 in.*lbf

Page 383 of 2000

SERVICE SPECIFICATIONS – 2GR-FE ENGINE MECHANICALSS–21

SS

TORQUE SPECIFICATIONS

Part Tightened N*m kgf*cm ft.*lbf

Front suspension member reinforcement RH x Front

crossmember95 969 70

Front suspension member reinforcement RH x Front

suspension crossmember95 969 70

Radiator reservoir tank x Bract 5.0 51 44 in.*lbf

Engine coolant temperature sensor x Water outlet 20 204 14

Engine oil pressure sensor x Oil pan 21 214 15

No. 1 front engine mounting bracket LH x Timing chain

cover54 551 40

No. 2 idler pulley x Timing chain cover 43 438 32

No. 2 timing gear cover x Timing chain cover 6.0 61 53 in.*lbf

V-ribbed belt tensioner x Timing chain cover 43 438 32

V-ribbed belt tensioner x Cylinder block 43 438 32

Drive shaft bearing bracket x Cylinder block 64 653 47

Exhaust manifold LH x Cylinder head 21 214 15

No. 2 exhaust heat insulator x Exhaust manifold 8.5 87 75 in.*lbf

No. 2 manifold stay x Exhaust manifold 34 347 25

No. 2 manifold stay x Cylinder block 34 347 25

No. 1 oil dipstick guide x Cylinder block 21 214 15

No. 2 oil dipstick guide x Cylinder head 21 214 15

Exhaust manifold RH x Cylinder head 21 214 15

Intake manifold x Cylinder head 21 214 15

No. 2 engine mounting stay RH x Intake manifold 21 214 15

No. 2 engine mounting stay RH x Timing chain cover 21 214 15

Ignition coil x Cylinder head cover 10 102 7

Intake air surge tank x

Intake manifold5 mm hexagon wrench 18 184 13

for Bolt 21 214 15

for Nut 16 163 12

Vacuum hose clamp x Intake air surge tank 5.4 55 48 in.*lbf

Drive plate and ring gear x Crankshaft 178 1,815 132

Engine mounting bracket RR x Engine mounting

insulator RR95 969 70

Engine mounting bracket FR x Engine mounting

insulator FR145 1,479 107

Engine mounting bracket LH x Engine mounting

insulator LH56 571 41

Engine mounting insulator

RH x Front No. 1 engine

mounting bracketfor Bolt and nut A 95 969 70

for Nut B 52 530 38

Front crossmember x

Bodyfor Bolt A 96 979 71

Front suspension member

x Bodyfor Bolt B 145 1,478 107

Front suspension member

brace rear x Bodyfor Bolt C 145 1,478 107

for Bolt D 93 948 69

Air cleaner case x Engine mounting insulator LH 5.0 51 44 in.*lbf

Battery bracket reinforcement x Body 19 194 14

Front battery bracket x Body 19 194 14

Front battery bracket x Battery bracket reinforcement 19 194 14

Battery clamp x Body 5.0 51 44 in.*lbf

Page 579 of 2000

EM–222AZ-FE ENGINE MECHANICAL – TIMING CHAIN

EM

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

2. REMOVE RADIATOR SUPPORT OPENING COVER

3. REMOVE FRONT WHEEL RH

4. REMOVE NO. 1 ENGINE UNDER COVER

5. REMOVE FRONT FENDER APRON RH

6. REMOVE NO. 1 ENGINE COVER

(a) Remove the 2 nuts and cover.

7. DRAIN ENGINE OIL (See page LU-4)

8. REMOVE FRONT EXHAUST PIPE (See page EX-3)

9. REMOVE FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-6)

10. REMOVE FAN AND GENERATOR V BELT (See page

EM-6)

11. REMOVE GENERATOR ASSEMBLY (See page CH-9)

12. REMOVE RADIATOR RESERVOIR

(a) Remove the 2 bolts and radiator reservoir.

13. REMOVE ENGINE MOUNTING INSULATOR RH

(a) Remove the bolt of the wire harness protector.

(b) Disconnect the 2 clamps of the engine wire.

