start TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 96 of 2000

ENGINE - 2GR-FE ENGINE

01MEG38Y

Water Pump Pulley

Crankshaft Pulley

Air Conditioning

Compressor PulleyIdler Pulley for

Automatic

Te n s i o n e rGenerator Pulley Belt Idler

285EG78

Idler

PulleySpring

Arm

BracketBelt Pulling

Direction

Belt Tension

Direction

Fulcrum

Cross Section EG-98

STARTING SYSTEM

The 2GR-FE engine uses the same starter as the 2AZ-FE engine. For details, see page EG-27.

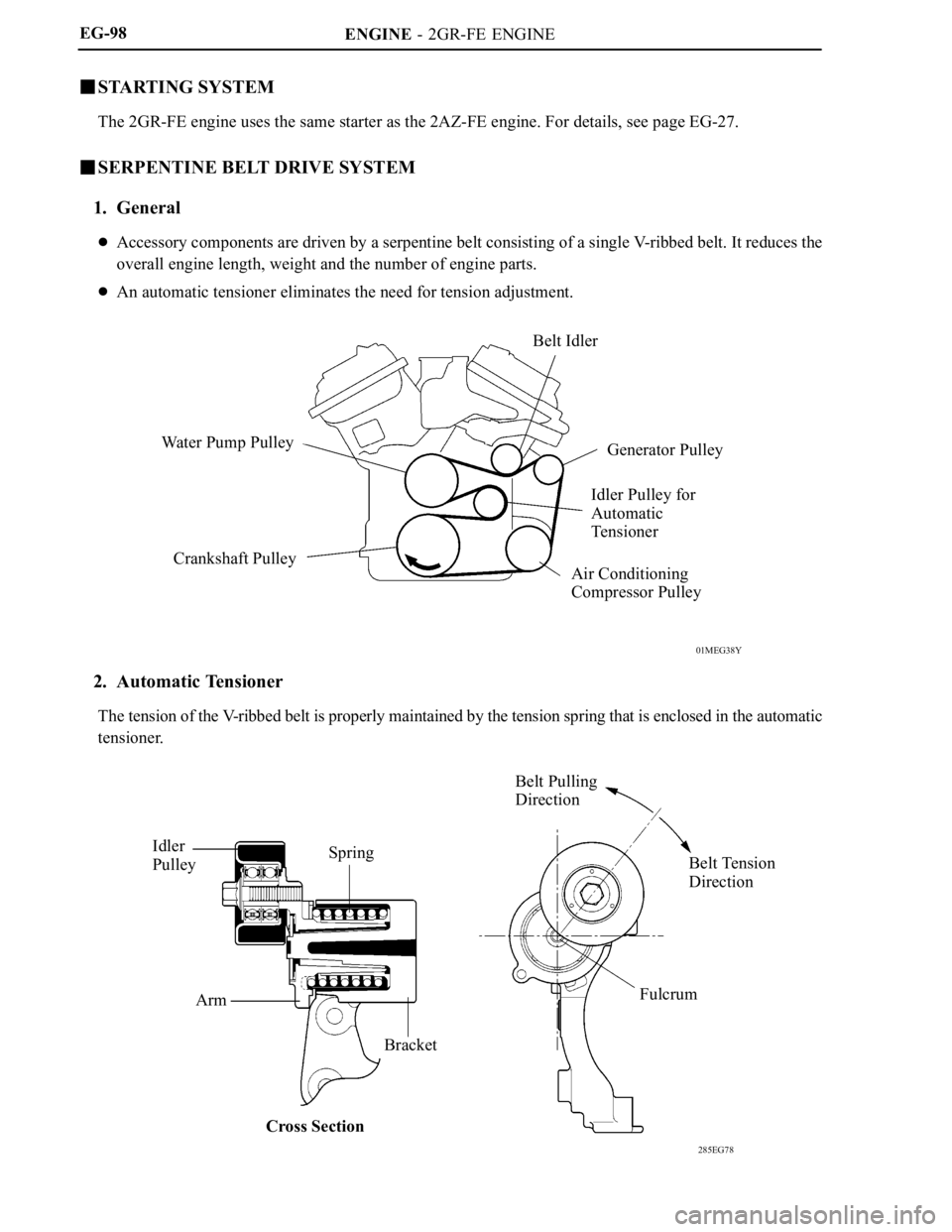

SERPENTINE BELT DRIVE SYSTEM

1. General

Accessory components are driven by a serpentine belt consisting of a single V-ribbed belt. It reduces the

overall engine length, weight and the number of engine parts.

An automatic tensioner eliminates the need for tension adjustment.

2. Automatic Tensioner

The tension of the V-ribbed belt is properly maintained by the tension spring that is enclosed in the automatic

tensioner.

