start TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1 of 2000

ENGINE - 2AZ-FE ENGINE EG-4

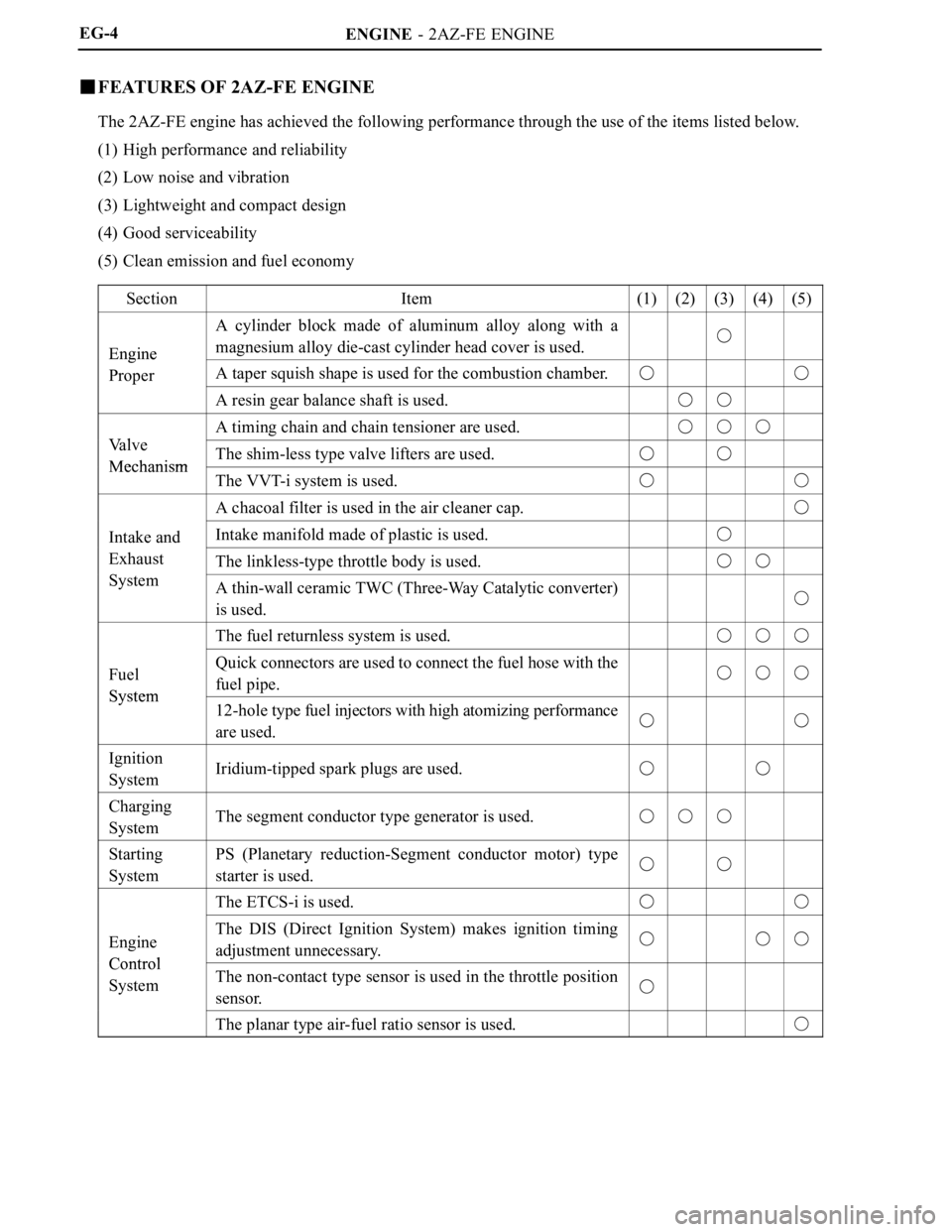

FEATURES OF 2AZ-FE ENGINE

The 2AZ-FE engine has achieved the following performance through the use of the items listed below.

(1) High performance and reliability

(2) Low noise and vibration

(3) Lightweight and compact design

(4) Good serviceability

(5) Clean emission and fuel economy

Section

Item(1)(2)(3)(4)(5)

Engine

A cylinder block made of aluminum alloy along with a

magnesium alloy die-cast cylinder head cover is used.

Engine

ProperA taper squish shape is used for the combustion chamber.p

A resin gear balance shaft is used.

Vl

A timing chain and chain tensioner are used.

Va l v e

MechanismThe shim-less type valve lifters are used.MechanismThe VVT-i system is used.

A chacoal filter is used in the air cleaner cap.

Intake andIntake manifold made of plastic is used.Intake and

ExhaustThe linkless-type throttle body is used.

SystemA thin-wall ceramic TWC (Three-Way Catalytic converter)

is used.

The fuel returnless system is used.

Fuel

System

Quick connectors are used to connect the fuel hose with the

fuel pipe.

System12-hole type fuel injectors with high atomizing performance

are used.

Ignition

SystemIridium-tipped spark plugs are used.

Charging

SystemThe segment conductor type generator is used.

Starting

SystemPS (Planetary reduction-Segment conductor motor) type

starter is used.

The ETCS-i is used.

Engine

Control

The DIS (Direct Ignition System) makes ignition timing

adjustment unnecessary.

Control

SystemThe non-contact type sensor is used in the throttle position

sensor.

The planar type air-fuel ratio sensor is used.

