check engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 709 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–423

ES

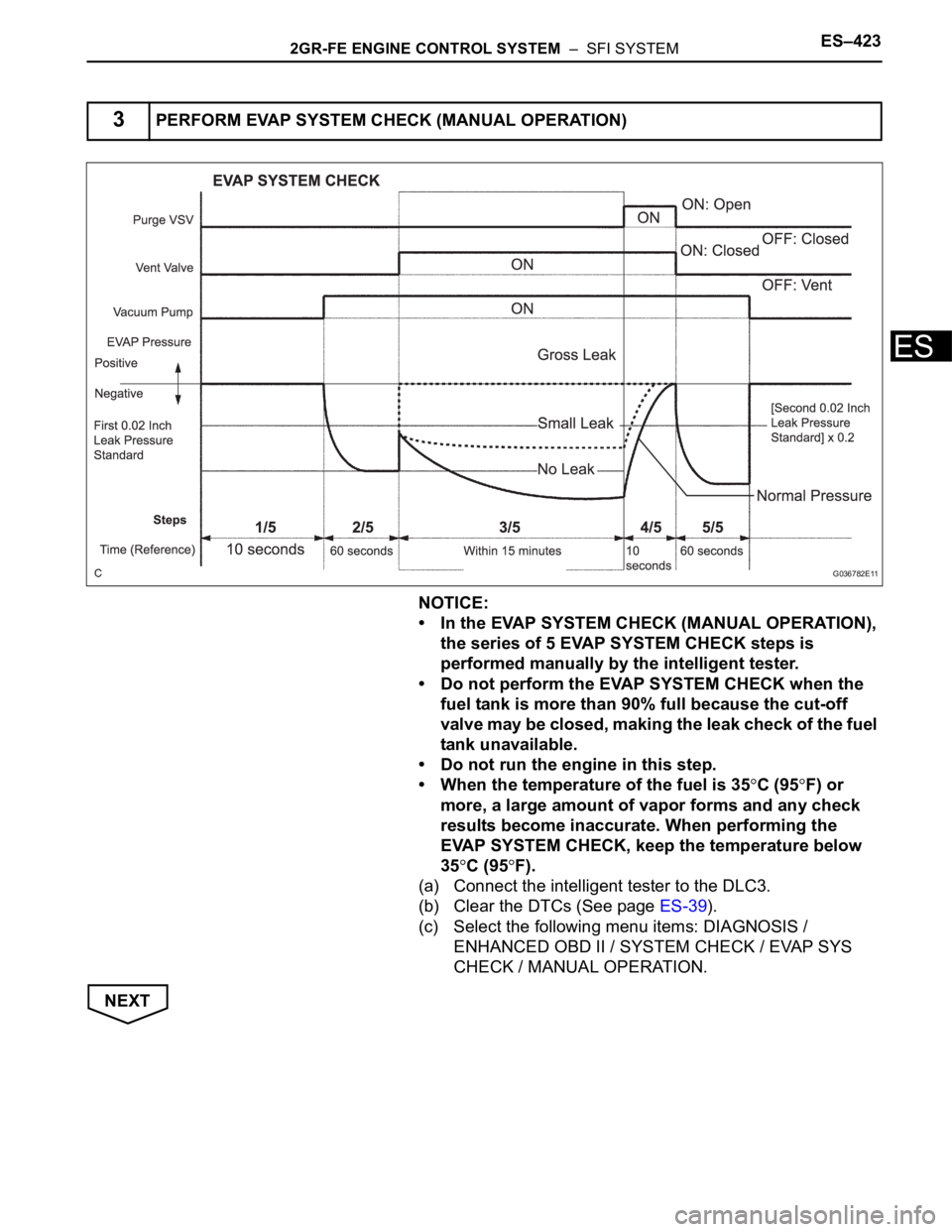

NOTICE:

• In the EVAP SYSTEM CHECK (MANUAL OPERATION),

the series of 5 EVAP SYSTEM CHECK steps is

performed manually by the intelligent tester.

• Do not perform the EVAP SYSTEM CHECK when the

fuel tank is more than 90% full because the cut-off

valve may be closed, making the leak check of the fuel

tank unavailable.

• Do not run the engine in this step.

• When the temperature of the fuel is 35

C (95F) or

more, a large amount of vapor forms and any check

results become inaccurate. When performing the

EVAP SYSTEM CHECK, keep the temperature below

35

C (95F).

(a) Connect the intelligent tester to the DLC3.

(b) Clear the DTCs (See page ES-39).

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / SYSTEM CHECK / EVAP SYS

CHECK / MANUAL OPERATION.

NEXT

3PERFORM EVAP SYSTEM CHECK (MANUAL OPERATION)

