engine removal TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 21 of 3000

2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–521

ES

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

(See page FU-13)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-4)

5. REMOVE FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-27)

6. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

7. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

8. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(a) Disconnect the 2 water by-pass hoses from the

throttle body [A].

(b) Disconnect the vapor feed hose [B].

(c) Disconnect the throttle body connector and clamp

[C].

(d) Disconnect the ventilation hose [D].

(e) Disconnect the union to check valve hose [E].

(f) Disconnect the connector [F].

A129464E07

A138457E04

A129467

Page 25 of 3000

EM–262GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

REMOVAL

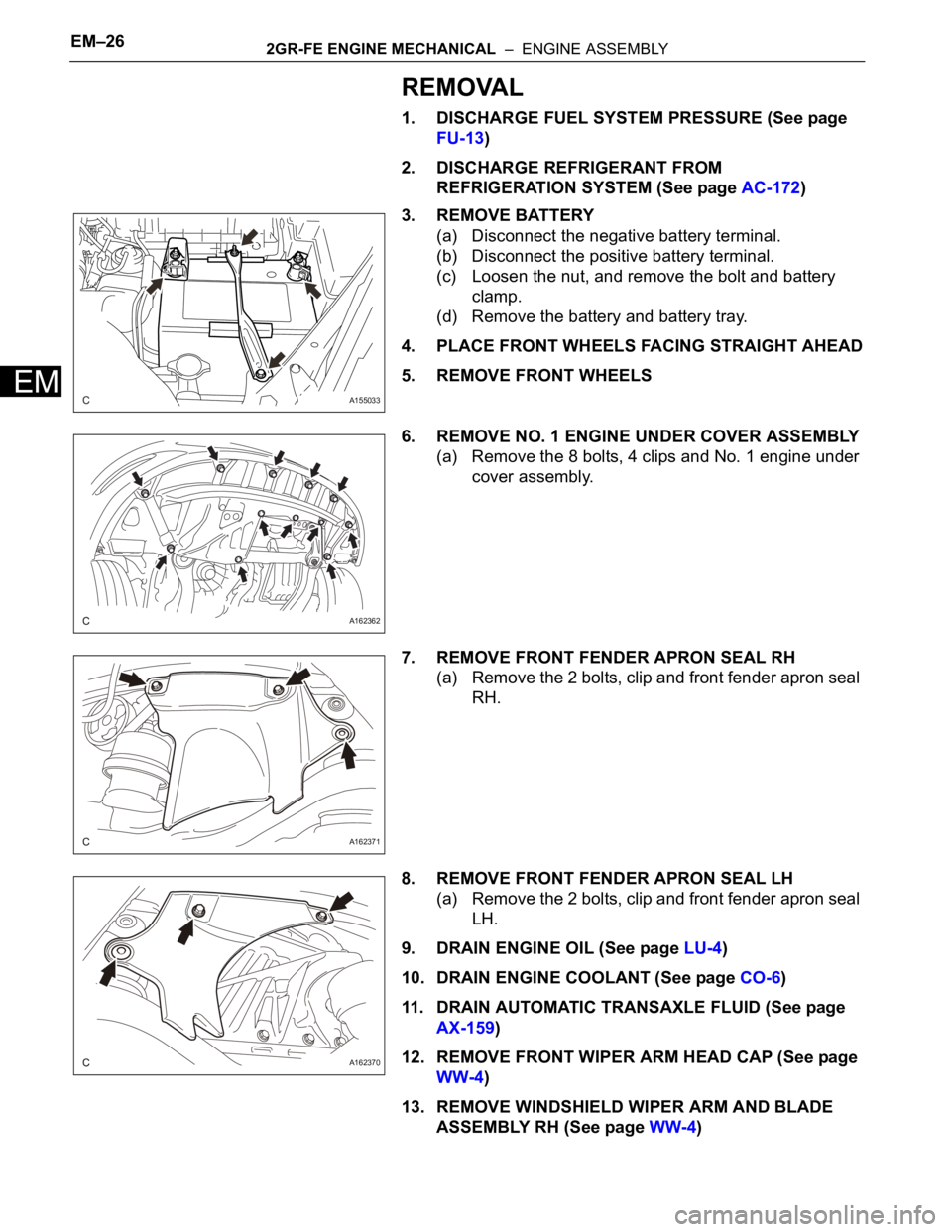

1. DISCHARGE FUEL SYSTEM PRESSURE (See page

FU-13)

2. DISCHARGE REFRIGERANT FROM

REFRIGERATION SYSTEM (See page AC-172)

3. REMOVE BATTERY

(a) Disconnect the negative battery terminal.

(b) Disconnect the positive battery terminal.

(c) Loosen the nut, and remove the bolt and battery

clamp.

(d) Remove the battery and battery tray.

4. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

5. REMOVE FRONT WHEELS

6. REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY

(a) Remove the 8 bolts, 4 clips and No. 1 engine under

cover assembly.

7. REMOVE FRONT FENDER APRON SEAL RH

(a) Remove the 2 bolts, clip and front fender apron seal

RH.

8. REMOVE FRONT FENDER APRON SEAL LH

(a) Remove the 2 bolts, clip and front fender apron seal

LH.