A112206

A124838

A098189E02

Page 583 of 2000

EM–262AZ-FE ENGINE MECHANICAL – TIMING CHAIN

EM

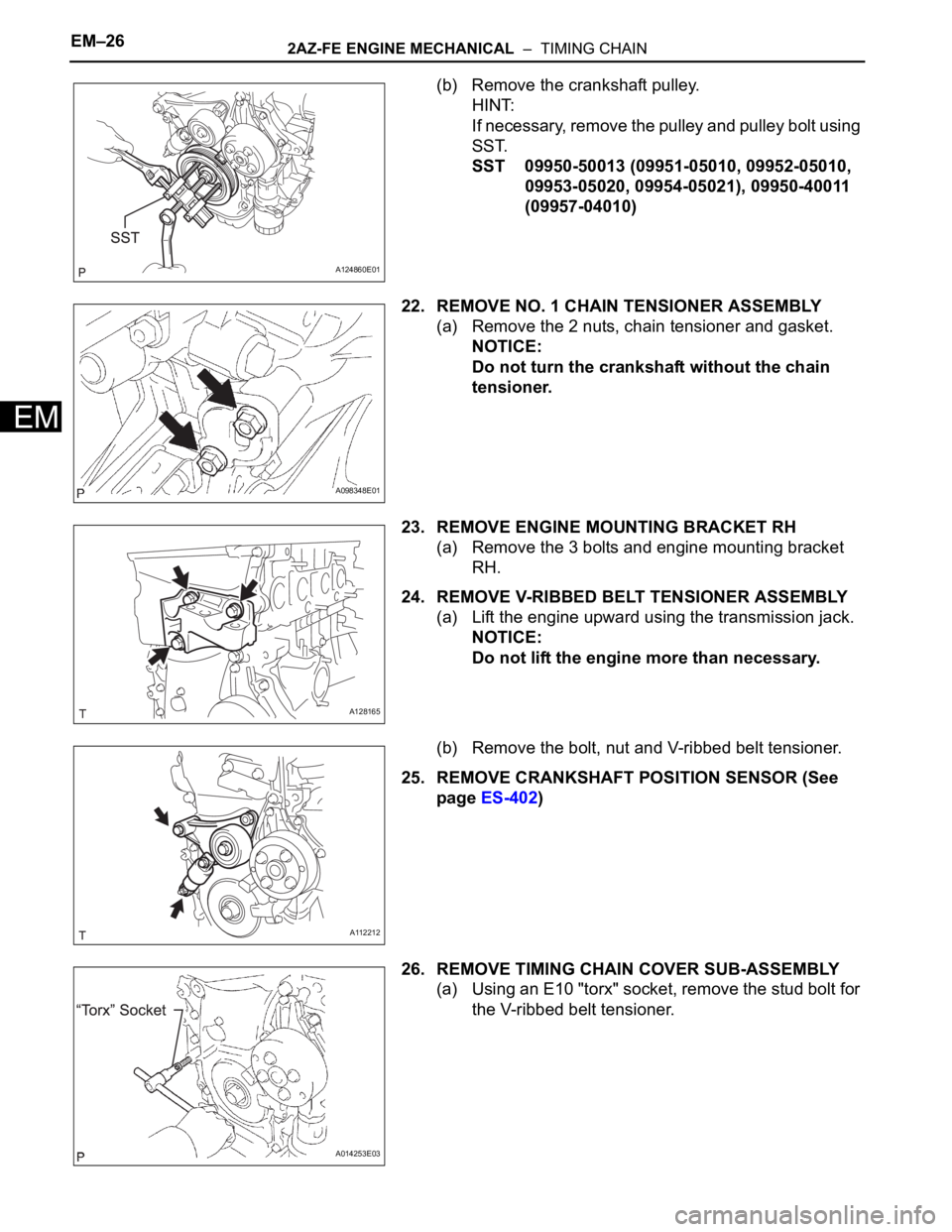

(b) Remove the crankshaft pulley.

HINT:

If necessary, remove the pulley and pulley bolt using

SST.

SST 09950-50013 (09951-05010, 09952-05010,

09953-05020, 09954-05021), 09950-40011

(09957-04010)

22. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

(a) Remove the 2 nuts, chain tensioner and gasket.

NOTICE:

Do not turn the crankshaft without the chain

tensioner.

23. REMOVE ENGINE MOUNTING BRACKET RH

(a) Remove the 3 bolts and engine mounting bracket

RH.

24. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(a) Lift the engine upward using the transmission jack.

NOTICE:

Do not lift the engine more than necessary.