Page 22 of 2000

ENGINE - 2AZ-FE ENGINE

206EG40206EG41

206EG42

Stator Segment

ConductorStator

Joined

Joined Segment

Conductor SystemSegment

ConductorStator

StatorConductor

Wire

Conductor Wire

A

AA - A Cross

Section

Segment Conductor Type GeneratorB

BB - B Cross

Section

Conventional Type GeneratorWinding System

Stator

Segment

Conductor

Cross Section

Stator of Segment Conductor Type GeneratorEG-25

CHARGING SYSTEM

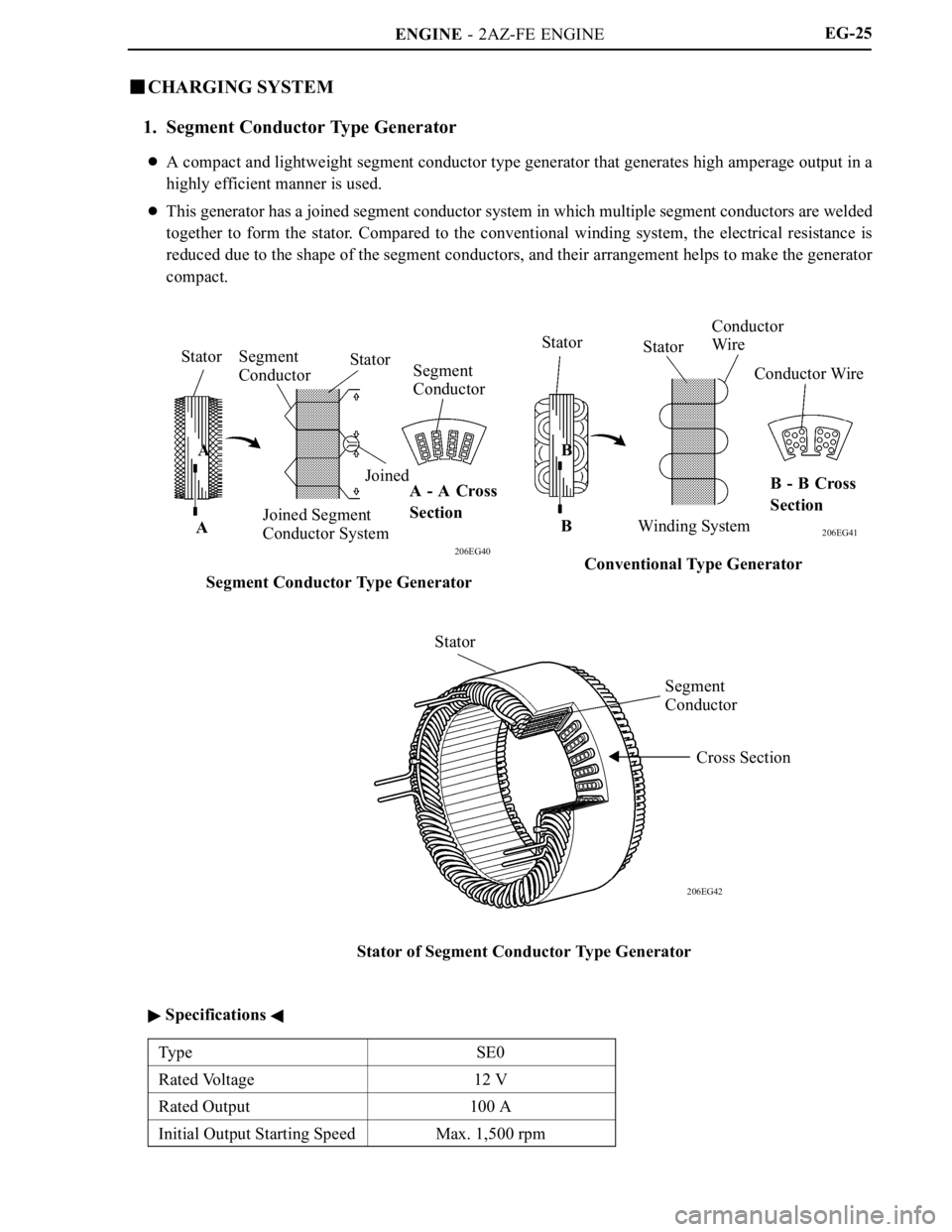

1. Segment Conductor Type Generator

A compact and lightweight segment conductor type generator that generates high amperage output in a

highly efficient manner is used.

This generator has a joined segment conductor system in which multiple segment conductors are welded

together to form the stator. Compared to the conventional winding system, the electrical resistance is

reduced due to the shape of the segment conductors, and their arrangement helps to make the generator

compact.

