engine removal TOYOTA SIENNA 2007 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 812 of 3000

ES–5042GR-FE ENGINE CONTROL SYSTEM – MASS AIR FLOW METER

ES

ON-VEHICLE INSPECTION

1. INSPECT MASS AIR FLOW METER

NOTICE:

• Perform the mass air flow (MAF) meter inspection

by following the procedures below.

• Only replace the MAF meter when the MAF value

in the DATA LIST (with the engine stopped) are

not within the normal operating range or there is

foreign matter on the MAF meter platinum hot

wire (heater).

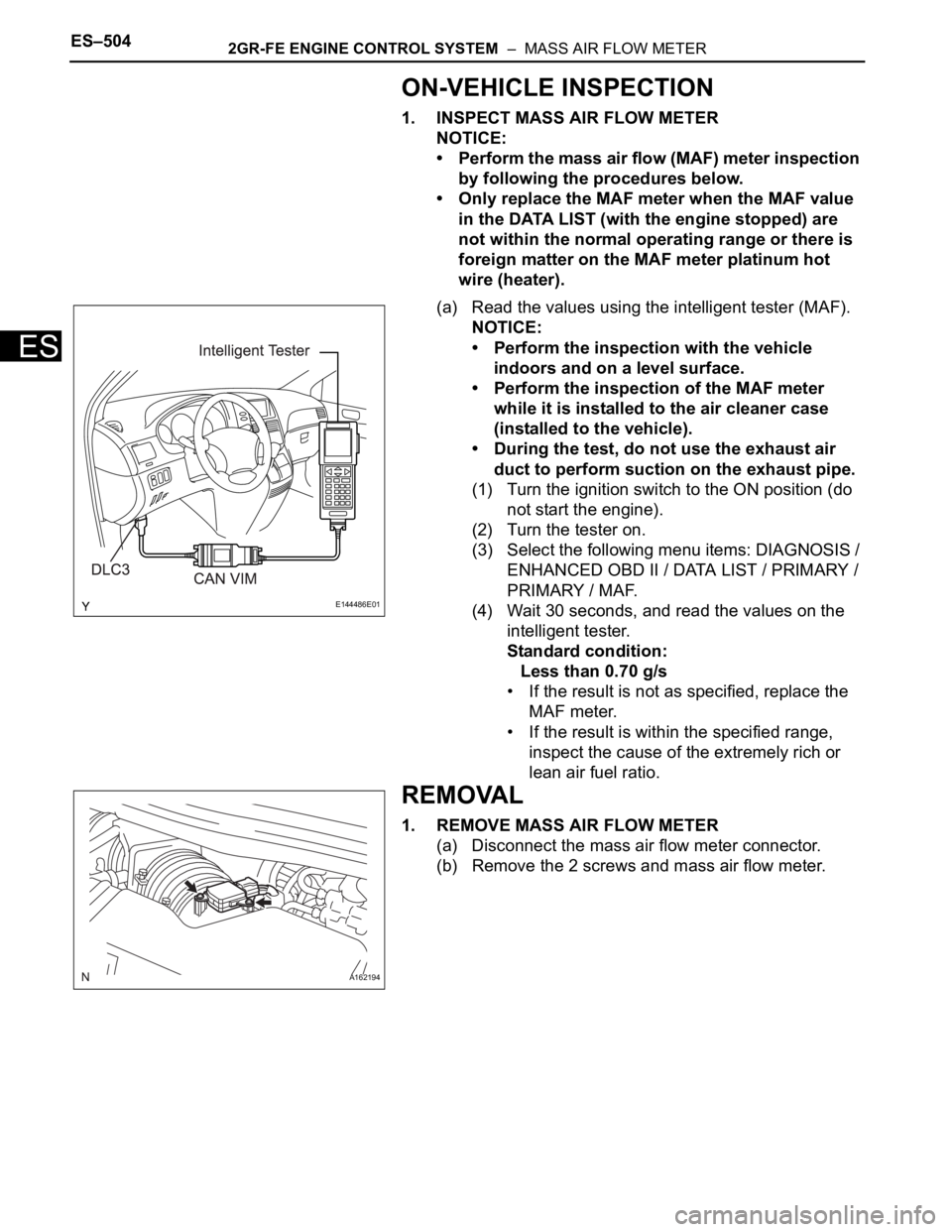

(a) Read the values using the intelligent tester (MAF).

NOTICE:

• Perform the inspection with the vehicle

indoors and on a level surface.

• Perform the inspection of the MAF meter

while it is installed to the air cleaner case

(installed to the vehicle).

• During the test, do not use the exhaust air

duct to perform suction on the exhaust pipe.

(1) Turn the ignition switch to the ON position (do

not start the engine).

(2) Turn the tester on.

(3) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / PRIMARY /

PRIMARY / MAF.

(4) Wait 30 seconds, and read the values on the

intelligent tester.

Standard condition:

Less than 0.70 g/s

• If the result is not as specified, replace the

MAF meter.

• If the result is within the specified range,

inspect the cause of the extremely rich or

lean air fuel ratio.

REMOVAL

1. REMOVE MASS AIR FLOW METER

(a) Disconnect the mass air flow meter connector.

(b) Remove the 2 screws and mass air flow meter.