(b) Remove the bolt, nut and V-ribbed belt tensioner.

25. REMOVE CRANKSHAFT POSITION SENSOR (See

page ES-402)

26. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

(a) Using an E10 "torx" socket, remove the stud bolt for

the V-ribbed belt tensioner.

A124860E01

A098348E01

A128165

A112212

A014253E03

Page 594 of 2000

2AZ-FE ENGINE MECHANICAL – TIMING CHAINEM–37

EM

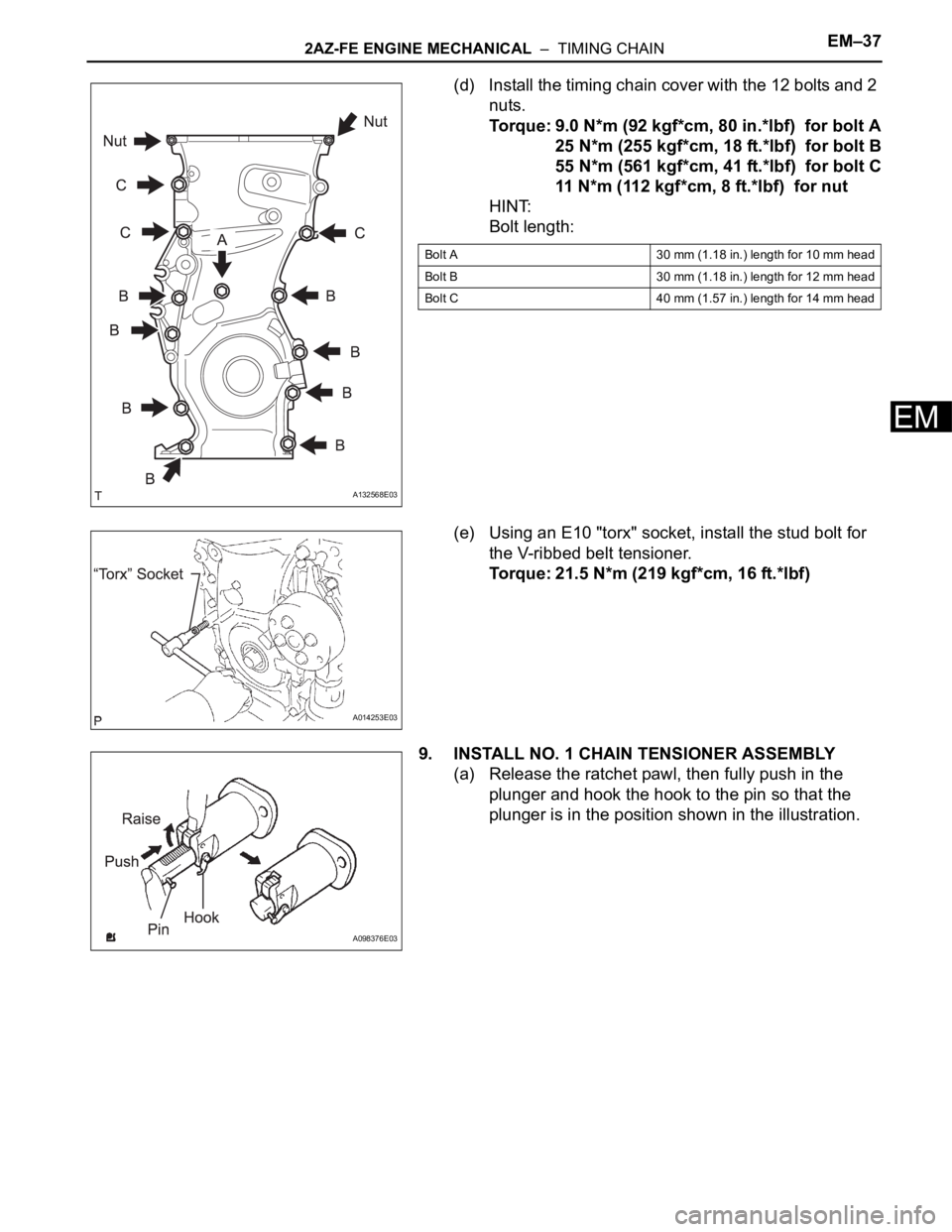

(d) Install the timing chain cover with the 12 bolts and 2

nuts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf) for bolt A

25 N*m (255 kgf*cm, 18 ft.*lbf) for bolt B

55 N*m (561 kgf*cm, 41 ft.*lbf) for bolt C

11 N*m (112 kgf*cm, 8 ft.*lbf) for nut

HINT:

Bolt length:

(e) Using an E10 "torx" socket, install the stud bolt for

the V-ribbed belt tensioner.