9. DRAIN ENGINE OIL (See page LU-4)

10. DRAIN ENGINE COOLANT (See page CO-6)

11. DRAIN AUTOMATIC TRANSAXLE FLUID (See page

AX-159)

12. REMOVE FRONT WIPER ARM HEAD CAP (See page

WW-4)

13. REMOVE WINDSHIELD WIPER ARM AND BLADE

ASSEMBLY RH (See page WW-4)

A155033

A162362

A162371

A162370

Page 45 of 3000

EC–62GR-FE EMISSION CONTROL – EMISSION CONTROL SYSTEM

EC

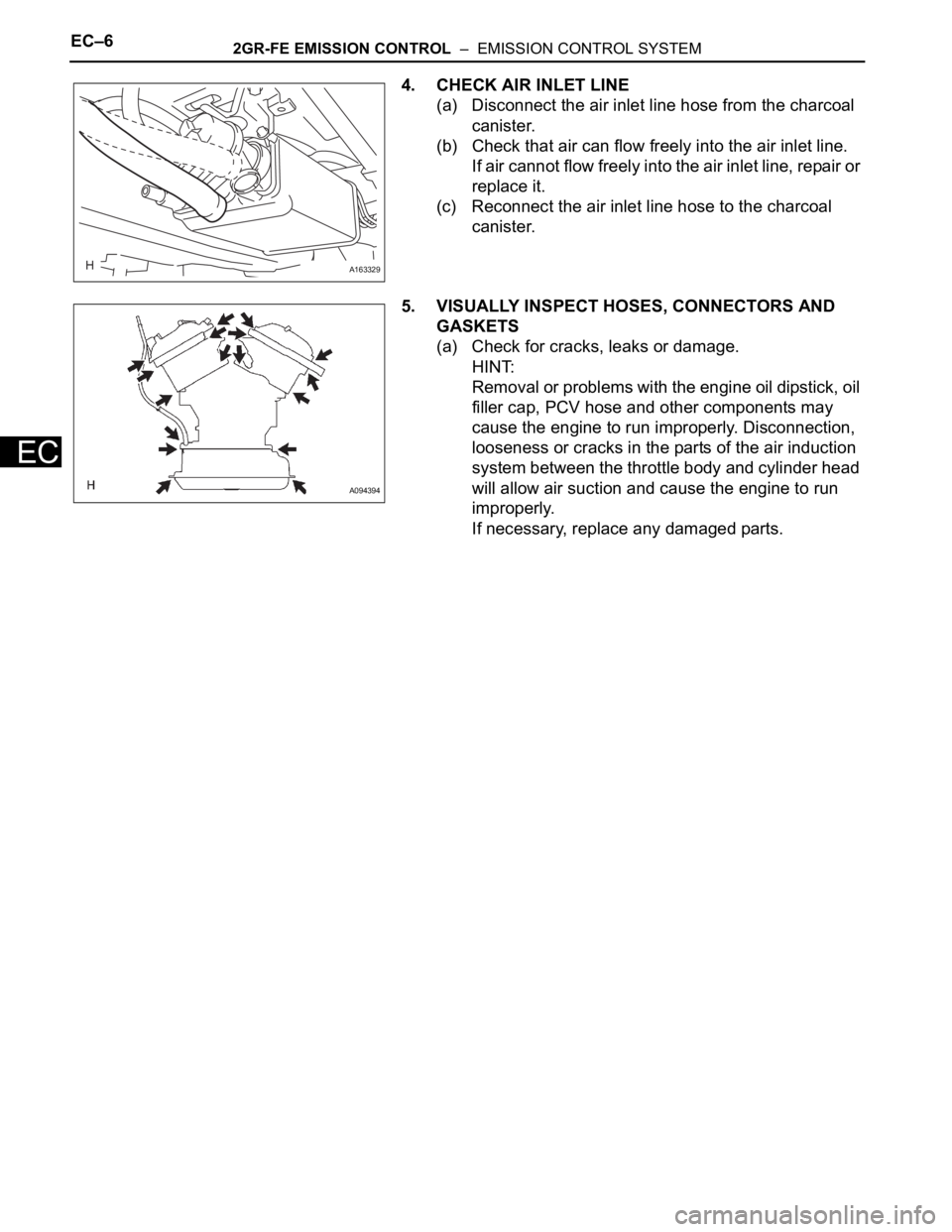

4. CHECK AIR INLET LINE

(a) Disconnect the air inlet line hose from the charcoal

canister.

(b) Check that air can flow freely into the air inlet line.

If air cannot flow freely into the air inlet line, repair or

replace it.

(c) Reconnect the air inlet line hose to the charcoal

canister.

5. VISUALLY INSPECT HOSES, CONNECTORS AND

GASKETS

(a) Check for cracks, leaks or damage.

HINT:

Removal or problems with the engine oil dipstick, oil

filler cap, PCV hose and other components may

cause the engine to run improperly. Disconnection,

looseness or cracks in the parts of the air induction

system between the throttle body and cylinder head

will allow air suction and cause the engine to run

improperly.

If necessary, replace any damaged parts.