E144486E01

A162194

Page 822 of 3000

ES–5102GR-FE ENGINE CONTROL SYSTEM – VVT SENSOR

ES

REMOVAL

1. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-4)

2. REMOVE FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-27)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

5. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

6. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

7. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

8. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

9. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(See page ES-521)

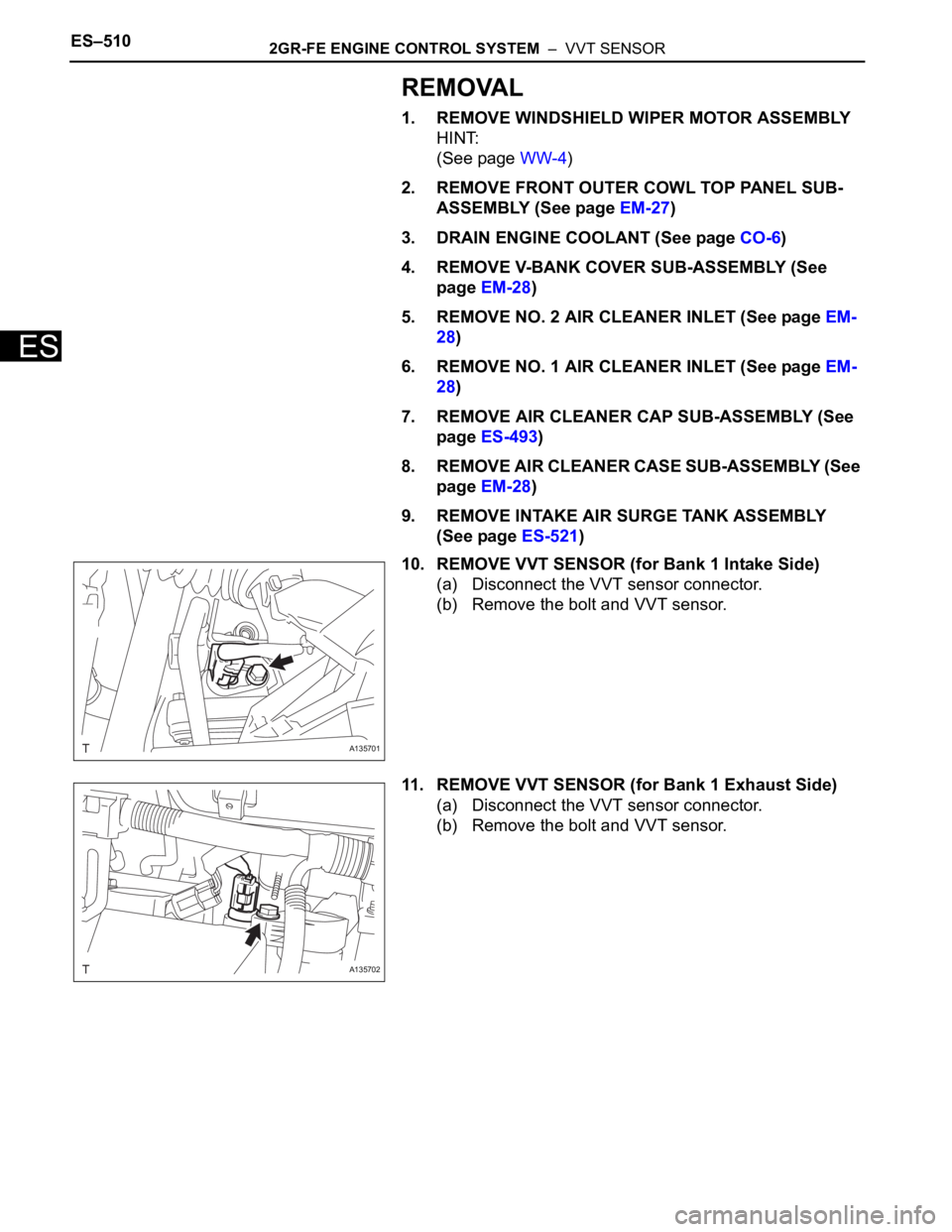

10. REMOVE VVT SENSOR (for Bank 1 Intake Side)

(a) Disconnect the VVT sensor connector.

(b) Remove the bolt and VVT sensor.

11. REMOVE VVT SENSOR (for Bank 1 Exhaust Side)

(a) Disconnect the VVT sensor connector.

(b) Remove the bolt and VVT sensor.

A135701

A135702

Page 829 of 3000

ES–5142GR-FE ENGINE CONTROL SYSTEM – CRANKSHAFT POSITION SENSOR

ES

REMOVAL

1. REMOVE COMPRESSOR AND MAGNETIC CLUTCH

HINT:

(See page AC-227 )