Specifications

Ty p eSE0

Rated Voltage12 V

Rated Output100 A

Initial Output Starting SpeedMax. 1,500 rpm

Page 24 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG46Y

ArmatureSurface Commutator

Permanent Magnet

Brush

LengthEG-27

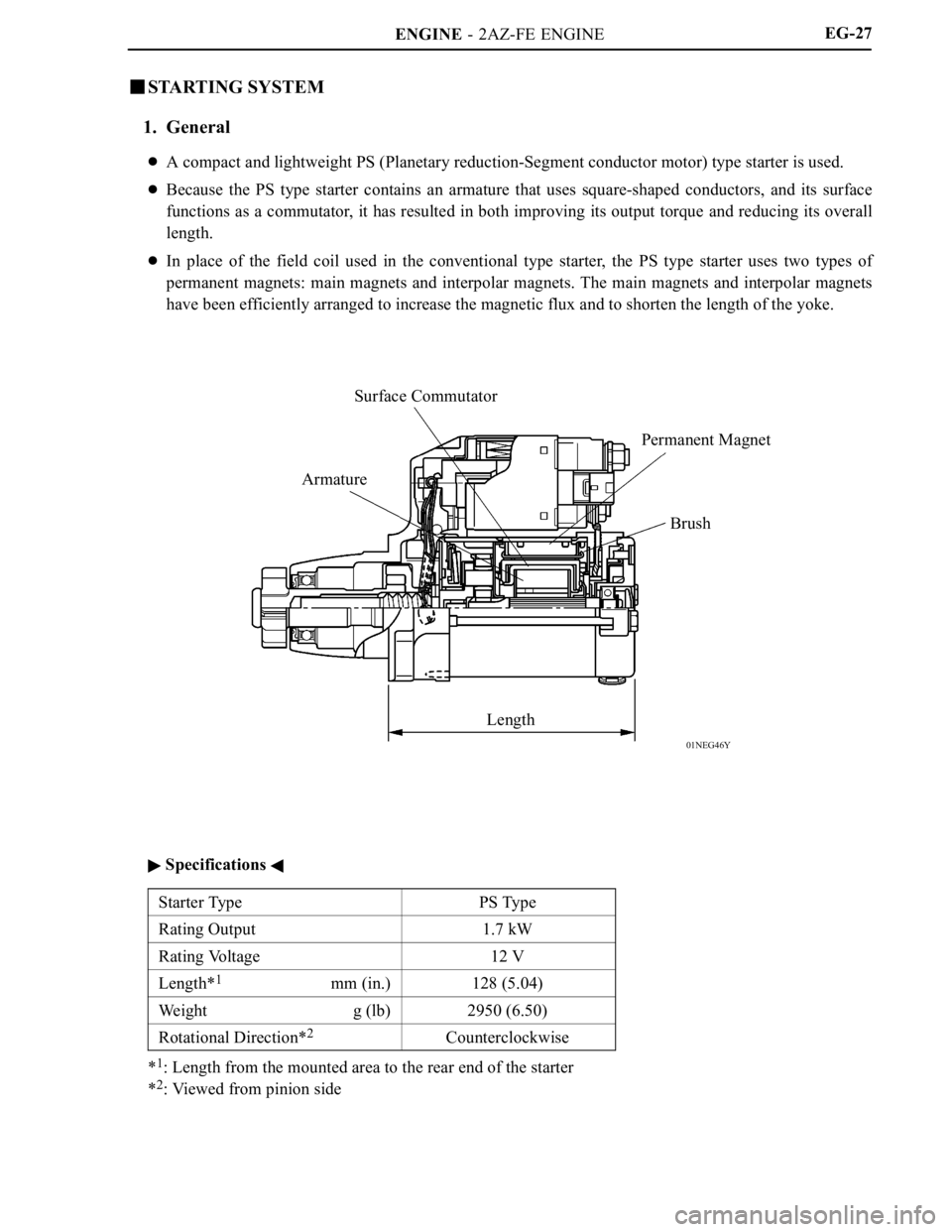

STARTING SYSTEM

1. General

A compact and lightweight PS (Planetary reduction-Segment conductor motor) type starter is used.

Because the PS type starter contains an armature that uses square-shaped conductors, and its surface

functions as a commutator, it has resulted in both improving its output torque and reducing its overall

length.

In place of the field coil used in the conventional type starter, the PS type starter uses two types of

permanent magnets: main magnets and interpolar magnets. The main magnets and interpolar magnets

have been efficiently arranged to increase the magnetic flux and to shorten the length of the yoke.

Specifications

Starter TypePS Type

Rating Output1.7 kW

Rating Voltage12 V

Length*1mm (in.)128 (5.04)

Weight g (lb)2950 (6.50)

Rotational Direction*2Counterclockwise

*1: Length from the mounted area to the rear end of the starter

*

2: Viewed from pinion side

Page 25 of 2000

ENGINE - 2AZ-FE ENGINE

206EG20

Conventional Type

A - A

Cross Section

(PS Type)B - B

Cross Section

(Conventional Type)