A163329

A094394

Page 78 of 3000

2GR-FE LUBRICATION – OIL PUMPLU–11

LU

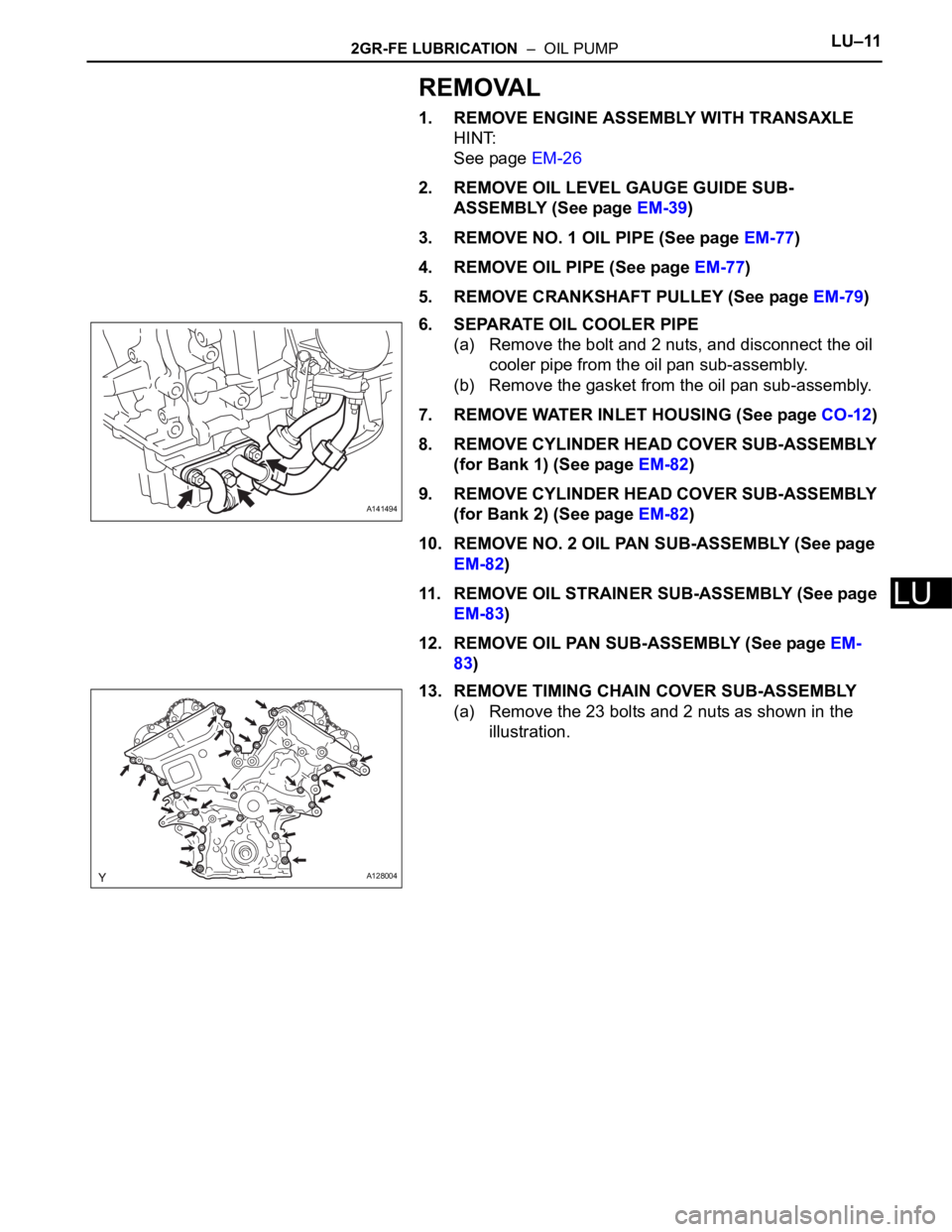

REMOVAL

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

HINT:

See page EM-26

2. REMOVE OIL LEVEL GAUGE GUIDE SUB-

ASSEMBLY (See page EM-39)

3. REMOVE NO. 1 OIL PIPE (See page EM-77)

4. REMOVE OIL PIPE (See page EM-77)

5. REMOVE CRANKSHAFT PULLEY (See page EM-79)

6. SEPARATE OIL COOLER PIPE

(a) Remove the bolt and 2 nuts, and disconnect the oil

cooler pipe from the oil pan sub-assembly.

(b) Remove the gasket from the oil pan sub-assembly.

7. REMOVE WATER INLET HOUSING (See page CO-12)

8. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(for Bank 1) (See page EM-82)

9. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(for Bank 2) (See page EM-82)

10. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY (See page

EM-82)

11. REMOVE OIL STRAINER SUB-ASSEMBLY (See page

EM-83)

12. REMOVE OIL PAN SUB-ASSEMBLY (See page EM-

83)

13. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

(a) Remove the 23 bolts and 2 nuts as shown in the

illustration.