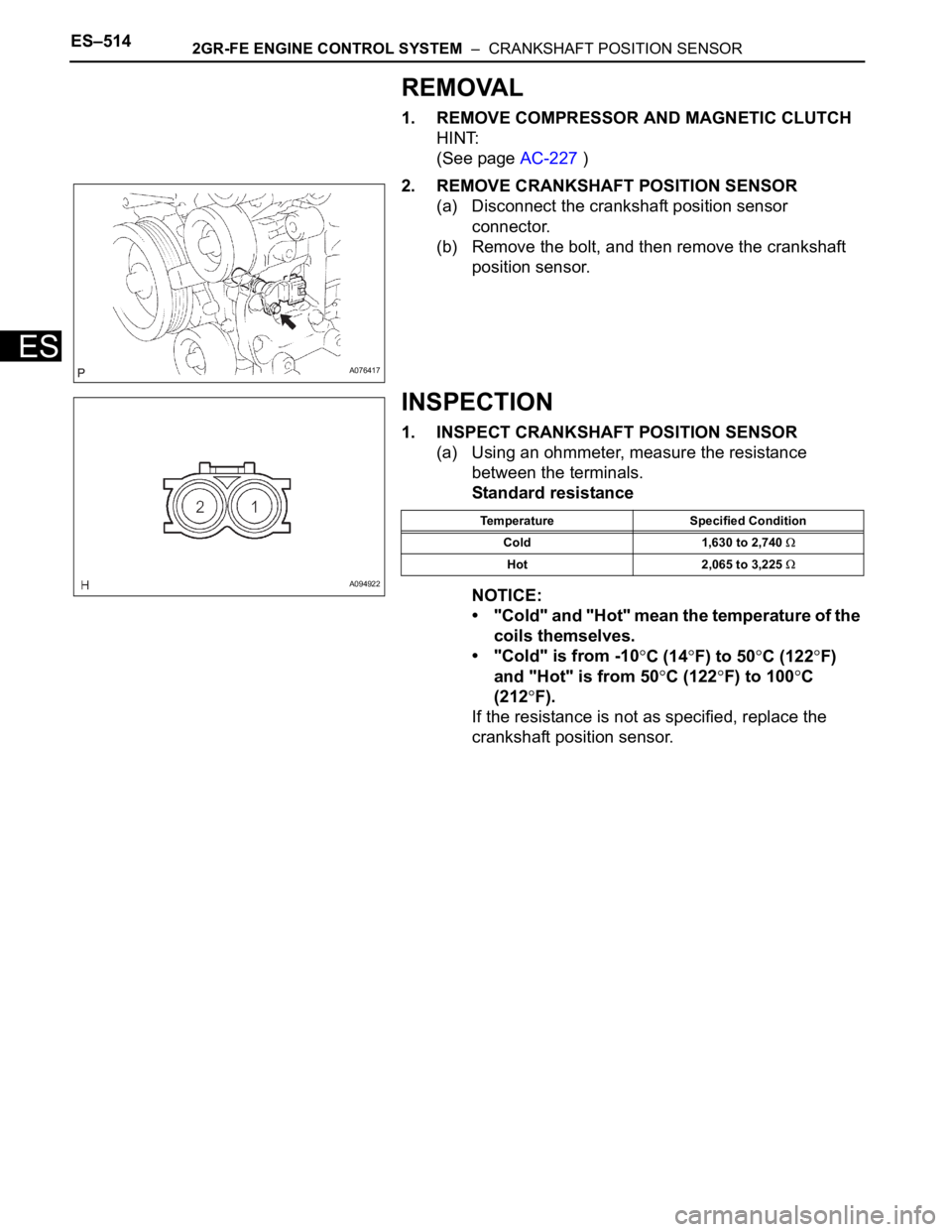

2. REMOVE CRANKSHAFT POSITION SENSOR

(a) Disconnect the crankshaft position sensor

connector.

(b) Remove the bolt, and then remove the crankshaft

position sensor.

INSPECTION

1. INSPECT CRANKSHAFT POSITION SENSOR

(a) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

NOTICE:

• "Cold" and "Hot" mean the temperature of the

coils themselves.

• "Cold" is from -10

C (14F) to 50C (122F)

and "Hot" is from 50

C (122F) to 100C

(212

F).

If the resistance is not as specified, replace the

crankshaft position sensor.

A076417

A094922

Temperature Specified Condition

Cold 1,630 to 2,740

Hot 2,065 to 3,225

Page 835 of 3000

ES–5162GR-FE ENGINE CONTROL SYSTEM – ENGINE COOLANT TEMPERATURE SENSOR

ES

REMOVAL

1. DRAIN ENGINE COOLANT (See page CO-6)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

4. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

5. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

6. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

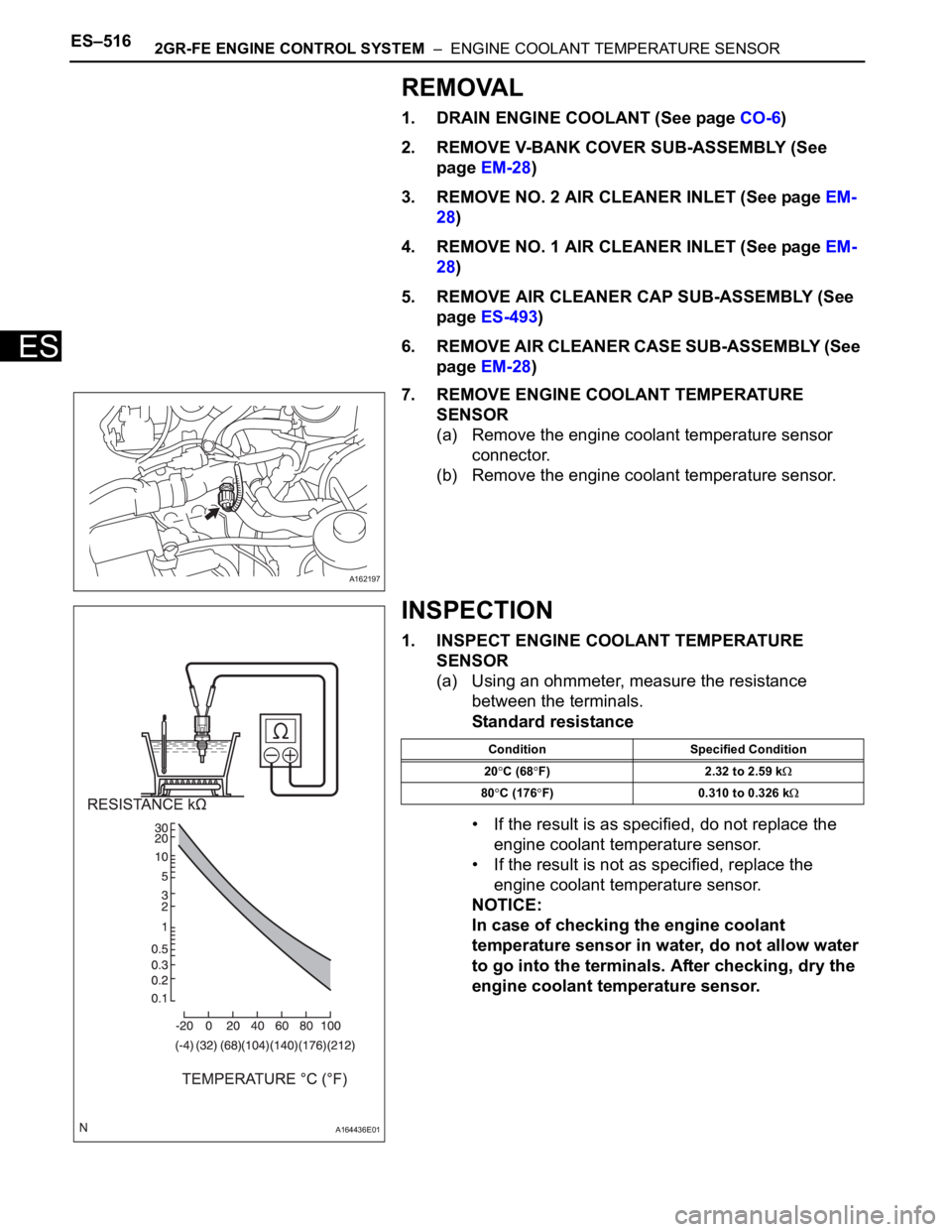

7. REMOVE ENGINE COOLANT TEMPERATURE

SENSOR

(a) Remove the engine coolant temperature sensor

connector.