Torque: 21.5 N*m (219 kgf*cm, 16 ft.*lbf)

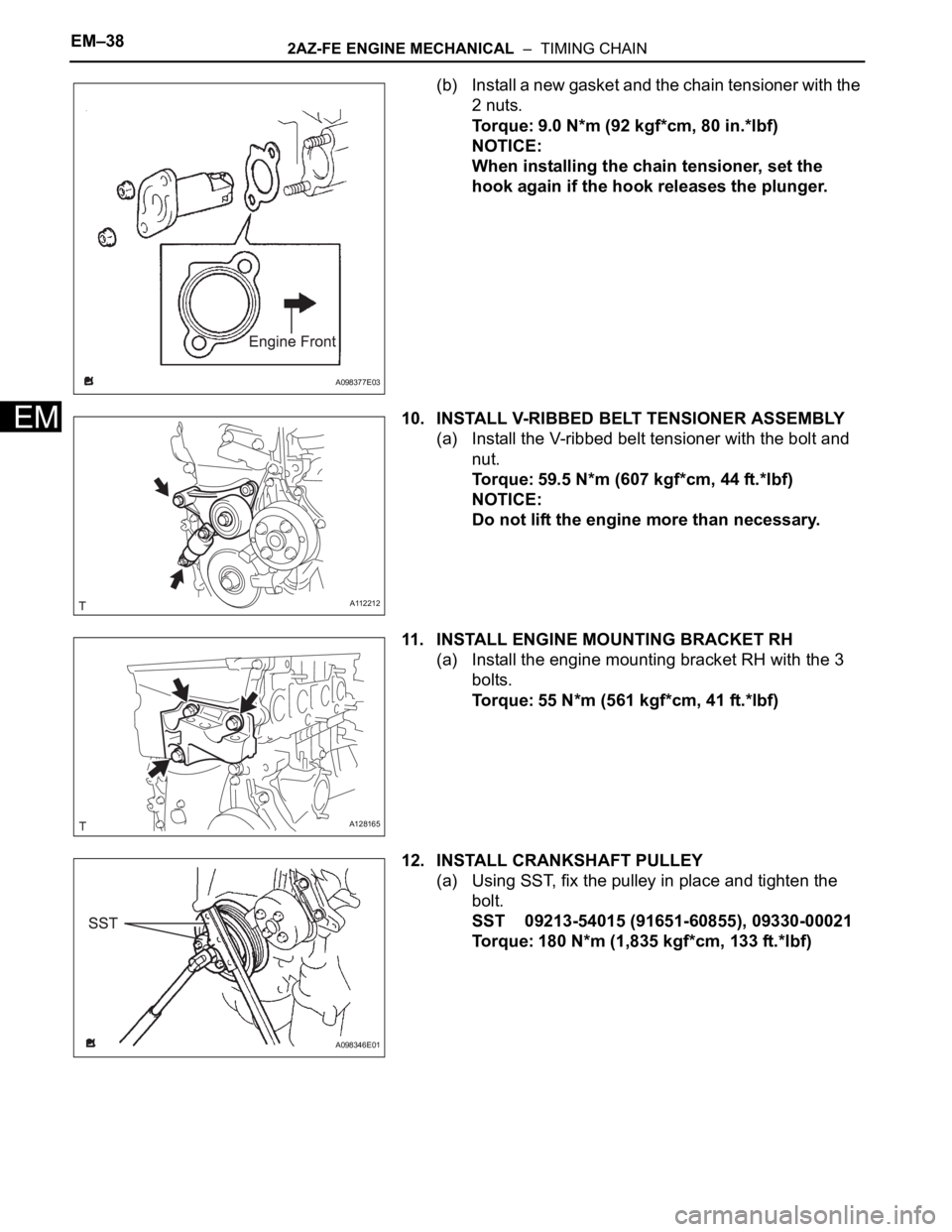

9. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY

(a) Release the ratchet pawl, then fully push in the

plunger and hook the hook to the pin so that the

plunger is in the position shown in the illustration.