Page 98 of 2000

ENGINE - 2GR-FE ENGINE EG-102

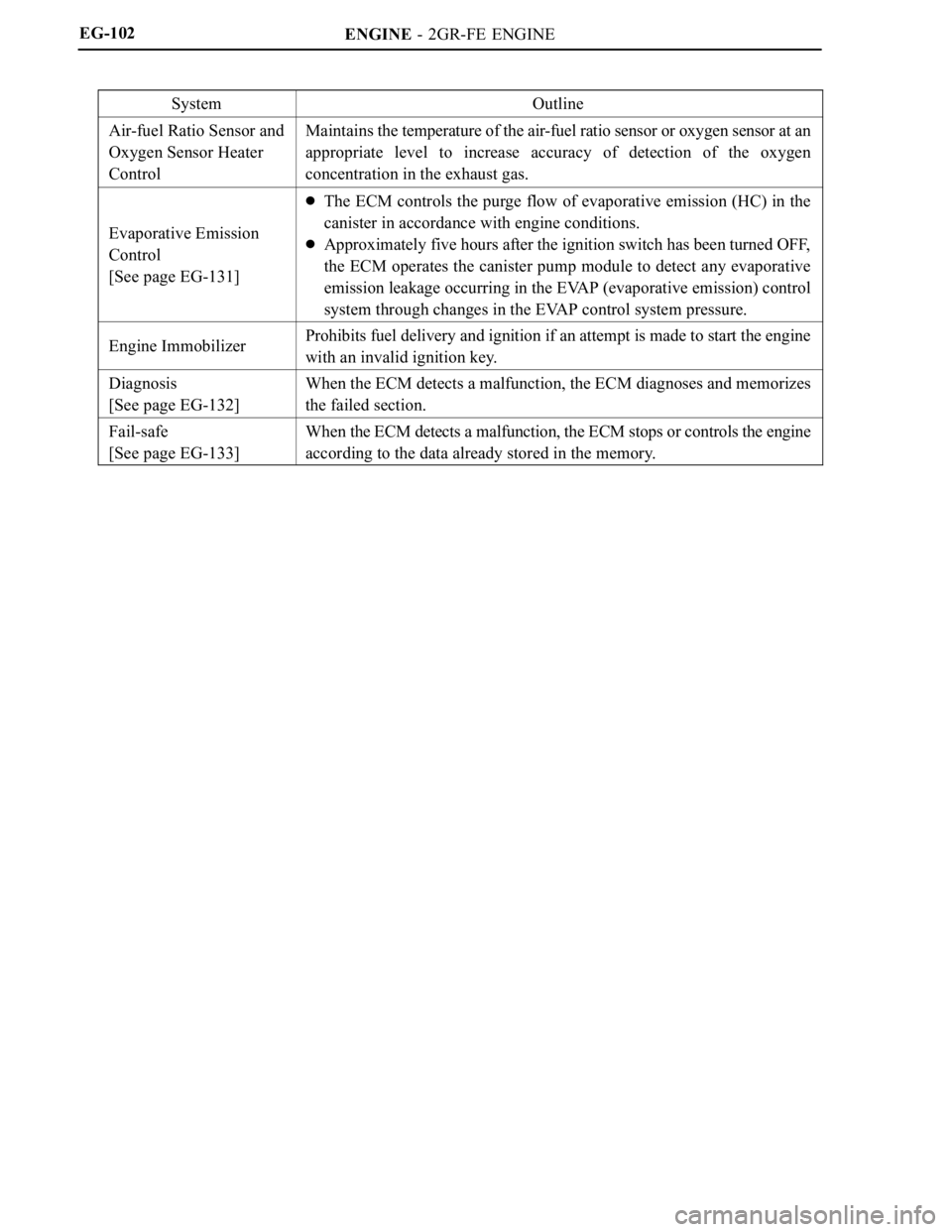

System

Outline

Air-fuel Ratio Sensor and

Oxygen Sensor Heater

ControlMaintains the temperature of the air-fuel ratio sensor or oxygen sensor at an

appropriate level to increase accuracy of detection of the oxygen

concentration in the exhaust gas.

Evaporative Emission

Control

[See page EG-131]

The ECM controls the purge flow of evaporative emission (HC) in the

canister in accordance with engine conditions.

Approximately five hours after the ignition switch has been turned OFF,

the ECM operates the canister pump module to detect any evaporative

emission leakage occurring in the EVAP (evaporative emission) control

system through changes in the EVAP control system pressure.

Engine ImmobilizerProhibits fuel delivery and ignition if an attempt is made to start the engine

with an invalid ignition key.

Diagnosis

[See page EG-132]When the ECM detects a malfunction, the ECM diagnoses and memorizes

the failed section.

Fail-safe

[See page EG-133]When the ECM detects a malfunction, the ECM stops or controls the engine

according to the data already stored in the memory.