B

B

A

A Armature

ArmatureBrushCommutator Brush

Surface CommutatorSquare-shaped

ConductorRound-shaped

Conductor

PS Type

222EG15

Main Magnet

Interpolar Magnet

Yo k e

Main Magnet

Armature

Cross Section of YokeMagnetic Flux Generated by

Relationship between Main Magnets

Magnetic Flux Generated

by Interpolar Magnets

N

N

N

S

S

S EG-28

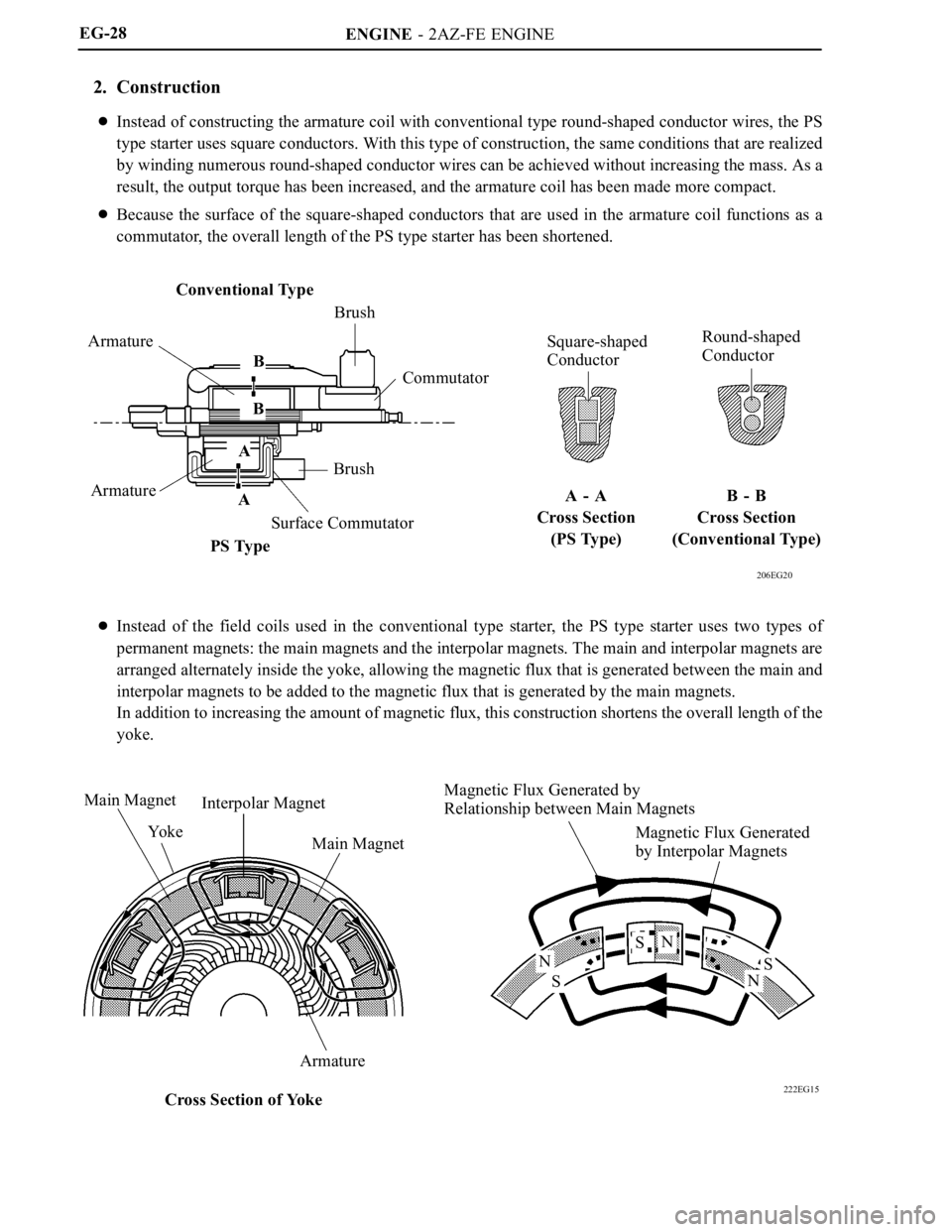

2. Construction

Instead of constructing the armature coil with conventional type round-shaped conductor wires, the PS

type starter uses square conductors. With this type of construction, the same conditions that are realized

by winding numerous round-shaped conductor wires can be achieved without increasing the mass. As a

result, the output torque has been increased, and the armature coil has been made more compact.

Because the surface of the square-shaped conductors that are used in the armature coil functions as a

commutator, the overall length of the PS type starter has been shortened.

Instead of the field coils used in the conventional type starter, the PS type starter uses two types of

permanent magnets: the main magnets and the interpolar magnets. The main and interpolar magnets are

arranged alternately inside the yoke, allowing the magnetic flux that is generated between the main and

interpolar magnets to be added to the magnetic flux that is generated by the main magnets.

In addition to increasing the amount of magnetic flux, this construction shortens the overall length of the

yoke.

Page 28 of 2000

ENGINE - 2AZ-FE ENGINEEG-31

System

Outline

Engine

Immobilizer*

2

Prohibits fuel delivery and ignition if an attempt is made to start the engine with

an invalid ignition key.

Diagnosis

(See page EG-67)When the ECM detects a malfunction, the ECM diagnoses and memorizes the

failed section.

Fail-safe

(See page EG-67)When the ECM detects a malfunction, the ECM stops or controls the engine

according to the data already stored in memory.

*2: Models with Engine Immobilizer System

Page 29 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG04Y

SENSORSACTUATORS

MASS AIR FLOW METER

INTAKE AIR TEMPERATURE

SENSOR

ENGIEN COOLANT

TEMPERATURE SENSOR

THROTTLE POSITION

SENSOR

CRANKSHAFT POSITION

SENSOR

CAMSHAFT POSITION

SENSOR

ACCELERATOR PEDAL

POSITION SENSOR

AIR-FUEL RATIO SENSOR

(Bank 1, Sensor 1)

HEATED OXYGEN SENSOR

(Bank 1, Sensor 2)

KNOCK SENSOR

COMBINATION METER

Vehicle Speed Signal

IGNITION SWITCH

Ignition Signal

Starter Signal

PA R K / N E U T R A L P O S I T I O N

SWITCH

TRANSMISSION CONTROL

SWITCH

CRUISE CONTROL SWITCHVG

THA

THW

VTA1

VTA2

NE

G2

VPA

VPA2

A1A

OX1B

KNK1

SPD

IGSW

STA

D, 2, L

R, P, N

3

CCSECM#10

#20

#30

#40

IGT1 IGT4

IGF1

M

OC1

FC

HA1A

HT1BSFI

No.1 INJECTOR

No.2 INJECTOR

No.3 INJECTOR

No.4 INJECTOR

ESA

IGNITION COIL

with IGNITER

SPARK PLUGS

ETCS-i

THROTTLE CONTROL

MOTOR

VVT-i

CAMSHAFT TIMING OIL

CONTROL VALVE

FUEL PUMP CONTROL

CIRCUIT OPENING

RELAY

AIR-FUEL RATIO AND

HEATED OXYGEN SENSOR

HEATER CONTROL

AIR-FUEL RATIO SENSOR

HEATER (Bank1, Sensor1)

HEATED OXYGEN SENSOR

HEATER (Bank1, Sensor2)