G036782E11

Page 710 of 3000

ES–4242GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

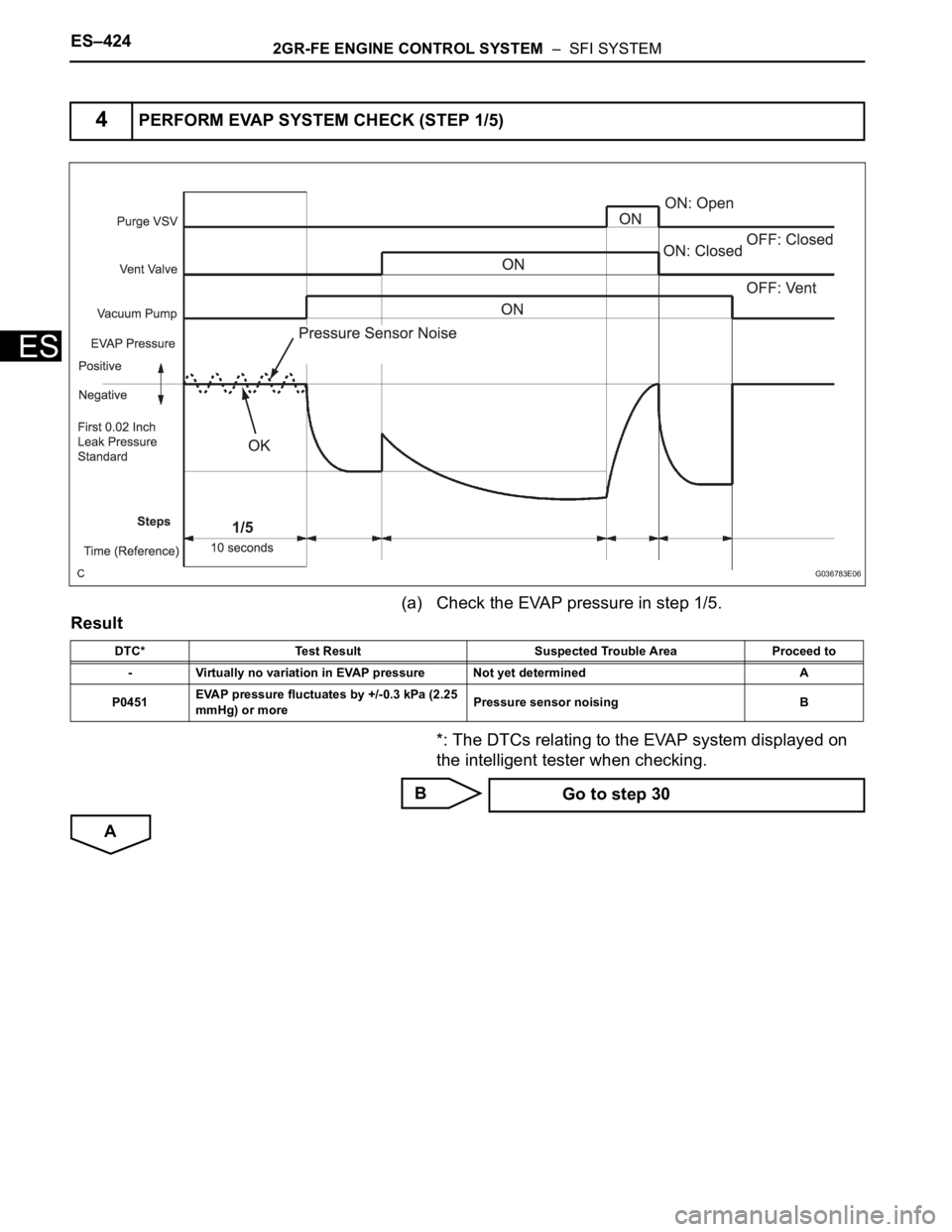

(a) Check the EVAP pressure in step 1/5.

Result

*: The DTCs relating to the EVAP system displayed on

the intelligent tester when checking.

B

A

4PERFORM EVAP SYSTEM CHECK (STEP 1/5)