(b) Remove the engine coolant temperature sensor.

INSPECTION

1. INSPECT ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

• If the result is as specified, do not replace the

engine coolant temperature sensor.

• If the result is not as specified, replace the

engine coolant temperature sensor.

NOTICE:

In case of checking the engine coolant

temperature sensor in water, do not allow water

to go into the terminals. After checking, dry the

engine coolant temperature sensor.

A162197

A164436E01

Condition Specified Condition

20

C (68F) 2.32 to 2.59 k

80C (176F) 0.310 to 0.326 k

Page 836 of 3000

2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–521

ES

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

(See page FU-13)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-4)

5. REMOVE FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-27)

6. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

7. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

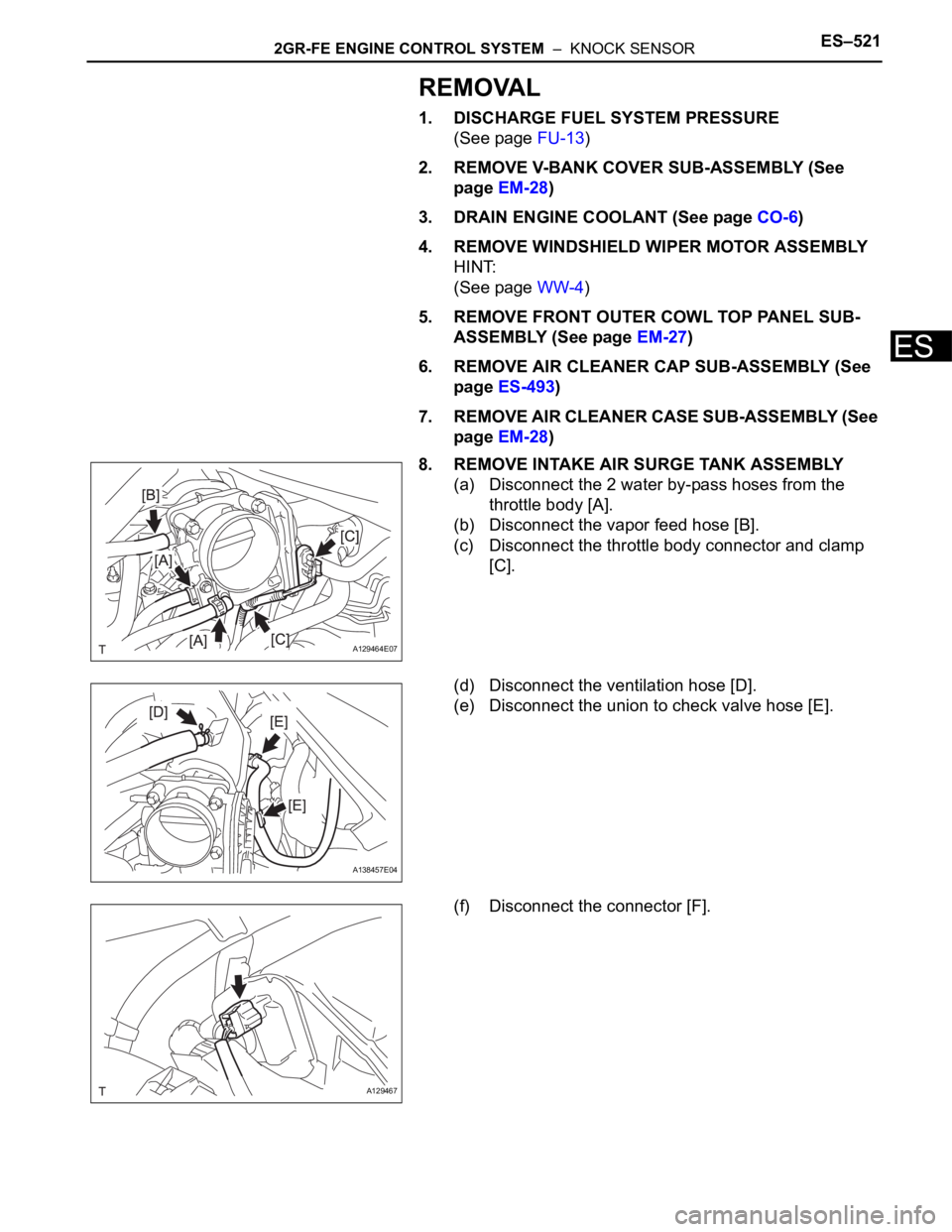

8. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(a) Disconnect the 2 water by-pass hoses from the

throttle body [A].

(b) Disconnect the vapor feed hose [B].

(c) Disconnect the throttle body connector and clamp

[C].