EG-32

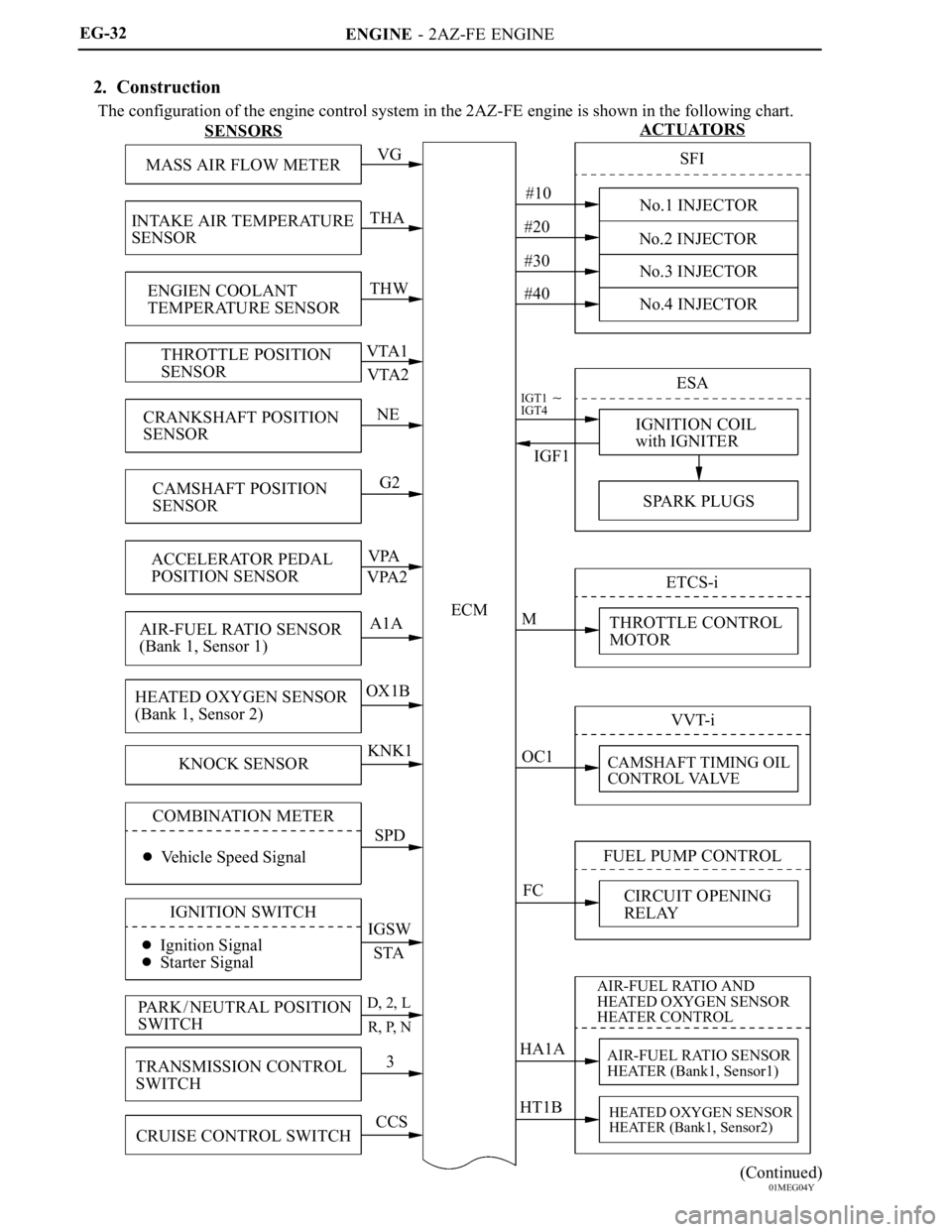

2. Construction

The configuration of the engine control system in the 2AZ-FE engine is shown in the following chart.

(Continued)