G036783E06

DTC* Test Result Suspected Trouble Area Proceed to

- Virtually no variation in EVAP pressure Not yet determined A

P0451EVAP pressure fluctuates by +/-0.3 kPa (2.25

mmHg) or morePressure sensor noising B

Go to step 30

Page 711 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–425

ES

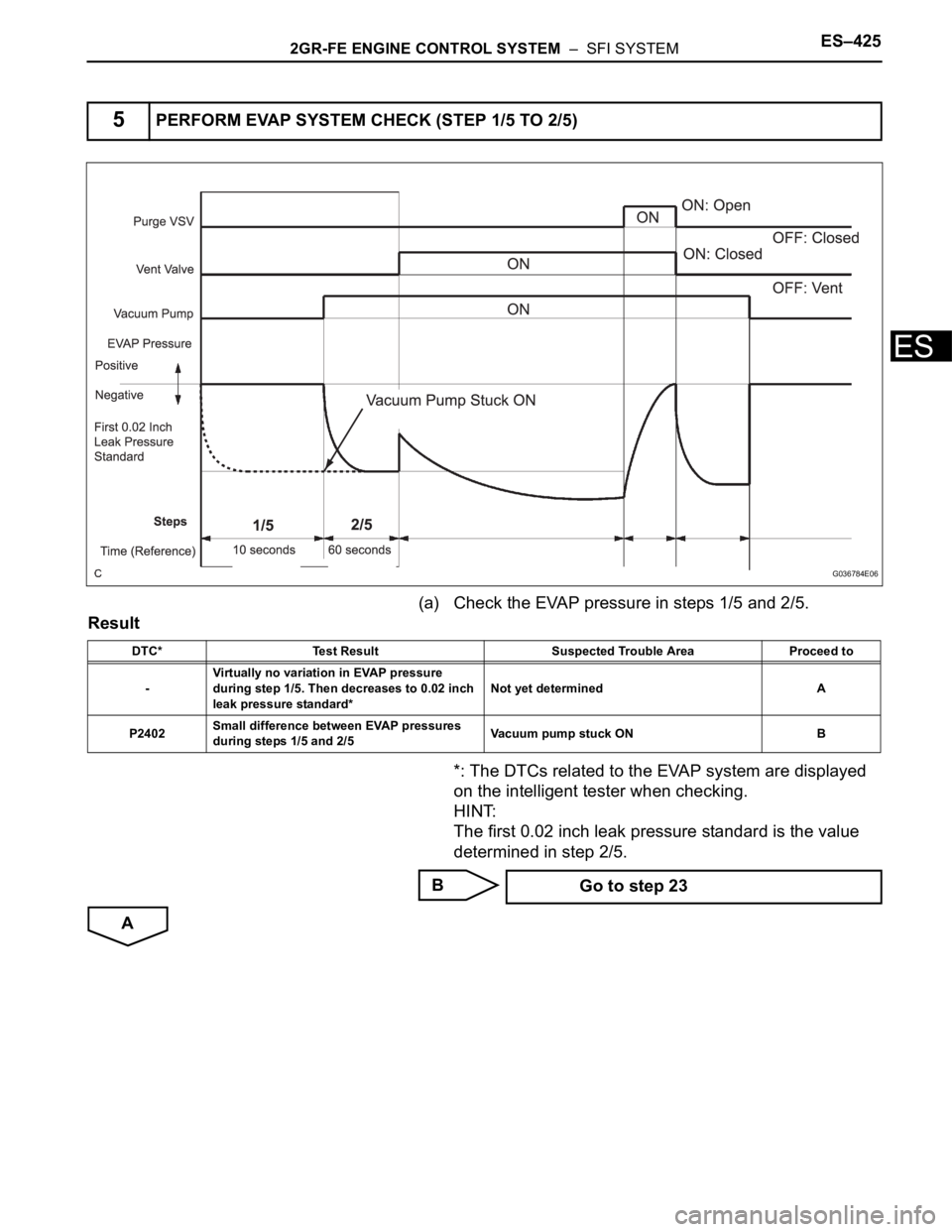

(a) Check the EVAP pressure in steps 1/5 and 2/5.

Result

*: The DTCs related to the EVAP system are displayed

on the intelligent tester when checking.

HINT:

The first 0.02 inch leak pressure standard is the value

determined in step 2/5.

B

A

5PERFORM EVAP SYSTEM CHECK (STEP 1/5 TO 2/5)

G036784E06

DTC* Test Result Suspected Trouble Area Proceed to

-Virtually no variation in EVAP pressure

during step 1/5. Then decreases to 0.02 inch

leak pressure standard*Not yet determined A

P2402Small difference between EVAP pressures

during steps 1/5 and 2/5Vacuum pump stuck ON B

Go to step 23

Page 712 of 3000

ES–4262GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

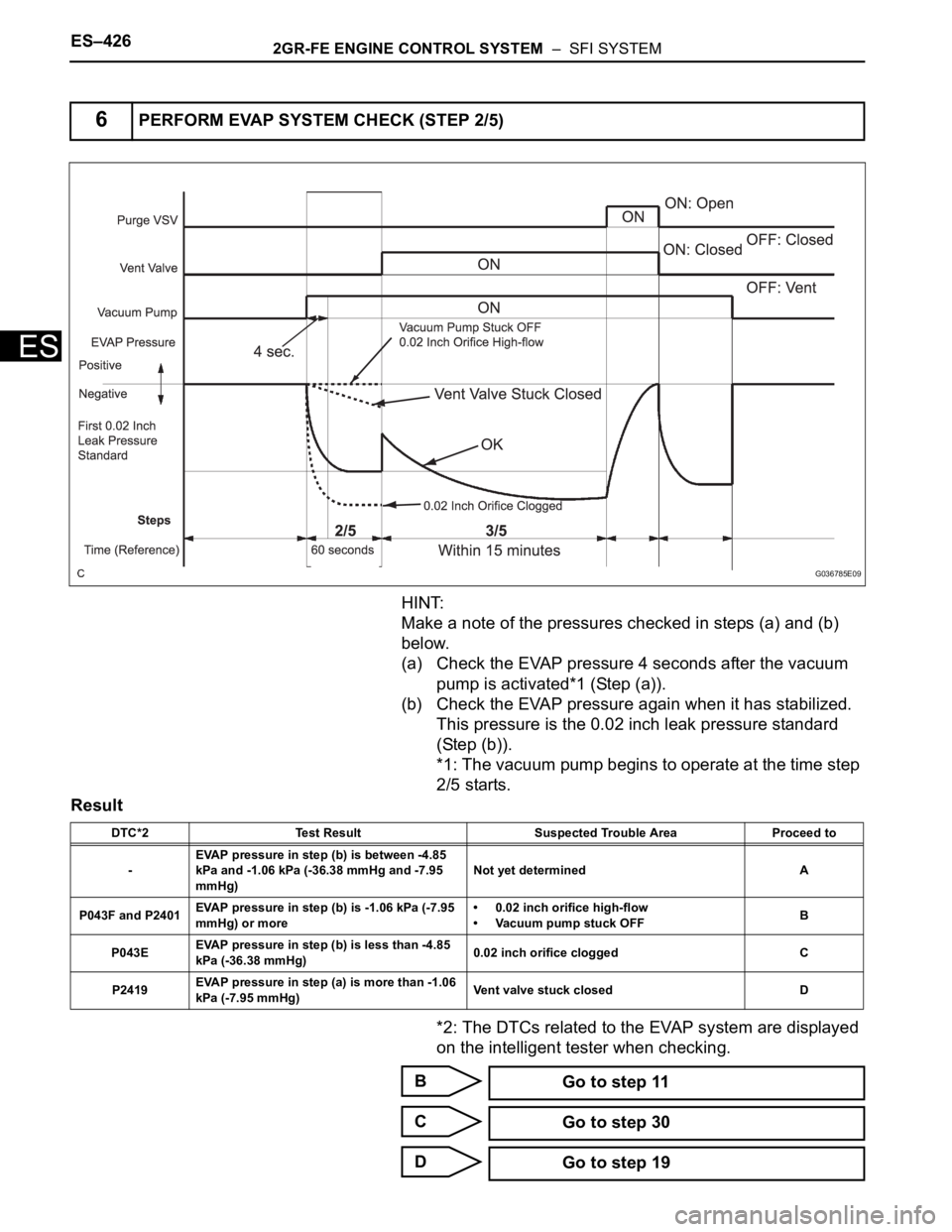

HINT:

Make a note of the pressures checked in steps (a) and (b)

below.

(a) Check the EVAP pressure 4 seconds after the vacuum

pump is activated*1 (Step (a)).

(b) Check the EVAP pressure again when it has stabilized.