A132568E03

Bolt A 30 mm (1.18 in.) length for 10 mm head

Bolt B 30 mm (1.18 in.) length for 12 mm head

Bolt C 40 mm (1.57 in.) length for 14 mm head

A014253E03

A098376E03

Page 595 of 2000

EM–382AZ-FE ENGINE MECHANICAL – TIMING CHAIN

EM

(b) Install a new gasket and the chain tensioner with the

2 nuts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

NOTICE:

When installing the chain tensioner, set the

hook again if the hook releases the plunger.

10. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

(a) Install the V-ribbed belt tensioner with the bolt and

nut.

Torque: 59.5 N*m (607 kgf*cm, 44 ft.*lbf)

NOTICE:

Do not lift the engine more than necessary.

11. INSTALL ENGINE MOUNTING BRACKET RH

(a) Install the engine mounting bracket RH with the 3

bolts.

Torque: 55 N*m (561 kgf*cm, 41 ft.*lbf)

12. INSTALL CRANKSHAFT PULLEY

(a) Using SST, fix the pulley in place and tighten the

bolt.

SST 09213-54015 (91651-60855), 09330-00021

Torque: 180 N*m (1,835 kgf*cm, 133 ft.*lbf)

A098377E03

A112212

A128165

A098346E01

Page 599 of 2000

EM–422AZ-FE ENGINE MECHANICAL – TIMING CHAIN

EM

(b) Connect the 2 clamps of the engine wire.

(c) Install the wire harness protector with the bolt.