A141494

A128004

Page 90 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–163

AX

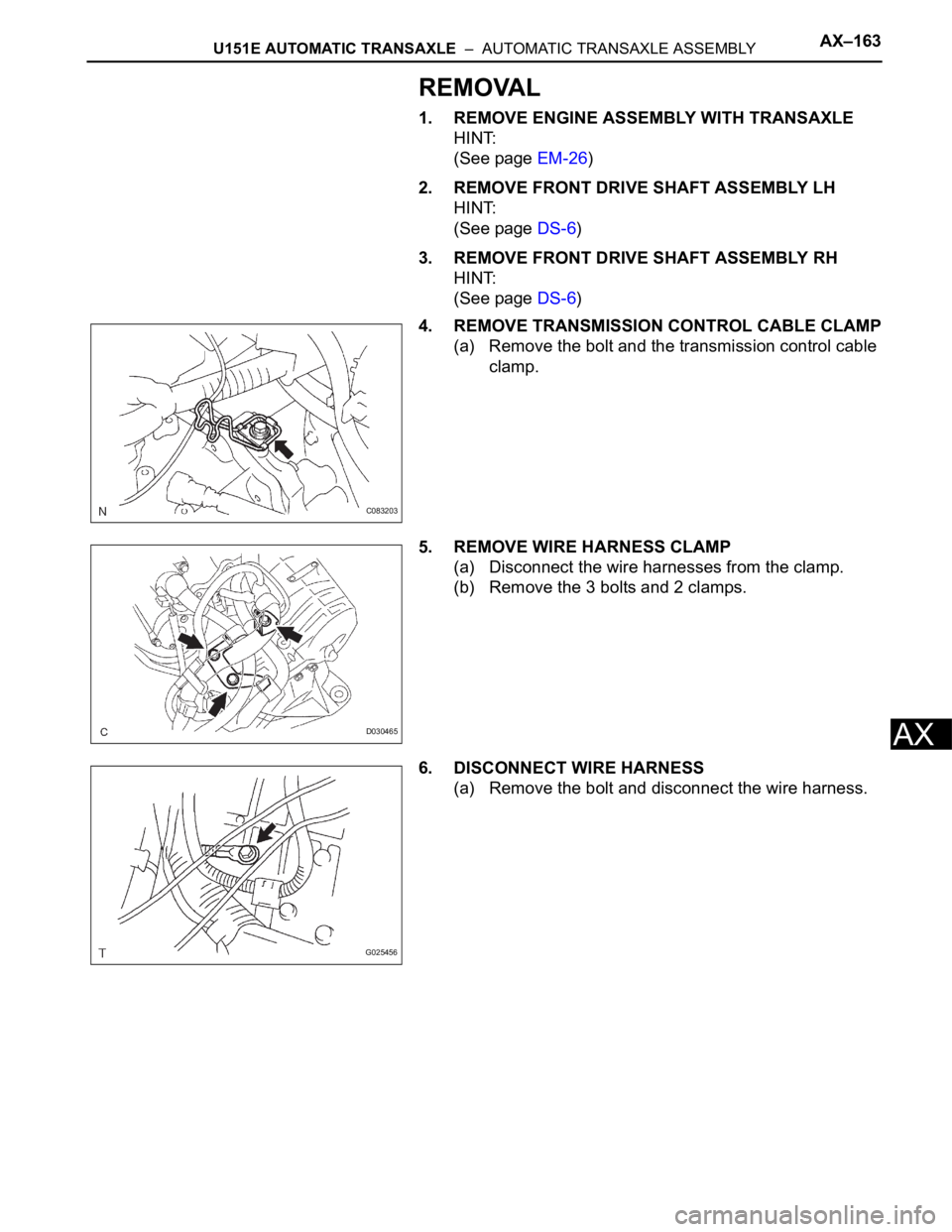

REMOVAL

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

HINT:

(See page EM-26)

2. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

HINT:

(See page DS-6)

3. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH

HINT:

(See page DS-6)

4. REMOVE TRANSMISSION CONTROL CABLE CLAMP

(a) Remove the bolt and the transmission control cable

clamp.

5. REMOVE WIRE HARNESS CLAMP

(a) Disconnect the wire harnesses from the clamp.

(b) Remove the 3 bolts and 2 clamps.

6. DISCONNECT WIRE HARNESS

(a) Remove the bolt and disconnect the wire harness.