This pressure is the 0.02 inch leak pressure standard

(Step (b)).

*1: The vacuum pump begins to operate at the time step

2/5 starts.

Result

*2: The DTCs related to the EVAP system are displayed

on the intelligent tester when checking.

B

C

D

6PERFORM EVAP SYSTEM CHECK (STEP 2/5)

G036785E09

DTC*2 Test Result Suspected Trouble Area Proceed to

-EVAP pressure in step (b) is between -4.85

kPa and -1.06 kPa (-36.38 mmHg and -7.95

mmHg)Not yet determined A

P043F and P2401EVAP pressure in step (b) is -1.06 kPa (-7.95

mmHg) or more• 0.02 inch orifice high-flow

• Vacuum pump stuck OFFB

P043EEVAP pressure in step (b) is less than -4.85

kPa (-36.38 mmHg)0.02 inch orifice clogged C

P2419EVAP pressure in step (a) is more than -1.06

kPa (-7.95 mmHg)Vent valve stuck closed D

Go to step 11

Go to step 30

Go to step 19

Page 713 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–427

ES

A

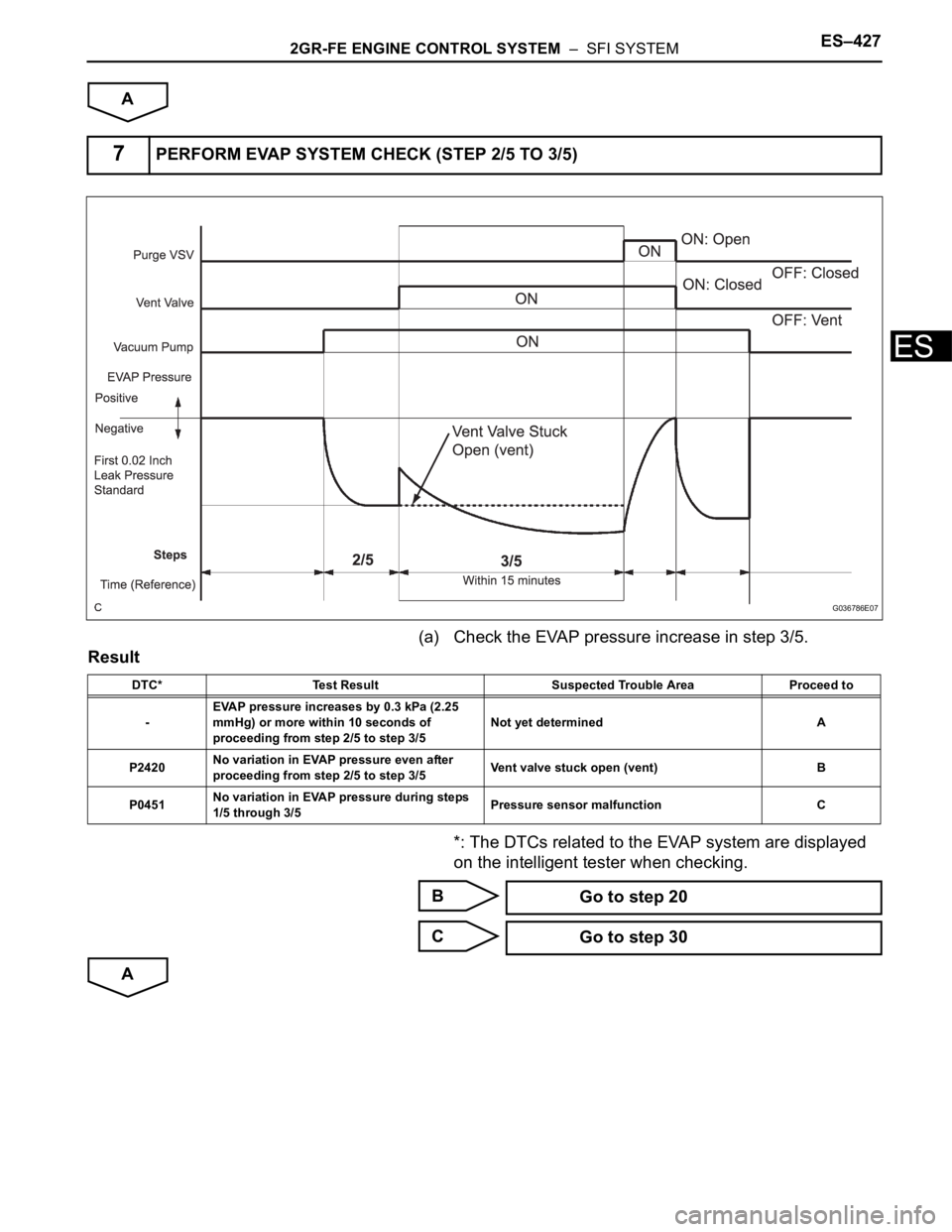

(a) Check the EVAP pressure increase in step 3/5.

Result

*: The DTCs related to the EVAP system are displayed

on the intelligent tester when checking.

B

C

A

7PERFORM EVAP SYSTEM CHECK (STEP 2/5 TO 3/5)