Page 46 of 2000

ENGINE - 2AZ-FE ENGINE

185EG48

185EG49

185EG50

287EG34

185EG48

185EG48

TDCLatest Timing

EX IN

BDC

To Advance Side

EX IN

EX IN

To Advance Side

EX IN

To Retard Side

Latest Timing

EX IN

Latest Timing

EX INEG-49

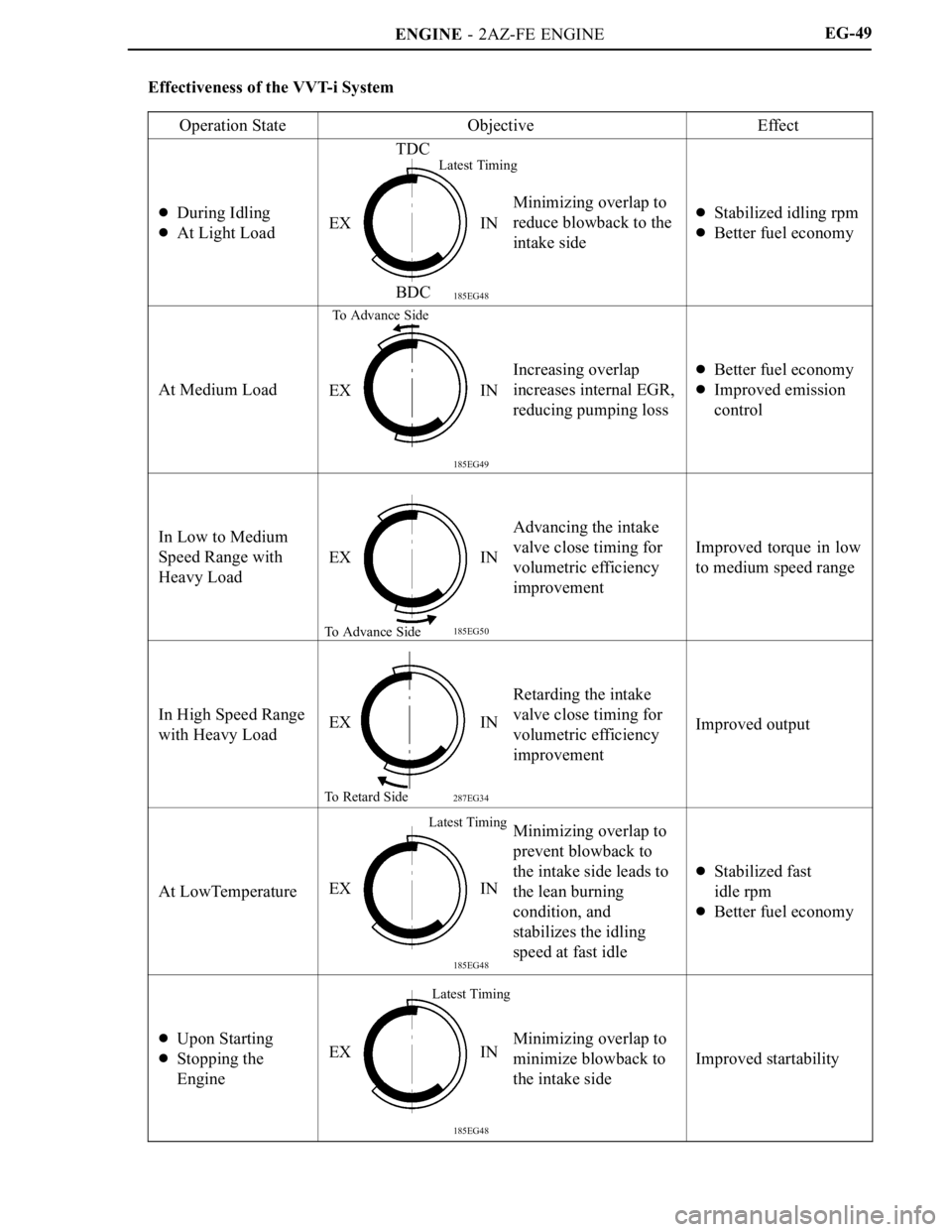

Effectiveness of the VVT-i System

Operation State

ObjectiveEffect

During Idling

At Light Load

Minimizing overlap to

reduce blowback to the

intake sideStabilized idling rpm

Better fuel economy

At Medium Load

Increasing overlap

increases internal EGR,

reducing pumping lossBetter fuel economy

Improved emission

control

In Low to Medium

Speed Range with

Heavy LoadAdvancing the intake

valve close timing for

volumetric efficiency

improvement

Improved torque in low

to medium speed range

In High Speed Range

with Heavy Load

Retarding the intake

valve close timing for

volumetric efficiency

improvement

Improved output

At LowTemperature

Minimizing overlap to

prevent blowback to

the intake side leads to

the lean burning

condition, and

stabilizes the idling

speed at fast idle

Stabilized fast

idle rpm

Better fuel economy

Upon Starting

Stopping the

Engine

Minimizing overlap to

minimize blowback to

the intake side

Improved startability

Page 47 of 2000

ENGINE - 2AZ-FE ENGINE

169EG36

HousingLock Pin

Intake Camshaft

Vane (Fixed on Intake Camshaft)

Oil Pressure

At a Stop In Operation

Lock Pin

221EG17

To VVT-i Controller

(Advance Side)To V V T- i C o n t r o l l e r

(Retard Side)