C083203

D030465

G025456

Page 99 of 3000

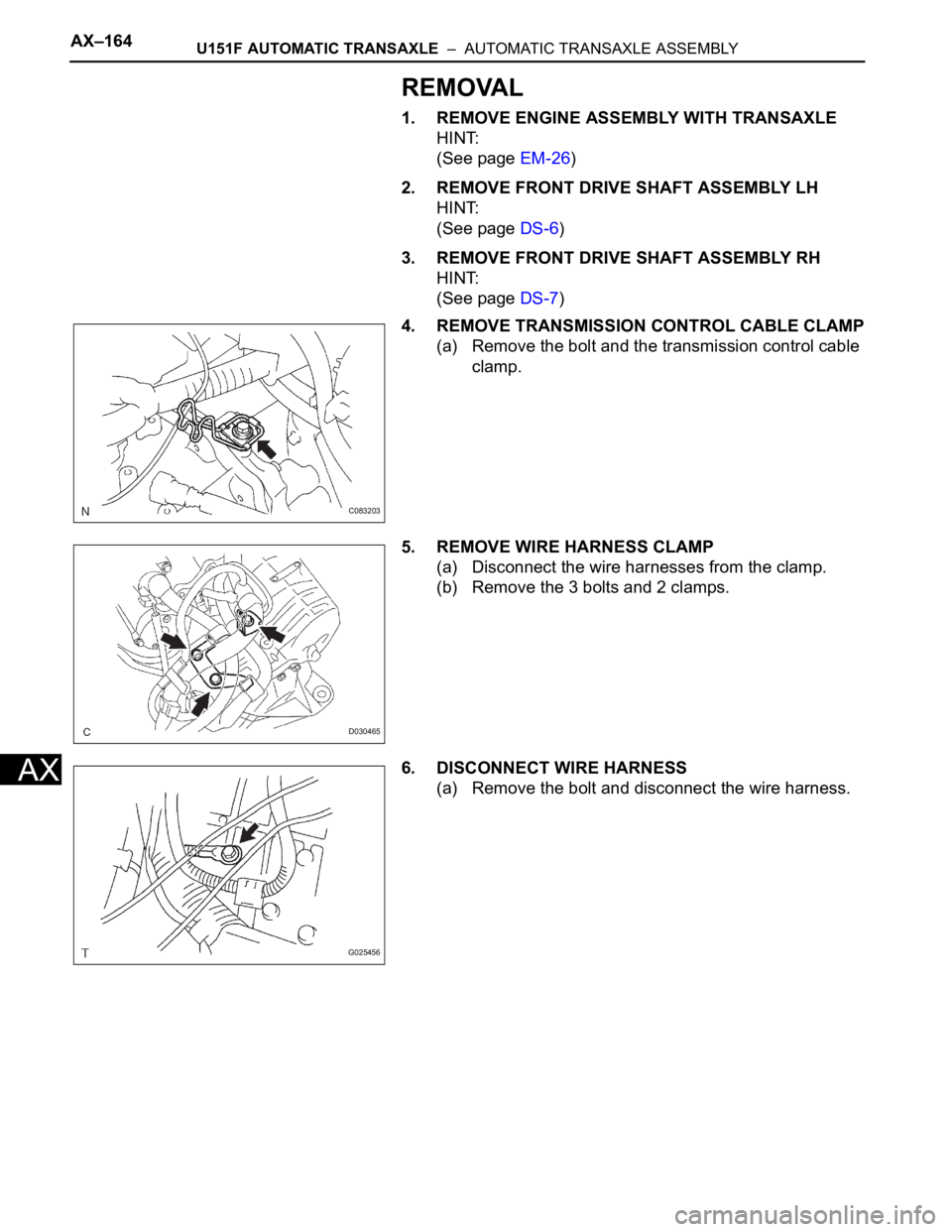

AX–164U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

REMOVAL

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

HINT:

(See page EM-26)

2. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

HINT:

(See page DS-6)

3. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH

HINT:

(See page DS-7)

4. REMOVE TRANSMISSION CONTROL CABLE CLAMP

(a) Remove the bolt and the transmission control cable

clamp.

5. REMOVE WIRE HARNESS CLAMP

(a) Disconnect the wire harnesses from the clamp.

(b) Remove the 3 bolts and 2 clamps.

6. DISCONNECT WIRE HARNESS

(a) Remove the bolt and disconnect the wire harness.