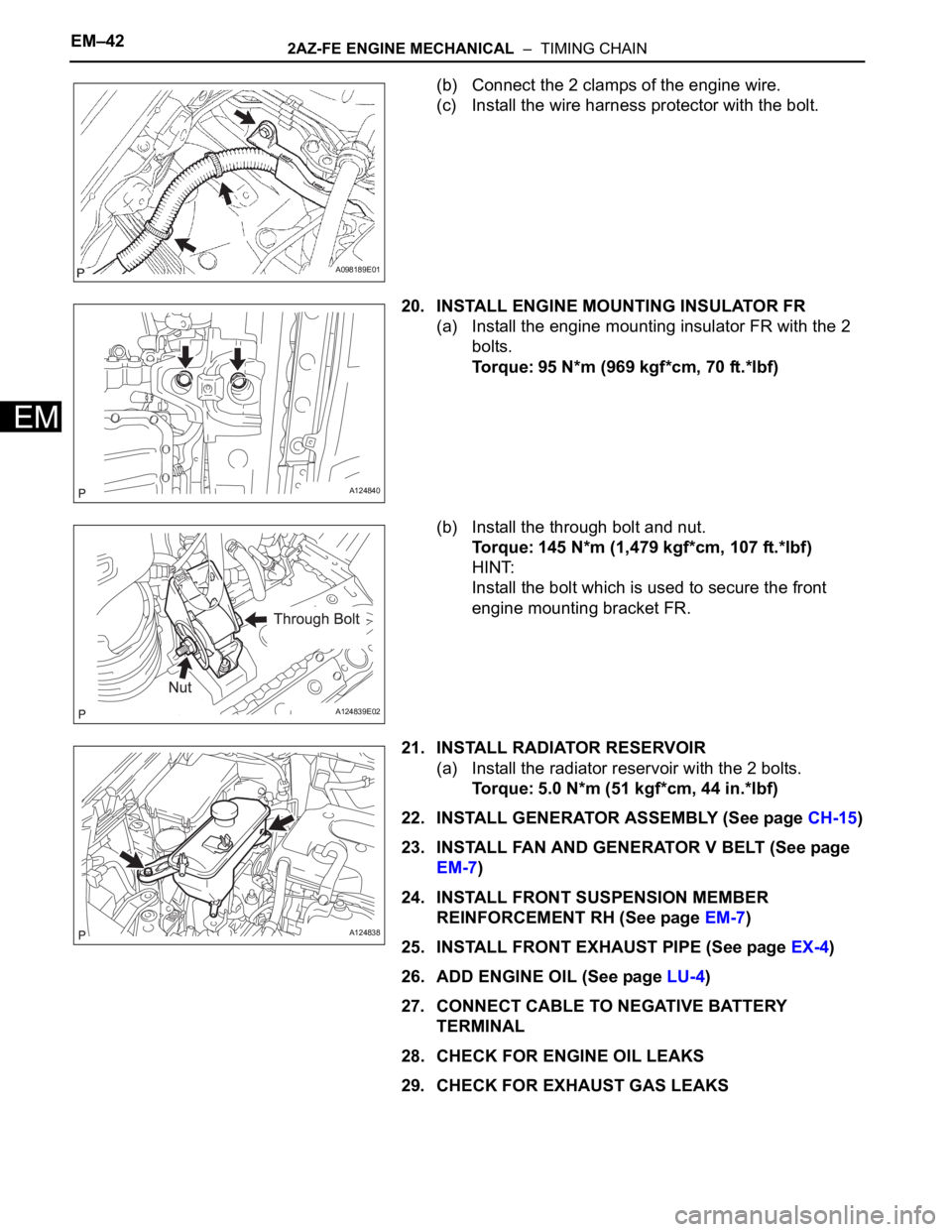

20. INSTALL ENGINE MOUNTING INSULATOR FR

(a) Install the engine mounting insulator FR with the 2

bolts.

Torque: 95 N*m (969 kgf*cm, 70 ft.*lbf)

(b) Install the through bolt and nut.

Torque: 145 N*m (1,479 kgf*cm, 107 ft.*lbf)

HINT:

Install the bolt which is used to secure the front

engine mounting bracket FR.

21. INSTALL RADIATOR RESERVOIR

(a) Install the radiator reservoir with the 2 bolts.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

22. INSTALL GENERATOR ASSEMBLY (See page CH-15)

23. INSTALL FAN AND GENERATOR V BELT (See page

EM-7)