Page 108 of 2000

ENGINE - 2GR-FE ENGINE

271EG160

Timing Rotor

Intake VVT

Sensor

VC

VV1+

VV1 -ECM

Intake VVT Sensor (Bank 1) EG-112

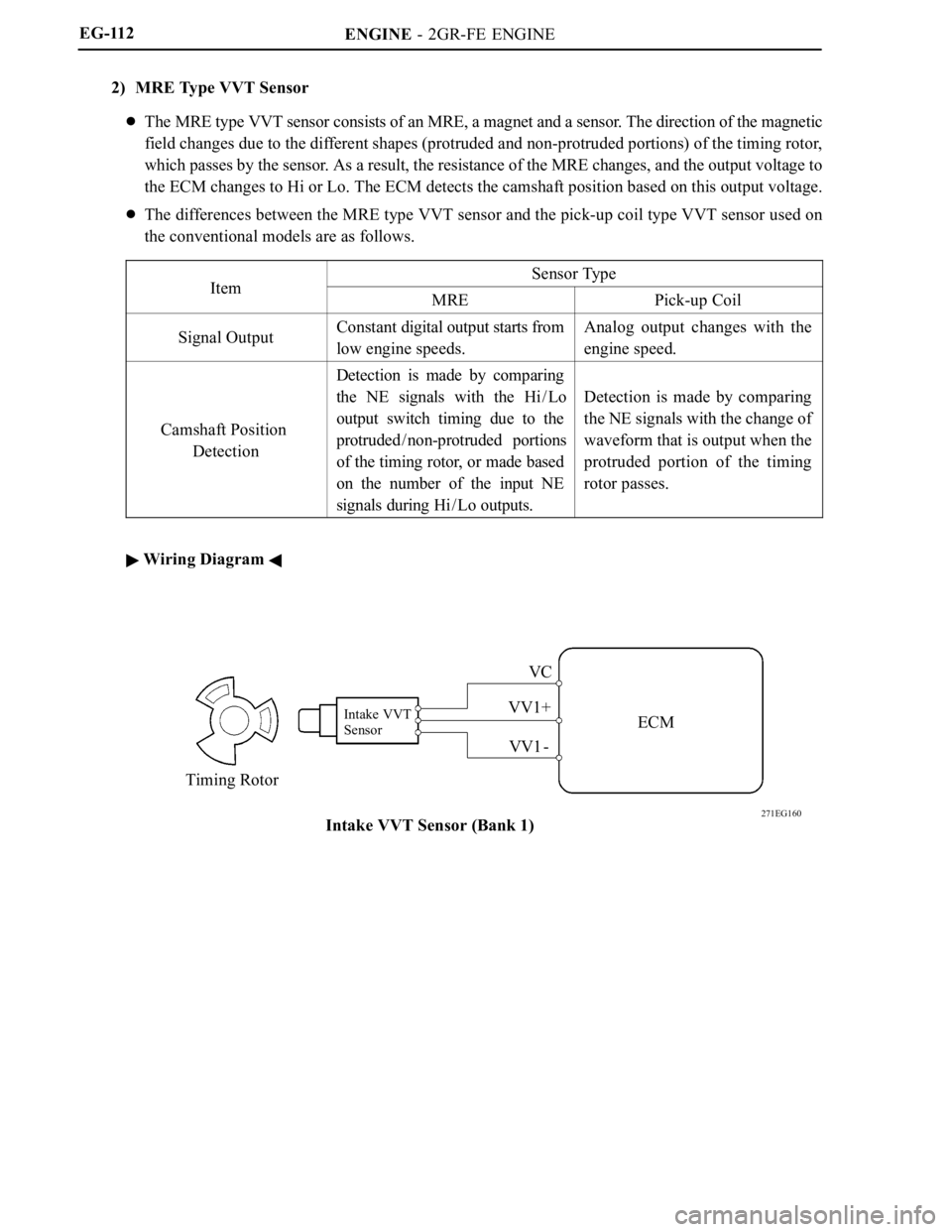

2) MRE Type VVT Sensor

The MRE type VVT sensor consists of an MRE, a magnet and a sensor. The direction of the magnetic

field changes due to the different shapes (protruded and non-protruded portions) of the timing rotor,

which passes by the sensor. As a result, the resistance of the MRE changes, and the output voltage to

the ECM changes to Hi or Lo. The ECM detects the camshaft position based on this output voltage.

The differences between the MRE type VVT sensor and the pick-up coil type VVT sensor used on

the conventional models are as follows.

ItemSensor TypeItemMREPick-up Coil

Signal OutputConstant digital output starts from

low engine speeds.Analog output changes with the

engine speed.

Camshaft Position

Detection

Detection is made by comparing

the NE signals with the Hi / Lo

output switch timing due to the

protruded / non-protruded portions

of the timing rotor, or made based

on the number of the input NE

signals during Hi / Lo outputs.

Detection is made by comparing

the NE signals with the change of

waveform that is output when the

protruded portion of the timing

rotor passes.

Wiring Diagram

Page 117 of 2000

ENGINE - 2GR-FE ENGINE

285EG62 285EG61 285EG60

285EG63

285EG59

285EG59 285EG59

Earliest Timing

(EX)Latest Timing

(IN)TDC

EX IN

BDC

To Advance

Side (EX)To R e t a r d

Side (IN)

EX IN

To Advance

Side (IN)To R e t a r d

Side (EX)

EX IN

EX IN

EX IN

To Retard

Side (EX)To Advance

Side (IN)

To R e t a r d

Side (IN)To A d v a n c e

Side (EX)

Earliest Timing

(EX)Latest Timing

(IN)

Earliest Timing

(EX)Latest Timing

(IN)