Sleeve

Spring

Drain

Oil PressureDrain

Spool ValveCoil

Plunger EG-50

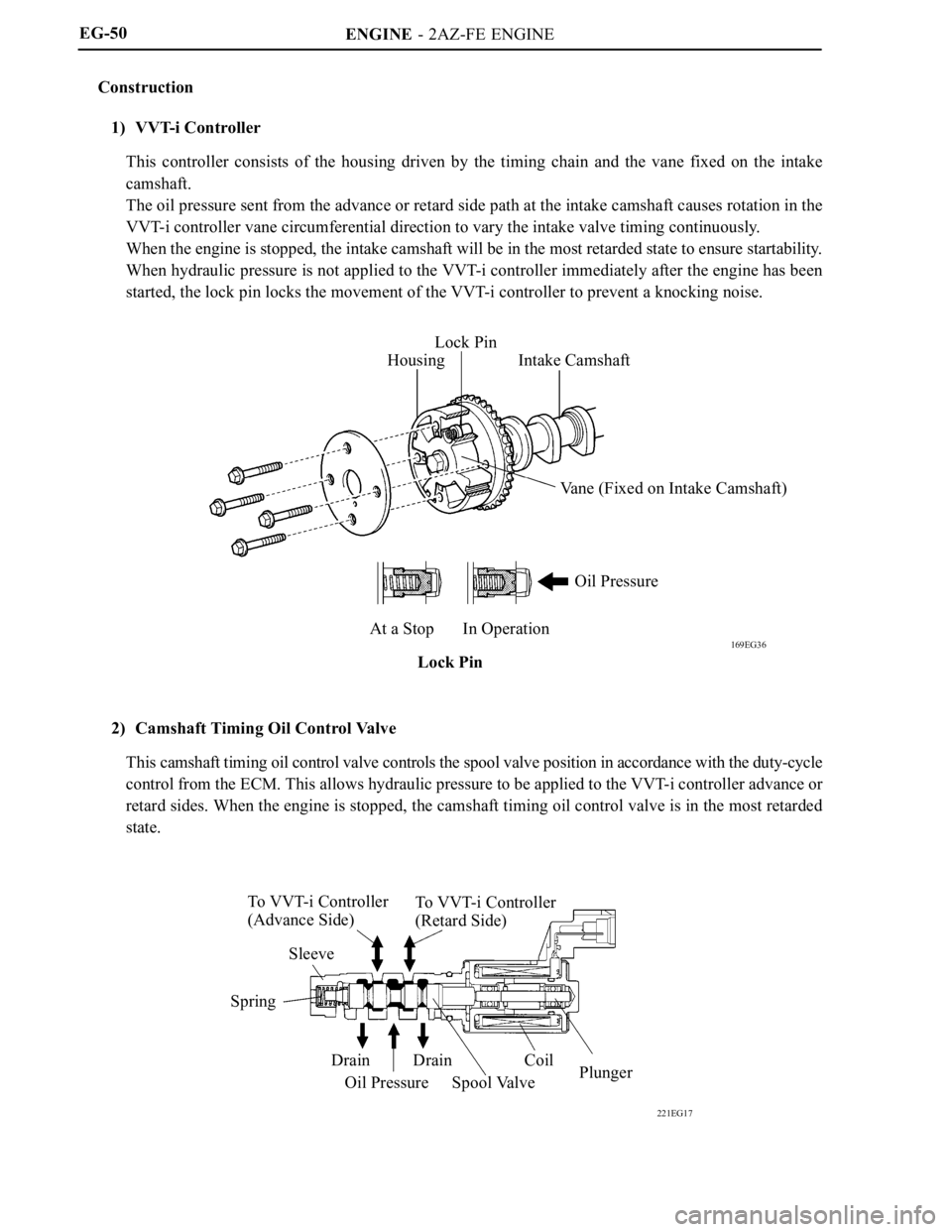

Construction

1) VVT-i Controller

This controller consists of the housing driven by the timing chain and the vane fixed on the intake

camshaft.

The oil pressure sent from the advance or retard side path at the intake camshaft causes rotation in the

VVT-i controller vane circumferential direction to vary the intake valve timing continuously.

When the engine is stopped, the intake camshaft will be in the most retarded state to ensure startability.

When hydraulic pressure is not applied to the VVT-i controller immediately after the engine has been

started, the lock pin locks the movement of the VVT-i controller to prevent a knocking noise.

2) Camshaft Timing Oil Control Valve

This camshaft timing oil control valve controls the spool valve position in accordance with the duty-cycle

control from the ECM. This allows hydraulic pressure to be applied to the VVT-i controller advance or

retard sides. When the engine is stopped, the camshaft timing oil control valve is in the most retarded

state.

Page 50 of 2000

ENGINE - 2AZ-FE ENGINE

00REG18Y

Front Airbag

Sensor

(RH and LH)

Curtain Shield

Airbag Sensor*

(RH and LH)Airbag

Sensor

Side Airbag

Sensor*

(RH or LH)ECMCircuit

Opening

Relay

Fuel

Pump

Motor

: CANEG-53

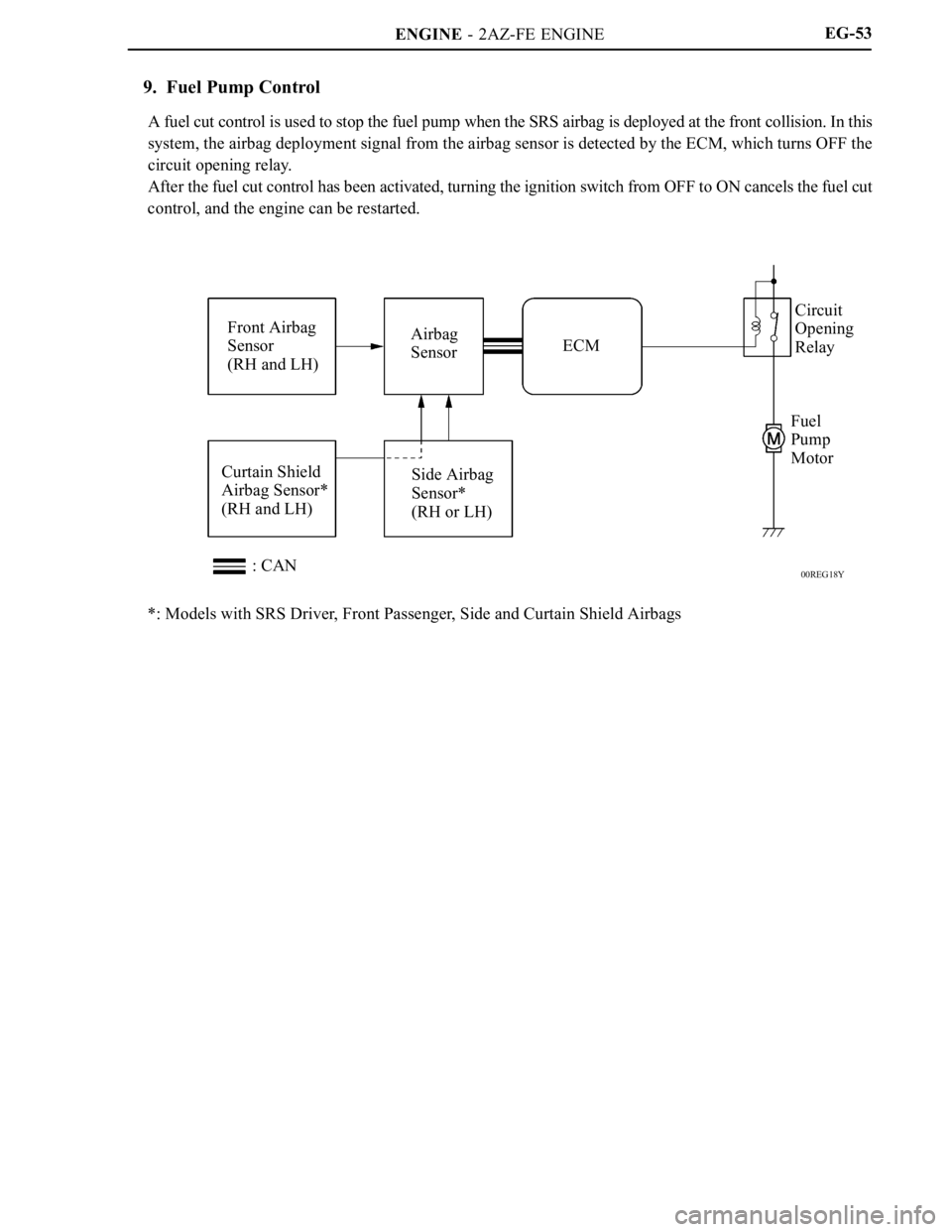

9. Fuel Pump Control

A fuel cut control is used to stop the fuel pump when the SRS airbag is deployed at the front collision. In this