C083203

D030465

G025456

Page 780 of 3000

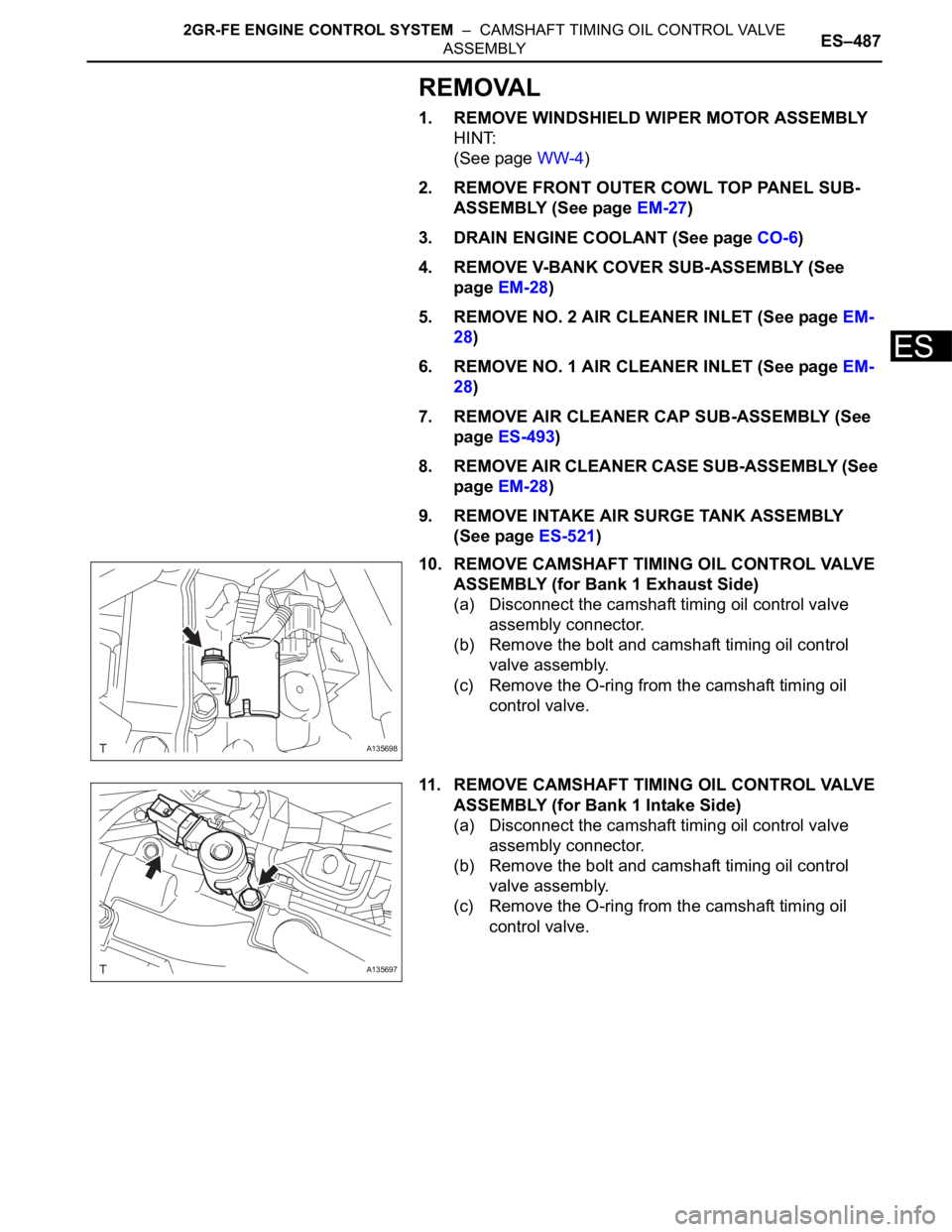

2GR-FE ENGINE CONTROL SYSTEM – CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLYES–487

ES

REMOVAL

1. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-4)

2. REMOVE FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-27)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

5. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

6. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

7. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

8. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

9. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(See page ES-521)

10. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY (for Bank 1 Exhaust Side)

(a) Disconnect the camshaft timing oil control valve

assembly connector.

(b) Remove the bolt and camshaft timing oil control

valve assembly.

(c) Remove the O-ring from the camshaft timing oil

control valve.

11. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY (for Bank 1 Intake Side)

(a) Disconnect the camshaft timing oil control valve

assembly connector.

(b) Remove the bolt and camshaft timing oil control

valve assembly.

(c) Remove the O-ring from the camshaft timing oil

control valve.

A135698

A135697

Page 790 of 3000

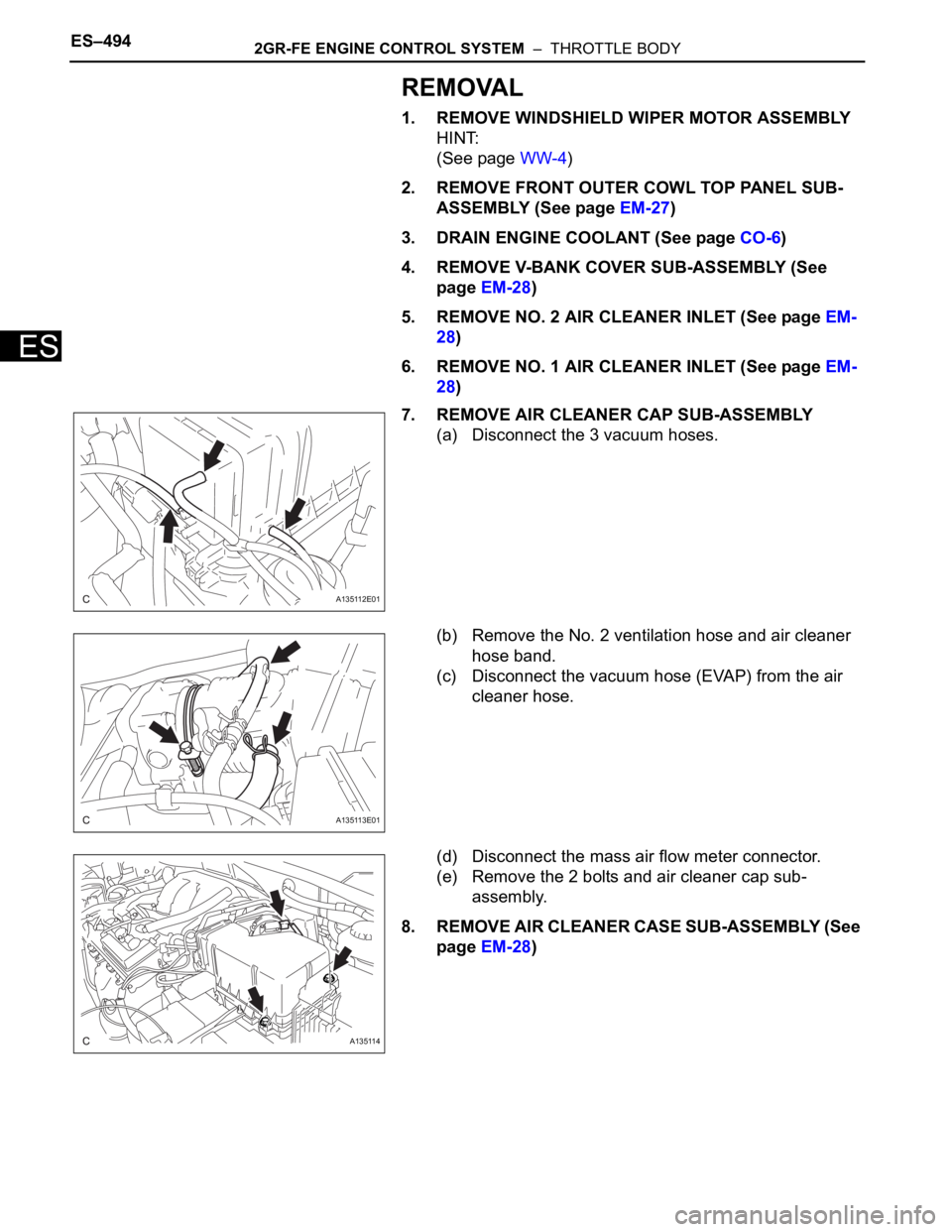

ES–4942GR-FE ENGINE CONTROL SYSTEM – THROTTLE BODY

ES

REMOVAL

1. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-4)