EX IN

EX IN

EG-121

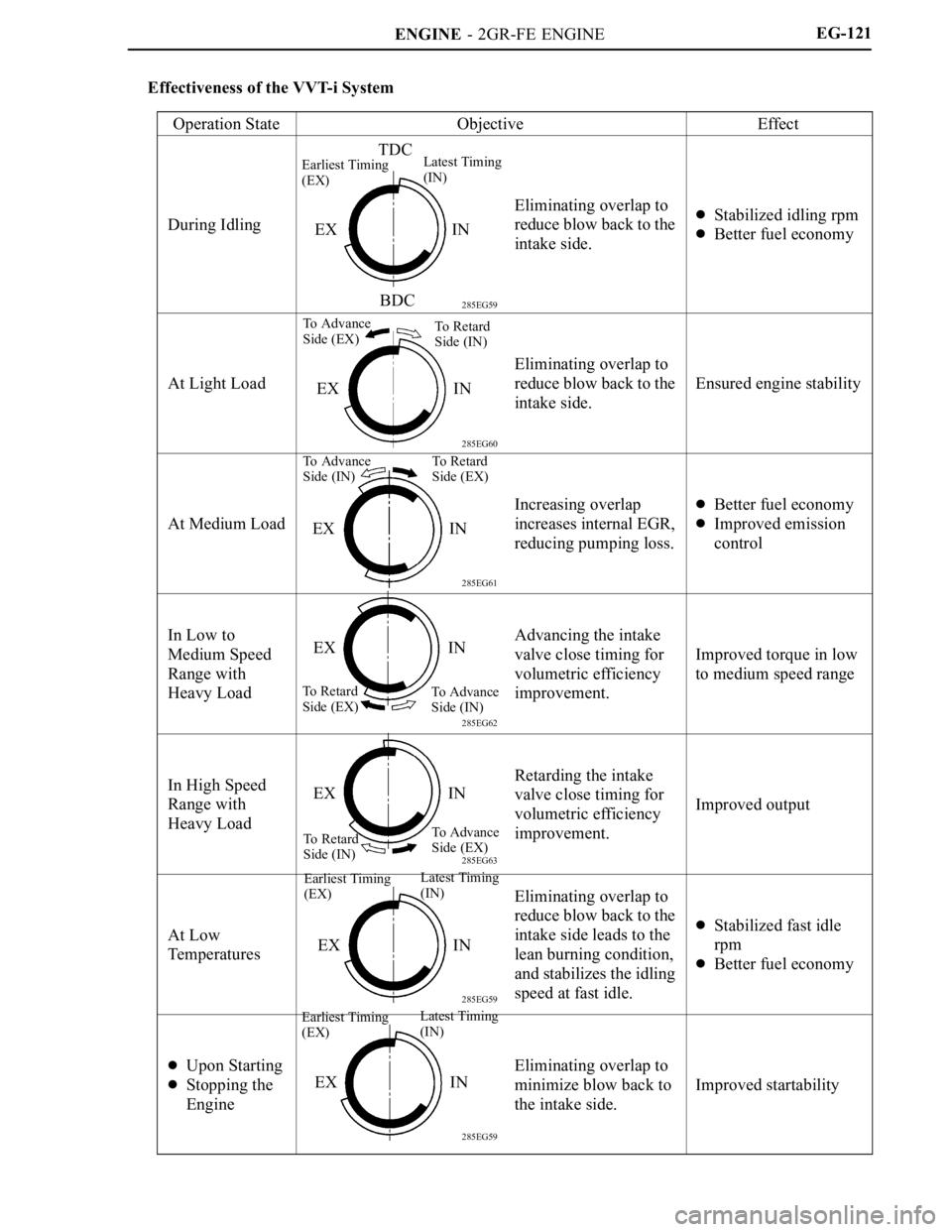

Effectiveness of the VVT-i System

Operation State

ObjectiveEffect

During Idling

Eliminating overlap to

reduce blow back to the

intake side.Stabilized idling rpm

Better fuel economy

At Light Load

Eliminating overlap to

reduce blow back to the

intake side.

Ensured engine stability

At Medium Load

Increasing overlap

increases internal EGR,

reducing pumping loss.Better fuel economy

Improved emission

control

In Low to

Medium Speed

Range with

Heavy LoadAdvancing the intake

valve close timing for

volumetric efficiency

improvement.

Improved torque in low

to medium speed range

In High Speed

Range with

Heavy LoadRetarding the intake

valve close timing for

volumetric efficiency

improvement.

Improved output

At Low

Temperatures

Eliminating overlap to

reduce blow back to the

intake side leads to the

lean burning condition,

and stabilizes the idling

speed at fast idle.

Stabilized fast idle

rpm

Better fuel economy

Upon Starting

Stopping the

Engine

Eliminating overlap to

minimize blow back to

the intake side.

Improved startability

Page 118 of 2000

ENGINE - 2GR-FE ENGINE

271EG93

Timing RotorHousingLock PinSprocket

Intake Camshaft

Vane (Fixed on Intake Camshaft)

Oil Pressure

In Operation At a Stop

Lock Pin

281EG47

Housing

Advanced Angle Assist SpringVane (Fixed on Exhaust Camshaft)Lock PinExhaust Camshaft Sprocket EG-122

Construction

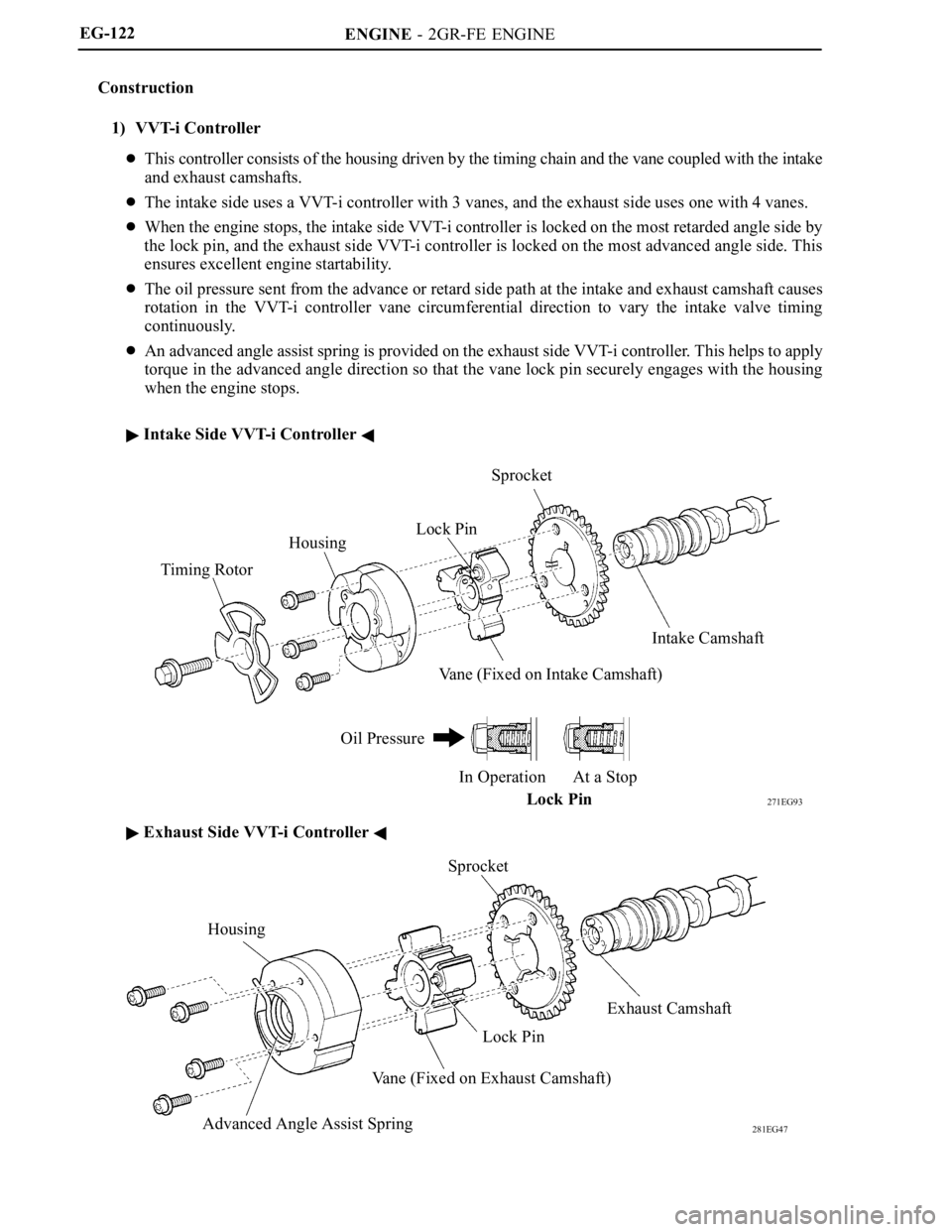

1) VVT-i Controller

This controller consists of the housing driven by the timing chain and the vane coupled with the intake

and exhaust camshafts.

