Fuel System TOYOTA SIENNA 2007 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 327 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–259

ES

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

MONITOR RESULT

Refer to CHECKING MONITOR STATUS (See page ES-19).

CONDITIONING FOR SENSOR TESTING

HINT:

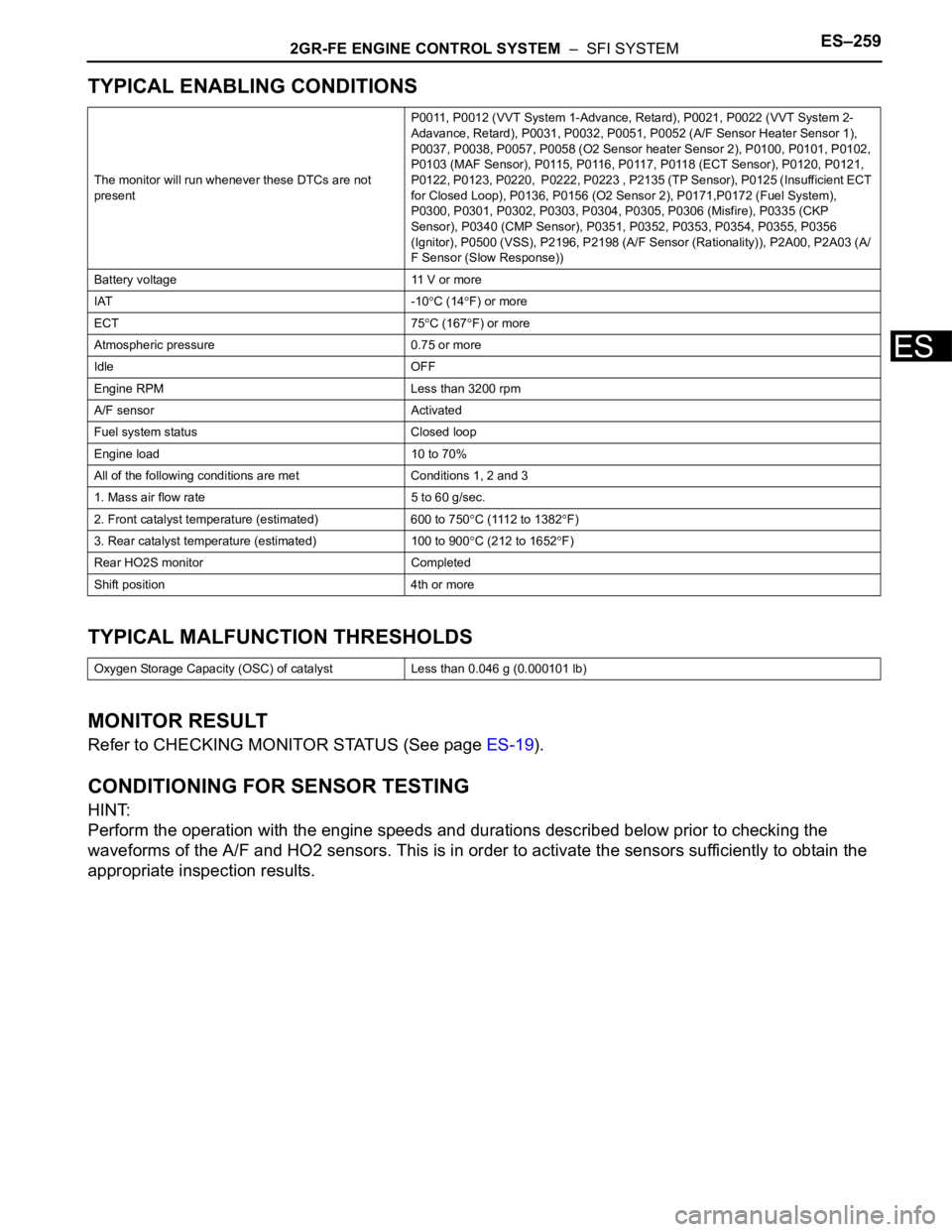

Perform the operation with the engine speeds and durations described below prior to checking the

waveforms of the A/F and HO2 sensors. This is in order to activate the sensors sufficiently to obtain the

appropriate inspection results.

The monitor will run whenever these DTCs are not

presentP0011, P0012 (VVT System 1-Advance, Retard), P0021, P0022 (VVT System 2-

Adavance, Retard), P0031, P0032, P0051, P0052 (A/F Sensor Heater Sensor 1),

P0037, P0038, P0057, P0058 (O2 Sensor heater Sensor 2), P0100, P0101, P0102,

P0103 (MAF Sensor), P0115, P0116, P0117, P0118 (ECT Sensor), P0120, P0121,

P0122, P0123, P0220, P0222, P0223 , P2135 (TP Sensor), P0125 (Insufficient ECT

for Closed Loop), P0136, P0156 (O2 Sensor 2), P0171,P0172 (Fuel System),

P0300, P0301, P0302, P0303, P0304, P0305, P0306 (Misfire), P0335 (CKP

Sensor), P0340 (CMP Sensor), P0351, P0352, P0353, P0354, P0355, P0356

(Ignitor), P0500 (VSS), P2196, P2198 (A/F Sensor (Rationality)), P2A00, P2A03 (A/

F Sensor (Slow Response))

Battery voltage 11 V or more

IAT -10

C (14F) or more

ECT 75

C (167F) or more

Atmospheric pressure 0.75 or more

Idle OFF

Engine RPM Less than 3200 rpm

A/F sensor Activated

Fuel system status Closed loop

Engine load 10 to 70%

All of the following conditions are met Conditions 1, 2 and 3

1. Mass air flow rate 5 to 60 g/sec.

2. Front catalyst temperature (estimated) 600 to 750

C (1112 to 1382F)

3. Rear catalyst temperature (estimated) 100 to 900

C (212 to 1652F)

Rear HO2S monitor Completed

Shift position 4th or more

Oxygen Storage Capacity (OSC) of catalyst Less than 0.046 g (0.000101 lb)

Page 328 of 3000

ES–2602GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

1. Connect the intelligent tester to the DLC3 (Procedure "A").

2. Start the engine and warm it up with all the accessories switched off, until the engine coolant

temperature stabilizes (Procedure "B").