G036786E07

DTC* Test Result Suspected Trouble Area Proceed to

-EVAP pressure increases by 0.3 kPa (2.25

mmHg) or more within 10 seconds of

proceeding from step 2/5 to step 3/5Not yet determined A

P2420No variation in EVAP pressure even after

proceeding from step 2/5 to step 3/5Vent valve stuck open (vent) B

P0451No variation in EVAP pressure during steps

1/5 through 3/5Pressure sensor malfunction C

Go to step 20

Go to step 30

Page 714 of 3000

ES–4282GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

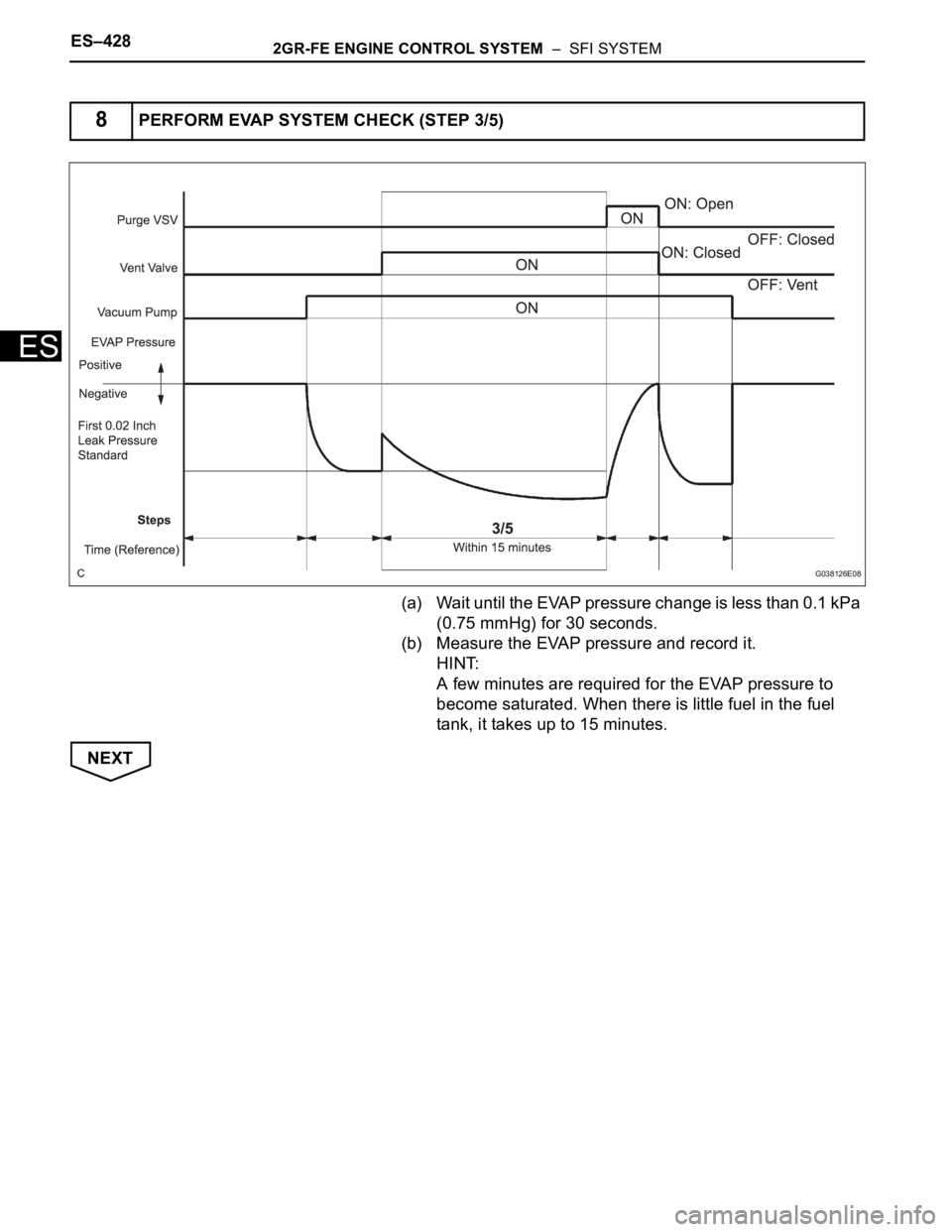

(a) Wait until the EVAP pressure change is less than 0.1 kPa

(0.75 mmHg) for 30 seconds.

(b) Measure the EVAP pressure and record it.

HINT:

A few minutes are required for the EVAP pressure to

become saturated. When there is little fuel in the fuel

tank, it takes up to 15 minutes.

NEXT

8PERFORM EVAP SYSTEM CHECK (STEP 3/5)