The intake side uses a VVT-i controller with 3 vanes, and the exhaust side uses one with 4 vanes.

When the engine stops, the intake side VVT-i controller is locked on the most retarded angle side by

the lock pin, and the exhaust side VVT-i controller is locked on the most advanced angle side. This

ensures excellent engine startability.

The oil pressure sent from the advance or retard side path at the intake and exhaust camshaft causes

rotation in the VVT-i controller vane circumferential direction to vary the intake valve timing

continuously.

An advanced angle assist spring is provided on the exhaust side VVT-i controller. This helps to apply

torque in the advanced angle direction so that the vane lock pin securely engages with the housing

when the engine stops.

Intake Side VVT-i Controller

Exhaust Side VVT-i Controller

Page 133 of 2000

CHASSIS - 4WD SYSTEM CH-66

4WD SYSTEM

DESCRIPTION

The 4WD system of the ’06 RAV4 uses an active torque control 4WD system.

It is a compact, lightweight, and high performance 4WD system that optimally controls the torque

distribution to the front and rear wheels through the electric control coupling in the rear differential.

ACTIVE TORQUE CONTROL 4WD SYSTEM

1. General

Based on information provided by various sensors, the 4WD ECU controls the amperage that is applied

to the electric control coupling, in order to transmit drive torque to the rear wheels when needed, and in

the amount needed. The following describes the features of the active torque control 4WD system.

Traction performance

Realizes stable start-off and acceleration performance

Driving stability performanceRealizes stable cornering performance

Fuel economyRealizes better fuel economy by transmitting drive torque to the rear

wheels when needed, in the amount needed.

A four-wheel drive lock switch has been provided. This enables the driver to select between the AUTO

and LOCK modes by operating the switch. The system optimally controls the torque distribution to the

front and rear wheels in the respective modes.

Mode

Four-wheel Drive

Lock Switch and

Indicator Light

Outline

AUTOOFF

Optimally distributes drive torque to the front and rear wheels.

Ensures optimal start-off performance during a start-off, based on

information provided by various sensors.

Suppresses the tight corner braking phenomenon* during low-speed

cornering.

Reduces the amount of torque distribution to the rear wheels and

improves fuel economy when the system judges that the vehicle is

traveling steadily.

Disengages the 4WD during braking deceleration.

LOCKON

Distributes the maximum torque limit to the rear wheels.

Distributes the maximum torque limit to the rear wheels during

start-off.

Distributes optimal torque during low-speed cornering.

Disengages the 4WD during braking deceleration.

Disengages the LOCK mode and transfers to the AUTO mode when

the vehicle speed exceeds 40 km / h (25 mph).

*: Tight corner braking phenomenon: a condition in which the brakes are applied due to a rotational difference

between the front and rear wheels, such as during low-speed cornering in the 4WD mode.

The 4WD ECU effects cooperative control with the skid control ECU, in order to control the drive torque

distribution to the front and rear wheels in accordance with information received from the skid control

ECU. These controls ensure a smooth acceleration and driving stability.

Page 137 of 2000

CHASSIS - 4WD SYSTEM

01NCH38Y

Torque Distribution

to Rear WheelsTorque Distribution

to Rear Wheels

Straightline Driving Low-Speed Cornering

01NCH39Y

Torque Distribution

to Rear WheelsTorque Distribution

to Rear Wheels

Steady Driving Straightline Acceleration

NOTICE

In the LOCK mode after the four-wheel drive lock switch is pressed, the system starts control upon

judging that the vehicle is operating in a stable manner. During this judgment, the 4WD LOCK

indicator light blinks.