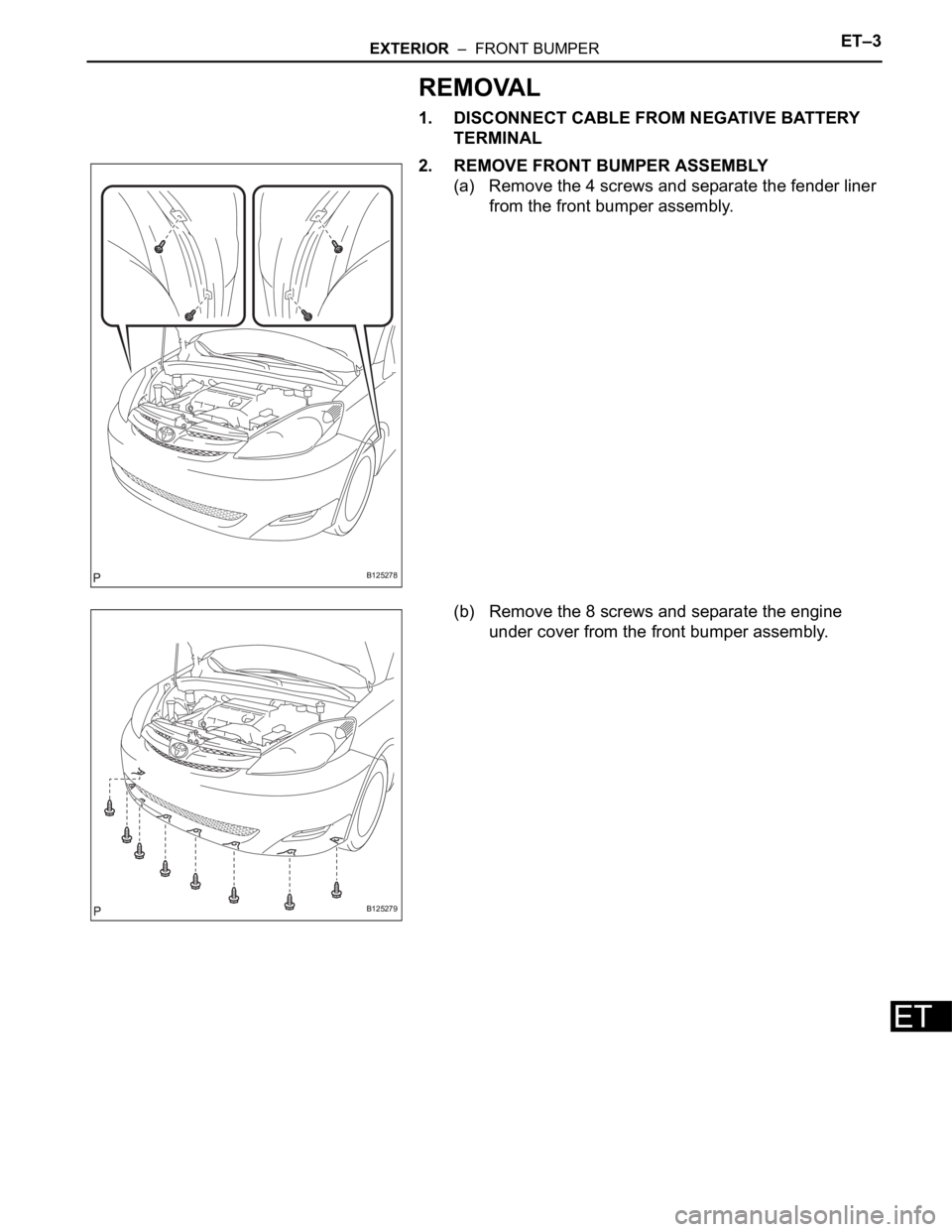

(d) Disconnect the ventilation hose [D].

(e) Disconnect the union to check valve hose [E].

(f) Disconnect the connector [F].