G038126E08

Page 715 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–429

ES

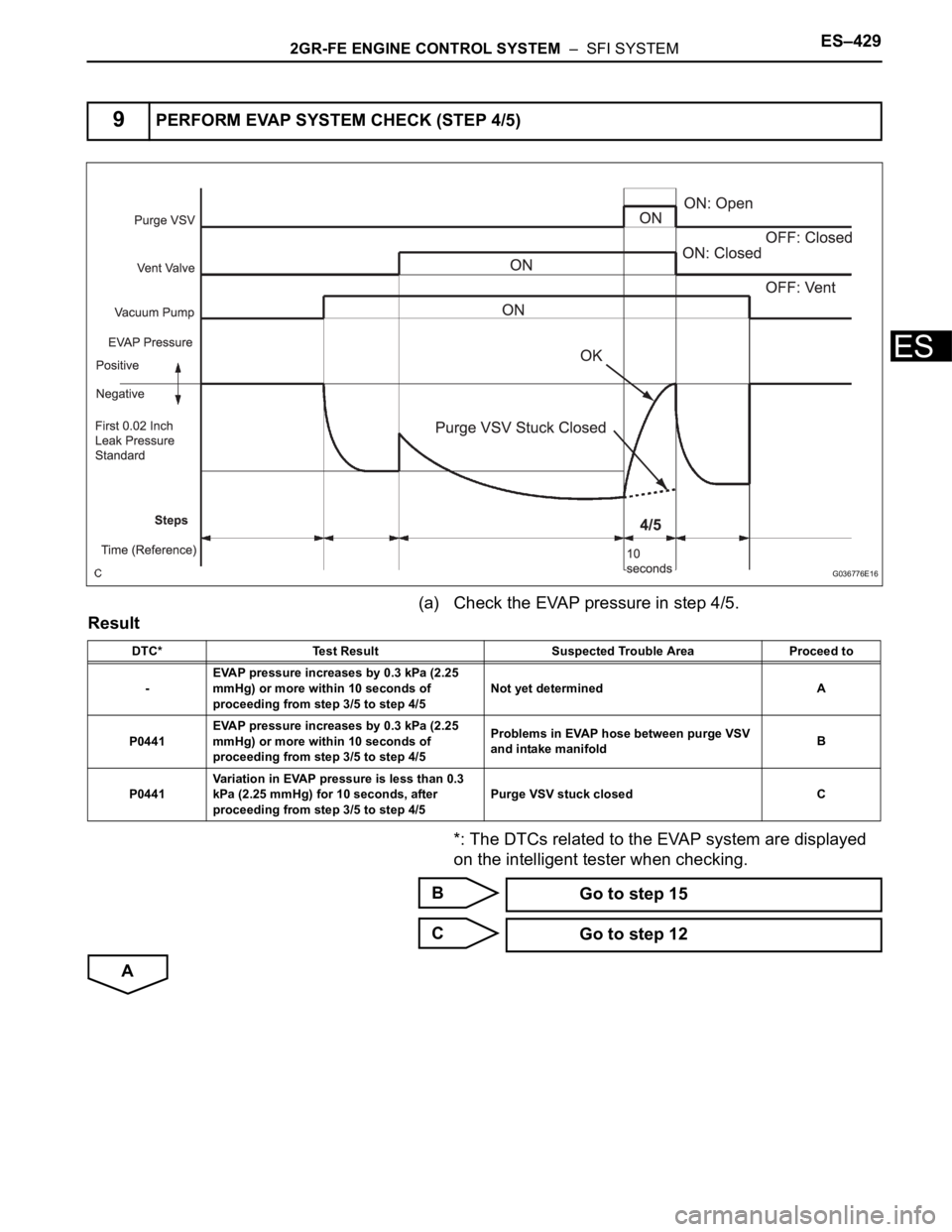

(a) Check the EVAP pressure in step 4/5.

Result

*: The DTCs related to the EVAP system are displayed

on the intelligent tester when checking.

B

C

A

9PERFORM EVAP SYSTEM CHECK (STEP 4/5)

G036776E16

DTC* Test Result Suspected Trouble Area Proceed to

-EVAP pressure increases by 0.3 kPa (2.25

mmHg) or more within 10 seconds of

proceeding from step 3/5 to step 4/5Not yet determined A

P0441EVAP pressure increases by 0.3 kPa (2.25

mmHg) or more within 10 seconds of

proceeding from step 3/5 to step 4/5Problems in EVAP hose between purge VSV

and intake manifoldB

P0441Variation in EVAP pressure is less than 0.3

kPa (2.25 mmHg) for 10 seconds, after

proceeding from step 3/5 to step 4/5Purge VSV stuck closed C

Go to step 15

Go to step 12

Page 716 of 3000

ES–4302GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

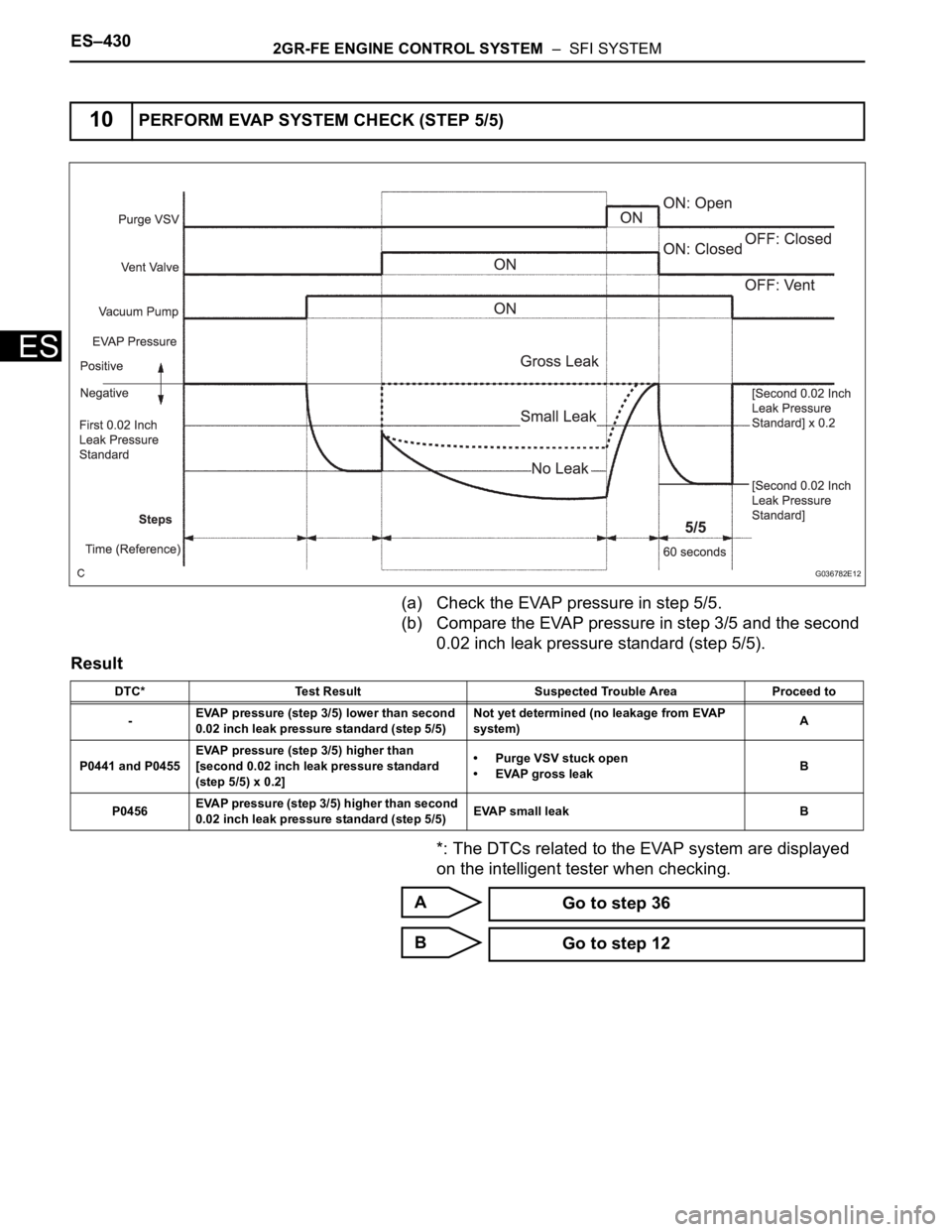

(a) Check the EVAP pressure in step 5/5.