CH-70

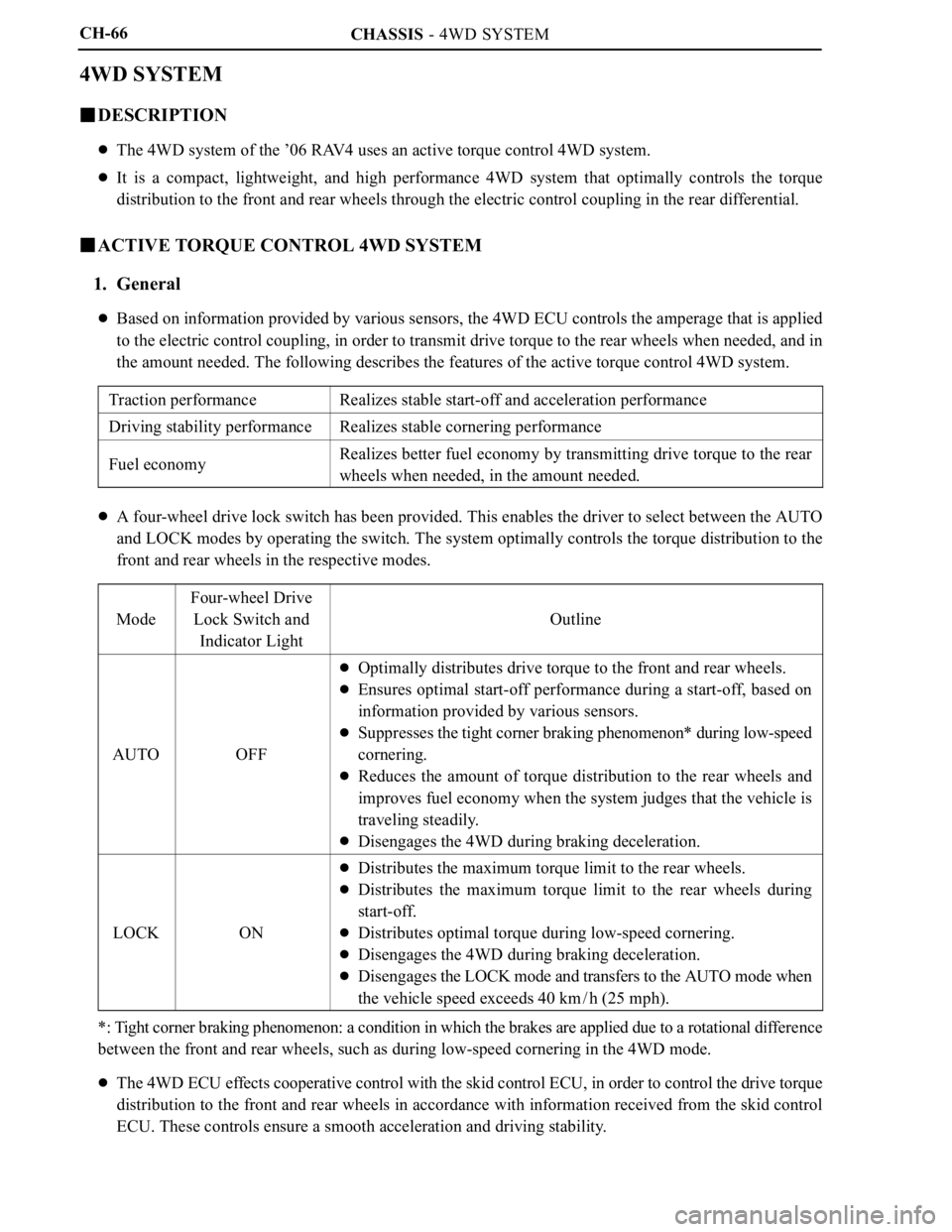

5. System Operation

Auto Mode

1) Starting Off

The system ensures start-off performance by optimally distributing the entire drive torque, which is

transmitted by the engine, to the front and rear wheels.

To prevent the tight corner braking phenomenon from occurring during low-speed cornering, the

system reduces the amount of torque distribution to the rear wheels.

2) Normal Driving

During normal driving, when the system judges that the vehicle is traveling steadily, it reduces the

amount of torque distribution to the rear wheels. This allows the vehicle to operate in conditions

similar to front-wheel-drive, which improves fuel economy.

To ensure excellent acceleration performance during straightline acceleration and excellent driving

stability during cornering, the system controls the amount of torque distribution to the rear wheels.

Lock Mode

When the vehicle is in a situation that poses difficulty for it to pull itself out, such as sand, the driver can

switch to LOCK mode by operating the four-wheel drive lock switch. Thus, this mode effects optimal

control in accordance with the driving conditions and transmits as much drive torque as possible to the rear

wheels, in a mode that is similar to the locked 4WD mode.