A129464E07

A138457E04

A129467

Page 840 of 3000

EXTERIOR – FRONT BUMPERET–3

ET

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

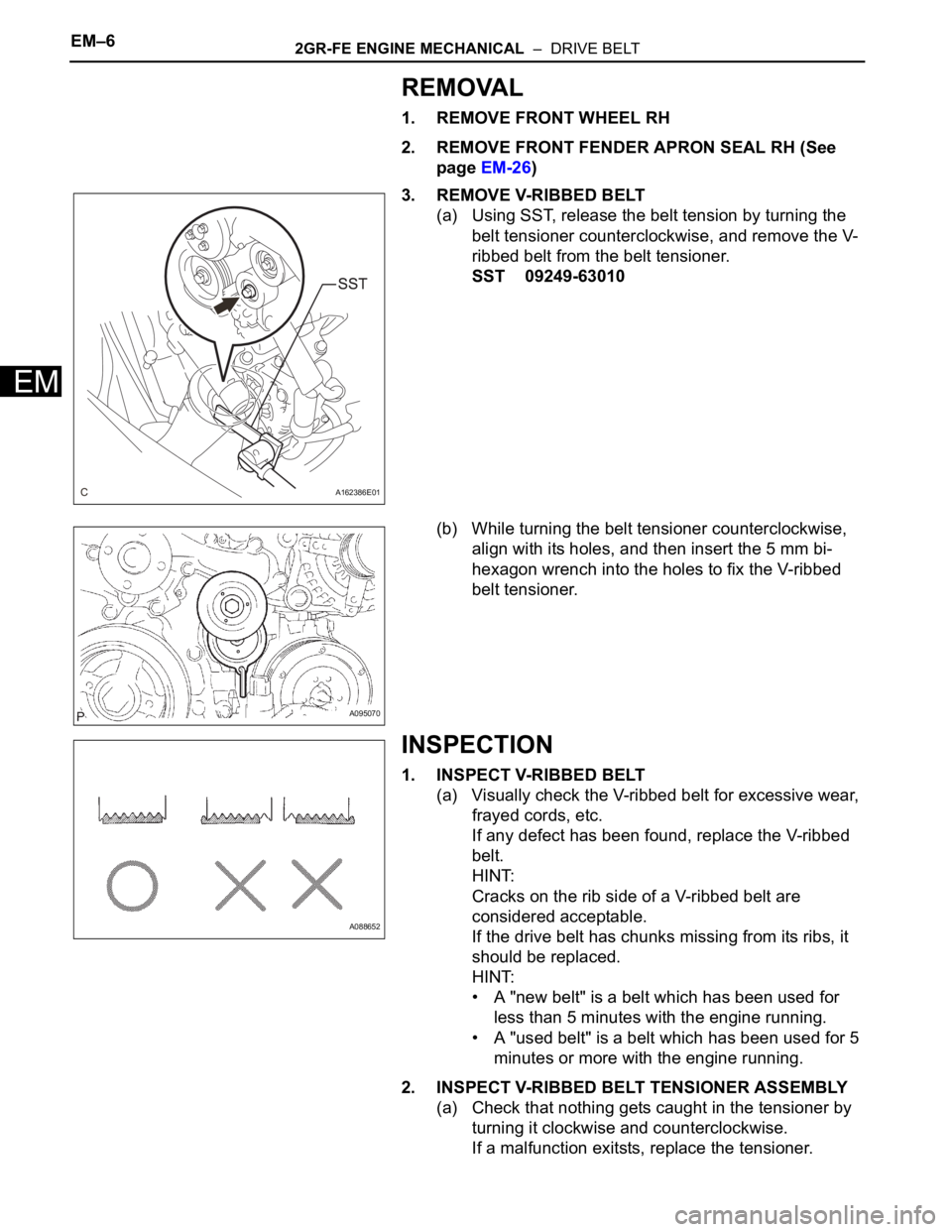

2. REMOVE FRONT BUMPER ASSEMBLY

(a) Remove the 4 screws and separate the fender liner

from the front bumper assembly.

(b) Remove the 8 screws and separate the engine

under cover from the front bumper assembly.

B125278

B125279

Page 980 of 3000

EM–62GR-FE ENGINE MECHANICAL – DRIVE BELT

EM

REMOVAL

1. REMOVE FRONT WHEEL RH

2. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

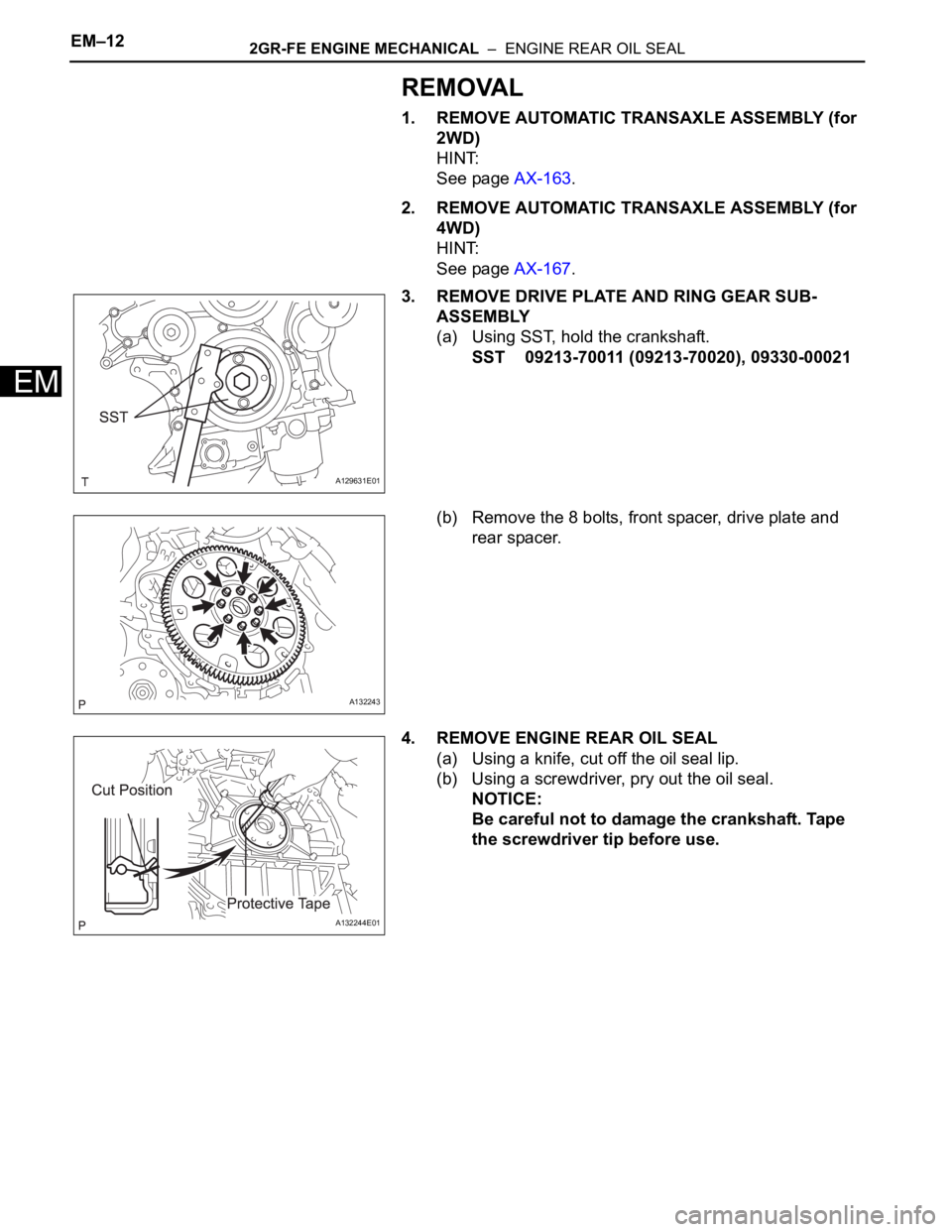

3. REMOVE V-RIBBED BELT

(a) Using SST, release the belt tension by turning the

belt tensioner counterclockwise, and remove the V-

ribbed belt from the belt tensioner.