system, the airbag deployment signal from the airbag sensor is detected by the ECM, which turns OFF the

circuit opening relay.

After the fuel cut control has been activated, turning the ignition switch from OFF to ON cancels the fuel cut

control, and the engine can be restarted.

*: Models with SRS Driver, Front Passenger, Side and Curtain Shield Airbags

Page 68 of 2000

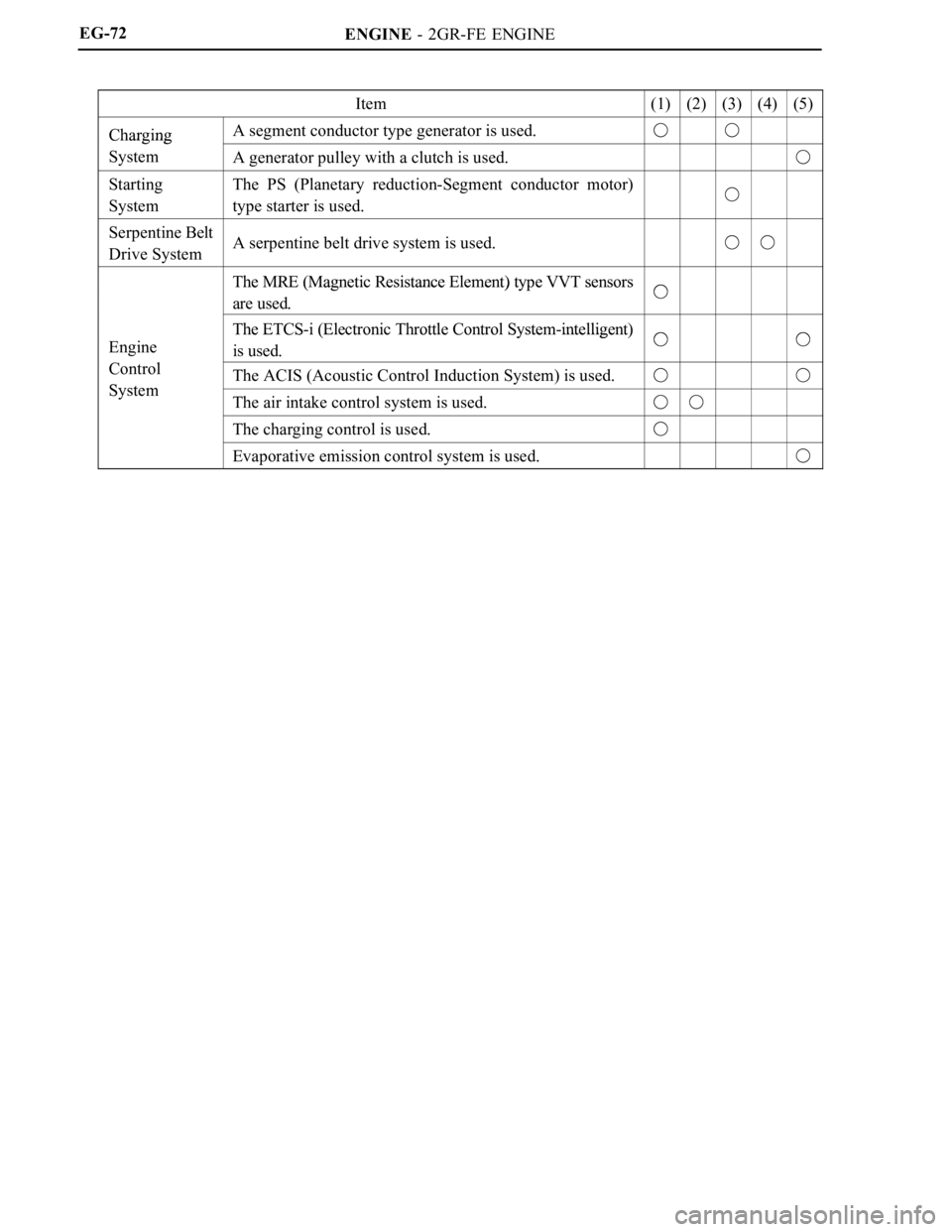

ENGINE - 2GR-FE ENGINE EG-72

Item

(1)(2)(3)(4)(5)

ChargingA segment conductor type generator is used.Charging

SystemA generator pulley with a clutch is used.

Starting

SystemThe PS (Planetary reduction-Segment conductor motor)

type starter is used.

Serpentine Belt

Drive SystemA serpentine belt drive system is used.

The MRE (Magnetic Resistance Element) type VVT sensorsThe MRE (Magnetic Resistance Element) type VVT sensors

are used.

The ETCS-i (Electronic Throttle Control System-intelligent)

Engine

The ETCS i (Electronic Throttle Control System intelligent)

is used.

Control

SystemThe ACIS (Acoustic Control Induction System) is used.SystemThe air intake control system is used.

The charging control is used.

Evaporative emission control system is used.