Page 179 of 2000

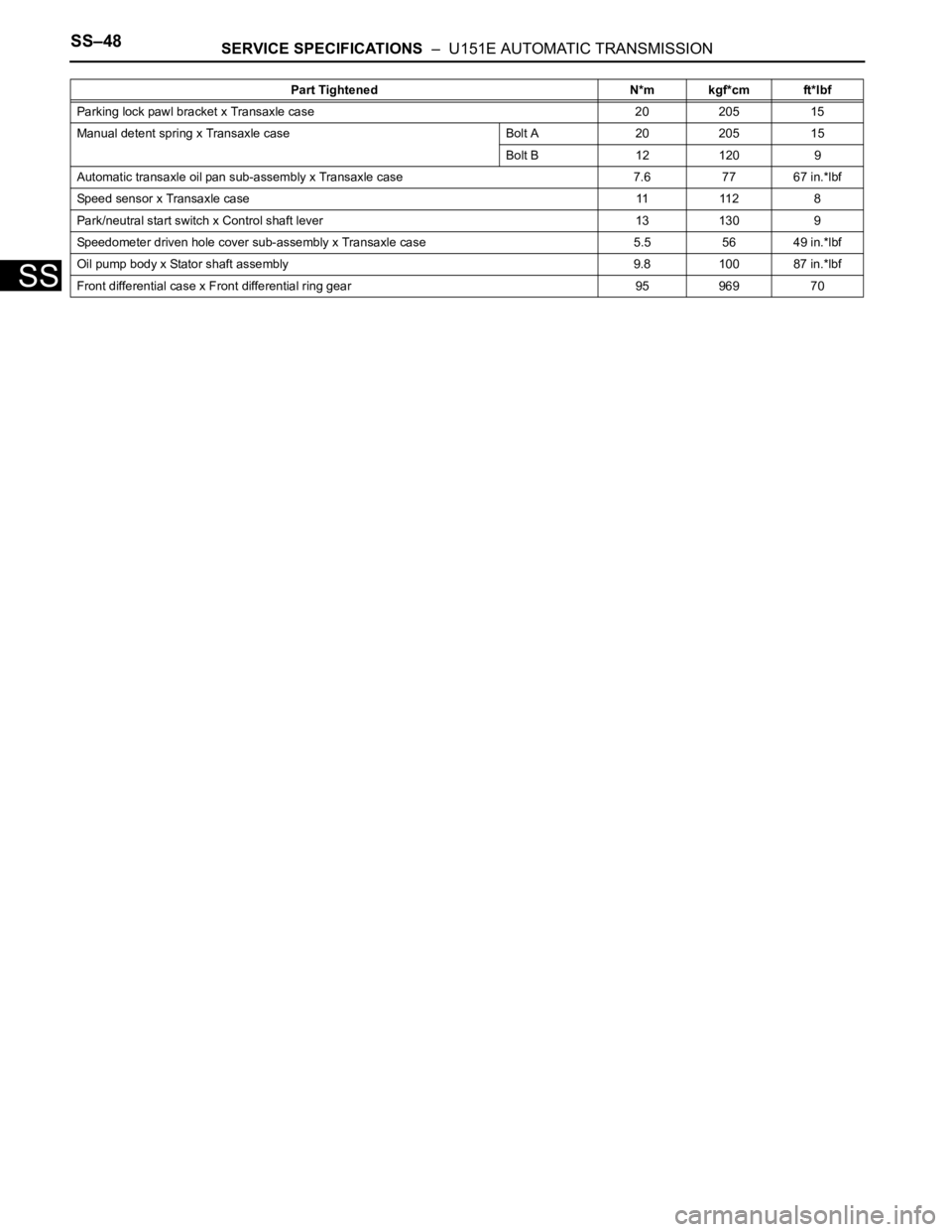

SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSMISSIONSS–47

SS

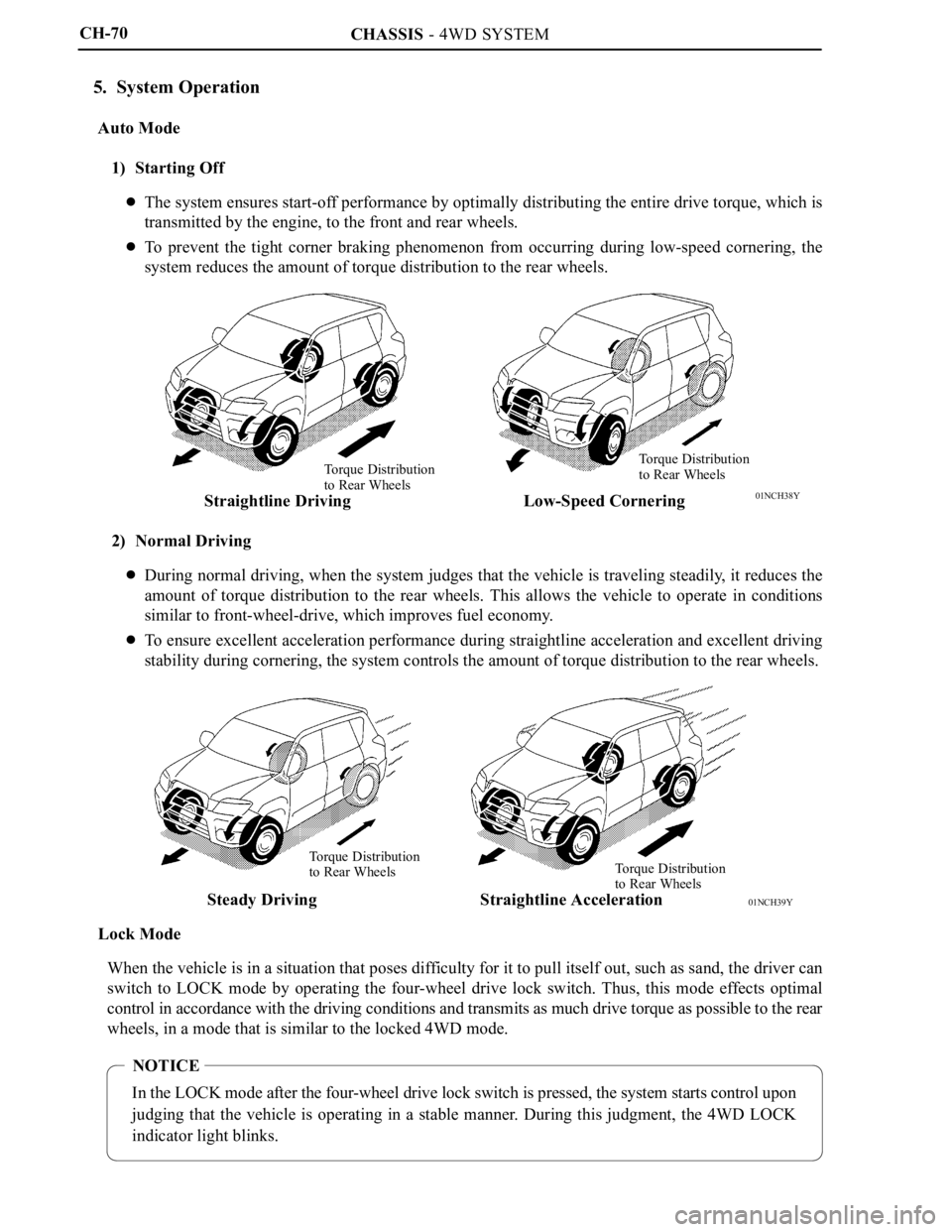

TORQUE SPECIFICATIONS

Automatic Transaxle Assembly

Part Tightened N*m kgf*cm ft*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 13 133 10

Shift control cable x Control shaft lever 15 153 11

Transaxle housing x Engine block Upper side bolt 64 653 47

Lower side bolt

A37 377 27

Lower side bolt

B46 470 34

Torque converter clutch x Drive plate 41 418 30

Flywheel housing under cover x Automatic transaxle 7.8 80 69 in.*lbf

Front engine mounting bracket x Transaxle 64 653 47

Rear engine mounting bracket x Transaxle 45 459 33

Engine mounting bracket LH x Transaxle 64 653 47

Oil filler tube x Transaxle

Oil filler tube x Front engine mounting bracket5.5 56 49 in.*lbf

Control cable bracket No. 1 x Transaxle 12 122 9

Control cable bracket No. 2 x Transaxle 12 122 9

Oil cooler inlet elbow x Transaxle 27 276 20

Oil cooler outlet elbow x Transaxle 27 276 20

Starter x Transaxle37 377 27

Starter wire x Starter9.8 100 88 in.*lbf

Speed sensor (NC) x Transaxle 11 112 8

Speed sensor (NT) x Transaxle 11 112 8

Drain plug x Oil pan47 479 35

Transmission wire x Transaxle 5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.8 80 69 in.*lbf

Solenoid valve x Valve body SL2, DSL, S4 11 110 8

SL1, SL3 6.6 67 58 in.*lbf

Valve body x Transaxle11 11 2 8

Oil strainer x Valve body11 11 2 8

Floor shift assembly x Body12 122 9

Control cable clamp x Engine mounting insulator 12 122 9

Differential gear lube apply tube x Transaxle housing 9.8 100 87 in.*lbf

Front planetary gear lock nut 280 3,355 207

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 19 194 14

Other bolt 25 255 18

Parking lock pawl shaft x Transaxle case 9.8 100 87 in.*lbf

Oil pump assembly x Transaxle case 22 226 16

Transaxle housing x Transaxle case Bolt A 22 254 16

Bolt B 29 295 21

Bolt C 29 295 21

Bolt D 22 254 16

Automatic transmission case plug x Transaxle housing 7.4 75 65 in.*lbf

Automatic transmission case plug x Transaxle case 7.4 75 65 in.*lbf

Page 180 of 2000

SS–48SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSMISSION

SS

Parking lock pawl bracket x Transaxle case 20 205 15

Manual detent spring x Transaxle case Bolt A 20 205 15

Bolt B 12 120 9

Automatic transaxle oil pan sub-assembly x Transaxle case 7.6 77 67 in.*lbf

Speed sensor x Transaxle case 11 112 8

Park/neutral start switch x Control shaft lever 13 130 9

Speedometer driven hole cover sub-assembly x Transaxle case 5.5 56 49 in.*lbf

Oil pump body x Stator shaft assembly 9.8 100 87 in.*lbf

Front differential case x Front differential ring gear 95 969 70Part Tightened N*m kgf*cm ft*lbf