24. INSTALL FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-7)

25. INSTALL FRONT EXHAUST PIPE (See page EX-4)

26. ADD ENGINE OIL (See page LU-4)

27. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

28. CHECK FOR ENGINE OIL LEAKS

29. CHECK FOR EXHAUST GAS LEAKS

A098189E01

A124840

A124839E02

A124838

Page 603 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–59

EM

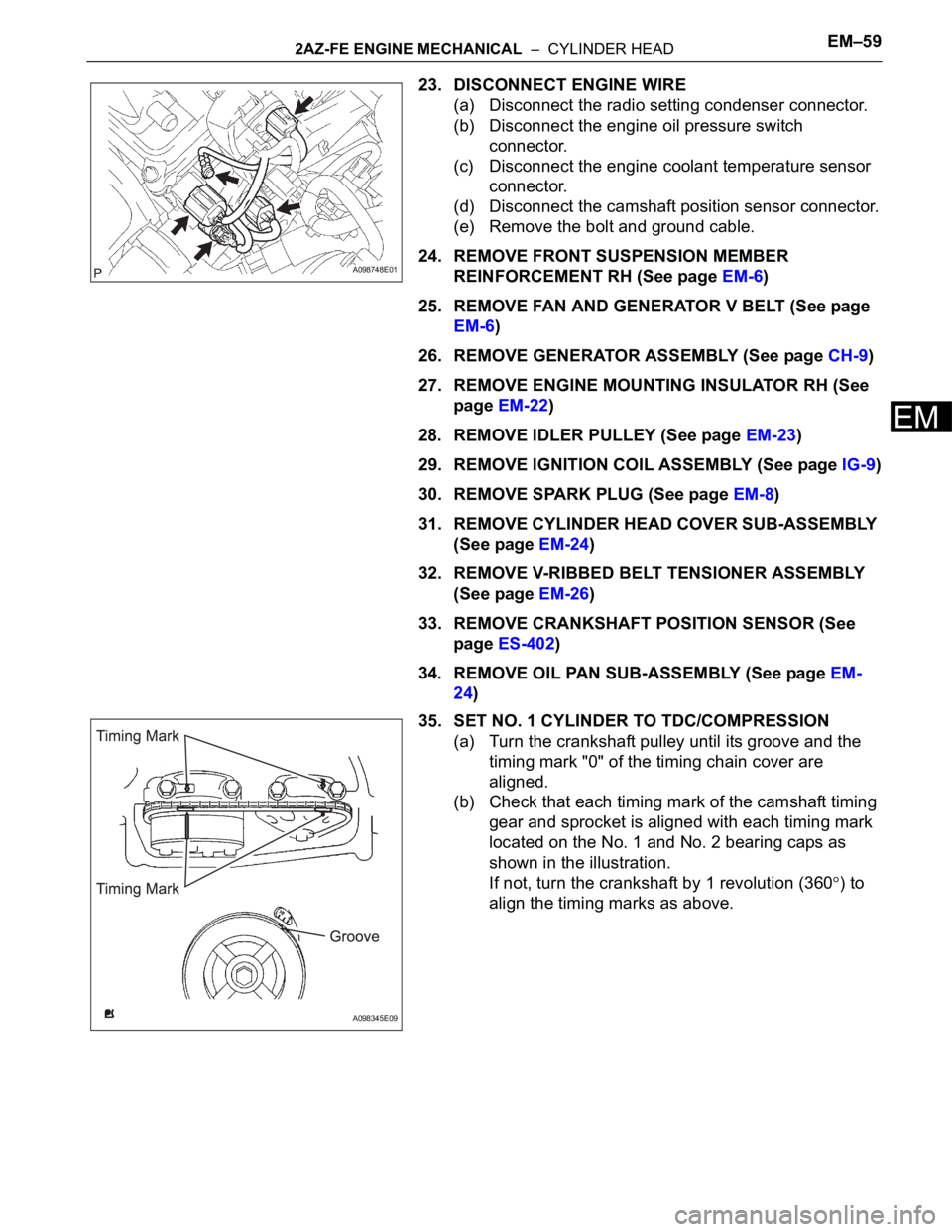

23. DISCONNECT ENGINE WIRE

(a) Disconnect the radio setting condenser connector.

(b) Disconnect the engine oil pressure switch

connector.

(c) Disconnect the engine coolant temperature sensor

connector.

(d) Disconnect the camshaft position sensor connector.

(e) Remove the bolt and ground cable.

24. REMOVE FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-6)

25. REMOVE FAN AND GENERATOR V BELT (See page

EM-6)

26. REMOVE GENERATOR ASSEMBLY (See page CH-9)

27. REMOVE ENGINE MOUNTING INSULATOR RH (See

page EM-22)

28. REMOVE IDLER PULLEY (See page EM-23)

29. REMOVE IGNITION COIL ASSEMBLY (See page IG-9)

30. REMOVE SPARK PLUG (See page EM-8)

31. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(See page EM-24)

32. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(See page EM-26)

33. REMOVE CRANKSHAFT POSITION SENSOR (See

page ES-402)

34. REMOVE OIL PAN SUB-ASSEMBLY (See page EM-

24)

35. SET NO. 1 CYLINDER TO TDC/COMPRESSION

(a) Turn the crankshaft pulley until its groove and the

timing mark "0" of the timing chain cover are

aligned.

(b) Check that each timing mark of the camshaft timing

gear and sprocket is aligned with each timing mark

located on the No. 1 and No. 2 bearing caps as

shown in the illustration.

If not, turn the crankshaft by 1 revolution (360

) to

align the timing marks as above.