2. REMOVE FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-27)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

5. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

6. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

7. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

(a) Disconnect the 3 vacuum hoses.

(b) Remove the No. 2 ventilation hose and air cleaner

hose band.

(c) Disconnect the vacuum hose (EVAP) from the air

cleaner hose.

(d) Disconnect the mass air flow meter connector.

(e) Remove the 2 bolts and air cleaner cap sub-

assembly.

8. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

A135112E01

A135113E01

A135114

Page 799 of 3000

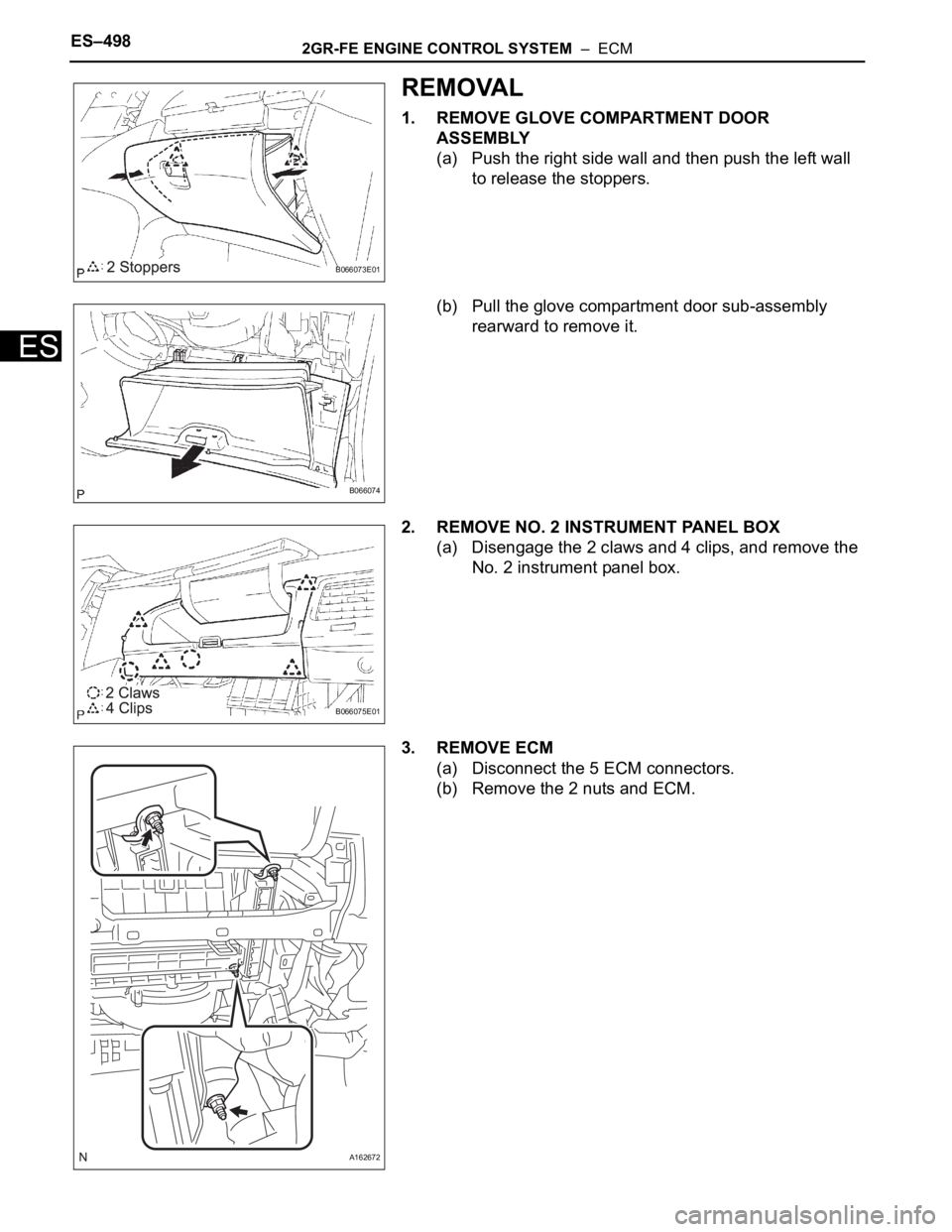

ES–4982GR-FE ENGINE CONTROL SYSTEM – ECM

ES

REMOVAL

1. REMOVE GLOVE COMPARTMENT DOOR

ASSEMBLY

(a) Push the right side wall and then push the left wall

to release the stoppers.

(b) Pull the glove compartment door sub-assembly

rearward to remove it.