Page 198 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–23

EM

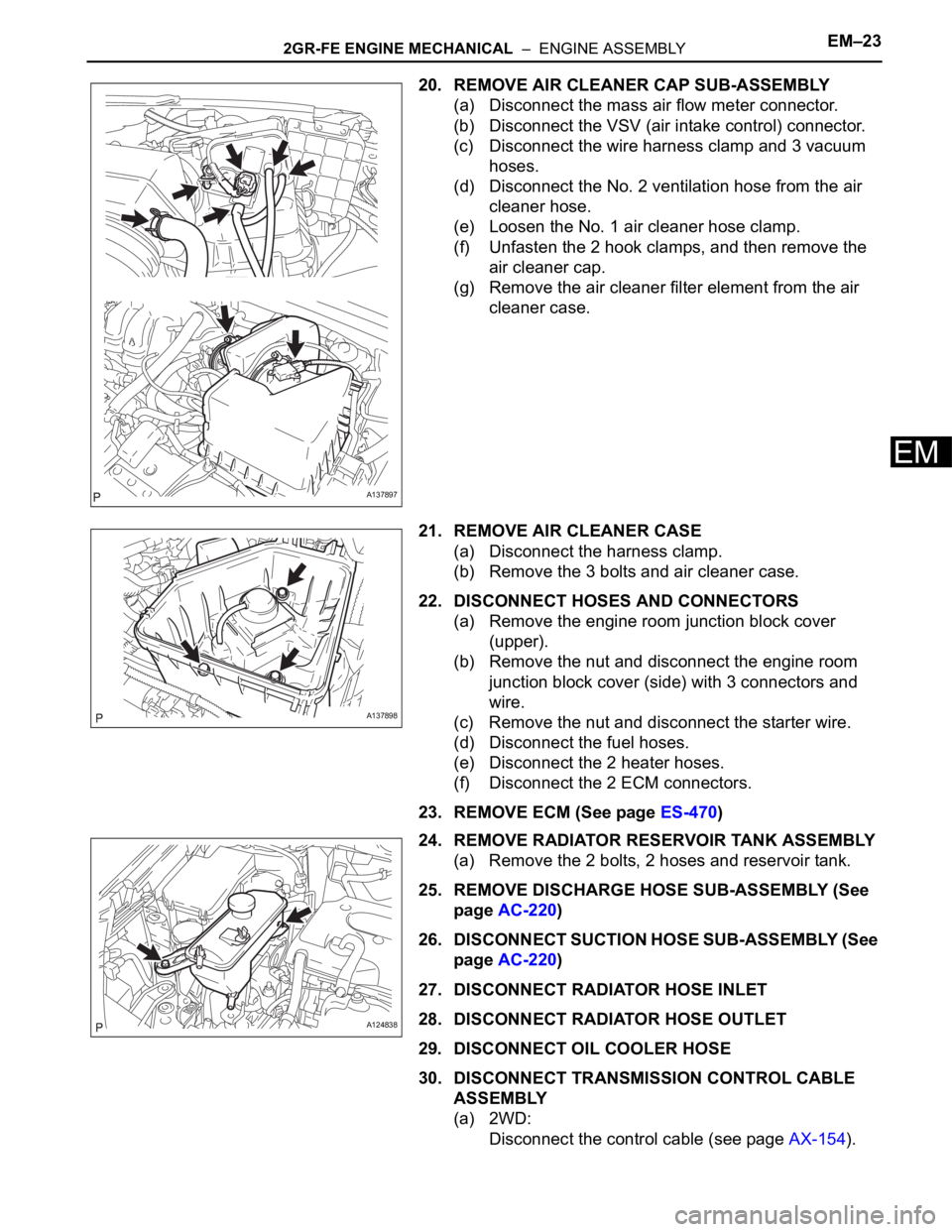

20. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

(a) Disconnect the mass air flow meter connector.

(b) Disconnect the VSV (air intake control) connector.

(c) Disconnect the wire harness clamp and 3 vacuum

hoses.

(d) Disconnect the No. 2 ventilation hose from the air

cleaner hose.

(e) Loosen the No. 1 air cleaner hose clamp.

(f) Unfasten the 2 hook clamps, and then remove the

air cleaner cap.

(g) Remove the air cleaner filter element from the air

cleaner case.

21. REMOVE AIR CLEANER CASE

(a) Disconnect the harness clamp.

(b) Remove the 3 bolts and air cleaner case.

22. DISCONNECT HOSES AND CONNECTORS

(a) Remove the engine room junction block cover

(upper).

(b) Remove the nut and disconnect the engine room

junction block cover (side) with 3 connectors and

wire.

(c) Remove the nut and disconnect the starter wire.

(d) Disconnect the fuel hoses.

(e) Disconnect the 2 heater hoses.

(f) Disconnect the 2 ECM connectors.

23. REMOVE ECM (See page ES-470)

24. REMOVE RADIATOR RESERVOIR TANK ASSEMBLY

(a) Remove the 2 bolts, 2 hoses and reservoir tank.

25. REMOVE DISCHARGE HOSE SUB-ASSEMBLY (See

page AC-220)

26. DISCONNECT SUCTION HOSE SUB-ASSEMBLY (See

page AC-220)

27. DISCONNECT RADIATOR HOSE INLET

28. DISCONNECT RADIATOR HOSE OUTLET

29. DISCONNECT OIL COOLER HOSE

30. DISCONNECT TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) 2WD:

Disconnect the control cable (see page AX-154).

A137897

A137898

A124838