(b) Compare the EVAP pressure in step 3/5 and the second

0.02 inch leak pressure standard (step 5/5).

Result

*: The DTCs related to the EVAP system are displayed

on the intelligent tester when checking.

A

B

10PERFORM EVAP SYSTEM CHECK (STEP 5/5)

G036782E12

DTC* Test Result Suspected Trouble Area Proceed to

-EVAP pressure (step 3/5) lower than second

0.02 inch leak pressure standard (step 5/5)Not yet determined (no leakage from EVAP

system)A

P0441 and P0455EVAP pressure (step 3/5) higher than

[second 0.02 inch leak pressure standard

(step 5/5) x 0.2]• Purge VSV stuck open

• EVAP gross leakB

P0456EVAP pressure (step 3/5) higher than second

0.02 inch leak pressure standard (step 5/5)EVAP small leak B

Go to step 36

Go to step 12

Page 717 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–431

ES

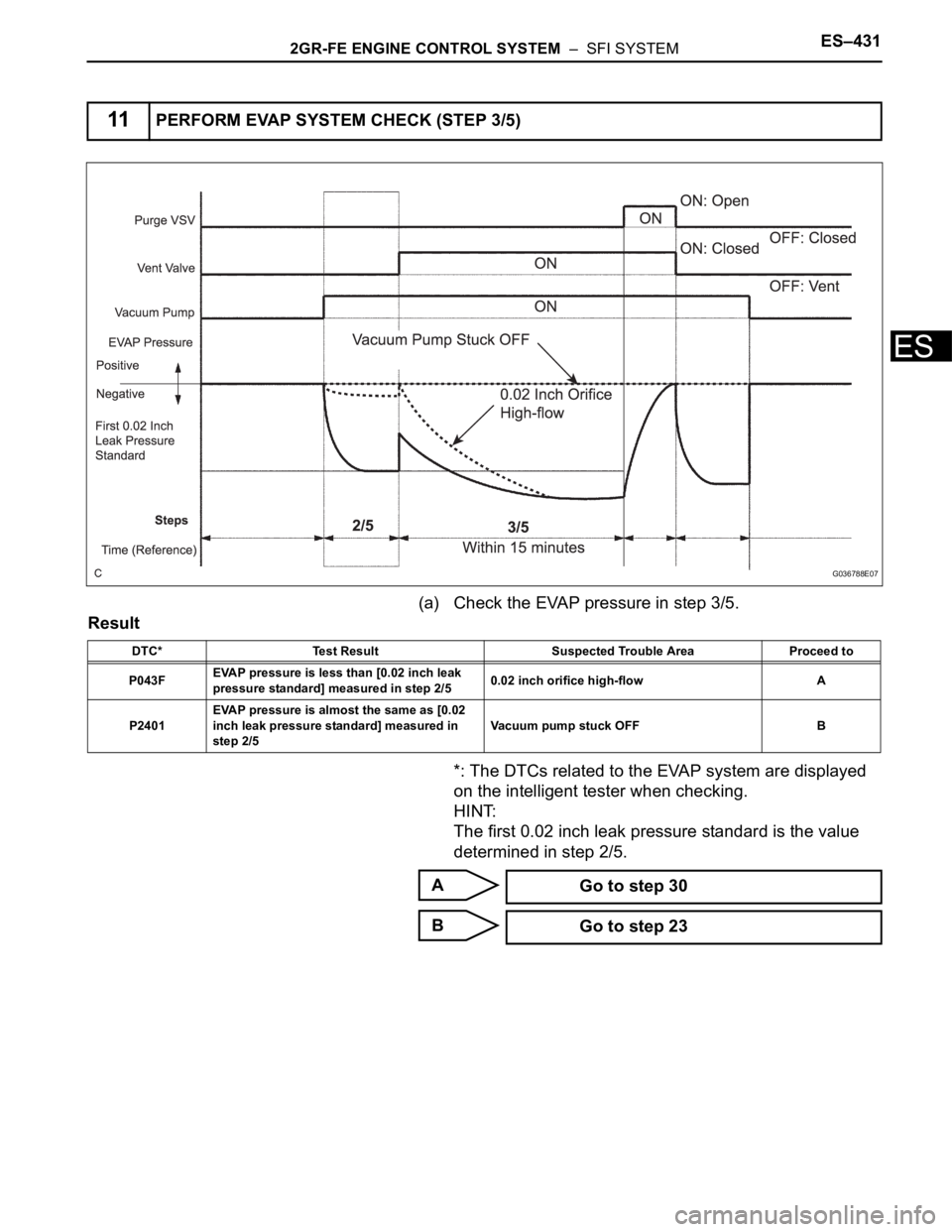

(a) Check the EVAP pressure in step 3/5.

Result

*: The DTCs related to the EVAP system are displayed

on the intelligent tester when checking.

HINT:

The first 0.02 inch leak pressure standard is the value

determined in step 2/5.