3. Run the engine at an engine speed of between 2500 rpm and 3000 rpm for at least 3 minutes

(Procedure "C").

4. While running the engine at 3000 rpm for 2 seconds and at 2000 rpm for 2 seconds, check the

waveforms of the A/F and HO2 sensors using the tester (Procedure "D").

HINT:

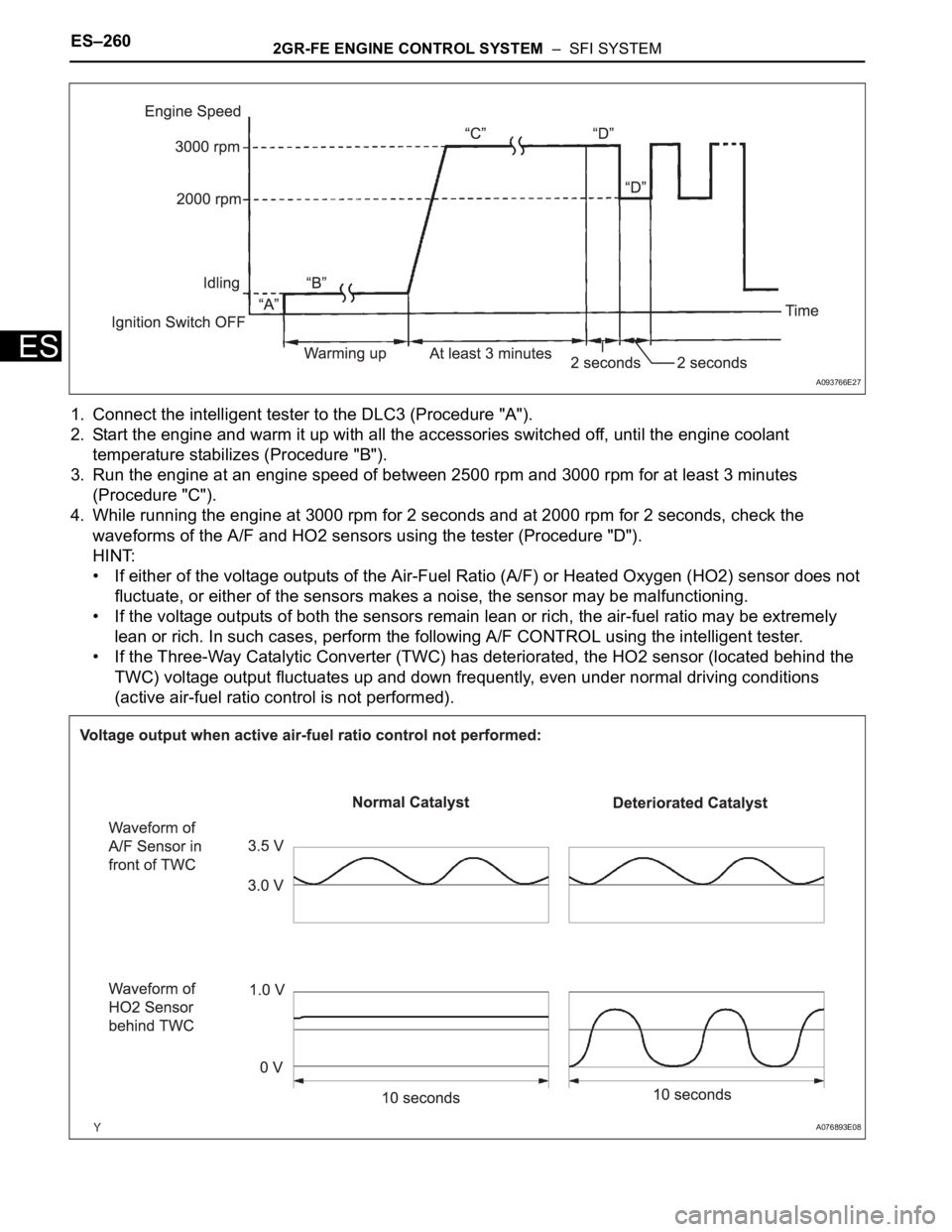

• If either of the voltage outputs of the Air-Fuel Ratio (A/F) or Heated Oxygen (HO2) sensor does not

fluctuate, or either of the sensors makes a noise, the sensor may be malfunctioning.

• If the voltage outputs of both the sensors remain lean or rich, the air-fuel ratio may be extremely

lean or rich. In such cases, perform the following A/F CONTROL using the intelligent tester.

• If the Three-Way Catalytic Converter (TWC) has deteriorated, the HO2 sensor (located behind the

TWC) voltage output fluctuates up and down frequently, even under normal driving conditions

(active air-fuel ratio control is not performed).