2. REMOVE NO. 2 INSTRUMENT PANEL BOX

(a) Disengage the 2 claws and 4 clips, and remove the

No. 2 instrument panel box.

3. REMOVE ECM

(a) Disconnect the 5 ECM connectors.

(b) Remove the 2 nuts and ECM.

B066073E01

B066074

B066075E01

A162672

Page 808 of 3000

ES–5022GR-FE ENGINE CONTROL SYSTEM – ACCELERATOR PEDAL ROD

ES

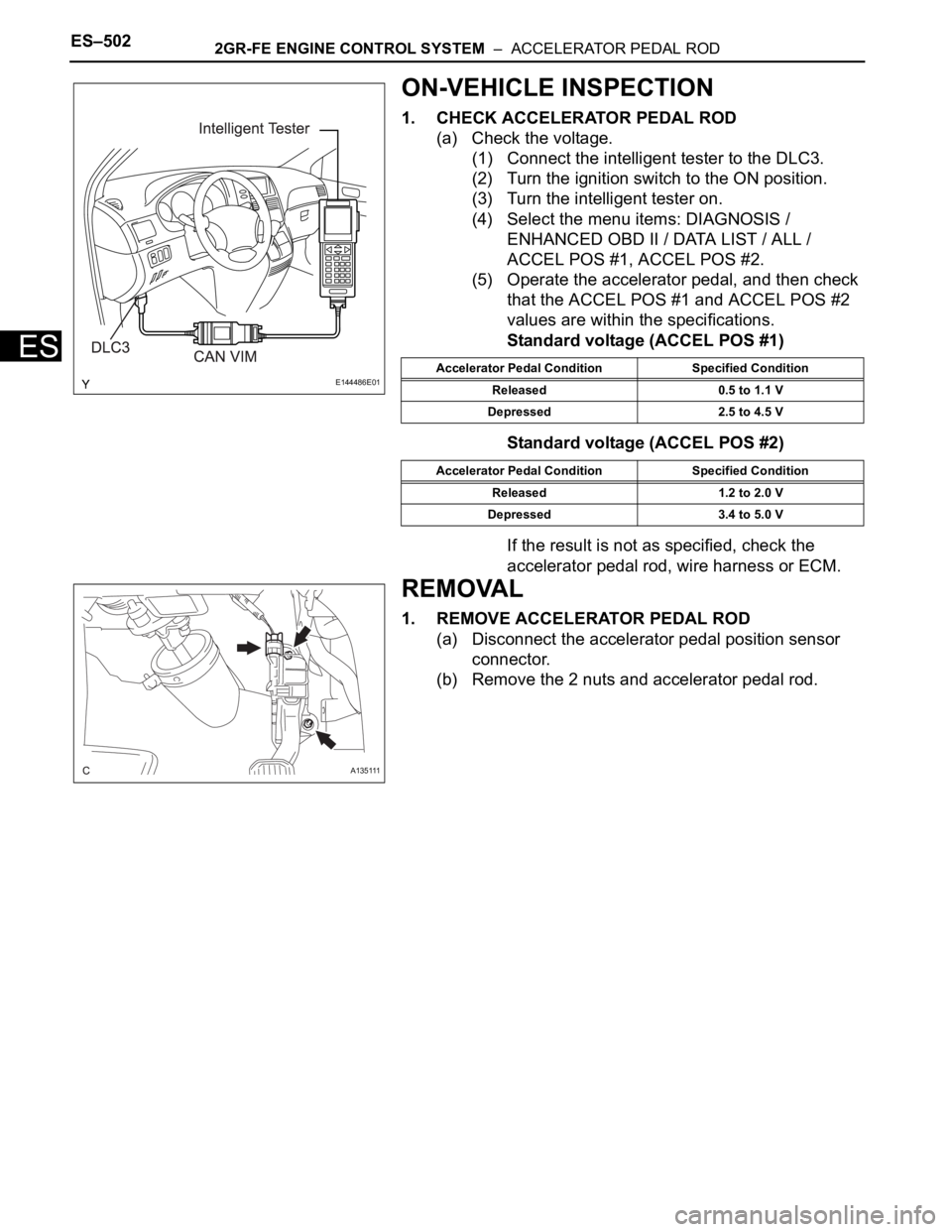

ON-VEHICLE INSPECTION

1. CHECK ACCELERATOR PEDAL ROD

(a) Check the voltage.

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the intelligent tester on.

(4) Select the menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / ALL /

ACCEL POS #1, ACCEL POS #2.

(5) Operate the accelerator pedal, and then check

that the ACCEL POS #1 and ACCEL POS #2

values are within the specifications.

Standard voltage (ACCEL POS #1)

Standard voltage (ACCEL POS #2)

If the result is not as specified, check the

accelerator pedal rod, wire harness or ECM.

REMOVAL

1. REMOVE ACCELERATOR PEDAL ROD

(a) Disconnect the accelerator pedal position sensor

connector.

(b) Remove the 2 nuts and accelerator pedal rod.

E144486E01Accelerator Pedal Condition Specified Condition

Released 0.5 to 1.1 V

Depressed 2.5 to 4.5 V

Accelerator Pedal Condition Specified Condition

Released 1.2 to 2.0 V

Depressed 3.4 to 5.0 V

A135111