A

B

11PERFORM EVAP SYSTEM CHECK (STEP 3/5)

G036788E07

DTC* Test Result Suspected Trouble Area Proceed to

P043FEVAP pressure is less than [0.02 inch leak

pressure standard] measured in step 2/50.02 inch orifice high-flow A

P2401EVAP pressure is almost the same as [0.02

inch leak pressure standard] measured in

step 2/5Vacuum pump stuck OFF B

Go to step 30

Go to step 23

Page 718 of 3000

ES–4322GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

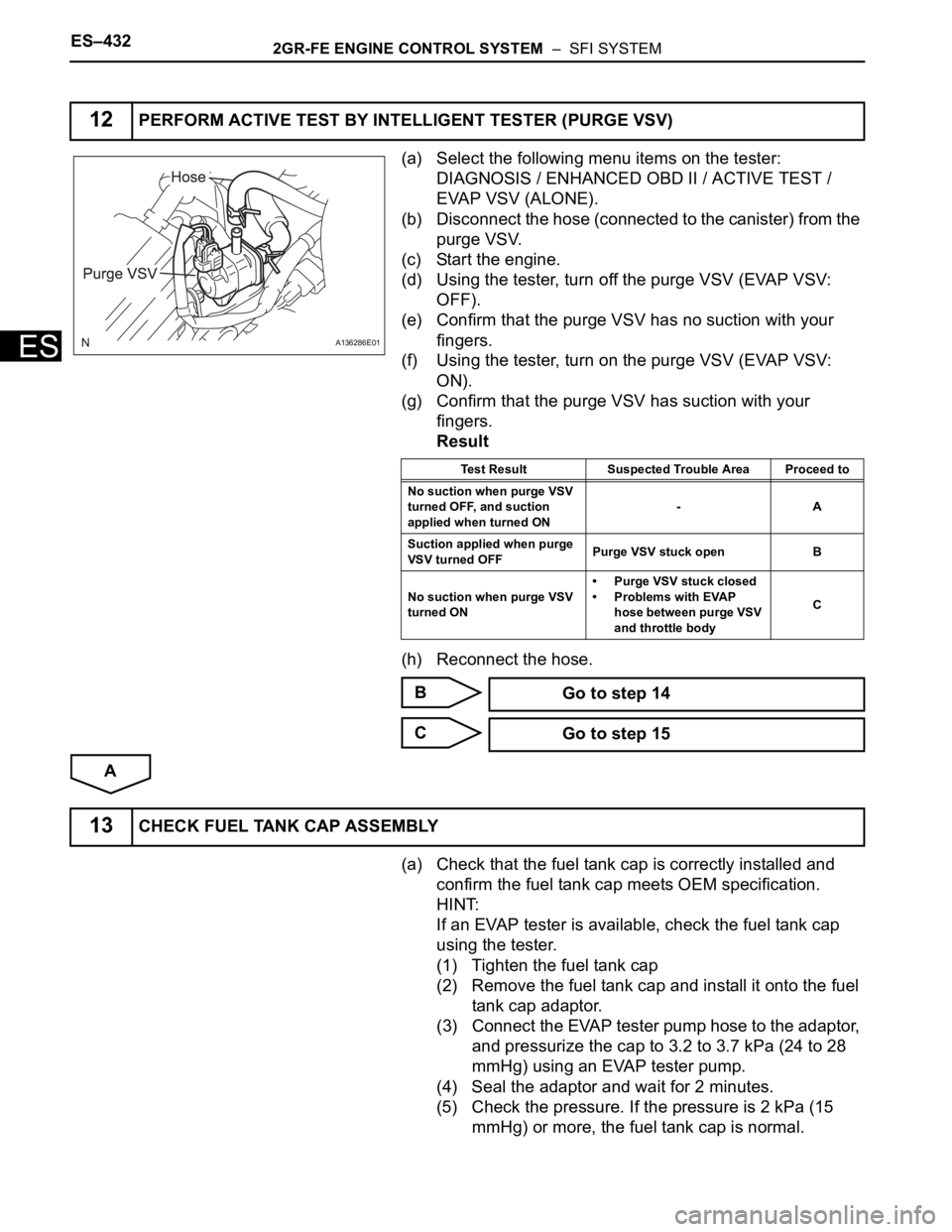

(a) Select the following menu items on the tester:

DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST /

EVAP VSV (ALONE).

(b) Disconnect the hose (connected to the canister) from the

purge VSV.

(c) Start the engine.

(d) Using the tester, turn off the purge VSV (EVAP VSV:

OFF).

(e) Confirm that the purge VSV has no suction with your

fingers.

(f) Using the tester, turn on the purge VSV (EVAP VSV:

ON).

(g) Confirm that the purge VSV has suction with your

fingers.

Result

(h) Reconnect the hose.

B

C

A

(a) Check that the fuel tank cap is correctly installed and

confirm the fuel tank cap meets OEM specification.

HINT:

If an EVAP tester is available, check the fuel tank cap

using the tester.

(1) Tighten the fuel tank cap

(2) Remove the fuel tank cap and install it onto the fuel

tank cap adaptor.

(3) Connect the EVAP tester pump hose to the adaptor,

and pressurize the cap to 3.2 to 3.7 kPa (24 to 28

mmHg) using an EVAP tester pump.

(4) Seal the adaptor and wait for 2 minutes.

(5) Check the pressure. If the pressure is 2 kPa (15

mmHg) or more, the fuel tank cap is normal.

12PERFORM ACTIVE TEST BY INTELLIGENT TESTER (PURGE VSV)

A136286E01

Test Result Suspected Trouble Area Proceed to

No suction when purge VSV

turned OFF, and suction

applied when turned ON-A

Suction applied when purge

VSV turned OFFPurge VSV stuck open B

No suction when purge VSV

turned ON• Purge VSV stuck closed

• Problems with EVAP

hose between purge VSV

and throttle bodyC

Go to step 14

Go to step 15

13CHECK FUEL TANK CAP ASSEMBLY