A093766E27

A076893E08

Page 329 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–261

ES

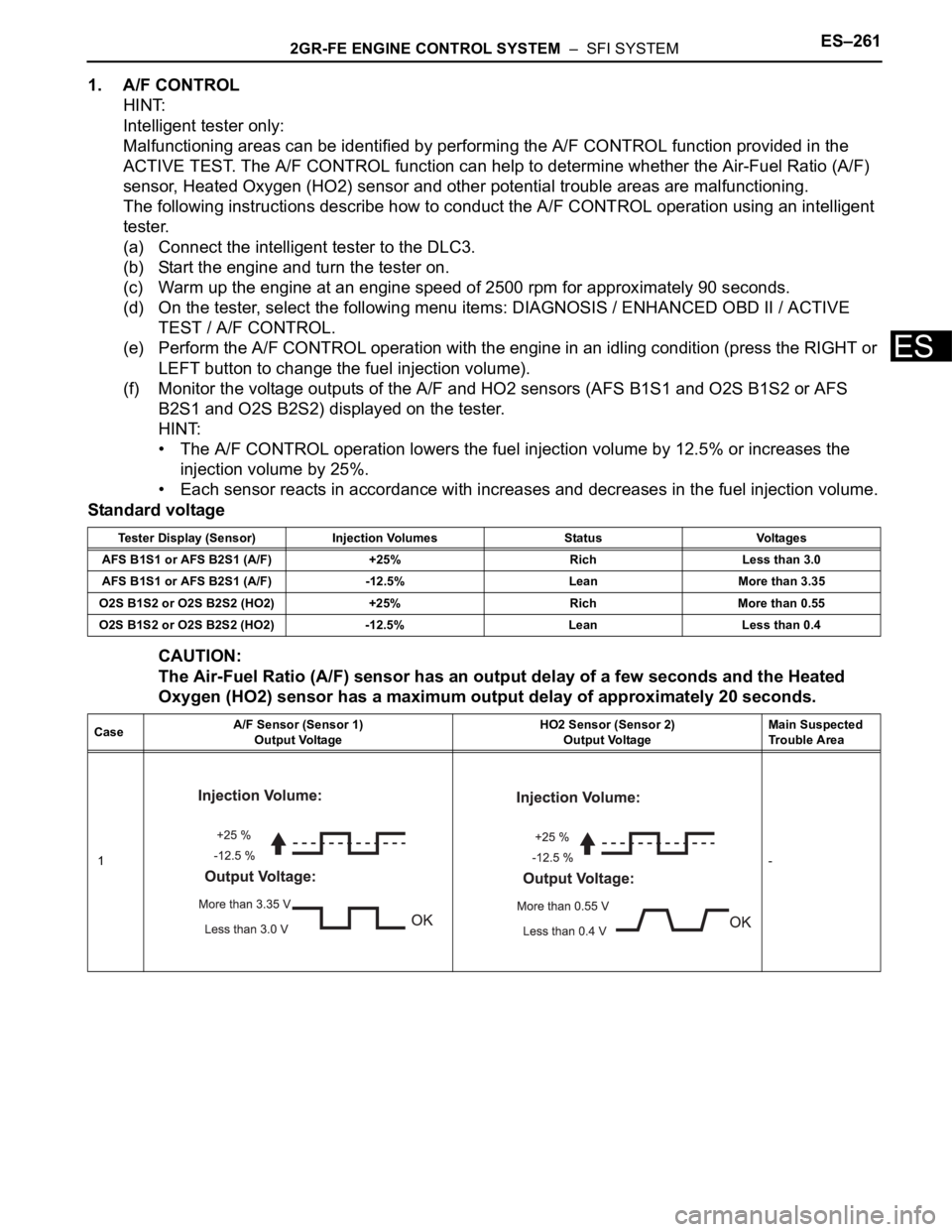

1. A/F CONTROL

HINT:

Intelligent tester only:

Malfunctioning areas can be identified by performing the A/F CONTROL function provided in the

ACTIVE TEST. The A/F CONTROL function can help to determine whether the Air-Fuel Ratio (A/F)

sensor, Heated Oxygen (HO2) sensor and other potential trouble areas are malfunctioning.

The following instructions describe how to conduct the A/F CONTROL operation using an intelligent

tester.

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the tester on.

(c) Warm up the engine at an engine speed of 2500 rpm for approximately 90 seconds.

(d) On the tester, select the following menu items: DIAGNOSIS / ENHANCED OBD II / ACTIVE

TEST / A/F CONTROL.

(e) Perform the A/F CONTROL operation with the engine in an idling condition (press the RIGHT or

LEFT button to change the fuel injection volume).

(f) Monitor the voltage outputs of the A/F and HO2 sensors (AFS B1S1 and O2S B1S2 or AFS

B2S1 and O2S B2S2) displayed on the tester.

HINT:

• The A/F CONTROL operation lowers the fuel injection volume by 12.5% or increases the

injection volume by 25%.

• Each sensor reacts in accordance with increases and decreases in the fuel injection volume.

Standard voltage

CAUTION:

The Air-Fuel Ratio (A/F) sensor has an output delay of a few seconds and the Heated

Oxygen (HO2) sensor has a maximum output delay of approximately 20 seconds.

Tester Display (Sensor) Injection Volumes Status Voltages

AFS B1S1 or AFS B2S1 (A/F) +25% Rich Less than 3.0

AFS B1S1 or AFS B2S1 (A/F) -12.5% Lean More than 3.35

O2S B1S2 or O2S B2S2 (HO2) +25% Rich More than 0.55

O2S B1S2 or O2S B2S2 (HO2) -12.5% Lean Less than 0.4

CaseA/F Sensor (Sensor 1)

Output VoltageHO2 Sensor (Sensor 2)