SST 09249-63010

(b) While turning the belt tensioner counterclockwise,

align with its holes, and then insert the 5 mm bi-

hexagon wrench into the holes to fix the V-ribbed

belt tensioner.

INSPECTION

1. INSPECT V-RIBBED BELT

(a) Visually check the V-ribbed belt for excessive wear,

frayed cords, etc.

If any defect has been found, replace the V-ribbed

belt.

HINT:

Cracks on the rib side of a V-ribbed belt are

considered acceptable.

If the drive belt has chunks missing from its ribs, it

should be replaced.

HINT:

• A "new belt" is a belt which has been used for

less than 5 minutes with the engine running.

• A "used belt" is a belt which has been used for 5

minutes or more with the engine running.

2. INSPECT V-RIBBED BELT TENSIONER ASSEMBLY

(a) Check that nothing gets caught in the tensioner by

turning it clockwise and counterclockwise.

If a malfunction exitsts, replace the tensioner.

A162386E01

A095070

A088652

Page 983 of 3000

EM–122GR-FE ENGINE MECHANICAL – ENGINE REAR OIL SEAL

EM

REMOVAL

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for

2WD)

HINT:

See page AX-163.

2. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for

4WD)

HINT:

See page AX-167.

3. REMOVE DRIVE PLATE AND RING GEAR SUB-

ASSEMBLY

(a) Using SST, hold the crankshaft.

SST 09213-70011 (09213-70020), 09330-00021

(b) Remove the 8 bolts, front spacer, drive plate and

rear spacer.

4. REMOVE ENGINE REAR OIL SEAL

(a) Using a knife, cut off the oil seal lip.

(b) Using a screwdriver, pry out the oil seal.

NOTICE:

Be careful not to damage the crankshaft. Tape

the screwdriver tip before use.

A129631E01

A132243

A132244E01

Page 985 of 3000

EM–262GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

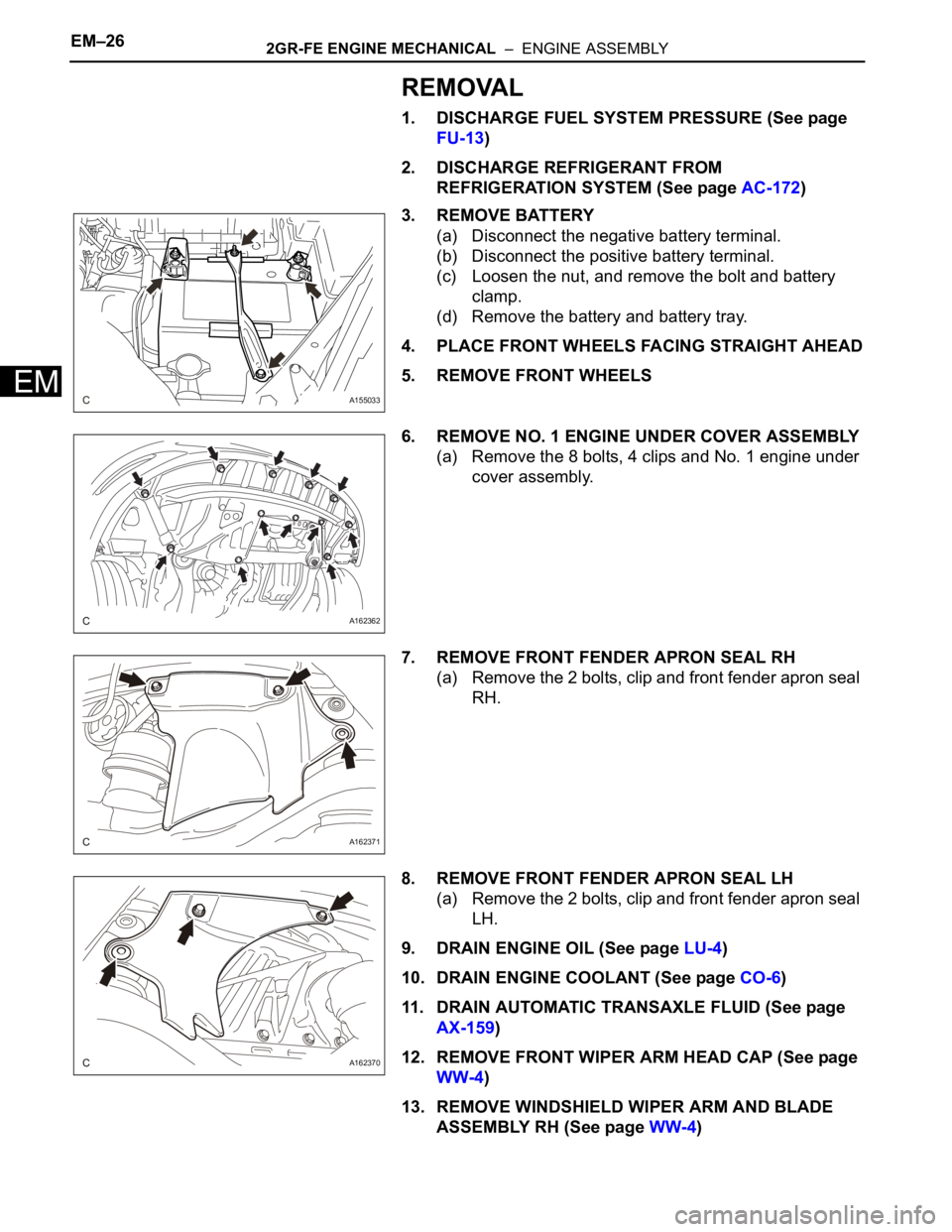

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE (See page

FU-13)

2. DISCHARGE REFRIGERANT FROM

REFRIGERATION SYSTEM (See page AC-172)

3. REMOVE BATTERY

(a) Disconnect the negative battery terminal.

(b) Disconnect the positive battery terminal.

(c) Loosen the nut, and remove the bolt and battery

clamp.

(d) Remove the battery and battery tray.

4. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

5. REMOVE FRONT WHEELS

6. REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY

(a) Remove the 8 bolts, 4 clips and No. 1 engine under

cover assembly.

7. REMOVE FRONT FENDER APRON SEAL RH

(a) Remove the 2 bolts, clip and front fender apron seal

RH.

8. REMOVE FRONT FENDER APRON SEAL LH

(a) Remove the 2 bolts, clip and front fender apron seal

LH.

9. DRAIN ENGINE OIL (See page LU-4)

10. DRAIN ENGINE COOLANT (See page CO-6)

11. DRAIN AUTOMATIC TRANSAXLE FLUID (See page

AX-159)

12. REMOVE FRONT WIPER ARM HEAD CAP (See page

WW-4)

13. REMOVE WINDSHIELD WIPER ARM AND BLADE

ASSEMBLY RH (See page WW-4)

A155033

A162362

A162371

A162370

Page 1119 of 3000

2GR-FE FUEL – FUEL INJECTORFU–13

FU

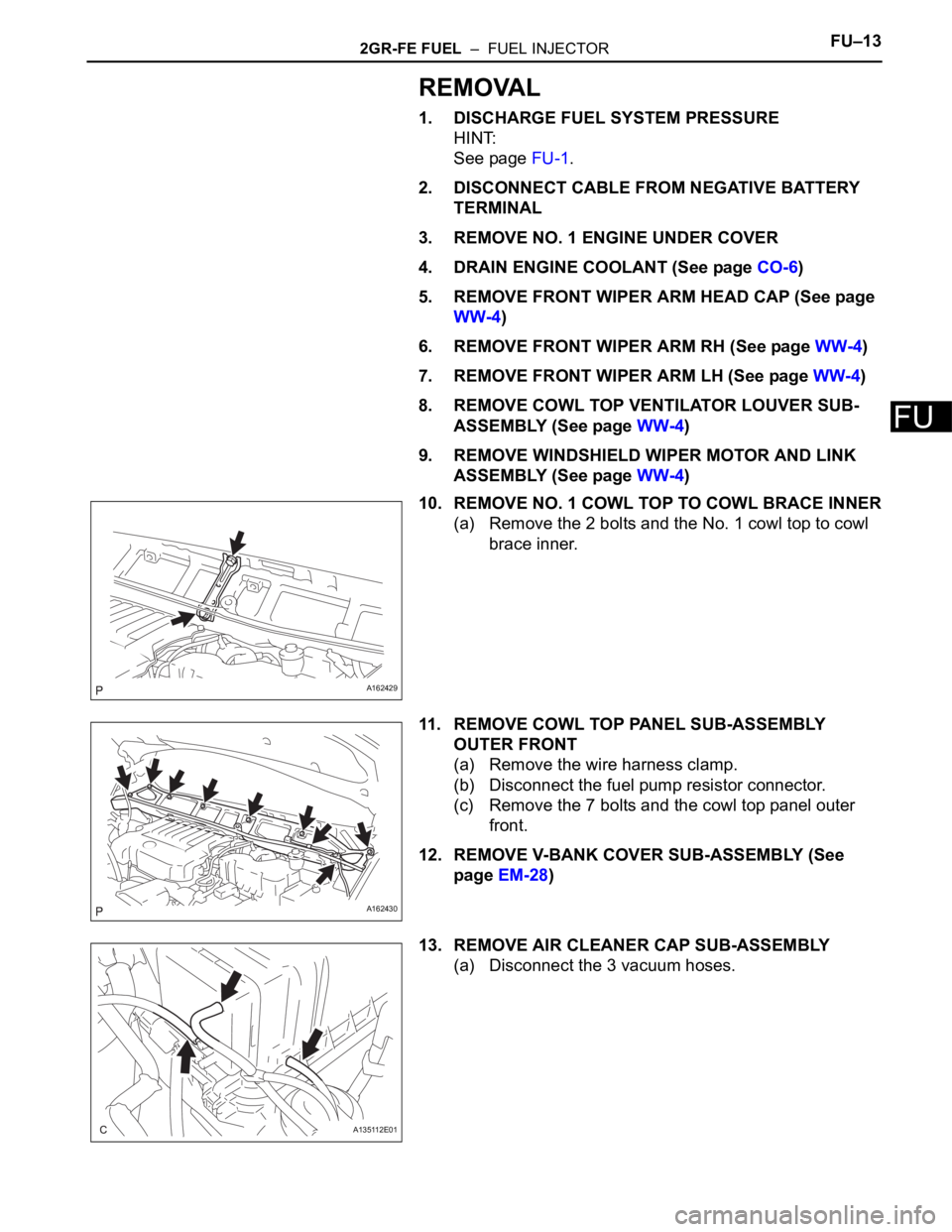

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

See page FU-1.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

3. REMOVE NO. 1 ENGINE UNDER COVER

4. DRAIN ENGINE COOLANT (See page CO-6)

5. REMOVE FRONT WIPER ARM HEAD CAP (See page

WW-4)

6. REMOVE FRONT WIPER ARM RH (See page WW-4)

7. REMOVE FRONT WIPER ARM LH (See page WW-4)

8. REMOVE COWL TOP VENTILATOR LOUVER SUB-

ASSEMBLY (See page WW-4)

9. REMOVE WINDSHIELD WIPER MOTOR AND LINK

ASSEMBLY (See page WW-4)

10. REMOVE NO. 1 COWL TOP TO COWL BRACE INNER

(a) Remove the 2 bolts and the No. 1 cowl top to cowl

brace inner.

11. REMOVE COWL TOP PANEL SUB-ASSEMBLY

OUTER FRONT

(a) Remove the wire harness clamp.

(b) Disconnect the fuel pump resistor connector.

(c) Remove the 7 bolts and the cowl top panel outer

front.

12. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

13. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

(a) Disconnect the 3 vacuum hoses.

A162429

A162430

A135112E01