A098748E01

A098345E09

Page 629 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–85

EM

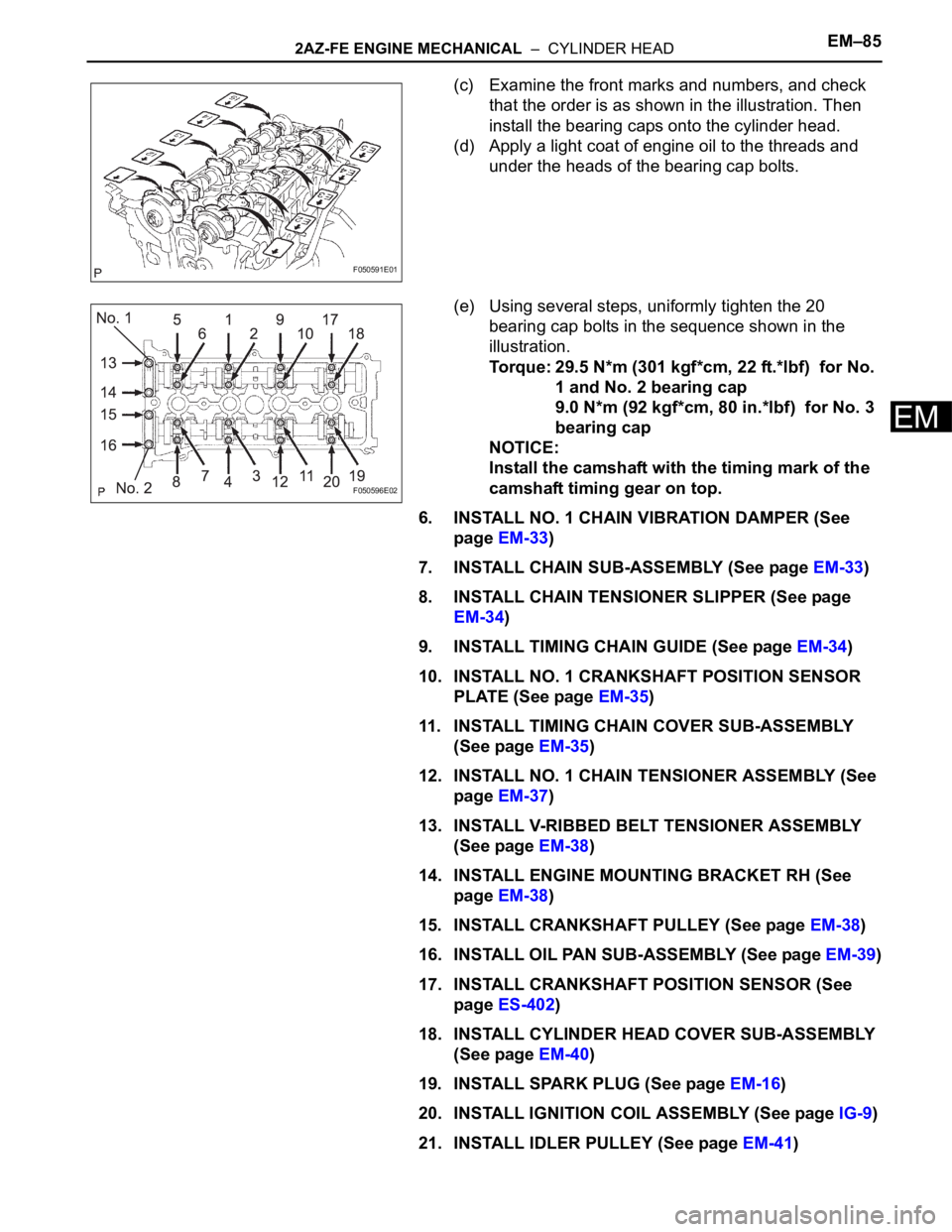

(c) Examine the front marks and numbers, and check

that the order is as shown in the illustration. Then

install the bearing caps onto the cylinder head.

(d) Apply a light coat of engine oil to the threads and

under the heads of the bearing cap bolts.

(e) Using several steps, uniformly tighten the 20

bearing cap bolts in the sequence shown in the

illustration.

Torque: 29.5 N*m (301 kgf*cm, 22 ft.*lbf) for No.

1 and No. 2 bearing cap

9.0 N*m (92 kgf*cm, 80 in.*lbf) for No. 3

bearing cap

NOTICE:

Install the camshaft with the timing mark of the

camshaft timing gear on top.

6. INSTALL NO. 1 CHAIN VIBRATION DAMPER (See

page EM-33)

7. INSTALL CHAIN SUB-ASSEMBLY (See page EM-33)

8. INSTALL CHAIN TENSIONER SLIPPER (See page

EM-34)

9. INSTALL TIMING CHAIN GUIDE (See page EM-34)

10. INSTALL NO. 1 CRANKSHAFT POSITION SENSOR

PLATE (See page EM-35)

11. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY

(See page EM-35)

12. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY (See

page EM-37)

13. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

(See page EM-38)

14. INSTALL ENGINE MOUNTING BRACKET RH (See

page EM-38)

15. INSTALL CRANKSHAFT PULLEY (See page EM-38)

16. INSTALL OIL PAN SUB-ASSEMBLY (See page EM-39)

17. INSTALL CRANKSHAFT POSITION SENSOR (See

page ES-402)

18. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

(See page EM-40)

19. INSTALL SPARK PLUG (See page EM-16)

20. INSTALL IGNITION COIL ASSEMBLY (See page IG-9)

21. INSTALL IDLER PULLEY (See page EM-41)

F050591E01

F050596E02