Output VoltageMain Suspected

Trouble Area

1-

Page 330 of 3000

ES–2622GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

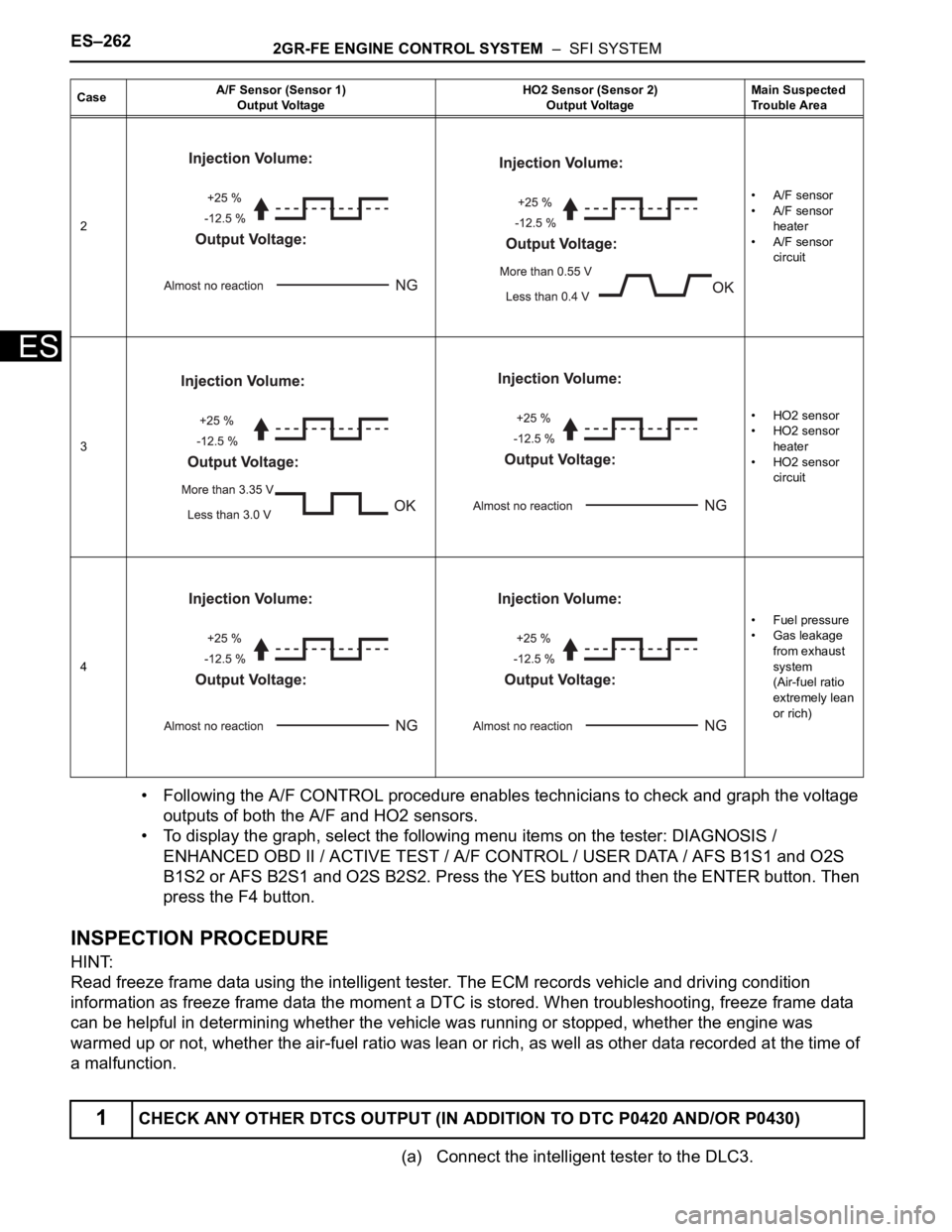

• Following the A/F CONTROL procedure enables technicians to check and graph the voltage

outputs of both the A/F and HO2 sensors.

• To display the graph, select the following menu items on the tester: DIAGNOSIS /

ENHANCED OBD II / ACTIVE TEST / A/F CONTROL / USER DATA / AFS B1S1 and O2S

B1S2 or AFS B2S1 and O2S B2S2. Press the YES button and then the ENTER button. Then

press the F4 button.

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

(a) Connect the intelligent tester to the DLC3.

2• A/F sensor

• A/F sensor

heater

• A/F sensor

circuit

3• HO2 sensor

• HO2 sensor

heater

• HO2 sensor

circuit

4•Fuel pressure

• Gas leakage

from exhaust

system

(Air-fuel ratio

extremely lean

or rich)

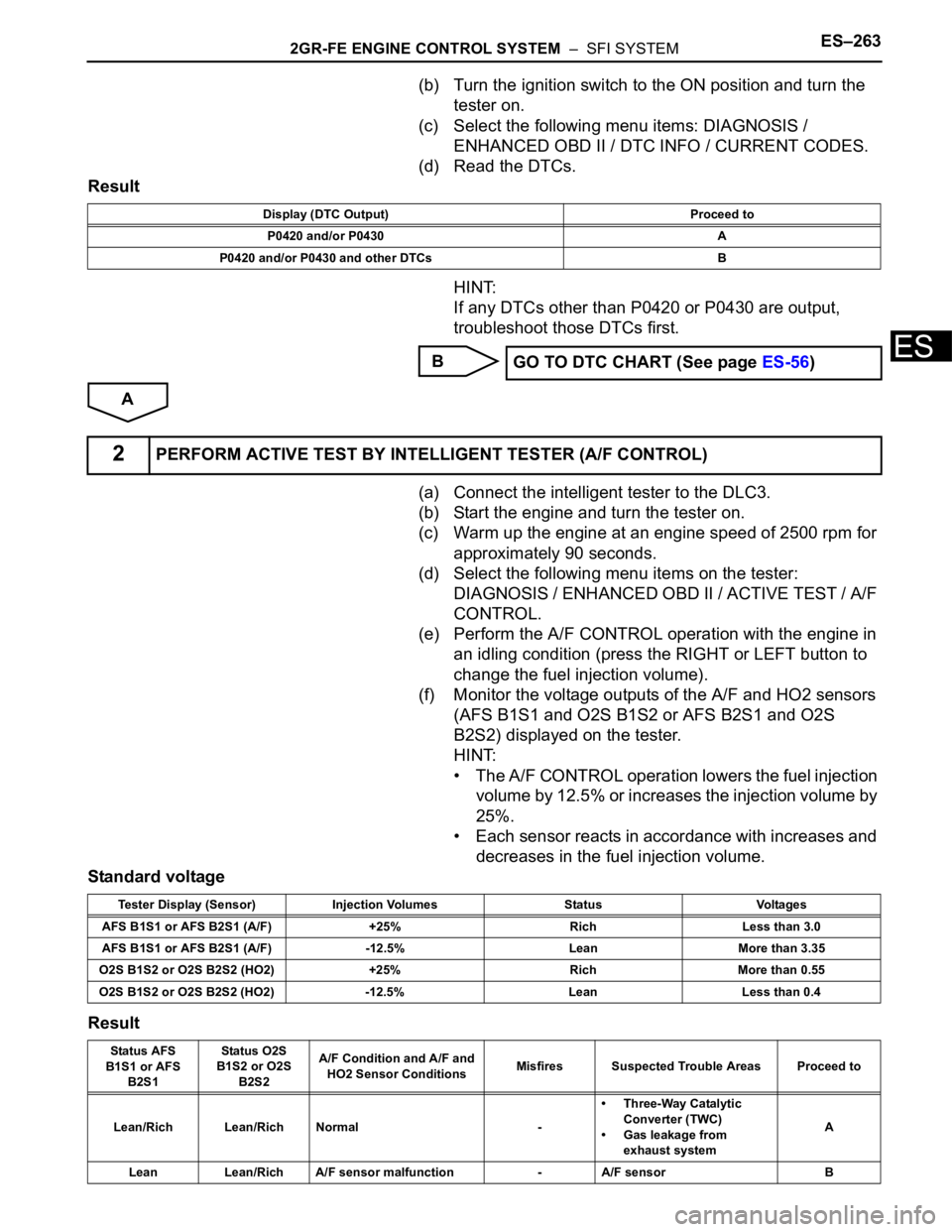

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0420 AND/OR P0430)

CaseA/F Sensor (Sensor 1)

Output VoltageHO2 Sensor (Sensor 2)

Output VoltageMain Suspected

Trouble Area

Page 331 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–263

ES

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(d) Read the DTCs.

Result

HINT:

If any DTCs other than P0420 or P0430 are output,

troubleshoot those DTCs first.

B

A

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the tester on.

(c) Warm up the engine at an engine speed of 2500 rpm for

approximately 90 seconds.

(d) Select the following menu items on the tester:

DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / A/F

CONTROL.

(e) Perform the A/F CONTROL operation with the engine in

an idling condition (press the RIGHT or LEFT button to

change the fuel injection volume).

(f) Monitor the voltage outputs of the A/F and HO2 sensors

(AFS B1S1 and O2S B1S2 or AFS B2S1 and O2S

B2S2) displayed on the tester.

HINT:

• The A/F CONTROL operation lowers the fuel injection

volume by 12.5% or increases the injection volume by

25%.

• Each sensor reacts in accordance with increases and

decreases in the fuel injection volume.

Standard voltage

Result

Display (DTC Output) Proceed to

P0420 and/or P0430 A

P0420 and/or P0430 and other DTCs B

GO TO DTC CHART (See page ES-56)

2PERFORM ACTIVE TEST BY INTELLIGENT TESTER (A/F CONTROL)

Tester Display (Sensor) Injection Volumes Status Voltages

AFS B1S1 or AFS B2S1 (A/F) +25% Rich Less than 3.0

AFS B1S1 or AFS B2S1 (A/F) -12.5% Lean More than 3.35

O2S B1S2 or O2S B2S2 (HO2) +25% Rich More than 0.55

O2S B1S2 or O2S B2S2 (HO2) -12.5% Lean Less than 0.4

Status AFS

B1S1 or AFS

B2S1Status O2S

B1S2 or O2S

B2S2A/F Condition and A/F and

HO2 Sensor ConditionsMisfires Suspected Trouble Areas Proceed to

Lean/Rich Lean/Rich Normal -• Three-Way Catalytic

Converter (TWC)

• Gas leakage from

exhaust systemA

Lean Lean/Rich A/F sensor malfunction - A/F sensor B

Page 332 of 3000

ES–2642GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

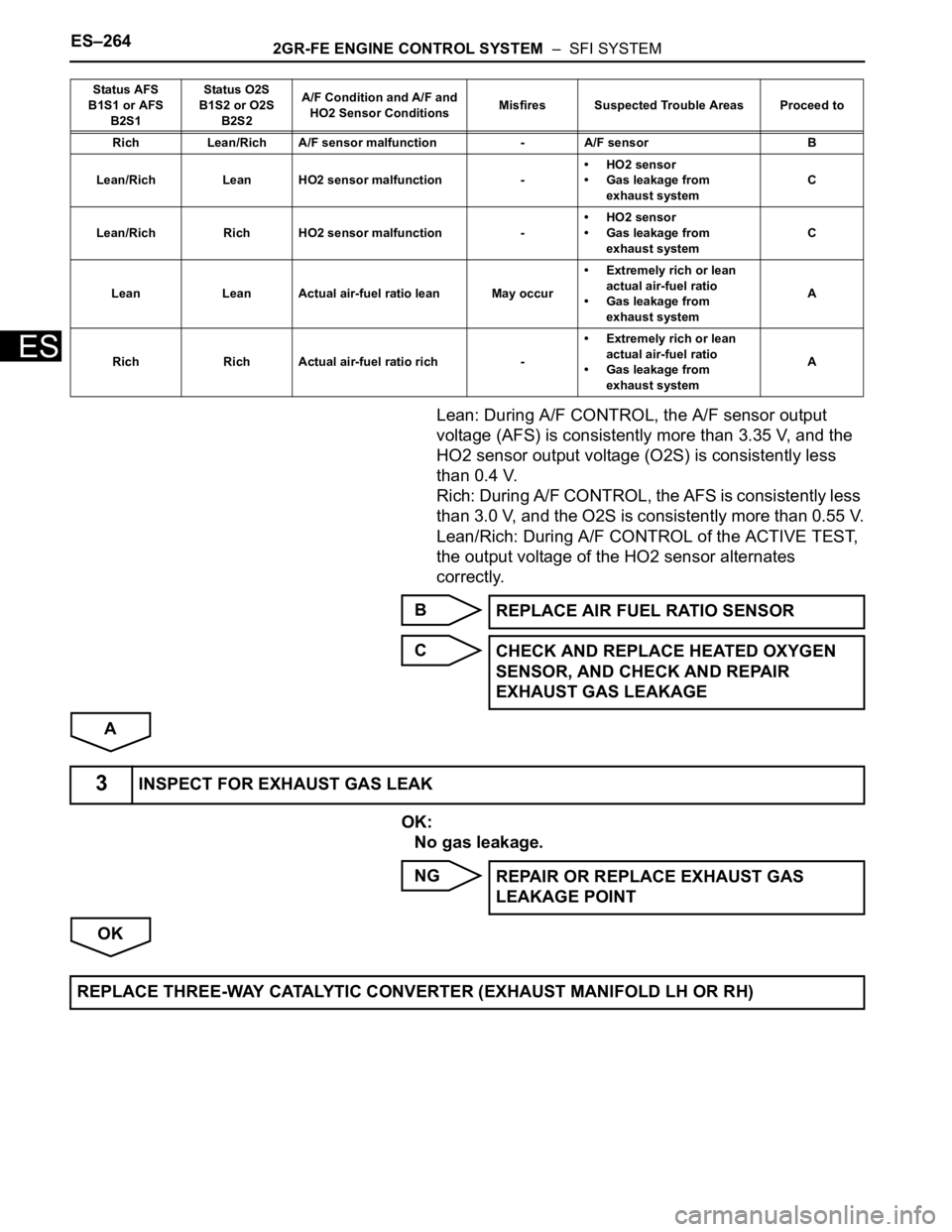

ES

Lean: During A/F CONTROL, the A/F sensor output

voltage (AFS) is consistently more than 3.35 V, and the

HO2 sensor output voltage (O2S) is consistently less

than 0.4 V.

Rich: During A/F CONTROL, the AFS is consistently less

than 3.0 V, and the O2S is consistently more than 0.55 V.

Lean/Rich: During A/F CONTROL of the ACTIVE TEST,

the output voltage of the HO2 sensor alternates

correctly.

B

C

A

OK:

No gas leakage.

NG

OK

Rich Lean/Rich A/F sensor malfunction - A/F sensor B

Lean/Rich Lean HO2 sensor malfunction -• HO2 sensor

• Gas leakage from

exhaust systemC

Lean/Rich Rich HO2 sensor malfunction -• HO2 sensor

• Gas leakage from

exhaust systemC

Lean Lean Actual air-fuel ratio lean May occur• Extremely rich or lean

actual air-fuel ratio

• Gas leakage from

exhaust systemA

Rich Rich Actual air-fuel ratio rich -• Extremely rich or lean

actual air-fuel ratio

• Gas leakage from

exhaust systemA Status AFS

B1S1 or AFS

B2S1Status O2S

B1S2 or O2S

B2S2A/F Condition and A/F and

HO2 Sensor ConditionsMisfires Suspected Trouble Areas Proceed to

REPLACE AIR FUEL RATIO SENSOR

CHECK AND REPLACE HEATED OXYGEN

SENSOR, AND CHECK AND REPAIR

EXHAUST GAS LEAKAGE

3INSPECT FOR EXHAUST GAS LEAK

REPAIR OR REPLACE EXHAUST GAS

LEAKAGE POINT

REPLACE THREE-WAY CATALYTIC CONVERTER (EXHAUST MANIFOLD LH OR RH)

Page 342 of 3000

ES–162GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

NG

OK

(a) Check the fuel pressure (See page FU-7).

NG

OK

(a) Check for sparks (See page ES-217).

NG

OKTROUBLESHOOT IDLING SPEED AND

PROCEED TO NEXT STEP

6CHECK FUEL PRESSURE

TROUBLESHOOT FUEL PRESSURE AND

PROCEED TO NEXT STEP

7CHECK FOR SPARKS

TROUBLESHOOT SPARK AND PROCEED

TO NEXT STEP

PROCEED TO PROBLEM SYMPTOMS TABLE

Page 353 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–27

ES

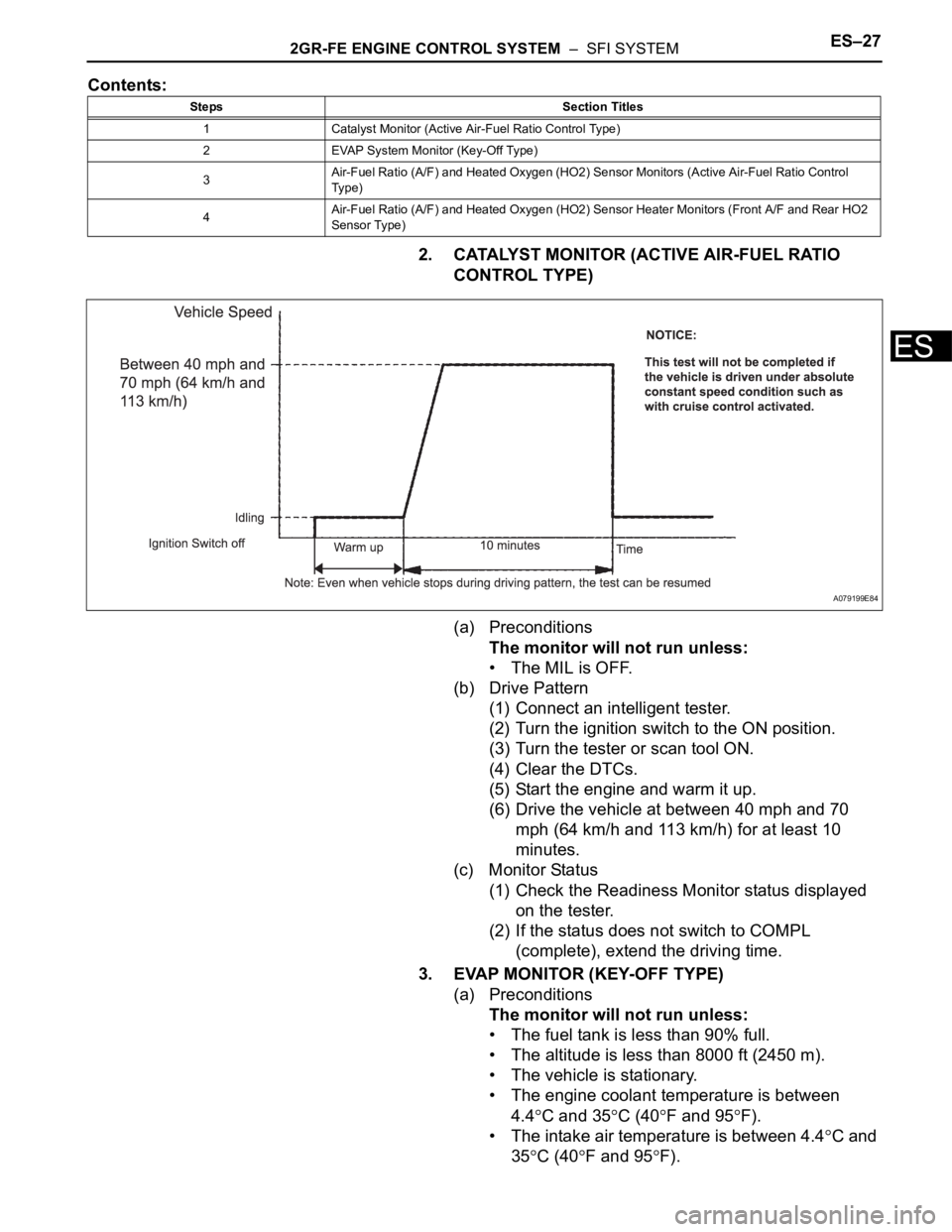

Contents:

2. CATALYST MONITOR (ACTIVE AIR-FUEL RATIO

CONTROL TYPE)

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect an intelligent tester.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester or scan tool ON.

(4) Clear the DTCs.

(5) Start the engine and warm it up.

(6) Drive the vehicle at between 40 mph and 70

mph (64 km/h and 113 km/h) for at least 10

minutes.

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), extend the driving time.

3. EVAP MONITOR (KEY-OFF TYPE)

(a) Preconditions

The monitor will not run unless:

• The fuel tank is less than 90% full.

• The altitude is less than 8000 ft (2450 m).

• The vehicle is stationary.

• The engine coolant temperature is between

4.4

C and 35C (40F and 95F).

• The intake air temperature is between 4.4

C and

35

C (40F and 95F).

Steps Section Titles

1 Catalyst Monitor (Active Air-Fuel Ratio Control Type)

2 EVAP System Monitor (Key-Off Type)

3Air-Fuel Ratio (A/F) and Heated Oxygen (HO2) Sensor Monitors (Active Air-Fuel Ratio Control

Ty p e )

4Air-Fuel Ratio (A/F) and Heated Oxygen (HO2) Sensor Heater Monitors (Front A/F and Rear HO2

Sensor Type)

A079199E84

Page 354 of 3000

ES–282GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

• Vehicle was driven in the city area (or on free-

way) for 10 minutes or more.

(b) Monitor Conditions

(1) Turn the ignition switch off and wait for 6 hours.

HINT:

Do not start the engine until checking Readiness

Monitor status. If the engine is started, the step

described above must be repeated.

(c) Monitor Status

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester or scan tool ON.

(4) Check the Readiness Monitor status displayed

on the tester or scan tool.

If the status does not switch to COMPL

(complete), restart the engine, make sure that

the preconditions have been met, and then

perform the Monitor Conditions again.

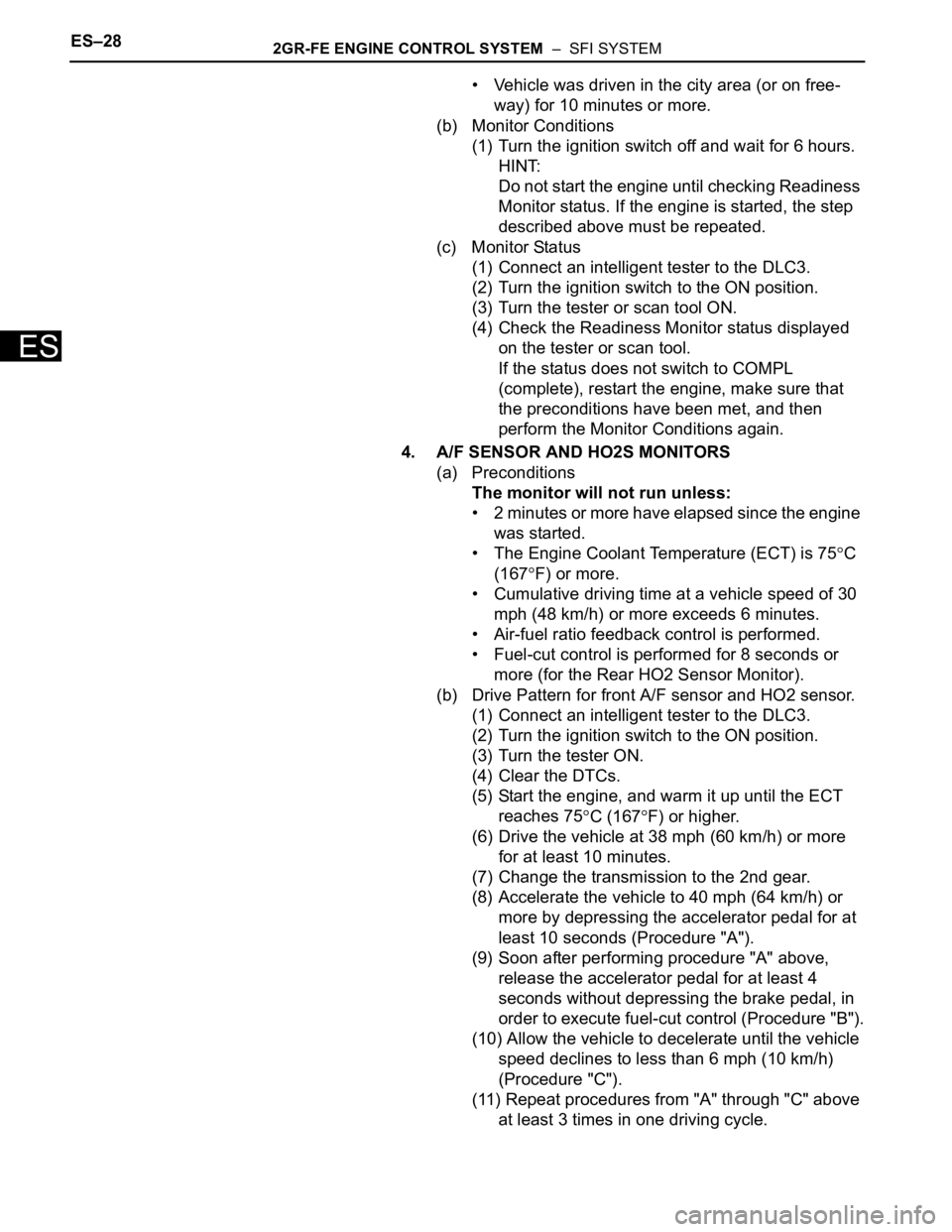

4. A/F SENSOR AND HO2S MONITORS

(a) Preconditions

The monitor will not run unless:

• 2 minutes or more have elapsed since the engine

was started.

• The Engine Coolant Temperature (ECT) is 75

C

(167

F) or more.

• Cumulative driving time at a vehicle speed of 30

mph (48 km/h) or more exceeds 6 minutes.

• Air-fuel ratio feedback control is performed.

• Fuel-cut control is performed for 8 seconds or

more (for the Rear HO2 Sensor Monitor).

(b) Drive Pattern for front A/F sensor and HO2 sensor.

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester ON.

(4) Clear the DTCs.

(5) Start the engine, and warm it up until the ECT

reaches 75

C (167F) or higher.

(6) Drive the vehicle at 38 mph (60 km/h) or more

for at least 10 minutes.

(7) Change the transmission to the 2nd gear.

(8) Accelerate the vehicle to 40 mph (64 km/h) or

more by depressing the accelerator pedal for at

least 10 seconds (Procedure "A").

(9) Soon after performing procedure "A" above,

release the accelerator pedal for at least 4

seconds without depressing the brake pedal, in

order to execute fuel-cut control (Procedure "B").

(10) Allow the vehicle to decelerate until the vehicle

speed declines to less than 6 mph (10 km/h)

(Procedure "C").

(11) Repeat procedures from "A" through "C" above

at least 3 times in one driving cycle.

Page 355 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–29

ES

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), make sure that the preconditions

have been met and then perform the Drive

Pattern again.

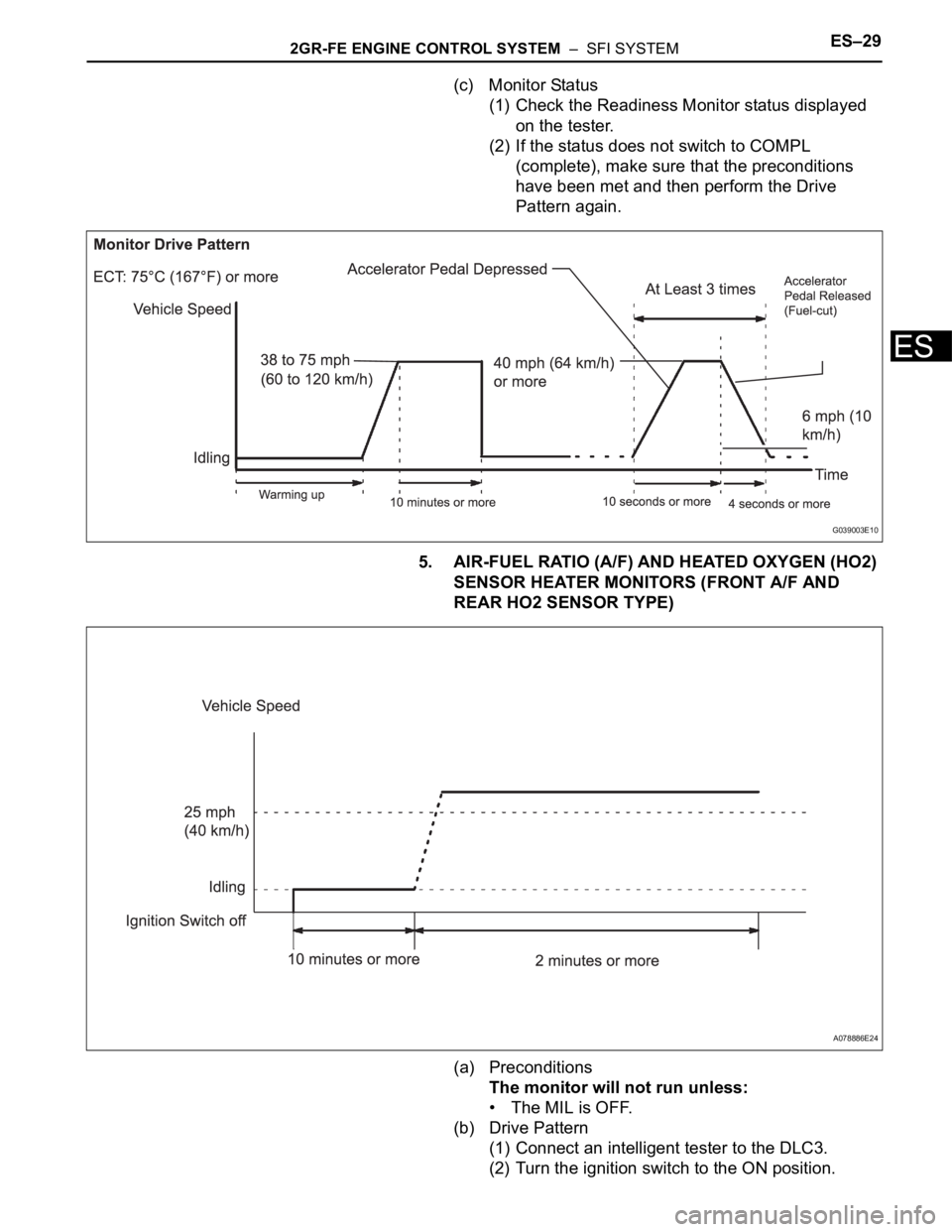

5. AIR-FUEL RATIO (A/F) AND HEATED OXYGEN (HO2)

SENSOR HEATER MONITORS (FRONT A/F AND

REAR HO2 SENSOR TYPE)

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

G039003E10

A078886E24